Preparation method of dispersive aluminum oxide for castable and castable

A dispersive and alumina technology, applied in the field of refractory materials, can solve problems affecting construction performance, non-condensation phenomenon, and affecting demoulding strength, etc., and achieve the effects of improving constructability, reducing water addition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0052] (1) Active α-Al 2 o 3 Alumina powder is obtained by ball milling in a corundum ball mill, active α-Al 2 o 3 Middle Al 2 o 3 The mass fraction ≥ 95wt%, the ball-to-material ratio and ball milling time are shown in Table 1.

[0053] According to the ball milling conditions shown in Table 1, the particle size of the obtained alumina powder satisfies D 50 ≤10μm, D 90 ≤20μm.

[0054] (2) Mix the alumina powder, water reducer and coagulation regulator to obtain dispersible alumina. Table 2 shows the weight ratio of alumina powder, water reducer and coagulation regulator.

[0055] Examples 1-3 adopt mechanical mixing. The ball-to-material ratio of Example 1 is 1:2.5, the ball-to-material ratio of Example 2 is 1:3, and the ball-to-material ratio of Example 3 is 1:5. Examples 1-3 The ball milling time is 5 hours.

[0056] Embodiment 4~6 adopts airflow mixing, and embodiment 4 is mixed at 300rpm rotating speed for 120s; Embodiment 5 is first mixed at 100rpm rotating spee...

Embodiment 7

[0057] Examples 7-8 adopt spray granulation, dissolve alumina powder, water reducing agent and coagulation regulator in water to obtain raw material slurry, and then spray the raw material slurry into a granulation tower for drying and granulation. Example 7 The mass percentage of the solute in the raw material slurry is 70%; the mass percentage of the solute in the raw material slurry in Example 8 is 80%.

[0058] Table 1

[0059]

[0060] Table 2

[0061]

[0062]

[0063] In Table 2, X stands for retarded dispersible alumina, D stands for accelerated set dispersible alumina, and each example corresponds to a retarded disperse alumina and a set accelerated disperse alumina.

