Patents

Literature

307results about How to "High ball rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

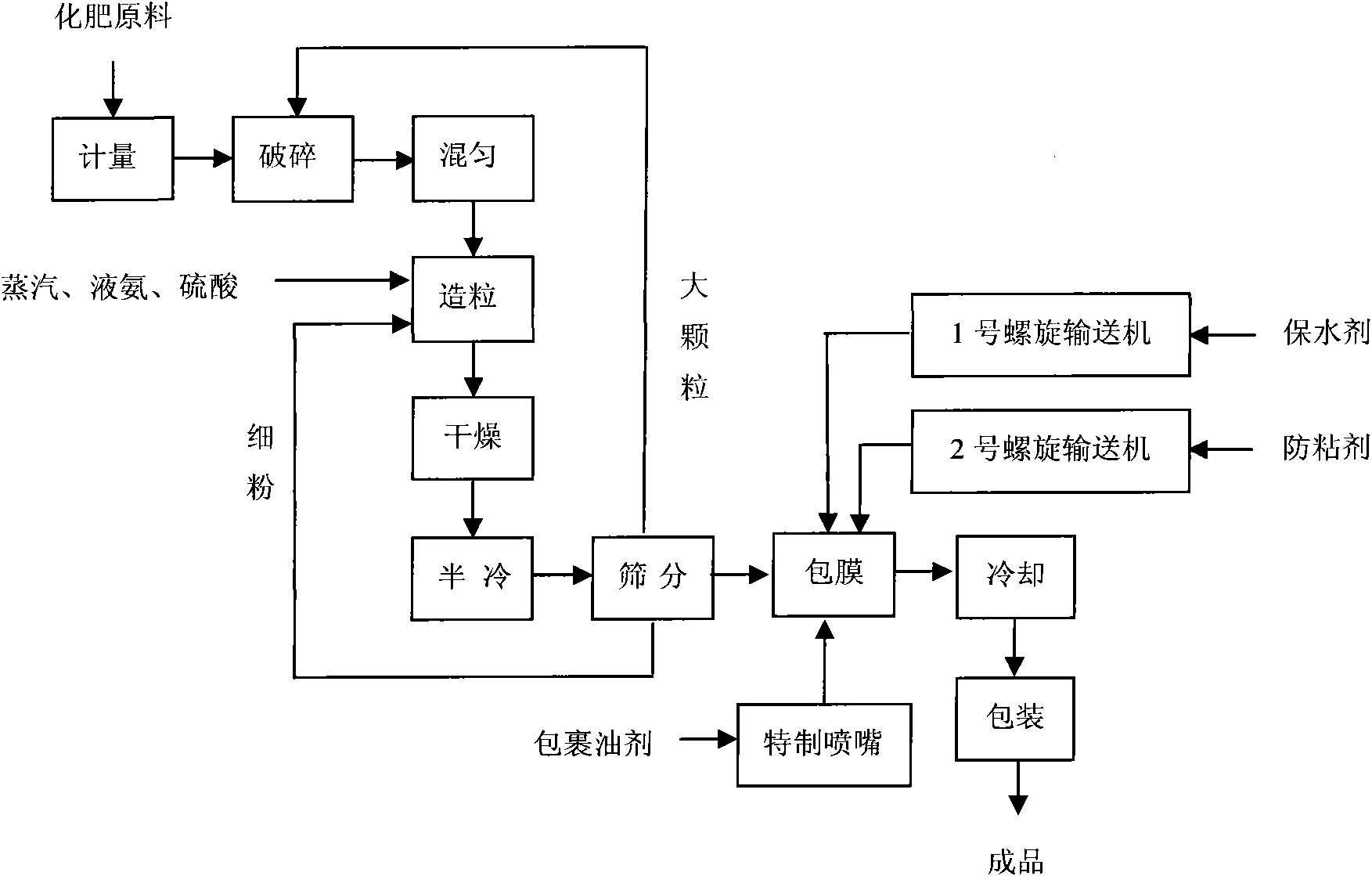

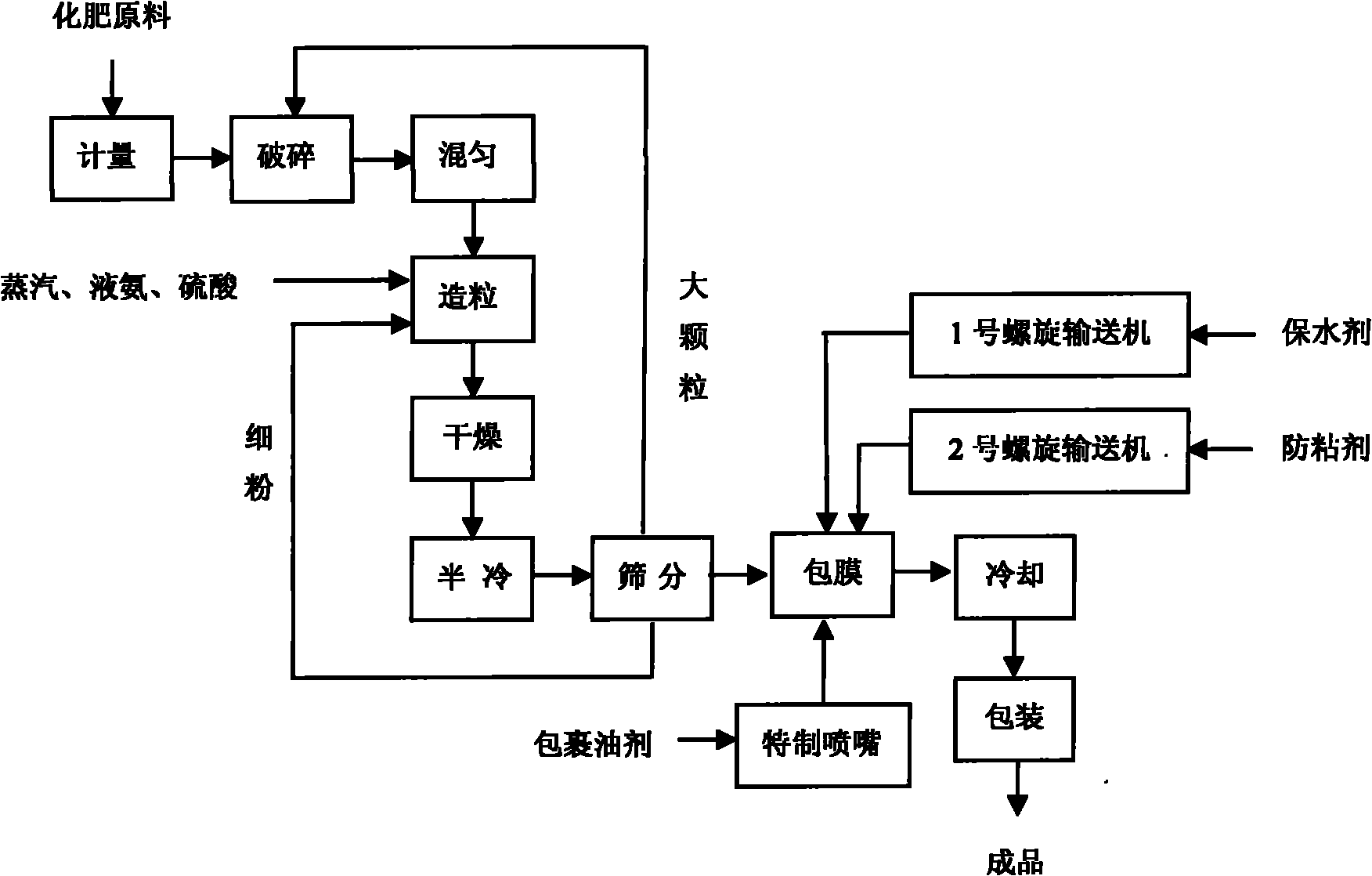

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

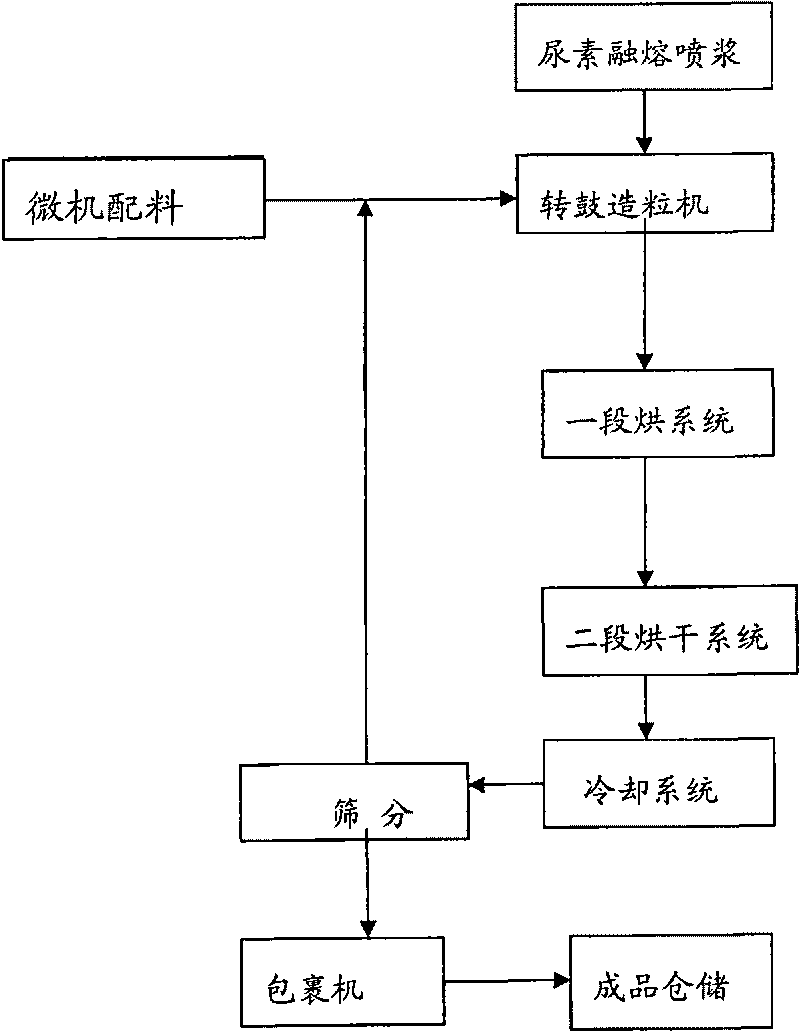

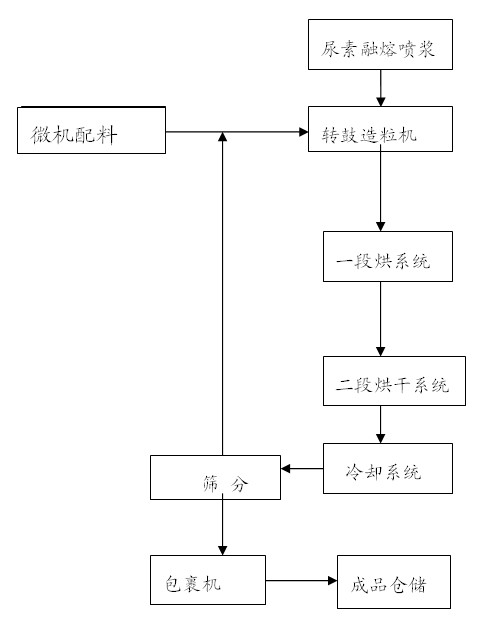

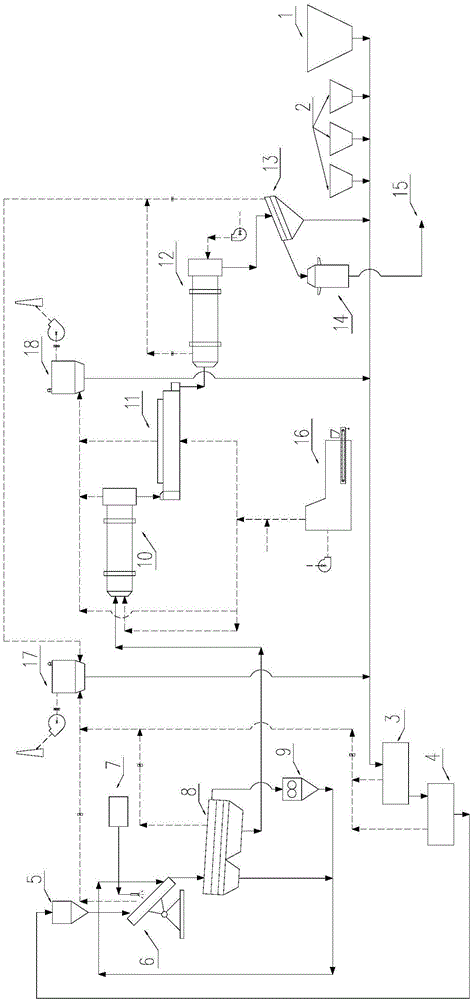

Industrial production method and device of urea-formaldehyde slow-release compound fertilizer

ActiveCN103011982ALow free formaldehyde contentMeet needsAgriculture gas emission reductionFertilizer mixturesPotassiumNitrogen

The invention relates to an industrial production method and device of a urea-formaldehyde slow-release compound fertilizer and a device thereof. The industrial production method comprises the steps of adding water and oxidized starch to a reaction still and then pasting, adding urea of which the nitrogen content is 46wt% and formalin, stirring, dissolving and then adjusting the pH value to 8.5-8.8 by an alkaline matter, reacting at constant temperature of 60 DEG C to obtain reaction liquid; adjusting the pH value to 5.4-5.1 by the reaction liquid; reacting for 45 minutes at the constant temperature of 65-68 DEG C, then adjusting the pH value to 6.8-7.2, and terminating reaction to obtain the urea formaldehyde condensation product solution; mixing the urea formaldehyde condensation product solution with nitrogen, phosphorus and potassium materials, pelletizing, drying and cooling to below 35 DEG C, and screening to obtain the urea-formaldehyde slow-release compound fertilizer. The industrial production device of the urea-formaldehyde slow-release compound fertilizer is also provided by the invention. Urea formaldehyde is taken as a skeleton; rapid disintegration phenomenon of fertilizer particles caused by water absorption expansion is effectively prevented; the urea-formaldehyde slow-release compound fertilizer has good nutrient slow-release performance, and is high in pelletizing rate in the production process and strong in granule hardness, and the total nutrient content is improved.

Owner:河南豫邮金大地科技服务有限公司

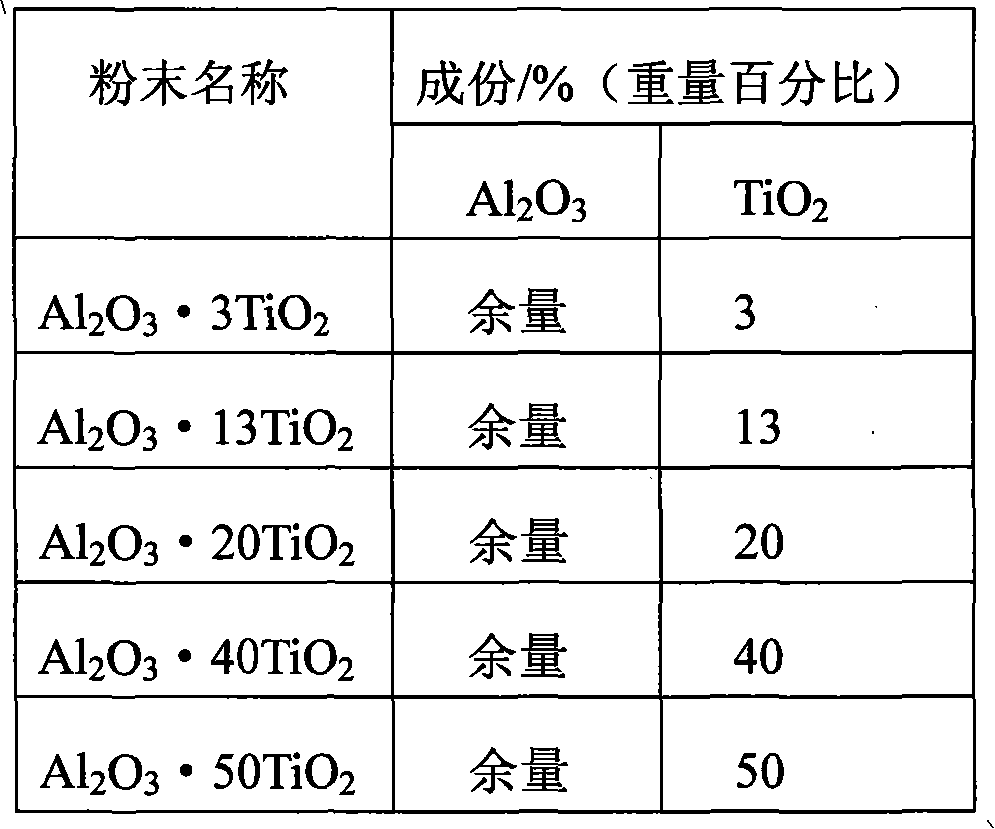

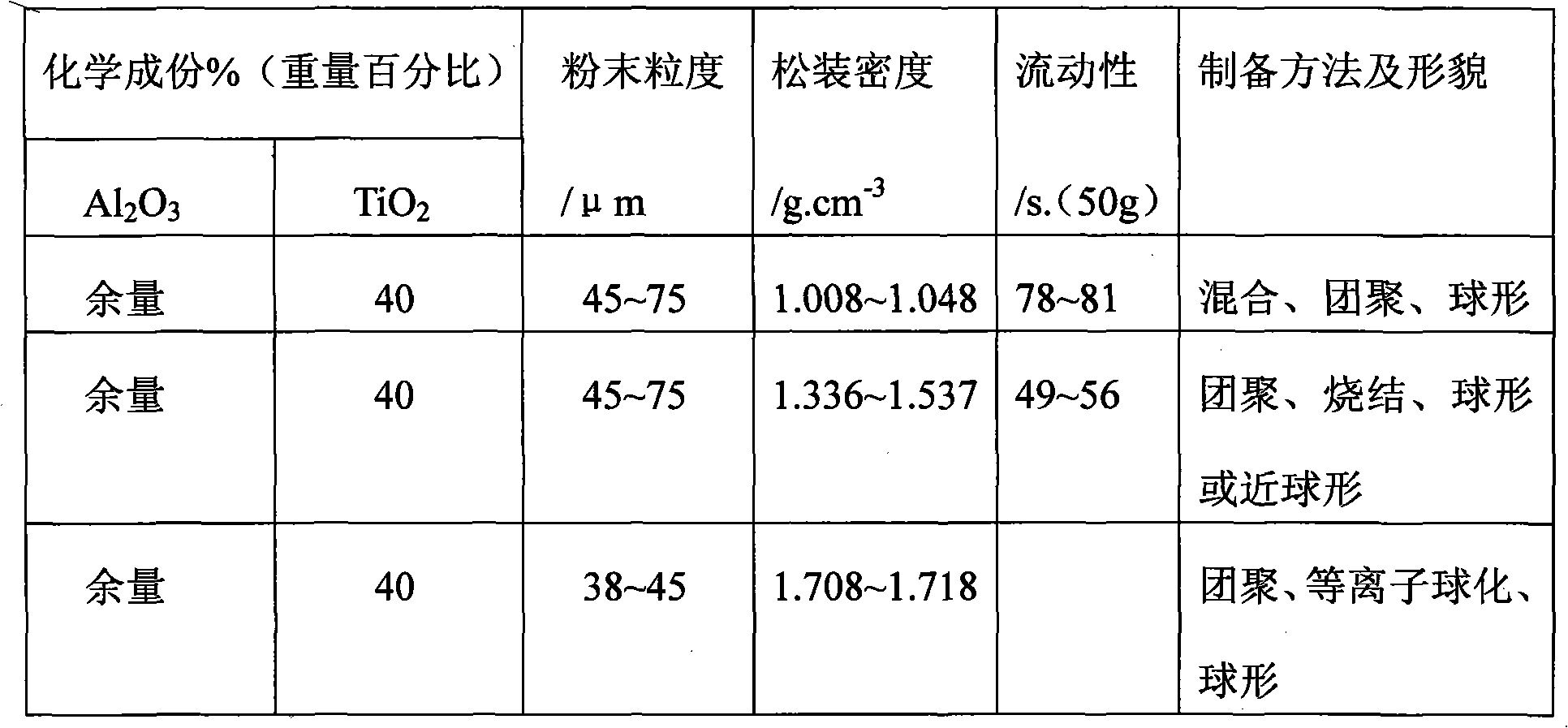

Preparation method of aluminium oxide and titanium dioxide compound ceramic powder

