Powder extrusion preparing method of Fe-Si mixed soft magnetic material thin strip with 6.5% of Si

A fe-6.5%si, soft magnetic material technology, applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of difficult forming of thin alloy strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

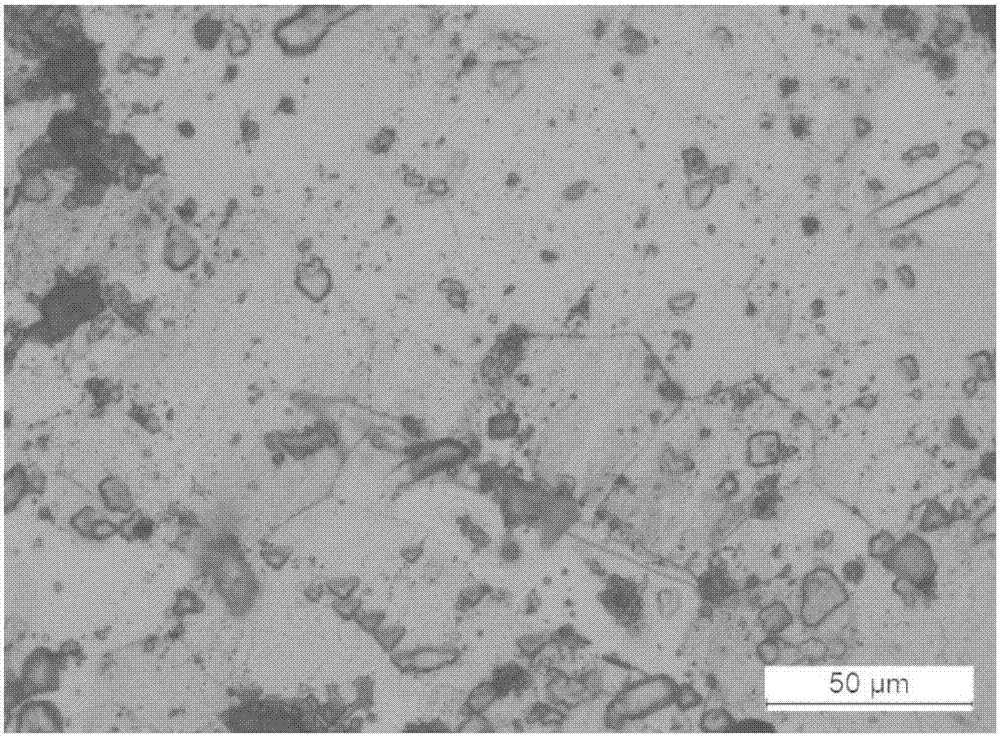

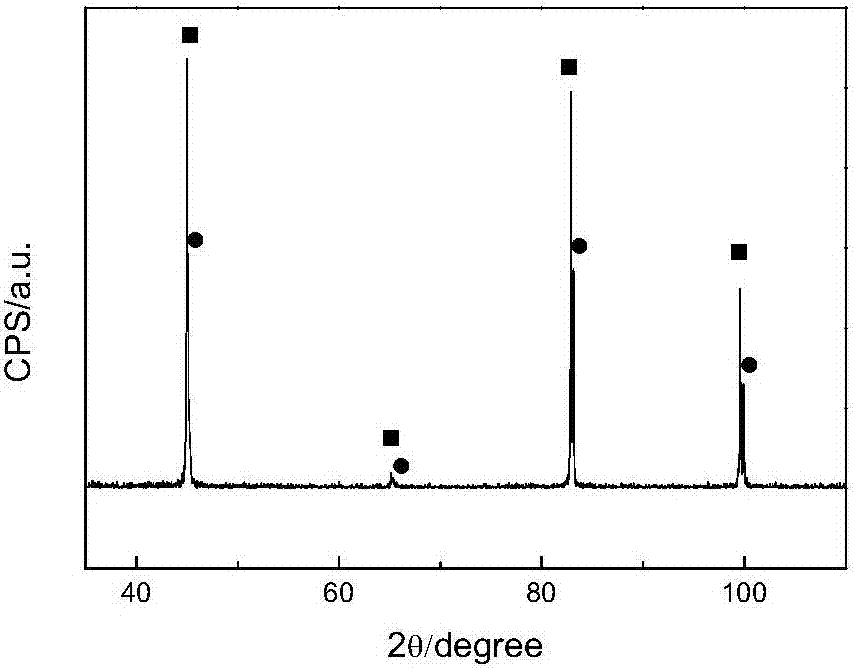

[0048] Mix -100 mesh water atomized Fe powder with Fe-80% Si high-purity powder with particle size ≤ 10 μm according to the ratio of 91.625:8.375 to form Fe-6.7% Si mixed powder. When mixing, add 0.6% paraffin micropowder and 0.1% engine oil of the total amount of raw materials. Dehydrated alcohol is added according to the amount of 200ml / ton. The above powders were mixed for 4 h using a V-shaped blender.

