Patents

Literature

33 results about "Aluminum lactate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum lactate is a white powder salt made from lactic acid and aluminum. Aluminum ions are astringent (convergent) with skin and mucous membranes. Due to this characteristic, aluminum lactate is used as material for toothpaste.

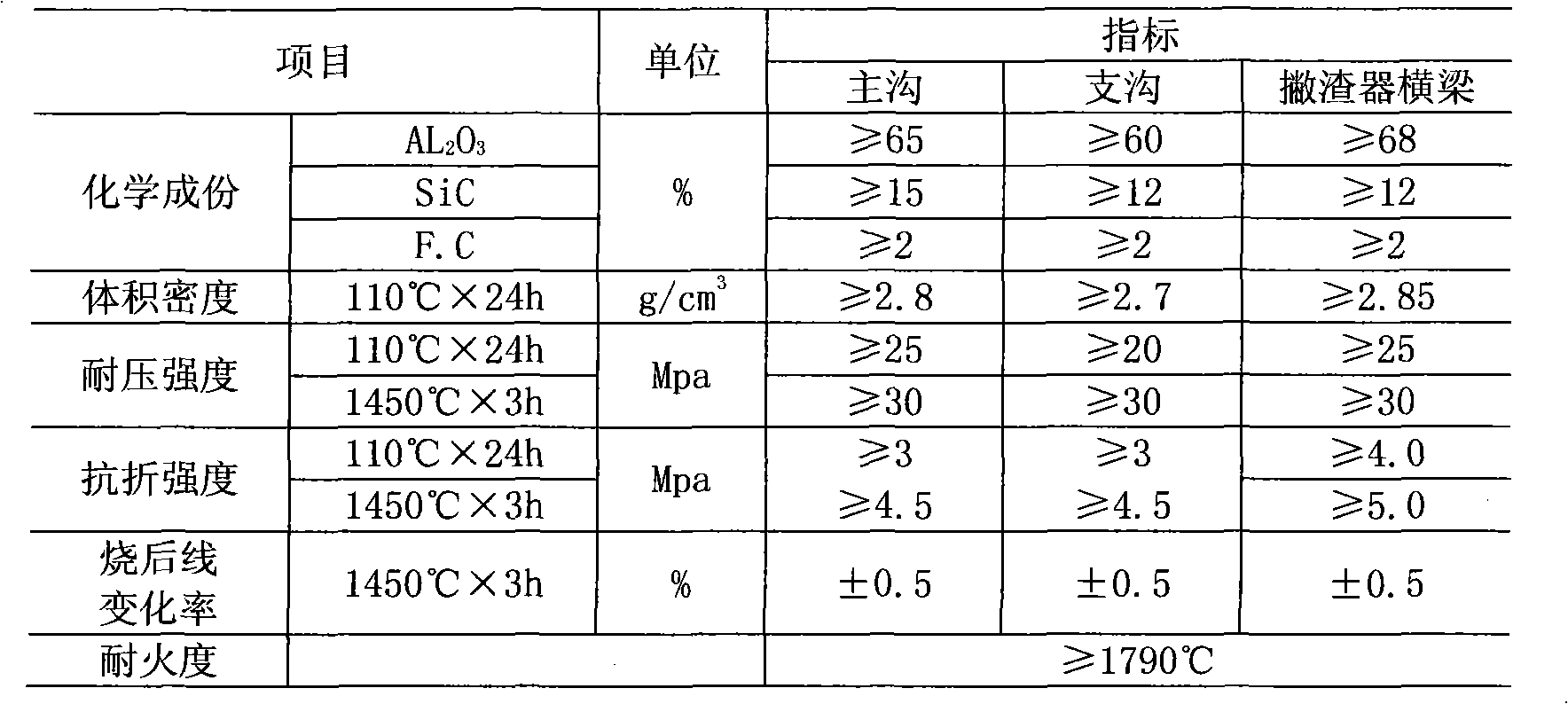

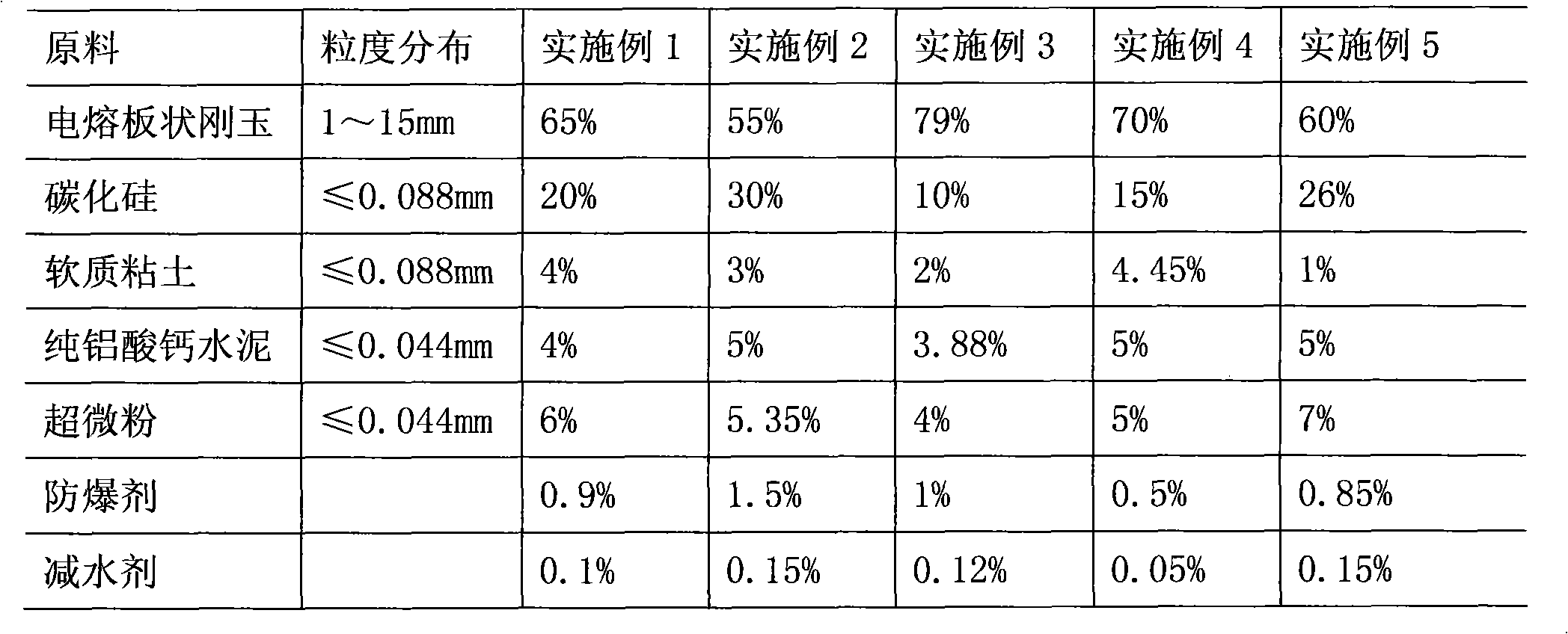

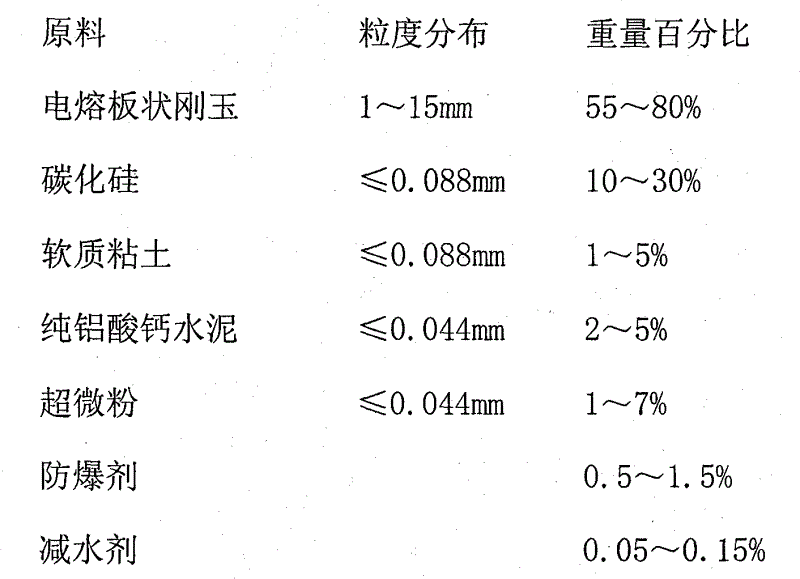

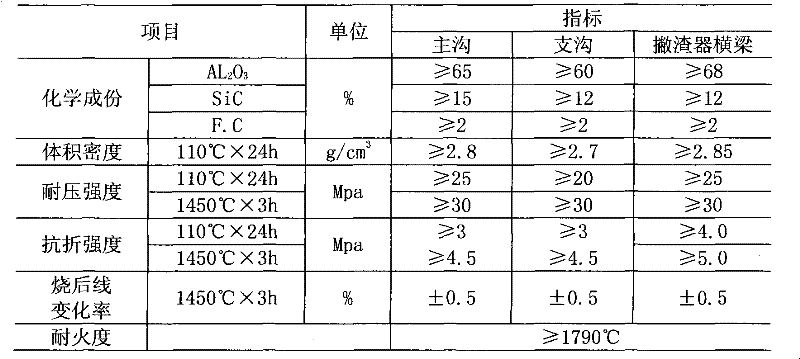

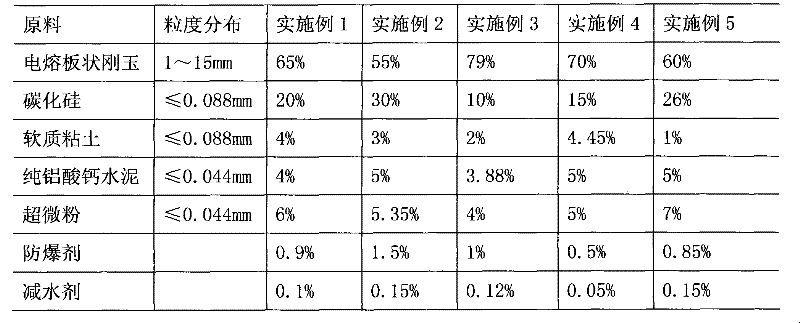

Explosion-proof iron runner castable

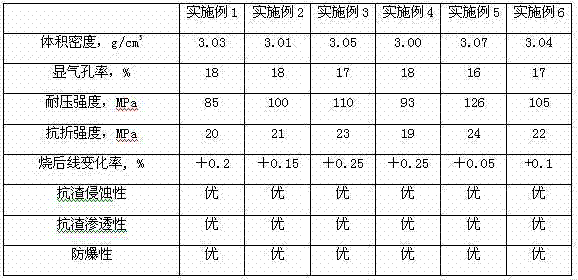

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

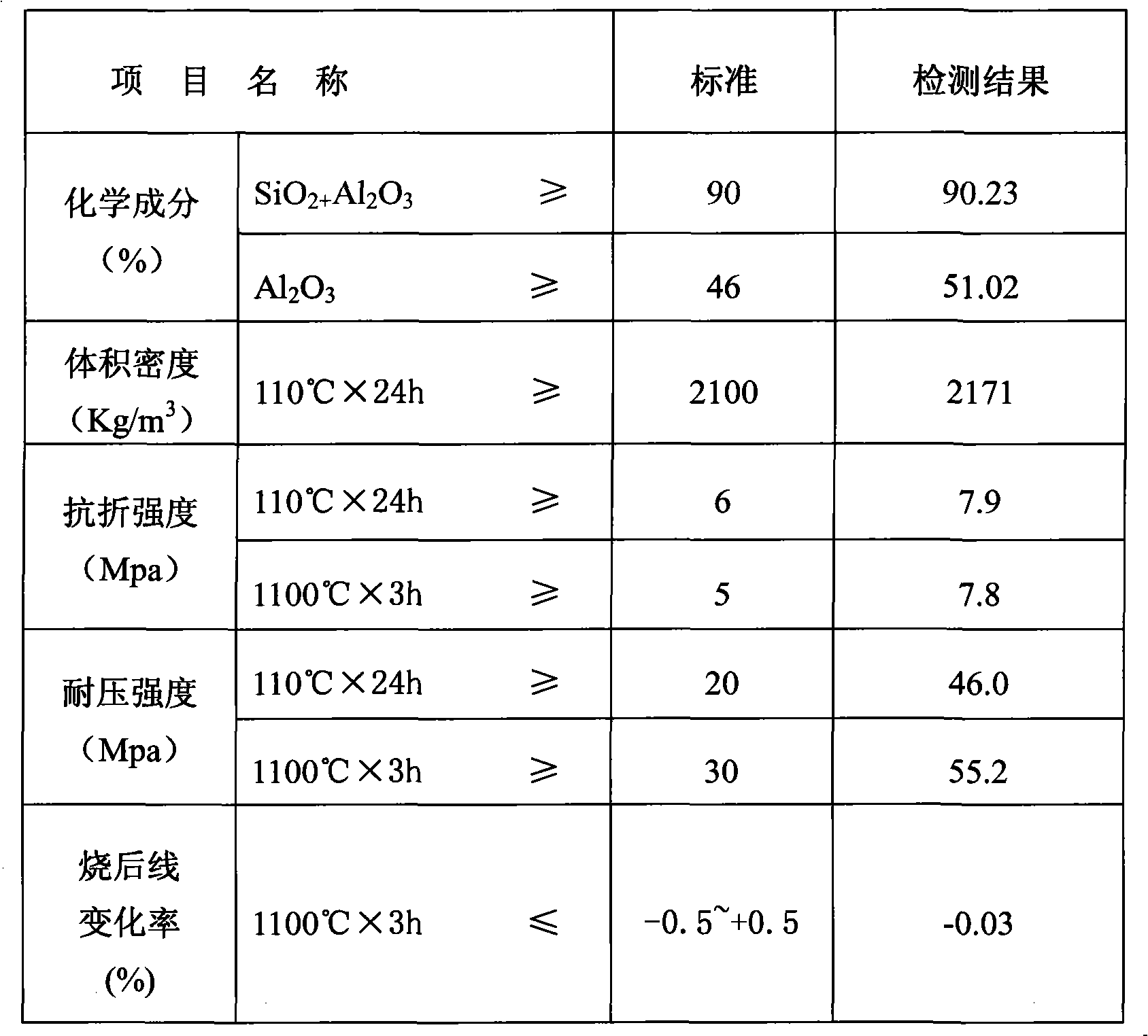

Refractory pouring material used for melten iron desulfur agitator

The present invention discloses a refractory pouring material for molten iron desulfurization stirrer. It is formed from pouring material base material and proper quantity of additive. The composition of the base material of pouring material includes (by wt%) 55-65% of general electrofused mullite 3-10% of jiaobaoshi, 3-7% of silicon micropowder, 5-10% of alpha-Al2O3 micropowder, 3-10% of pure calcium aluminate cement and 1.5-2.5% of compact corundum fine powder, and the described additive is formed from heat-resistant steel fibre, aluminium lactate and / or metal aluminium powder and sodium triphosphate and / or trimeric cyanamide.