The invention relates to a preparation method of aluminium oxide and titanium dioxide (Al2O3.TiO2)compound ceramic, which comprises the preparation of Al2O3.3TiO2 powder, Al2O3.13TiO2 powder, Al2O3.20TiO2 powder, Al2O3.40TiO2 powder and Al2O3.50TiO2 powder. The preparation process is characterized in that (1) the process is in a straight line type, and three types of powder are prepared, i.e. a mixed type, an aggregation type, an aggregation sintering type and an aggregation plasma spheroidizing type; (2) in the aspect of slurry preparation, PVA (Polyvinyl Alcohol) with high degree of polymerization and high molecular weight is adopted as a binder, and simultaneously, a right amount of defoaming agent, dispersing agent and lubricating agent is added; (3) in the aspect of equipment, a high-efficiency circulating stirring mill and a high-speed centrifugal spray drying pelletizer are adopted; and (4) a settling separation grading method is adopted for the granularity and the granularity distribution of the powder. The preparation method has high production efficiency, stable powder performance and good reproducibility and simultaneously reduces the pollution of dust to the environment.

Owner:上海大豪纳米材料喷涂有限公司 +2

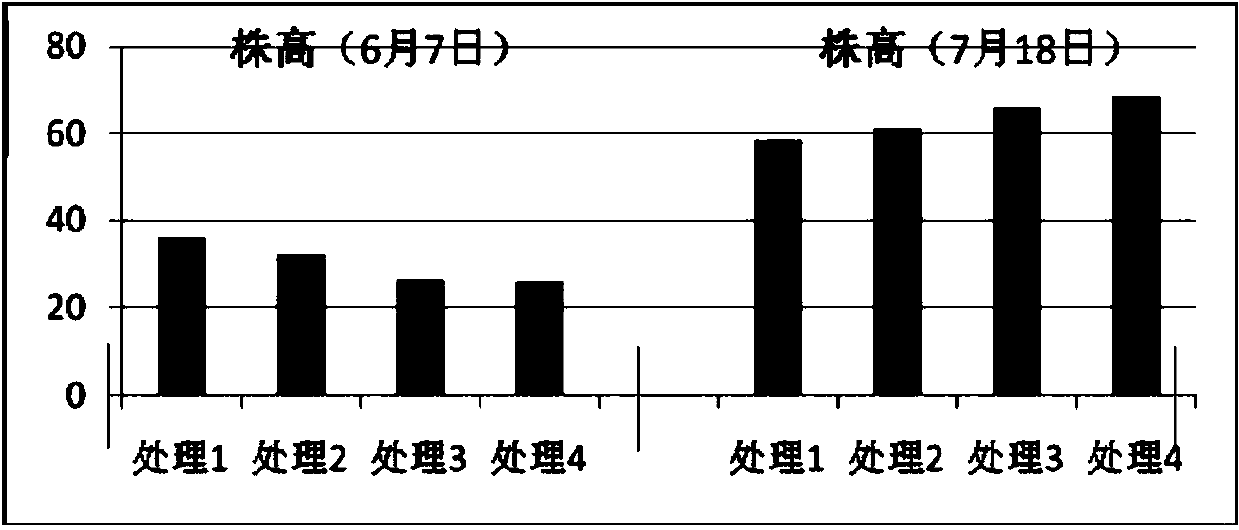

Special fertilizer for lawn and granulating method thereof

InactiveCN101165013AFast fertilizerFast and obvious fertilizer effectFertilizer mixturesAdhesiveChemistry

The fertilizer specially for lawn includes inorganic fertilizer 35-75 wt%, organic fertilizer 25-35 wt%, and stuffing and adhesive for the rest. Its production includes one improved pelletizing process, in which, one improved granulating disc resulting in high balling degree and fine homogeneous pellets, one improved drier with external heating and completing one second balling at 60-65 deg.c and one improved sieving system coompleting one third balling comprising sieving, polishing, rounding, coating, oil coating and fine treatment are adopted. The present invention provides one new pelletizing technology.

Owner:李涛

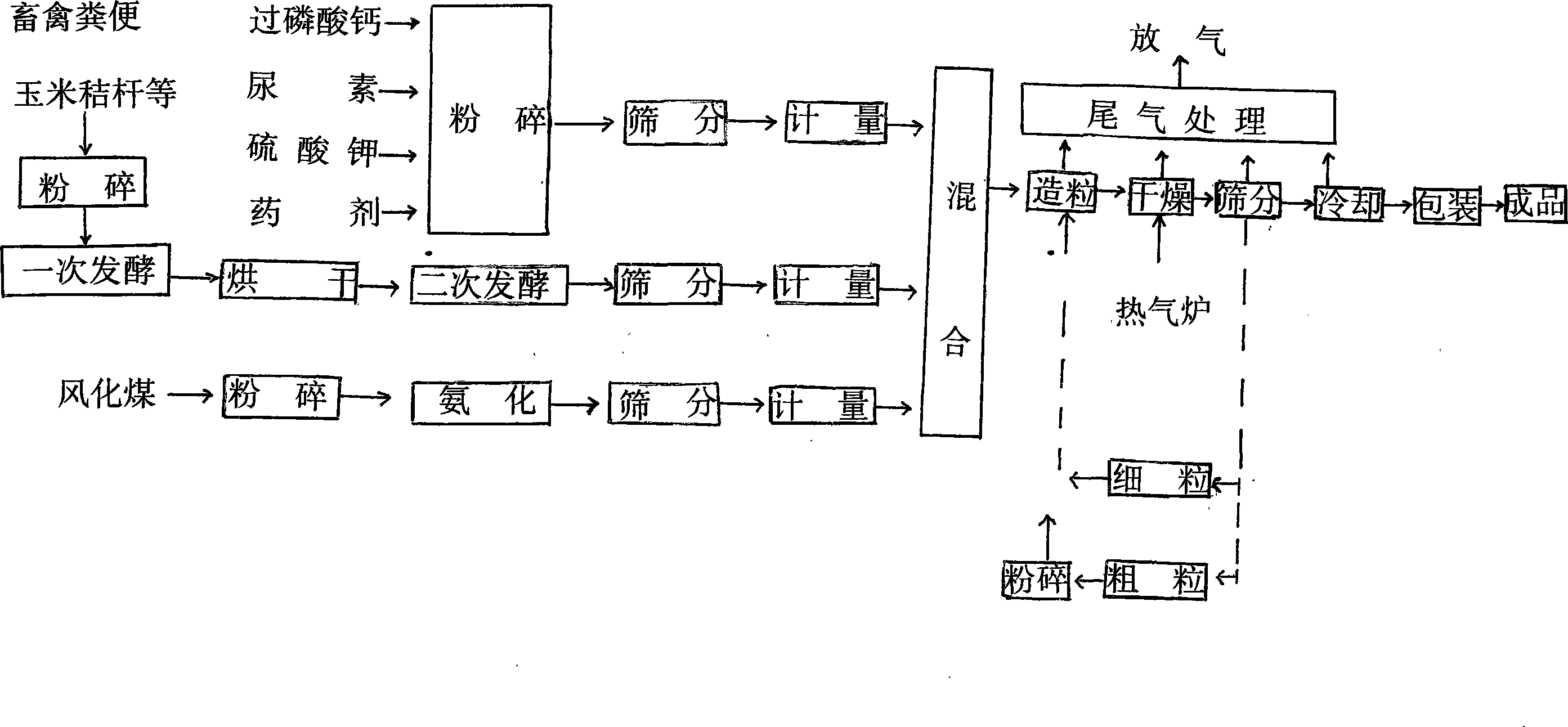

Biochemical fertilizer and producing method thereof

InactiveCN101033153AReduce salinityPrevent compactionBio-organic fraction processingMicroorganism based processesBiological activationBiochemical Process

This invention provides a biochemical organic fertilizer containing rich active humid acid, N, P and K necessary for plants combined with biobacteriums and its production method, in which, the technical target of the fertilizer is: NPK 4-14%, organic matters 30-50%, available active bacteriums 0.2-1.0x108 / g, microelements 2-6%, active humid acid 10-20% and amino acid 2-5%. The production method includes: activation and biochemical process of organic materials, granulation, drying, cooling, screening, enveloping and measuring and packaging.

Owner:山东普金肥料有限公司

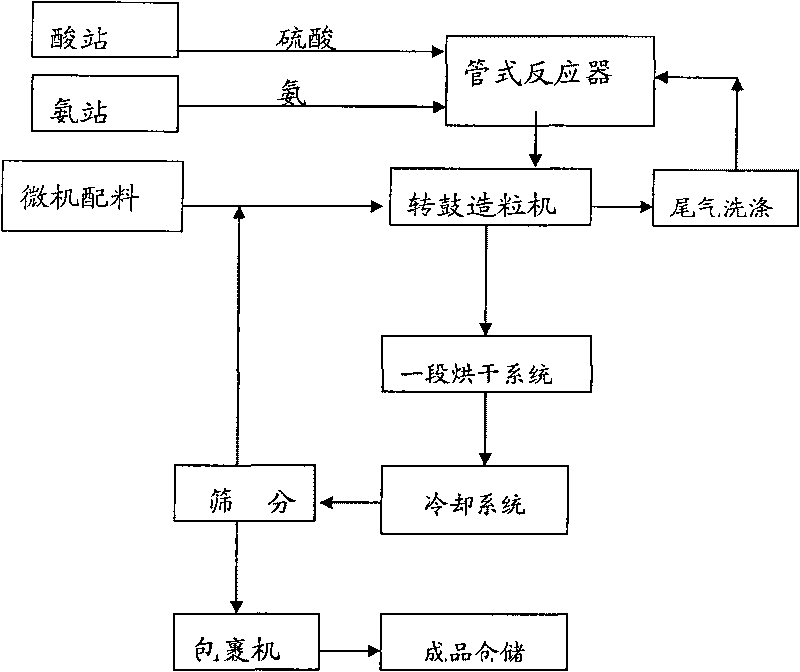

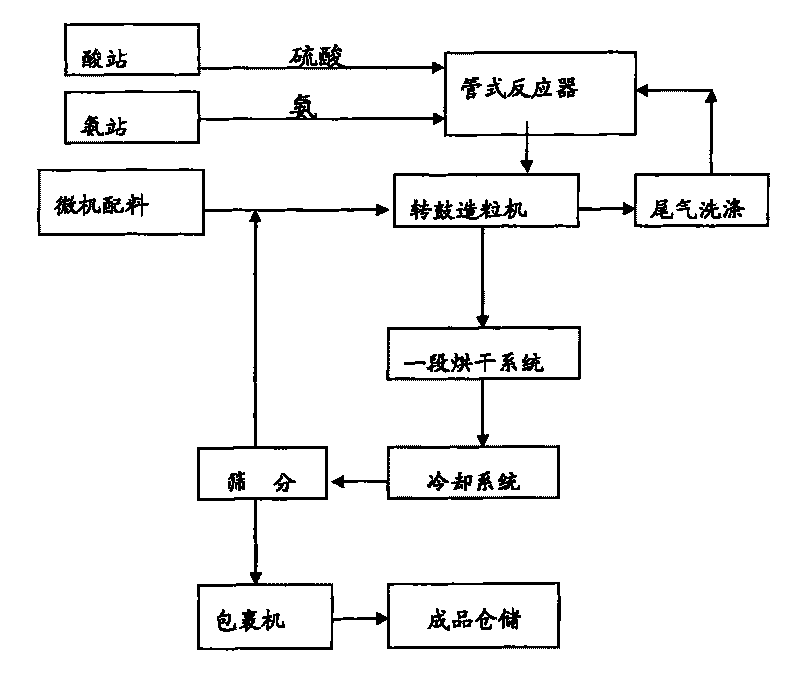

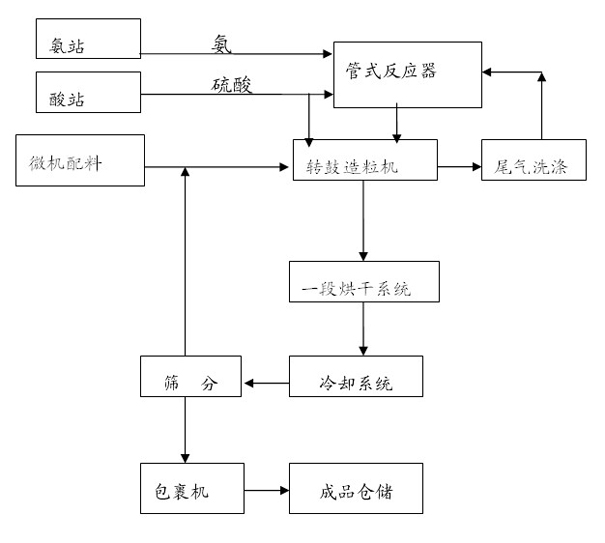

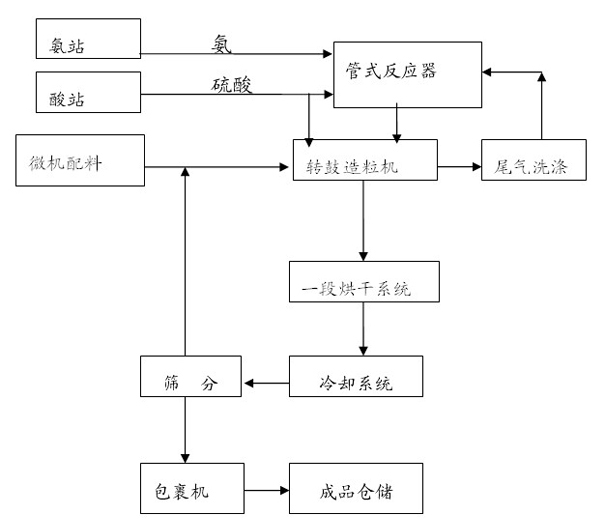

Method for producing Nitrogen-Phosphorus-Potassium compound fertilizer by ammonia and acid tubular reactor

The invention discloses a method for producing a Nitrogen-Phosphorus-Potassium compound fertilizer by using an ammonia and acid tubular reactor. The method comprises the following steps of: preparing an ammonium sulfate solution at 180-220 DEG C by concentrated sulfuric acid, ammonia and water; controlling the reaction heat of ammonia and acid by the addition amount of the water; spraying in a granulator to granulate with other base fertilizers containing nitrogen, phosphorus and potassium; drying; cooling; screening; and filming to obtain a nitrogen-phosphorus-potassium compound fertilizer. The reaction heat of the ammonia and the acid is fully utilized, the ammonium sulfate solution generated by the reaction is in liquid phase and viscosity, the balling rate is high, the moisture of granulation materials is obviously reduced, the drying load is lowered, the production need can be satisfied by changing two-section drying into one-section drying, and the equipment investment and great energy consumption are saved.

