Liquid cooling temperature control and management method of power lithium ion battery

A technology of lithium ion battery and management method, which is applied in the field of control and management of liquid cooling temperature of power lithium ion battery, can solve the problems of no description or report, and no ceramic material has been collected, so as to solve the problem of heat dissipation lag and prevent battery performance loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

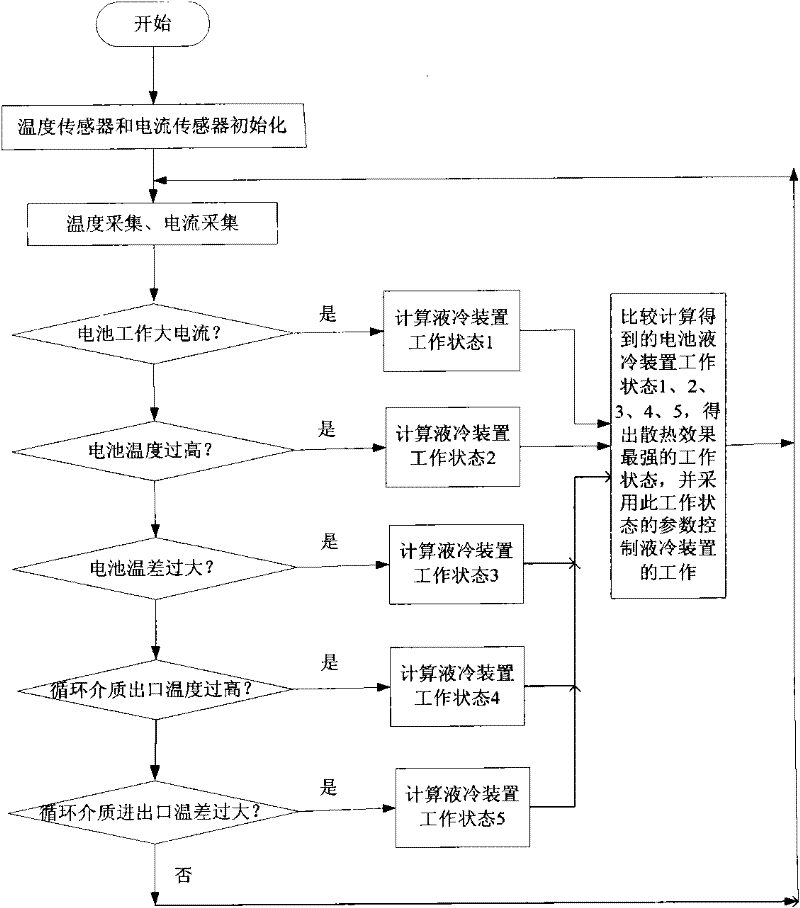

[0027] In order to dissipate heat to the power lithium-ion battery, a liquid cooling device is installed in the battery pack, the device has a circulating cooling medium passage, and the driving device of the circulating medium makes the circulating medium flow between the battery pack system and the cooling device. The method of the present invention is based on this A liquid cooling device, the structure of the liquid cooling device, the company is applying for a patent in another case.

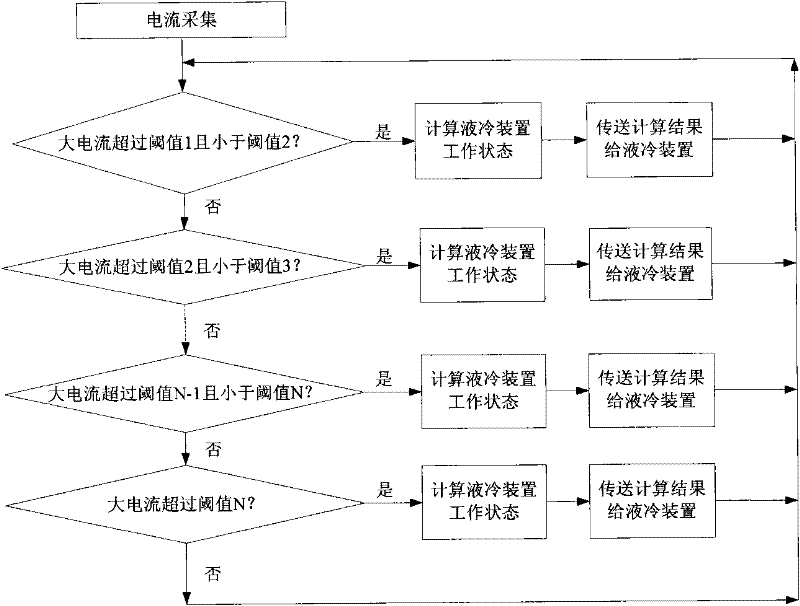

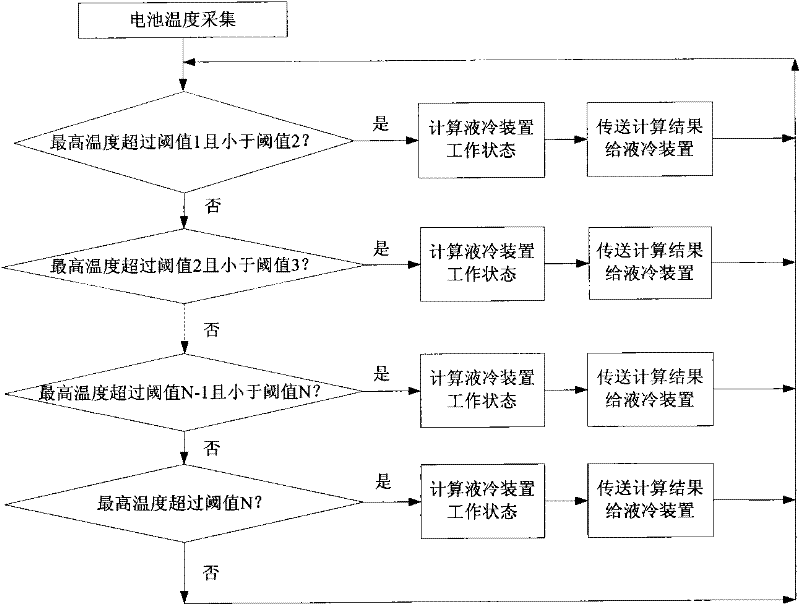

[0028] The liquid cooling temperature control and management method of the power lithium ion battery of the present invention is to control and manage the liquid cooling system through the temperature detected on the surface of the power battery and the operating current of the power battery, and the working state of the liquid cooling device is controlled by the circulating medium. The working state of the driving device is realized, so as to ensure that the battery works in the optimal tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com