Owner:武钢集团有限公司

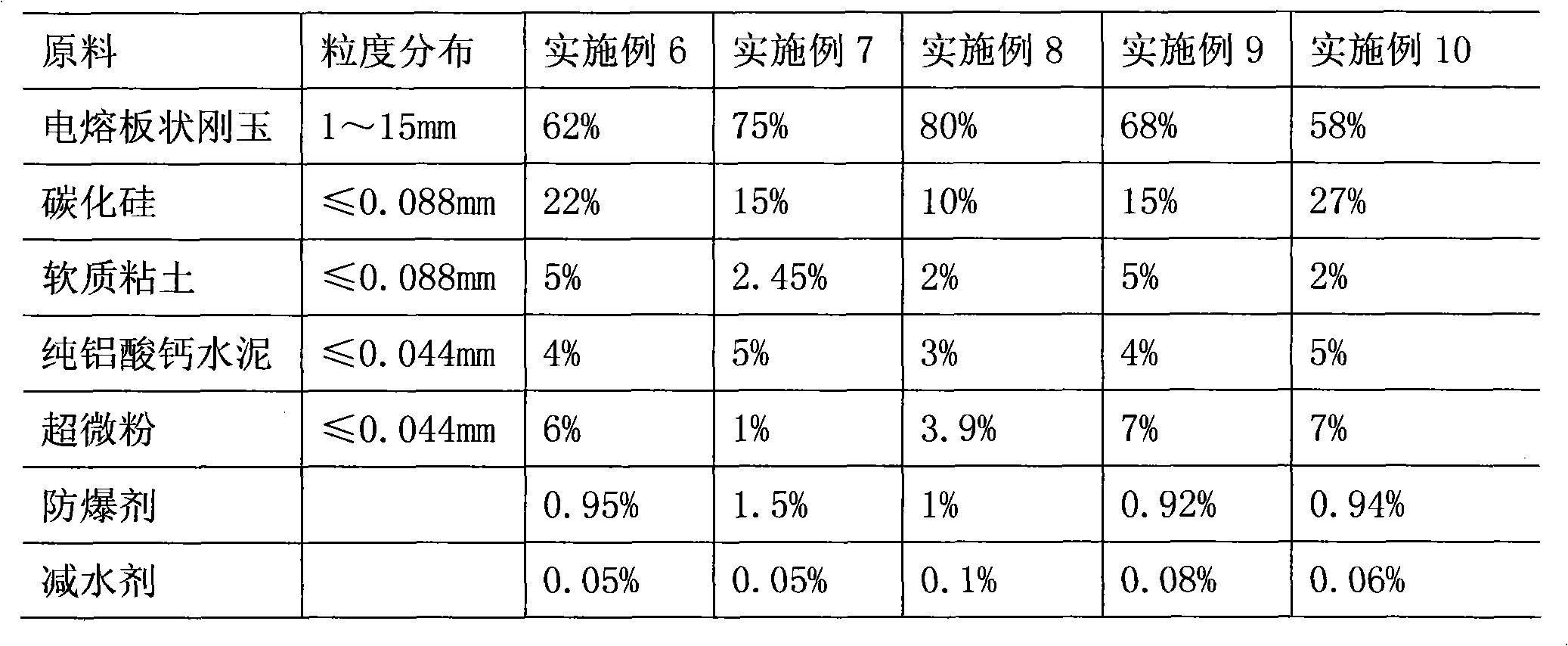

Cement-free aluminum-magnesium castable for rapidly baking ladle

InactiveCN102452836AExtended service lifeOvercoming the inadequacy of not being able to achieve fast bakingCooking & bakingSilicon dioxide

The invention discloses a cement-free aluminum-magnesium castable for rapidly baking a ladle. The castable consists of the following components in percentage by mass: 45-75 percent of corundum (granularity of 25-0.074 millimeters), 15-35 percent of fine alumina powder, 3-7 percent of magnesia powder of which the magnesite content is over 96 percent, 0.5-1.5 percent of alkaline aluminum lactate powder, 0.02-0.06 percent of metal aluminum powder, 0.1-0.3 percent of polypropylene fibers of which the melting point is lower than 200 DEG C, 0.5-1.5 percent of micro silicon dioxide powder, 0.1-0.3 percent of a water reducing agent, 5-35 percent of aluminum-magnesium spinel (granularity of 25-0.074 millimeters) and 0.5-3 percent of hydrated alumina powder. The castable disclosed by the invention has the advantages of difficulty in cracking during quick baking, superior molten steel erosion, residue erosion resistance and residue permeation resistance; and the castable does not pollute molten steel when taken as a refractory material of an inner lining of a container for accommodating the molten steel during smelting of pure steel, and has relatively long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

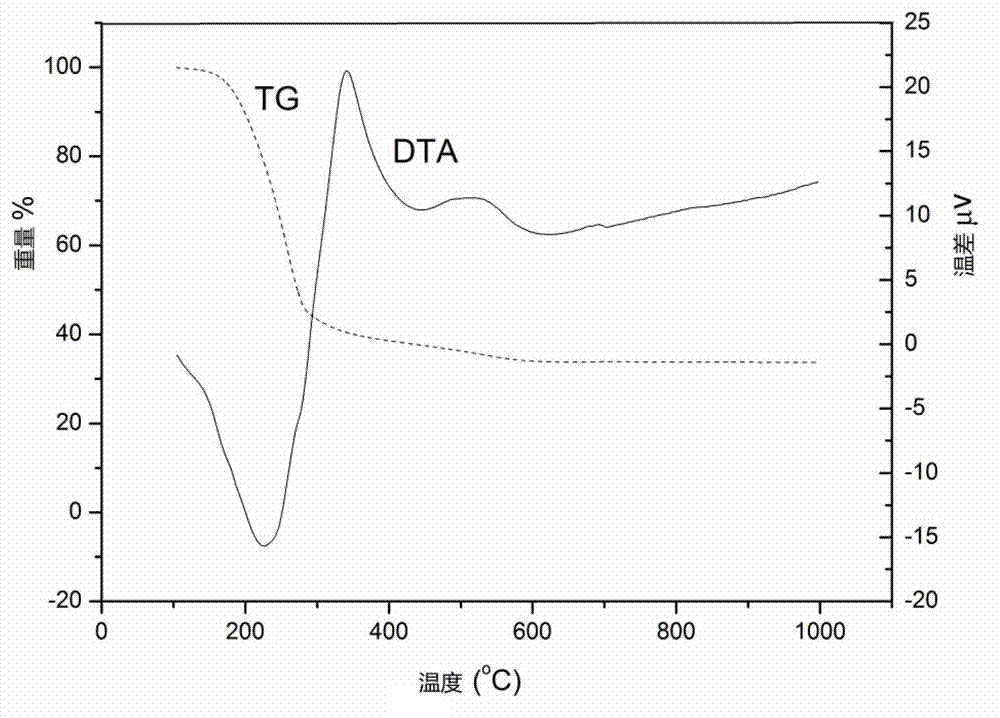

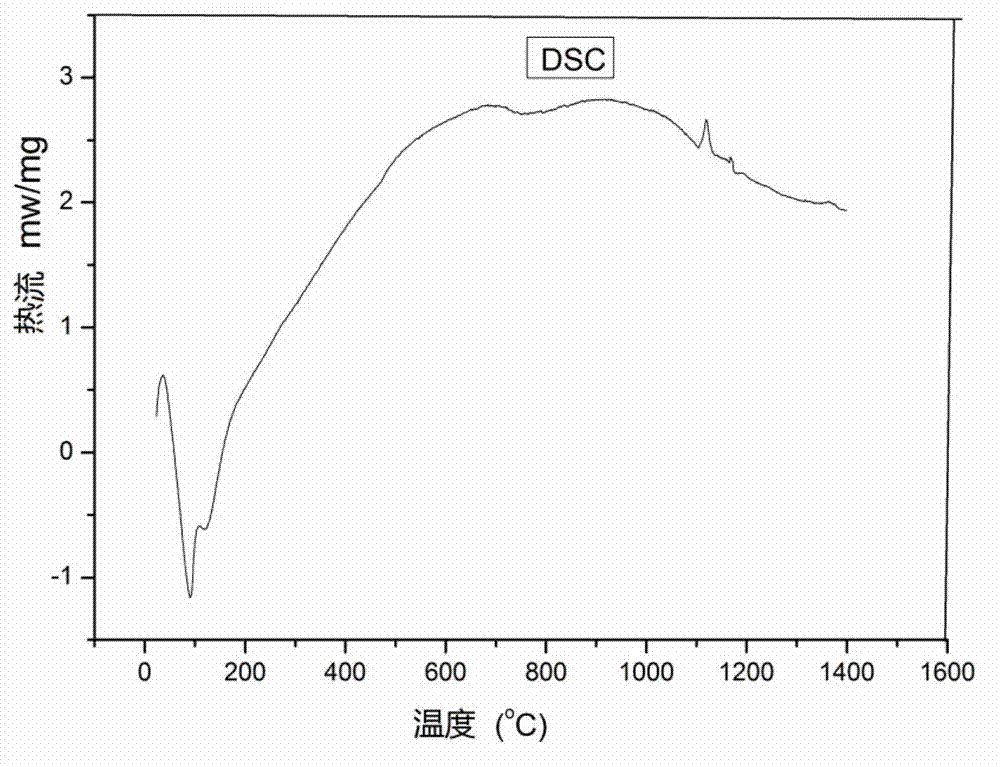

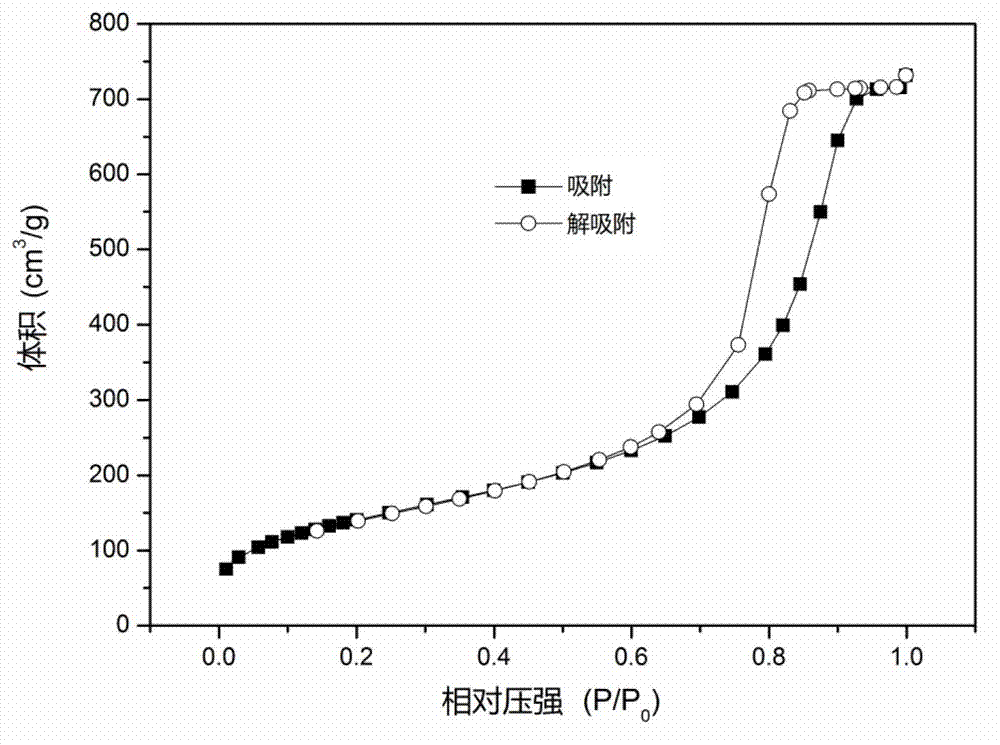

Mesoporous aluminum phosphate glass with large specific surface area and preparation method thereof

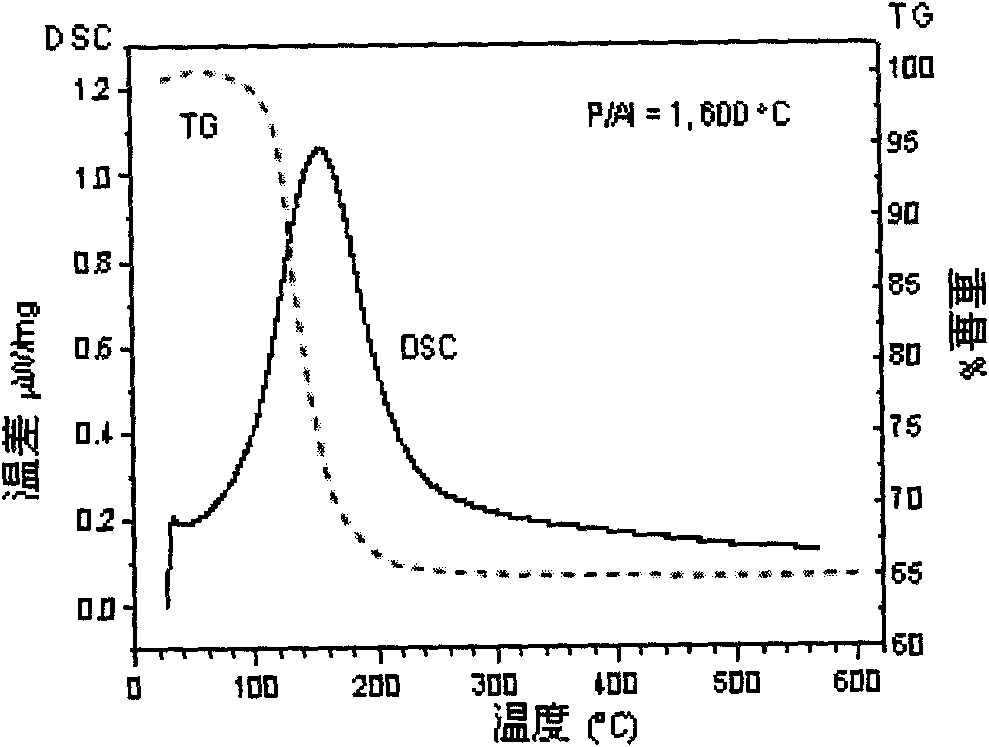

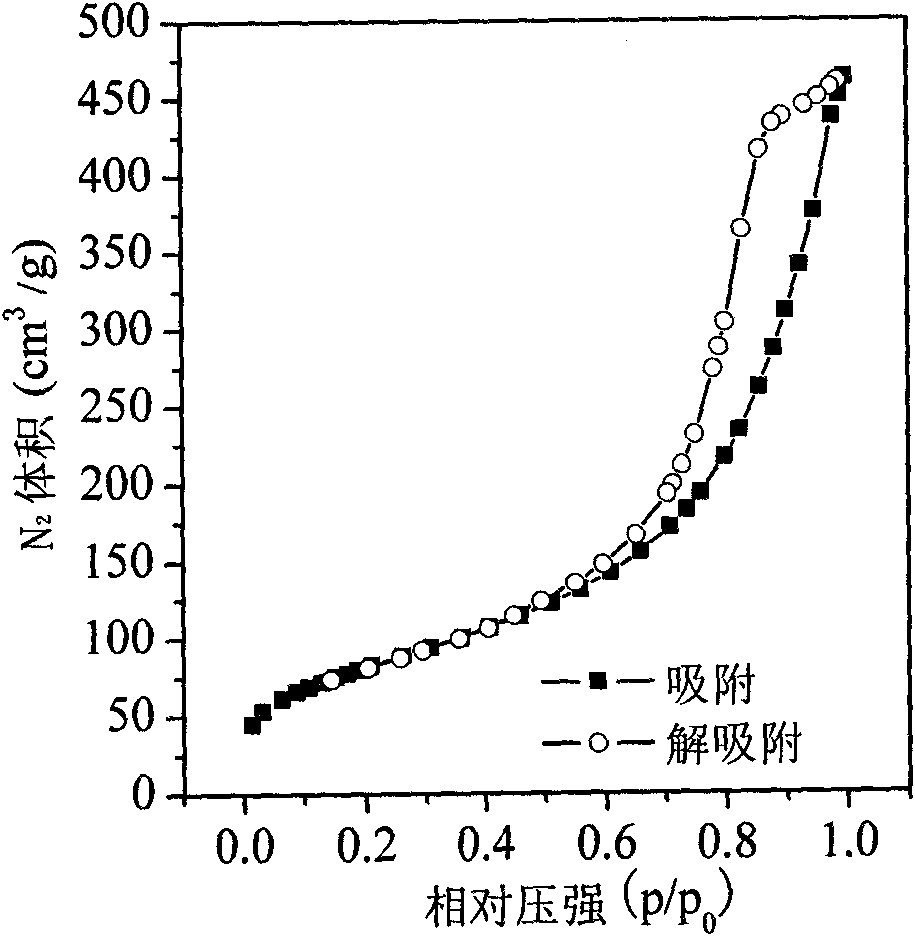

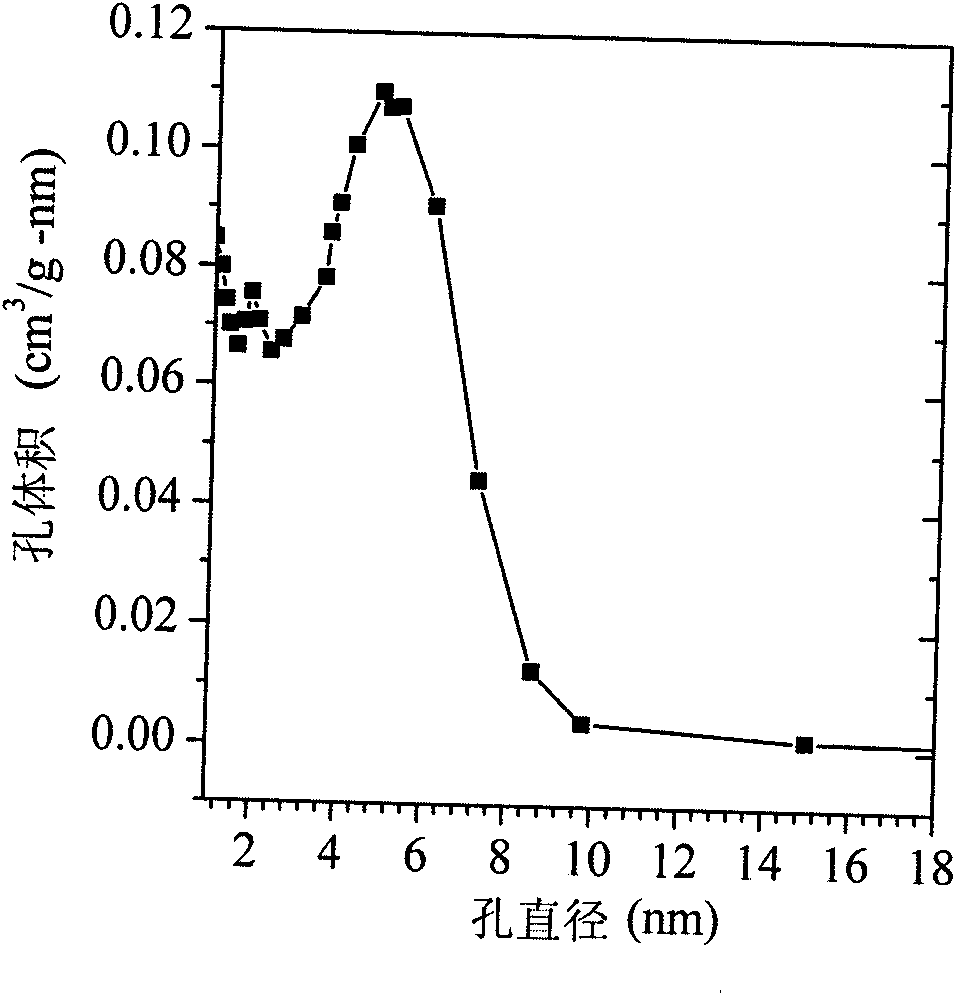

InactiveCN101792259AHigh glass transition temperatureImprove stabilityGlass furnace apparatusPhosphoric acidRoom temperature