Owner:天津达汇丰生物科技有限公司

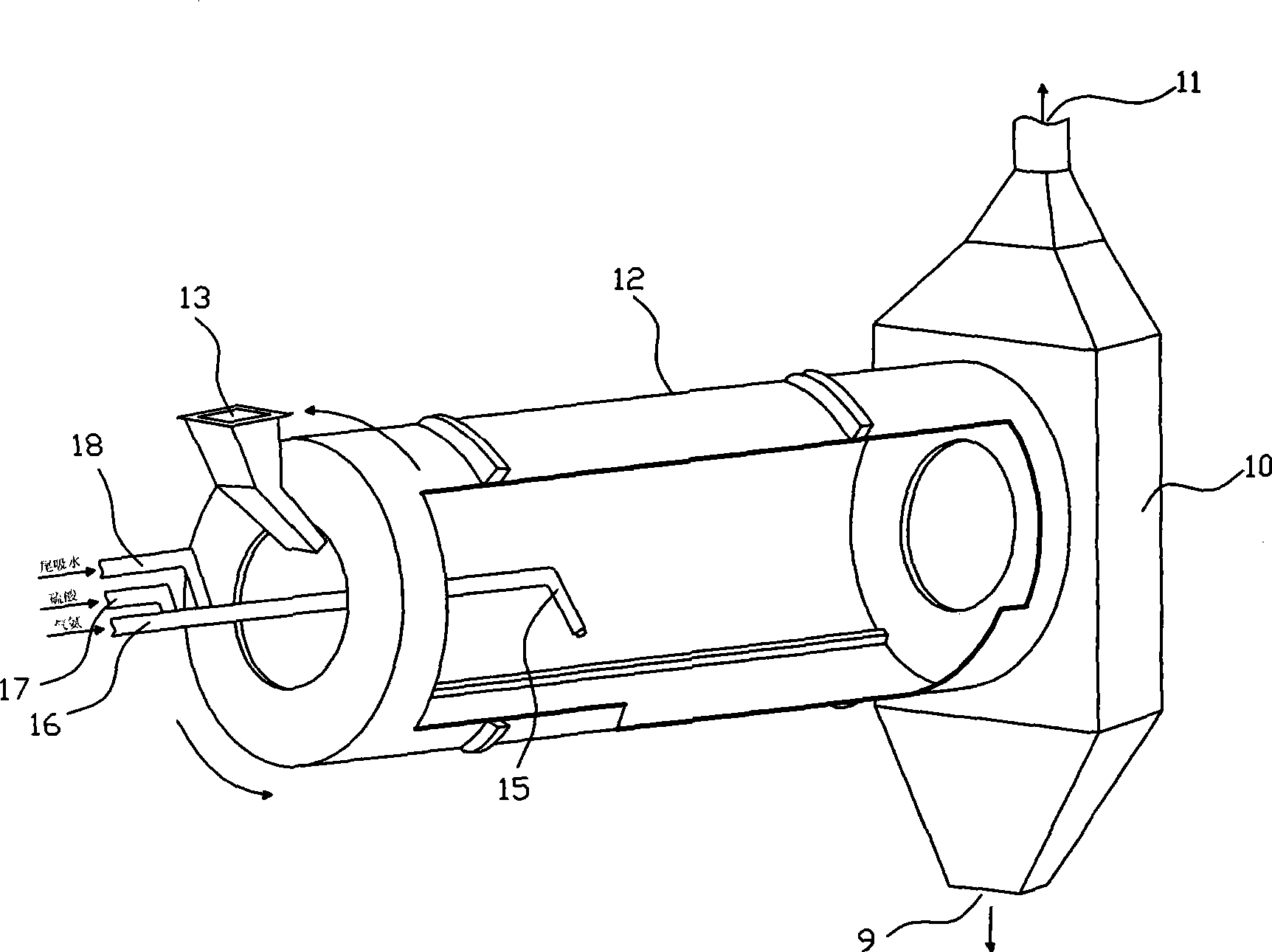

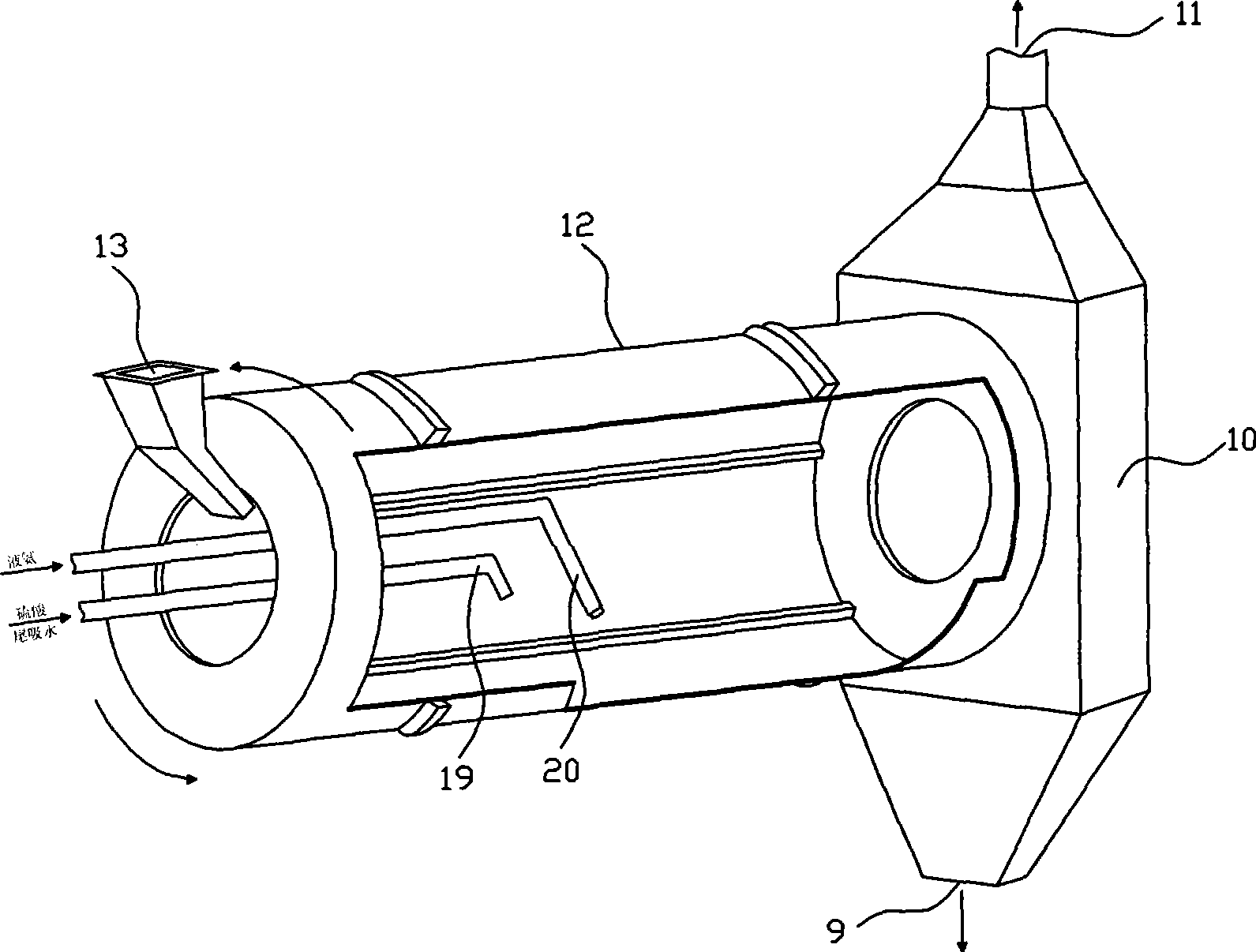

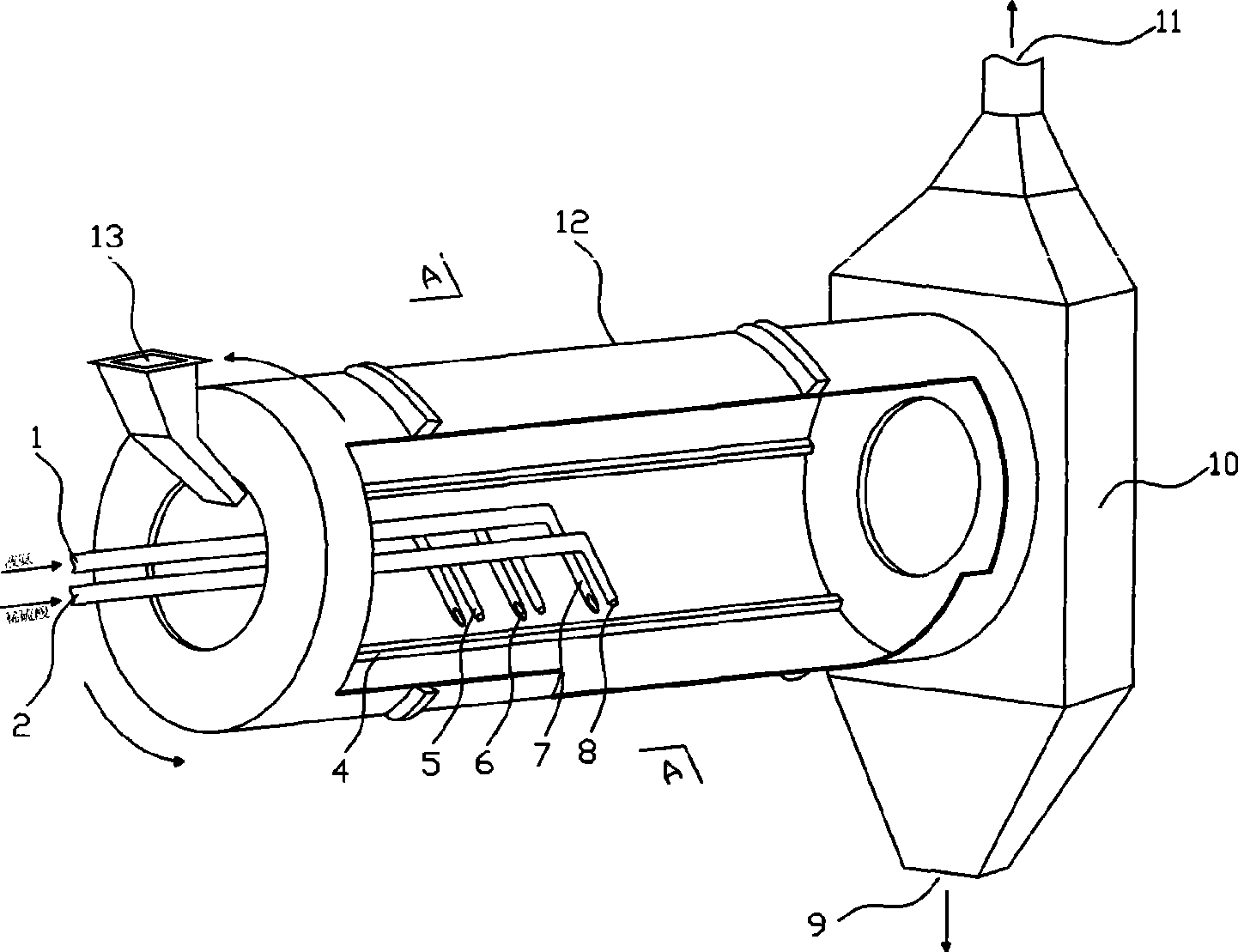

Ammoniation granulator and composite fertilizer production novel technique

InactiveCN101391934AEasy to adjustIncrease elasticityFertiliser formsFertilizer mixturesSolid particleWater resistant

The invention relates to an ammoniation granulator and a compound fertilizer production technology by an amino acid method, aiming at solving the technical problems in the compound fertilizer production process that: biuret is easy to generate, the granulating effect is not good, the production efficiency is low and the energy consumption is high. An amino acid distributor of the ammoniation granulator is respectively and independently arranged, an amino spraying branch pipe provided with an inclined plane spout has an angle of 30 to 60 degrees with a vertical line on the cross section of a cylinder, the rotating directions of the inclined plane spout and the cylinder are consistent; the spout of an acid spraying branch pipe is correspondingly arranged in the opening direction of the inclined spout of the amino spraying branch pipe; and when ammoniation granulating, the granulator sprays liquid ammonia in a material layer with the pressure of 0.5 to 1.0MPa through the amino distributor, an acid distributor sprays sulphuric acid of 50 to 70 percent in the material layer with the pressure of 0.2 to 0.5Mpa, and each ton of solid material is injected with 15 to 25kg of liquid ammonia and 16.8 to 39.2kg of dilute sulphuric acid. The invention is applied in various raw materials and suitable for the scale production of various compound fertilizers; and the finished products have perfectly round and solid particles, are water resistant and movement resistant and not easy to be crushed and agglomerated.

Owner:JIANGSU ABOLUO COMPOUND FERTILIZER

Sustained-release adhesive, preparation method and application thereof

ActiveCN101362666ALess investmentEasy to makeUrea compound fertilisersFertilizer mixturesControl releaseAdhesive

The invention discloses a sustained release binder and a preparation method thereof. The sustained release binder is obtained by stirring reaction of urea, 37 percent of formaldehyde and oxidized starch at the temperature of 75 DEG C to 80 DEG C, wherein, the molar ratio of the urea and the formaldehyde is 1.2-1.6:1, and the amount of the oxidized starch is 8 to 10 percent of weight of the urea. The sustained release binder of the invention can solve the problems that common compound fertilizer nutrient releases too fast, the hardness and appearance of the product are not ideal, etc. The sustained release compound fertilizer made from the sustained release binder improves the nutrient content of sustained / controlled releases (mixed) fertilizer. In addition, the processing of the invention has the advantages of high granulation rate, high hardness of fertilizer and good granular appearance.

Owner:KINGENTA ECOLOGICAL ENG GRP

Preparation method of N/S-codoped carbon microspheres with high oxygen reduction catalytic activity

ActiveCN104953133AThe synthesis steps are simpleThe post-processing process is simpleCell electrodesArgon atmosphereMicrosphere

The invention provides a preparation method of N / S-codoped carbon microspheres with high oxygen reduction catalytic activity. The preparation method comprises the following steps: adding a carbon source, a nitrogen source, a sulfur source and an analytically pure surfactant into a stainless steel reaction kettle in sequence under nitrogen protection, stirring, sealing, heating in a crucible furnace, and taking out a mixture when the reaction kettle is cooled naturally to room temperature; washing and filtering the mixture; drying obtained powder in a vacuum drying oven; uniformly mixing an obtained product with analytically pure potassium hydroxide powder, activating in an argon atmosphere; washing with distilled water; and finally, drying in vacuum in the vacuum drying oven. The preparation method has the advantages of simple process, mild reaction condition, high repeatability and low cost; in an alkaline environment, the generated product has excellent oxygen reduction catalytic property, is relatively high in catalytic activity, good in stability and relatively good in tolerance to methyl alcohol and carbon monoxide and has huge application potential on the aspect of fuel cell catalysts.

