Low-heat-conduction multi-layer mullite brick and preparation method thereof

A multi-layer composite, mullite brick technology, applied in lighting and heating equipment, furnace components, furnace types, etc., to achieve significant energy saving and consumption reduction, lower cylinder surface temperature, and improve thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

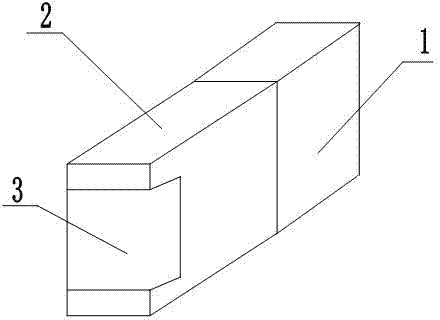

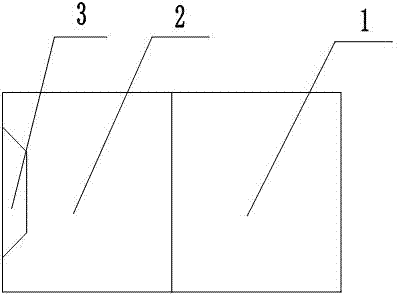

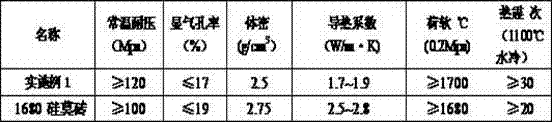

[0022] Such as Figure 1-2 Shown, a kind of low thermal conductivity multi-layer composite mullite brick, it comprises working layer 1, heat insulating layer 2 and heat insulating layer 3, described working layer 1 and heat insulating layer 2 are connected, on heat insulating layer 2 there is A gap, the heat insulation layer 3 is located in the gap; the working layer 1 is made of aggregate, powder and antioxidant plus a new type of binder according to the following proportions by weight: 55 parts of aggregate, of which the particle size is 0-1mm 10 parts of sintered mullite, 20 parts of sintered mullite with a particle size of 1-3 mm, 25 parts of sintered mullite with a particle size of 3-5 mm, the mass percentage of the chemical composition of the sintered mullite is: mullite phase 80-90% , Fe 2 o 3 2 O+Na 2 O97%, 3 parts of antioxidant , the antioxidant is metal aluminum powder and metal silicon powder mixed evenly in a weight ratio of 1 to 2:1, the average particle size...

Embodiment 2

[0033] Such as Figure 1-2 Shown, a kind of low thermal conductivity multi-layer composite mullite brick, it comprises working layer 1, heat insulating layer 2 and heat insulating layer 3, described working layer 1 and heat insulating layer 2 are connected, on heat insulating layer 2 there is A gap, the heat insulation layer 3 is located in the gap; the working layer 1 is made of aggregate, powder and antioxidant plus a new type of binder according to the following proportions by weight: 55 parts of aggregate, of which the particle size is 0-1mm 15 parts of sintered mullite, 20 parts of sintered mullite with a particle size of 1-3 mm, 20 parts of sintered mullite with a particle size of 3-5 mm, the mass percentage of the chemical composition of the sintered mullite is: mullite phase 80-90% , Fe 2 o 3 2 O+Na 2 O97%, 5 parts of antioxidant , the antioxidant is metal aluminum powder and metal silicon powder mixed evenly in a weight ratio of 1 to 2:1, the average particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com