Environment-friendly method for preparing mullite fiber based porous ceramic through gel casting

A technology of mullite fiber and gel injection molding, which is applied in the field of porous ceramics, can solve problems such as toxicity, nervous system damage, and increase production costs, and achieve the effects of high porosity, low thermal conductivity, and excellent high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

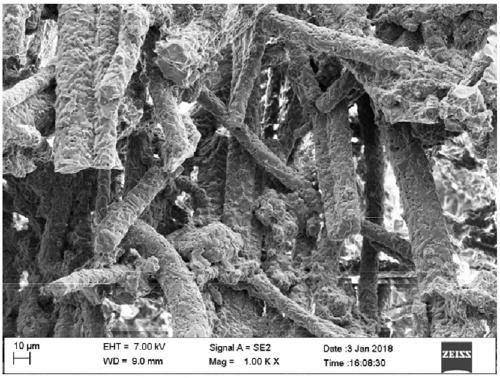

Embodiment 1

[0021] In this example, the raw material adopts ρ-Al 2 o 3 powder, kaolin powder and mullite fiber, ρ-Al 2 o 3 The particle size of the powder is 5 μm, the particle size of the kaolin powder is 25 μm, and the specification size range of the mullite fiber is 5-10 μm in diameter and 50-125 μm in length. Firstly, ρ-Al with a mass percentage of 23.5% 2 o 3 powder, 26.5% kaolin powder for mixing and batching, adding deionized water with 150% of the total mass of raw materials, stirring in a mechanical stirrer and ultrasonic oscillation for 5 minutes to obtain a stable and uniform ceramic slurry, and then adding a mass percentage of 50% % mullite fiber is evenly added to the ceramic slurry, and the stirring and vibration are continued for 30 minutes to obtain a gel-type ceramic-fiber slurry, which is then injection molded and solidified at room temperature, and the molded green body is placed in a 70°C Dry in a constant temperature drying oven for 96 hours, place in a high-temp...

Embodiment 2

[0024] In this example, the raw material adopts ρ-Al 2 o 3 powder, kaolin powder and mullite fiber, ρ-Al 2 o 3 The particle size of the powder is 3 μm, the particle size of the kaolin powder is 45 μm, and the specification size range of the mullite fiber is 5-10 μm in diameter and 50-125 μm in length. First, ρ-Al with a mass percentage of 15.7% 2 o 3 powder, 17.7% kaolin powder for mixing and batching, adding deionized water with 170% of the total mass of raw materials, stirring in a mechanical stirrer and ultrasonic oscillation for 5 minutes to obtain a stable and uniform ceramic slurry, and then adding a mass percentage of 66.6 % mullite fiber is evenly added to the ceramic slurry, and the stirring and vibration are continued for 30 minutes to obtain a gel-type ceramic-fiber slurry, which is then injection molded and solidified at room temperature, and the molded green body is placed in a 70°C Dry it in a constant temperature drying oven for 72 hours, place it in a high...

Embodiment 3

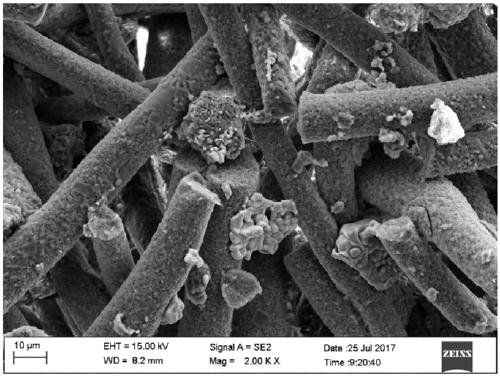

[0027] In this example, the raw material adopts ρ-Al 2 o 3 powder, zircon powder and mullite fiber, ρ-Al 2 o 3 The particle size of the powder is 10 μm, the particle size of the zircon powder is 45 μm, and the standard size range of the mullite fiber is 5-10 μm in diameter and 50-125 μm in length. Firstly, ρ-Al with a mass percentage of 11.9% 2 o 3 powder, 13.1% zircon powder for mixing and batching, adding deionized water with 160% of the total mass of raw materials, stirring in a mechanical stirrer and performing ultrasonic oscillation for 5 minutes to obtain a stable and uniform ceramic slurry, and then the mass percentage Add 75% mullite fiber evenly into the ceramic slurry, continue to stir and vibrate for 30 minutes to obtain a gel-type ceramic-fiber slurry, then injection mold and solidify at room temperature, and mold the green body at 70 ℃ in a constant temperature drying oven for 48 hours, after demoulding, put it in a high-temperature furnace and sinter at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com