Owner:YANSHAN UNIV

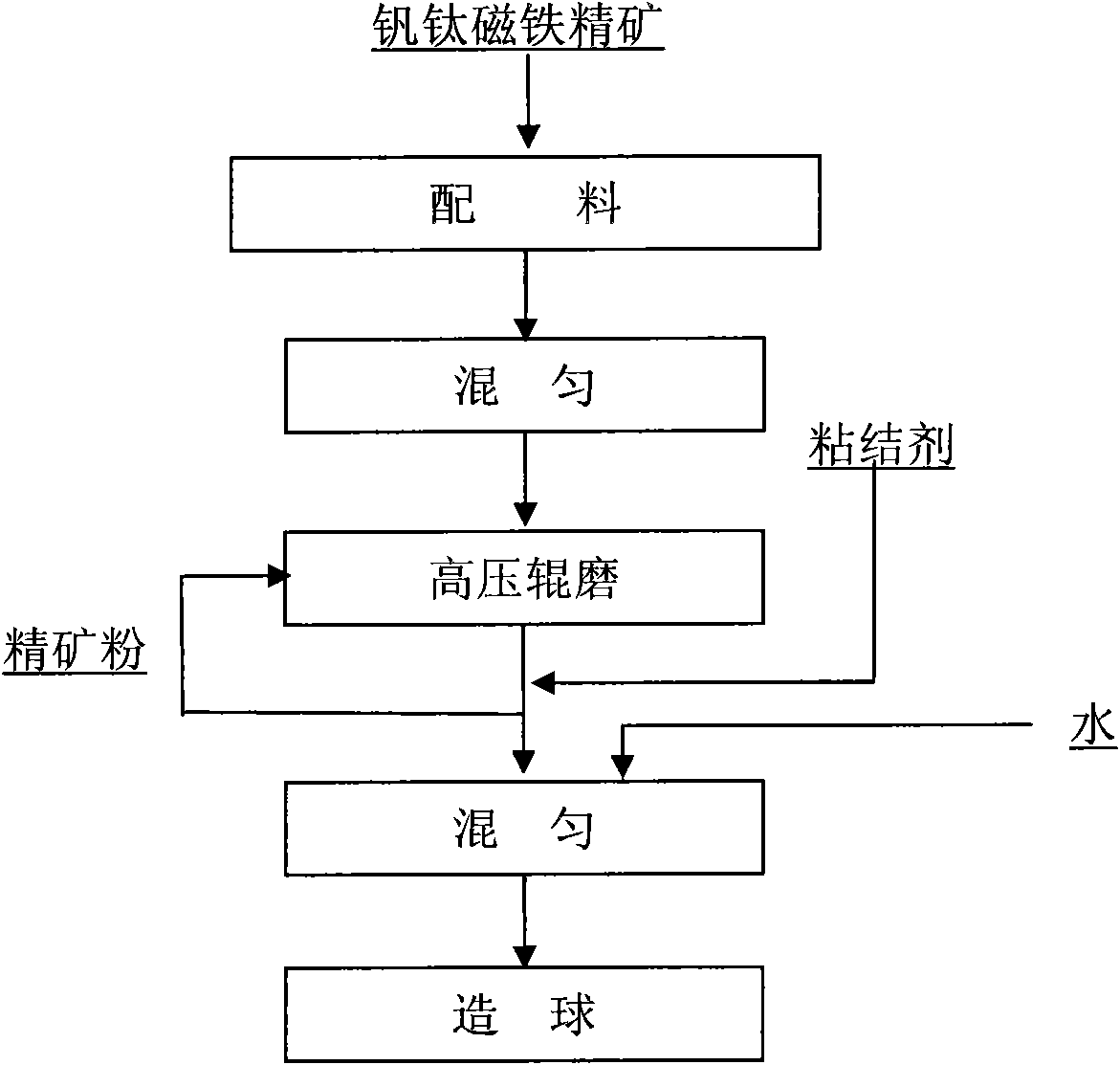

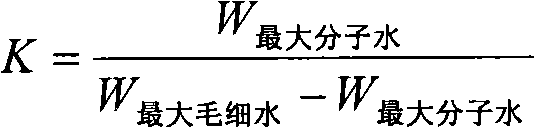

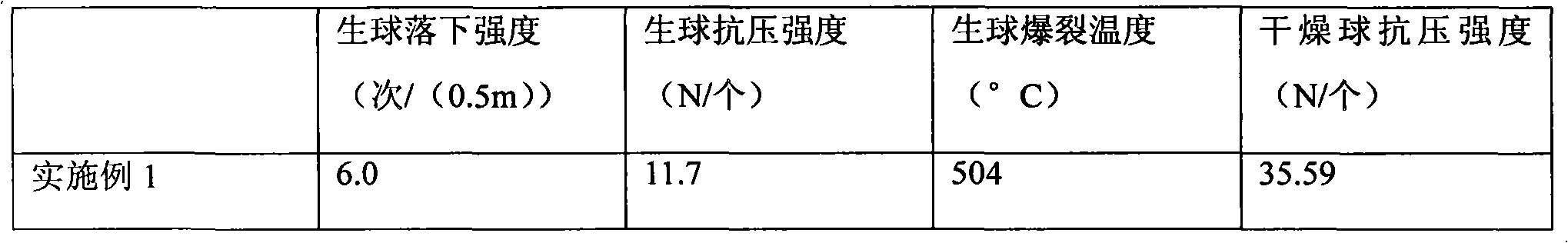

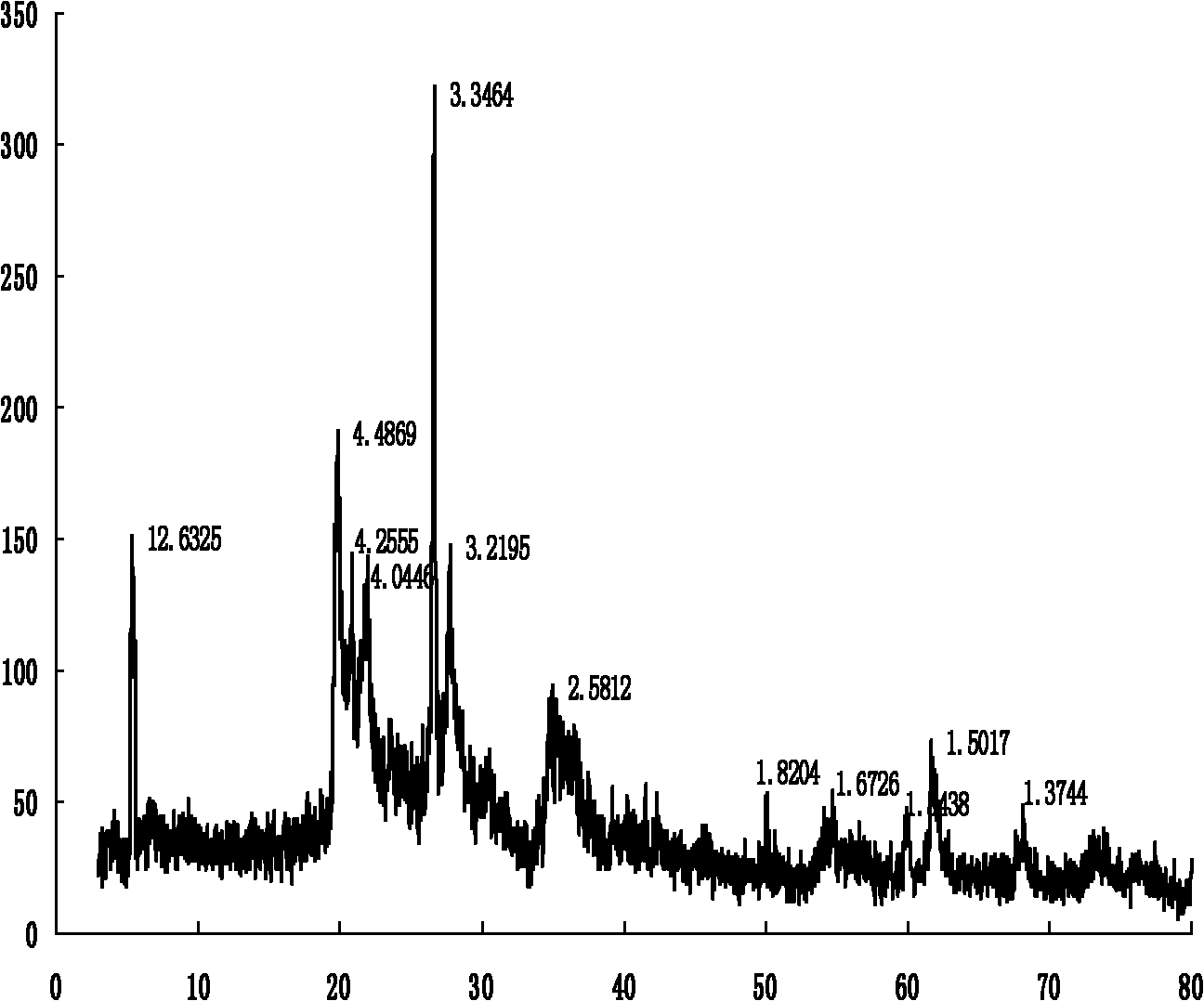

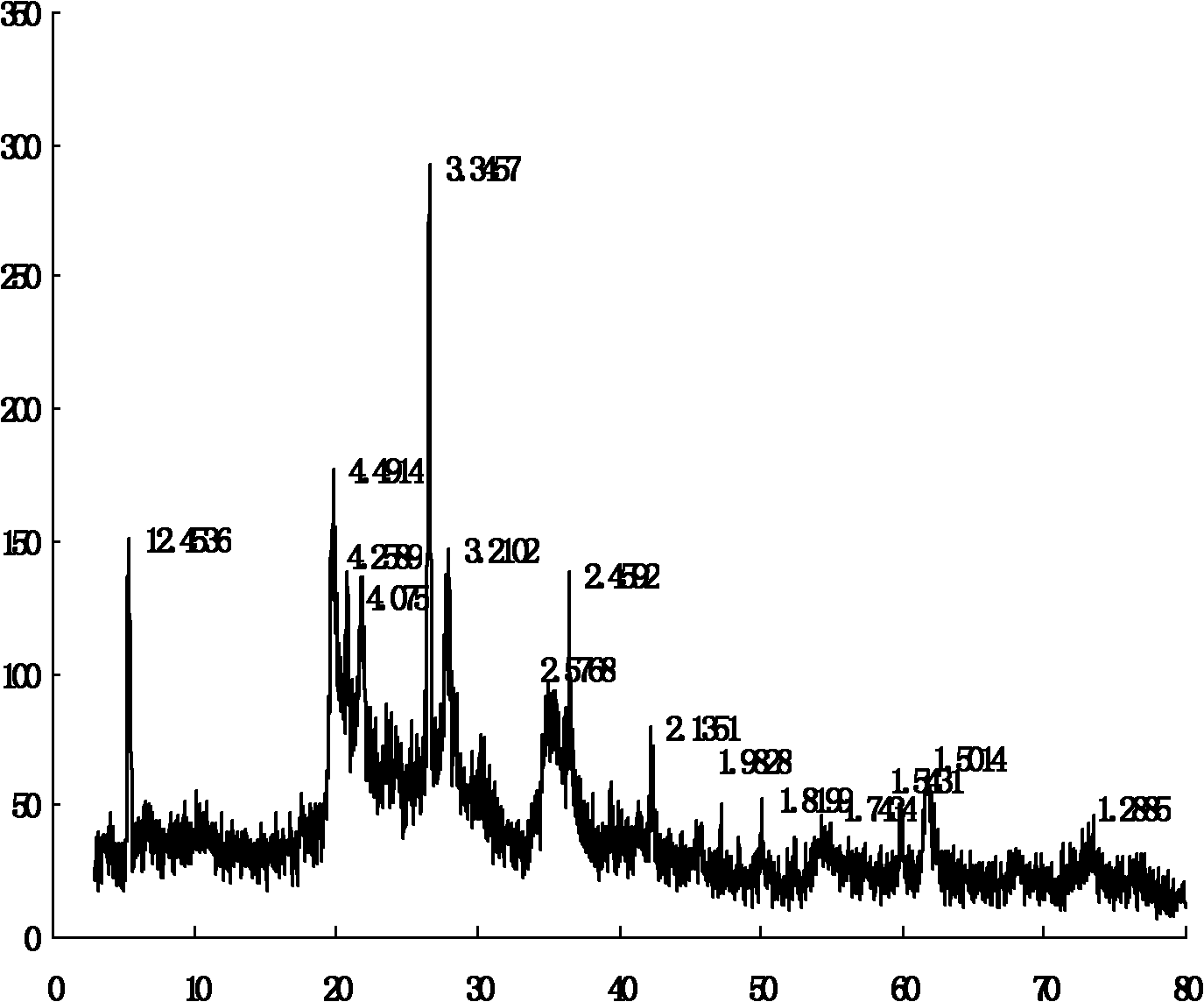

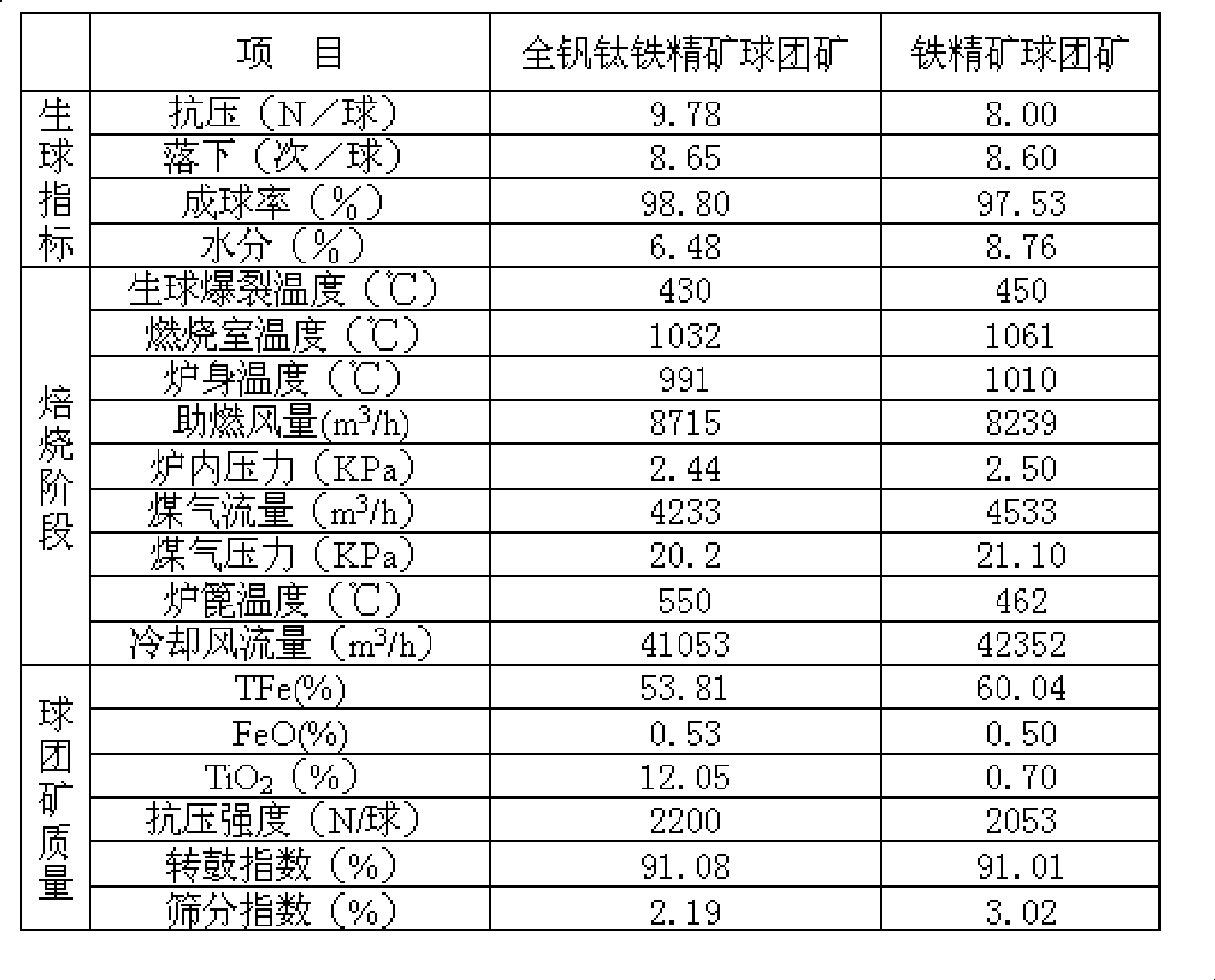

Pellet production method of vanadium-titanium magnetite concentrate

The invention relates to a pellet production method of a vanadium-titanium magnetite concentrate. The method comprises the following steps of: (1) conducting roll milling to a vanadium-titanium magnetite concentrate with a high pressure roller mill so as to obtain vanadium-titanium magnetite concentrate; (2) adding water and a binder into the vanadium-titanium magnetite concentrate powder to obtain a uniformly mixed material; (3) pelletizing the material with a pelletizer. Under the premise of guaranteeing that the green pellet drop strength, green pellet compression strength, green pellet cracking temperature, dry pellet compression strength, roasted pellet compression strength and other metallurgy performances can basically satisfy production needs simultaneously, the pellet concentrate produced by the method of the invention improves the pellet forming rate of a vanadium-titanium magnetite concentrate, reduces the adding amount of bentonite, and enhances the grade of iron sent into a furnace.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

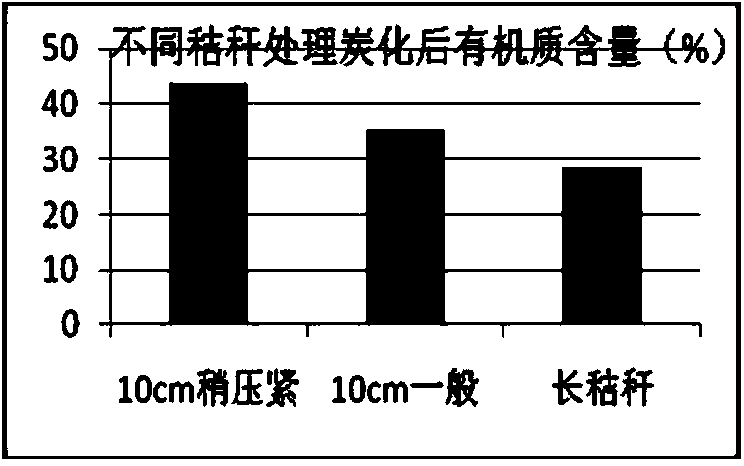

Method for preparing biochar-base fertilizer from cotton straws

The invention discloses a method for preparing a biochar-base fertilizer from cotton straws, which comprises the following steps: 1. preparing cotton straw biochar from cotton straws; 2. pulverizing gypsum, bentonite and cotton straw biochar, respectively passing the gypsum and bentonite through a 100-mesh screen, and passing the cotton straw biochar through a 40-mesh screen; 3. mixing 16-19 parts of weight of ammonium phosphate, 7-9 parts of weight of urea, 7-9 parts of weight of potassium sulfate, 1-2 parts of weight of zinc sulfate, 1-2 parts of weight of boric acid, 7-9 parts of weight of nitrohumic acid, 30-40 parts of weight of cotton straw biochar, 7-12 parts of weight of gypsum and 7-12 parts of weight of bentonite together, and stirring uniformly to obtain a fertilizer mixture; 4. carrying out primary granulation on the fertilizer mixture with a rotating drum granulator, and carrying out reshaping granulation with a disk granulator to obtain fertilizer granules; and 5. drying the fertilizer granules with a drying machine to obtain the biochar-base fertilizer.

Owner:INST OF SOIL & FERTILIZER XINJIANG ACAD OF AGRI SCI

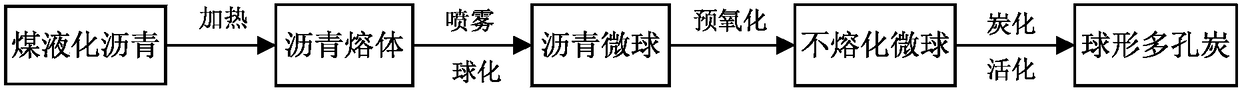

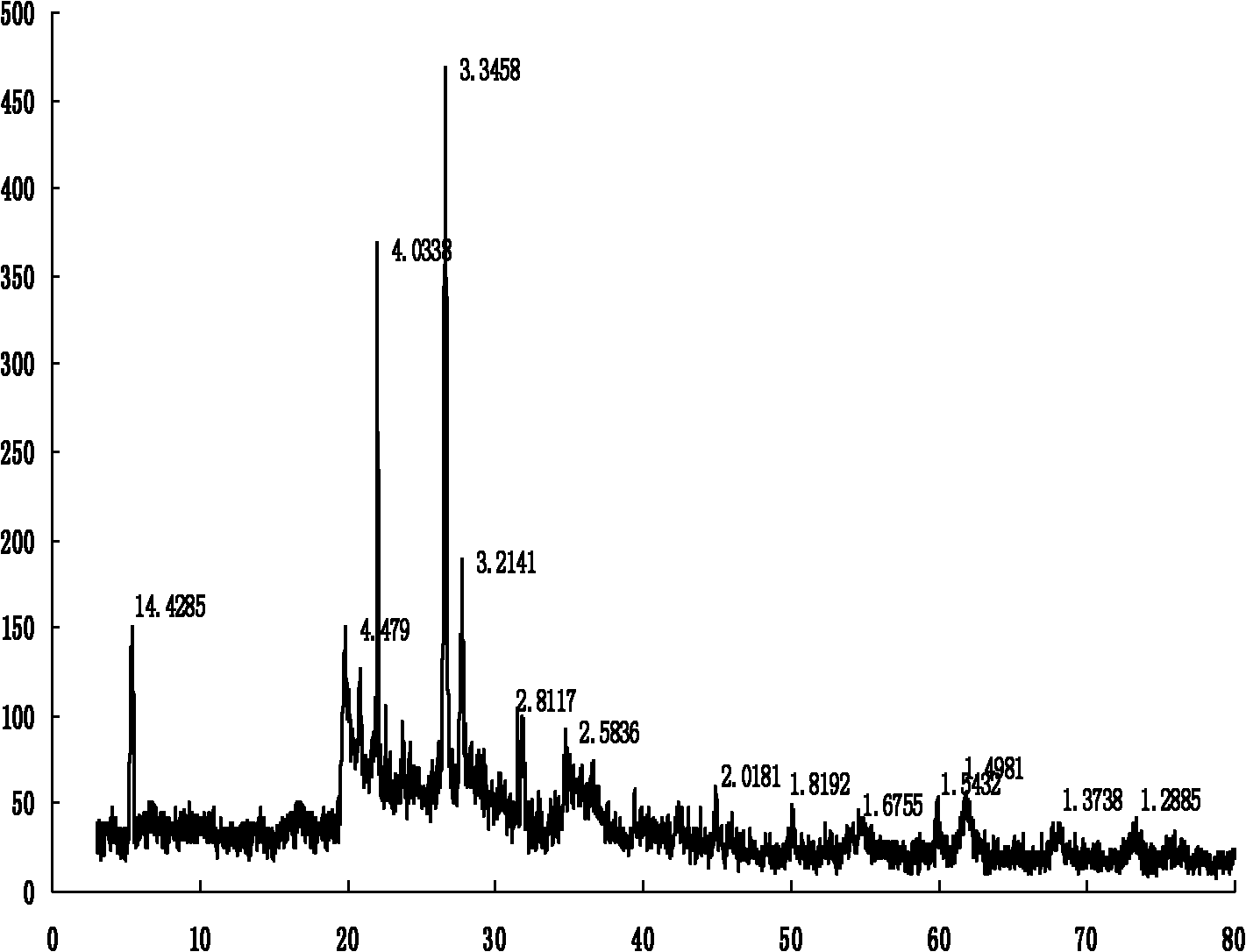

Spherical porous carbon and preparation method thereof

The invention provides a spherical porous carbon and a preparation method thereof. The preparation method comprises the following steps of: carrying out heating treatment on the coal liquefied asphaltto obtain an asphalt melt; carrying out spraying and drying treatment on the asphalt melt to obtain an asphalt microsphere, carrying out pre-oxidation on the asphalt microsphere to obtain a non-melted asphalt microsphere; carbonizing and activating the non-melted asphalt microsphere to obtain spherical porous carbon. The method prepares spherical porous carbon by using coal liquefied asphalt as araw material, high-value utilization of the asphaltene in the coal liquefaction oil slag can be carried out, and the characteristics of high aromatic degree, high carbon content, easy polymerizationor cross-linking are fully utilized. Furthermore, the preparation method of the spherical porous carbon has the advantages of simple steps, strong continuous operability, high sphere-forming rate, high sphericity and adjustable micro-sphere particle diameters.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Bentonite binder and preparation method thereof

InactiveCN102070153AReduce usageImprove bindingFoundry mouldsFoundry coresSodium BentoniteHexamethylenetetramine

The invention relates to a bentonite binder and a preparation method thereof, belonging to the processing field of bentonite, and aiming at providing a bentonite binder with a better sodiumizing modification effect and a preparation method of the bentonite binder. The preparation method of the bentonite binder comprises the following steps: using bentonite ore as raw material, adding a sodiumizing agent accounting for 2-5wt% of bentonite ore and an accelerator accounting for 0.35-1.2wt% of bentonite ore, wherein the accelerator is at least one of ammonium oxalate, sodium polyacrylate, hexamethylenetetramine and tripolycyanamide; evenly mixing and carrying out sodiumizing modification, drying, smashing to obtain the bentonite binder. In the preparation method, required equipment is simple and is convenient for maintenance, the production efficiency is high, and energy-saving effect is obvious, and the bentonite binder is suitable for continuous production. The bentonite binder of the invention has higher water absorption rate and is a bentonite binder with high adhesive property; and the bonding force of the iron ore concentrate is greatly increased after the bentonite binder is used in the iron ore pelletizing metallurgy industry, thus improving the pelletizing rate of the iron ore concentrate.

