Wood-plastic composite with flame-retardation effect and preparation method

A technology of wood-plastic materials and functions, which is applied in the field of wood-plastic materials and its preparation, can solve the problem of low flame retardancy of flame retardants, and achieve the effects of reduced resin consumption, excellent flame retardancy, good mechanical properties and easy processing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

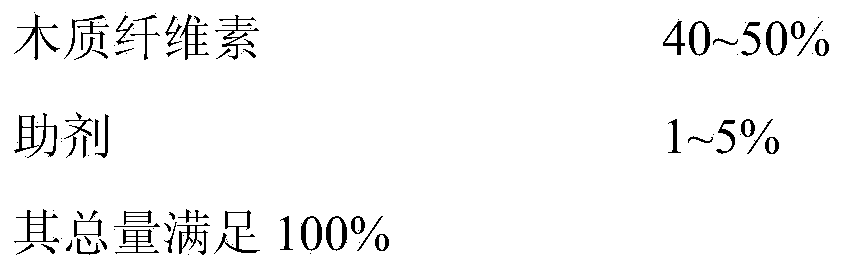

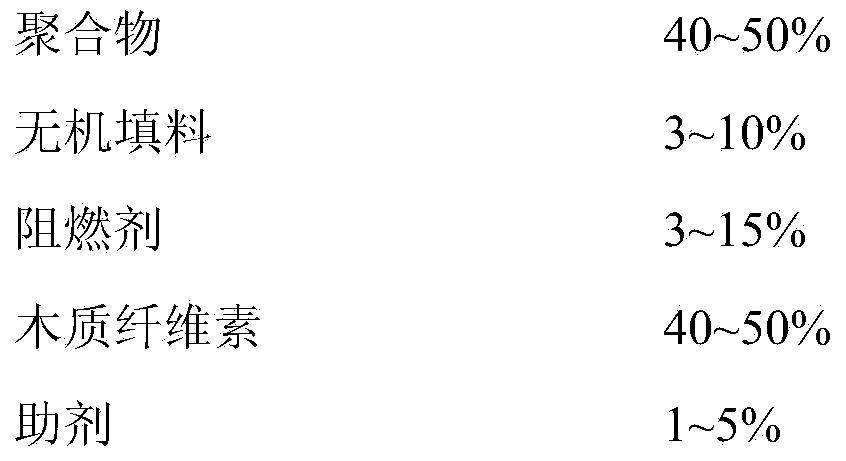

Method used

Image

Examples

Embodiment 1

[0033] Accurately weigh 3 parts of S15 hollow glass microspheres, 45 parts of S-1000 polyvinyl chloride, 40 parts of wood powder, 5 parts of HD A9 expandable graphite, 5 parts of No. 70 chlorinated paraffin, 2 parts of PPH-T03 maleic anhydride stick polypropylene. Dilute the silane coupling agent KH-560 with absolute ethanol to a 5% solution, add S15 hollow glass microspheres to the coupling agent solution for surface modification, stir for 30-60 minutes to form a viscous Dried to powder. Stir the flame retardant and lignocellulose in a high-speed kneader with a heating jacket at 100-120°C for 5-10 minutes, cool to 60°C, add inorganic fillers, additives, and polymers treated with coupling agents, and Mix in a high-speed mixer for 2-5 minutes. The obtained homogeneous material is fed into an extruder for extrusion and granulation. The temperature of each temperature zone of the extruder is 180-200, 190-210, 200-220, 200-220, 200-220, 180-190°C. The obtained polymer was drie...

Embodiment 2

[0035] Accurately weigh 3 parts of S15 hollow glass microspheres, 45 parts of S-1000 polyvinyl chloride, 40 parts of wood flour, 0.5 parts of straw ash, 4.5 parts of HD A9 expandable graphite, 5 parts of No. 70 chlorinated paraffin, 2 parts of PPH- T03 maleic anhydride grafted polypropylene. Dilute the silane coupling agent KH-560 with absolute ethanol to a 5% solution, add S15 hollow glass microspheres to the coupling agent solution for surface modification, stir for 30-60 minutes to form a viscous Dried to powder. Stir the flame retardant and lignocellulose in a high-speed kneader with a heating jacket at 100-120°C for 5-10 minutes, cool to 60°C, add inorganic fillers, additives, and polymers treated with coupling agents, and Mix in a high-speed mixer for 2-5 minutes. The obtained homogeneous material is fed into an extruder for extrusion and granulation. The temperature of each temperature zone of the extruder is 180-200, 190-210, 200-220, 200-220, 200-220, 180-190°C. T...

Embodiment 3

[0037] Accurately weigh 3 parts of S15 hollow glass microspheres, 45 parts of S-1000 polyvinyl chloride, 40 parts of wood flour, 5 parts of straw ash, 5 parts of HA-1509 guanidine sulfamate, 1.7 parts of 135C isocyanate, and 0.3 parts of DCP peroxidation dicumyl. Dilute the silane coupling agent KH-560 with absolute ethanol to a 5% solution, add S15 hollow glass microspheres to the coupling agent solution for surface modification, stir for 30-60 minutes to form a viscous Dried to powder. Stir the flame retardant and lignocellulose in a high-speed kneader with a heating jacket at 100-120°C for 5-10 minutes, cool to 60°C, add inorganic fillers, additives, and polymers treated with coupling agents, and Mix in a high-speed mixer for 2-5 minutes. The obtained homogeneous material is fed into an extruder for extrusion and granulation. The temperature of each temperature zone of the extruder is 180-200, 190-210, 200-220, 200-220, 200-220, 180-190°C. The obtained polymer was dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com