Low-alloy heat-resisting cast iron and preparation method thereof

A heat-resistant cast iron and low-alloy technology, applied in the field of heat-resistant metal materials, can solve the problems of large volume and quality of the crucible, unsatisfactory heat-resistant performance, low alloying degree, etc., to achieve difficult cracking and peeling, excellent oxidation resistance , the effect of improving the anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

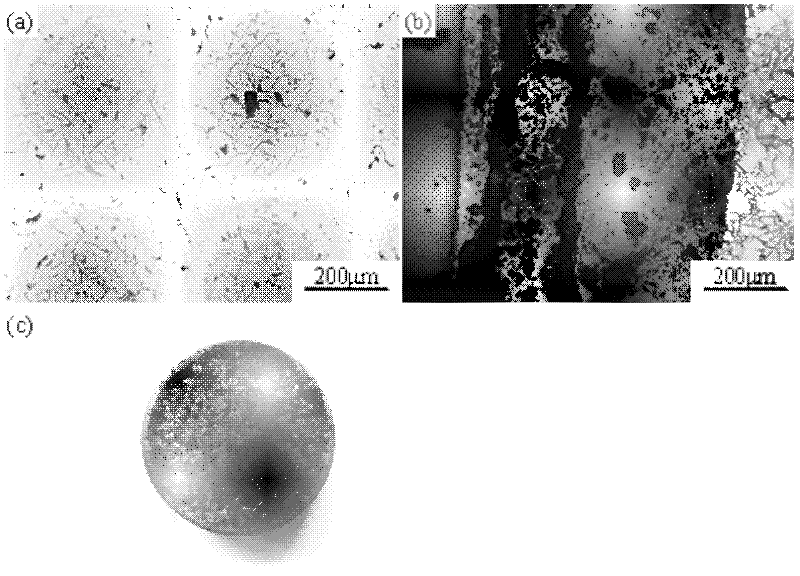

[0081] Embodiment 1: A low-alloyed heat-resistant cast iron material provided by the present invention contains the following chemical components and mass percentages: C: 3.5%; Si: 3.5%; Cr: 1.0%; Mn: 0.4%; P : 0.1%; S: 0.02%; Al: 4.0%; Sr: 0.1%; the balance is Fe. Mix steel scrap, ferrochrome, pig iron, ferrosilicon, pure aluminum, aluminum-strontium master alloy (Al-10Sr master alloy) according to the mass percentage of the chemical composition in the target product, and bake at 150-200°C for 0.5-1.5h to remove The surface water vapor is smelted in a cupola furnace. Among them, the prepared pure aluminum is placed on the bottom of the ladle in advance, and then the molten iron is put into the ladle. After the aluminum block is melted, the block-shaped aluminum-strontium master alloy is added, and then the 75SiFe inoculant with a particle size of 3-10 mm is washed in with the flow. Then quickly and fully stir the ferroalloy liquid in the ladle for about 1 min to make the Al ...