Owner:PANZHIHUA UNIV

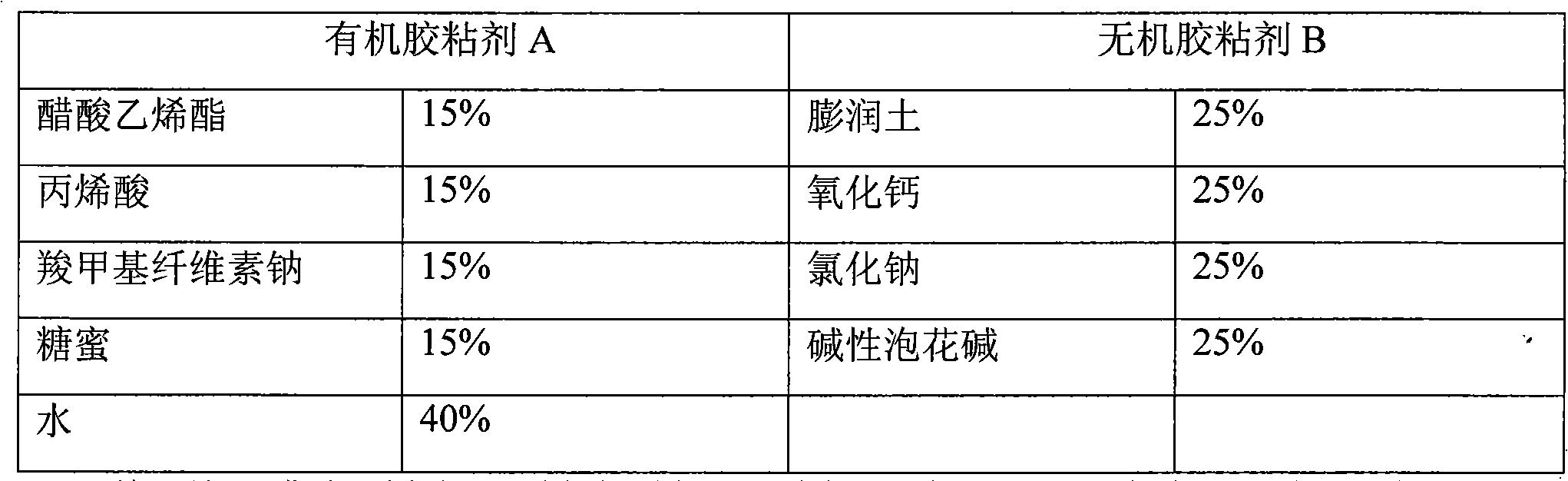

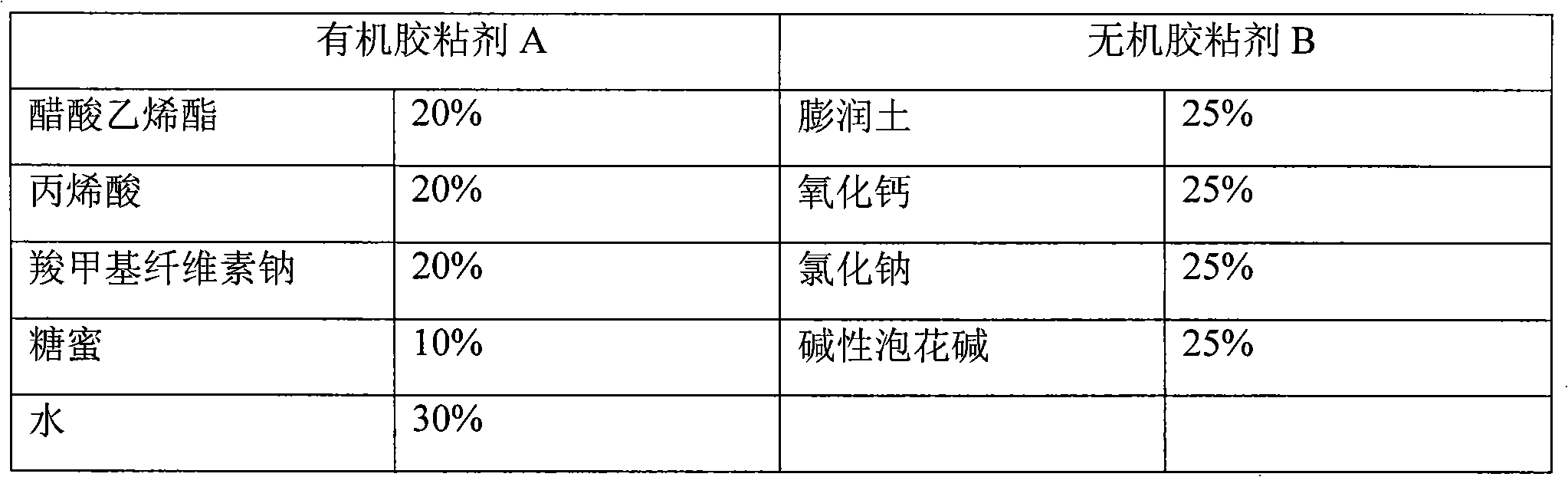

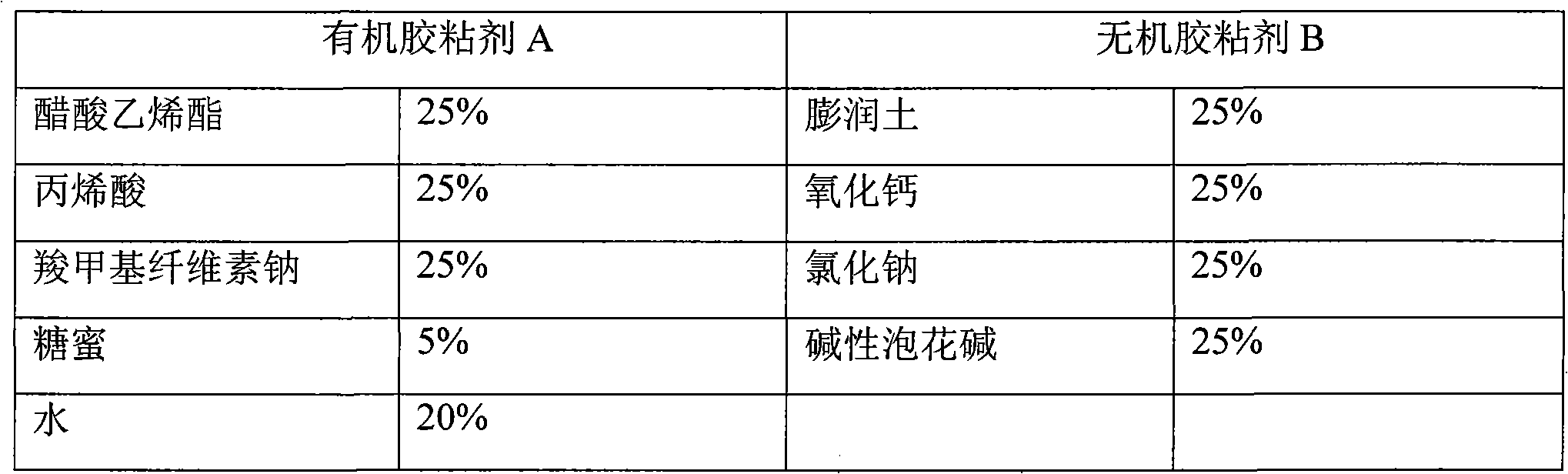

Method for preparing cold-bonded pellets from iron containing sludge by compound adhesive

InactiveCN101775489AReduce the amount of non-ferrous materialsReduce pollutionCelluloseSodium Bentonite

The invention relates to a method for preparing cold-bonded pellets from sludge containing iron by an compound adhesive, belonging to the technical field of adhesives for metallurgical ironmaking. The method of the invention comprises the following concrete steps: adopting the compound adhesive of an inorganic adhesive and an organic adhesive, wherein the organic adhesive in the compound adhesive comprises the following raw materials: vinyl acetate, acroleic acid, sodium cellulose glycolate, polyvinyl alcohol, polyisobutylene, molasses and coal tar; and the inorganic adhesive comprises the following raw materials: bentonite, calcium oxide, basic sodium silicate, sodium chloride, talcum powder and light calcium carbonate. When the organic adhesive and the inorganic adhesive in the adhesive are prepared, the components are proportioned and controlled strictly in a proper order, so that the defects of one adhesive singly used can be avoided, and the compound adhesive has good caking property on the iron containing sludge. The method of the invention recycles iron from iron containing sludge and changes waste into resources, thereby reducing pollution of storage and transport on the environment, and saving the energy consumption in the sintering and high furnace production.

Owner:TONGJI UNIV

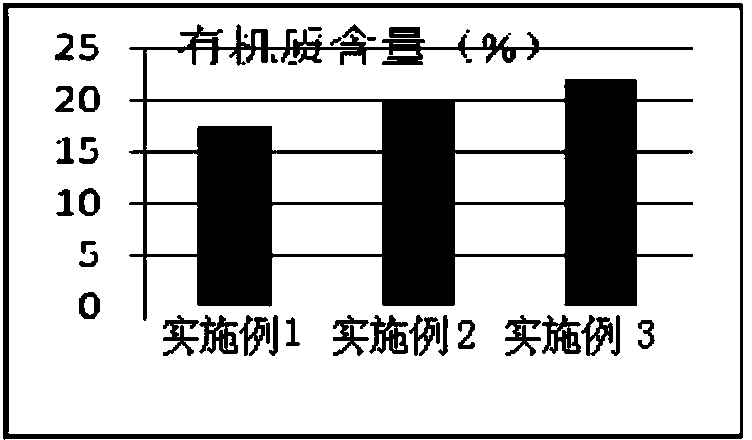

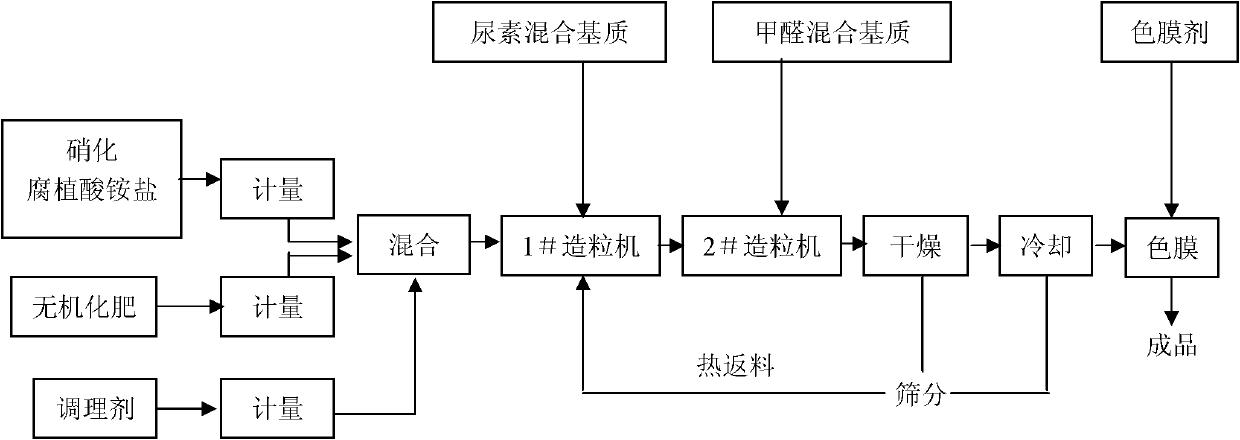

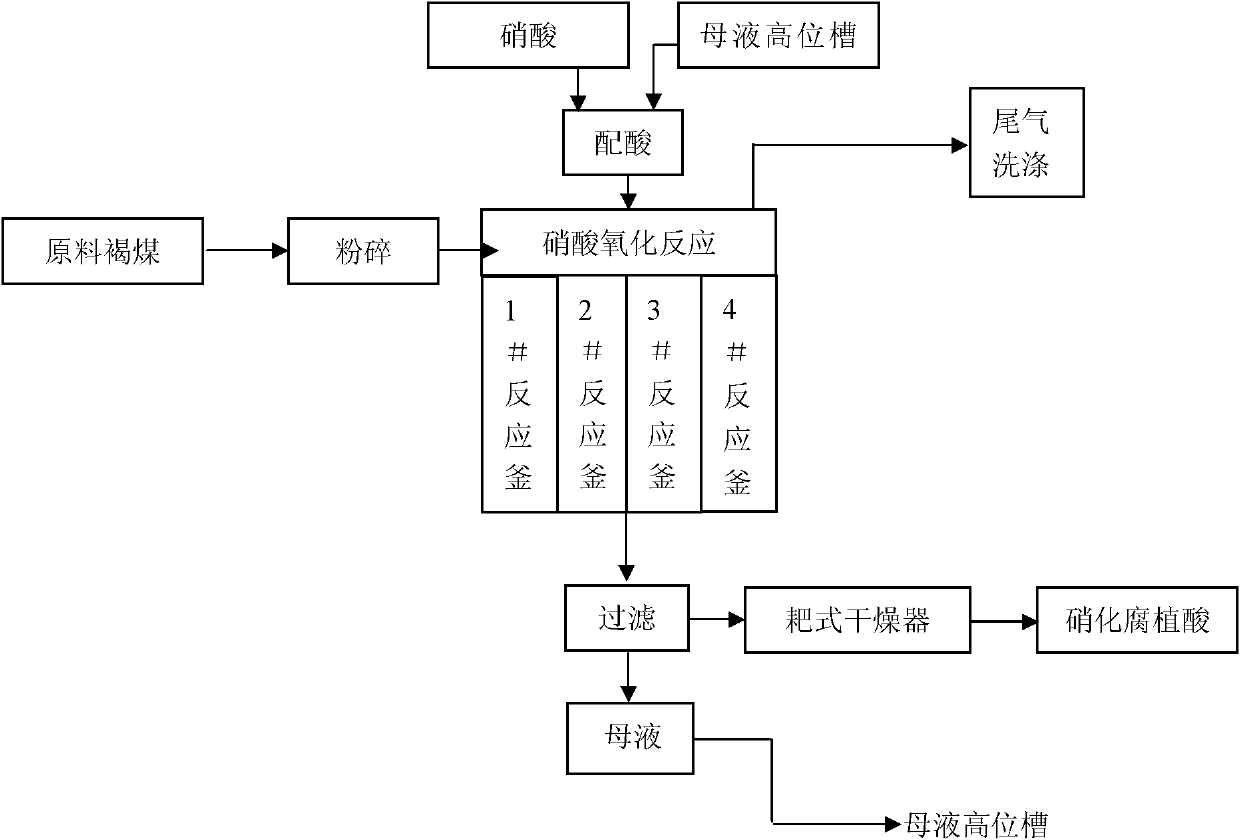

Preparation process for organic-inorganic compound fertilizer

InactiveCN101948349ASave resourcesIncrease profitFertiliser formsFertilizer mixturesOrganic matterOrganic inorganic

The invention discloses a preparation process for an organic-inorganic compound fertilizer. The preparation process comprises the following steps of: after reacting nitric acid with lignite, obtaining lignite nitrification humic acid-containing organic matter precipitate by filtering and separating; matching the lignite nitrification humic acid with an inorganic fertilizer; respectively preparing into lignite nitrification humate-urea secondary fertilizer granules and lignite nitrification humate-formaldehyde sustained-release composite granules; and obtaining the organic-inorganic compound fertilizer. A humic acid raw material is extracted by oxidizing the lignite with the nitric acid, so that the humic acid and fulvic acid are improved remarkably; and therefore, the production cost of a humid acid fertilizer can be reduced and resource is saved. The organic-inorganic compound fertilizer can improve soil nutrient status and granular structures and meets the growth demand of crops.

