Patents

Literature

32results about How to "Good performance at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

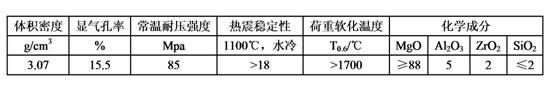

Magnesium-aluminum-zirconium composite spinel refractory material

The invention relates to a magnesium-aluminum-zirconium composite spinel refractory material. The refractory material is prepared from the following raw materials in percentage by weight: 50 to 95 percent of high-purity magnesia of which the granularity is less than or equal to 5 millimeters, 5 to 25 percent of magnesia-aluminum spine of which the granularity is less than or equal to 4 millimeters, 1 to 25 percent of desilicated zirconium or zircon sand of which the granularity is less than or equal to 3 millimeters and 1 to 6 percent of bonding agent in the raw materials. The refractory material is suitable for high temperature zones of large and medium-sized cement kilns, has high service performance and long service life, can completely replace magnesium-chromium refractory material tobe applied to the high temperature zone of a cement kiln, avoids environmental pollution caused by a magnesium-chromium brick after being used, and has very good economic benefit and social benefit.

Owner:河南瑞泰耐火材料科技有限公司

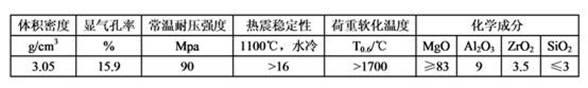

Aluminum/zinc composite ultralow-carbon alumina-magnesite carbon brick for ladle lining

The invention discloses an aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick for a ladle lining. The aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick is made by the following steps of: mixing raw materials, aging, molding, carrying out heat treatment at 180-250 DEG C and curing for 16-36 hours. The aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick comprises the following raw materials in percentage by weight: 40-60% of magnesite granule, 5-15% of magnesia alumina spinel granule, 25-35% of magnesite fine powder, 3-8% of aluminum / zinc metallic composite powder, 0-1% of crystalline flake graphite, 0.5-2% of boracic antioxidant and 3-4% of organic bond. The volume density of the aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick is greater than or equal to 3.0g / cm<3>, the apparent porosity is not more than 5%, the cold compressive strength is not lower than 45 MPa, the carbon-embedded high-temperature folding strength at 1400 DEG C is not lower than 25MPa, the content of MgO is not less than 75%, and the carbon content is not more than 2%.

Owner:ZHENGZHOU UNIV

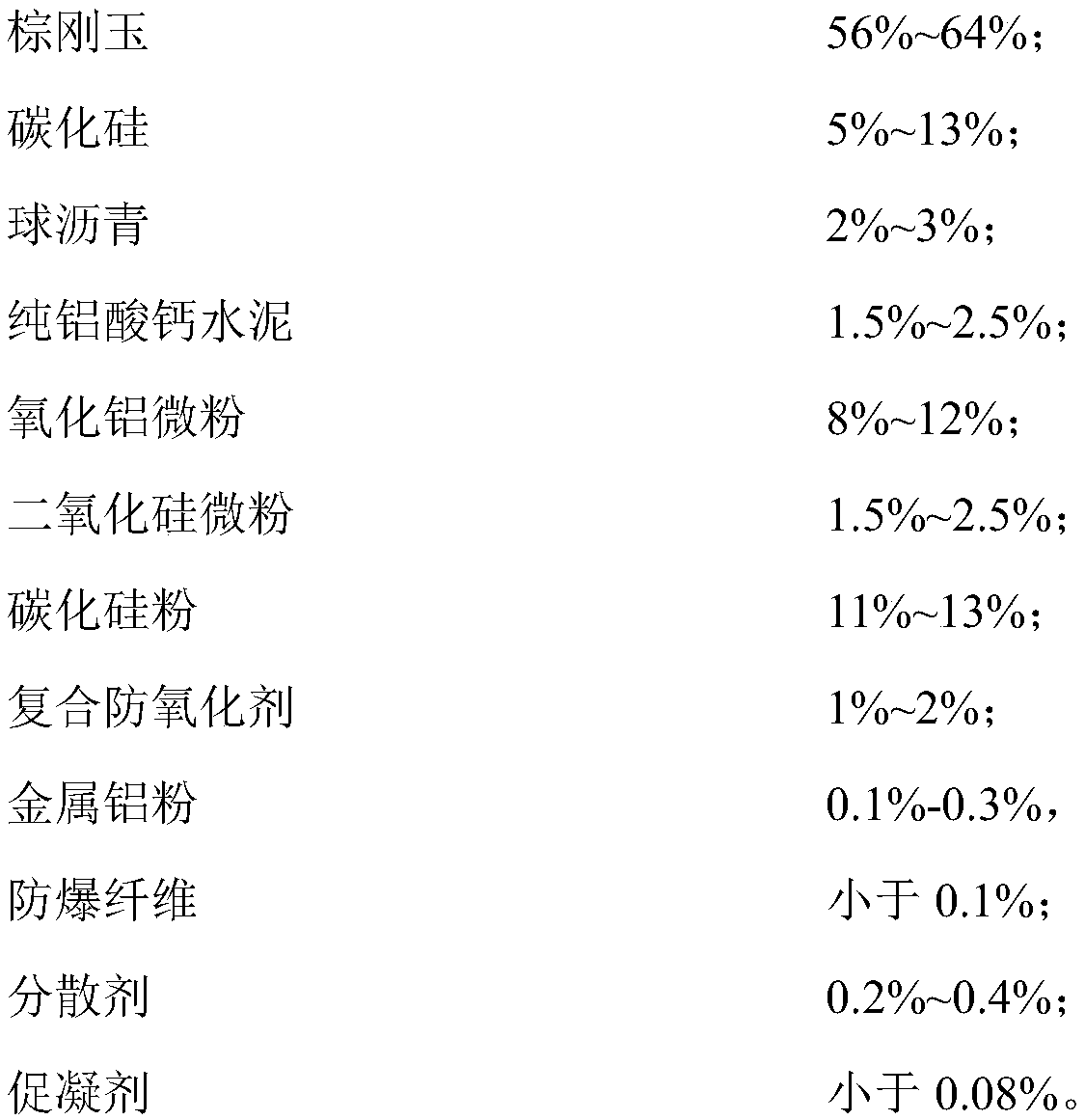

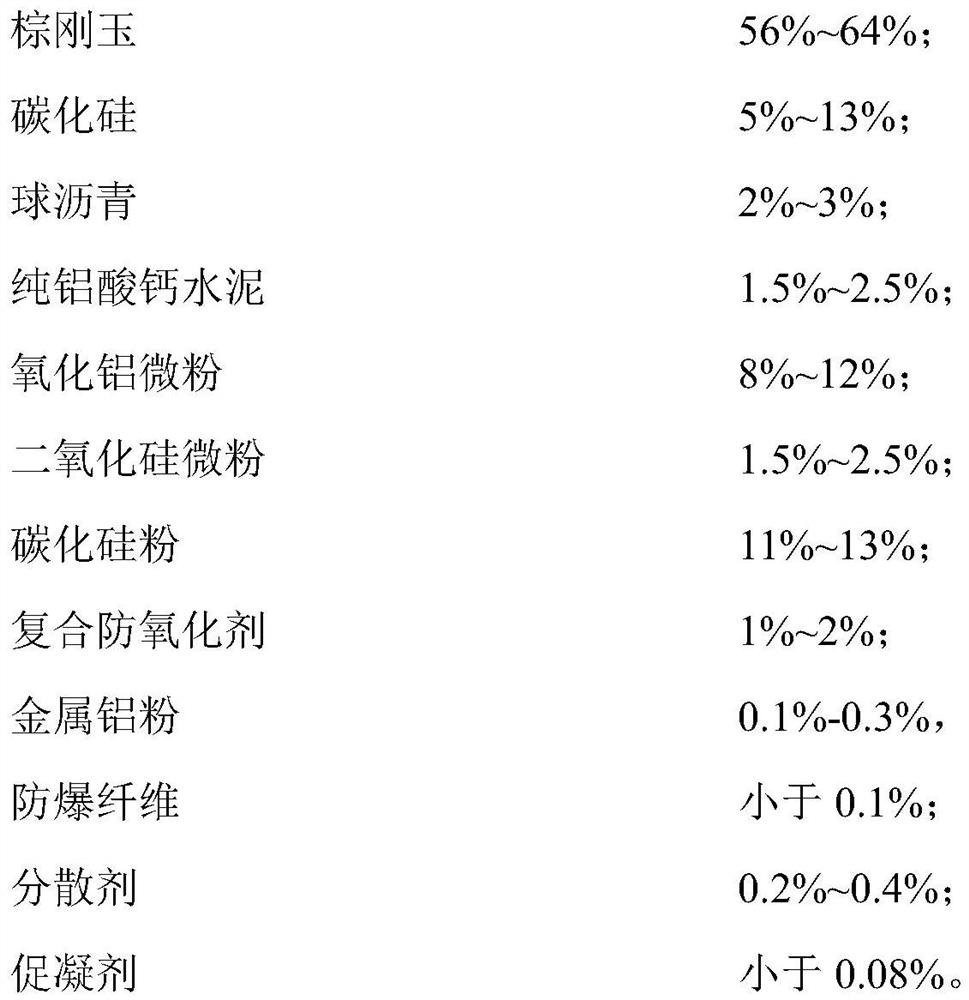

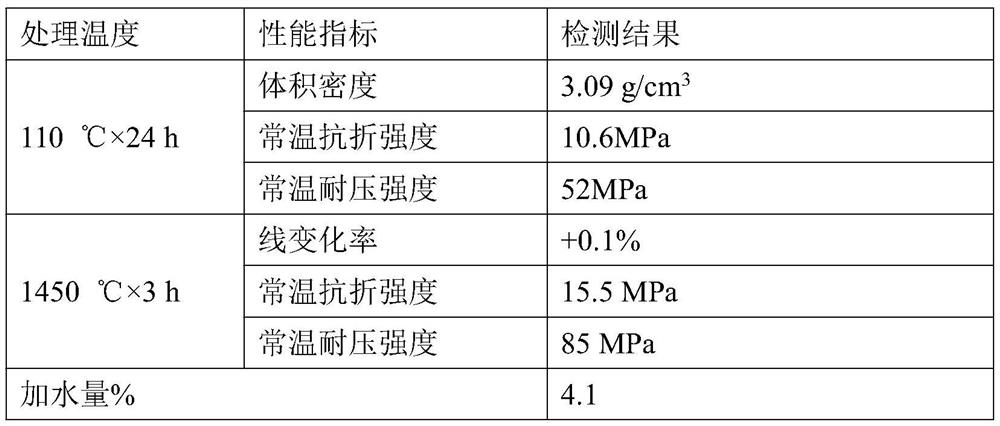

Long-service-life iron runner castable for hot repair

The invention discloses a long-service-life iron runner castable for hot repair. The long-service-life iron runner castable for hot repair comprises the following components in percentage by mass: 56%-64% of brown fused alumina, 5%-13% of silicon carbide, 2%-3% of ball pitch, 1.5%-2.5% of calcium aluminate cement, 8%-12% of alumina micro-powder, 1.5%-2.5% of silicon dioxide micro-powder, 11%-13% of silicon carbide powder, 1%-2% of a composite antioxidant, 0.1%-0.3% of metal aluminum powder, less than 0.1% of explosion-proof fibers, 0.2%-0.4% of a dispersing agent and 0.08% of a coagulant. Thenovel coagulant is used for the iron runner castable, thus, the metal aluminum powder in the iron runner castable produces hydrogen ahead of time, the gas is generated to open an exhaust hole when thecastable is not cured, then, the castable is matched with the suitable metal aluminum powder and the low-melting-point explosion-proof fibers, and it ensures that the castable has excellent high-temperature usability while meeting the condition of construction.

