Magnesium-zirconium spinel ramming material for furnace bottom

A technology of zirconium spinel and magnesium aluminum spinel, which is applied in the field of zirconium spinel furnace bottom ramming materials, can solve the problems of low shrinkage, furnace lining settlement, and steel wear, and achieve low linear shrinkage and excellent Good performance in high temperature use and corrosion resistance of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 A kind of magnesium-zirconium spinel furnace bottom ramming material

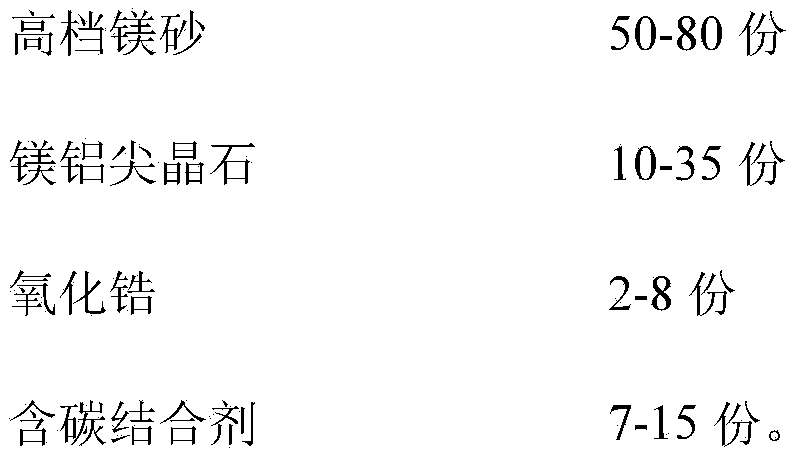

[0017] The raw materials adopted are formulated according to the following parts by weight:

[0018]

[0019]

[0020] High-grade magnesia is aggregate magnesium content greater than or equal to 97%, particle size ≤ 5 mesh, magnesia-alumina spinel particle size ≤ 4 mesh, zirconia particle size ≤ 800 mesh, the above-mentioned high-grade magnesia, magnesia-alumina spinel, oxide Zirconium and high-temperature asphalt are mixed and stirred evenly in proportion to obtain the finished product.

[0021] The ramming material is mixed with an appropriate amount of water to make a billet, and the compressive strength and permanent linear change rate test after burning are carried out. The results are shown in Table 1. As can be seen from Table 1, the ramming material has very high bonding strength. After calcination at a temperature of not less than 1200°C for 3 hours, the compressive stren...

Embodiment 2

[0022] Embodiment 2 A kind of magnesium-zirconium spinel furnace bottom ramming material

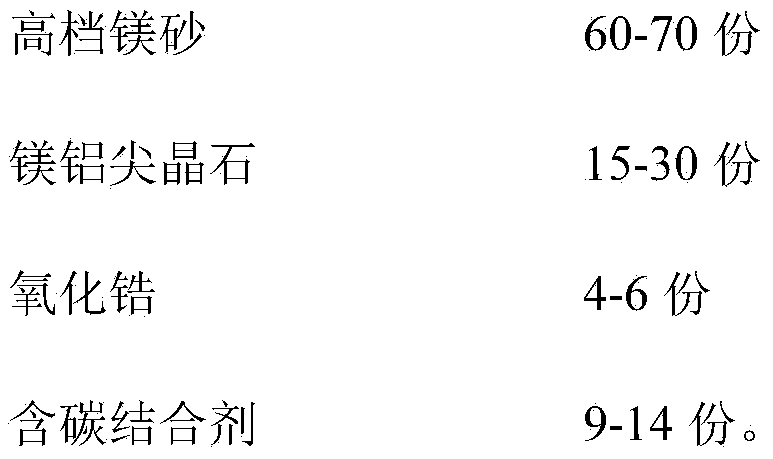

[0023] The raw materials adopted are formulated according to the following parts by weight:

[0024]

[0025] High-grade magnesia is aggregate magnesium content greater than or equal to 97%, particle size ≤ 5 mesh, magnesia-alumina spinel particle size ≤ 4 mesh, zirconia particle size ≤ 800 mesh, the above-mentioned high-grade magnesia, magnesia-alumina spinel, oxide Zirconium and sodium tripolyphosphate are mixed and stirred evenly in proportion to obtain a finished product.

[0026] The ramming material is mixed with an appropriate amount of water to make a billet, and the compressive strength and permanent linear change rate test after burning are carried out. The results are shown in Table 1. As can be seen from Table 1, the ramming material has very high bonding strength. After being calcined at a temperature not less than 1200°C for 3 hours, the compressive strength can still r...

Embodiment 3

[0027] Embodiment 3 A kind of magnesium-zirconium spinel furnace bottom ramming material

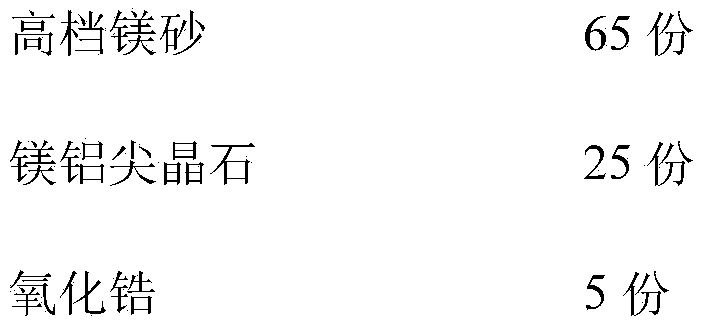

[0028] The raw materials adopted are formulated according to the following parts by weight:

[0029]

[0030] High-grade magnesia is aggregate magnesium content greater than or equal to 97%, particle size ≤ 5 mesh, magnesia-alumina spinel particle size ≤ 4 mesh, zirconia particle size ≤ 800 mesh, the above-mentioned high-grade magnesia, magnesia-alumina spinel, oxide Zirconium, sodium hexametaphosphate and uropintor are mixed and stirred evenly in proportion to obtain a finished product.

[0031] The ramming material is mixed with an appropriate amount of water to make a billet, and the compressive strength and permanent linear change rate test after burning are carried out. The results are shown in Table 1. As can be seen from Table 1, the ramming material has very high bonding strength. After being calcined at a temperature of not less than 1200°C for 3 hours, the compressive stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com