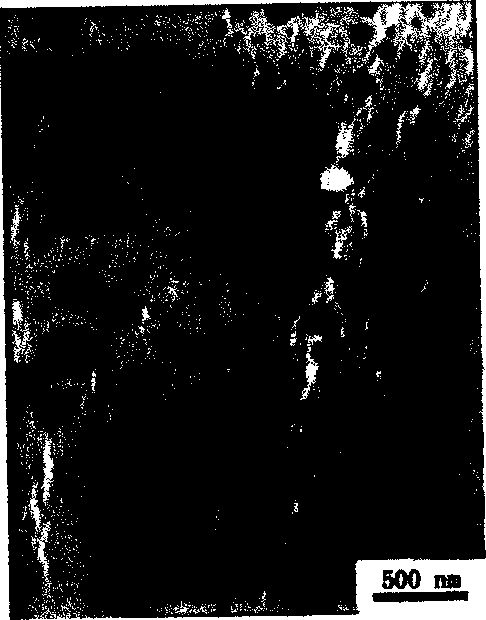

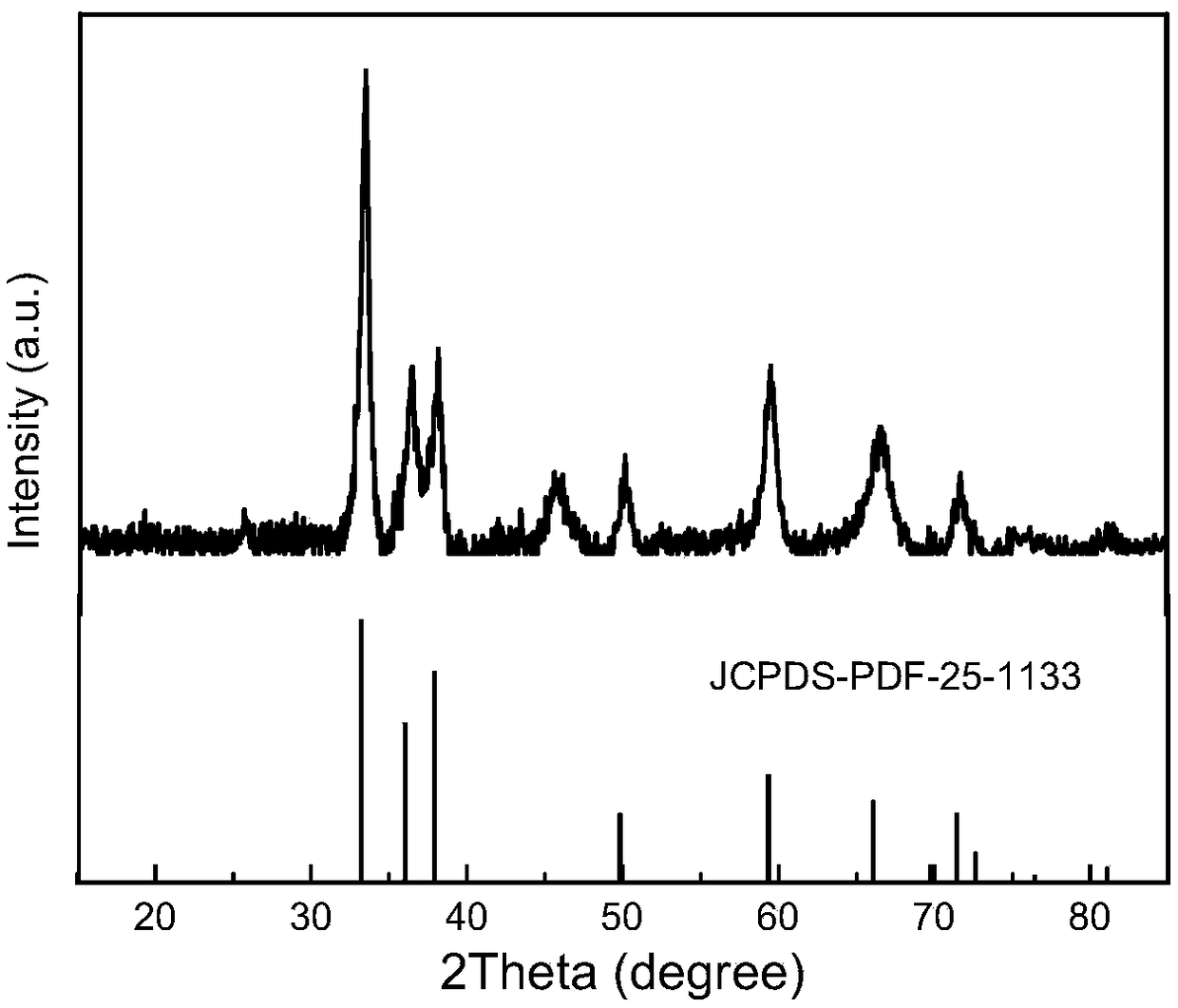

The invention relates to mesoporous aluminum phosphate glass with large specific surface area and a preparation method thereof. The glass is prepared from AlPO4. The preparation method of the mesoporous aluminum phosphate glass with large specific surface area comprises the following steps of: dissolving aluminum lactate and orthophosphoric acid as precursors in deionized water; then, adjusting a pH range to 2.00 to 4.00 with ammonia; standing at a room temperature for gelation; drying the gel in an oven; and thermally processing the gel in a muffle furnace into mesoporous aluminum phosphate glass. Proved by tests, the glass has the glass transition temperature Tg higher than or equal to 1000 DEG C, the specific surface area SBET larger than 400 m<2> / g and the average mesoporous diameter dp equal to 2.0-8.0 nm, thereby being the mesoporous glass with large specific surface area.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Refractory pouring material used for melten iron desulfur agitator

The present invention discloses a refractory pouring material for molten iron desulfurization stirrer. It is formed from pouring material base material and proper quantity of additive. The composition of the base material of pouring material includes (by wt%) 55-65% of general electrofused mullite 3-10% of jiaobaoshi, 3-7% of silicon micropowder, 5-10% of alpha-Al2O3 micropowder, 3-10% of pure calcium aluminate cement and 1.5-2.5% of compact corundum fine powder, and the described additive is formed from heat-resistant steel fibre, aluminium lactate and / or metal aluminium powder and sodium triphosphate and / or trimeric cyanamide.

Owner:武钢集团有限公司

Ramming mass for medium-frequency induction furnace and preparing method thereof

ActiveCN106278315ASimple processGood performance at high temperatureAluminum lactateMedium frequency

The invention relates to ramming mass for a medium-frequency induction furnace and a preparing method thereof. According to the technical scheme, 58-74 wt% of fused corundum, 6-18 wt% of tabular corundum, 8-16 wt% of fused magnesite, 2-9 wt% of alpha-Al2O3 micro powder, 1-3 wt% of aluminum lactate and 1-6 wt% of magnesium lactate are used as raw materials and mixed uniformly to obtain the ramming mass for the medium-frequency induction furnace, wherein the particle size of aluminum lactate and magnesium lactate is smaller than 0.18 mm, the particle size of fused corundum is 0.088-5 mm, and the content of Al2O3 of the fused corundum is 94-99.5 wt%; the particle size of tabular corundum is 0.044-1 mm, the particle size of the fused magnesite is 0.044-1 mm, and the content of MgO of fused magnesite is larger than or equal to 95 wt%; the raw materials are mixed in a mixer for 10-25 min. The preparing method has the advantages of being simple in process and environmentally friendly. The prepared ramming mass for the medium-frequency induction furnace is high in refractoriness, erosion resistance and scouring resistance and long in service life.

Owner:LENGSHUIJIANG HUAKE PERFORMANCE MATERIALS

Mullite flame-proof spray paint

The invention discloses a refractory coat-spraying material of mullite, comprising the following components according to the weight percentage: 70-80% of mullite, 7-10% of pure calcium aluminate cement, 3-10% of silica fume, 3-6% of aluminum lactate and 5-10% of water. In the invention, with the proposal adopted, firstly, interconnected micro-pores are generated on cast basal bodies by adding antiknock agent aluminum lactate (polynuclear fluor-complex polymerized by hydroxylated aluminum ions), so that the steam generated during baking is easily exhausted, thus reducing gas pressure in liners and attaining the aims of fast drying and explosion prevention; secondly, low aluminum mullite is adopted as a primary raw material, so that the products have the advantages of low volume density and high early strength, etc. At the same time, the low volume density can ensure both heat preservative function and refractory function; thirdly, the coat-spraying material can adopt such forms of construction as spraying, smearing or casting, thus improving the flexibility of the construction of products.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Light mullite refractory coating

The invention relates to a light mullite refractory coating which is prepared from the following components in parts by weight: 50-60 parts of low-aluminium-content mullite, 10-25 parts of special-grade kaolin, 5-20 parts of aluminum lactate, 6-8 parts of pure calcium aluminate cement, 5-10 parts of silica fume, and 5-10 parts of water; after being mixed, the low-aluminium-content mullite and the special-grade kaolin are prepared into 30-70 parts by weight of particles and 30-70 parts by weight of fine powder; the particle diameter of the particles is in the range of 2.0-1.5 mm; the particle diameter of the fine powder is in the range of 1.4-0.5 mm. The light mullite refractory coating disclosed by the invention can be applied in a spraying manner. Compared with the traditional pouring manner, a spray manner of the light mullite refractory coating disclosed by the invention has the advantages that more than 60% of time can be saved.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Tundish working lining for clean steel smelting and preparation method thereof

InactiveCN103058693AEvenly distributedHigh bulk densityMelt-holding vesselsUltimate tensile strengthMagnesite

The invention relates to a tundish working lining for clean steel smelting and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: mixing 43-49 wt% of magnesite particle with particle size of 11-0.2 mm, 32-39 wt% of magnesite fine powder with particle size of 1-200 mu m, 8-22 wt% of magnesium-aluminum sol and 2-5 wt% of mixture, uniformly stirring, and coating or casting to form. The mixture is prepared by mixing aluminum oxide micropowder, aluminum lactate and calcium lignosulphonate in a mass ratio of 10:(1.8-2.2):(0.7-1.3); the MgO content in the magnesite particle and magnesite fine powder is greater than or equal to 95 wt%; the mol ratio of magnesium to aluminum in the magnesium-aluminum sol is 1:(0.5-2); the Al2O3 content in the aluminum oxide micropowder is greater than or equal to 98 wt%; and the particle size of the aluminum oxide micropowder is 1-20 mu m. The tundish working lining for clean steel smelting has the advantages of low impurity content, higher strength, high molten steel corrosion resistance, high molten steel penetrating resistance, low influence on total oxygen content in molten steel, and low influence on the quantity of oxide inclusions, and is suitable to be used as a tundish working lining for clean steel smelting.

Owner:WUHAN UNIV OF SCI & TECH

Cigarette paper additive and its preparation method

InactiveCN1757826AGood water solubilityNot easy to scatterInorganic compound additionWater solubleAluminium

A functional improver for the cigarette paper is prepared from perchlorate (20-90 Wt%) and alkaline aluminium lactate Al(OH)2 Lac (10-80 Wt%) through mixing. It is applied through dissolving it in water and spraying the solution onto cigarette paper to prevent the burnt paper from being broken for wrapping the tobacco ash well.

Owner:郑州瑞普生物工程有限公司

Nanometer grade liposome aluminium lactates addictive for daily used chemical product

InactiveCN1736361AGood against dentin hypersensitivityGood skin astringencyCosmetic preparationsHair cosmeticsEmulsionAdditive ingredient

The invention discloses a nano grade liposome aluminum lactate additive used for toothpaste, deodorant, emulsion, face cream, lipstick, hair jelly, shampoo and liquid cleaner. The core of the additive is aluminum lactate, and the main ingredients of the liposome include lecithin, cholesterin and vitamin E.

Owner:CHONGQING NORMAL UNIVERSITY

Method for preparing AlN powder

InactiveCN109264679AHigh purity powderHigh purityMaterial nanotechnologyNitrogen compoundsAir atmospherePhenanthroline

The invention discloses a method for preparing AlN powder. The method includes first dissolving an aluminum source and a nitrogen source completely in a solvent according to the Al:N molar ratio of 1:1-1:35, mixing evenly, drying the solvent by evaporating, roasting an obtained solid mixture at 500-1000 DEG C for 1-9h in a roasting atmosphere, and then decarburizing the mixture at 200-750 DEG C for 1 to 5h in an air atmosphere to obtain the high-purity AlN powder. The aluminum source is aluminum chloride hydrate, aluminum lactate, aluminum glycinate, aluminum stearate and the like; the nitrogen source is guanidine hydrochloride, guanidine acetate, chitosan, 1,10-phenanthroline; the solvent is any one of deionized water, methanol, ethanol, ethyl acetate, acetone, diethyl ether, benzene andtoluene; the roasting atmosphere is one or two of nitrogen, ammonia, argon and helium. Compared with the conventional AlN preparation method, the method has the advantages of wide reactant range, environmentally-friendly process, simple operation, high product purity and low cost.