Owner:中冶武汉冶金建筑研究院有限公司

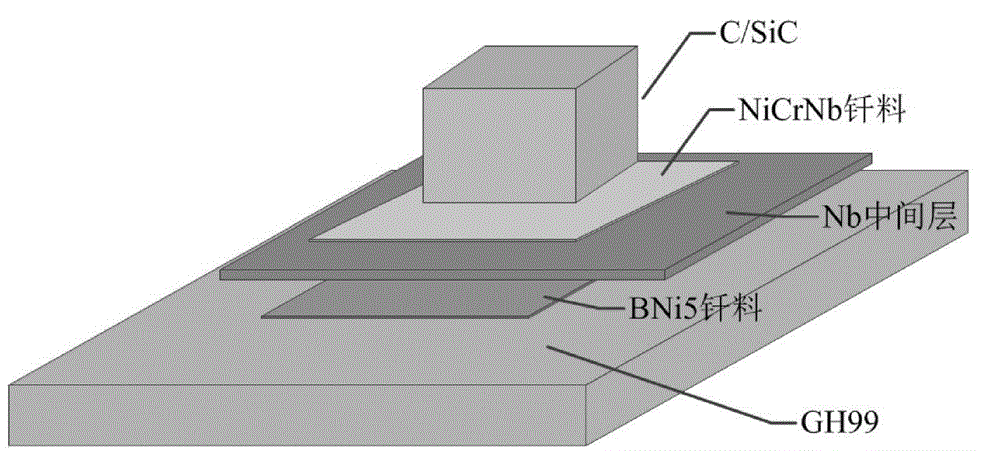

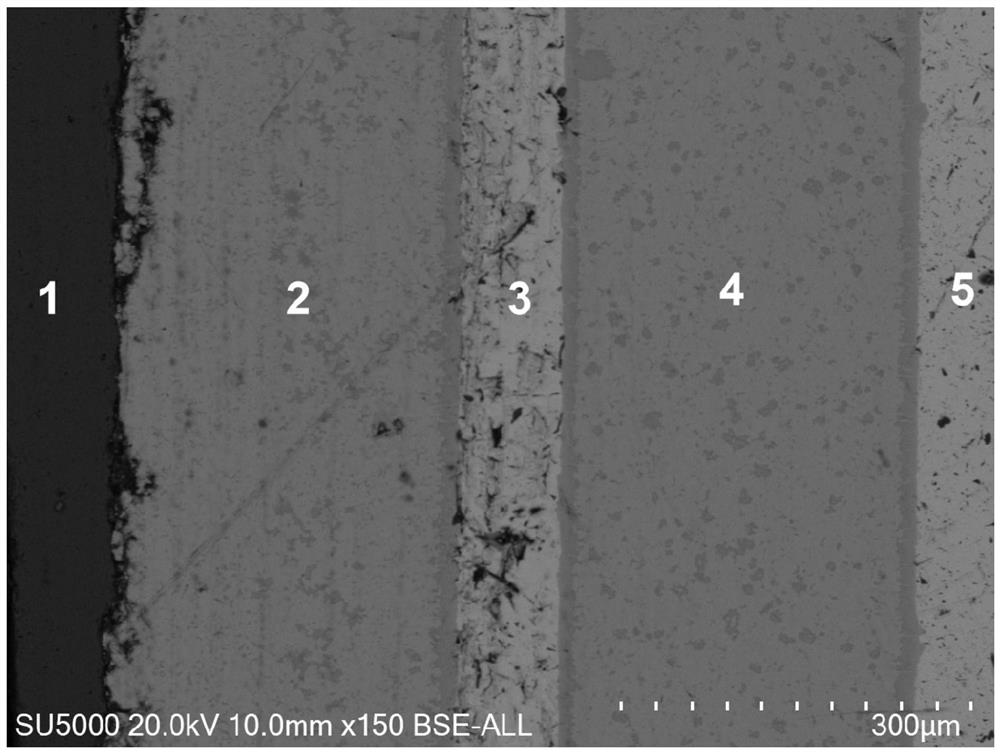

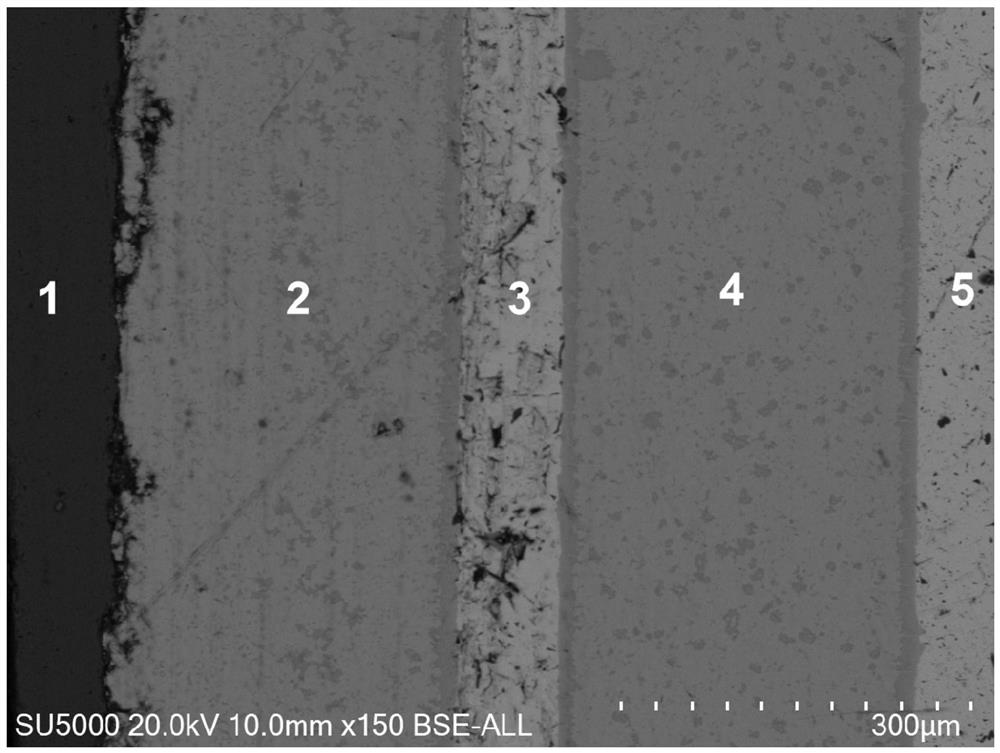

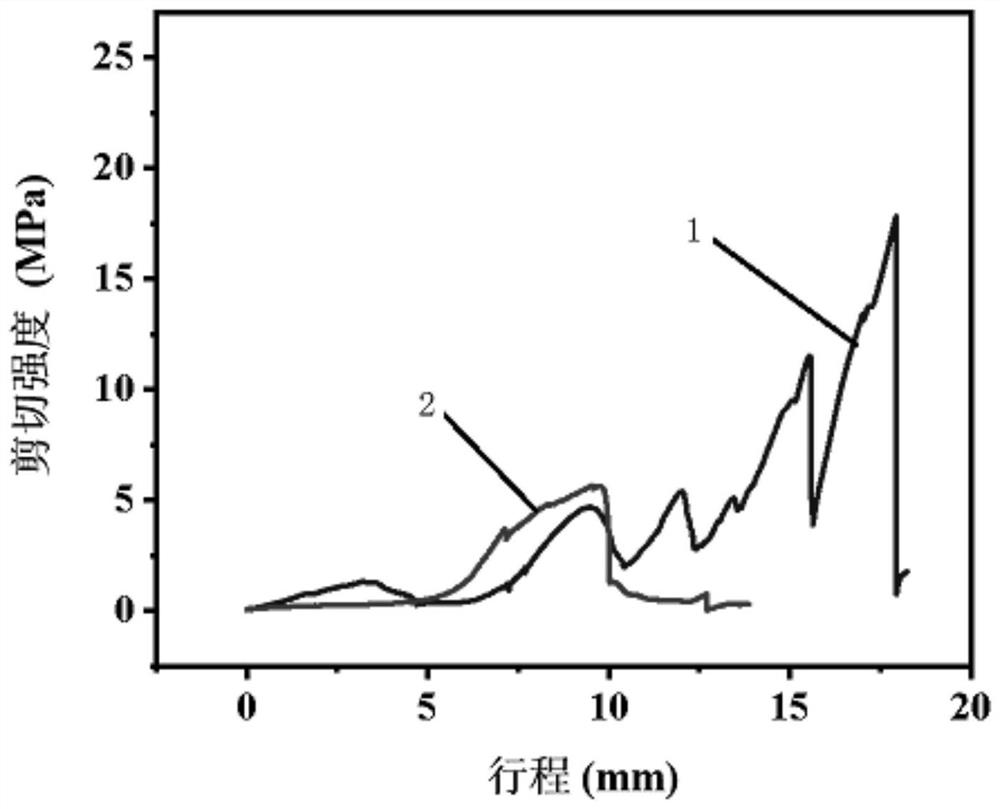

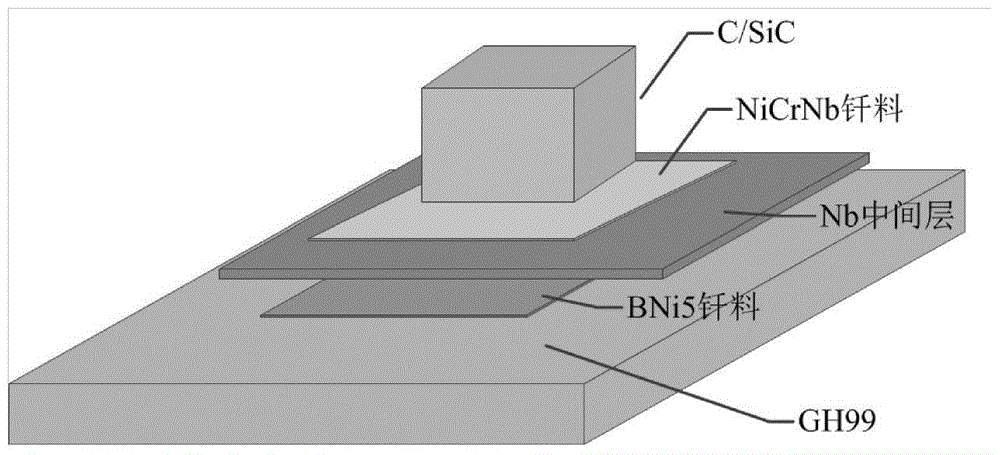

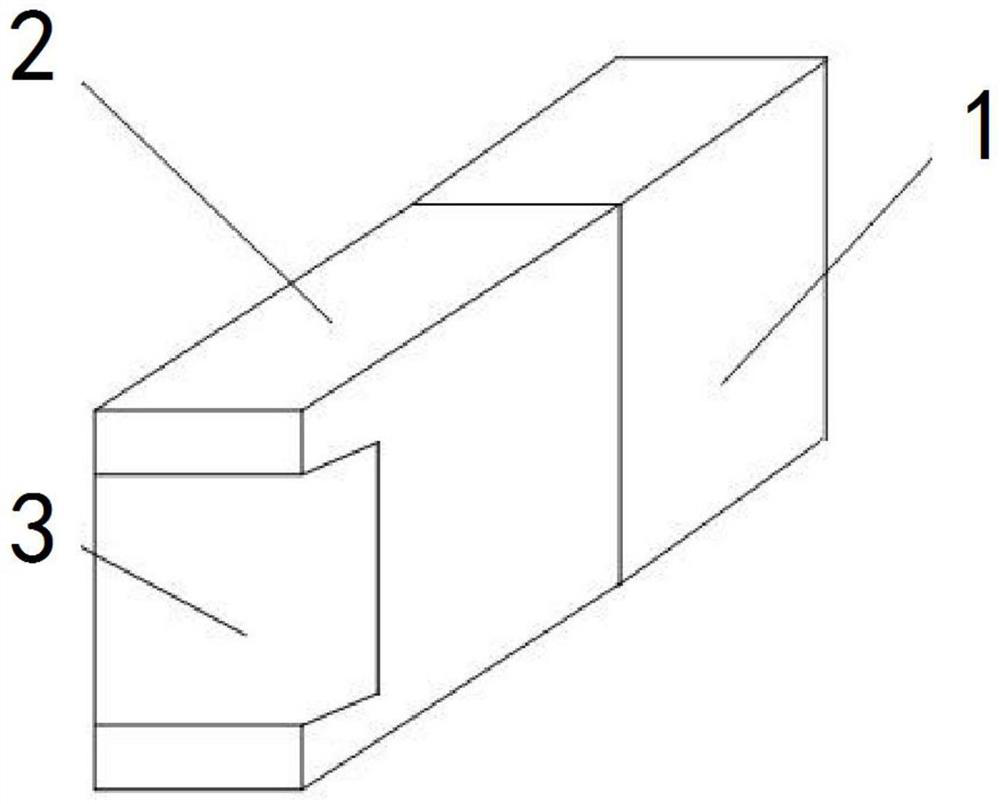

Composite interlayer and method for brazing metal with ceramic and ceramic matrix composite material by utilizing same

ActiveCN104690385AReduce contentReduce formationWelding/cutting media/materialsWelding/soldering/cutting articlesMaterials preparationMetal

The invention relates to a composite interlayer and a method for brazing metal with a ceramic and ceramic matrix composite material by utilizing the same, and solves a difficult problem of poor connector performance caused by a large amount of brittle phases generated in a strong reaction of a connector interface during brazing of the metal and the ceramic and ceramic matrix composite material by adopting an active brazing material and large residual stress of the connector after welding. The composite interlayer comprises an upper-layer brazing material, a soft interlayer and a lower-layer brazing material. The method comprises the following steps: 1, brazing material preparation, wherein the brazing material is prepared at a certain ratio; 2, cleaning, wherein cleaning is performed by acetone; 3, assembling, wherein a to-be-welded base material and the composite interlayer are assembled according to a certain sequence; 4, welding, wherein welding is performed in a vacuum brazing furnace. The operation is simple, and the addition of the interlayer inhibits over-reaction of the brazing material and the base material, reduces residual stress of the connector, and greatly improves the connector performance. The method is used for brazing the metal with the ceramic and ceramic matrix composite material.