[0049] A square compact was prepared by compression molding. The length and width of the compact were 120 mm and 80 mm, respectively, and the height was 40 mm. It was pressed with a surface pressure of 600 MPa, and the total output pressure of the press was 576 tons. The green density obtained is 6.37g / cm 3 .

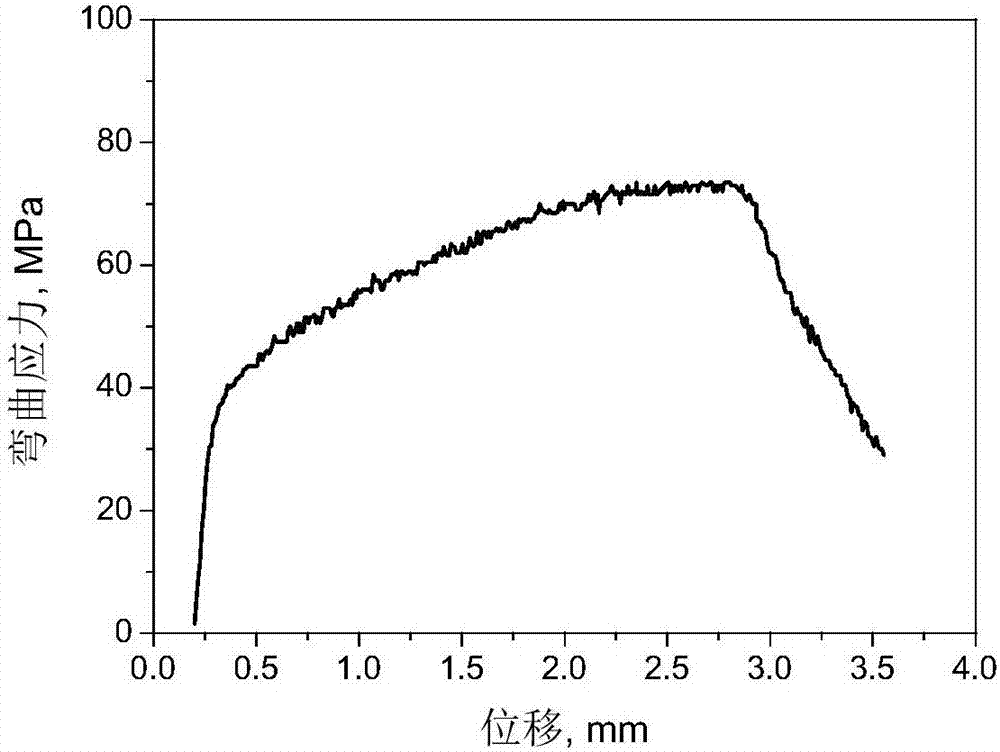

[0050] A square extrusion cylinder of 40×120mm is used, and the extrusion dies are 5×120mm respectively, corresponding to an extrusion ratio of 8. Before extrusion, the molded billet was heated to 950°C under the protection of nitrogen and kept for 4 hours. The ...

Embodiment 2

[0055] Mix -100 mesh water atomized Fe powder with Fe-70% Si high-purity powder with a particle size of ≤10 μm in a ratio of 93.57:6.42 to form Fe-4.5% Si mixed powder. When mixing, add 0.7% zinc stearate and 0.1% machine oil of the total amount of raw materials. Dehydrated alcohol is added according to the amount of 400ml / ton. The above powders were mixed for 6 h using a drum mixer.

[0056] A square compact was prepared by compression molding. The length and width of the compact were 120 mm and 80 mm, respectively, and the height was 40 mm. It was pressed with a surface pressure of 600 MPa, and the total output pressure of the press was 576 tons. The obtained compact density is 6.54g / cm 3 .

[0057] A square extrusion cylinder of 40×120mm is adopted, the extrusion die is 2.5×120mm, and the corresponding extrusion ratio is 16. Before extrusion, the molded billet was heated to 1050°C under the protection of nitrogen and kept for 2 hours. The extrusion barrel and extrusion...

Embodiment 3

[0062] Mix -100 mesh water atomized Fe powder with Fe-76% Si high-purity powder with a particle size of ≤10 μm in a ratio of 91.45:8.55 to form Fe-6.5% Si mixed powder. When mixing, add 0.4% paraffin micropowder, 0.2% methylcellulose, and 0.1% motor oil in the total amount of raw materials. Dehydrated alcohol is added according to the amount of 400ml / ton. The above powders were mixed for 6 h using a drum mixer.

[0063] A square compact was prepared by compression molding. The length and width of the compact were 120 mm and 80 mm, respectively, and the height was 40 mm. It was pressed with a surface pressure of 600 MPa, and the total output pressure of the press was 576 tons. The obtained compact density is 6.40g / cm 3 .

[0064]A square extrusion cylinder of 40×120mm is adopted, the extrusion die is 4×120mm, and the corresponding extrusion ratio is 10. Before extrusion, the molded billet was heated to 1000°C under the protection of nitrogen and kept for 3 hours. The extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com