Owner:SHAANXI UNIV OF SCI & TECH +1

Anticorrosion thermal shock-resistant ceramic wear-resistant material and construction molding method thereof

The invention discloses an anticorrosion thermal shock-resistant ceramic wear-resistant material. The anticorrosion thermal shock-resistant ceramic wear-resistant material comprises 30% of brown fused alumina particles with granularity of 5-3mm, 15% of fused alumina zirconia particles with granularity of 3-1mm, 10% of silicon carbide particles with granularity of 1-0.2mm, 10% of sintered alumina with granularity of 1-0.1mm, 10-20% of composite ceramic nanometer powder, 5-30% of aluminate cement, 1-5% of a compound antiknock agent, 0.25% of a compound water reducer and 5-8% of industrial softened water. The compound antiknock agent comprises two or more of water-soluble explosion-proof fibers, aluminum lactate, metal aluminum and stainless steel fibers. The compound water reducer comprises two or more of sodium polyphosphate, sodium tripolyphosphate, sodium hexametaphosphate, sodium humate and sodium silicate. The anticorrosion thermal shock-resistant ceramic wear-resistant material is used for a blast furnace roof gas sealing plate, a cyclone dust collector, a granulation tower water granulated slag trench of a blast furnace granulating slag system, sintering machine bellows, a sintering machine flue gas cycle pipe and a sintering machine dedusting pipe and has good wear resistance, high temperature resistance, corrosion resistance and thermal shock stability.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

Wear-resistant ceramic material for repairing dry quenching furnace bracket support part and forming method thereof

The invention discloses a wear-resistant ceramic material for repairing a dry quenching furnace bracket support part. The wear-resistant ceramic material for repairing the dry quenching furnace bracket support part comprises 20%-40% of fused mullite particles with the particle size ranging from 5 mm to 3 mm, 10%-25% of fused dense corundum with the particle size ranging from 8 mm to 3 mm, 5%-15% of fused alumina zirconia particles with the particle size ranging from 3 mm to 1 mm, 3%-20% of sintered alumina particles with the particle size ranging from 1 mm to 0 mm, 5%-20% of composite ceramic nano powder, 3%-15% of aluminate cement, 1%-5% of composite antiknock agents, 0.25% of composite water reducers and 4%-6% of industrial softened water, wherein the composite antiknock agents adopt two or more of water-soluble explosion-proof fibers or aluminum lactate or aluminum metal or stainless steel fibers, the water reducers adopt two or more of sodium polyphosphate or sodium tripolyphosphate or sodium hexametaphosphate or sodium humate or water glass. The wear-resistant ceramic material is used for repairing the dry quenching furnace bracket support part, the integral structure is completed after forming in conducted, abrasion loss is small, the creep value is low, very high strength and toughness are achieved, and shock resistance and abrasion resistance are better.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

