Patents

Literature

135results about How to "Easy to carve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

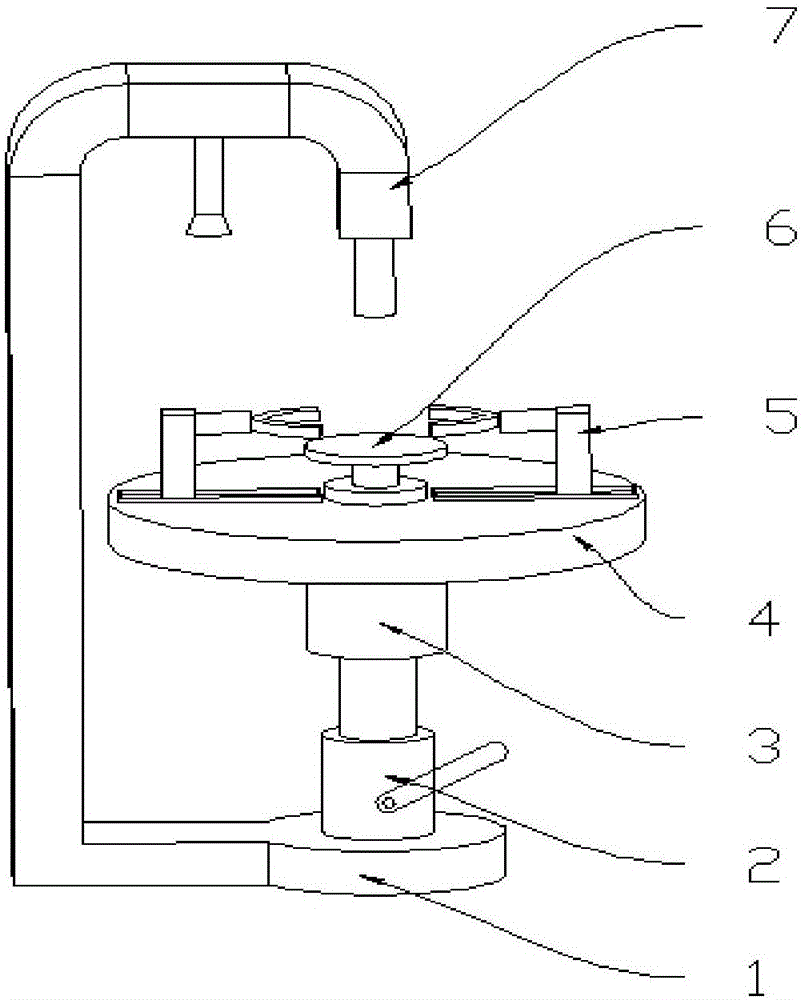

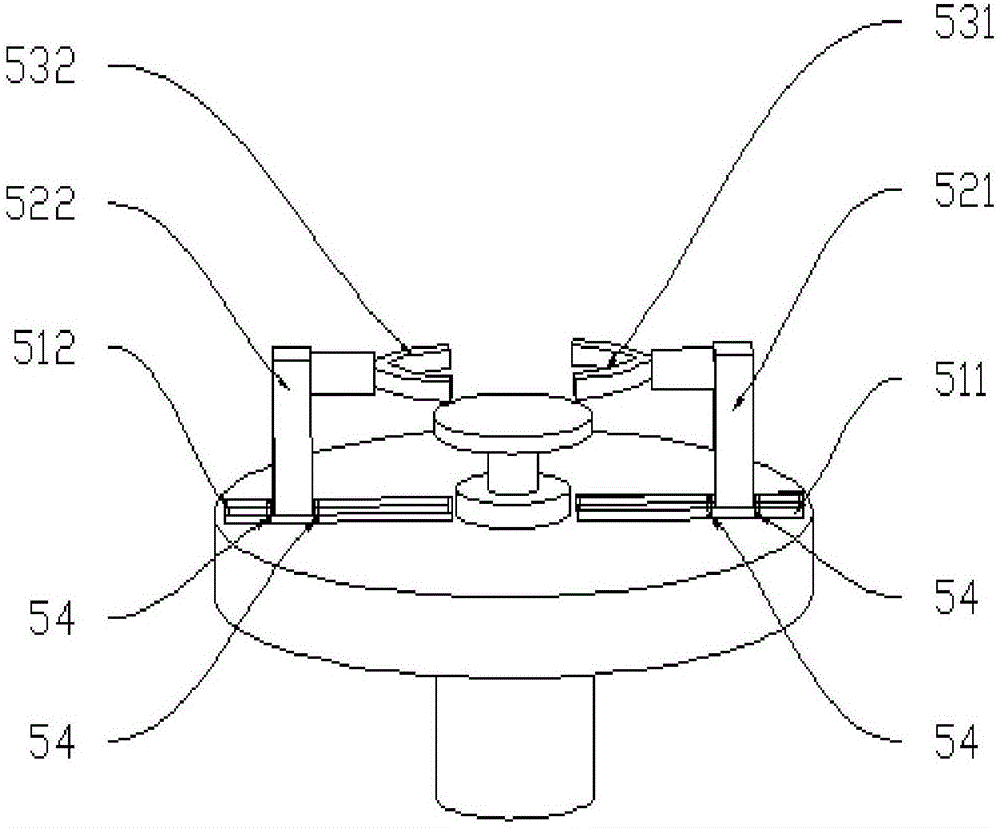

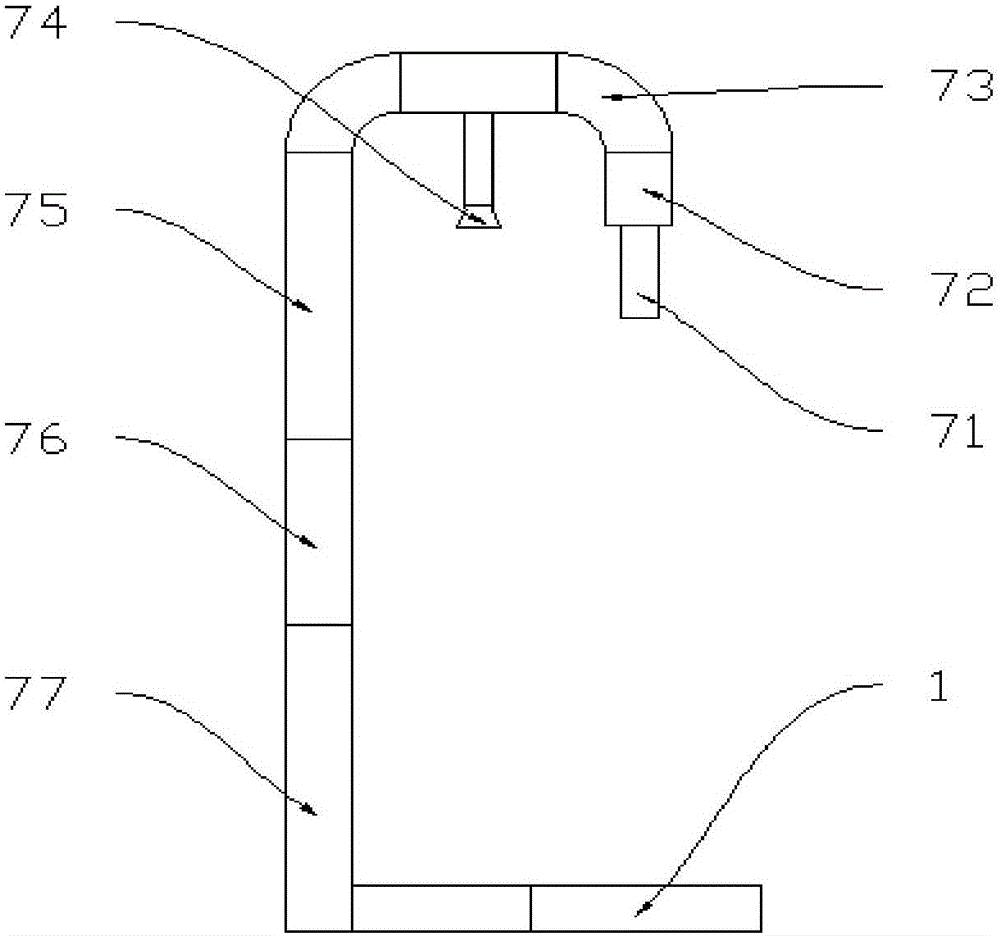