Embodiment 2

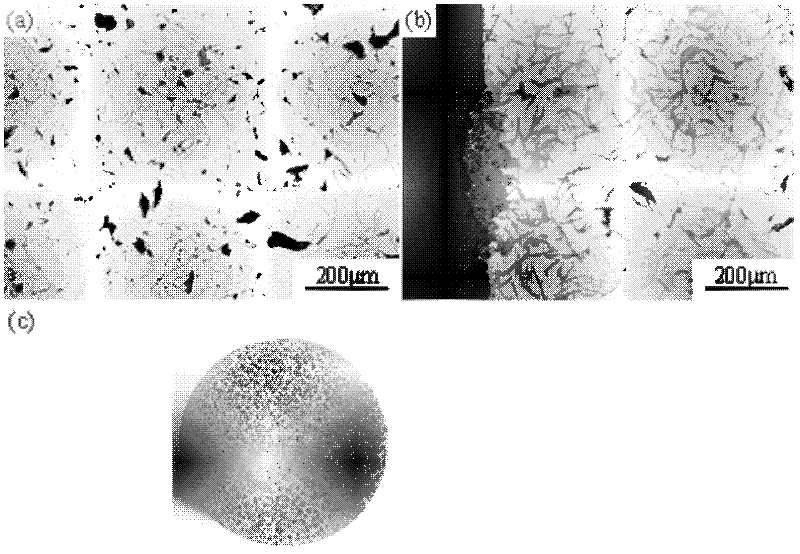

[0082] Embodiment 2: A low-alloyed heat-resistant cast iron material provided by the present invention contains the following chemical components and mass percentages: C: 2.7%; Si: 2.9%; Cr: 0.3%; Mn: 0.4; P: 0.1%; S: 0.02%; Al: 3.0%; Sr: 0.075%; the balance is Fe. Mix steel scrap, ferrochrome, pig iron, ferrosilicon, pure aluminum, aluminum-strontium master alloy (Al-10Sr master alloy) according to the mass percentage of the chemical composition in the target product, and bake at 150-200°C for 0.5-1.5h to remove The surface water vapor is smelted in a cupola furnace. Among them, the prepared pure aluminum is placed on the bottom of the ladle in advance, and then the molten iron is put into the ladle. After the aluminum block is melted, the block-shaped aluminum-strontium master alloy is added, and then the 75SiFe inoculant with a particle size of 3-10 mm is washed in with the flow. Then quickly and fully stir the ferroalloy liquid in the ladle for about 1 min to make the Al ...

Embodiment 3

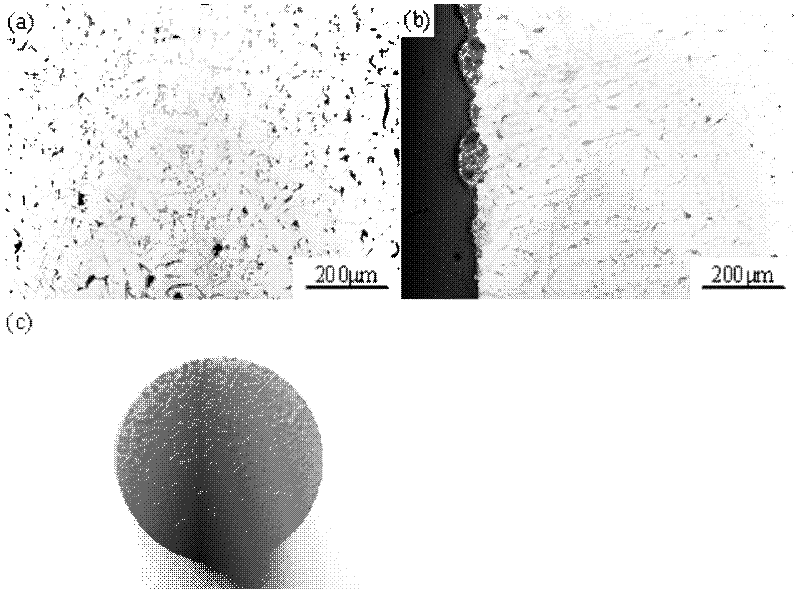

[0083]Embodiment 3: A low-alloyed heat-resistant cast iron material, which contains chemical components and mass percentages: C: 2.5%; Si: 2.5%; Cr: 0.1%; Mn: 0.4%; P: 0.1%; S: 0.02%; Al: 1.8%; Sr: 0.05%; the balance is Fe. Mix steel scrap, ferrochrome, pig iron, ferrosilicon, pure aluminum, aluminum-strontium master alloy (Al-10Sr master alloy) according to the mass percentage of the chemical composition in the target product, and bake at 150-200°C for 0.5-1.5h to remove The surface water vapor is smelted in a cupola furnace. Among them, the prepared pure aluminum is placed on the bottom of the ladle in advance, and then the molten iron is put into the ladle. After the aluminum block is melted, the block-shaped aluminum-strontium master alloy is added, and then the 75SiFe inoculant with a particle size of 3-10 mm is washed in with the flow. Then quickly and fully stir the ferroalloy liquid in the ladle for about 1 min to make the Al and Sr elements diffuse evenly. After sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com