Owner:HARBIN INST OF TECH

Low-alloy heat-resisting cast iron and preparation method thereof

The invention relates to low-alloy heat-resisting cast iron, which comprises the ingredients of 2.5 to 3.5 percent of C, 2.5 to 3.5 percent of Si, 0.1 to 1.0 percent of Cr, less than 1.0 percent of Mn, less than 0.3 percent of P, less than 0.1 percent of S, 1.8 to 4.0 percent of Al, 0.05 to 0.1 percent of Sr and the balance of Fe. The preparation method comprises the steps that: scrap steel, chromium iron, pig iron, silicon iron, pure aluminum and aluminum-strontium intermediate alloy are mixed and smelted according to the mass percentage of the chemical ingredients in the target product, wherein the pure aluminum is placed at the bottom of a casting ladle in advance, after an aluminum block is smelted, the aluminum-strontium intermediate alloy is added, 75SiFe nucleating agents are filled along with flows, and the drossing and the casting are carried out after stirring; in the preparation method, the aluminum content is low, the aluminum-strontium intermediate alloy is matched for carrying out spheroidisation on molten iron; and a protecting film is promoted to be formed on the surface of the cast iron at a high temperature. The low-alloy heat-resisting cast iron has the advantages that the process method is simple, the operation is convenient, the production cost is low, the comprehensive mechanical performance is good, the inoxidizability is high, and the low-alloy heat-resisting cast iron adapts to various application processes requiring repeated heating and cooling, such as crucibles, fire grates and the like for nonferrous metal smelting. The low-alloy heat-resistingcast iron is suitable for industrial production.

Owner:CENT SOUTH UNIV

Ramming mass for medium-frequency induction furnace and preparing method thereof

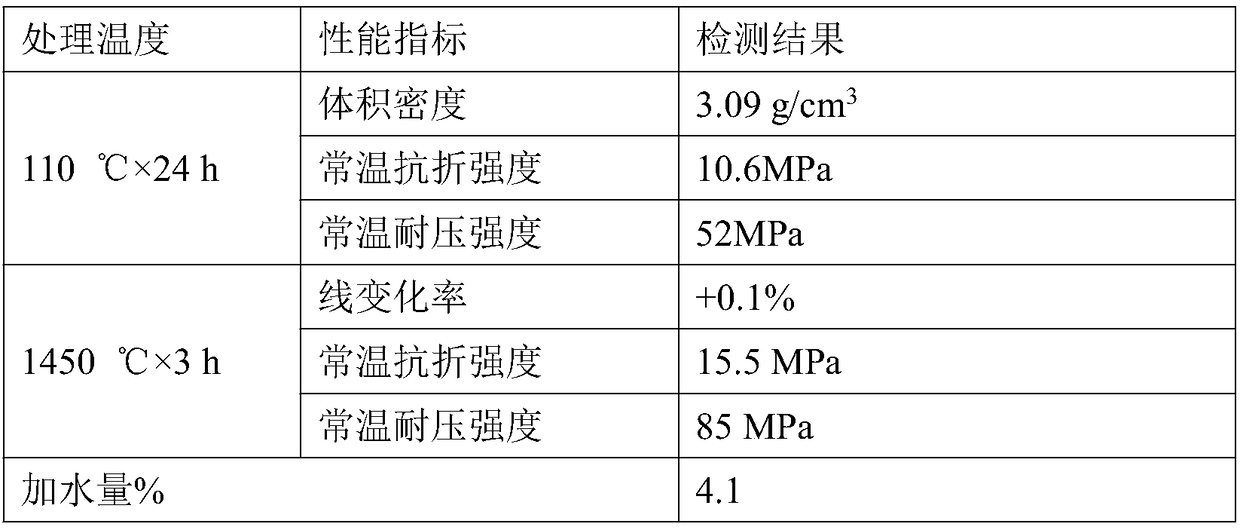

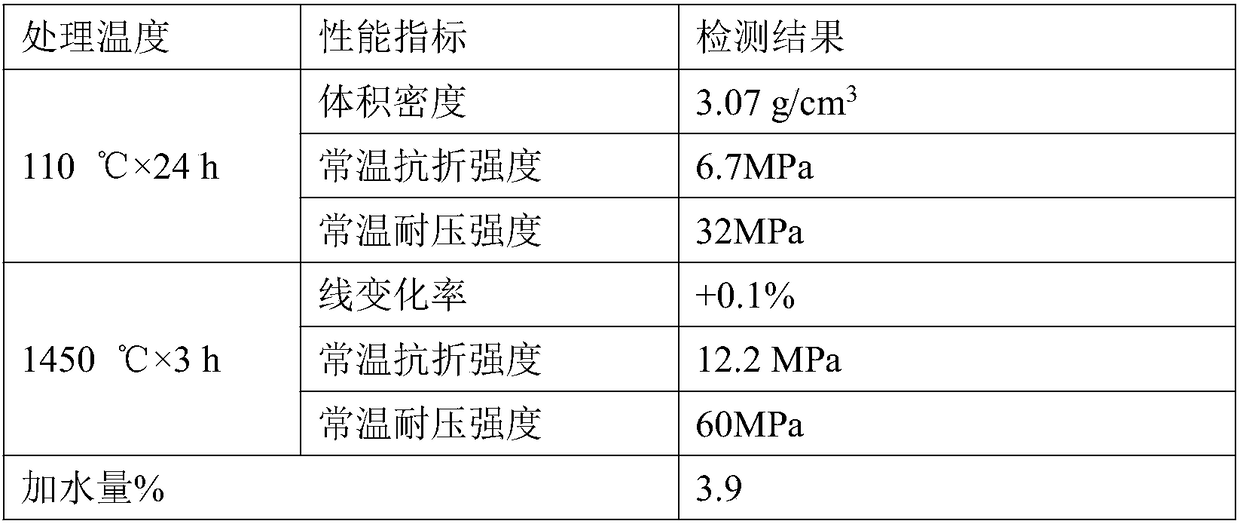

ActiveCN106278315ASimple processGood performance at high temperatureAluminum lactateMedium frequency

The invention relates to ramming mass for a medium-frequency induction furnace and a preparing method thereof. According to the technical scheme, 58-74 wt% of fused corundum, 6-18 wt% of tabular corundum, 8-16 wt% of fused magnesite, 2-9 wt% of alpha-Al2O3 micro powder, 1-3 wt% of aluminum lactate and 1-6 wt% of magnesium lactate are used as raw materials and mixed uniformly to obtain the ramming mass for the medium-frequency induction furnace, wherein the particle size of aluminum lactate and magnesium lactate is smaller than 0.18 mm, the particle size of fused corundum is 0.088-5 mm, and the content of Al2O3 of the fused corundum is 94-99.5 wt%; the particle size of tabular corundum is 0.044-1 mm, the particle size of the fused magnesite is 0.044-1 mm, and the content of MgO of fused magnesite is larger than or equal to 95 wt%; the raw materials are mixed in a mixer for 10-25 min. The preparing method has the advantages of being simple in process and environmentally friendly. The prepared ramming mass for the medium-frequency induction furnace is high in refractoriness, erosion resistance and scouring resistance and long in service life.