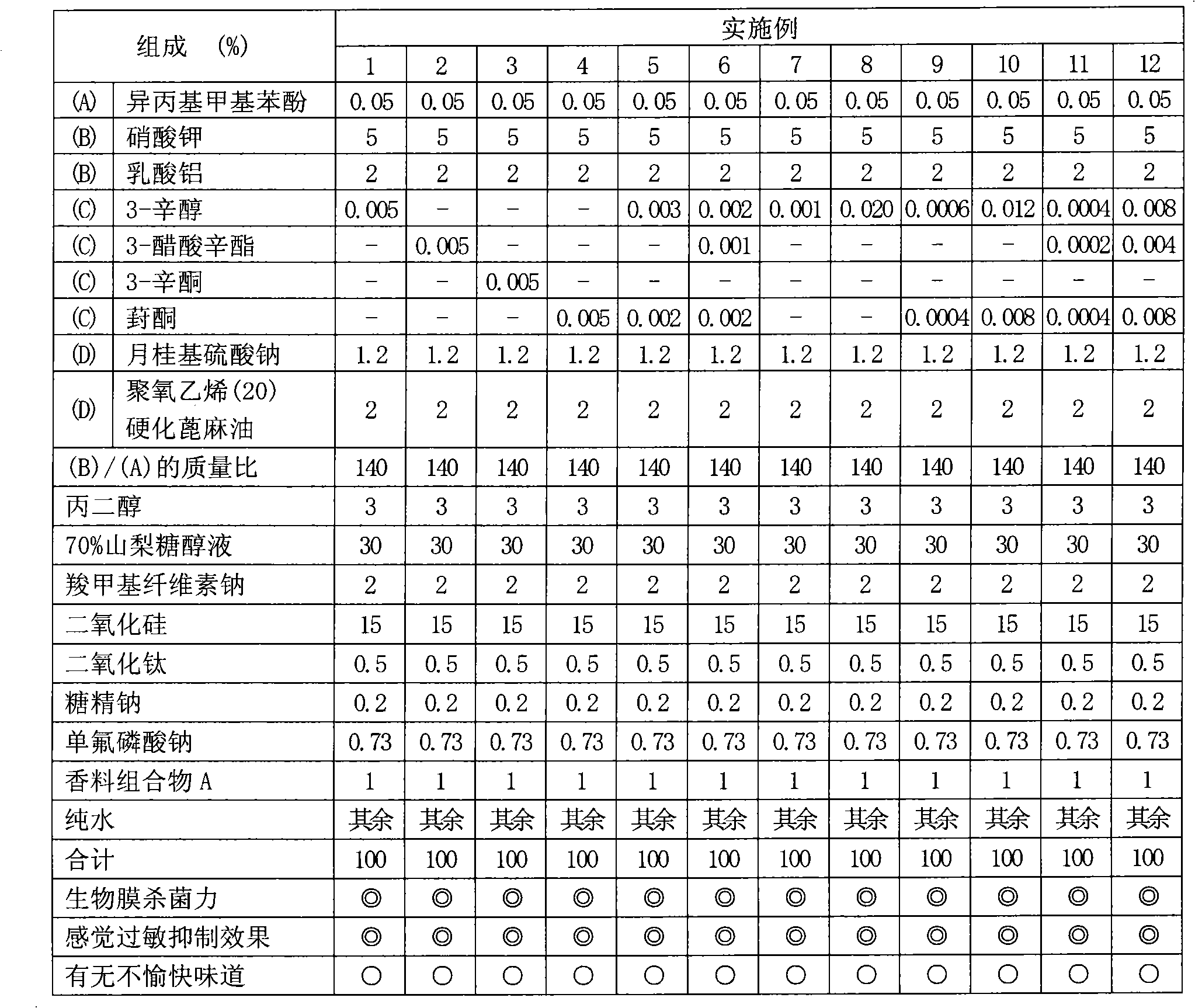

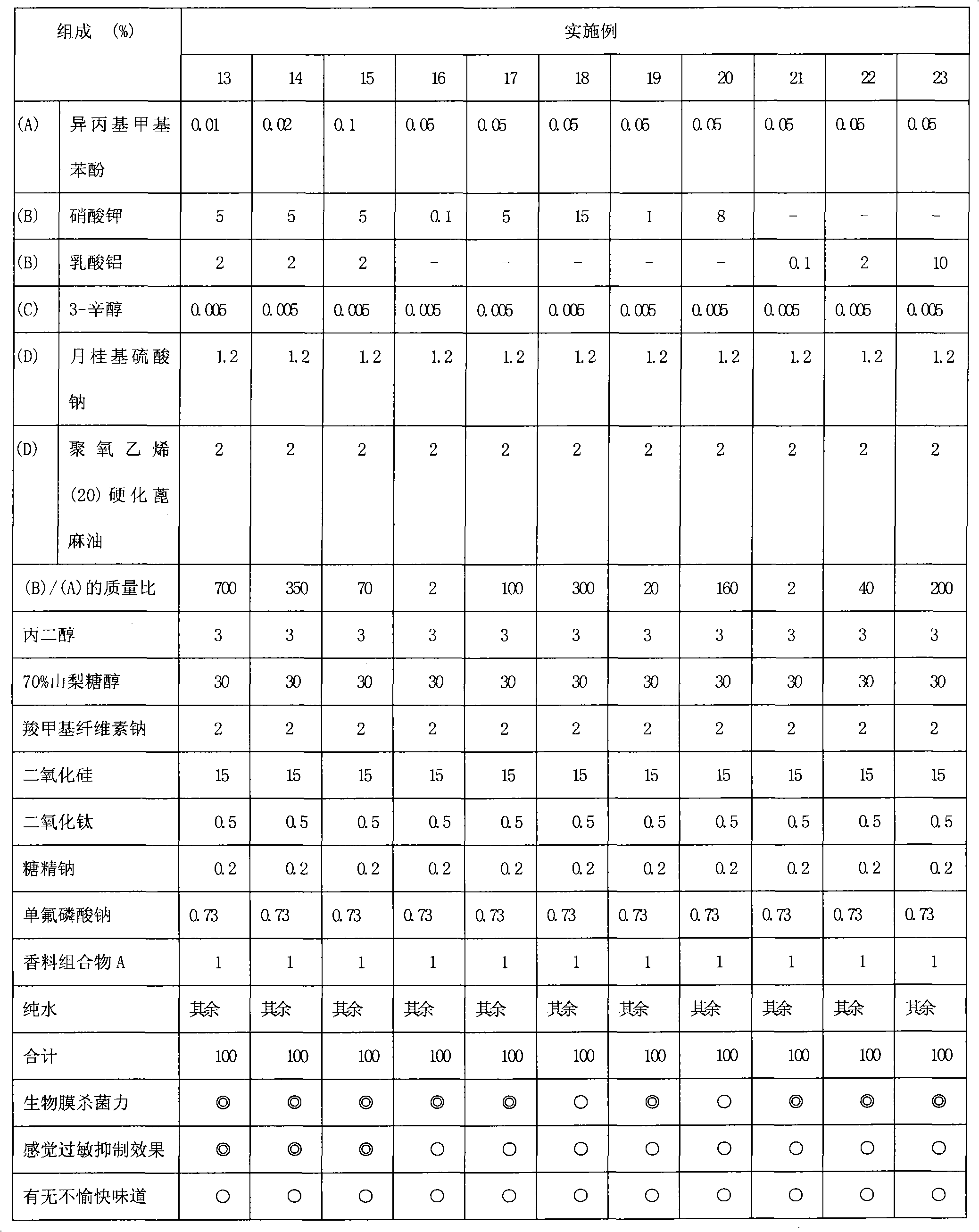

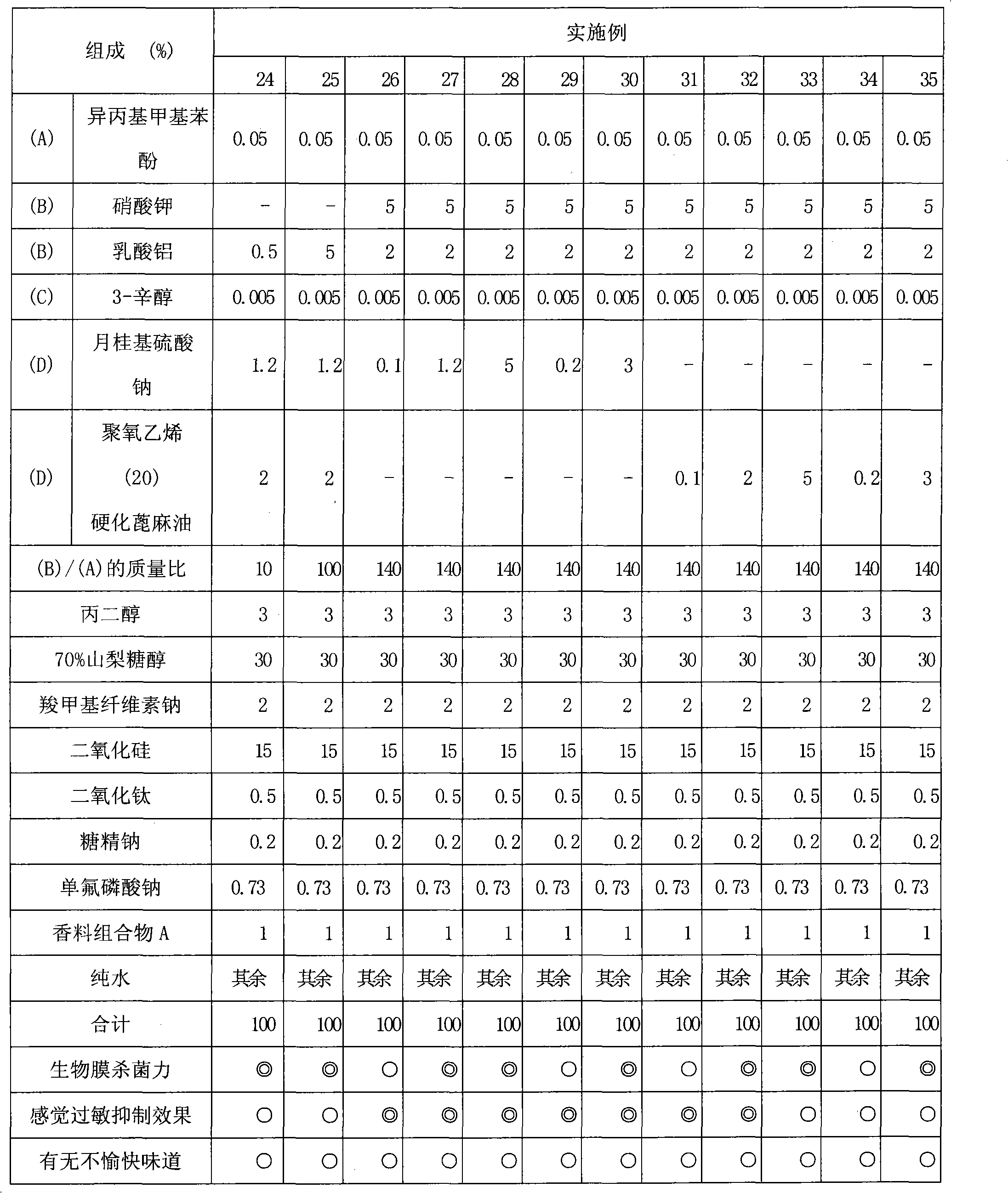

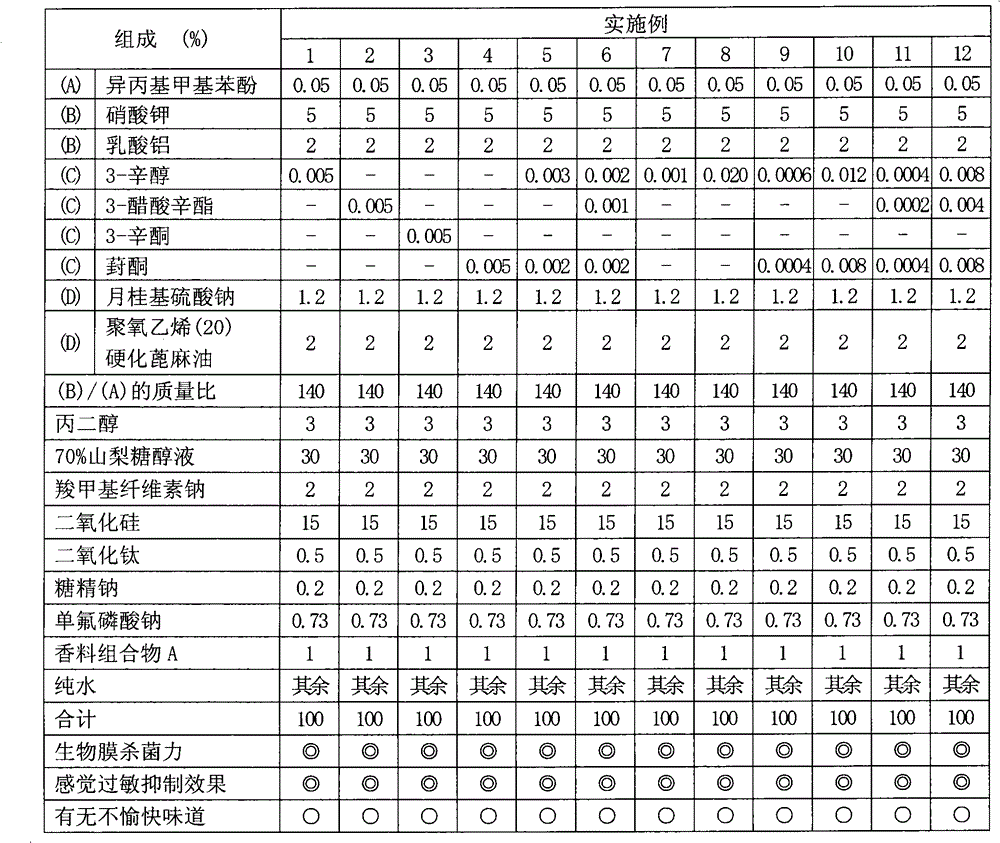

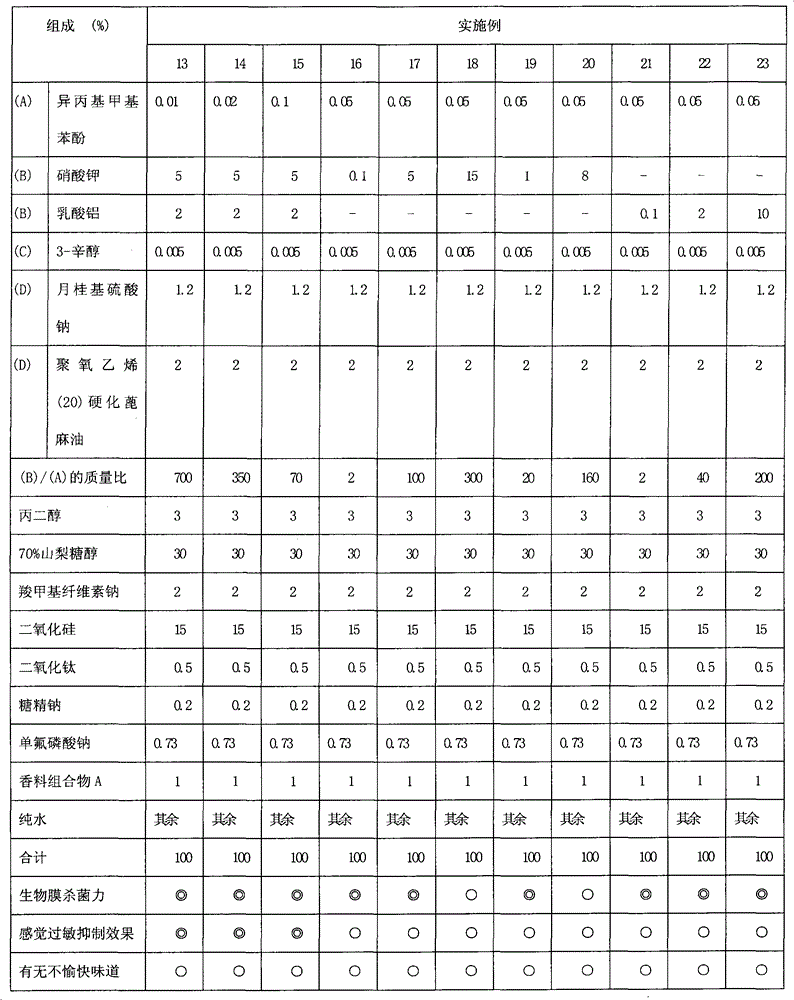

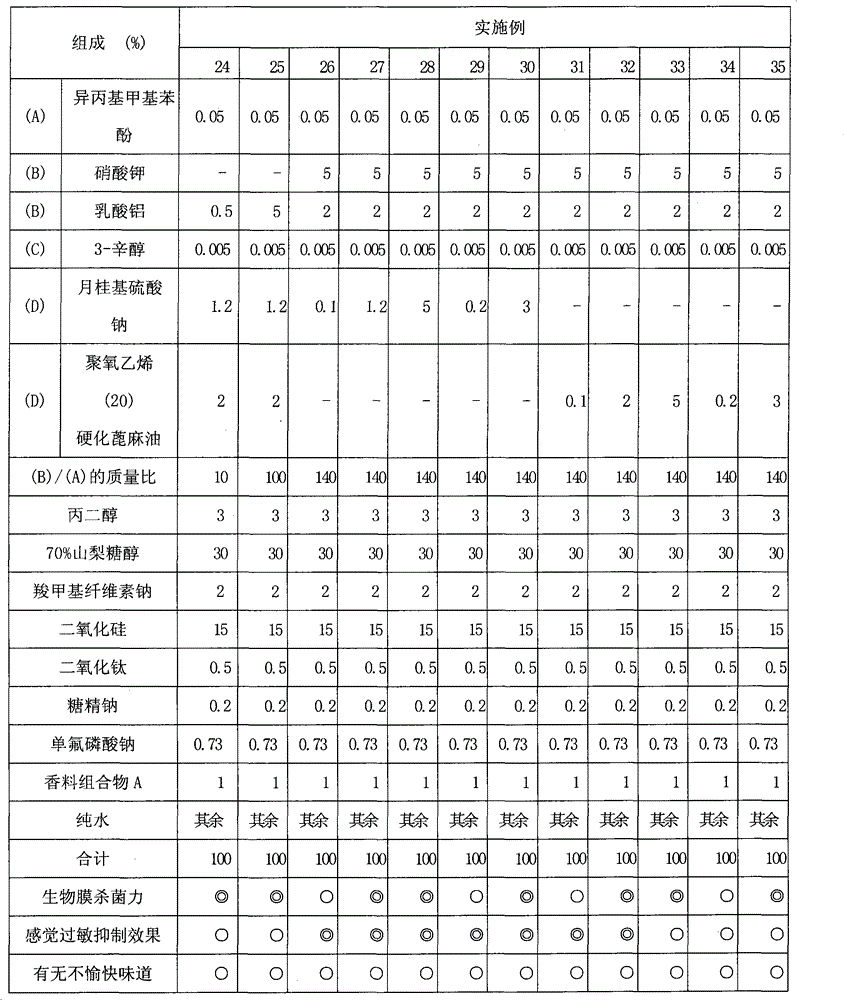

Dentifrice composition

ActiveCN102548526AEasy to useImprove the bactericidal effectCosmetic preparationsToilet preparationsOctanolPhenol

Disclosed is a dentifrice composition which exhibits excellent bactericidal effect on biofilms, while having excellent hyperesthesia suppressing activity. The dentifrice composition is free from unpleasant taste and provides excellent feeling of use. Specifically disclosed is a dentifrice composition which is characterized by containing (A) isopropyl methyl phenol, (B) one or more substances selected from among potassium nitrate, aluminum lactate and strontium chloride, (C) one or more fragrance material components selected from among 3-octanol, 3-octyl acetate, 3-octanone and fenchone, and (D) an anionic surfactant and / or a nonionic surfactant. The dentifrice composition additionally contains (E) anisaldehyde.

Owner:LION CORP

High-specific-surface-area mesoporous aluminum gallium phosphate glass and preparation method thereof

The invention relates to high-specific-surface-area mesoporous aluminum gallium phosphate glass and a preparation method thereof. The composition of the glass is xGa-(1-x)Al-PO4, wherein 0<x<0.3. The preparation method comprises the following steps: dissolving aluminum lactate, gallium nitrate and orthophosphoric acid used as precursors in deionized water, regulating the pH value to 2.00-4.00 with ammonia water, and standing to perform gelation at room temperature; and drying the gel in a baking oven at 50-100 DEG C, and then performing heat treatment in a muffle furnace at 400-800 DEG C, thus obtaining the mesoporous glass. Tests prove that the glass transition temperature Tg of the glass is not lower than 1000 DEG C, the specific surface area SBET is larger than 300 m<2> / g, and the average mesoporous diameter dp is 1.0-20.0 nm. Thus, the glass can be used as an optical gain and catalyst carrier in the field of photoelectrons.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Baking-free castable