Owner:NORTHWEST A & F UNIV +1

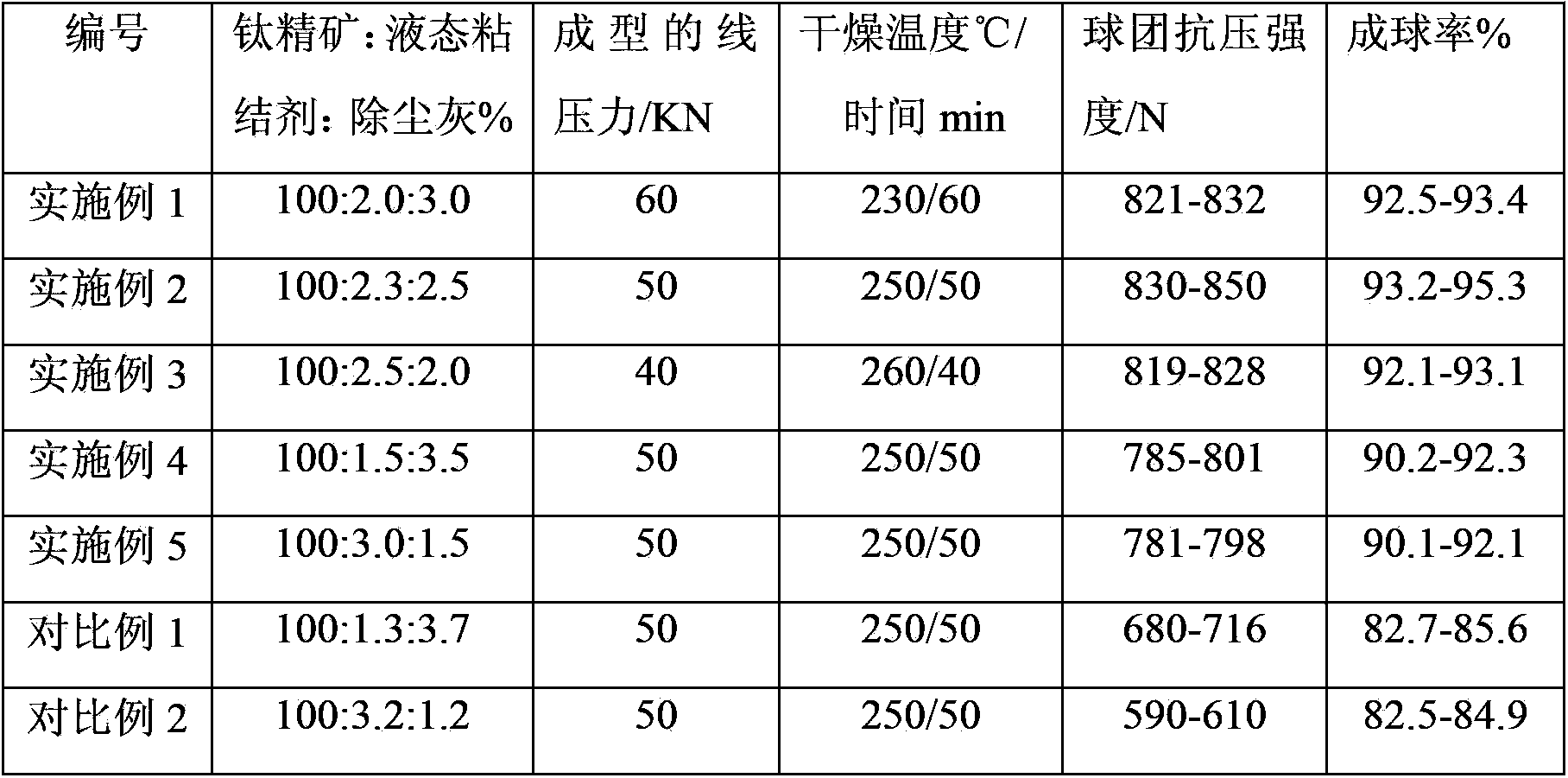

Method for preparing titanium concentrate pellet

The invention provides a method for preparing titanium concentrate pellets. The method comprises the following steps: mixing titanium concentrate, a liquid adhesive and collected dust, and pelleting, wherein the collected dust is generated from an electric titanium slag furnace in a titanium slag smelting process. By adopting the method, the collected dust of the electric titanium slag furnace can be sufficiently utilized, the resource is saved, and good economic benefits are achieved. The pellet manufactured by using the method is high in pellet rate and good in pressure resistance.

Owner:PANGANG GROUP TITANIUM INDAL

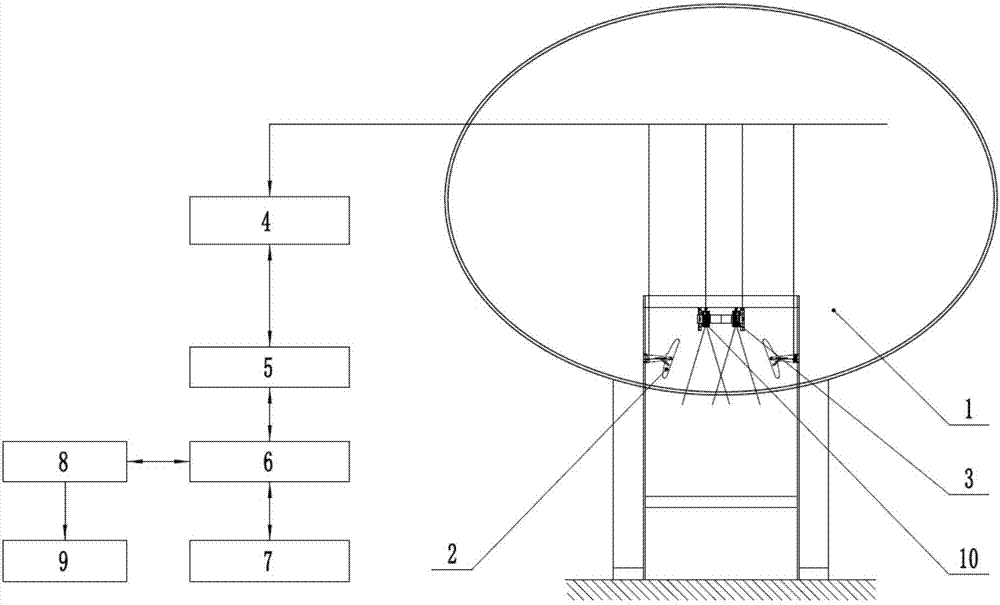

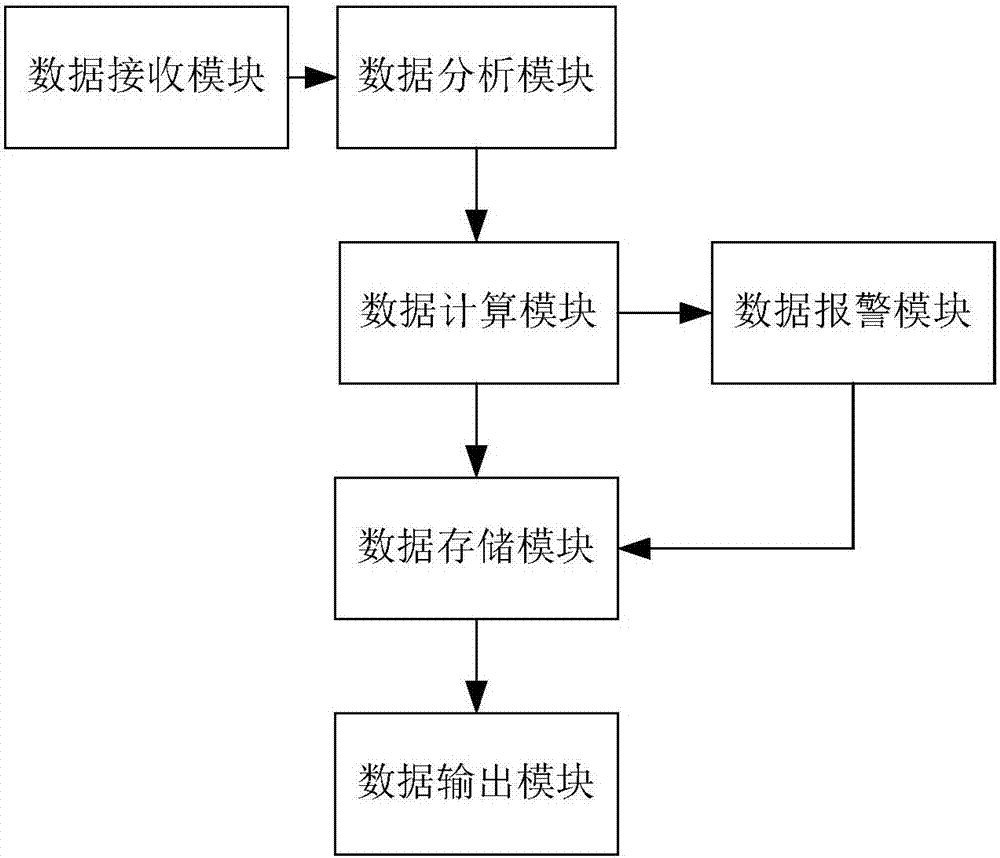

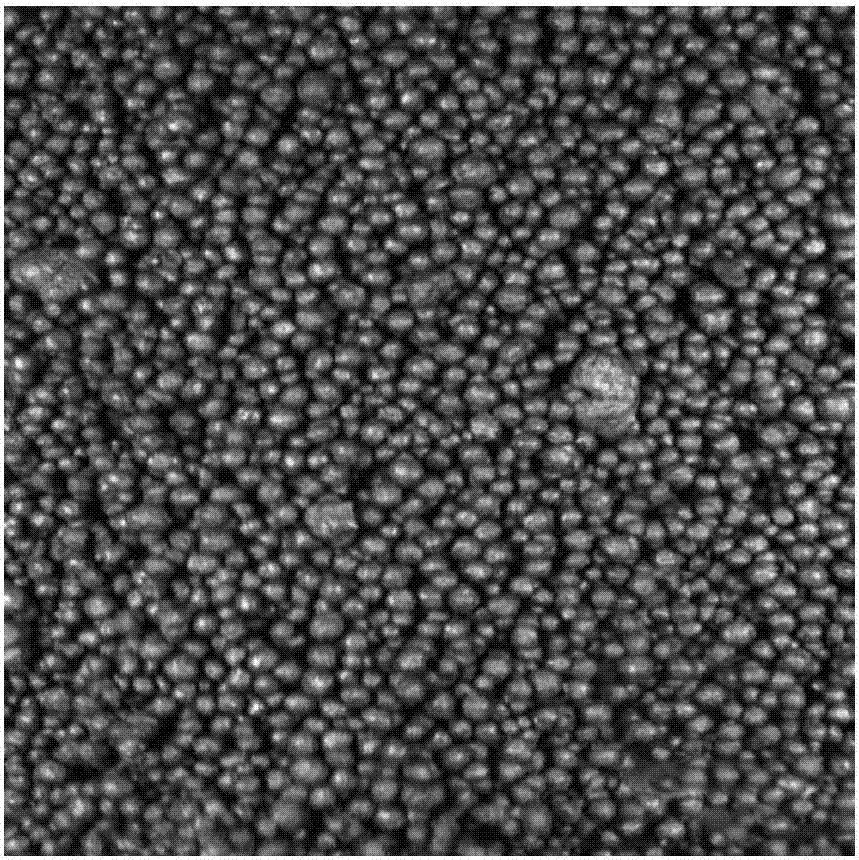

Video generated ball grain-size instrument and generated ball grain size state detection method therefor

ActiveCN107063946AReal-time dynamic monitoring of production statusDynamic monitoring of production statusParticle size analysisCollection systemEngineering

The invention discloses a video generated ball grain-size instrument and a generated ball grain size state detection method therefor. The video generated ball grain-size instrument comprises an image collection system, a data transmission system and a data processing system, wherein the image collection system comprises an imaging device arranged between two LED light sources, and the width of an effective material collected in a balling area is not smaller than 1.4m; the two LED light sources oppositely light at a low angle and carry out light source compensation on the imaging device; and denoising, balancing, smoothing, strengthening, sharpening, adaptive threshold binaryzation and corrosion and expansion operation are sequentially carried out on an original image collected on the spot to obtain the particle size and block number information of furnace charge fed into a blast furnace through coordination with the generated ball grain size state detection method. According to the video generated ball grain-size instrument and the generated ball grain size state detection method therefor, accurate monitoring of the pelletizing quality and state of the balling area of a pelletizer and image processing can be achieved, and an abnormal material can be timely alarmed.

Owner:天津市三特电子有限公司

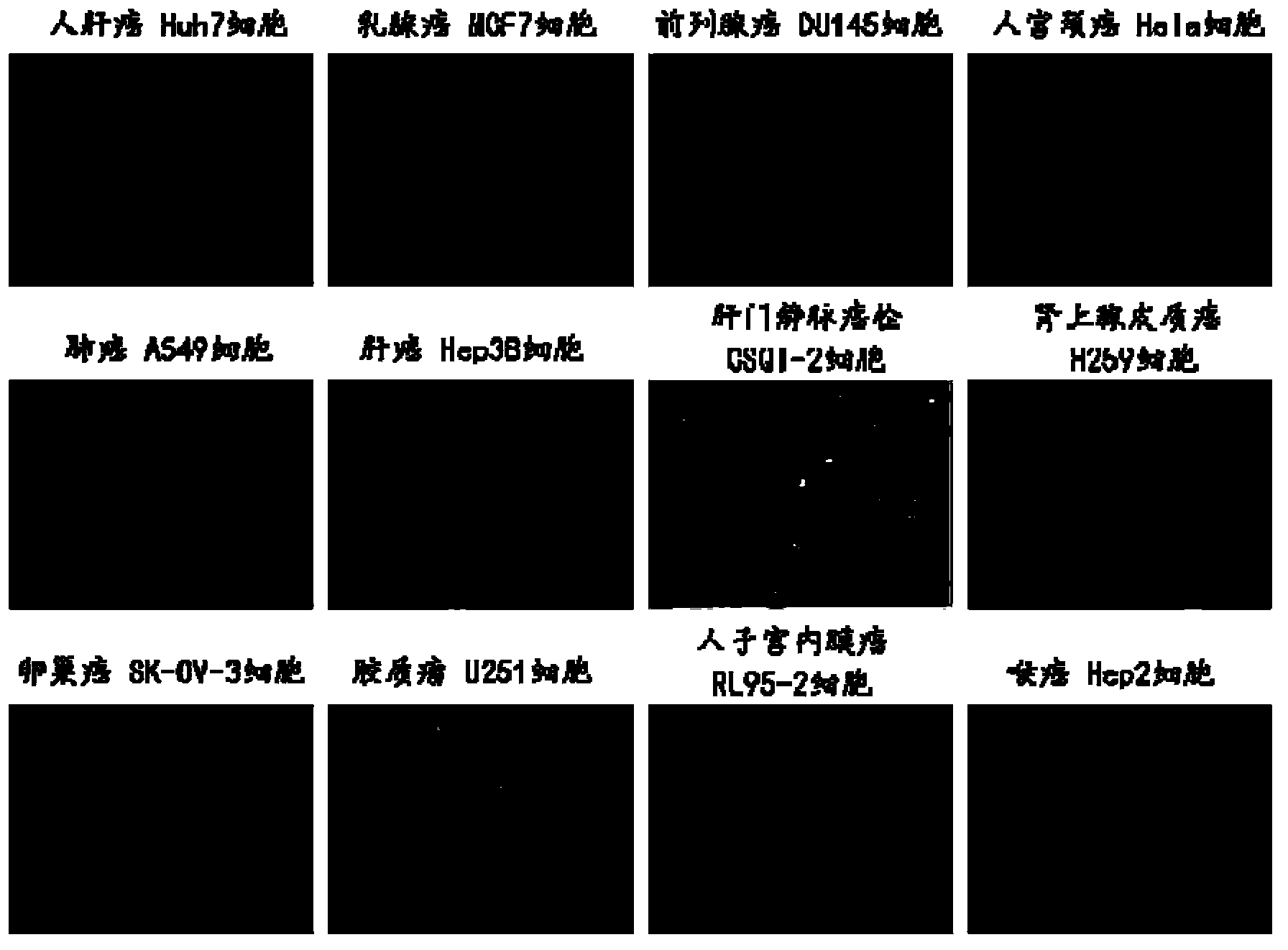

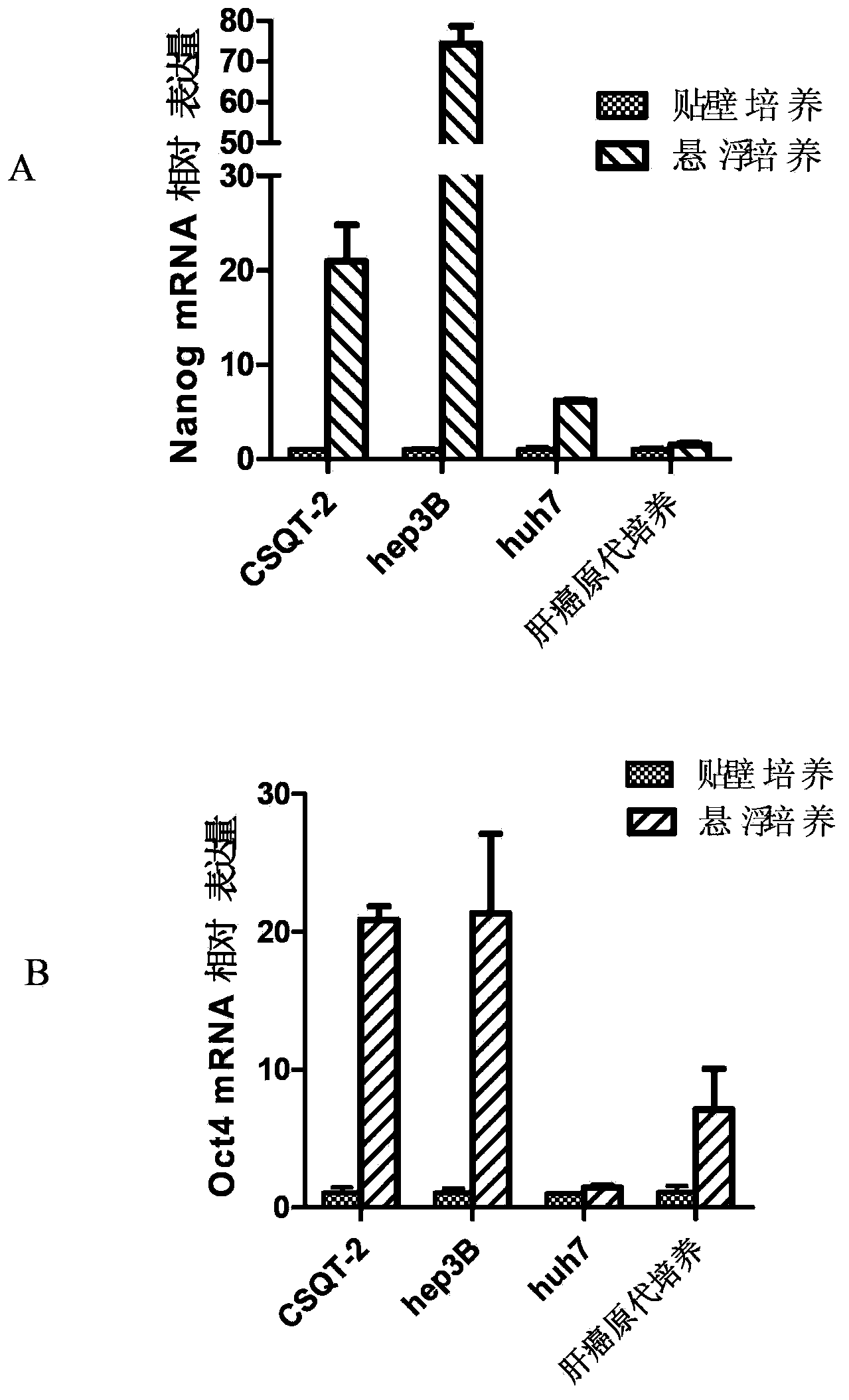

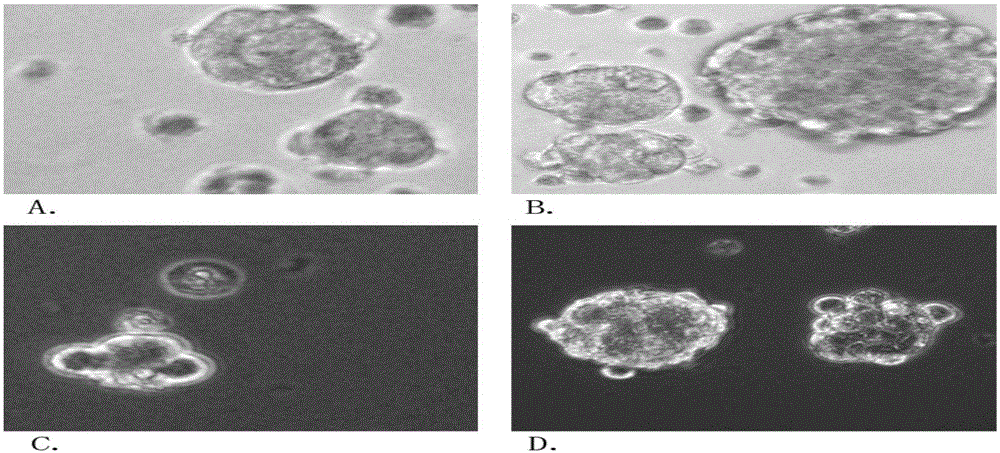

Tumor stem cell suspension culture method

The invention belongs to the technical field of modern biotechnology cell culture. A purpose of the invention is to provide a tumor stem cell suspension culture method, which can be used for culture of tumor cells with different tissue sources, and tumor stem cells obtained through the culture method have characteristics of self-renewal capacity and enrichment. The tumor stem cell suspension culture method comprises: carrying out digestion centrifugation collection on tumor cells requiring culture, adopting PBS to carry out resuspending centrifugation, adding to a prepared suspension culture medium of the invention, carrying out beating-up into a single cell suspension, inoculating into a paved ultra-low absorption culture dish, and carrying out cell culture. The tumor stem cell suspension culture method has the following characteristics that: ball forming rates of various in vitro cultured tumor cells are high, multi-function factors are expressed, the OCT4 proportion and the NANOG proportion are increased, rich and comprehensive experimental materials are provided for tumor stem cell researches, and broad application prospects are provided in basic researches and clinical applications.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