Owner:LENGSHUIJIANG HUAKE PERFORMANCE MATERIALS

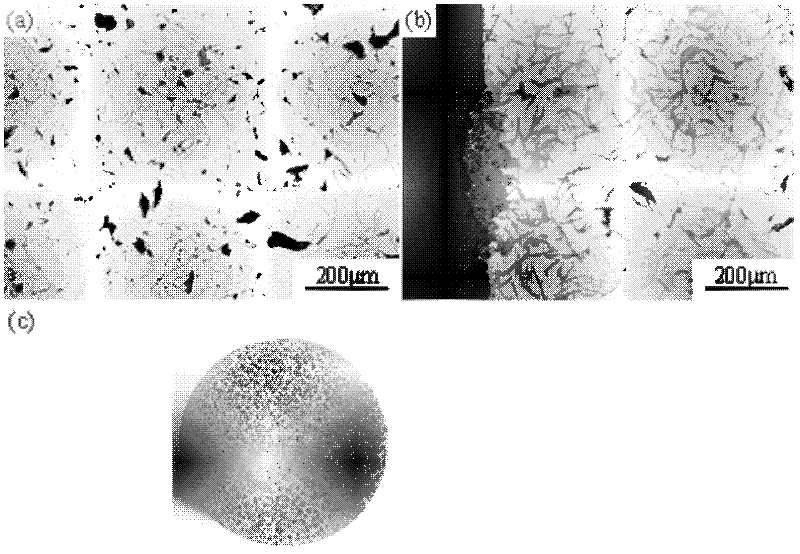

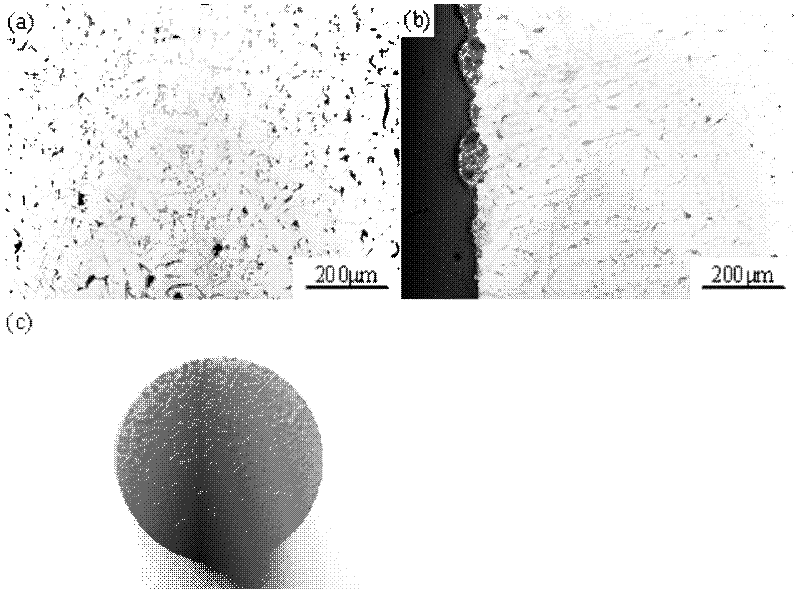

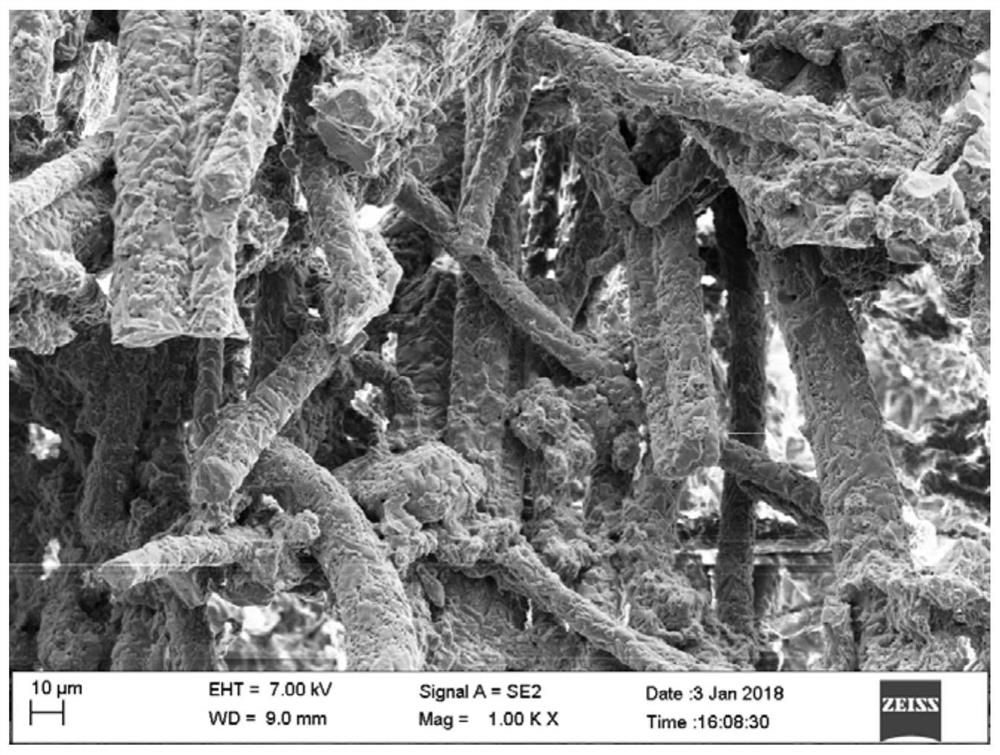

Environment-friendly method for preparing mullite fiber based porous ceramic through gel casting

The invention belongs to the field of porous ceramic and in particular relates to an environment-friendly method for preparing mullite fiber based porous ceramic through gel casting. The mullite fiberbased porous ceramic is prepared from the following raw materials in percentage by mass: 11 to 32 percent of rho-Al2O3 powder, 13 to 36 percent of kaolin or zircon powder and 33 to 75 percent of mullite fiber. The method comprises the following steps: taking the rho-Al2O3 powder and the kaolin or zircon powder; adding a certain amount of de-ionized water; mechanically stirring and carrying out ultrasonic oscillation to obtain stable and uniform ceramic slurry; then uniformly adding the mullite fibers into the ceramic slurry; continually stirring and oscillating to obtain gel ceramic-fiber slurry; then carrying out injection molding and curing at room temperature; putting a molded biscuit into a constant-temperature drying box and drying; after de-molding, putting into a high-temperature furnace; sintering under an air atmosphere to obtain mullite combined or ZrO2-mullite combined mullite fiber based porous ceramic. The environment-friendly method has a simple and feasible technology and is environmentally friendly; the prepared mullite fiber based porous ceramic has high porosity, low heat conductivity and relatively high strength.

Owner:NORTHEASTERN UNIV

Refractory material for carbon furnace and preparation method thereof

The invention belongs to a refractory material field, and concretely, relates to a refractory material for a carbon furnace and a preparation method thereof. The refractory material for the carbon furnace contains 50-70% of flint clay, 10-30% of bauxite clinker, 5-18% of silicon carbide, 5-15% of alumina, and 5-10% of binding clay, and further contains 3-7% by total weight of binder, wherein the binder is phosphoric acid or phosphate solution with proportion being 1.4-1.5g / cm3, and the refractory material for the carbon furnace of the invention can be obtained by the following steps: batching, mixedly grinding, ageing, forming, roasting under 500-600 DEG C, etc. The refractory material has the advantages of high overpressure resistant intensity, high load softening temperature, good creep resistant performance, low porosity, good thermal shock resistance stability, small linear expansion coefficient, good CO resistant performance, etc., thereby greatly increasing the service life of the carbon furnace. Particularly, the refractory material is roasted without high temperature, so the purposes of energy saving and emission reduction, are achieved.

Owner:巩义市第五耐火材料有限公司

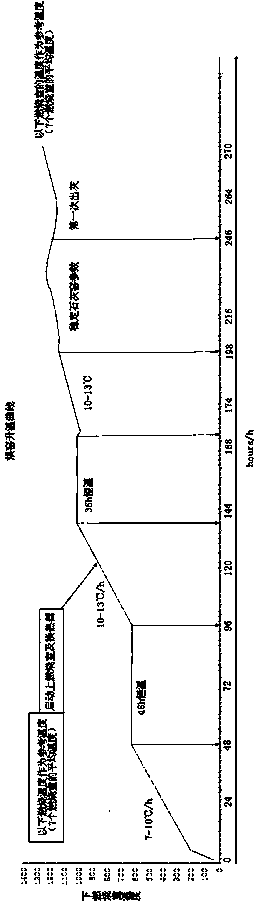

Sleeve lime kiln empty-kiln baking method

The invention relates to a sleeve lime kiln. A sleeve lime kiln empty-kiln baking method comprises the steps: introducing coal gas to temporary burners of the sleeve lime kiln; starting up an exhaust gas draught fan to allow a negative pressure in the kiln to be greater than or equal to -0.05 kPa; igniting the temporary burners in order, inserting ash discharging devices from ash discharging device observation holes, and making the burners upward and fixing; when the temperature in the kiln rises to 50 DEG C, controlling the temperature rising speed at 3 DEG C to 5 DEG C per hour for rising the temperature; when the temperature rises to 280 to 300 DEG C, carrying out heat preservation; 24 hours later after beginning to baking the kiln, opening burner drainage screws and exhaust gas flue drainage holes, after the burners drain, tightening the screws, and timing for every 4 hours to drain once; carrying out continuous heat preservation until drainage ports have no obvious water, that is to said moisture of a refractory material in the kiln is baked to a reasonable control range; cutting off temporary burner coal gas valves; closing the exhaust gas draught fan; and eight hours later, closing a cooling draught fan. The method can effectively remove the moisture in the refractory material and ensure the high-temperature using performance of the refractory material.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

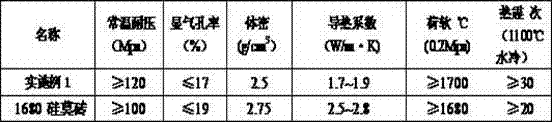

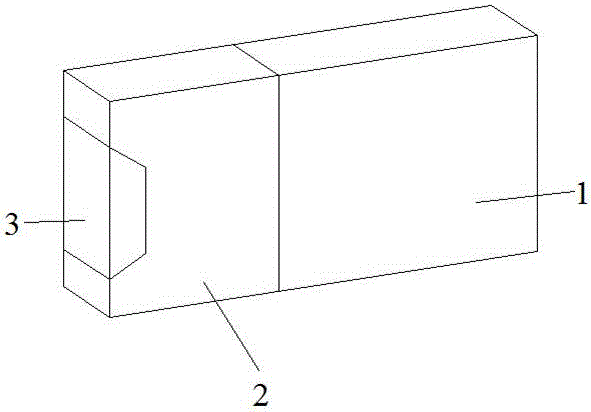

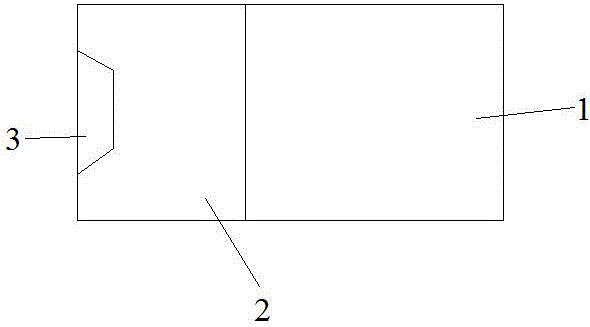

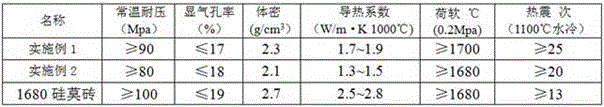

Low-heat-conduction multi-layer mullite brick and preparation method thereof

ActiveCN103234346BLow thermal conductivityHigh strengthFurnace componentsRotary drum furnacesBrickMullite

Owner:郑州瑞泰耐火科技有限公司

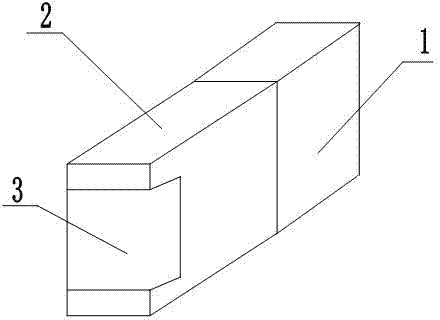

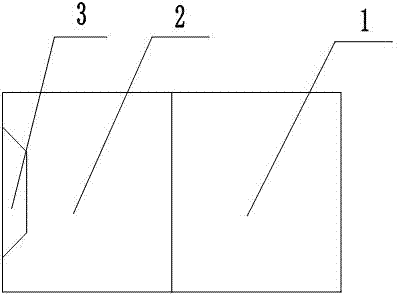

Low-heat-conductivity multilayer composite potassium aluminosilicate brick and preparing method thereof

ActiveCN105777149AGood resistance to alkali corrosionExtended service lifeCeramicwareComposite structureAntioxidant

The invention discloses a low-heat-conductivity multilayer composite potassium aluminosilicate brick and a preparing method thereof.The low-heat-conductivity multilayer composite potassium aluminosilicate brick comprises a working layer, a heat preservation layer and a heat insulation layer, wherein the working layer and the heat preservation layer are connected into a whole in the length direction of the brick, a notch is formed in the end face, located in the width direction of the heat preservation layer, of the heat preservation layer, the shape of the heat insulation layer is matched with that of the notch, and the heat insulation layer is arranged in the notch.The working layer is prepared from synthesis potassium aluminate with the particle size ranging from 0 to 1 mm, silicon carbide with the particle size ranging from 1 mm to 3 mm, silicon carbide with the particle size ranging from 3 mm to 5 mm, synthesis potassium aluminate with the particle size smaller than 0.074 mm, silicon carbide with the particle size smaller than 0.074 mm, an antioxidant and a binding agent.The heat preservation layer is prepared from synthesis potassium aluminate with the particle size ranging from 0 to 1 mm, silicon carbide with the particle size ranging from 1 mm to 3 mm, silicon carbide with the particle size ranging from 3 mm to 5 mm, synthesis potassium aluminate with the particle size smaller than 0.074 mm, silicon carbide with the particle size smaller than 0.074 mm, a high-temperature reinforcing agent, a composite organic pore forming agent and a binding agent.The heat insulation layer is made of an aluminum oxide fiberboard.The low-heat-conductivity multilayer composite potassium aluminosilicate brick has excellent high-temperature usability by means of the advantages of the multilayer composite structure, and the heat conductivity coefficient and the body density are far lower than those of products of the same kind.

Owner:郑州瑞泰耐火科技有限公司

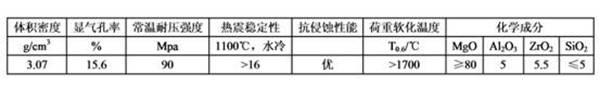

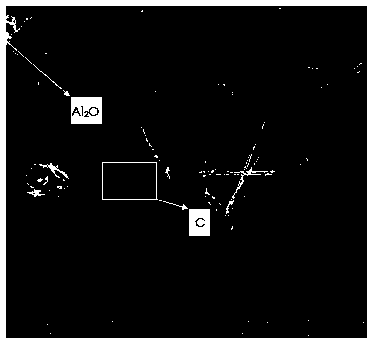

Al2O3-SiC-C iron runner casting material and preparation method thereof

The invention specifically relates to an Al2O3-SiC-C iron trench castable and a preparation method thereof. The technical solution is: first, 50-60wt% of fused brown corundum particles, 8-12wt% of fused brown corundum fine powder, 3-10wt% of silicon carbide particles, 6-11wt% of silicon carbide fine powder, 3 ~7wt% α-Al2O3 micropowder, 2~4wt% spherical pitch, 2~4wt% silica micropowder, 2~4wt% calcium aluminate cement, 2~4wt% metal antioxidant and 0.1~0.3wt% % dispersant as the raw material, plus 0.1-3wt% catalyst of the raw material, and dry-mix evenly to obtain the Al2O3-SiC-C iron channel castable. The preparation cost of the present invention is relatively low, and the prepared Al2O3-SiC-C iron ditch castable has the advantages of low water addition, large flow value, good high-temperature service performance and strong thermal shock stability, so that the blast furnace iron channel has a large amount of iron and refractory materials Less consumption.