Embodiment 3

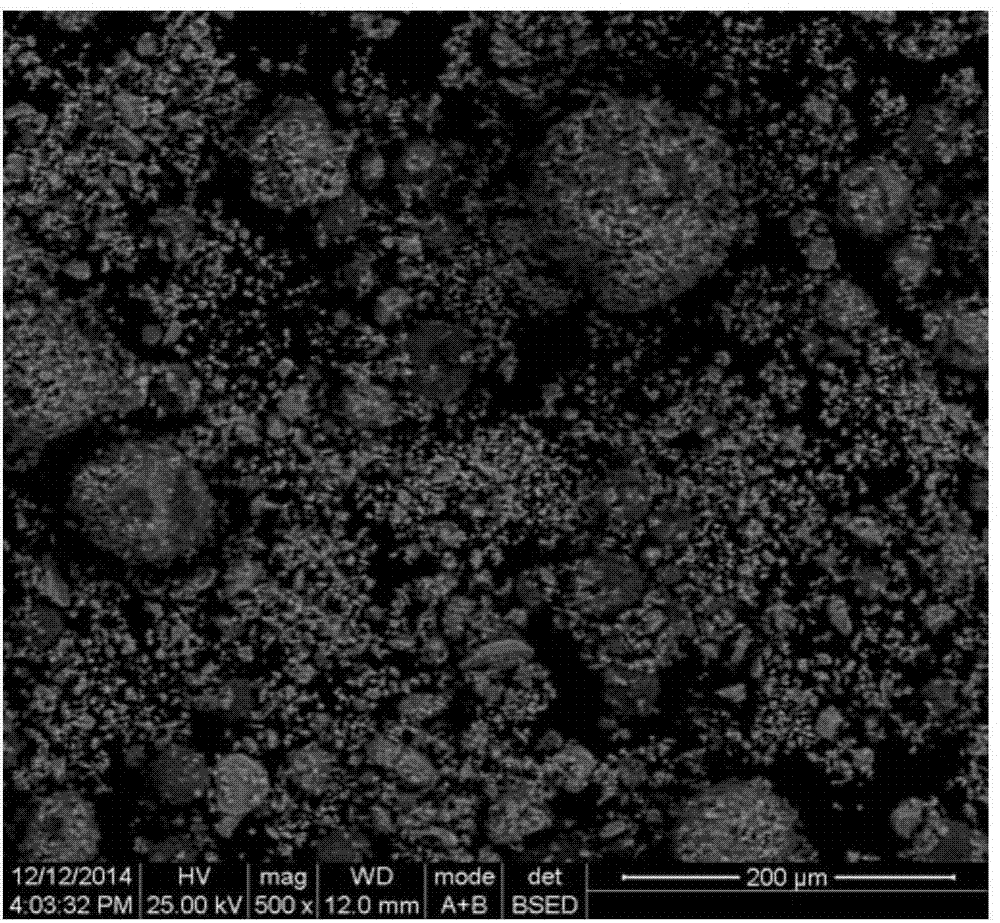

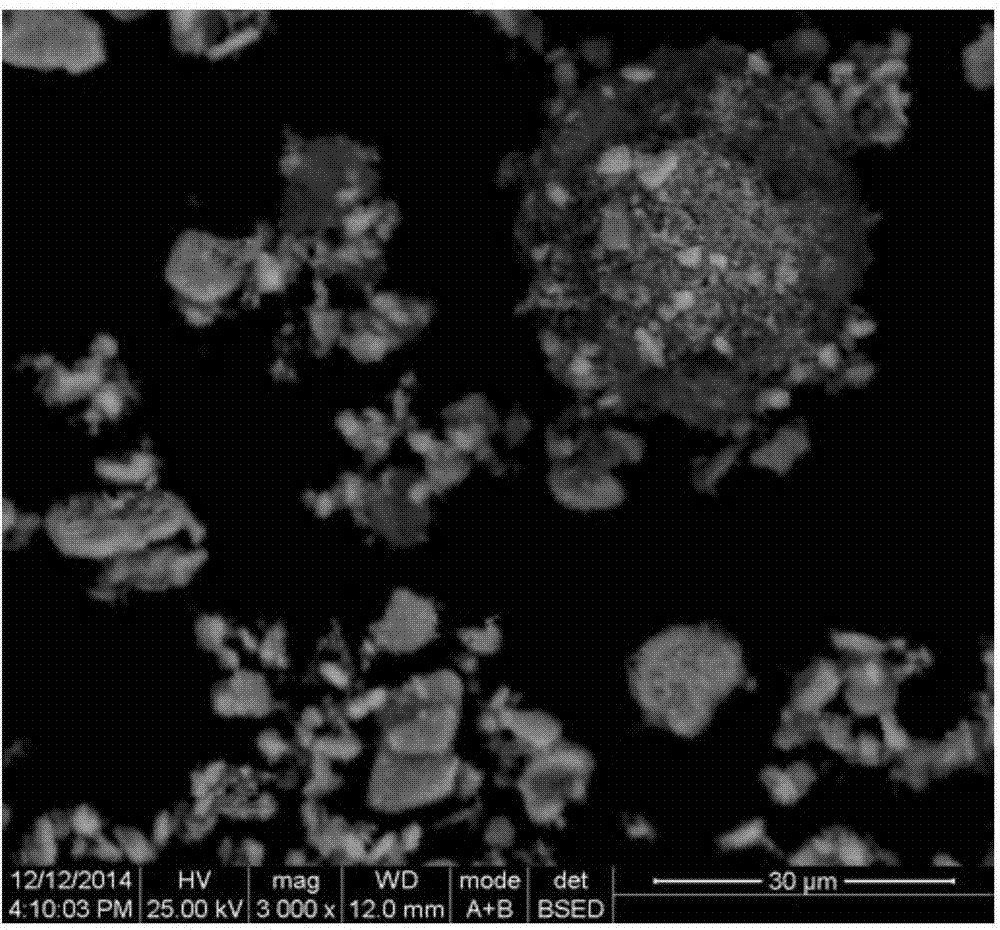

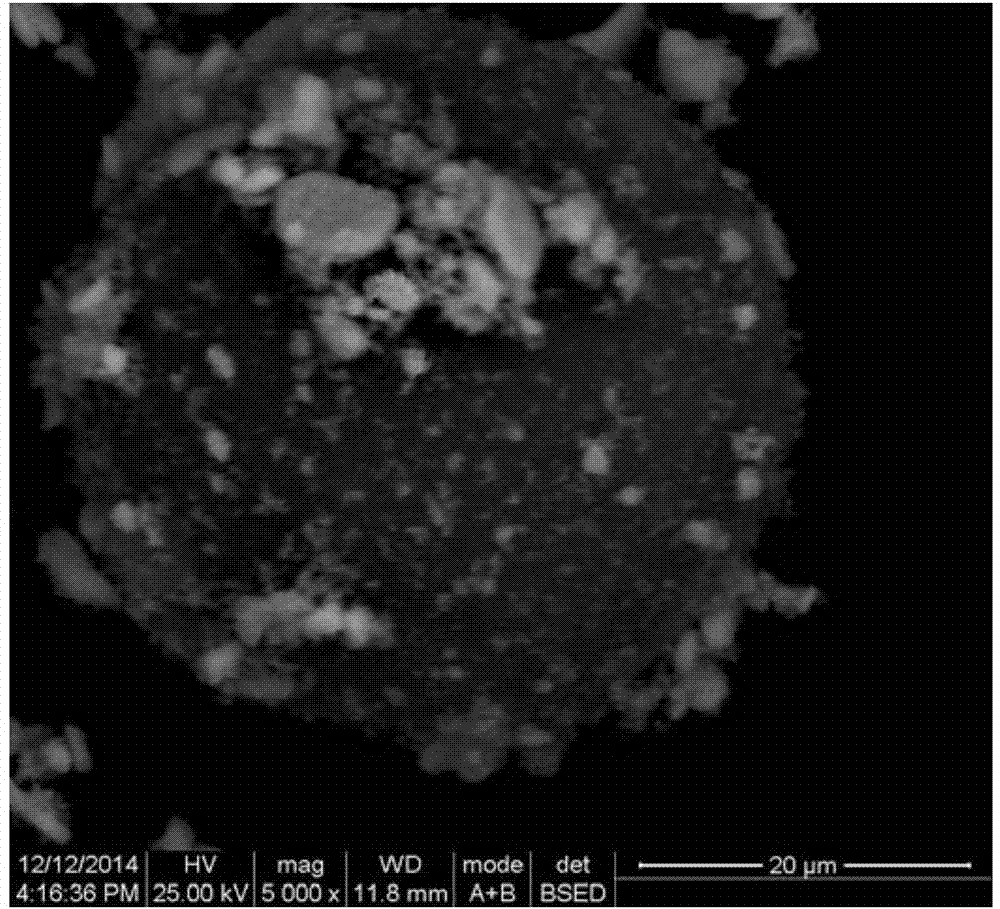

[0074] The microstructure photo of the dispersed alumina prepared in embodiment 3 is as follows figure 1 , figure 2 , image 3 It can be seen from the figure that in the dispersed alumina, the water reducer and the coagulation regulator are attached to the outer surface of the alumina particles.

[0075] Add the dispersible alumina prepared in each example to the castable, and use a fluidity tester to put the castable into the conical hopper of the detector. The size of the conical hopper is upper diameter / lower diameter / height = 70 / 100 / 60mm, the castable is poured into the conical hopper, the upper surface of the castable is flush with the upper end of the conical hopper, when the hopper is lifted, the castable automatically flows out and spreads, and the measurement is made when the spreading diameter of the castable reaches 170mm The amount of water added is used to characterize the water-reducing performance of dispersible alumina.

[0076] Table 4

[0077]

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com