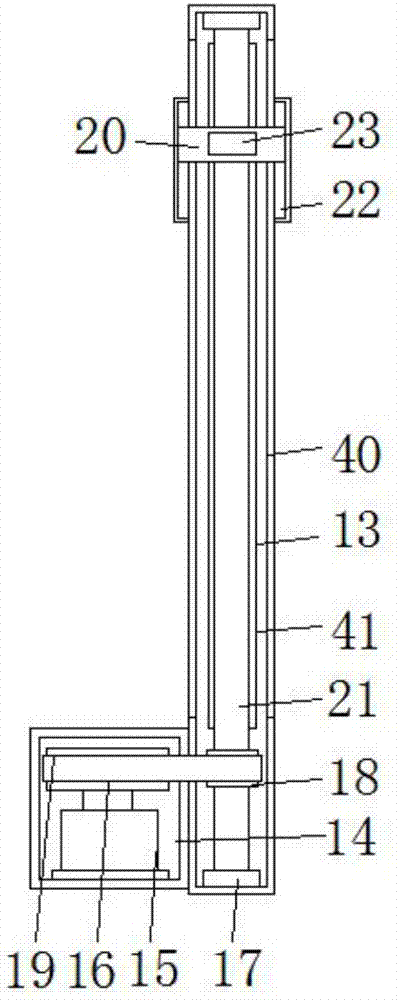

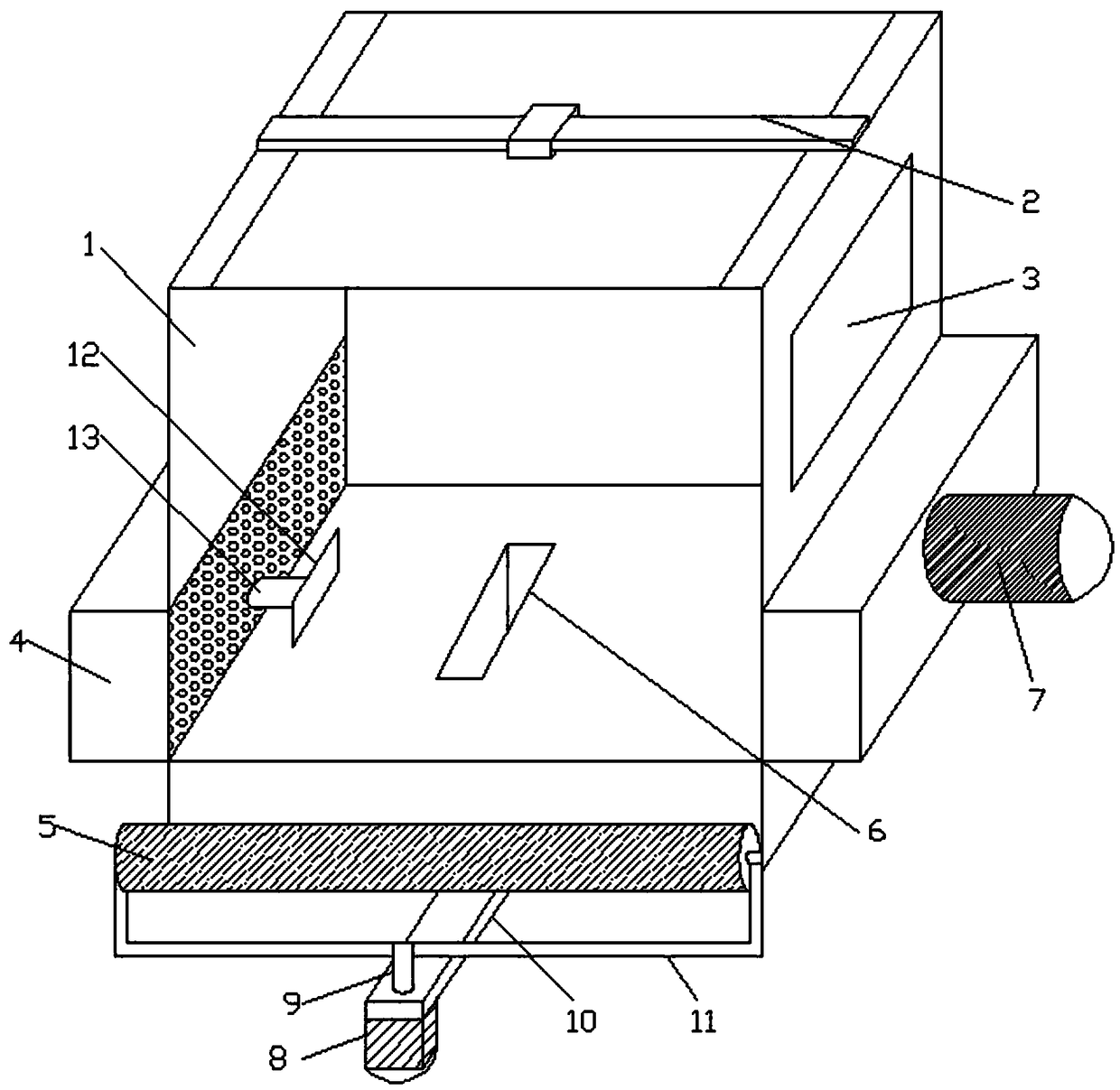

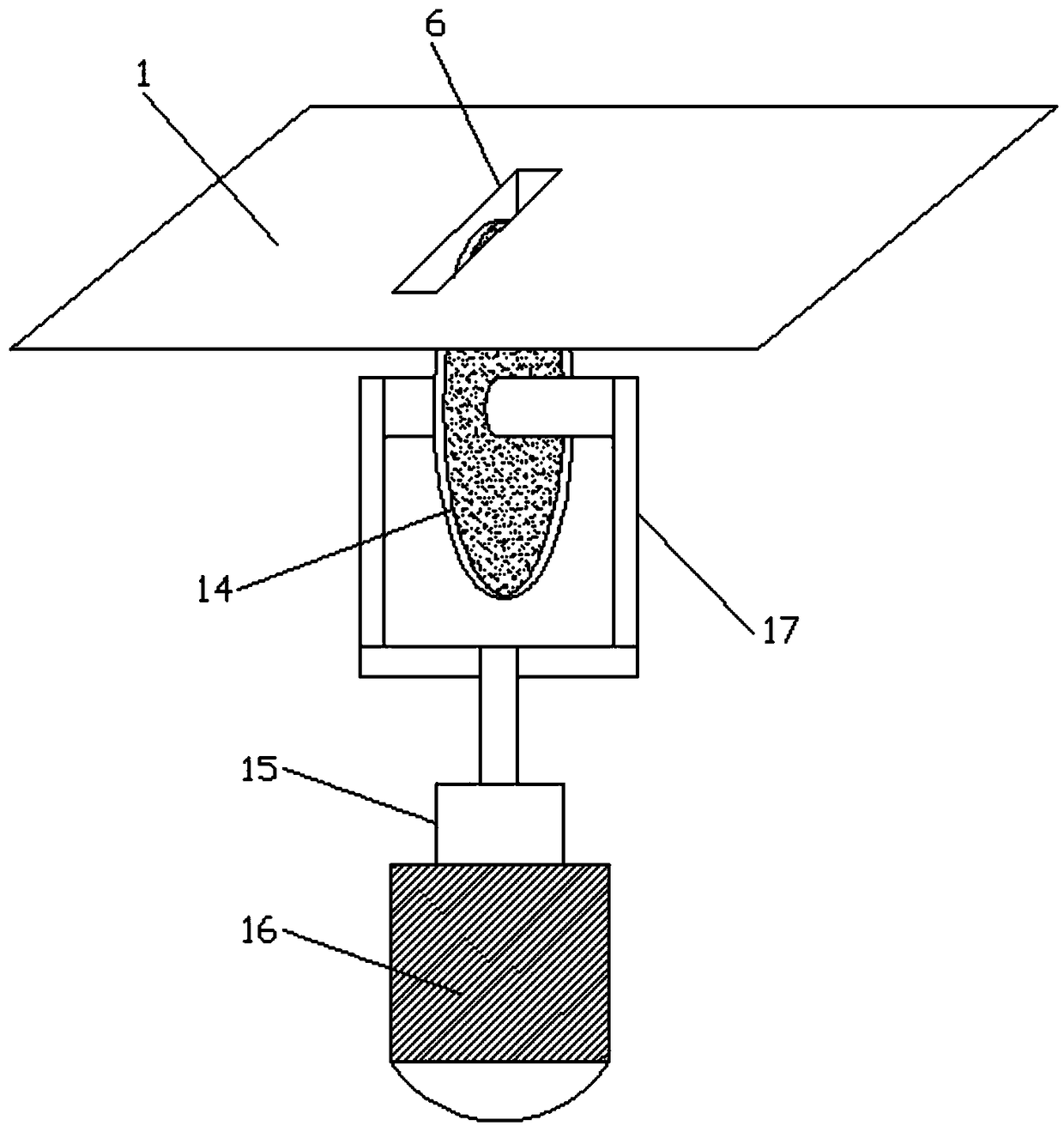

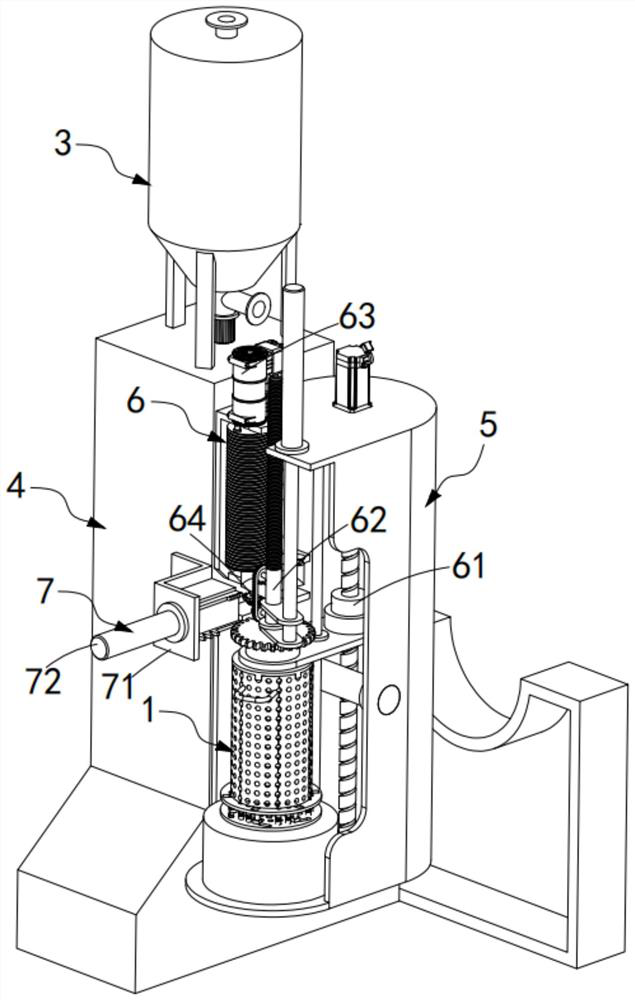

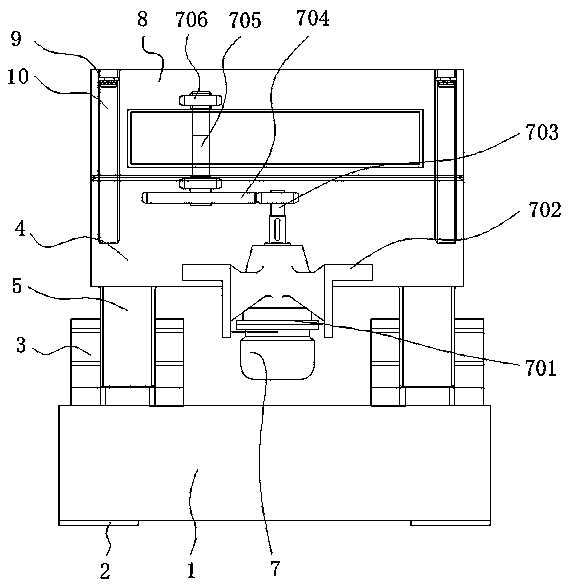