The invention discloses a zero-baking castable which is prepared from the raw materials including, by weight, 55-70 parts of a high-aluminum aggregate, 15-20 parts of high-aluminum fine powder, 2-6 parts of aluminum oxide micro-powder, 2-6 parts of silicon micro-powder, 0.5-3 parts of calcium aluminate cement, 0.03-0.2 parts of sodium tripolyphosphate, and 0.2-0.8 parts of a comprehensive explosion-proof agent which is prepared from the raw materials including, by weight, 5-10 parts of aluminum powder in 200 meshes, 10-15 parts of aluminum powder in 100 meshes, 5-8 parts of aluminum powder in 40 meshes, 8-12 parts of basic aluminum lactate, 5-8 parts of azodicarbonamide and 20-30 parts of water-soluble fiber at 60 DEG C. The zero-baking castable is free of maintenance and furnace baking, can be applied directly, can save the cost of furnace baking and can save the time of maintenance and furnace baking.

Owner:焦作诺尔曼炉业有限公司

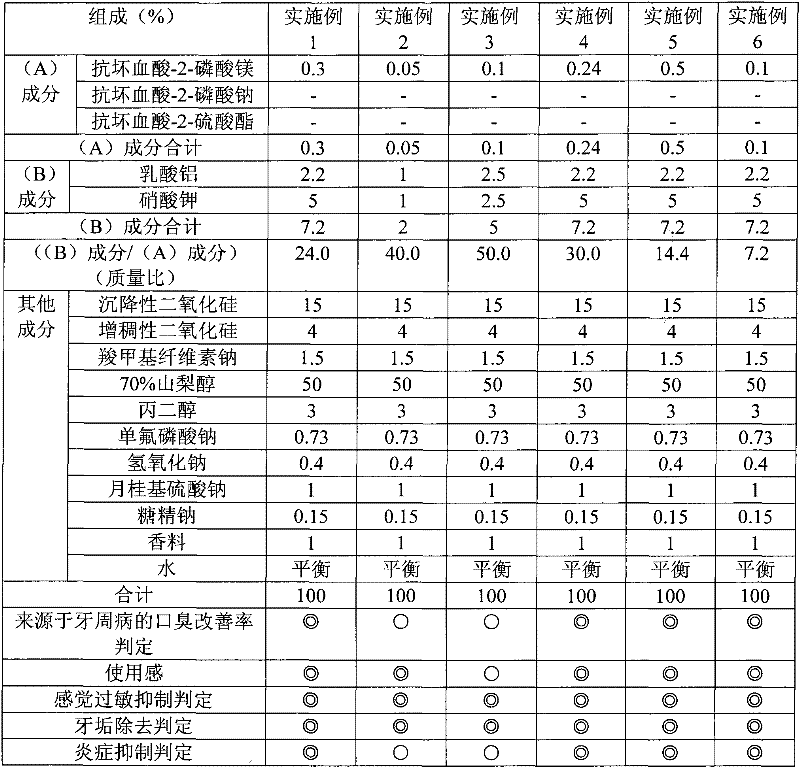

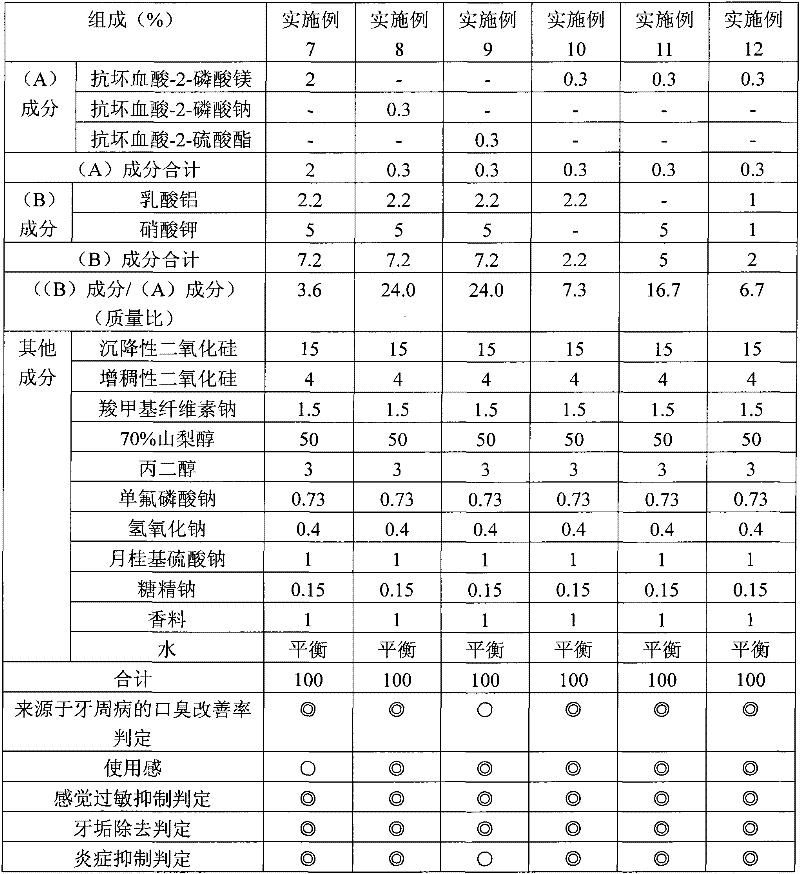

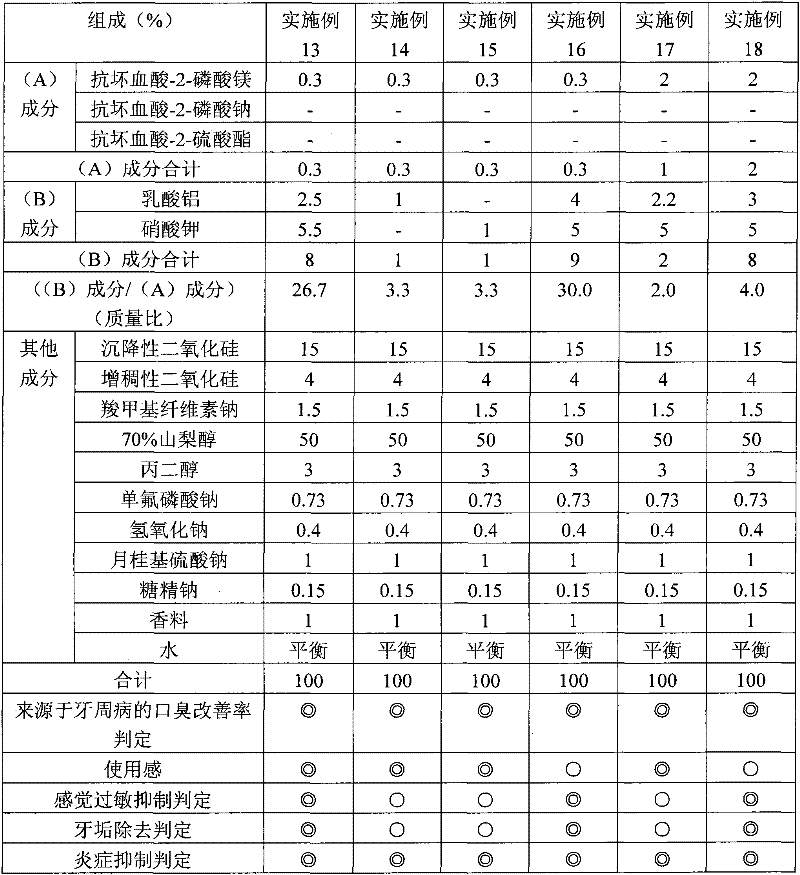

Dentifrice Composition

ActiveCN102264342AImprove bitternessEasy to useCosmetic preparationsToilet preparationsPotassium nitrateAluminum lactate

Disclosed is a dentifrice composition characterized by containing (A) at least one or more selected from ascorbic acid ester and salts thereof and (B) aluminum lactate and / or potassium nitrate, wherein the content ratio of ingredient (B) / ingredient (A) is 2-50 by mass ratio.

Owner:LION CORP

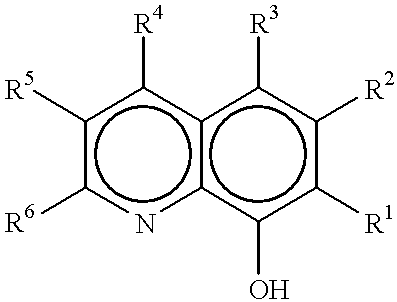

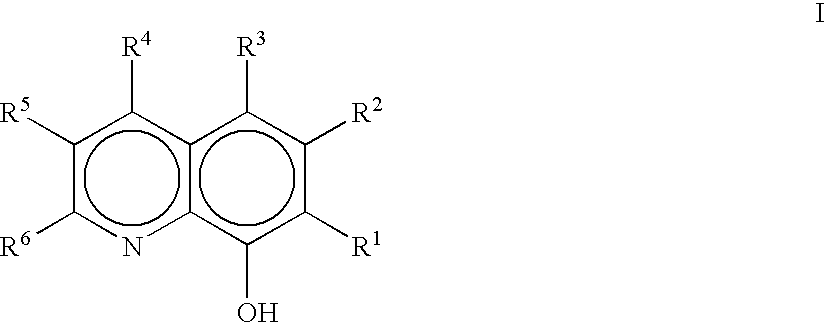

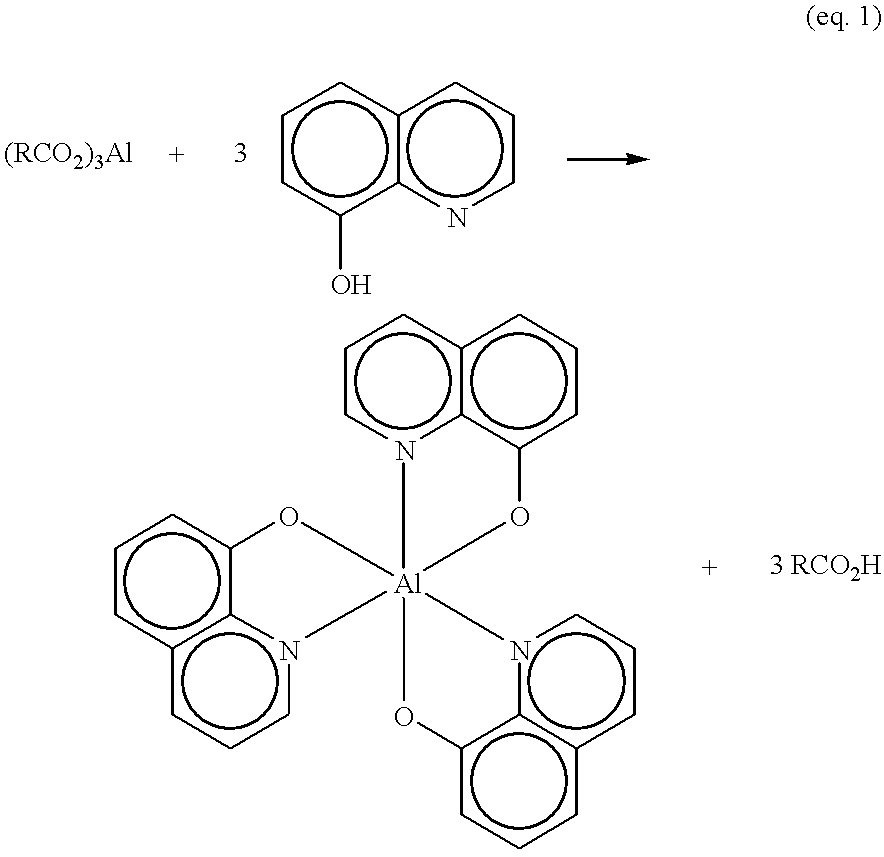

Method of making metal 8-quinolinolato complexes

InactiveUS20020040143A1High potential demandHigh purityGroup 3/13 element organic compoundsZinc organic compoundsALUMINUM STEARATESStearic acid

A method for making metal (8-quinolinolate) complexes from air and moisture stable reagents is described. For example, the making of aluminum tris(quinolinolates), such as tris(8-hydroxyquinolinato), from aluminum (III) carboxylates, such as aluminum lactate and aluminum stearate, is described. Examples of bis and tris metal (8-quinolinolates) as well as single and mixed ligand complexes are given.