Owner:WUHAN UNIV OF SCI & TECH

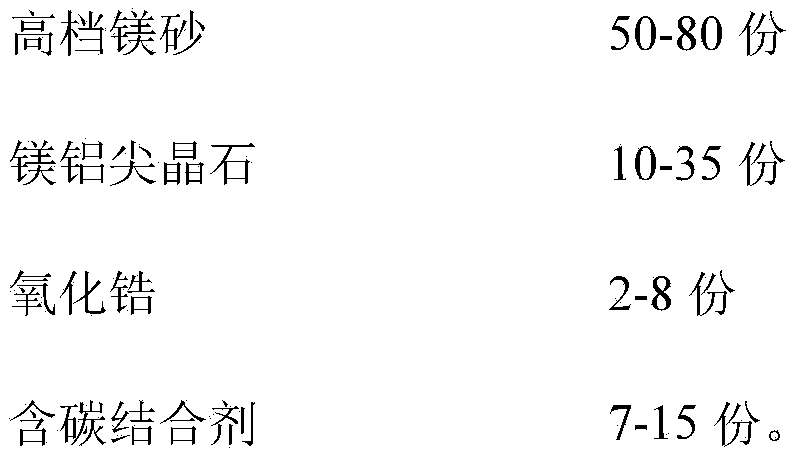

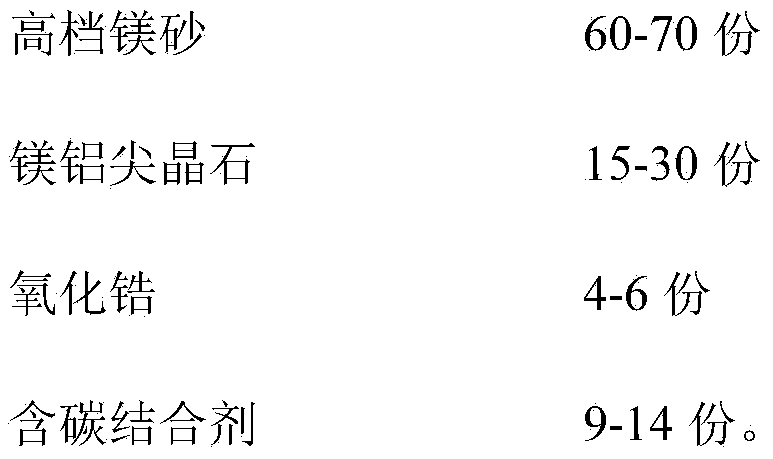

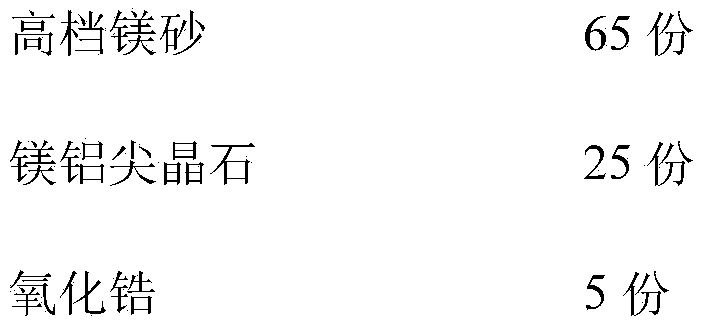

Magnesium-zirconium spinel ramming material for furnace bottom

ActiveCN104108944ALow linear shrinkageGood high temperature performanceMagnesium AluminateWork safety

The invention discloses a magnesium-zirconium spinel ramming material for a furnace bottom. The ramming material is prepared from the following raw materials in parts by weight: 50-80 parts of high-grade magnesia, 10-35 parts of magnesium aluminate spinel, 2-8 parts of zirconium oxide and 7-15 parts of carbon-contained binding agent. The ramming material can be used for improving the filling condition of a triangle area part at the furnace bottom and providing a certain protection for a furnace shell in a high-temperature state, so that the furnace life is prolonged, and the working safety is favorably realized.

Owner:LIAONING ZHONGMEI HLDG

Aluminum/zinc composite ultralow-carbon alumina-magnesite carbon brick for ladle lining

The invention discloses an aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick for a ladle lining. The aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick is made by the following steps of: mixing raw materials, aging, molding, carrying out heat treatment at 180-250 DEG C and curing for 16-36 hours. The aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick comprises the following raw materials in percentage by weight: 40-60% of magnesite granule, 5-15% of magnesia alumina spinel granule, 25-35% of magnesite fine powder, 3-8% of aluminum / zinc metallic composite powder, 0-1% of crystalline flake graphite, 0.5-2% of boracic antioxidant and 3-4% of organic bond. The volume density of the aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick is greater than or equal to 3.0g / cm<3>, the apparent porosity is not more than 5%, the cold compressive strength is not lower than 45 Mpa, the carbon-embedded high-temperature folding strength at 1400 DEG C is not lower than 25MPa, the content of MgO is not less than 75%, and the carbon content is not more than 2%.