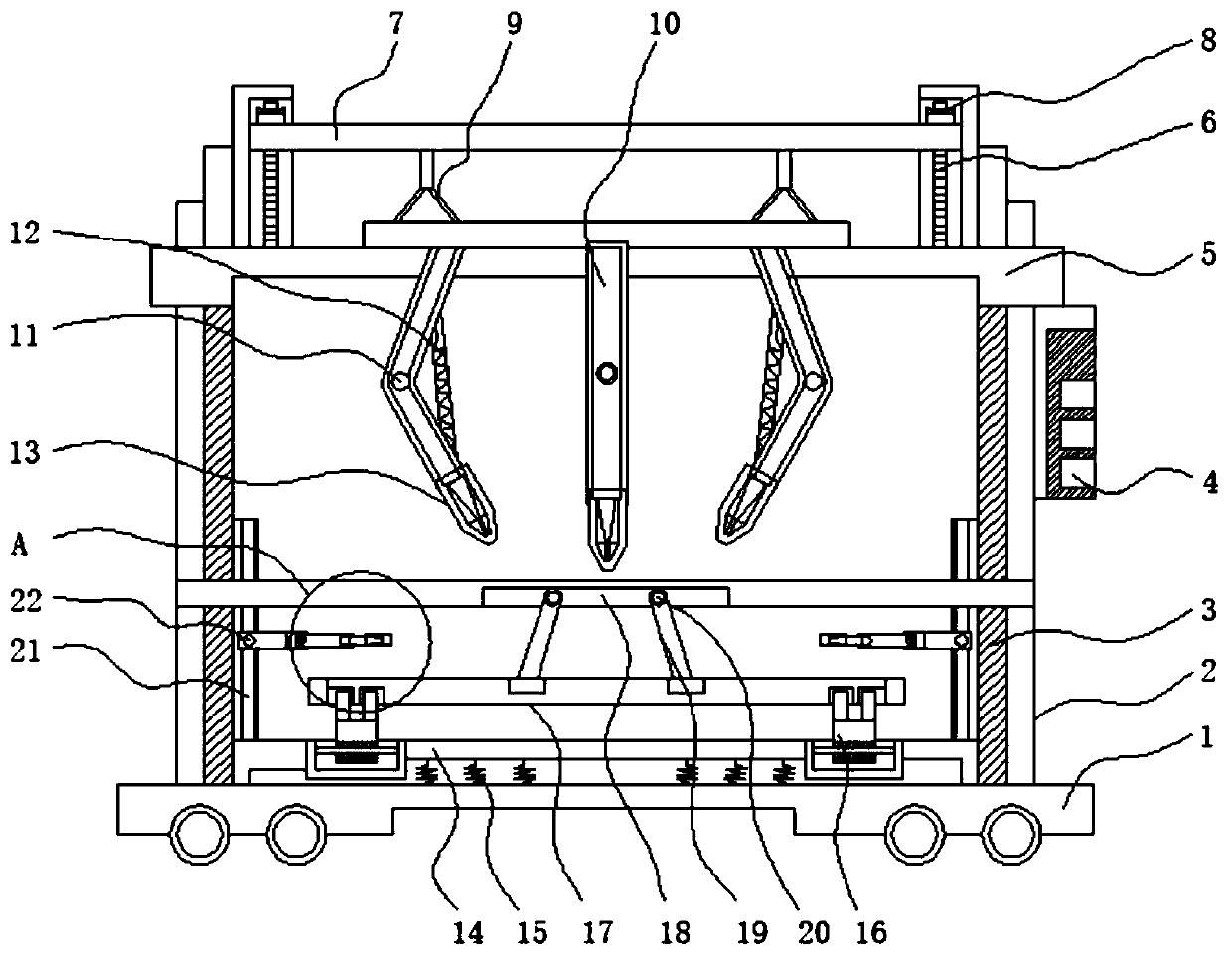

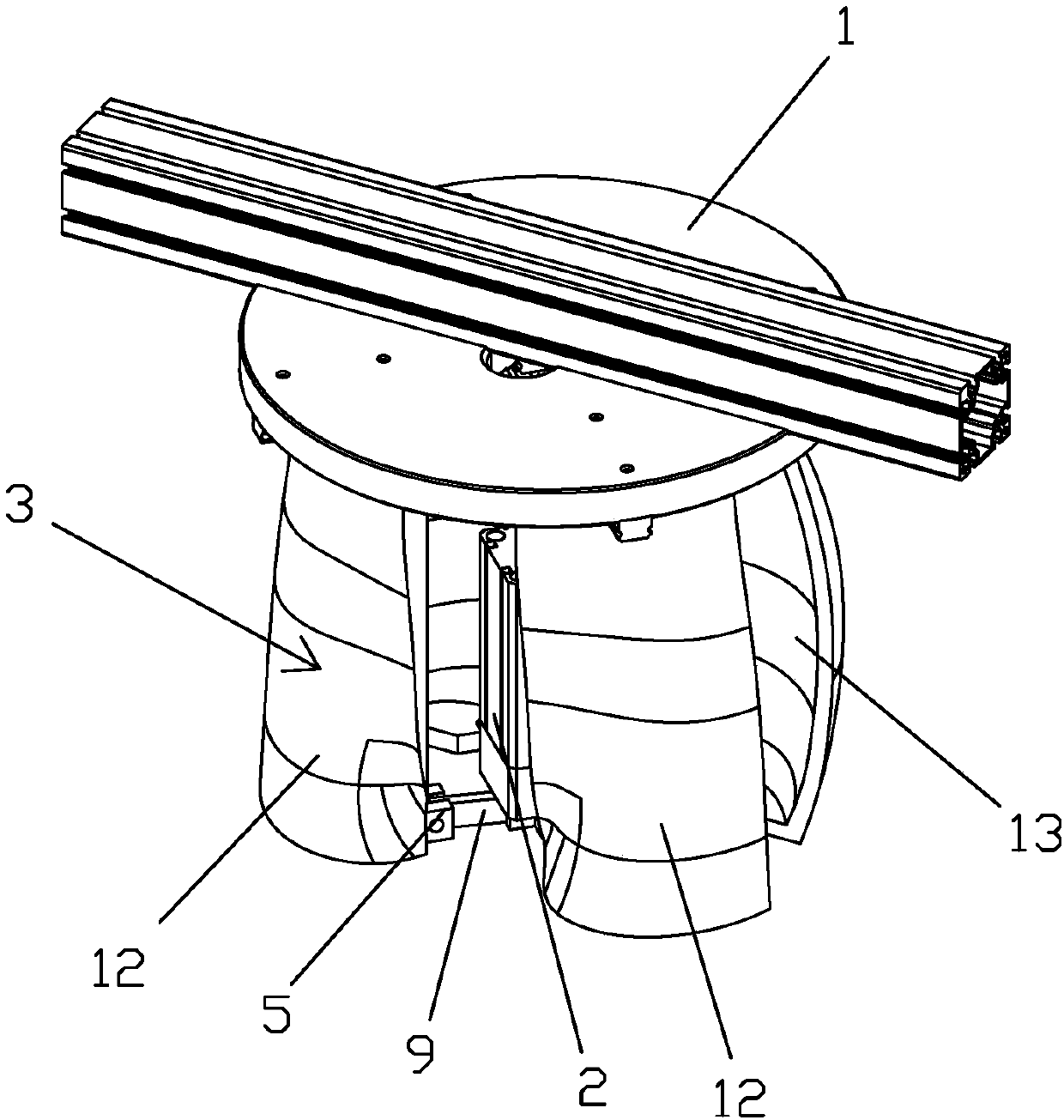

Artificial woodcarving working platform

InactiveCN106494143AFixed toHeight adjustableOther artistic work equipmentsEngravingEngineeringCarving

