Bentonite binder and preparation method thereof

A technology of bentonite and binder, applied in chemical instruments and methods, manufacturing tools, casting and molding equipment, etc., can solve the problems of short ion exchange time, incomplete sodiumization effect, easy blocking of Raymond machine, etc., and achieve shortening Sodiumization time, remarkable energy-saving effect, beneficial to continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 adopts the inventive method to prepare bentonite binder

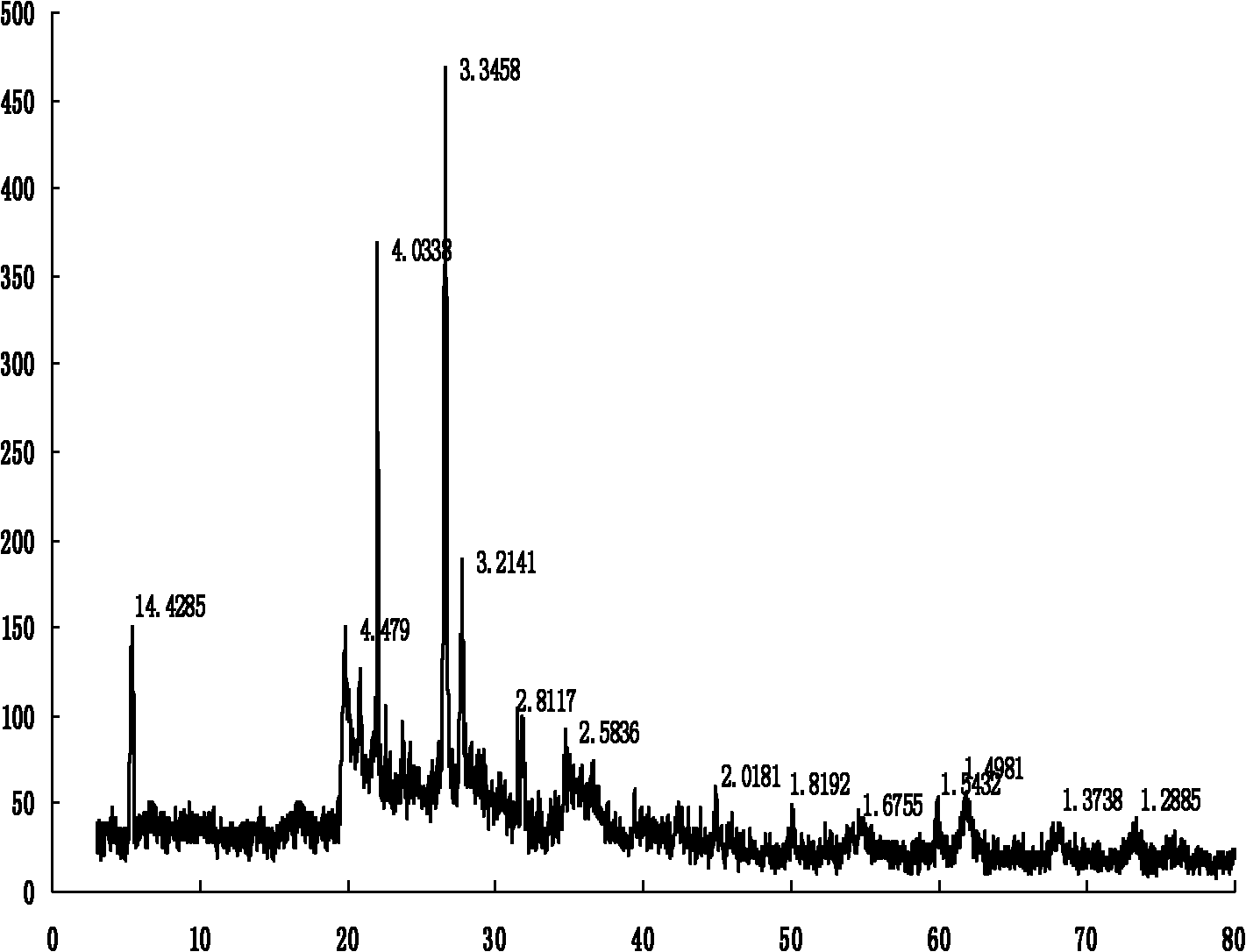

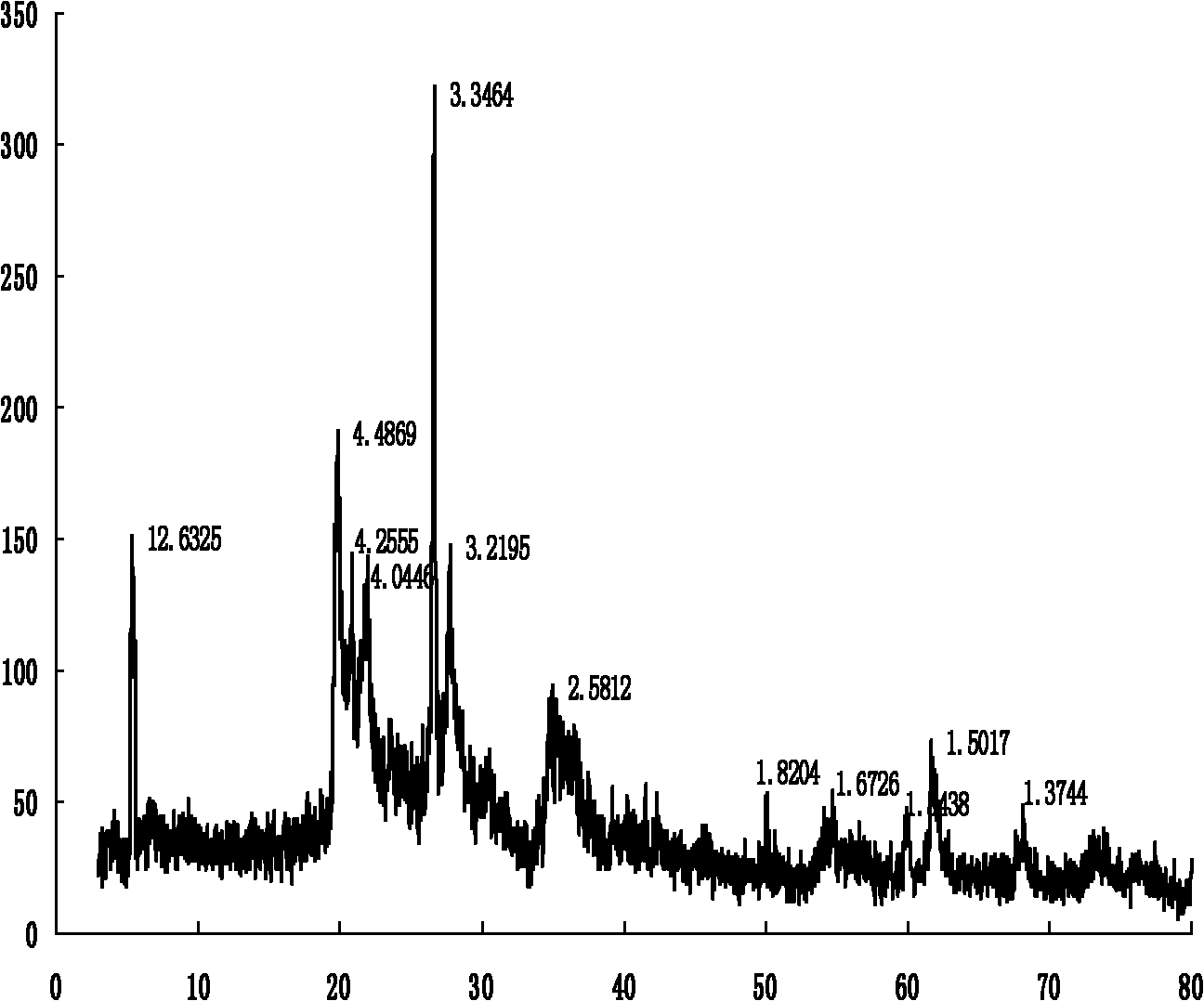

[0043] Grinding 250Kg of bentonite raw ore with a water content of 26% to a particle size of less than 5mm, adding a sodium reagent Na with a mass of 4% bentonite raw ore 2 CO 3 , bentonite raw ore quality 0.5% accelerator hexamethylenetetramine, the total water content of the mixture is adjusted to 45%, rolled in a wheel mill mixer for 40min, dried at 95°C to a water content of 7.6%, and ground to Particle size - 200 mesh and above 98.5% sodium-based bentonite binder. Tested by "GB / T 20973-2007 Bentonite Test Method", the results are shown in Table 1. According to X-ray diffraction analysis, the d(001) value of the montmorillonite decreased from 14.4285A° of the original ore to 12.4536A°, indicating that the calcium-magnesium-based bentonite has been modified into sodium-based bentonite. XRD graph of bentonite raw ore figure 1 Shown, the XRD figure of the bentonite binder prepared by the inventi...

