Method and equipment for producing C4-C6 diacid low-carbon alcohol ester

A production method and technology of dibasic acid, applied in the chemical industry, can solve the problems of long time and high energy consumption, and achieve the effects of short reaction time, low catalyst dosage and low catalyst dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

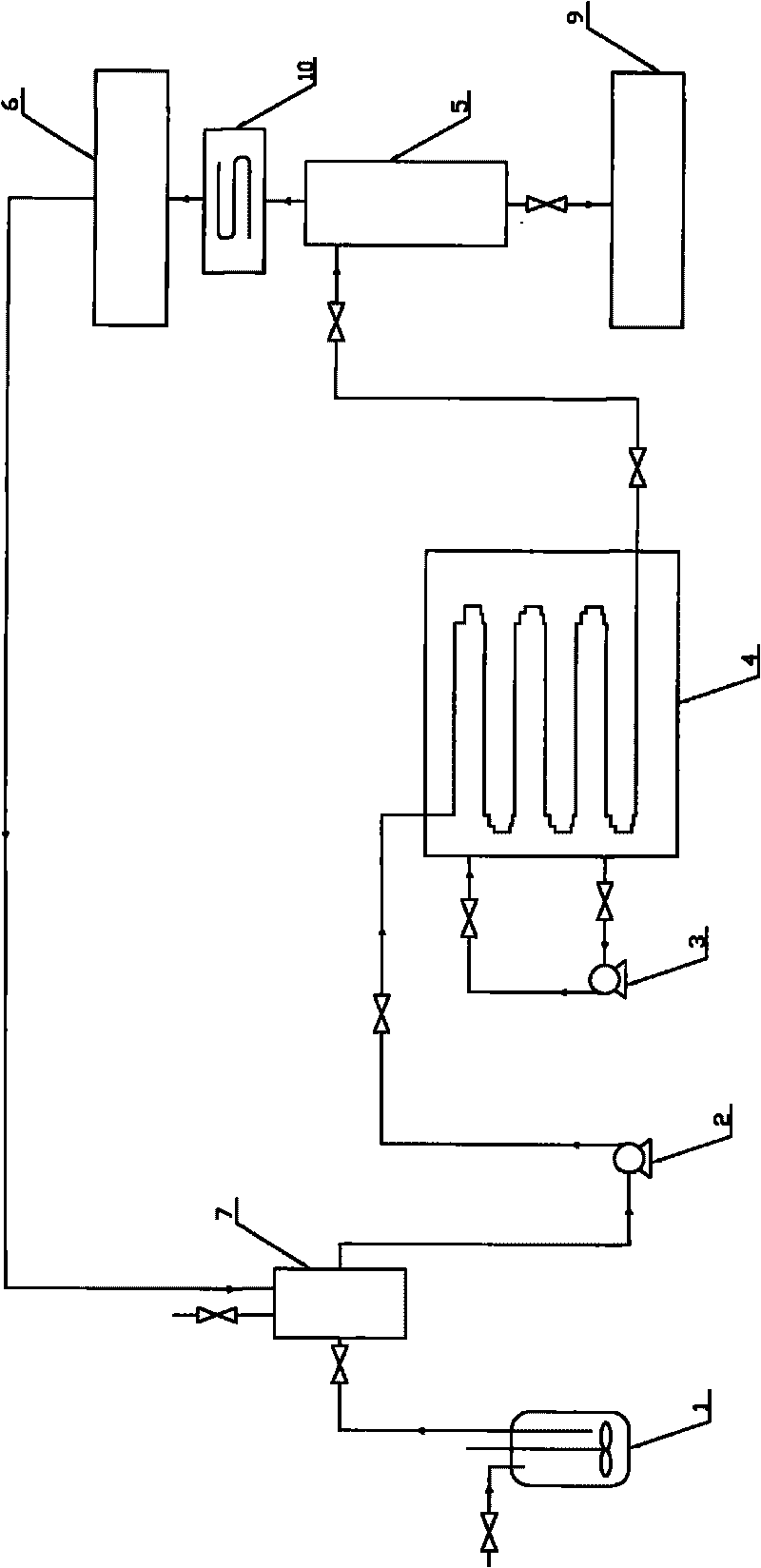

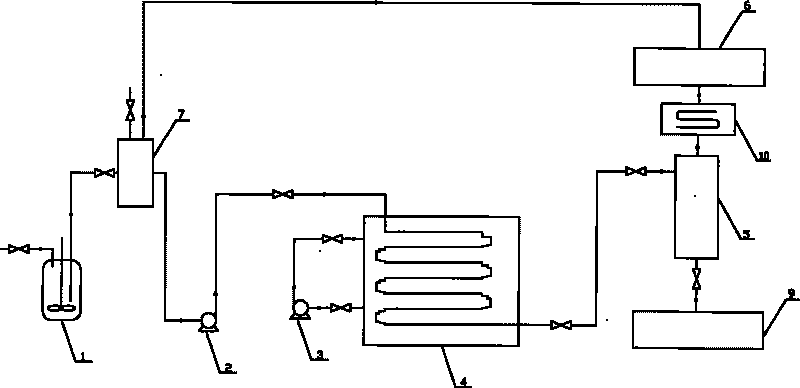

Method used

Image

Examples

example 1

[0032] The raw materials used are nylon acid and methanol, acid / alcohol=1:3 (mol / mol), and the amount of catalyst is 1% of the mass of nylon acid.

[0033] In the batching tank 1, add esterification catalyst p-toluenesulfonic acid, nylon acid, and methanol in sequence. After the addition is complete, turn on the stirring and raise the temperature to 60°C. After all the materials are dissolved, they are discharged into the material liquid storage tank 7 through the pipeline. The liquid material in the liquid storage tank 7 is sent to the continuous esterification reactor 4 through the feed metering pump 2. The continuous esterification reaction operation is controlled, the pressure is 1.0 MPa (gauge pressure), the reaction temperature is 130° C., and the esterification reaction residence time is 15 min. Under these conditions, the esterification is continued. When the continuous esterification reactor 4 reaches the above-mentioned operating conditions, slowly open the discharge po...

example 2

[0035] The raw materials used are nylon acid and ethanol, acid / alcohol=1:4 (mol / mol), and the amount of esterification catalyst is 1.5% of the mass of nylon acid.

[0036] The process of synthesizing diethyl nylonate from nylon acid and ethanol is the same as in Example 1. The differences are as follows: (1) The batching temperature is 75°C; (2) The operating pressure of the continuous esterification reaction is controlled to 1.2 MPa (gauge pressure), The reaction temperature is 130°C, and the residence time of the esterification reaction is 20min; (3) The flash evaporator system pressure is 0.07MPa and the temperature is 120°C. The experimental results are shown in Table 1.

example 3

[0038] The raw materials used are succinic acid and methanol, acid / alcohol=1:3 (mol / mol), and the amount of esterification catalyst is 1% of the mass of succinic acid.

[0039] The process of synthesizing dimethyl succinate from succinic acid and methanol is the same as that in Example 1, with the following differences: (1) The batching temperature is 65°C; (2) The operating pressure of the continuous esterification reaction is controlled to 0.9MPa (gauge pressure). ), the reaction temperature is 120°C, and the residence time of the esterification reaction is 10min; (3) The flasher system pressure is 0.09MPa and the temperature is 120°C. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com