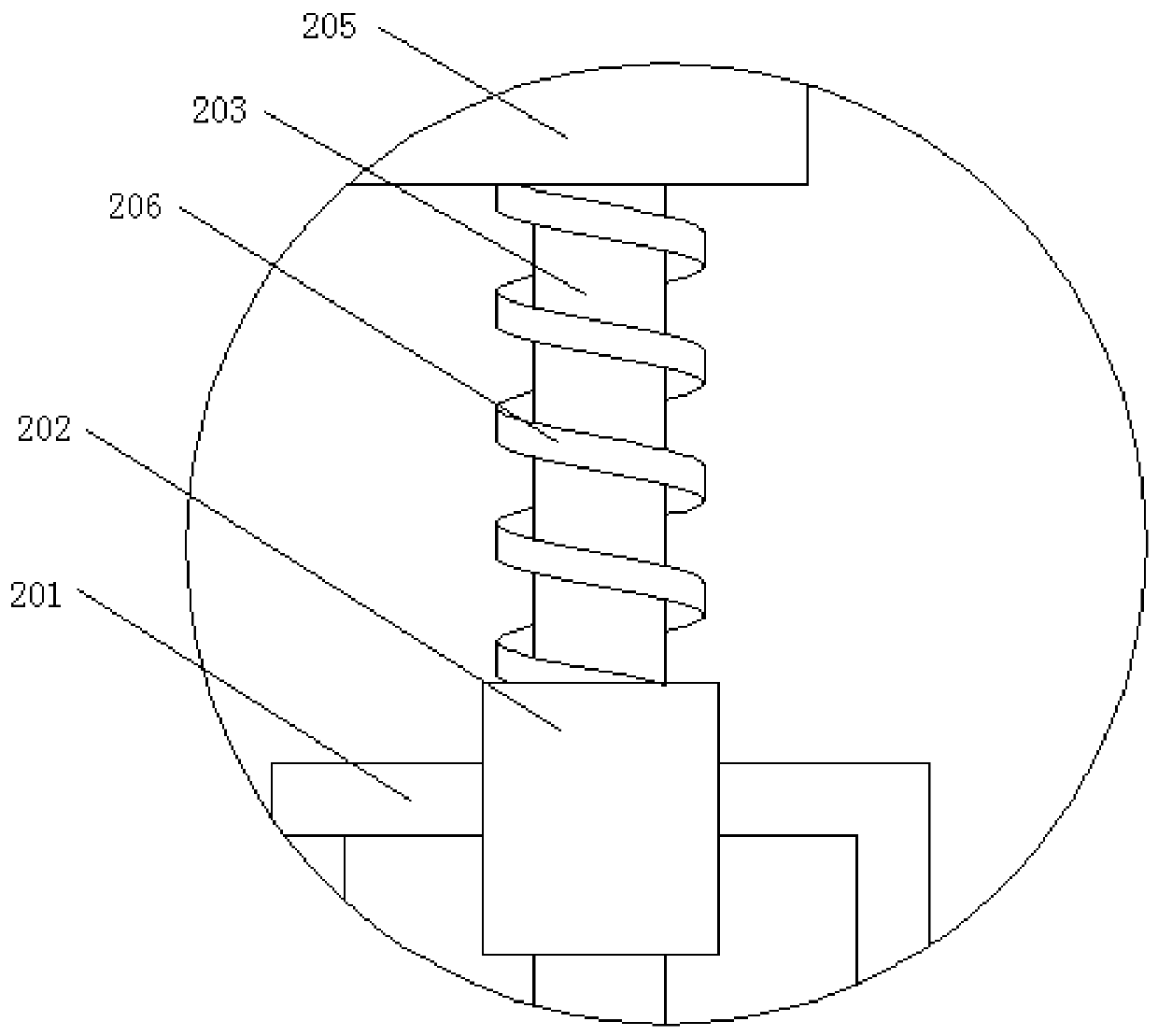

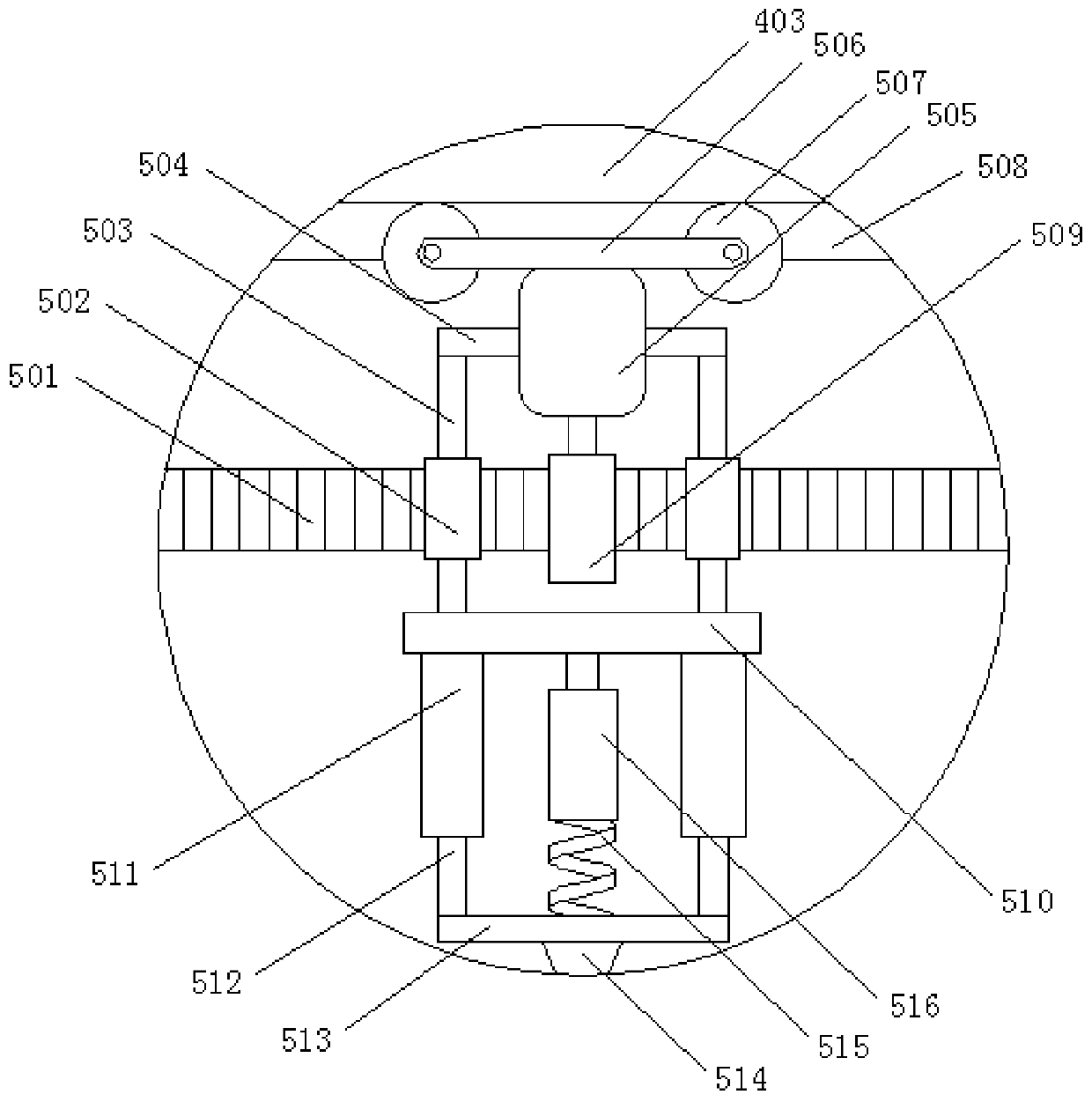

The invention provides an artificial woodcarving working platform, which belongs to the field of woodcarving craft auxiliary equipment. The artificial woodcarving working platform comprises a base, a lifting device, a rotary device, a working platform, a clamping device, a placing platform and a center support device, wherein the lower end of the center support device is fixedly connected to the left end of the base; the lifting device is fixedly connected to the upper end of the base; the rotary device is fixedly connected to the upper end of the lifting device; the working platform is installed on the upper end of the rotary device; the working platform is horizontally rotated along with the rotary device; and the lower end surface of the placing platform is installed in the center of the upper end surface of the working platform. According to the artificial woodcarving working platform, woodcarving materials are fixedly clamped by the clamping device, the placing platform and the center support shaft, and the working platform can be rotated for 360 degrees by the rotary device of the platform, so that carving is facilitated, the efficiency is high, and the structure is simple.

