Method for improving silicon carbide-niobium brazing connection quality through low-expansion 4J42 alloy interlayer auxiliary brazing filler metal

A technology of connection quality and intermediate layer, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of large residual stress in the brazing connection of silicon carbide and niobium, poor reaction of the ceramic side interface, etc., and optimize the weld structure. and interface reaction, improving plasticity and toughness, and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: present embodiment a kind of low-expansion 4J42 alloy interlayer assists the method for brazing filler metal to improve silicon carbide-niobium brazing connection quality, and it is carried out according to the following steps:

[0020] 1. Pre-processing:

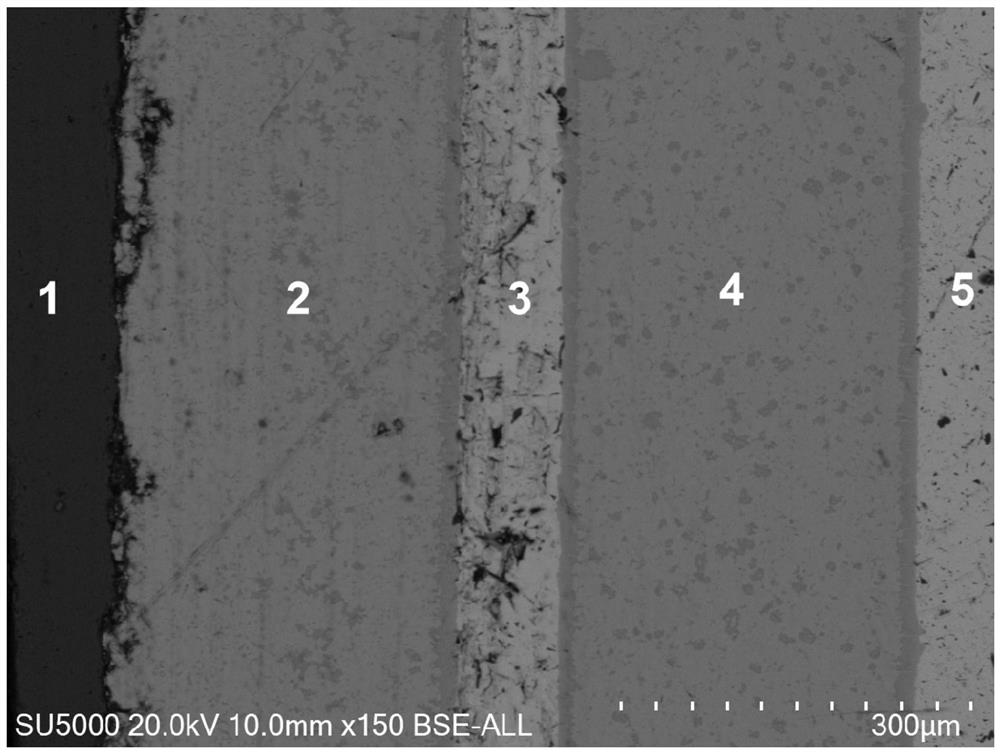

[0021] Add titanium-zirconium-copper-nickel solder into the binder to obtain solder containing the binder, and coat the solder containing the binder on the metal niobium surface to be welded to obtain the first solder layer. Place a 4J42 alloy foil with a thickness of 100 μm to 200 μm on the solder layer, and then coat a layer of solder containing an adhesive on the 4J42 alloy foil to obtain a second solder layer, and place on the second solder layer Silicon carbide is finally heated and dried to obtain the parts to be welded;

[0022] 2. Vacuum brazing:

[0023] Place the parts to be welded in a vacuum brazing furnace, and pump the air pressure of the vacuum furnace to 3×10 -3 Pa~5×10 -3...

specific Embodiment approach 2

[0028]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the binder described in step 1 is carboxymethyl cellulose or ethyl cellulose. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mass percentage of Ti in the titanium-zirconium-copper-nickel solder described in step 1 is 41.14%, and the mass percentage of Zr is 34.36%. The mass percentage of Cu is 14.67%, and the mass percentage of Ni is 9.83%. Others are the same as in the first or second embodiment.

[0030] The titanium-zirconium-copper-nickel solder is Ti41.14-Zr34.36-Cu14.67-Ni9.83.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com