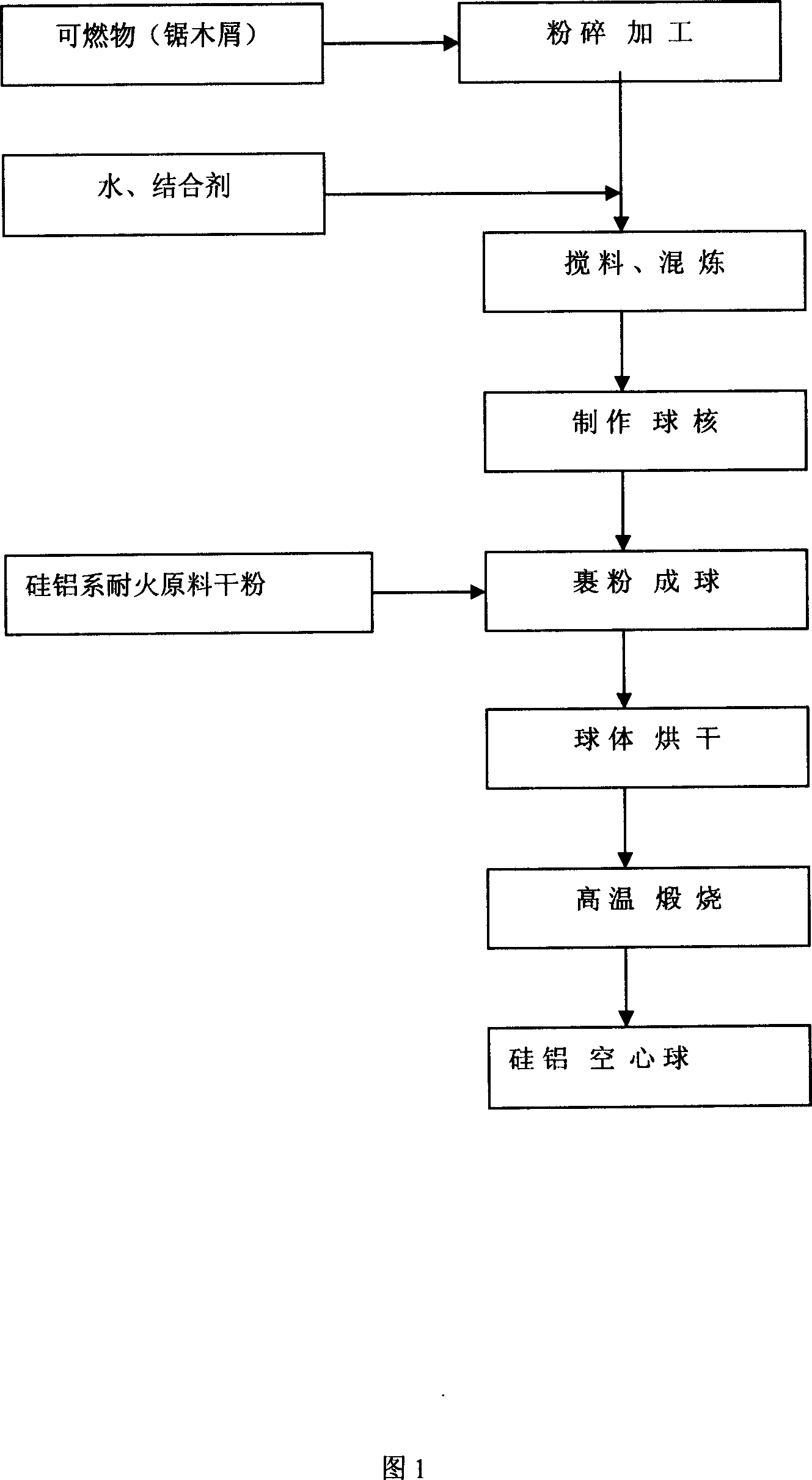

Calcining process of synthesizing hollow silica alumina ball

The calcining process of synthesizing hollow silica-alumina ball includes the steps of crushing sawdust, mixing with water and adhesive, making wet ball kernel, turning the wet ball kernel in ball forming machine in proper rotation speed while throwing proper amount of refractory silica-alumina powder for coating the ball kernel, and calcining at high temperature to produce the hollow silica-alumina ball. The hollow silica-alumina ball has low bulk density, low production cost and other advantages, and is used as the material for producing high grade refractory material. The present invention makes it possible to producing light refractory material with bulk density smaller than 0.6 g / cu cm.

Owner:平顶山新型耐材股份有限公司

Method for preparing spherical 3D printing powder by utilizing plasma

PendingCN108247072AFlat surfaceEvenly distributedAdditive manufacturing apparatusTransportation and packagingSlagWater cooling

The invention discloses a method for preparing spherical 3D printing powder by utilizing plasma. According to the method for preparing the spherical 3D printing powder by utilizing the plasma, multiple procedures including refining, deoxygenization, slag making, slag fishing treatment, ball forming through air blowing, atomization and the like are not required to be used for preparation, and the prepared spherical 3D printing powder is smooth in surface, uniform in distribution, free of pollution, large in loose weight and good in liquidity, and is a relatively excellent form at present; the plasma is utilized to prepare the 3D printing powder, so that simple and rapid preparation of the 3D printing powder is achieved, the process is simple, no dust or pollution exists, and furthermore, the prepared 3D printing powder is spherical in surface, good in liquidity, low in cost and worthy of being widely popularized; and the prepared 3D printing powder is subjected to quenching treatment byusing water, so that the balling probability of the prepared 3D printing powder is greatly improved, and meanwhile, water cooling greatly reduces the preparation cost and improves working efficiencyfor the preparation process, and is especially suitable for large-scale industrial production.

Owner:江民德

Application of shaft furnace in baking full-vanadium ferrotitanium ore concentrate pellet ore

InactiveCN101418371AHigh compressive strengthMeet strength requirementsShaft furnaceSodium BentoniteBlast furnace smelting

The invention relates to application of a shaft furnace to the roasting of full vanadium titanium iron ore concentrate pellet, which belongs to the technical field of the preparation method for the pellet. According to the method, the full vanadium titanium iron ore concentrate and 1.0 to 1.4 percent of bentonite are taken as raw materials which are used to prepare the full vanadium titanium iron ore concentrate pellet through even mixing, damp milling, pelletizing, drying and roasting, wherein the roasting temperature is 1,000 to 1,050 DEG C, and the roasting time is 30 to 60 minutes. The compressive strength of the full vanadium titanium iron ore concentrate pellet obtained by the method reaches 2,200N / piece. The pellet can be directly used for blast furnace smelting and also be used as a furnace protecting product during the blast furnace smelting of common ore.

Owner:攀钢集团成都钢铁有限责任公司

Method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membrane by using ammonia-acid method

The invention discloses a method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membranes by using an ammonia-acid method. The compound fertilizer comprises the following added raw materials: natural minerals capable of fixing and absorbing nutrients, and raw materials capable of forming shells with porous multiple layers of mesh inner membranes; and calcium salt is used to form a packaging skeleton and fix nutrients. The added concentrated sulfuric acid is divided into two parts, wherein one part is prepared into an ammonium sulfate solution of 180-220 DEG C with ammonia and water, amino acid reaction heat is controlled through controlling the added amount of water, and then the ammonium sulfate solution is sprayed into a granulator to granulate with powdery basic materials which contain nitrogen, phosphorus, potassium and natural minerals and are capable of forming shells with mesh inner membranes; and the other part is diluted and then directly added into the granulator to react with urea to generate thiocarbamide, and then drying, cooling, screening and enveloping are carried out on thiocarbamide after granulating to obtain the slow-release compound fertilizer containing nitrogen, phosphorus and potassium. In addition, two-section drying is changed to one-section drying, which can meet the requirements of production.

Owner:天津芦阳肥业股份有限公司

Method for preparing resin-based ball charcoal

The invention relates to a preparation method of ball carbon. Linear phenolic resin, alcohol and formamine are mixed and dissolved into isotrope solution substance according to a mass ratio that is 100:40 to 180:4 to 16. The mass of the phenolic resin is used as a standard, the 100 parts of the phenolic resin is added with pretreating material, the mass of which is 15 to 30 parts, the mixed liquid which is mixed by the phenolic resin and the pretreating material is stirred and heat-preserved for 30 to 150 minutes under 40 DEG C to 60 DEG C; then the mixed liquid is added into water solution which includes 0.5 to 5wt percent of dispersant, is stirred and heated to 110 DEG C to 140 DEG C at a heating rate of 0.5 to 10 DEG C / min, is heat-preserved for 0.5 to 2 hours, and then is cooled, filtered and dried, thereby gaining a resin-covered spherule. The invention has the advantages that the method and the technology are simple, the output is large, and the controllability of the ball diameter is high. The invention is suitable for carbon spherule, the producing diameter of which is 0.3mm to 2mm.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

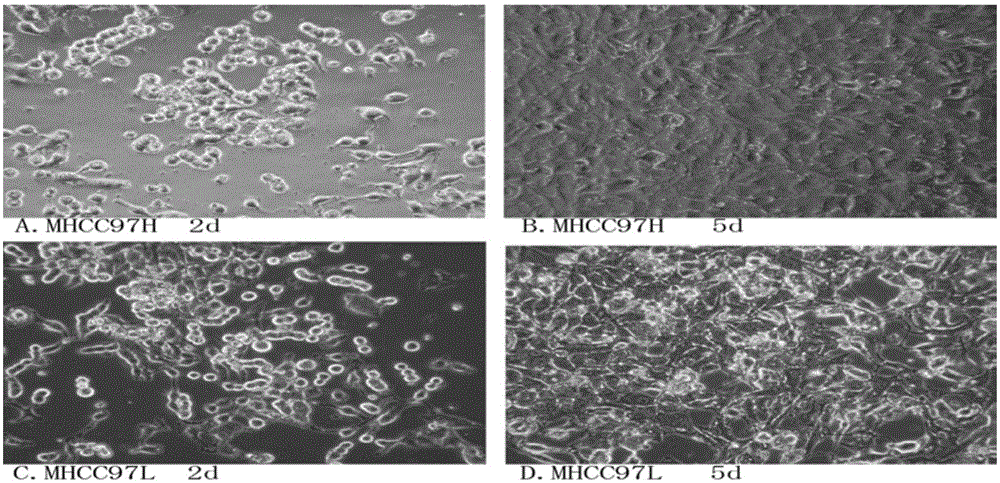

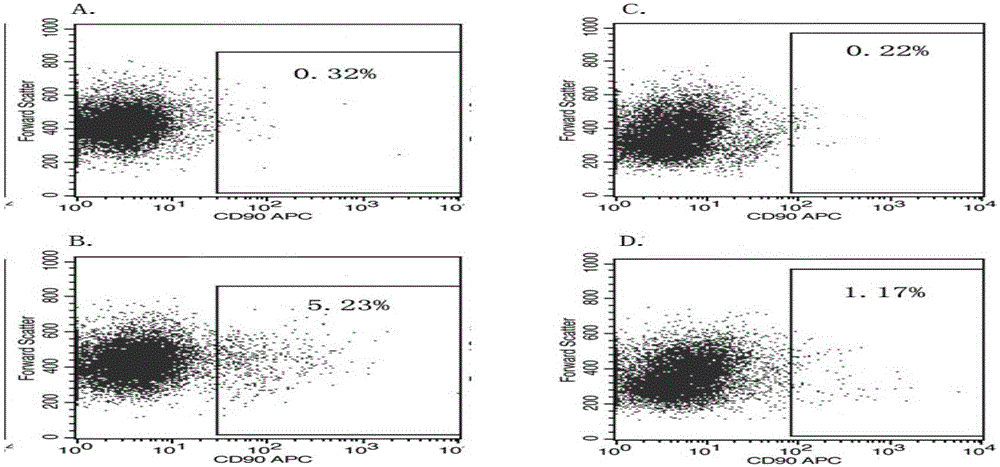

Serum-free medium for liver cancer stem cells and culture method for serum-free medium

The invention provides a serum-free medium for liver cancer stem cells and a culture method for the serum-free medium. Based on a DMEM / F12+GlutaMAXTM<-1> medium, the serum-free medium comprises a recombinant human epidermal growth factor, a recombinant human basic fibroblast growth factor-10, an insulin No.1 growth factor, a serum-free complementary nutritional ingredient, heparin and a penicillin and streptomycin double-resistant solution. The serum-free medium has the effects as follows: 1, three special growth factors are added to the serum-free medium in a corresponding proportion; direct serum-free culture is realized, so that liver cancer cells can be pelletized, the pelletizing rate is high, and continuous and stable passage can be realized; 2, the growth factors in the serum-free medium keep a small group of cells in an undifferentiated state; the serum-free medium and the culture method have wide prospect in fundamental research and clinical application of serum-free culture of the liver cancer stem cells and provide rich experiment materials for research of the liver cancer stem cells.

Owner:广西壮族自治区肿瘤医院

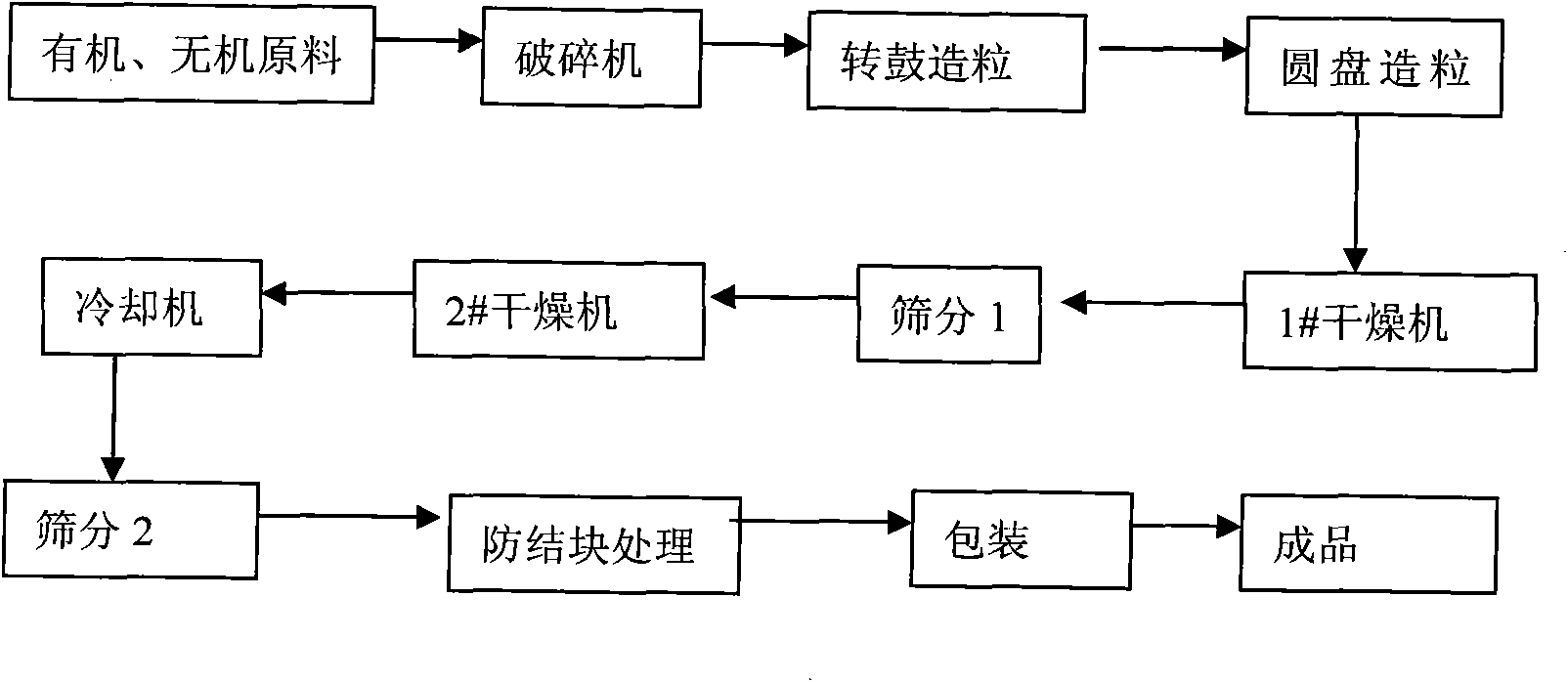

Production process of organic-inorganic compound fertilizer

InactiveCN101684051ASolve the problem of poor product appearance qualityHigh one-time ball forming rateFertiliser formsFertilizer mixturesCrusherOrganic fertilizer

A technology problem solved by the invention is to provide a production process of organic-inorganic compound fertilizer with high pelleting rate, round appearance and low moisture. The process has the steps of: fermenting organic raw materials into ecological organic fertilizer, adding inorganic raw material into a crusher; pelleting by assistantly adding water, steam and urine after crush of thematerial in the rotary drum comminutor; pelleting continuously using the material in the disk comminutor from the rotary drum comminutor; carrying out two-stage drying for the material after pelleting, and cooling the material; sieving macrobead in the cooled material; packing the sieved product after anti-blocking treatment and then delivering them out of factory. Using the technical scheme cansufficiently play the roles of the two kinds of pelleting methods, as well as solve the problems of bad appearance quality of product, and high moisture of pelleting.