Owner:兴业县金达木材有限公司

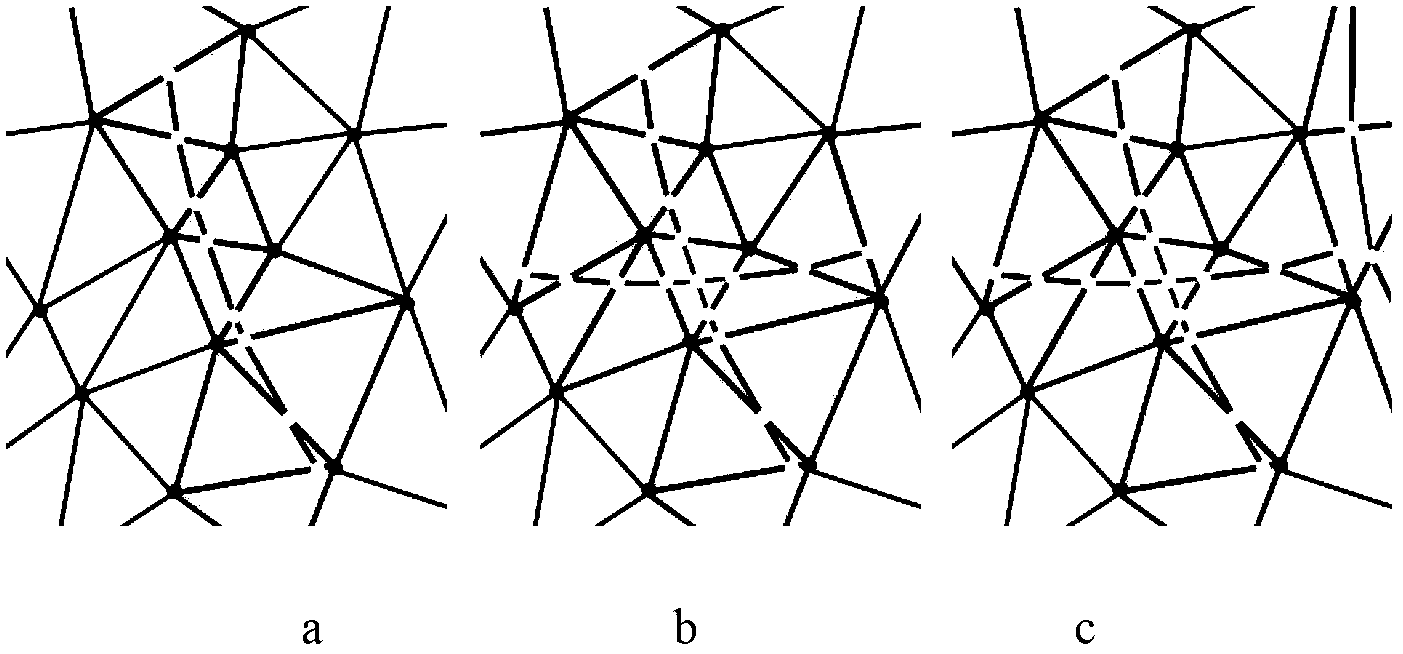

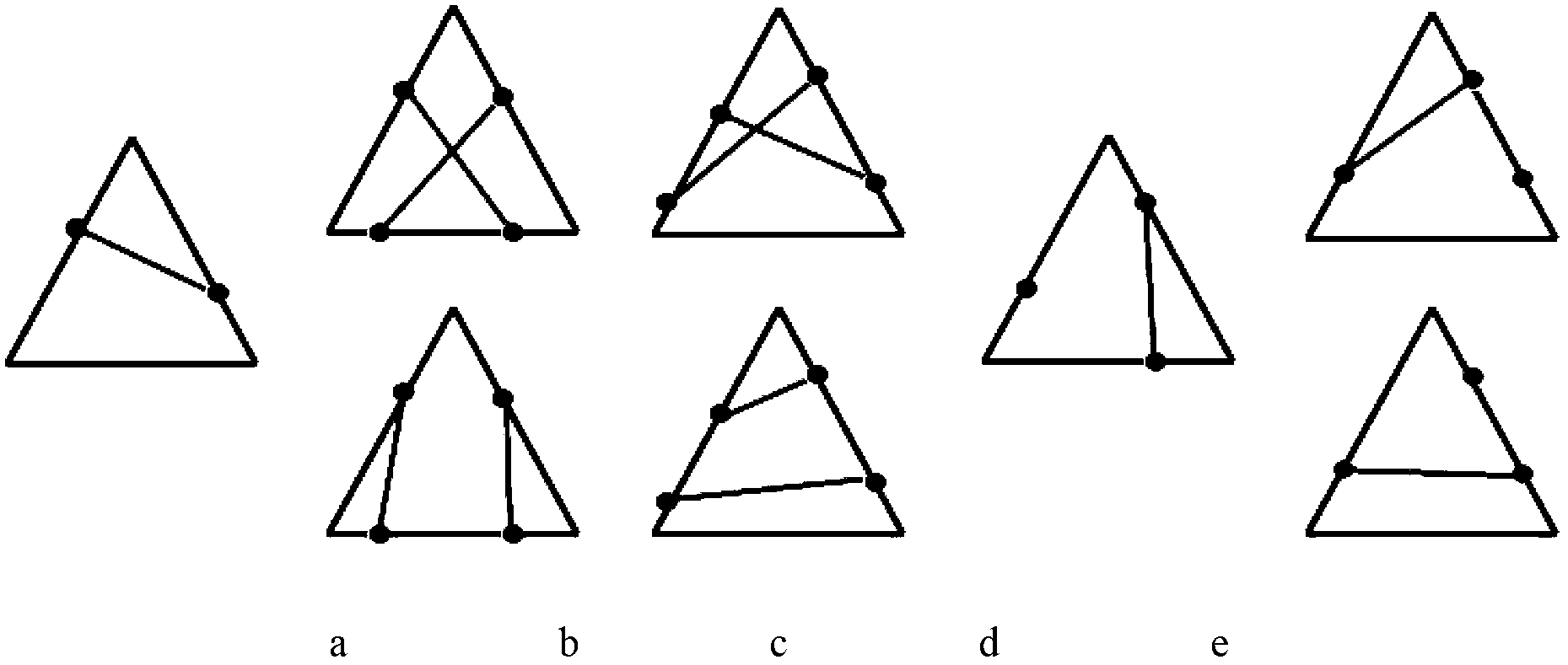

Three-dimensional carving method based on hand-drawn lines

The invention relates to a three-dimensional carving method based on hand-drawn lines. The method comprises the following four steps: 1) drawing a plurality of hand-drawn lines on a three-dimensional model in a user interaction mode, determining the edge points, which a hand-drawn curve passes through, of the surface of the three-dimensional model through curve refining operation, removing triangular surface patches, which the hand-draw curve passes through, of a network model, triangulating the removed part into small triangular surface patches, and inserting the small triangular surface patches into the original network mode; 2) calculating the distance between vertexes on the three-dimensional model and a hand-draw line set; 3) calculating the translation distance and the translation direction of the vertexes of the three-dimensional model according to the width of a carving line selected by the user and an outline function; and 4) according to the translation distance and the translation direction of the vertexes of the three-dimensional model, translating the vertexes on the three-dimensional model to achieve the three-dimensional carving effect of the network model, wherein the distance between the vertexes and the hand-drawn line set does not exceed the width of the given carving line. The three-dimensional carving method based on the hand-drawn lines provided by the invention is simple to operate, efficient and quick and is convenient to carve.

Owner:ZHEJIANG UNIV OF TECH

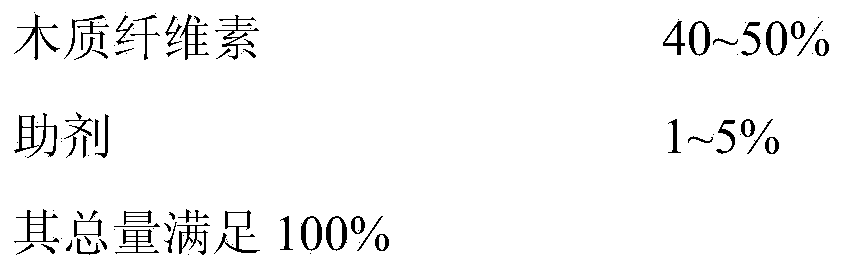

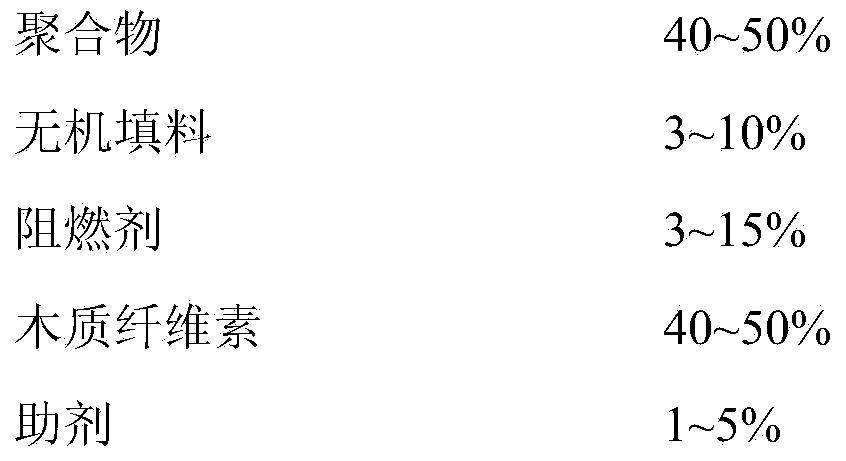

Wood-plastic composite with flame-retardation effect and preparation method

InactiveCN104312000AImprove flame retardant performanceImprove mechanical propertiesCelluloseFiltration

The invention relates to a wood-plastic composite with a flame-retardation effect and a preparation method. The wood-plastic composite is prepared from the following components in percent by weight: 40 to 50 percent of polymer, 3 to 10 percent of inorganic packing, 3 to 15 percent of a fire retardant, 40 to 50 percent of lignocellulose and 1 to 5 