A long-life heat repair castable for iron ditch

A iron channel castable and hot repair technology, which is applied in the field of iron channel castables, can solve the problems of gas mismatch of metal aluminum powder, etc., and achieve the effects of reducing the generation of low melting phase, increasing density, and ensuring high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

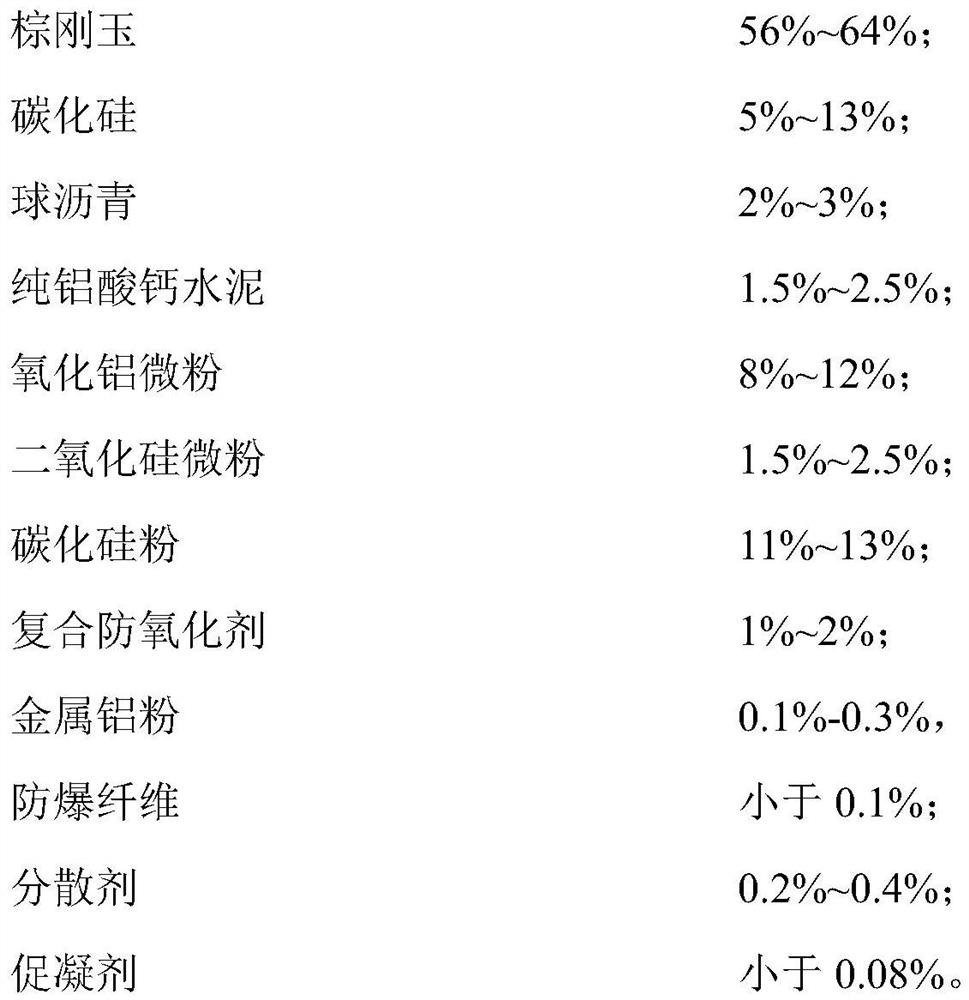

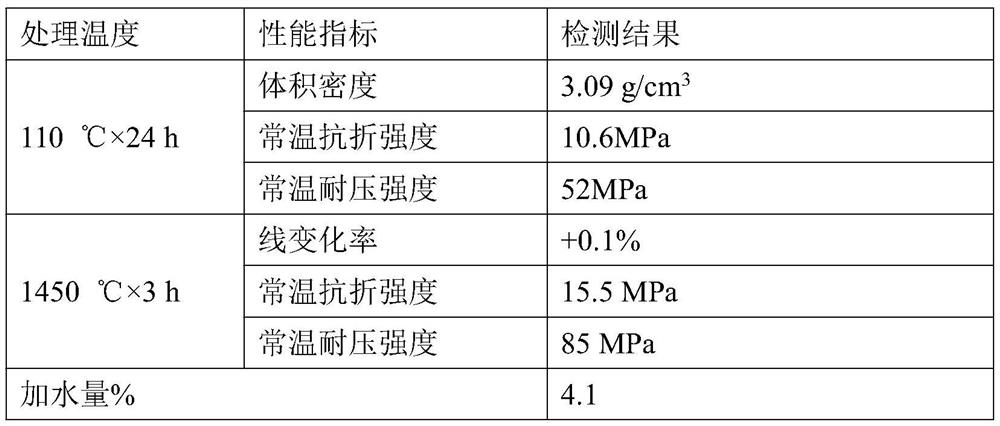

[0039] A long-life heat repair castable for iron ditch, the components and their mass percentages are: brown corundum 56%; silicon carbide 13%; ball pitch 2.4%; pure calcium aluminate cement 2.5%; alumina micropowder 10.905%; silicon dioxide powder 1.5%; silicon carbide powder 11%; composite antioxidant 2%; metal aluminum powder 0.3%, explosion-proof fiber 0.075; dispersant 0.3%; The raw materials were weighed according to the above proportions and fully mixed; then water was added (the mass of water was 4.1% of the total mass of each raw material) and stirred evenly, and then vibrated and formed; The heat treatment was carried out for 24 hours, and the iron trough castable sample for long-life hot repair was prepared.

[0040] The performance test of the iron channel castable sample for long-life hot repair prepared in this embodiment is performed, and the results are shown in Table 1. The performance testing method adopted is carried out in accordance with the current natio...

Embodiment 2

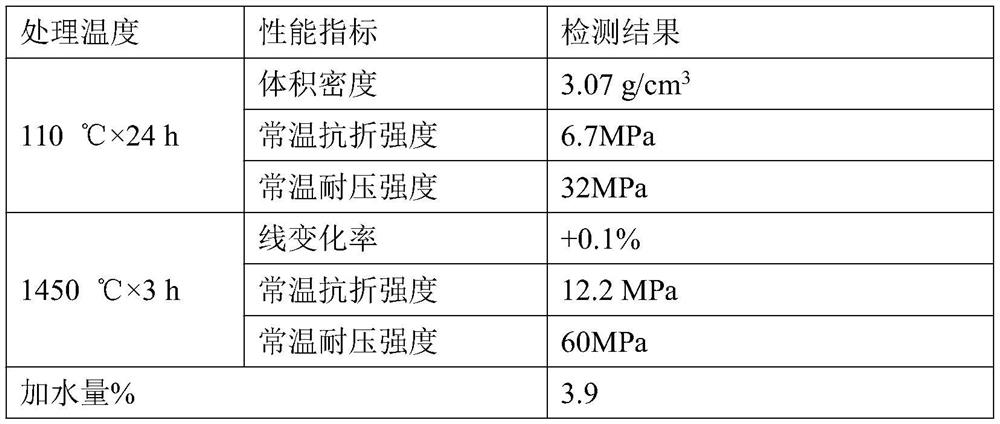

