Low-heat-conductivity multi-layer composite magnesium-hercynite brick and preparation process thereof

A magnesium-iron-aluminum spinel, multi-layer composite technology, applied in lighting and heating equipment, furnace types, furnaces, etc. Reduce the surface temperature of the cylinder and solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

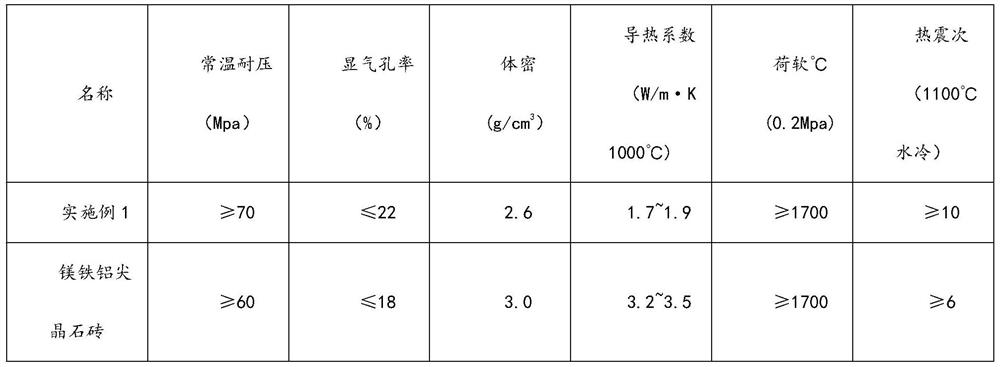

Embodiment 1

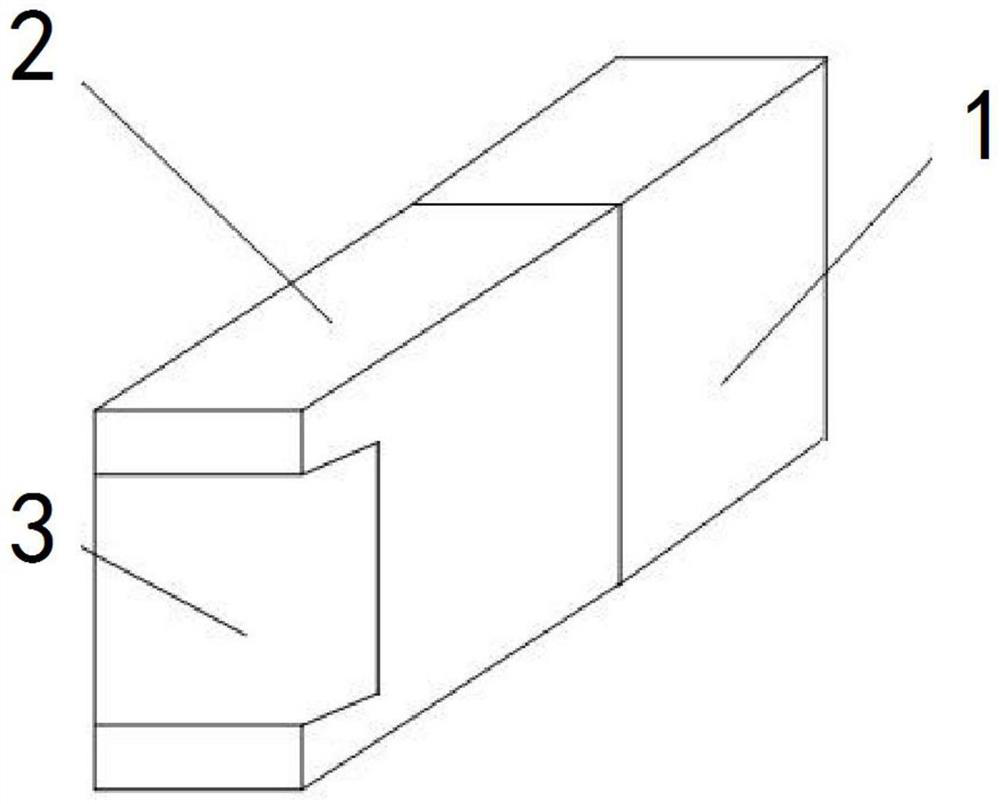

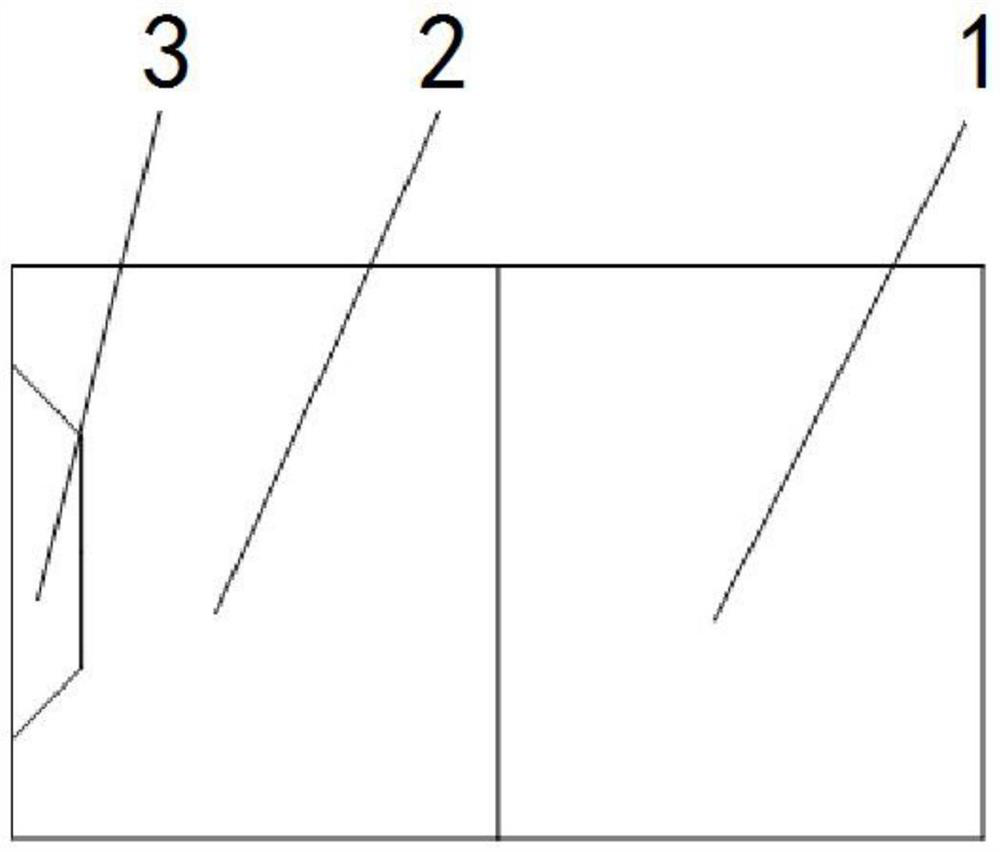

[0027] see Figure 1-2 , a low thermal conductivity multilayer composite magnesia-iron-aluminum spinel brick in this embodiment, comprising a working layer 1, a heat insulating layer 2 fixedly connected to the working layer 1, and a heat insulating layer 3 arranged in the heat insulating layer 2, wherein A notch recessed inward is provided on the side wall of the thermal insulation layer 2 away from the working layer 1, and the thermal insulation layer 3 is fixedly connected inside the notch.

[0028] The working layer 1 in this embodiment is prepared by aggregate, powder and external binder according to the following proportions by weight:

[0029] Aggregate: 55wt%, including 10wt% of microporous high-purity magnesia with a particle size of 0-1mm, 35wt% of microporous high-purity magnesia with a particle size of 1-3mm, and 15wt% of light forsterite with a particle size of 3-5mm;

[0030] Powder: 40wt%, microporous high-purity magnesia with particle size <0.074mm 40wt%;

[0...

Embodiment 2

[0049] Such as Figure 1-2 As shown, a low thermal conductivity multilayer composite magnesia-iron-aluminum spinel brick in this embodiment includes a working layer 1, an insulating layer 2 fixedly connected to the working layer 1, and an insulating layer 3 arranged in the insulating layer 2 , wherein, the side wall of the thermal insulation layer 2 away from the working layer 1 is provided with an inwardly recessed gap, and the thermal insulation layer 3 is fixedly connected to the inside of the gap.

[0050] The working layer 1 in this embodiment is prepared by aggregate, powder and binder according to the following proportions by weight:

[0051] Aggregate: 55wt%, including 15wt% of microporous high-purity magnesia with a particle size of 0-1mm, 25wt% of microporous high-purity magnesia with a particle size of 1-3mm, and 20wt% of light forsterite with a particle size of 3-5mm;

[0052] Powder: 40wt%, microporous high-purity magnesia with particle size <0.074mm 10wt%;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com