Owner:3M INNOVATIVE PROPERTIES CO

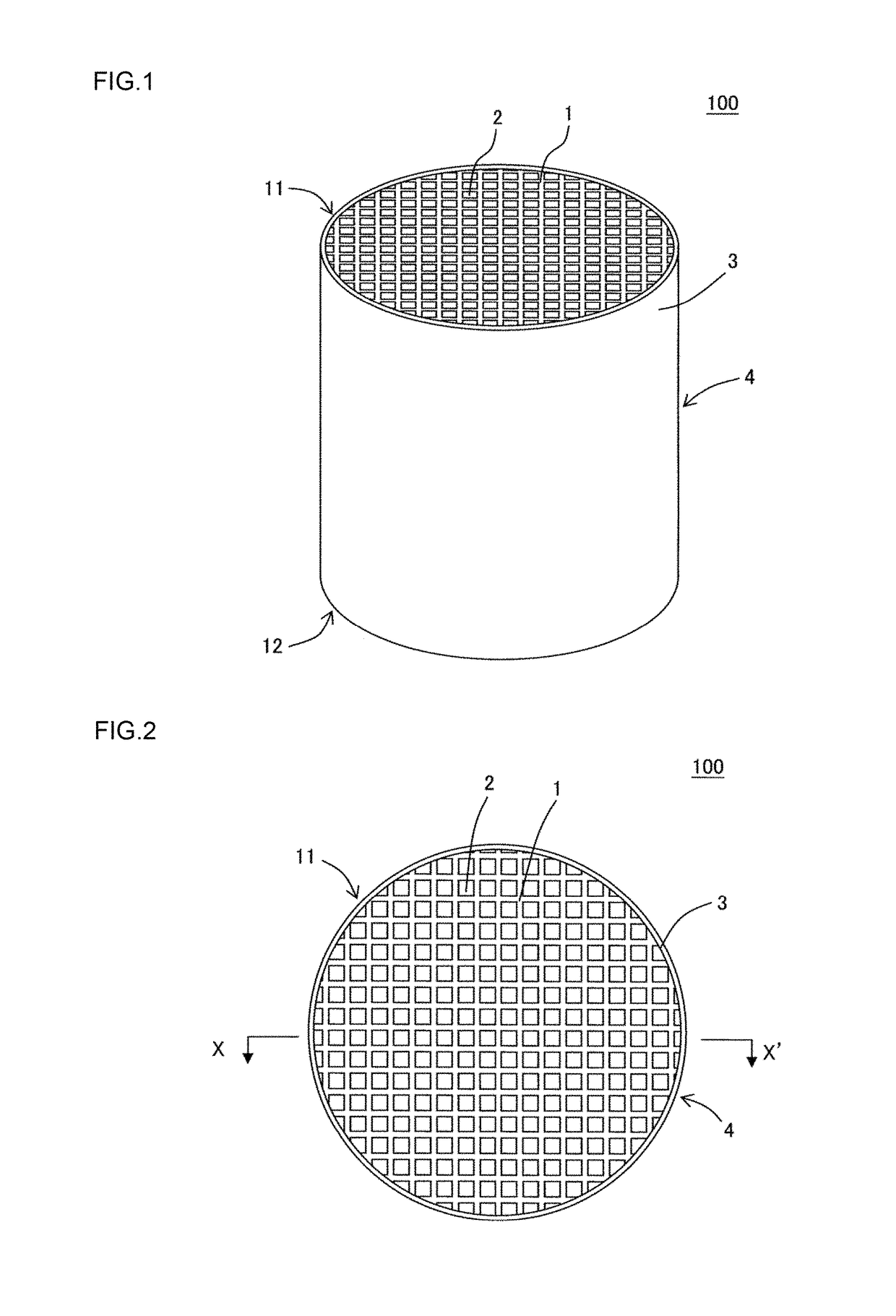

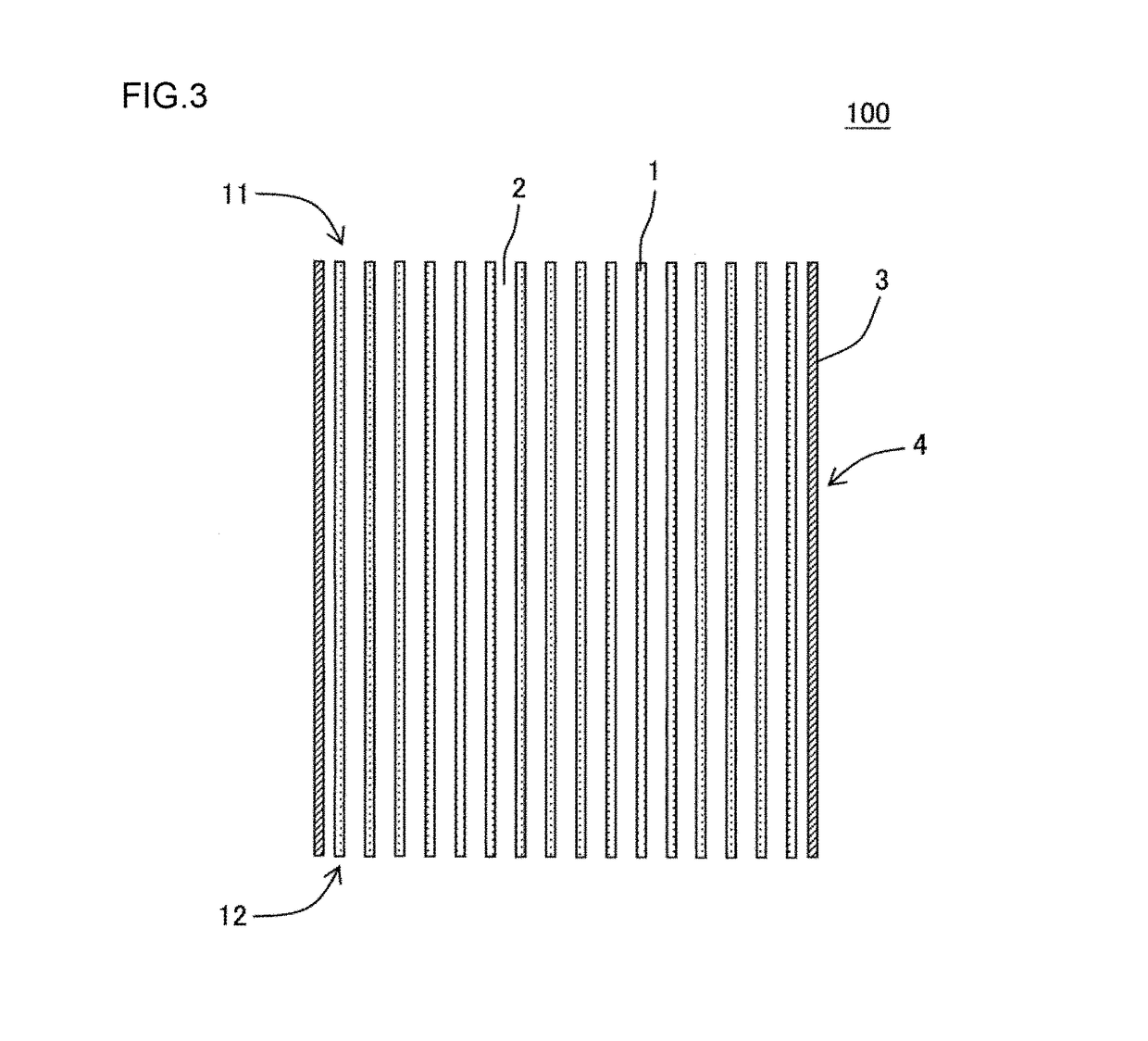

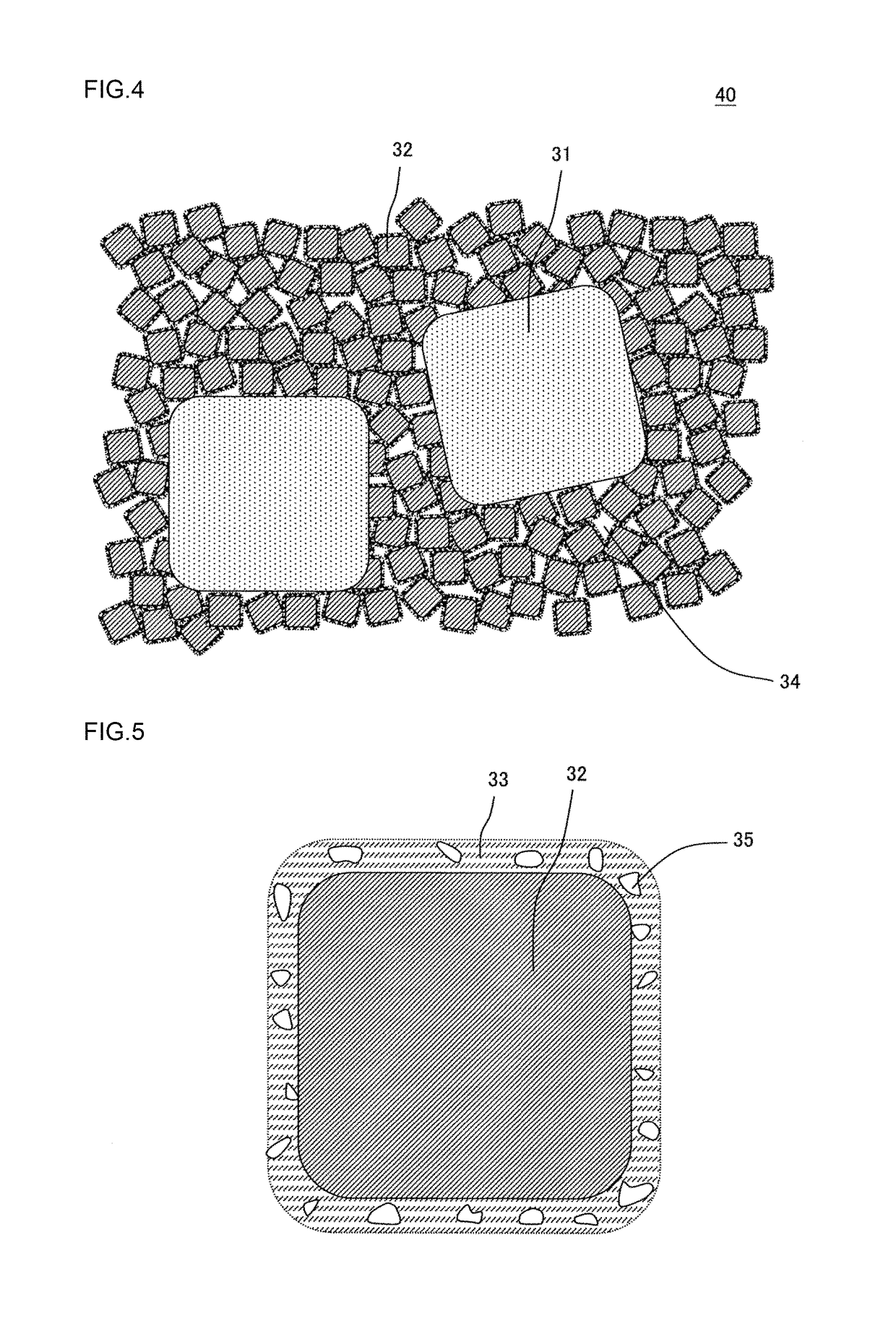

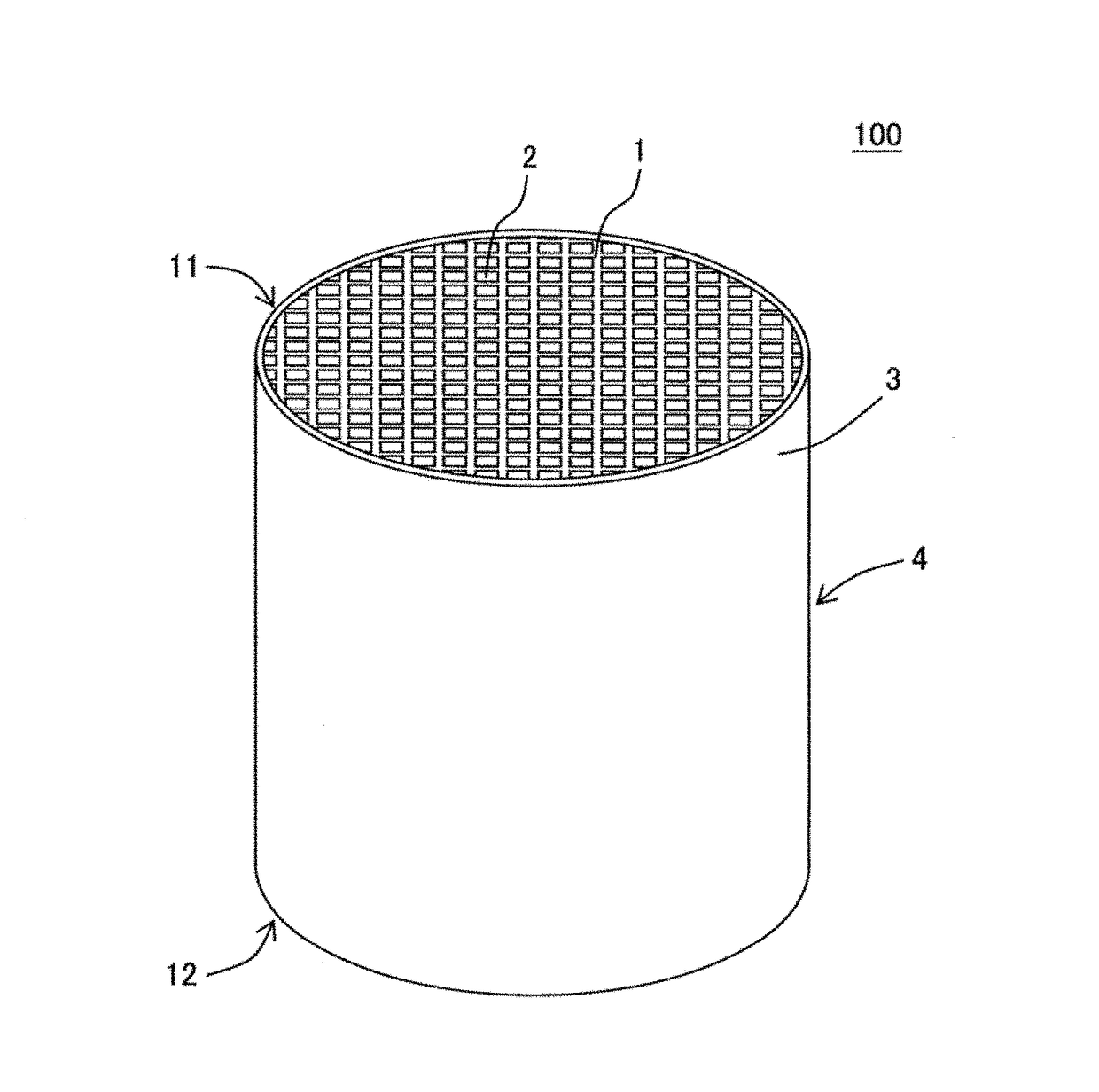

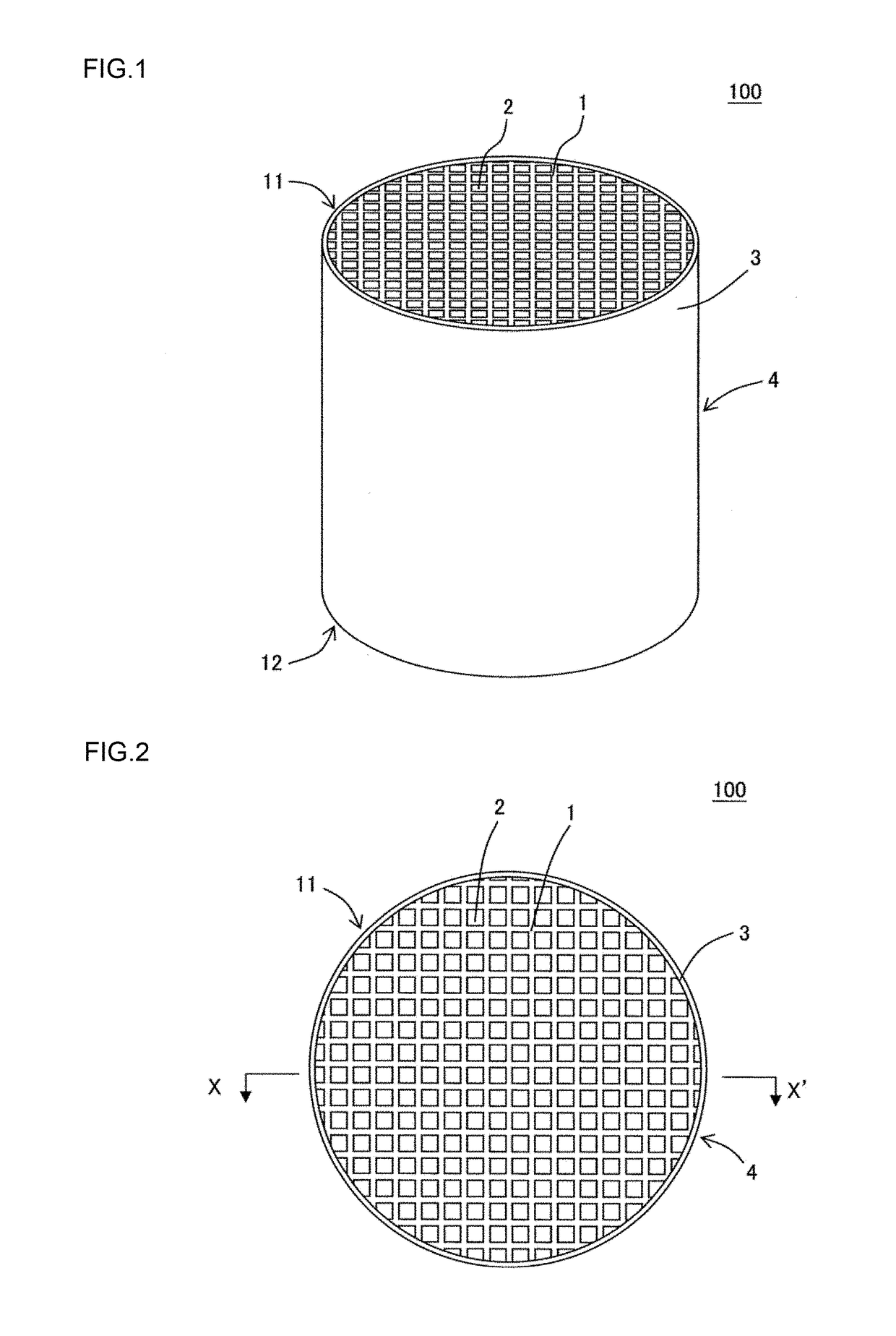

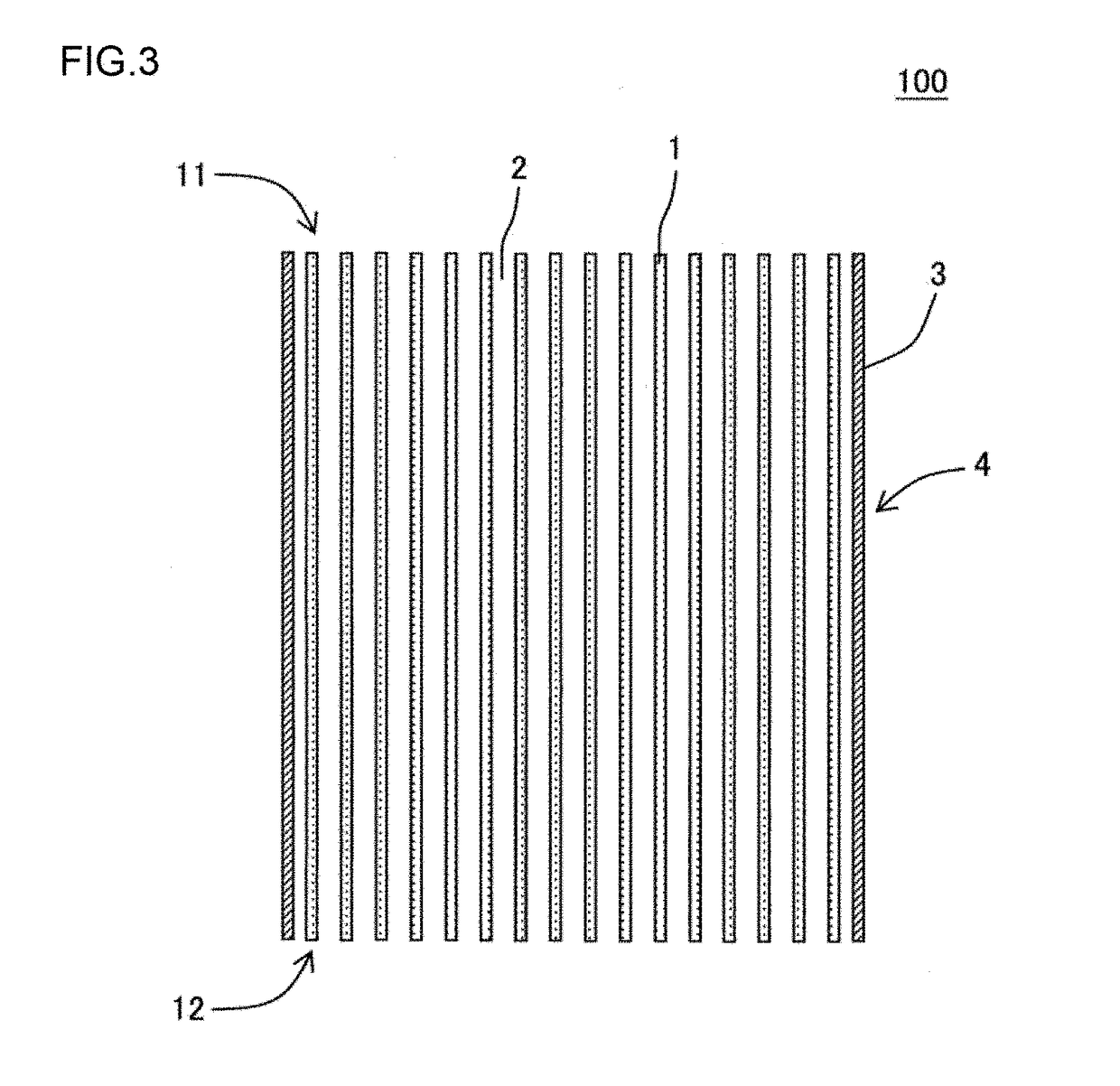

Manufacturing method of honeycomb structure

ActiveUS10195597B2Easily damagedLower performance requirementsGas treatmentMolecular sieve catalystsMetallurgyMicroparticle

The manufacturing method includes a step of mixing a coarse particle zeolite, a fine particle zeolite, and a raw material of an inorganic bonding material to prepare a zeolite raw material; a step of forming the prepared zeolite raw material into a honeycomb shape to prepare a honeycomb formed body; and a step of firing the prepared honeycomb formed body to prepare the honeycomb structure. In the step of preparing the zeolite raw material, as the coarse particle zeolite, a chabazite type zeolite having a specific average particle diameter, the fine particle zeolite having a specific average particle diameter, the raw material of the inorganic bonding material which includes at least basic aluminum lactate is used.

Owner:NGK INSULATORS LTD

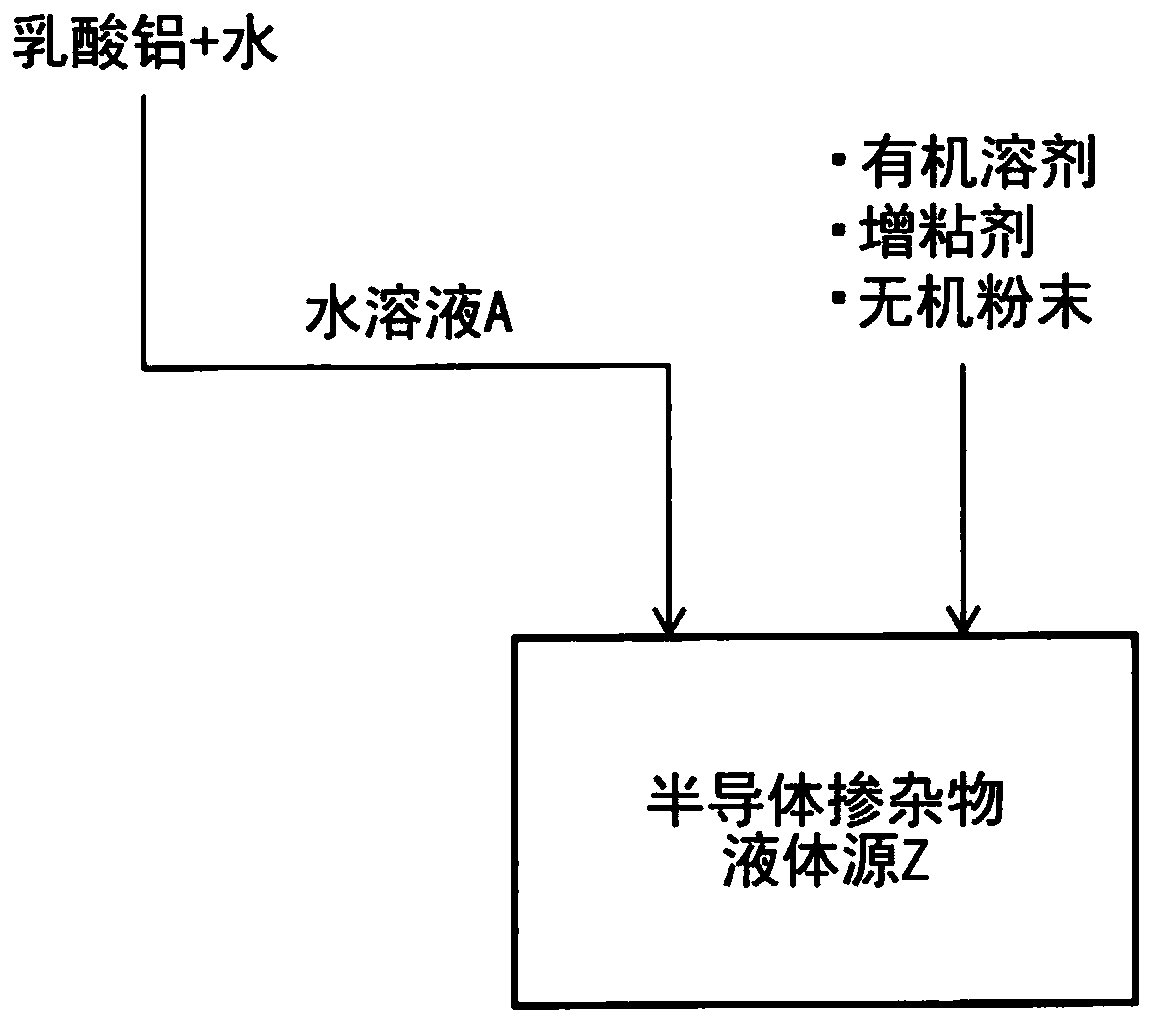

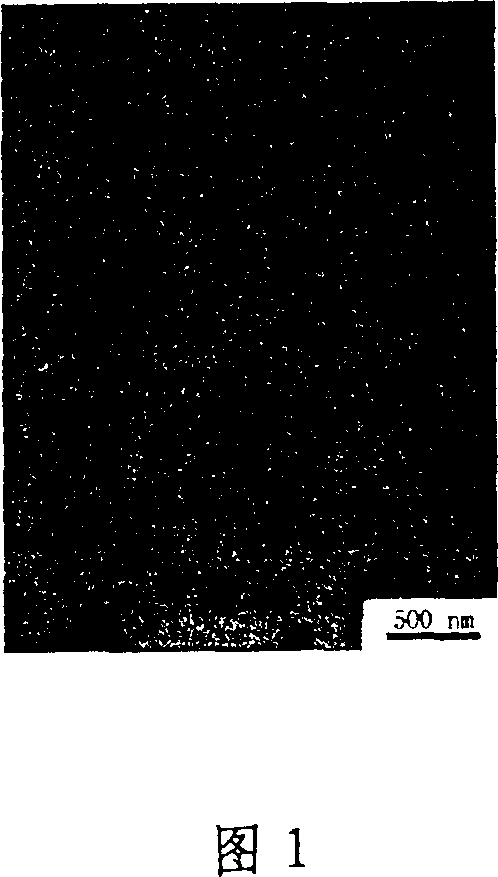

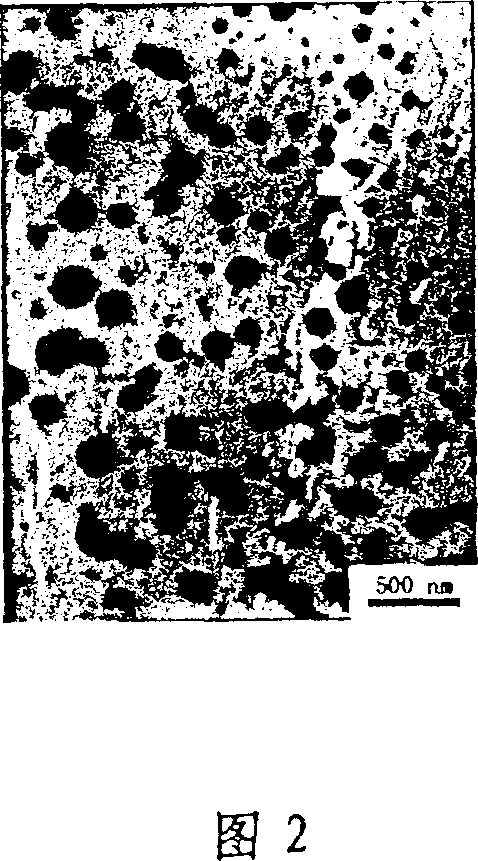

Method for producing semiconductor device

ActiveCN110352471ABroaden your optionsImprove controllabilitySemiconductor/solid-state device manufacturingOrganic solventDevice material

This method for producing a semiconductor device comprises: a dissolving step wherein aluminum lactate is dissolved in water, thereby preparing an aqueous solution; a mixing step wherein a mixed liquid is prepared by mixing the aqueous solution and an organic solvent with each other, and a semiconductor impurity liquid source that contains the mixed liquid is prepared; a coating step wherein the semiconductor impurity liquid source that contains the aqueous solution is applied onto a semiconductor substrate after the mixing step, thereby forming a diffusion source coating film on the semiconductor substrate; a firing step wherein the semiconductor substrate is subjected to a heat treatment at a first temperature in a first atmosphere after the coating step, thereby firing at least the organic solvent in the diffusion source coating film; and a diffusing step wherein the semiconductor substrate is subjected to a heat treatment at a second temperature that is higher than the first temperature in a second atmosphere after the firing step, thereby having the aluminum, which is contained in the diffusion source coating film, diffused into the semiconductor substrate so as to form a diffusion layer in the semiconductor substrate.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Nanometer grade liposome aluminium lactates addictive for daily used chemical product

InactiveCN1305458CGood against dentin hypersensitivityImprove the bactericidal effectCosmetic preparationsHair cosmeticsEmulsionAdditive ingredient

The invention discloses a nano grade liposome aluminum lactate additive used for toothpaste, deodorant, emulsion, face cream, lipstick, hair jelly, shampoo and liquid cleaner. The core of the additive is aluminum lactate, and the main ingredients of the liposome include lecithin, cholesterin and vitamin E.