Owner:河南财鑫实业化工有限责任公司

Round granule ore fertilizer pelleting process and device

ActiveCN106495811AAvoid cloggingHigh ball rateCalcareous fertilisersMagnesium fertilisersEngineeringUltimate tensile strength

The invention discloses a round granule ore fertilizer pelleting process which comprises the following steps: I) preparing raw materials; II) performing stirring mixing; III) performing pelleting; IV) screening wet granules; V) performing first-stage drying; VI) performing second-stage drying; VII) cooling; VIII) screening a finished product; IX) packaging the finished product. The invention further discloses a pelleting device with the process. The pelleting device comprises a mixing machine, a disc pelleting machine, a staged rotary screen, a rotary drying machine, a vibration fluid bed dryer, a rotary cooling machine and a vibration screen. The round granular ore fertilizer pelleting process is high in pelleting disc balling yield, low in granule crushing rate in the drying procedure, high in yield of the whole system, advanced in pelleting process, low in drying cost, small in water amount, high in granule strength of a round granule ore fertilizer product, good in sphericity degree and high in market acceptance degree.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Compound fertilizer containing efficient binder and production method of composite fertilizer

ActiveCN103011958AImprove adhesionHigh drum granulation rateFertilizer mixturesPhosphateINCREASED EFFECT

The invention discloses a granular compound fertilizer prepared by using modified starch as a binder. The compound fertilizer is characterized by comprising the following raw materials in parts by weight: 15-40 parts of nitrogenous fertilizer, 20-40 parts of phosphatic fertilizer, 20-42 parts of potash fertilizer and 0.5-2.0 parts of binder. The raw materials of the binder consist of 35-45 parts by weight of starch, 1-5 parts by weight of phosphate, 0.1-3 parts by weight of oxidant, 0.1-1 part by weight of coupling agent and 40-60 parts by weight of water. The binder contained in the granular compound fertilizer has good adhesion capability, so the granular compound fertilizer disclosed by the invention has the advantage that adhesive capability is good, the rotary drum granulation pelletizing ratio is high and the material returning rate is reduced; the pertinence is strong and the fertilizer efficiency is completely releases, so that the soil is hard to harden and the yield-increasing effect is prominent; and the virtuous circle of the soil nutrient can be maintained, the water and nutrient retention capability of the soil is improved and the resistance of the crops is enhanced.

Owner:广西农垦明阳生化有限公司

Method for producing granular organic fertilizer with high content of humic acid by using municipal sludge

ActiveCN101723718AImprove qualityHigh ball rateBio-organic fraction processingClimate change adaptationFiberSludge

The invention relates to a method for producing a granular organic fertilizer with high content of humic acid by using municipal sludge. The method is characterized by comprising the following steps of: mixing the municipal sludge, dry weathered coal powder and phosphogypsum in a weight ratio of 80-100:30-50:10-30; inoculating a ferment bacterium which is 2 to 4 percent of the total weight of raw materials into the mixture; mixing the mixture uniformly and fully; placing the mixture into a fermenting tank for aeration; performing composting fermentation for 10 to 15 days, wherein the temperature of a system can be raised to 50 to 70 DEG C in the process of fermentation; tedding and smashing the mixture; and then adding an organic aqueous binding agent which is 0.05 to 0.1 percent of the quantity of the smashed material to perform granulation to obtain the granular organic fertilizer. The method takes high-quality weathered coal powder, straws and an organic granulation binder to replace clay as materials of the municipal sludge to perform aerobic fermentation, can greatly improve the quality of the granular organic fertilizer, improves the content of organic matters from 20-25 percent to 40-55 percent, and improves the content of the humic acid from 15-20 percent to 20-40 percent; and the method solves the problem of difficult granulation of the organic fertilizer, can obviously improve the granulating ratio of the organic fertilizer in the granulation process, improves the production efficiency greatly, and reduces the energy source consumption. The obtained product has no fiber impurities, and has a greatly improved external appearance.

Owner:王萍

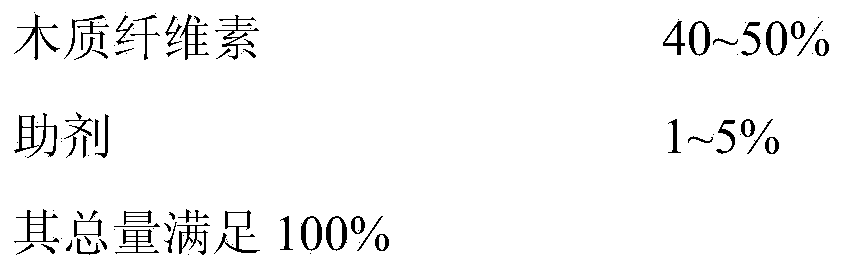

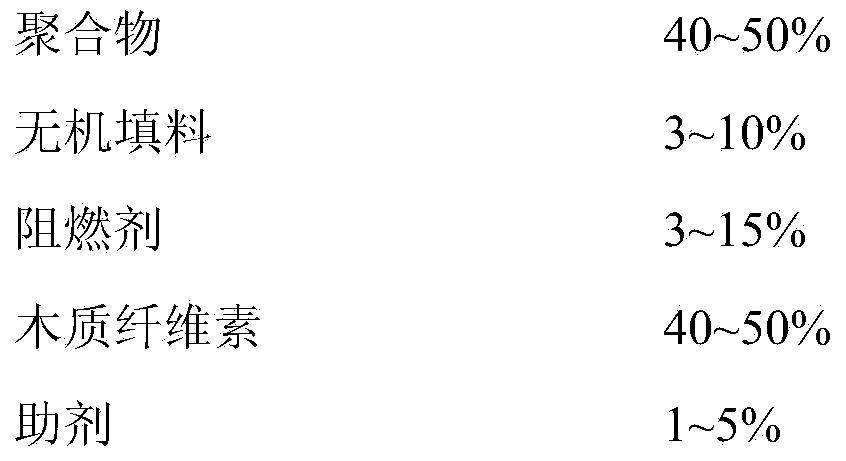

Wood-plastic composite with flame-retardation effect and preparation method

InactiveCN104312000AImprove flame retardant performanceImprove mechanical propertiesCelluloseFiltration

The invention relates to a wood-plastic composite with a flame-retardation effect and a preparation method. The wood-plastic composite is prepared from the following components in percent by weight: 40 to 50 percent of polymer, 3 to 10 percent of inorganic packing, 3 to 15 percent of a fire retardant, 40 to 50 percent of lignocellulose and 1 to 5 percent of other assistants. The inorganic packing is subjected to extraction and filtration after being processed by a silane coupling agent; in a drying oven, the temperature of 80 DEG C is kept and the constant temperature is kept for 2 to 5 hours; the fire retardant and the lignocellulose are stirred for 5 to 10min at a temperature of 100 to 120 DEG C in a high-speed kneading machine with a heating jacket; after the obtained product is cooled to the temperature of 60 DEG C, the inorganic packing, the assistants and the polymer which are processed by the coupling agent are added; the raw materials are mixed for 2 to 10min in a high-speed mixer; the obtained uniform materials are added into a double-screw extruder to carry out extrusion and pelletizing. The wood-plastic composite with the flame-retardation effect, which is prepared by the preparation method disclosed by the invention, has good flame retardation and adopts a simple process.

Owner:EAST CHINA UNIV OF SCI & TECH

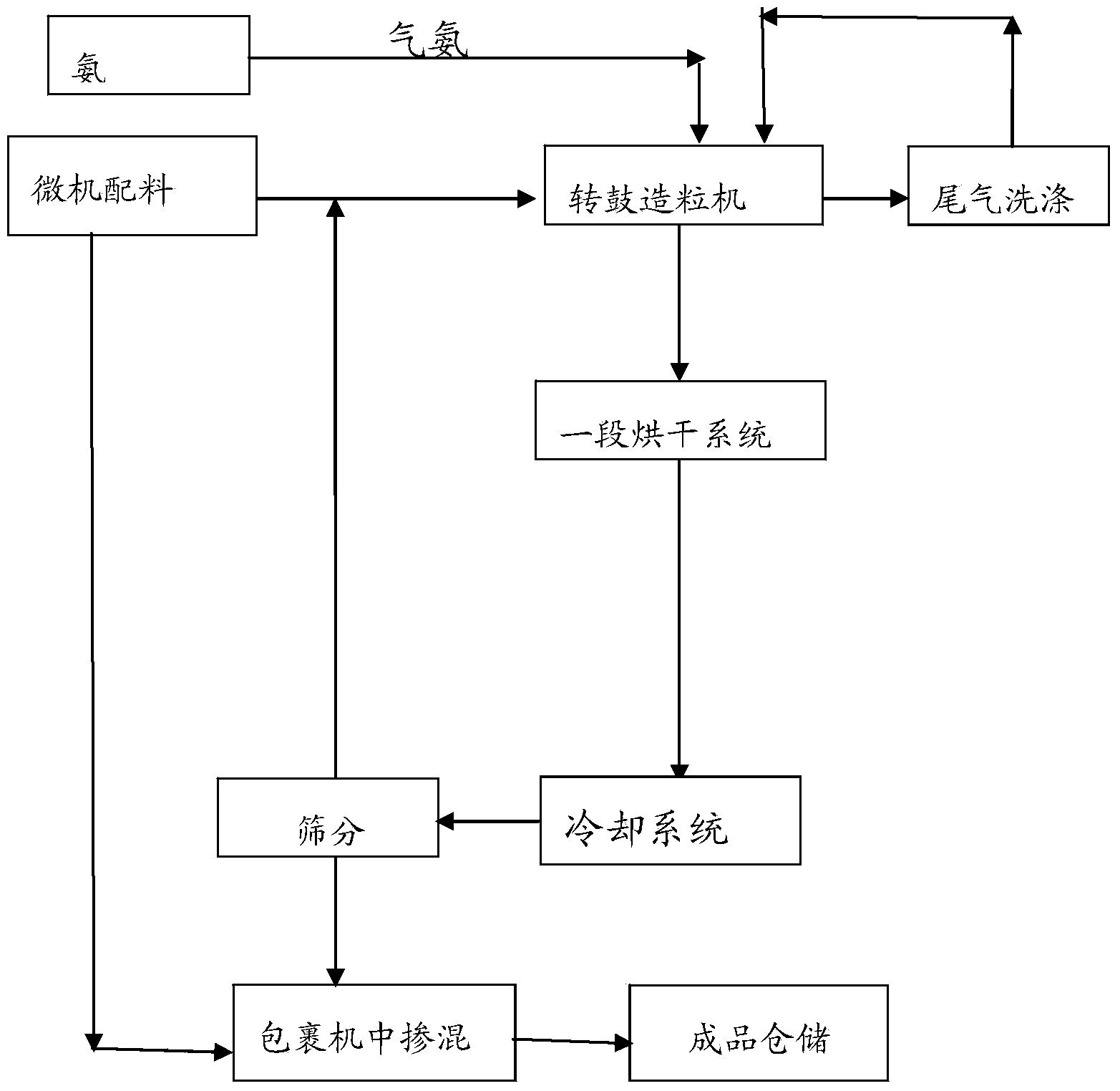

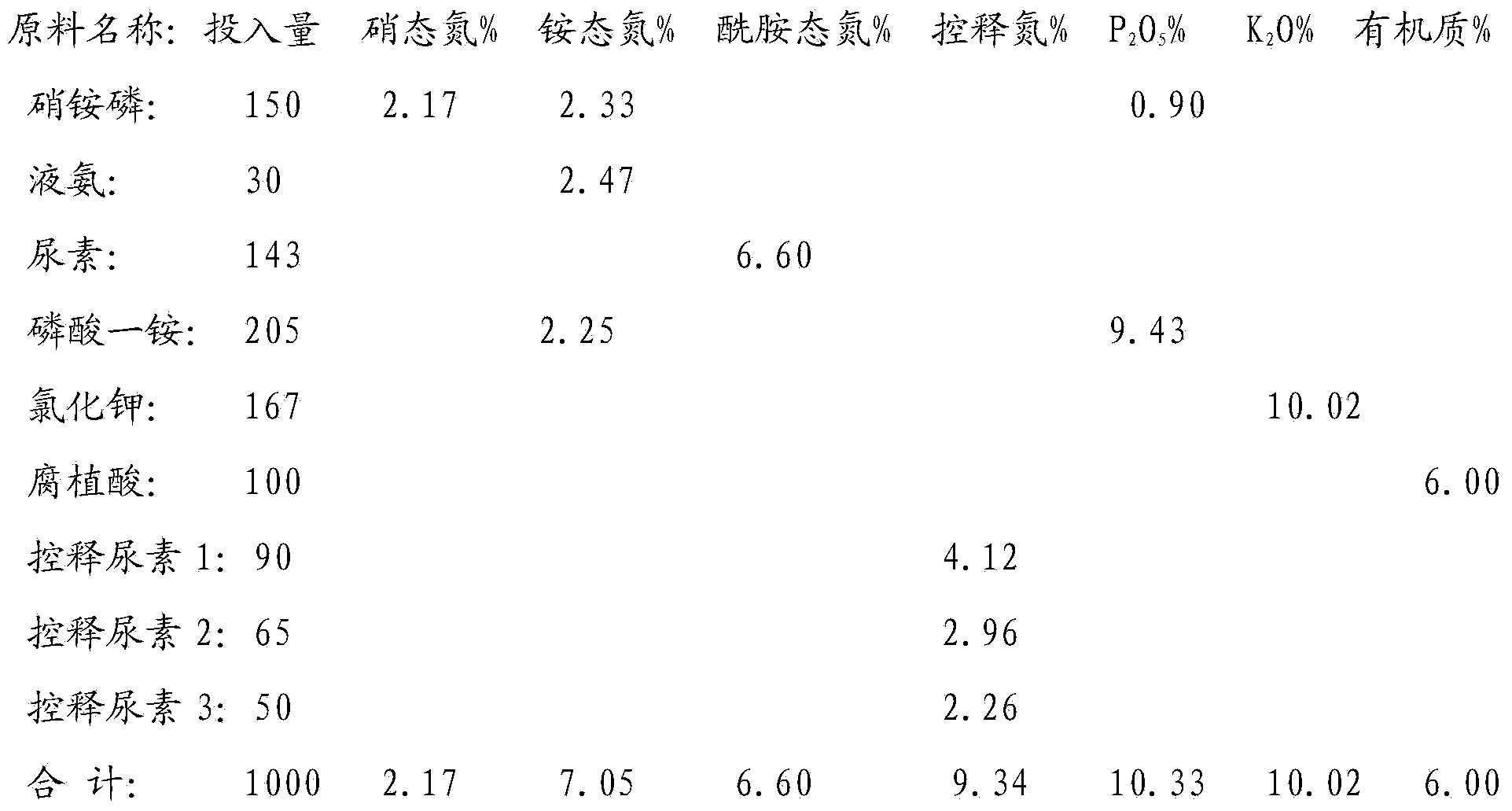

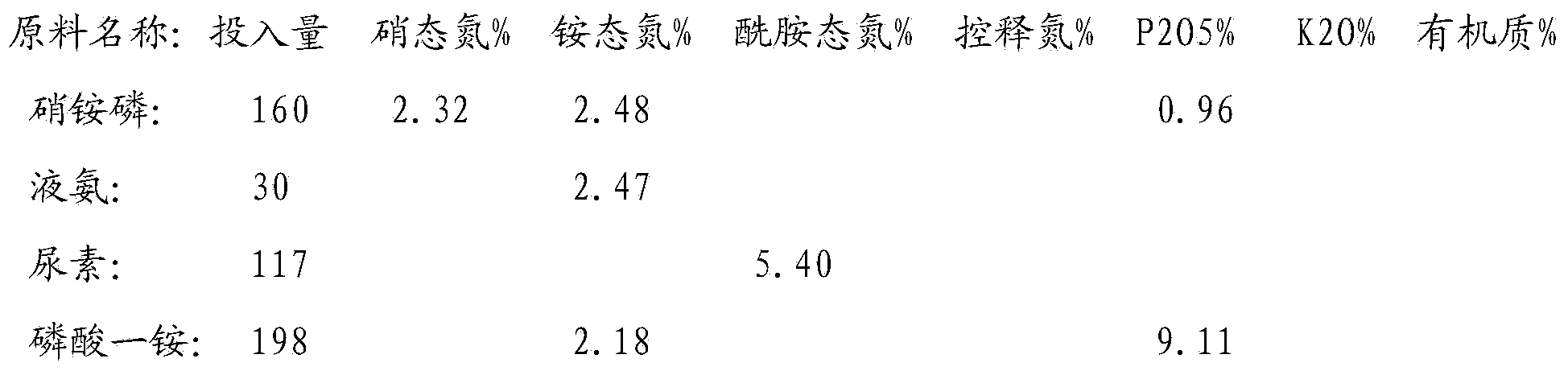

Whole-process nutrient supply type composite fertilizer and preparation method thereof

The invention discloses a whole-process nutrient supply type composite fertilizer and a preparation method thereof. A raw material containing nitrate nitrogen, ammonium nitrogen, amide nitrogen, controlled release nitrogen and organic matters is added in the material. The components of the whole-process nutrient feeding type composite fertilizer are effectively proportioned in percentage by mass on the basis of nitrogen content: 2-4% of nitrate nitrogen, 5-8% of ammonium nitrogen, 5-8% of amide nitrogen and 6-10% of controlled release nitrogen, the contents of phosphorus and potassium are determined according to different product proportions, and the content of the organic matters is not less than 6%. In the production process, the viscosity of urea nitrate generated in a reaction of ammonium nitrate phosphate and urea and granulation tail gas washing water are used as liquid phase amount necessary for granulation to finish the material granulation process, in order to prevent excessive urea nitrate from being generated in the granulation process, ammonia gas is directly introduced into the material layer of a rotor drum granulator to finish the ammoniation treatment of ammonium nitrate phosphate and control the quantity of the urea nitrate generated in the reaction. The fertilizer not only can improve the utilization rate of fertilizer nutrients and ensure the whole-process nutrient supply of crops so as to increase the yield of the crops and improve the quality, but also can avoid harm caused by escherichia coli and such toxic substances as heavy metal, improve the soil, reduce the soil salinity and fertilize the land.

Owner:天津芦阳肥业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com