Owner:ZHENGZHOU UNIV

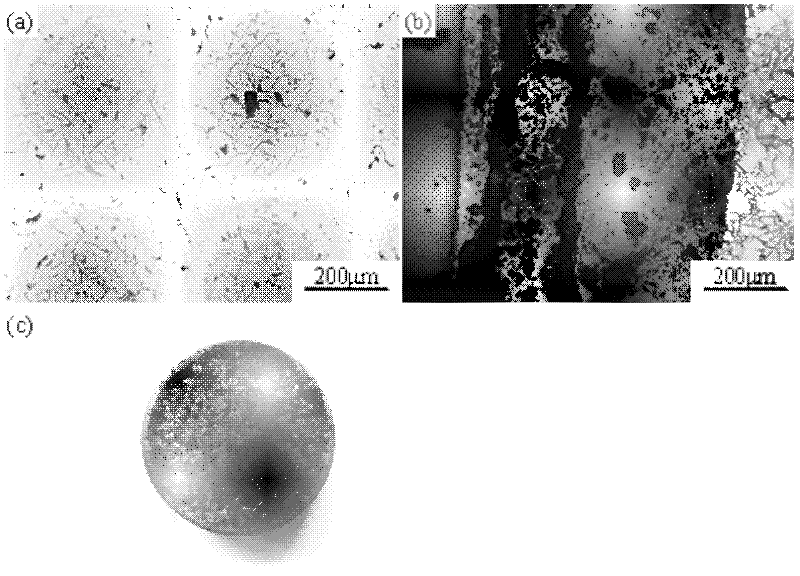

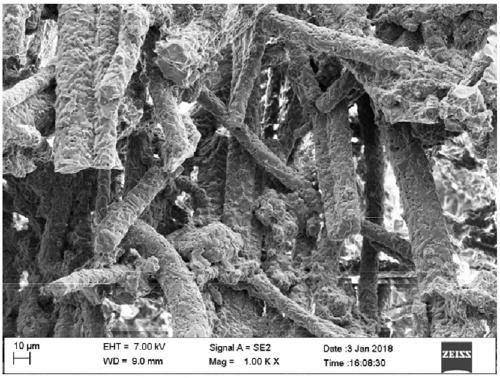

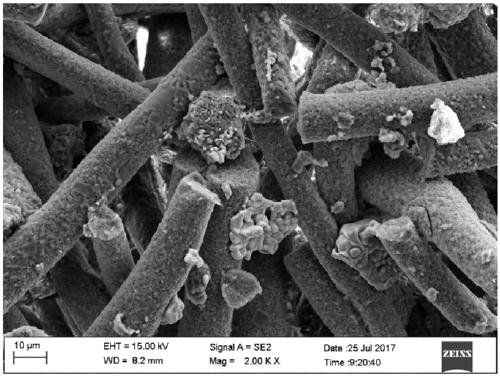

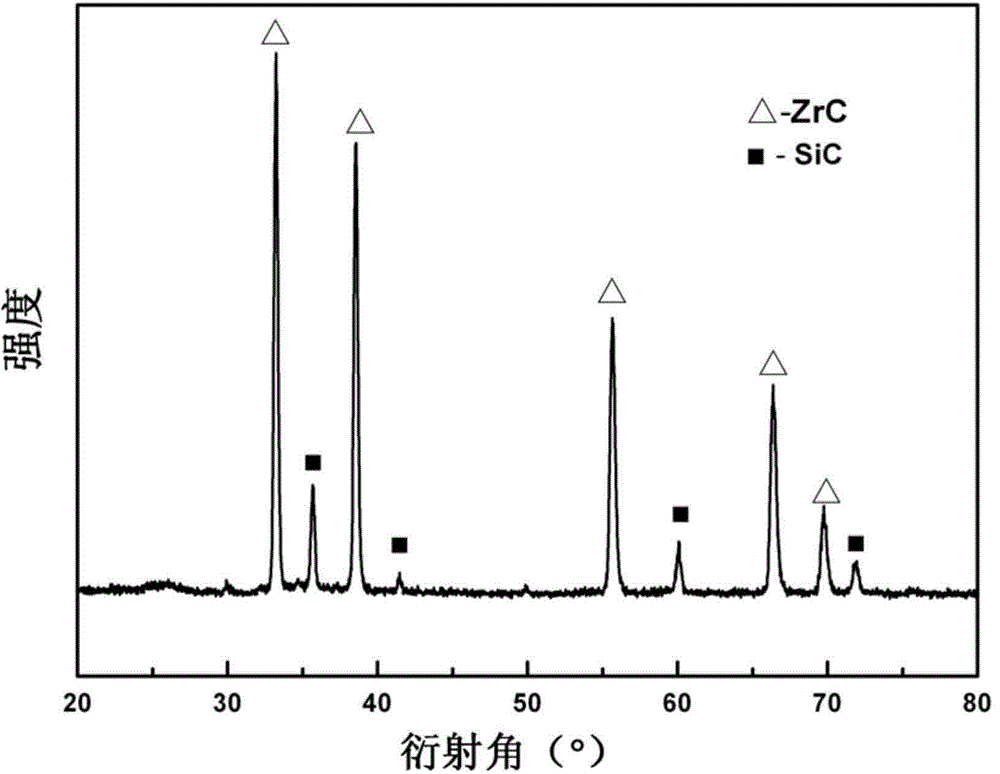

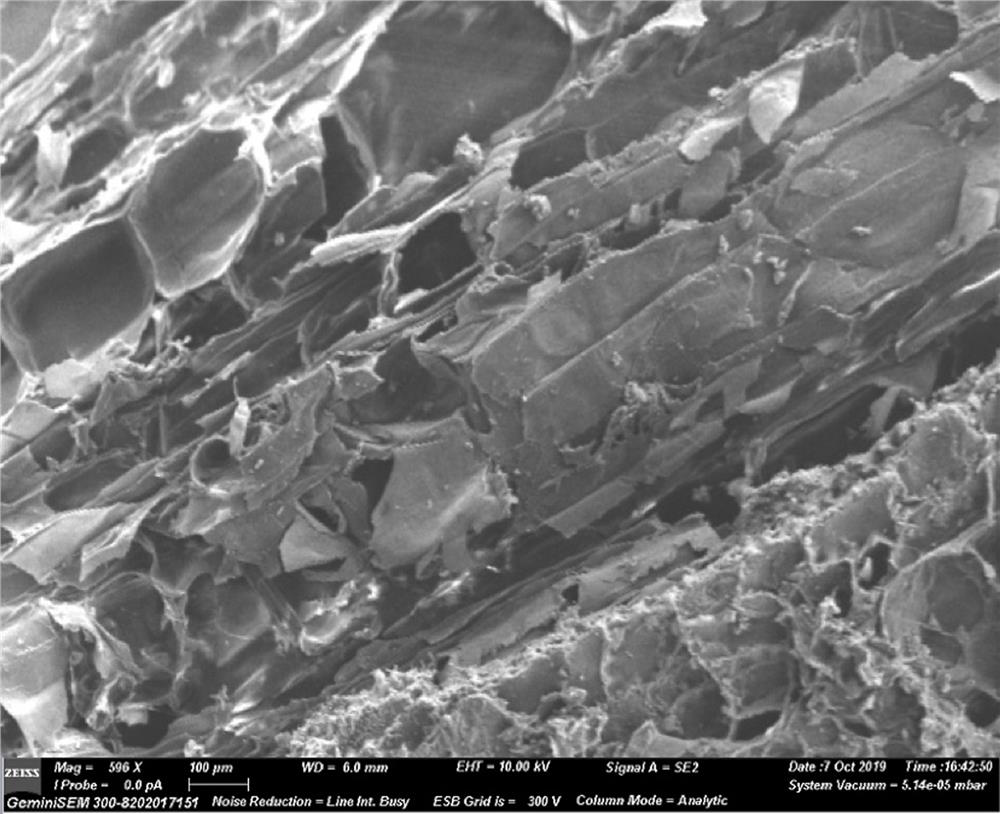

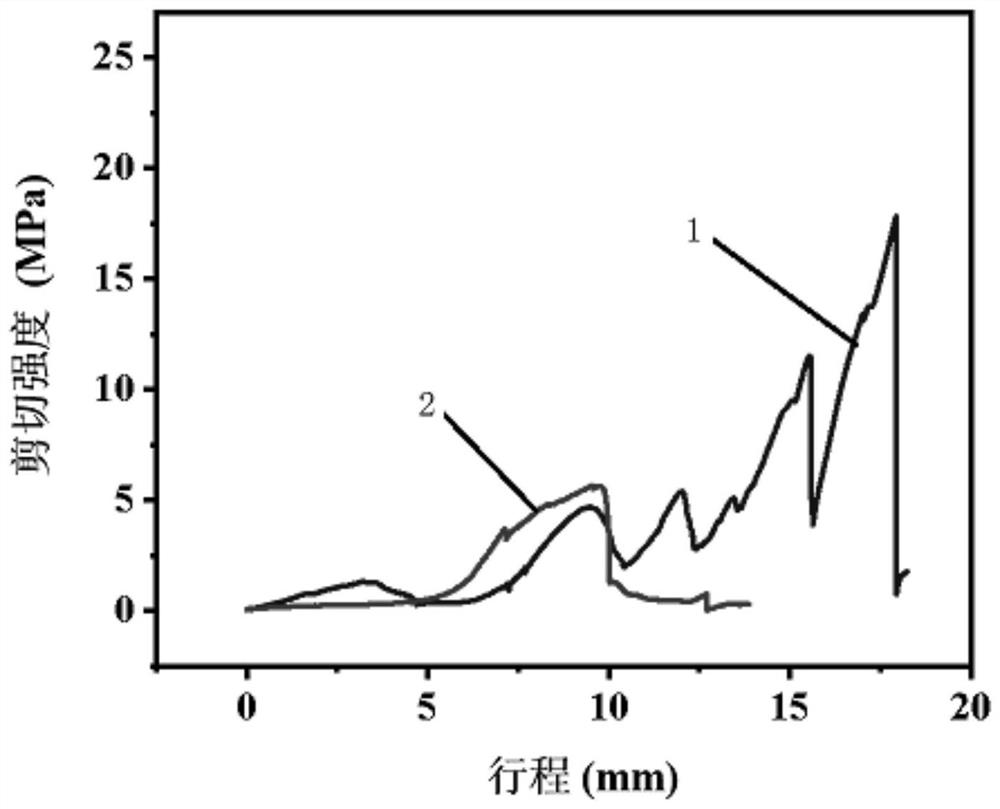

A method for preparing cf/zrc-sic ultra-high temperature ceramic composite materials by hot pressing sintering/precursor cracking method

ActiveCN104311090BGood performance at high temperatureMeet the practical applicationFiberCeramic composite

The invention relates to a method for preparing a Cf / ZrC-SiC superhigh-temperature ceramic composite material through a hot-pressing sintering / precursor cracking process, and concretely relates to an in-situ preparation method for the Cf / ZrC-SiC superhigh-temperature ceramic composite material by combining a precursor cracking process and a hot-pressing sintering process. The method comprises: introducing ZrSi2 powder into carbon fiber fabric, employing the hot-pressing sintering process for in-situ generation of ZrC and SiC ceramic base bodies, and employing the precursor cracking process to perform final densification processing, so as to obtain the compact Cf / ZrC-Si superhigh-temperature ceramic composite material. The superhigh-temperature ceramic composite material prepared by employing the preparation method has excellent superhigh temperature usage performance, and the method is simple in process and short in time consumption. The obtained Cf / ZrC-SiC superhigh-temperature ceramic composite material can basically satisfy practical application of some heatproof structural members, and has wide application prospect in extreme environments such as super hypersonic speed flight, aerosphere reentry, trans-atmospheric flight, rocket propulsion system and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Periclase-forsterite high-temperature spray coating

The invention provides a periclase-forsterite high-temperature spray coating. The raw materials of the spray coating comprise dead burnt magnesia, metal silicon powder, graphite or coke. The periclase-forsterite high-temperature spray coating has good high-temperature performance, can be used for high-temperature spray coating of a steel furnace lining and prolongs the service life of a kiln; and in a spray supplementing process, the raw materials are low in rebound rate, the spray coating causes less pollution to molten steel, and the spray coating is high in safety, and has a good application prospect.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

