Device and process for electrolytically extracting copper in acidic etching liquid

An acid etching solution and etching solution technology, applied in the direction of photography process, photography auxiliary process, process efficiency improvement, etc., can solve the problems of inability to recycle etching solution, loss of copper resources, low efficiency of electrolytic copper extraction, etc. Reasonable, high recycling rate, and the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

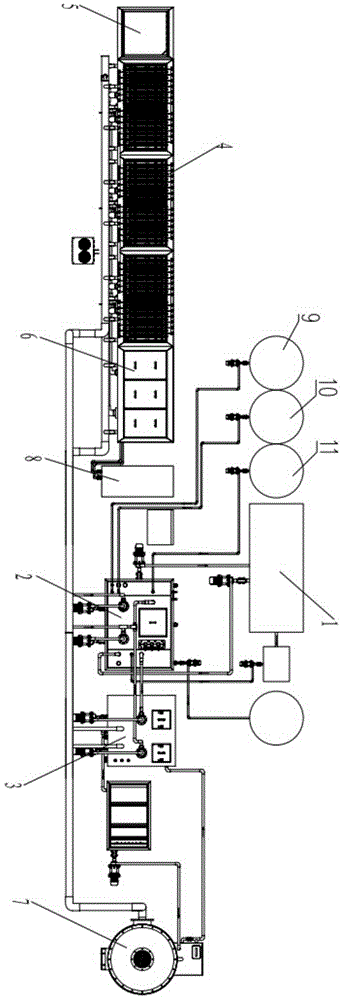

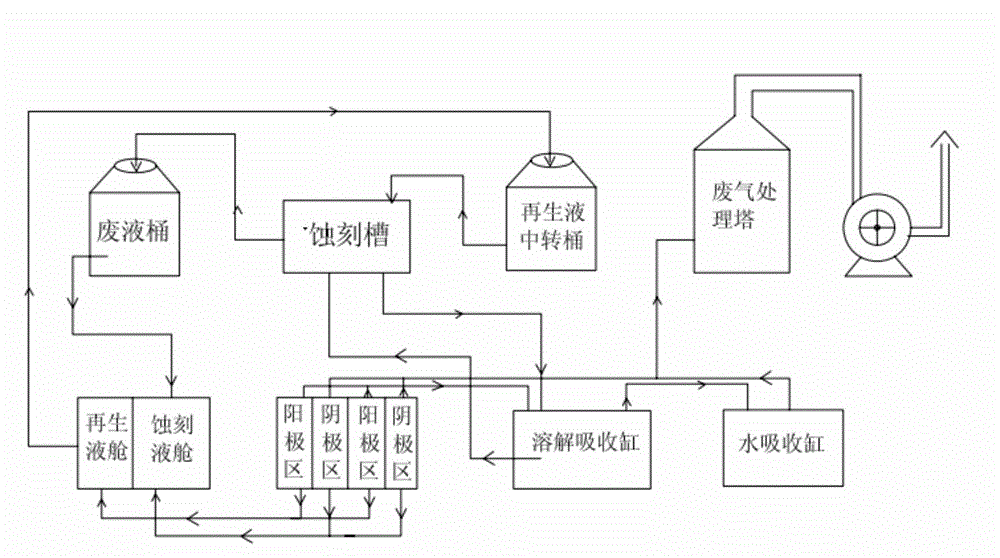

[0018] Combine Figure 1-2 The present invention proposes an acid etching solution electrolytic copper extraction device, which includes an etching tank 1, a waste liquid bucket 8, a copper extraction unit, a dissolving absorption tank 2, a water absorption tank 3; the etching tank 1 and the waste liquid bucket 8 is connected, the waste liquid bucket 8 is connected to the copper extraction unit; the copper extraction unit includes an etching solution chamber 6, a regeneration solution chamber 5, and an electrolysis reaction chamber 4, and the electrolysis reaction chamber 4 passes through a composite polymer ion membrane It is divided into a cathode area and an anode area arranged at intervals. A cathode plate is installed in the cathode area, and an anode plate is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com