[0044]A castable for long-life hot repairing iron trench, the components and their mass percentages are: brown corundum 64%; silicon carbide 5%; ball asphalt 2%; pure calcium aluminate cement 1.5%; alumina micropowder 12%; silicon dioxide powder 1.77%; silicon carbide powder 12%; composite antioxidant 1%; metal aluminum powder 0.2%, explosion-proof fiber 0.05%; dispersant 0.4%; coagulant 0.08%. The raw materials were weighed according to the above proportions and fully mixed; then water was added (the mass of water was 3.9% of the total mass of each raw material) and stirred evenly, and then vibrated and formed; after forming, the obtained samples were dried naturally for 24 hours and then reheated at 110°C. The heat treatment was carried out for 24 hours, and the iron trough castable sample for long-life hot repair was prepared.

[0045] The performance test of the iron channel castable sample for long-life hot repair prepared in this embodiment is performed, and the results ...

Embodiment 3

[0049] A long-life heat repair castable for iron ditch, the components and their mass percentages are: brown corundum 60%; silicon carbide 0-1mm: 9%; ball pitch 2.5%; pure calcium aluminate cement 2% 10% of alumina micropowder; 2% of silica micropowder; 13% of silicon carbide powder; 1.06% of composite antioxidant; 0.1% of metal aluminum powder, 0.1% of explosion-proof fiber; Weigh and mix each raw material according to the above ratio; then add water (the mass of water is 4% of the total mass of each raw material) and stir evenly, then vibrate and shape; after forming, the sample obtained is dried naturally for 24 hours and then reheated at 110°C. The heat treatment was carried out for 24 hours, and the iron trough castable sample for long-life hot repair was prepared.

[0050] The performance test of the iron channel castable sample for long-life hot repair prepared in this embodiment is performed, and the results are shown in Table 3. The performance testing method adopted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com