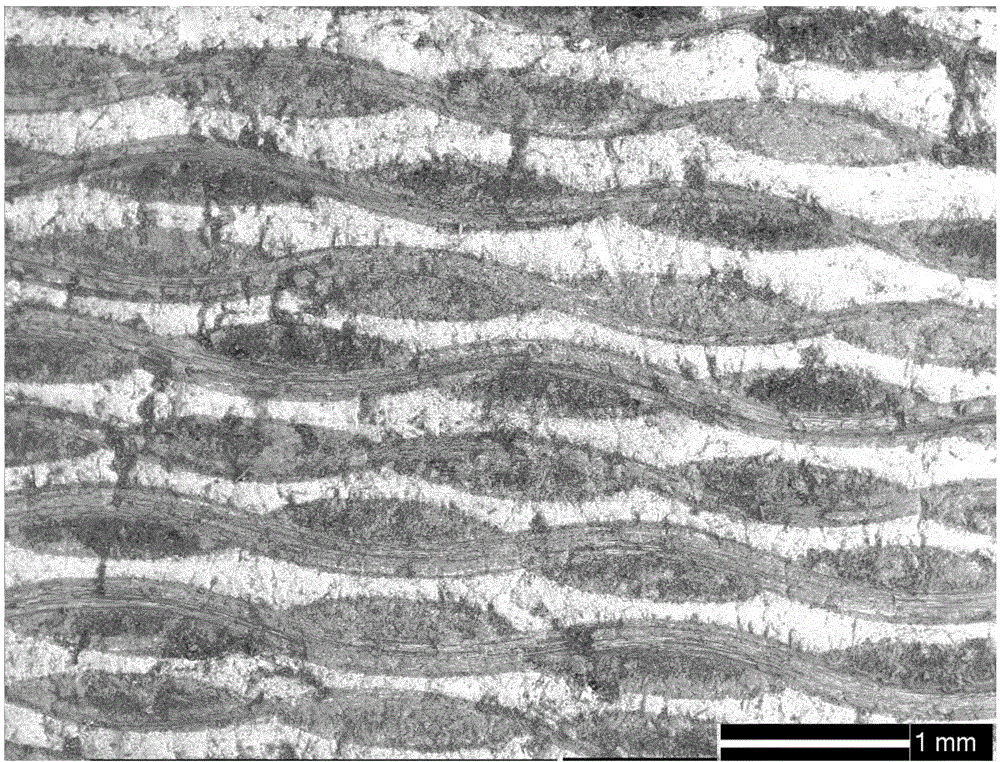

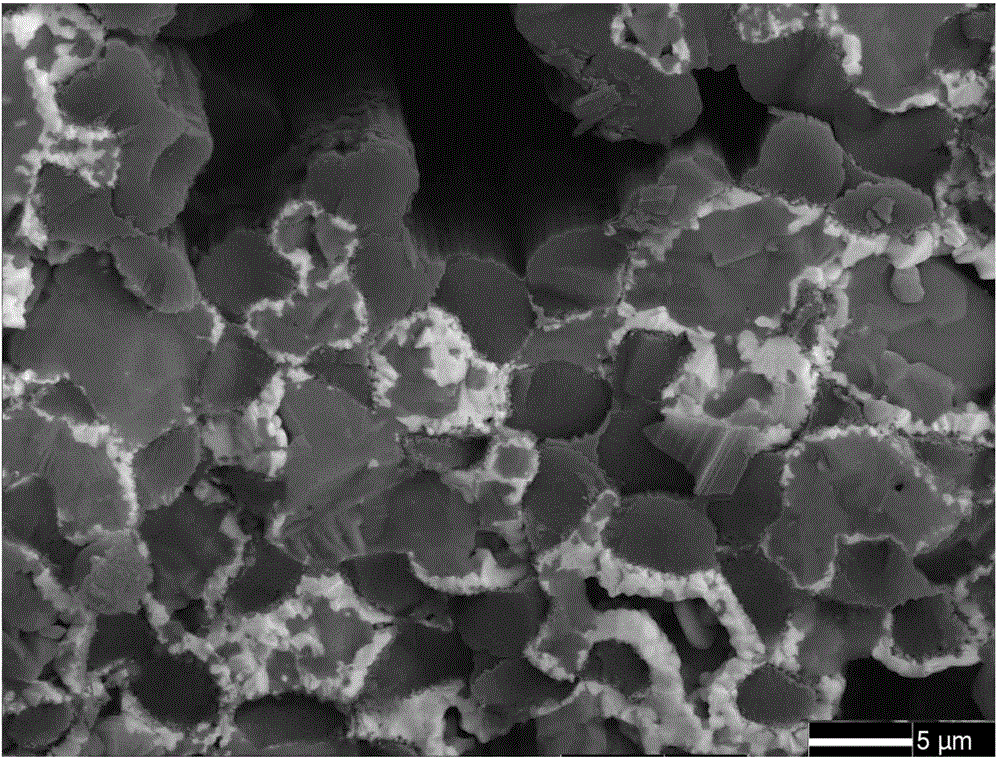

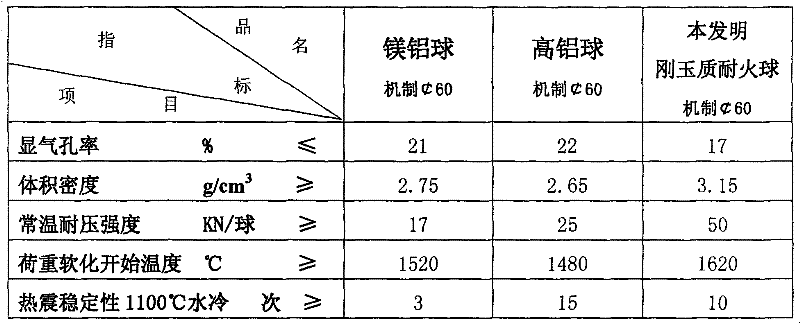

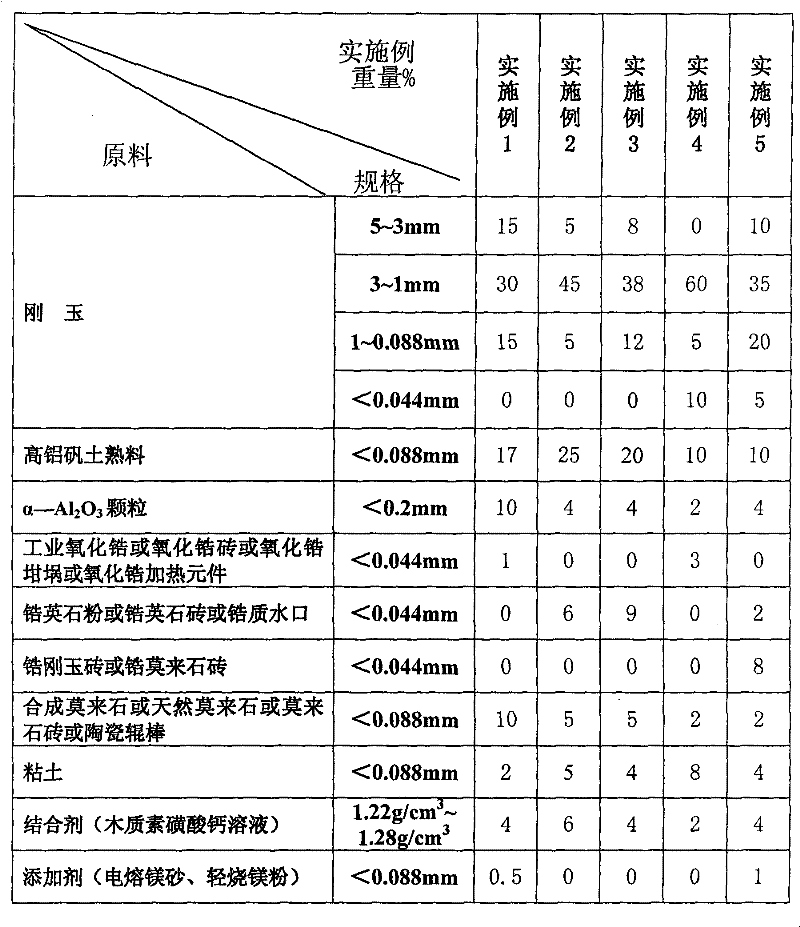

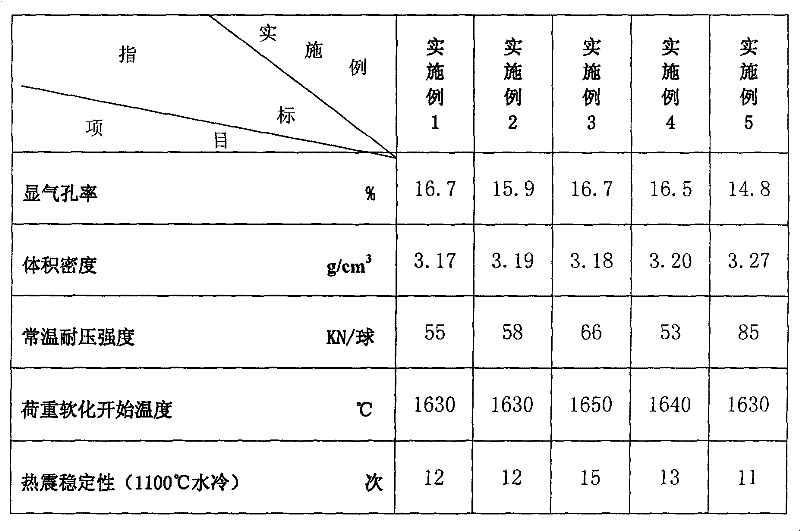

A corundum refractory ball for a ball-type hot blast stove and its preparation method

InactiveCN101555151BImprove dispersion uniformityReduce porosityBrick-hot blast stovesTunnel kilnPolymer science

A corundum refractory ball for a spherical hot blast stove and a preparation method thereof, characterized in that: the corundum refractory ball includes the following main ingredients, binders and additives; wherein the main ingredients include the following raw materials in weight percentages: 0-15% of corundum with a particle size of 5-3mm, 30-60% of corundum with a particle size of 3-1mm, 5-30% of corundum with a particle size of 1-0.088mm, 0-10% of corundum with a particle size of less than 0.044mm, and 0-10% of corundum with a particle size of less than 0.088mm High alumina bauxite clinker 10-25%, α-Al2O3 particles 2-10%, zirconia-containing material 1-10%, clay 2-8%, mullite or mullite-containing main phase material 2-10% %; the added amount of the binder is 1-6% of the weight of the main material; the added amount of the additive is 0-1% of the weight of the main material. The preparation method of the present invention adopts trapping, back-rolling, machine-pressing, drying the green body, and then firing in a tunnel kiln at a firing temperature of 1450°C to 1600°C.

Owner:巩义市金岭耐火材料有限公司

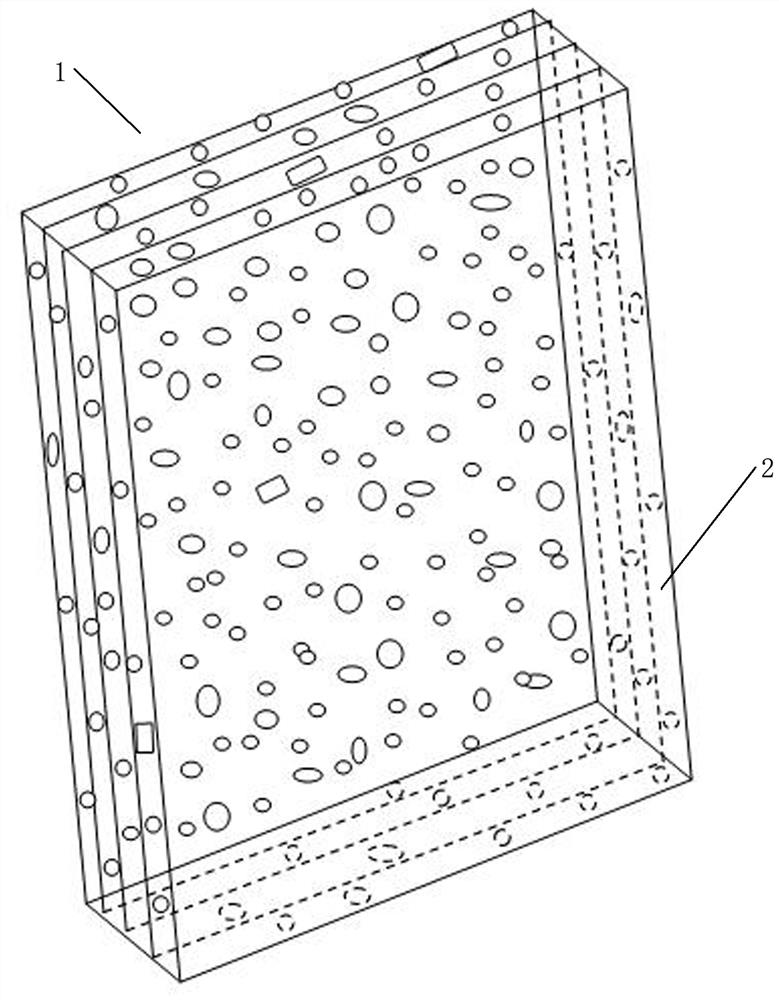

Bionic lamellar thermal insulation material

ActiveCN112297532AReduce conductionWith strengthLamination ancillary operationsLaminationThermal breakThermal insulation

The invention discloses a bionic lamellar thermal insulation material which simulates a fireproof, corrosion-resistant and excellent-thermal-insulation-performance American redwood bark multi-thin-layer laminated and thin-layer microporous structure, adopts low-thermal-conductivity microporous powder as a main raw material, and is supplemented with a reinforcing agent, a plasticizer and a pore-forming agent to form a microporous thin-layer unit, and the thin-layer units are boned to prepare the lamellar thermal insulation material. The heat conductivity coefficient of the finished product is as low as 0.02-0.05 W / m.k, and the finished product is good in heat-insulating property and mechanical property, can be used within the temperature range of 1000 DEG C or below, has better heat-insulating and energy-saving effects and toughness compared with common heat-insulating materials, remarkably reduces the thickness of the heat-insulating layer, and is suitable for large-scale popularization and application. The material can be widely applied to the fields of industrial kilns, thermotechnical devices, heat preservation pipelines and the like.

Owner:ZHENGZHOU UNIV

Silicon nitride-based ceramic welding sealing component and preparation method thereof

The invention discloses a silicon nitride-based ceramic welding sealing component and a preparation method thereof, and relates to the technical field of metallized ceramic processing. The invention discloses a silicon nitride-based ceramic welding sealing component which comprises a silicon nitride ceramic matrix and a metallization layer, the silicon nitride ceramic matrix is prepared from modified silicon nitride, mullite fiber, aluminum nitride, calcium oxide, titanium oxide, a binder and a dispersing agent through the steps of modified silicon nitride preparation, mixing, granulation, primary sintering, secondary sintering and the like; raw materials of the metallization layer comprise copper powder, tungsten powder, copper oxide, yttrium oxide, zinc oxide and an organic binding agent. The invention further discloses a preparation method of the silicon nitride-based ceramic welding sealing component composed of the metallization layer and the silicon nitride ceramic matrix. According to the silicon nitride-based ceramic welding sealing component, the density of the silicon nitride ceramic matrix is improved, the silicon nitride-based ceramic welding sealing component has excellent strength, hardness and fracture toughness, the tensile strength of the sealing component is improved, and the silicon nitride-based ceramic welding sealing component has excellent high-temperature resistance.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

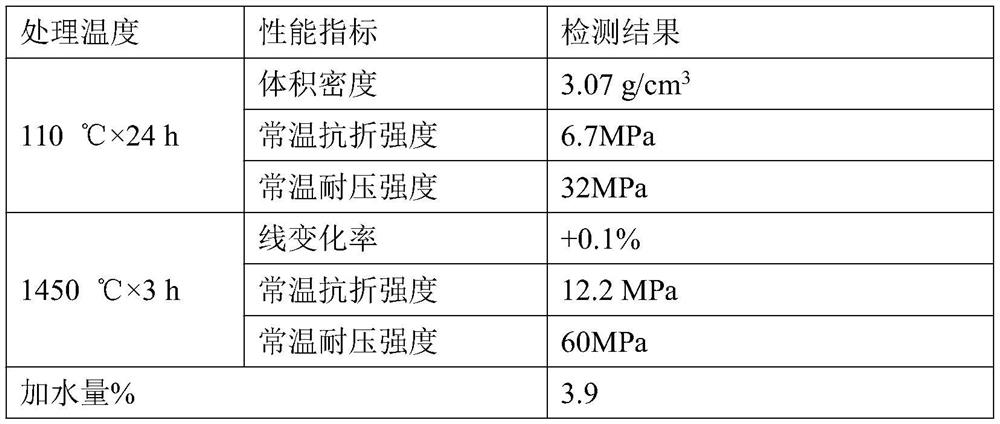

A long-life heat repair castable for iron ditch

ActiveCN109467418BReduce the amount of water addedReduce the amount addedCeramicwareCarbide siliconFiber

The invention discloses an iron ditch castable for long-life heat repair, the composition of which is calculated by mass percentage: 56%-64% of brown corundum; 5%-13% of silicon carbide; 2%-3% of ball pitch; pure aluminum Calcium acid cement 1.5% ~ 2.5%; alumina micropowder 8% ~ 12%; silica micropowder 1.5% ~ 2.5%; silicon carbide powder 11% ~ 13%; composite antioxidant 1% ~ 2%; %‑0.3%; explosion-proof fiber less than 0.1%; dispersant 0.2% to 0.4%; coagulant less than 0.08%. The iron ditch castable of the present invention adopts a new type of coagulant, so that the metal aluminum powder in the iron ditch castable can generate hydrogen in advance, and when the castable does not produce solidification strength, it will generate gas to open the vent hole, and the suitable metal aluminum powder Cooperating with low-melting-point explosion-proof fibers, it ensures that the castable has excellent high-temperature performance while meeting the construction conditions.

Owner:中冶武汉冶金建筑研究院有限公司

A method for preparing mullite fiber-based porous ceramics by environmentally friendly gel injection molding

The invention belongs to the field of porous ceramics, in particular to an environment-friendly method for preparing mullite fiber-based porous ceramics by gel injection molding. Raw material and mass percentage: 11-32% ρ-Al 2 o 3 Powder, 13-36% kaolin or zircon powder, 33-75% mullite fiber. Take ρ-Al 2 o 3 , kaolin or zircon powder, add a certain amount of deionized water, mechanically stir and perform ultrasonic oscillation to obtain a stable and uniform ceramic slurry; then add mullite fibers evenly into the ceramic slurry, continue to stir and oscillate to obtain Gel-type ceramic-fiber slurry; then injection molded and solidified at room temperature, the molded green body is dried in a constant temperature drying oven, placed in a high-temperature furnace after demoulding, and sintered in an air atmosphere to obtain mulai Stone bound or ZrO 2 ‑Mullite-bonded mullite fiber-based porous ceramics. The process of the invention is simple and easy, and is friendly to the environment, and the prepared mullite fiber-based porous ceramic has high porosity, low thermal conductivity and high strength.

