Sleeve lime kiln empty-kiln baking method

A technology of sleeve lime kiln and drying kiln, which is applied in the field of sleeve lime kiln, and can solve problems such as local cracks in refractory materials, influence of moisture removal effect, and lack of drying process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

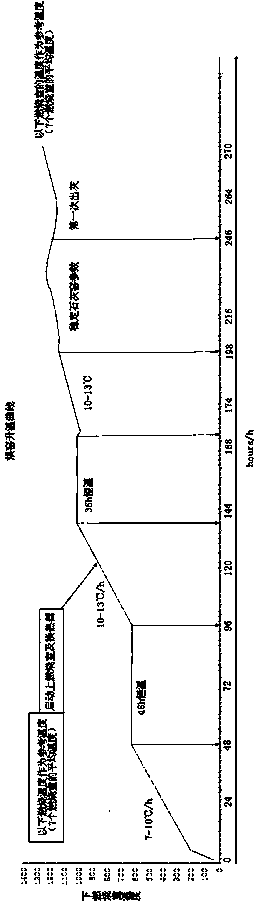

[0020] Such as figure 1 As shown, the air drying of the sleeve lime kiln is an important measure to prolong the service life of the refractory material in the kiln and reduce the clogging of the circulation channel after the kiln body is produced. The specific technological process of the empty kiln is as follows:

[0021] (1). Lead gas to the temporary burner of sleeve lime kiln;

[0022] (2). Start the exhaust fan, and control the speed (valve opening) at 5%~10%, so that the negative pressure in the kiln is ≥ -0.05kpa;

[0023] (3). Light the torch, open the valve of the ignition gun, and then open the gas pipeline valve of the temporary burner. After igniting the temporary burners one by one, insert the ash discharge device from the observation hole of the ash discharge device, and fix the burner upward;

[0024] (4). After ignition, when the temperature in the kiln rises to 50°C, the temperature will be increased by 3°C to 5°C per hour. The rising and falling temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com