percent of other assistants. The inorganic packing is subjected to extraction and filtration after being processed by a silane coupling agent; in a drying oven, the temperature of 80 DEG C is kept and the constant temperature is kept for 2 to 5 hours; the fire retardant and the lignocellulose are stirred for 5 to 10min at a temperature of 100 to 120 DEG C in a high-speed kneading machine with a heating jacket; after the obtained product is cooled to the temperature of 60 DEG C, the inorganic packing, the assistants and the polymer which are processed by the coupling agent are added; the raw materials are mixed for 2 to 10min in a high-speed mixer; the obtained uniform materials are added into a double-screw extruder to carry out extrusion and pelletizing. The wood-plastic composite with the flame-retardation effect, which is prepared by the preparation method disclosed by the invention, has good flame retardation and adopts a simple process.

Owner:EAST CHINA UNIV OF SCI & TECH

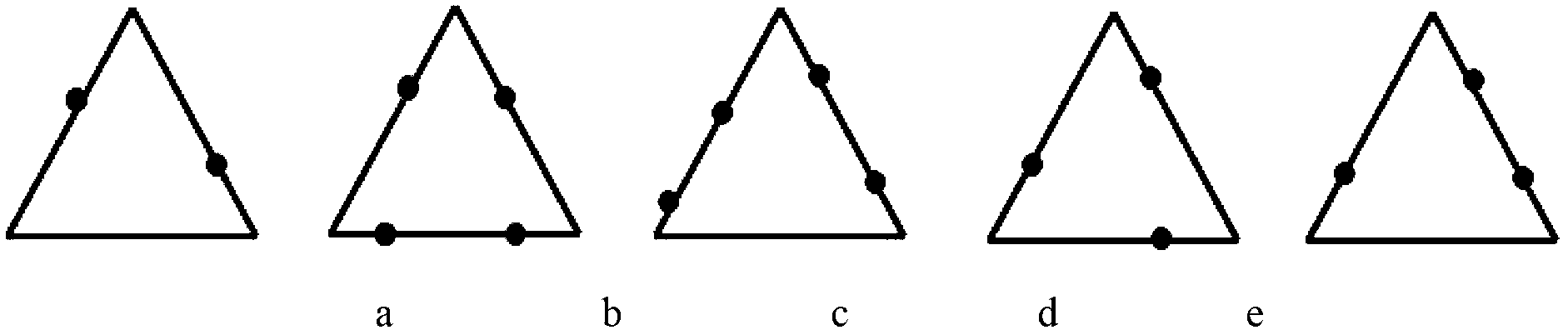

Method for engraving three-dimensional model based on line pattern

The invention discloses a method for engraving a three-dimensional model based on a line pattern. The method for engraving the three-dimensional model based on the line pattern comprises the steps that the two-dimensional line pattern needing to be engraved by a user is input, the input pattern is pre-processed according to a method, and the line center of the input line pattern is extracted by conducting edge shrinkage to serve as an engraving contour line; for different types of three-dimensional models, parameterization is conducted on areas to be engraved on the surface of the model; the obtained two-dimensional engraving contour line is discretized and is mapped into discrete engraving lines on the surface of the three-dimensional model through parameterized mapping; the distances between the peak to be engraved on the three-dimensional model and the three-dimensional engraving lines are calculated, the horizontally-moving distance and the direction of the peak of the area to be engraved are determined according to an engraving function, and the peak to be engraved is moved horizontally, so that the three-dimensional engraving effect of the model is achieved.