Owner:CHONGQING NORMAL UNIVERSITY

A blast furnace swing nozzle castable and its preparation process

The invention discloses a swing spout castable for blast furnace and a preparation process thereof. The swing spout castable comprises the following components in mass ratio: 20-30 parts of alumina, 5-10 parts of bauxite powder, 25-35 parts of mullite particle, 5-10 parts of mullite powder, 5-10 parts of tabular corundum, 4-8 parts of activated alumina powder, 4-8 parts of silica powder, 1-4 parts of steel fiber, 2-5 parts of silica sol, 1-3 parts of fused MgO powder, 3-8 parts of polycarboxylate superplasticizer, 0.5-2 parts of detonation inhibitor which is a mixture of an azodicarbonamide foaming agent, aluminum lactate and polypropylene fiber, and 0.5-1 part of antioxidant. According to the swing spout castable, carbon-contained components such as brown fused alumina, silicon carbide and asphalt in a conventional swing spout castable are omitted, oxidization is prevented; mullite with low thermal expansivity is introduced and a mullite phase is formed in a substrate so as to reinforce thermal shock resistance and improve high temperature bending strength; compared with the prior art, the swing spout castable has better oxidation resistance, explosion-proof performance and high-temperature strength.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

Tundish working lining for clean steel smelting and preparation method thereof

InactiveCN103058693BImprove erosion abilityImprove permeabilityMelt-holding vesselsUltimate tensile strengthMagnesite

The invention relates to a tundish working lining for clean steel smelting and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: mixing 43-49 wt% of magnesite particle with particle size of 11-0.2 mm, 32-39 wt% of magnesite fine powder with particle size of 1-200 mu m, 8-22 wt% of magnesium-aluminum sol and 2-5 wt% of mixture, uniformly stirring, and coating or casting to form. The mixture is prepared by mixing aluminum oxide micropowder, aluminum lactate and calcium lignosulphonate in a mass ratio of 10:(1.8-2.2):(0.7-1.3); the MgO content in the magnesite particle and magnesite fine powder is greater than or equal to 95 wt%; the mol ratio of magnesium to aluminum in the magnesium-aluminum sol is 1:(0.5-2); the Al2O3 content in the aluminum oxide micropowder is greater than or equal to 98 wt%; and the particle size of the aluminum oxide micropowder is 1-20 mu m. The tundish working lining for clean steel smelting has the advantages of low impurity content, higher strength, high molten steel corrosion resistance, high molten steel penetrating resistance, low influence on total oxygen content in molten steel, and low influence on the quantity of oxide inclusions, and is suitable to be used as a tundish working lining for clean steel smelting.

Owner:WUHAN UNIV OF SCI & TECH

Ramping material for intermediate frequency induction furnace and preparation method thereof

ActiveCN106278315BSimple processGood performance at high temperatureMedium frequencyInduction furnace

The invention relates to ramming mass for a medium-frequency induction furnace and a preparing method thereof. According to the technical scheme, 58-74 wt% of fused corundum, 6-18 wt% of tabular corundum, 8-16 wt% of fused magnesite, 2-9 wt% of alpha-Al2O3 micro powder, 1-3 wt% of aluminum lactate and 1-6 wt% of magnesium lactate are used as raw materials and mixed uniformly to obtain the ramming mass for the medium-frequency induction furnace, wherein the particle size of aluminum lactate and magnesium lactate is smaller than 0.18 mm, the particle size of fused corundum is 0.088-5 mm, and the content of Al2O3 of the fused corundum is 94-99.5 wt%; the particle size of tabular corundum is 0.044-1 mm, the particle size of the fused magnesite is 0.044-1 mm, and the content of MgO of fused magnesite is larger than or equal to 95 wt%; the raw materials are mixed in a mixer for 10-25 min. The preparing method has the advantages of being simple in process and environmentally friendly. The prepared ramming mass for the medium-frequency induction furnace is high in refractoriness, erosion resistance and scouring resistance and long in service life.

Owner:LENGSHUIJIANG HUAKE PERFORMANCE MATERIALS

Manufacturing method of honeycomb structure

ActiveUS20170282168A1High mechanical strengthExcellent NOx purification performanceGas treatmentMolecular sieve catalystsMetallurgyMicroparticle

The manufacturing method includes a step of mixing a coarse particle zeolite, a fine particle zeolite, and a raw material of an inorganic bonding material to prepare a zeolite raw material; a step of forming the prepared zeolite raw material into a honeycomb shape to prepare a honeycomb formed body; and a step of firing the prepared honeycomb formed body to prepare the honeycomb structure. In the step of preparing the zeolite raw material, as the coarse particle zeolite, a chabazite type zeolite having a specific average particle diameter, the fine particle zeolite having a specific average particle diameter, the raw material of the inorganic bonding material which includes at least basic aluminum lactate is used.

Owner:NGK INSULATORS LTD

Cigarette paper additive and its preparation method

InactiveCN1327082CGood water solubilityNot easy to scatterInorganic compound additionBiochemical engineeringPerchlorate

A functional improver for the cigarette paper is prepared from perchlorate (20-90 Wt%) and alkaline aluminium lactate Al(OH)2 Lac (10-80 Wt%) through mixing. It is applied through dissolving it in water and spraying the solution onto cigarette paper to prevent the burnt paper from being broken for wrapping the tobacco ash well.

Owner:郑州瑞普生物工程有限公司

Dentifrice composition

ActiveCN102548526BImprove the bactericidal effectGood effectCosmetic preparationsToilet preparationsOctanolPhenol

Disclosed is a dentifrice composition which exhibits excellent bactericidal effect on biofilms, while having excellent hyperesthesia suppressing activity. The dentifrice composition is free from unpleasant taste and provides excellent feeling of use. Specifically disclosed is a dentifrice composition which is characterized by containing (A) isopropyl methyl phenol, (B) one or more substances selected from among potassium nitrate, aluminum lactate and strontium chloride, (C) one or more fragrance material components selected from among 3-octanol, 3-octyl acetate, 3-octanone and fenchone, and (D) an anionic surfactant and / or a nonionic surfactant. The dentifrice composition additionally contains (E) anisaldehyde.

Owner:LION CORP

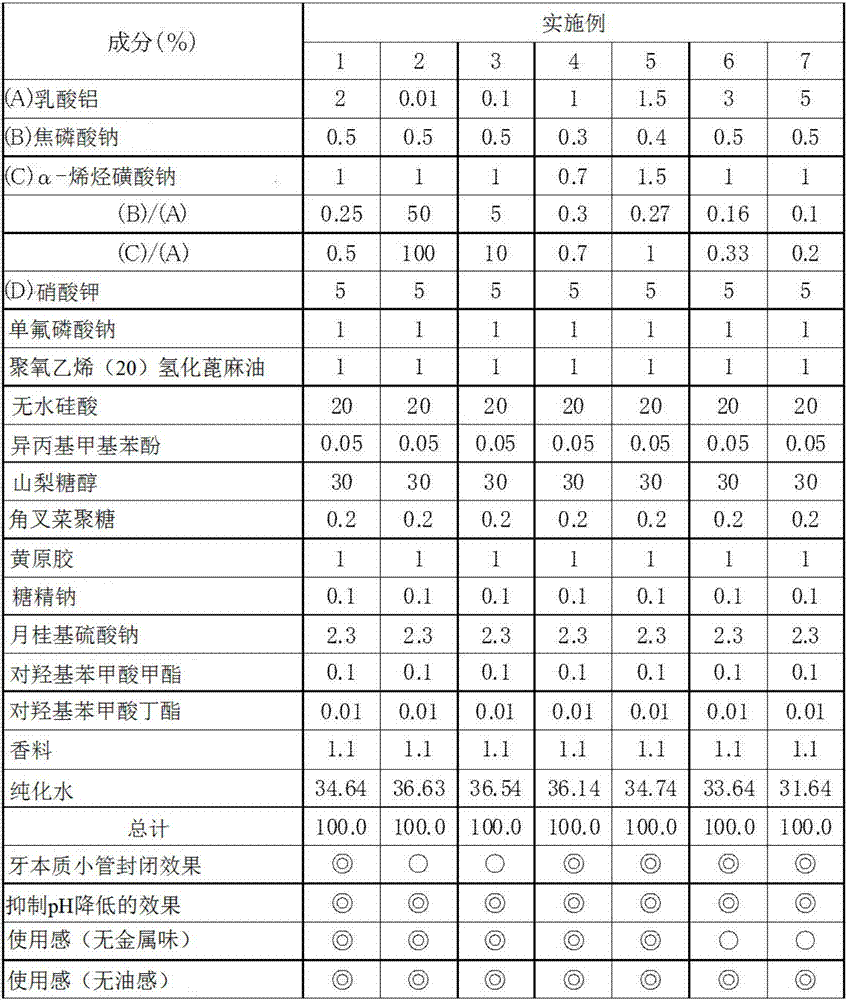

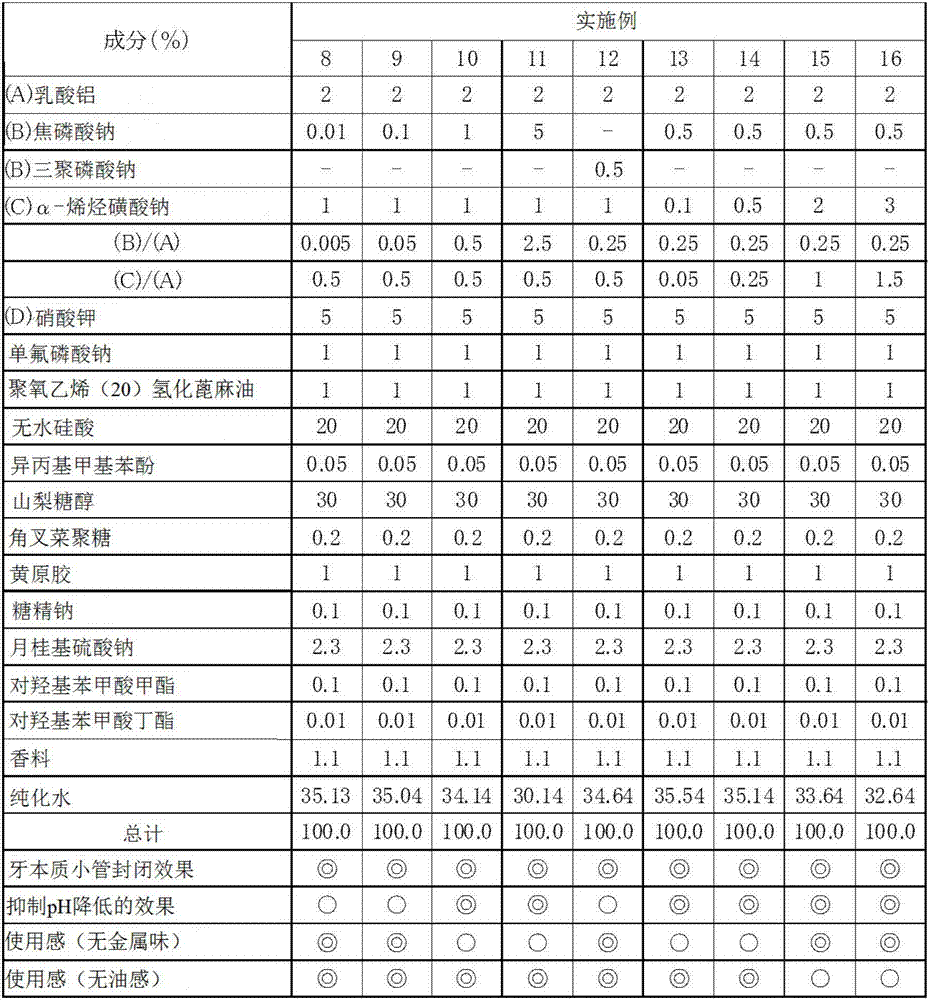

Dentifrice composition

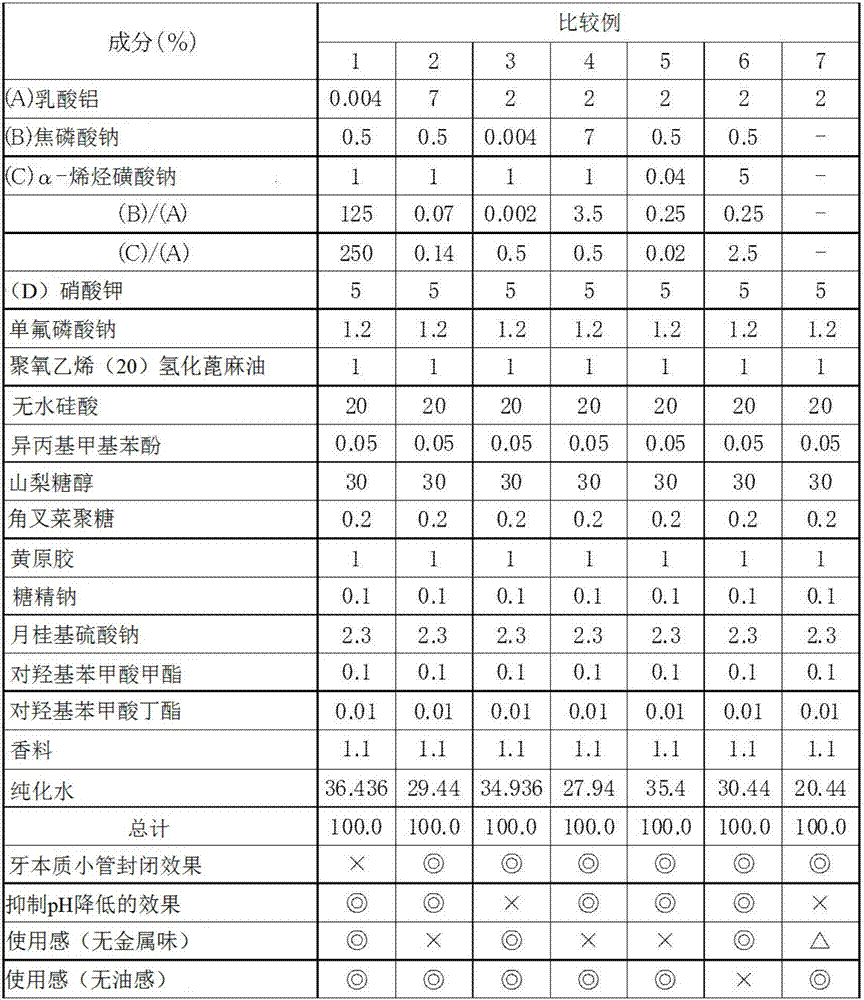

InactiveCN107205900AInhibit pHSuppress metallic tasteCosmetic preparationsToilet preparationsHyperesthesiaPhosphate

Provided is a dentifrice composition that exhibits an excellent effect of sealing dentinal fine tubules, effectively suppresses a lowering of pH, shows a controlled lowering of pH with the passage of time, gives a suppressed metallic taste and a good feeling in use and is appropriately usable for inhibiting dentinal hyperesthesia, the dentifrice composition comprising: (A) 0.01-5 mass% of aluminum lactate; (B) 0.01-5 mass% of a fused phosphate; and (C) 0.1-3 mass% of an alpha-olein sulfonic acid. Also provided is a method for suppressing a lowering of pH and expression of a metallic taste in the dentifrice composition. The method comprises blending a dentifrice composition containing 0.01-5 mass% of the component (A) with 0.01-5 mass% of the component (B) and 0.1-3 mass% of the component (C).

Owner:LION CORP

Explosion-proof iron runner castable

Owner:HENAN HUAXI FURNACE REFRACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com