Explosion proofing castable for steel ladle working layer

A technology of castables and working layers, which is applied in the field of refractory materials for ladles, and can solve problems such as poor air permeability, bursting, and low strength at medium and low temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

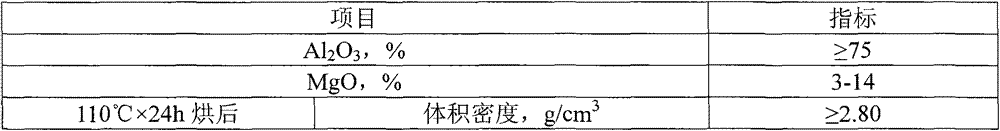

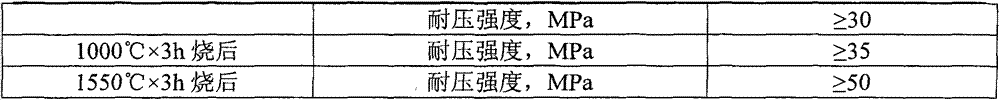

[0024] Embodiment one: the explosion-proof castable for the ladle working layer is configured with the following raw material components: high alumina bauxite (Al 2 o 3 : 88.1%, Fe 2 o 3 : 1.1%, CaO: 0.7%, bulk density: 3.22g / cm 3 ): 30%, fused white corundum (Al 2 o 3 : 99.5%, bulk density: 3.53g / cm 3 ): 58%, 97 fused magnesia (MgO: 97.2%, SiO 2 : 1.8%, CaO: 0.5%, bulk density: 3.19g / cm 3 ): 4.5%, 95 silica powder (SiO 2 : 95.6%, Al 2 o 3 : 0.6%): 1.1%, α-alumina fine powder (Al 2 o 3 : 99.7%, Fe 2 o 3 : 0.1%): 6%, composite explosion-proof agent (metal aluminum powder, 0.03%; low melting point explosion-proof fiber, 0.1%, aluminum lactate powder, 0.05%): 0.18%, organic-inorganic composite water reducer (ADW1, 0.1%, ADS1, 0.1%, sodium tripolyphosphate, 0.1%): 0.3%, respectively fully and evenly mix the raw materials according to the proportion. The actual amount of water added on site is 4.5-5.0%.

[0025] The explosion-proof castable for the working layer of ...

Embodiment 2

[0026] Embodiment two: the explosion-proof castable for the ladle working layer is configured with the following raw material components: the explosion-proof castable for the ladle working layer is configured with the following raw material components (WL%): 88 high alumina bauxite (Al 2 o 3 : 88.1%, Fe 2 o 3 : 1.1%, CaO: 0.7%, bulk density: 3.22g / cm 3 ): 66%, fused white corundum (Al 2 o 3 : 99.5%, bulk density: 3.53g / cm 3 ): 18.5%, 96 fused magnesia (MgO: 96.4%, SiO 2 : 2.1%, CaO: 0.6%, bulk density: 3.14g / cm 3 ): 9.5%, 92 silica powder (SiO 2 : 93.3%, Al 2 o 3 : 0.9%): 2%, α-alumina fine powder (Al 2 o 3 : 99.7%, Fe 2 o 3 : 0.1%): 4%, composite explosion-proof agent (metal aluminum powder, 0.03%; low melting point explosion-proof fiber, 0.1%, aluminum lactate powder, 0.05%): 0.18%, organic-inorganic composite water reducer (ADW1, 0.1%, ADS1, 0.1%, sodium tripolyphosphate, 0.1%): 0.3%, respectively fully and evenly mix the raw materials according to the proport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com