Owner:ZHEJIANG UNIV OF TECH

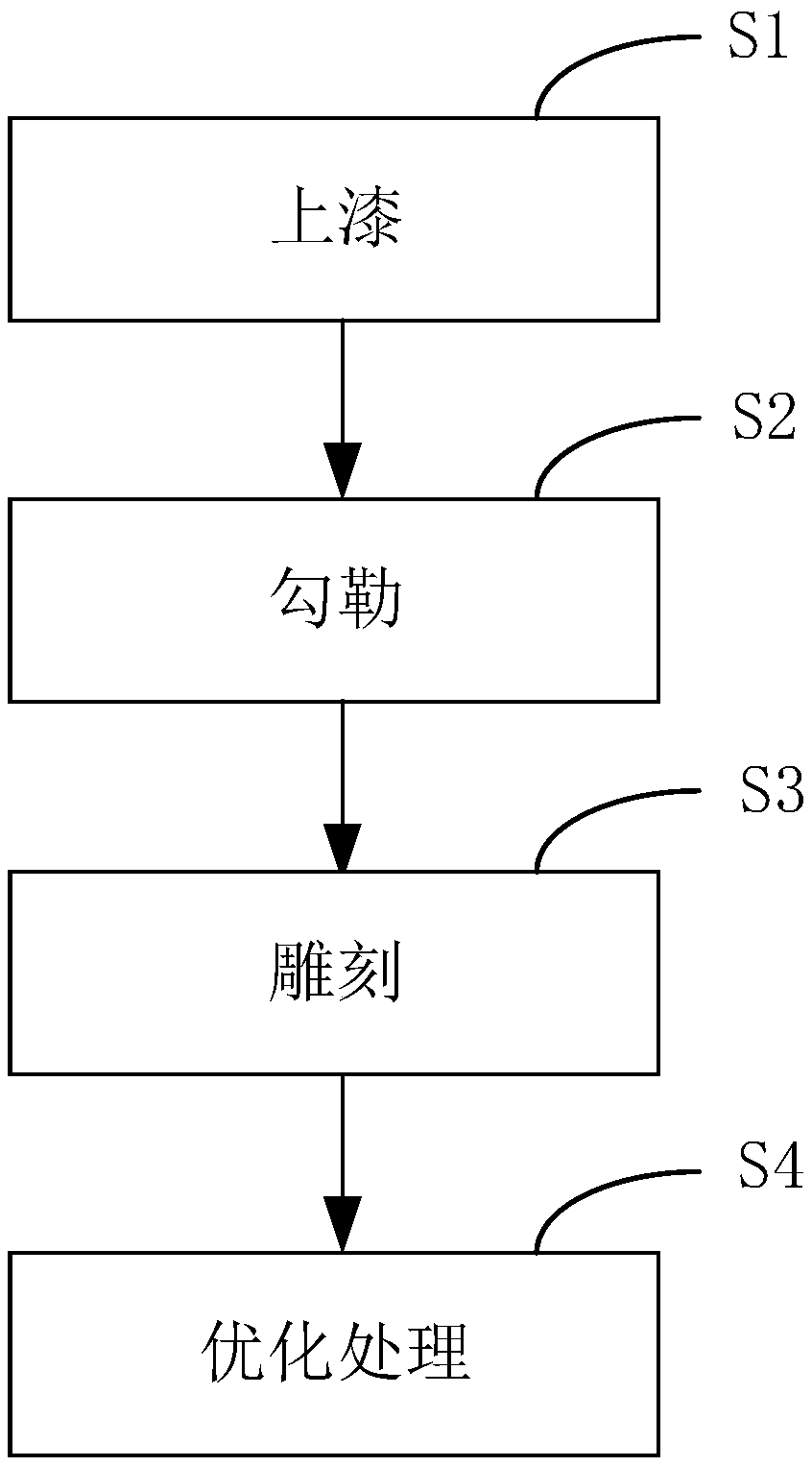

Colorful wood shadow sculpture and manufacture method

ActiveCN108973501AHigh artistic valueStrong three-dimensional senseDecorative surface effectsSpecial ornamental structuresColor depthMaterials science

The invention relates to the technical field of artware sculptures, in particular to a colorful wood shadow sculpture and a manufacture method. The manufacture method comprises the following steps: lacquering, drawing the outline, sculpturing and carrying out optimal processing. The step of lacquering is characterized in that the plate surface of a plate material is covered with a paint layer, andthe paint layer gradually darkens from inside to outside; the step of drawing the outline is characterized in that the outline of a pattern is drawn on the surface of the paint layer; the step of sculpturing is characterized in that a graver is used for sculpturing the surface of the paint layer according to the outline, the sculpturing depth of the graver is regulated according to the color depth of the pattern to realize different light and shade effects, different sculpturing angles are applied to the lines of the pattern to realize various different reflection effects of ray; the step ofoptimal processing is characterized in that luminance, shade and texture are optimized. According to the arrangement, the manufacture method for the colorful wood shadow sculpture is simple, is easy in selecting materials and is favorable for reducing cost and improving manufacture efficiency. In addition, the colorful wood shadow sculpture can show an obvious three-dimensional effect and strong stereoscopic impression and is favorable for improving the own artistic value of artware.

Owner:邢志鹏

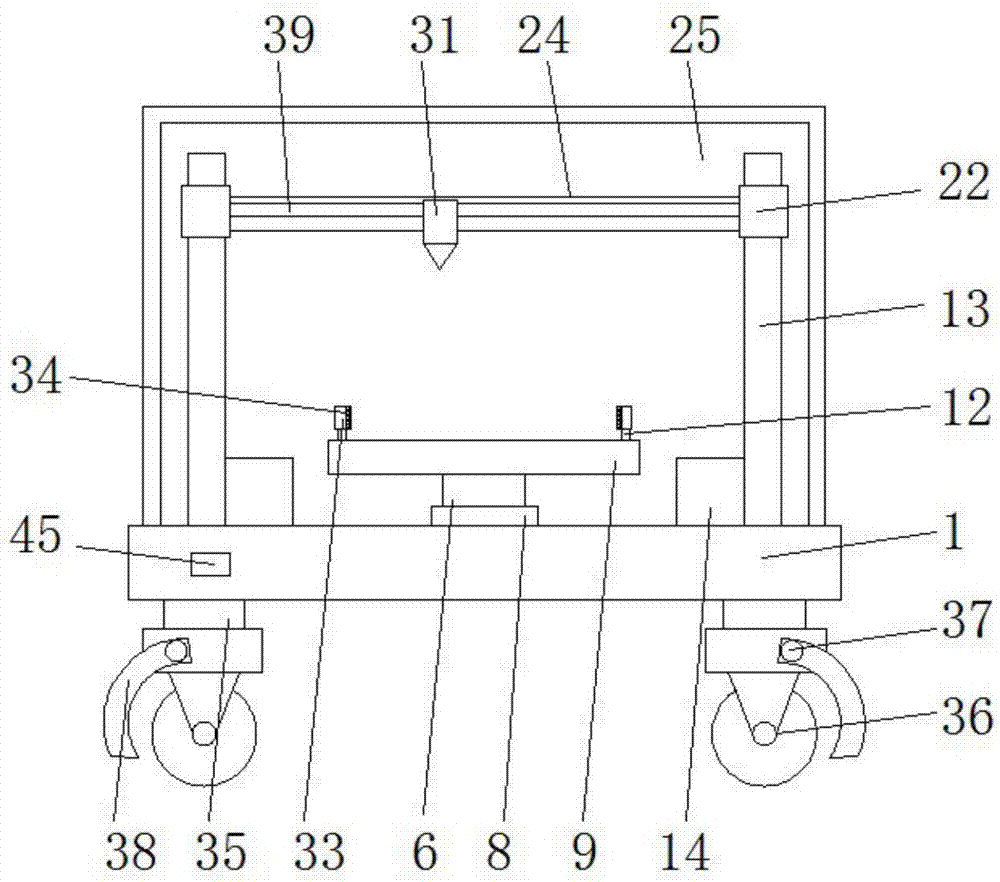

Small stone sculpture laser-engraving equipment convenient to use

InactiveCN107486631AEasy to useEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelStone carving

The invention provides small stone sculpture laser-engraving equipment convenient to use, relating to the field of laser engraving. The small stone sculpture laser-engraving equipment comprises a fixing seat, wherein a base is fixedly connected to the bottom part of the inner wall of the fixing seat; a first motor is fixedly connected to the top part of the base; and the output end of the first motor is fixedly connected with a driving wheel seat. According to the small stone sculpture laser-engraving equipment provided by the invention, the effect of driving a placement disc on a rotating rod to rotate is achieved by matching of a driving wheel, a driven wheel and a first bearing seat under the rotation of the first motor, so that the effect of rotating stones arranged on the placement disc and needing to be engraved is achieved, the stone engraving becomes simpler and is easy to operate, the all-directional no-dead-angle rotary engraving is achieved when the stones are engraved, and the problems of slow engraving work, low efficiency and difficult operation caused by inconvenience in use of the laser-engraving equipment when the small stone sculptures are engraved through conventional methods are solved.