Owner:NORTHEASTERN UNIV LIAONING

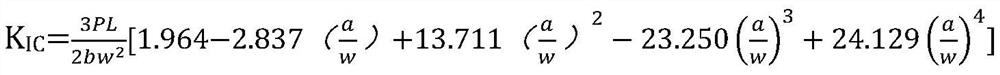

Preparation method of high-strength chrome-free brick for steel-making RH (Ruhstahl Hausen) vacuum refining slot

The invention relates to a preparation method of a high-strength chrome-free brick for a steel-making RH (Ruhstahl Hausen) vacuum refining slot. The high-strength chrome-free brick comprises the raw materials: one or two of 6-1 mm low silicon fused magnesia, 1-0.088mm low silicon fused magnesia and fused magnesia-alumina spinel, one or two of 180-mesh large crystal fused magnesite and fused magnesia-alumina spinel, fused magnesia-alumina spinel micro powder, one or two of modified graphite and carbon black, a boron nitride and ferro-silicon nitride composite additive, a paper pulp and sodium lignosulphonate composite bonding agent and polycrystalline zirconia fibers. The raw materials are stirred in special stirring equipment according to specified proportions and charging sequence and are subject to compression molding, drying, checking and the like to complete a preparation process. Compared with the prior art, the preparation method has the beneficial effects that as a carbon-containing material and an efficient antioxidant are added into a substrate, the high temperature corrosion-resistant property of the chrome-free brick is greatly improved; as the zirconia fibers are added, the high temperature hot strength and the normal temperature cold repair strength are obviously enhanced and the service life of a working lining is effectively prolonged.

Owner:鞍山市和丰耐火材料有限公司

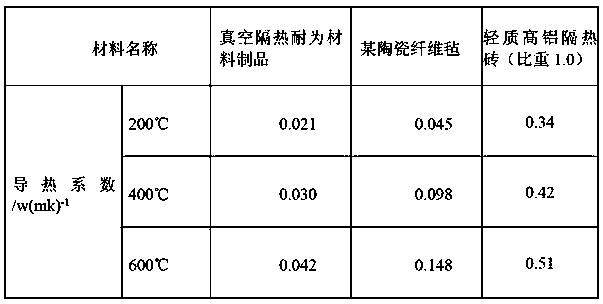

A vacuum heat-insulating refractory product and its preparation method

ActiveCN106631065BImprove insulation performanceLow thermal conductivityLinings repairGlass shaping apparatusThermal transmittanceKiln burner

The invention discloses a vacuum insulating refractory product and a preparation method thereof. The vacuum insulating refractory product is composed of a core material and a high-resistance film wrapped on the exterior of the core material, wherein the core material is formed by uniformly dispersing and then pressing 95-70wt% of low heat-conducting micro-pore powder and 5-30wt% of dispersed fire-resistant staples; a high-temperature resisting airtight film which is prepared from an inorganic material used as a main component in the manner of tape casting is served as the high-resistance film; the vacuum insulating refractory product is prepared after the pressed and molded core material is wrapped with the high-resistance film and then the vacuum hot-pressing packaging is performed; the product can be used under a temperature condition at 500-1200 DEG C, can maintain a vacuum structure and has ultralow thermal conductivity and high performance cost ratio; and the vacuum insulating refractory product is suitable for large-scale production, is convenient in mounting and use, can be matched with lightweight and heavy refractory materials and has an obvious energy-saving effect in effectively insulating the liner compound of a high-temperature industrial furnace.

Owner:ZHENGZHOU UNIV

Sleeve lime kiln empty kiln drying method

The invention relates to a sleeve lime kiln. A method for drying a sleeve lime kiln with an empty kiln, which includes introducing coal gas to the temporary burners of the sleeve lime kiln; starting the exhaust gas fan to make the negative pressure in the kiln ≥ -0.05kpa; The observation hole of the device is inserted into the ash discharge device, and the burner is facing upwards and fixed; when the temperature in the kiln rises to 50°C, control the temperature rise rate to 3°C to 5°C per hour to heat up; when the temperature rises to 280 to 300°C, start to keep warm; start kiln drying After 24 hours, open the burner drainage screw and the exhaust gas flue drainage hole, tighten the screw after the burner drains, and drain the water every 4 hours; keep warm until there is no obvious moisture at the drain, which means that the refractory in the kiln has been dried to Reasonable control range; cut off the temporary burner gas valve; turn off the exhaust fan; turn off the cooling fan after eight hours. The invention can effectively remove the moisture in the refractory material and ensure the high-temperature service performance of the refractory material.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

Method for improving silicon carbide-niobium brazing connection quality through low-expansion 4J42 alloy interlayer auxiliary brazing filler metal

ActiveCN113732424AAlleviate the problem of large thermal expansion coefficient differenceReduce residual stressSoldering auxillary devicesCarbide siliconInterfacial reaction

The invention relates to a silicon carbide-niobium brazing connection method, in particular to a method for improving the silicon carbide-niobium brazing connection quality through low-expansion 4J42 alloy interlayer auxiliary brazing filler metal. The method aims to solve the problems that residual stress of existing silicon carbide and niobium brazing connection is overlarge and the ceramic side interface reaction is poor. The method comprises the step 1 of pretreatment; and the step 2 of vacuum brazing. The method is used for improving the silicon carbide-niobium brazing connection quality through the low-expansion 4J42 alloy interlayer auxiliary brazing filler metal.

Owner:HARBIN INST OF TECH

A low-expansion 4j42 alloy interlayer auxiliary brazing material to improve the quality of silicon carbide-niobium brazing connection

ActiveCN113732424BAlleviate the problem of large thermal expansion coefficient differenceReduce residual stressSoldering auxillary devicesCarbide siliconMaterials science

Owner:HARBIN INST OF TECH

Ramping material for intermediate frequency induction furnace and preparation method thereof

ActiveCN106278315BSimple processGood performance at high temperatureMedium frequencyInduction furnace

The invention relates to ramming mass for a medium-frequency induction furnace and a preparing method thereof. According to the technical scheme, 58-74 wt% of fused corundum, 6-18 wt% of tabular corundum, 8-16 wt% of fused magnesite, 2-9 wt% of alpha-Al2O3 micro powder, 1-3 wt% of aluminum lactate and 1-6 wt% of magnesium lactate are used as raw materials and mixed uniformly to obtain the ramming mass for the medium-frequency induction furnace, wherein the particle size of aluminum lactate and magnesium lactate is smaller than 0.18 mm, the particle size of fused corundum is 0.088-5 mm, and the content of Al2O3 of the fused corundum is 94-99.5 wt%; the particle size of tabular corundum is 0.044-1 mm, the particle size of the fused magnesite is 0.044-1 mm, and the content of MgO of fused magnesite is larger than or equal to 95 wt%; the raw materials are mixed in a mixer for 10-25 min. The preparing method has the advantages of being simple in process and environmentally friendly. The prepared ramming mass for the medium-frequency induction furnace is high in refractoriness, erosion resistance and scouring resistance and long in service life.

Owner:LENGSHUIJIANG HUAKE PERFORMANCE MATERIALS

A composite intermediate layer and its method for brazing metal, ceramics and ceramic-based composite materials

ActiveCN104690385BReduce contentReduce formationWelding/cutting media/materialsWelding/soldering/cutting articlesMetalMaterials science

The invention relates to a composite interlayer and a method for brazing metal with a ceramic and ceramic matrix composite material by utilizing the same, and solves a difficult problem of poor connector performance caused by a large amount of brittle phases generated in a strong reaction of a connector interface during brazing of the metal and the ceramic and ceramic matrix composite material by adopting an active brazing material and large residual stress of the connector after welding. The composite interlayer comprises an upper-layer brazing material, a soft interlayer and a lower-layer brazing material. The method comprises the following steps: 1, brazing material preparation, wherein the brazing material is prepared at a certain ratio; 2, cleaning, wherein cleaning is performed by acetone; 3, assembling, wherein a to-be-welded base material and the composite interlayer are assembled according to a certain sequence; 4, welding, wherein welding is performed in a vacuum brazing furnace. The operation is simple, and the addition of the interlayer inhibits over-reaction of the brazing material and the base material, reduces residual stress of the connector, and greatly improves the connector performance. The method is used for brazing the metal with the ceramic and ceramic matrix composite material.

Owner:HARBIN INST OF TECH

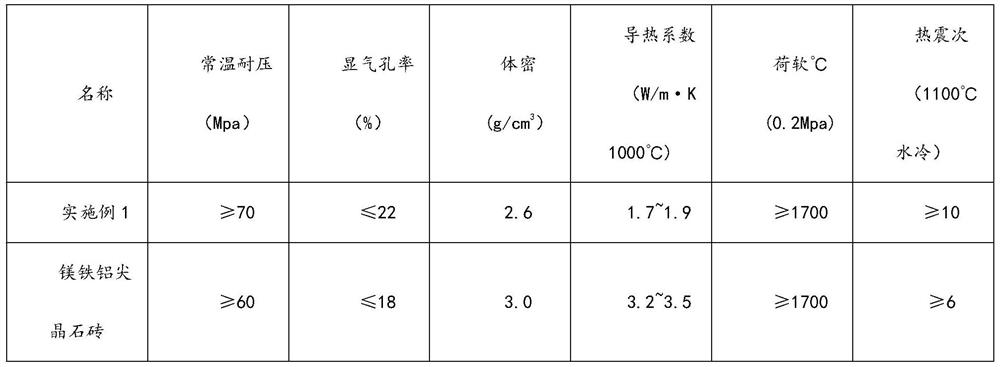

Low-heat-conductivity multi-layer composite magnesium-hercynite brick and preparation process thereof

PendingCN113698181ASolve the problem of energy consumptionSolve the problem of longevityRotary drum furnacesInsulation layerBrick

The invention relates to a low-heat-conductivity multi-layer composite magnesium-hercynite brick and a preparation process thereof. The low-heat-conductivity multi-layer composite magnesium-hercynite brick is prepared from the following raw materials in percentage by weight: 70-95% of microporous high-purity magnesia, 4-15% of hercynite, 2-10% of light forsterite, and 1-5% of a binding agent in a working layer, and 10-50% of microporous high-purity magnesia, 50-80%of light forsterite and 1-10% of nano aluminum oxide micro powder in a heat insulation layer. The heat insulation layer is a nano aerogel plate. According to the low-heat-conductivity multi-layer composite magnesium-hercynite brick and the preparation process thereof, the overall volume density is small, the heat conductivity coefficient is far lower than that of an existing product, the energy consumption of a thermotechnical kiln can be remarkably reduced, the purposes of saving energy and reducing consumption are achieved, and in the actual production process, production and preparation are convenient and efficient, so that actual application and popularization are facilitated, and therefore, the problems of high energy consumption and short service life of the existing cement kiln adopting pleonaste bricks are effectively solved.

Owner:郑州瑞泰耐火科技有限公司

Refractory material for carbon furnace and preparation method thereof

The invention belongs to the field of refractory materials, and in particular relates to a refractory material for a carbon roasting furnace and a preparation method thereof. The refractory material for the carbon roasting furnace of the present invention includes 50%-70% of burnt gemstone, 10%-30% of high alumina bauxite, 5%-18% of silicon carbide, 5%-15% of aluminum oxide, and 5%-10% of bonded clay. %, and also includes a binder of 3%-7% of the total weight of the above components, the binder is phosphoric acid or phosphate solution with a specific gravity of 1.4-1.5g / cm3, after batching, mixing, trapping, molding, 500-600 °C roasting and other steps to obtain the refractory material for the carbon roasting furnace of the present invention. The refractory material of the present invention has the advantages of high compressive strength, high softening temperature under load, good creep resistance, low porosity, good thermal shock resistance stability, small linear expansion coefficient, good CO resistance performance, etc., greatly improving carbon roasting performance. The service life of the furnace, especially without high temperature firing, has achieved the purpose of energy saving and emission reduction.

Owner:巩义市第五耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com