Embodiment 2

[0044] Embodiment 2 adopts the inventive method to prepare bentonite binder

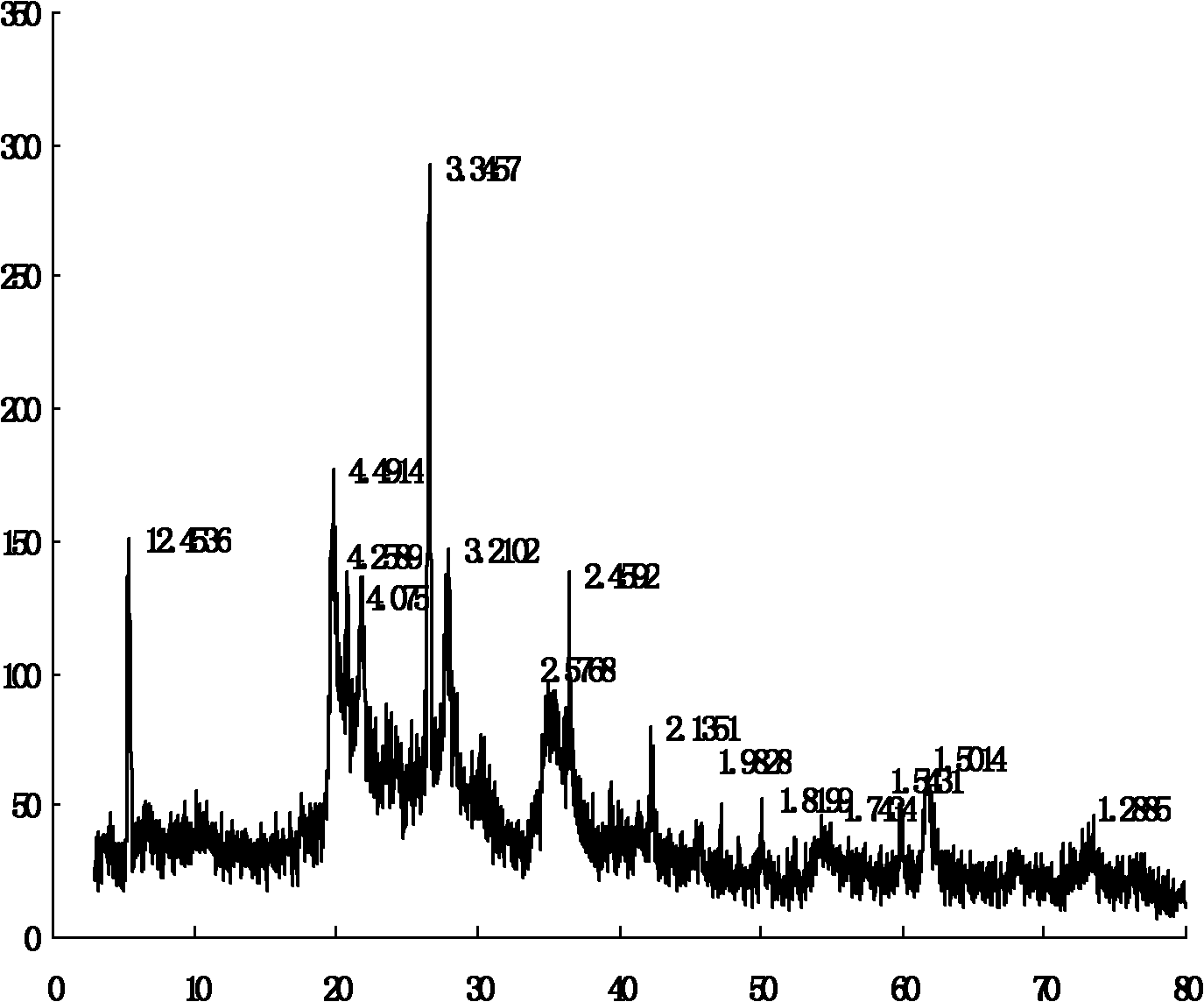

[0045] Grinding 250Kg of bentonite raw ore with a water content of 26% to a particle size of less than 5mm, adding a sodium reagent Na with a mass of 3% bentonite raw ore 2 CO 3 , bentonite raw ore quality 1.0% accelerator hexamethylenetetramine, adjust the total water content of the mixture to 45%, roll in a wheel mill mixer for 30min, dry at 95°C to a water content of 7.8%, and grind to Particle size - 200 mesh and above 98.5% sodium-based bentonite binder. Tested by "GB / T 20973-2007 Bentonite Test Method", the results are shown in Table 2. According to X-ray diffraction analysis, the d(001) value of the montmorillonite decreased from 14.4285A° of the original ore to 12.4254A°, indicating that the calcium-magnesium-based bentonite has been modified into sodium-based bentonite. XRD graph of bentonite raw ore figure 1 Shown, the XRD figure of the bentonite binder prepared by the inventive method ...

Embodiment 3

[0046] Embodiment 3 adopts the inventive method to prepare bentonite binder

[0047] Grinding 250Kg of bentonite raw ore with a water content of 26% to a particle size of less than 5mm, adding a sodium reagent Na with a mass of 4% bentonite raw ore 2 CO 3 , bentonite raw ore quality 1.0% accelerator hexamethylenetetramine, adjust the total water content of the mixture to 45%, roll in a wheel mill mixer for 30min, dry at 95°C to a water content of 7.5%, and grind to Particle size - 200 mesh and above 98.5% sodium-based bentonite binder. Tested by "GB / T 20973-2007 Bentonite Test Method", the results are shown in Table 1. According to X-ray diffraction analysis, the d(001) value of the montmorillonite decreased from 14.4285A° of the original ore to 12.4228A°, indicating that the calcium-magnesium-based bentonite has been modified into sodium-based bentonite. However, the d(001) value of montmorillonite is almost the same as that in Example 2, and has basically reached the mini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com