Pellet production method of vanadium-titanium magnetite concentrate

A technology of vanadium-titanium magnetite concentrate and production method, which is applied in the field of pellet production to achieve the effects of improving grade, increasing pelleting rate, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

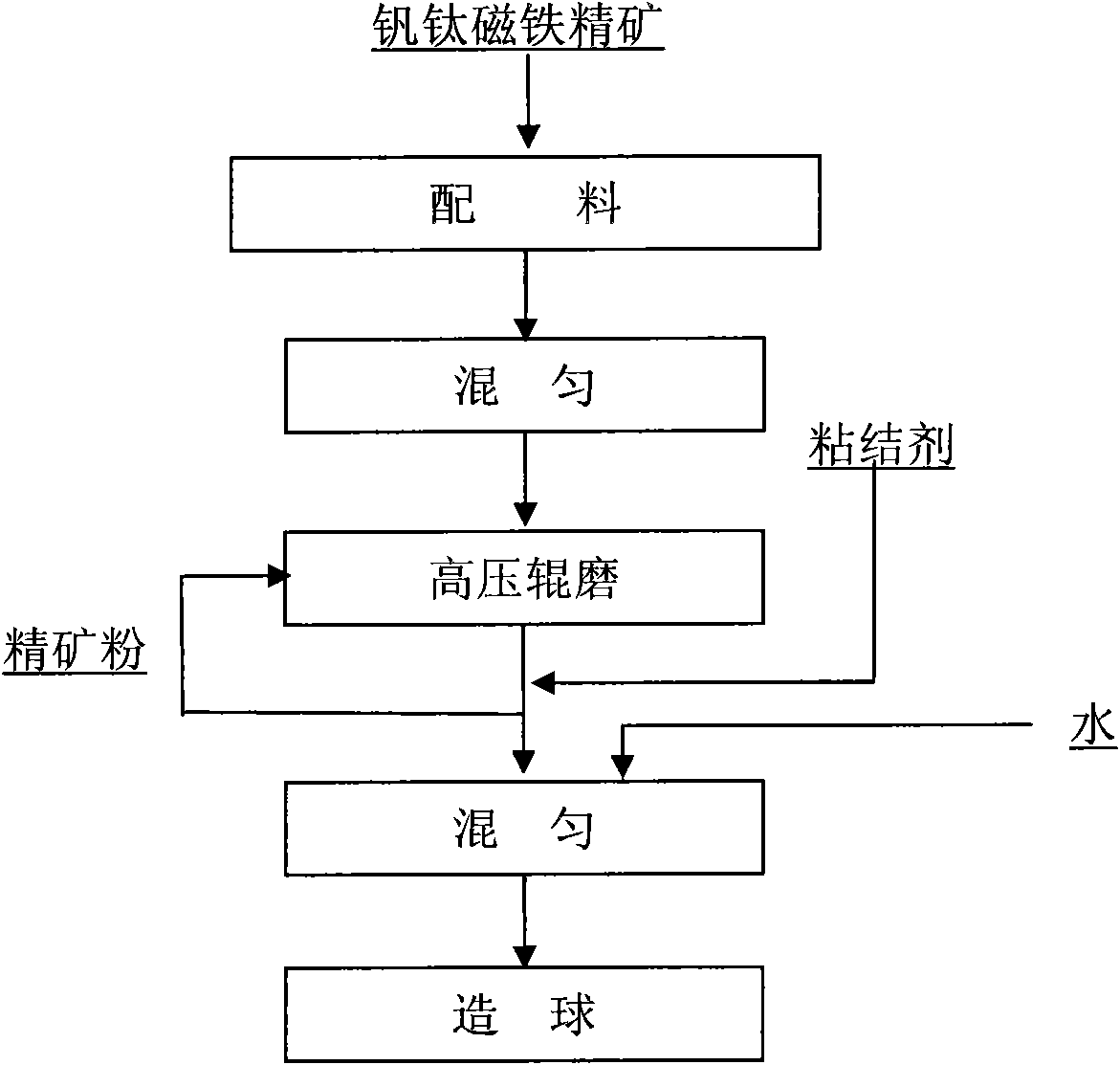

Method used

Image

Examples

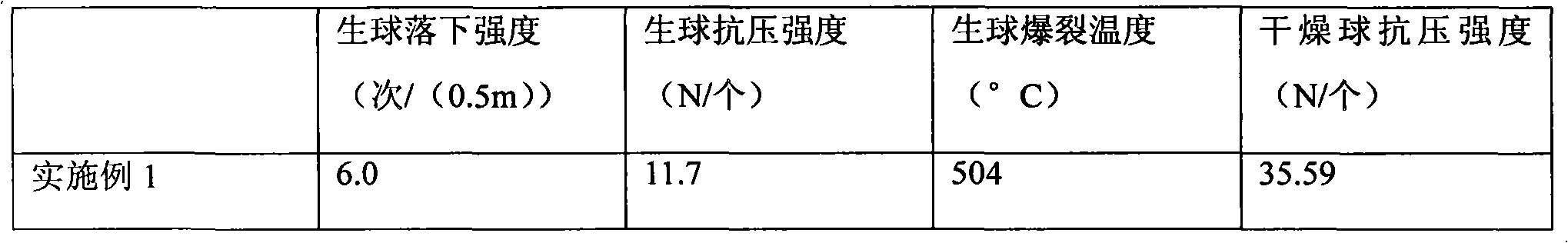

Embodiment 1

[0049] Use the Φ420×100mm high-pressure roller mill produced by Luoyang CITIC Group to carry out high-pressure roller milling for roller milling of Baima concentrate. The parameters selected during roller milling are: roller speed 14r / min, roller pressure 13MPa, and abrasive moisture of 8% by weight After the roller mill finishes, it is measured that the particle size in the Baima concentrate powder is less than 200 mesh, and the particle content is 76.9% by weight, and the specific surface area of the concentrate powder is 1668cm 2 / g, add water and 1.8% by weight of bentonite to the concentrate powder and mix well. A disc pelletizer with a diameter of 1800mm and a rotating speed of 15r / min was used to pelletize the vanadium-titanium magnetite concentrate powder after roller milling. Pre-add 400g of 3-5mm cue balls in the disc before pelletizing (reserved in advance), start the disc, start timing from the time of unloading, uniformly accelerate feeding and replenishing wate...

Embodiment 2

[0051]Using the pelletizing method described in Example 1, the difference is: the parameters selected during roller milling are roll speed 18r / min, roll pressure 11MPa, and 6.5% by weight of abrasive moisture; The particle size is less than 200 mesh particle content is 74.3% by weight, the specific surface area of the concentrate powder is 1430cm 2 / g, add water and 1.8% by weight of bentonite to the concentrate powder and mix evenly, and the pelletizing rate is 85% during pelletizing.

Embodiment 3

[0053] Using the pelletizing method described in Example 1, the raw material is Baima concentrate, and the difference is: the parameters selected during the roller mill are roll speed 16r / min, roll pressure 12MPa, and 7.3% by weight of abrasive moisture; In the white horse concentrate powder, the particle size less than 200 mesh particle content is 75.2% by weight, and the specific surface area of the concentrate powder is 1530cm 2 / g, add water and 1.8% by weight of bentonite to the obtained Baima concentrate powder and mix evenly, and the pelleting rate is 86% during pelletizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com