Owner:SUZHOU MIKE LASER TECH SERVICE CO LTD

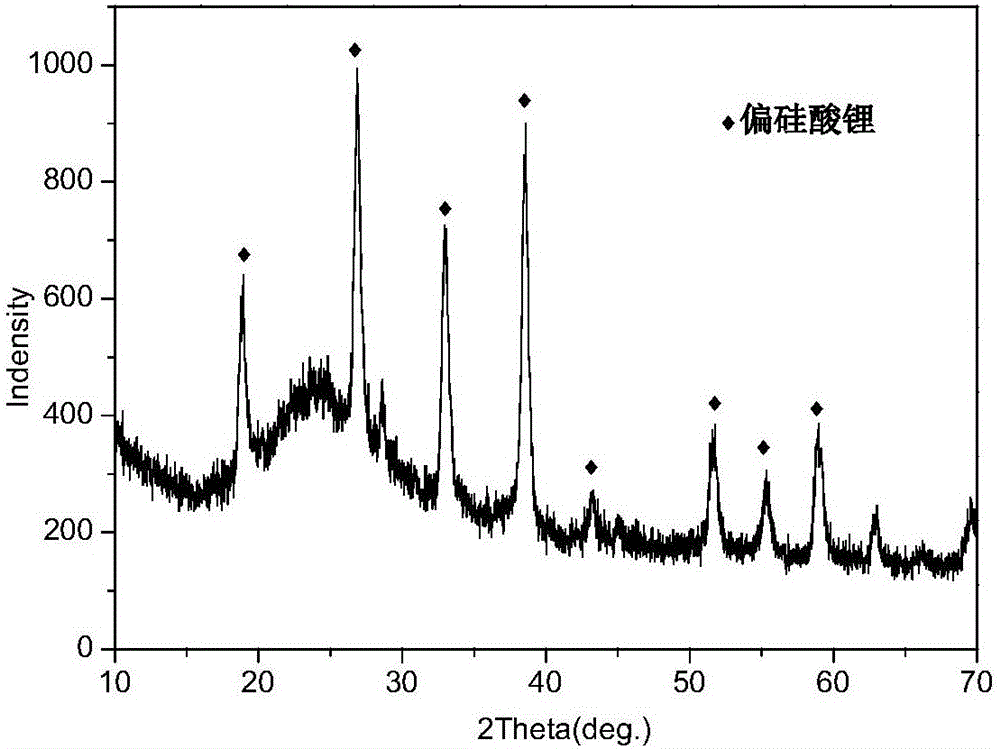

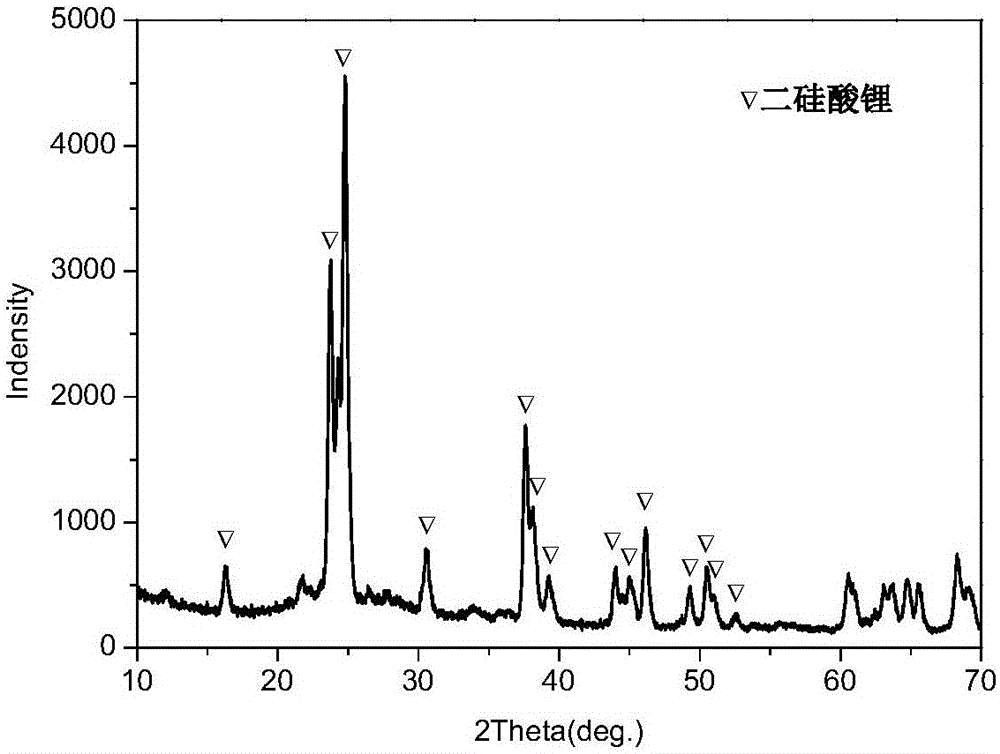

Imitated Hetian jade white glass-ceramics suitable for casting and then CAD processing and preparation method thereof

The invention relates to imitated Hetian jade white glass-ceramics suitable for casting and then CAD processing and a preparation method thereof and belongs to the field of glass-ceramics. The imitated Hetian jade white glass-ceramics comprise, by mass, 60-75% of SiO2, 0.5-7% of Al2O3, 0.5-8% of P2O5, 8-20% of Li2O, 1-8% of K2O, 0-5% of B2O3, a stabilizer and an additive, wherein a mole ratio of SiO2 to Li2O is 1.7 to 3.0. The preparation method comprises adjusting heat treatment and temperature schedule to control a growth process of lithium disilicate grains which are rod-shaped crossed aggregates and have three-dimensional interlacing and grain interlocking structures and high hardness and breaking strength.

Owner:DALIAN POLYTECHNIC UNIVERSITY

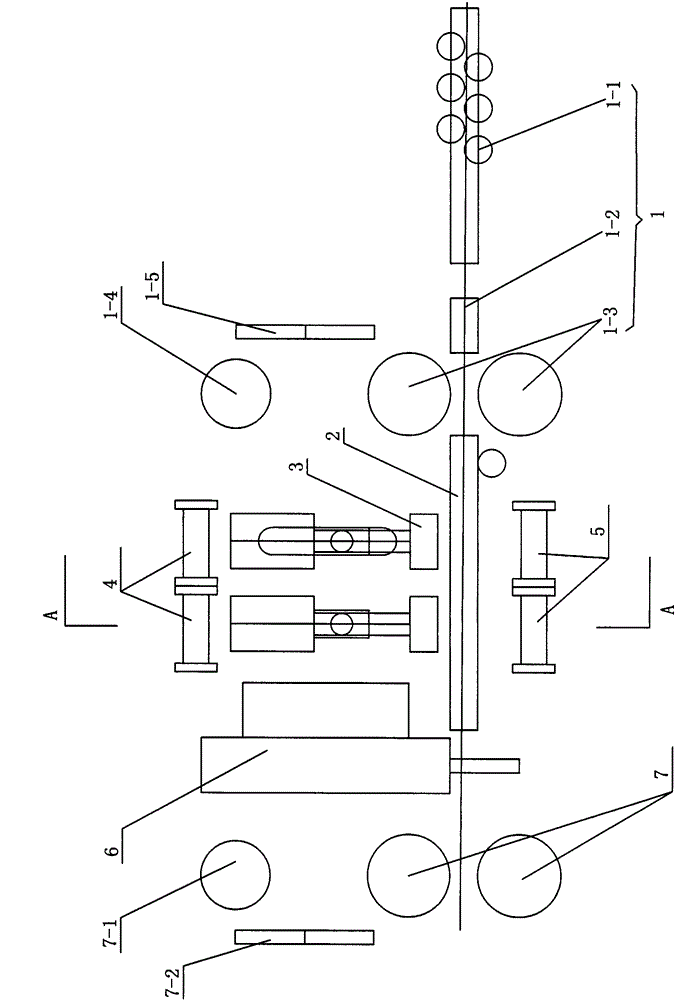

Cable-cutting and printing all-in-one machine and operating method thereof

InactiveCN105006305AReduce usage costsReduce manufacturing costsConductor/cable markingEngineeringElectric wire

The invention relates to a cable-cutting and printing all-in-one machine and an operating method thereof. The cable-cutting and printing all-in-one machine comprises: a material feeding mechanism for transporting a cable, a printing table arranged at the rear end of the material feeding mechanism, engraving modules capable of being moved up and down and printing ribbon rolling mechanisms, which are arranged above the printing table, printing ribbon rolling mechanisms arranged below the printing table, and a cable cutting mechanism, for cutting the cable, arranged at the rear end of the printing table. Printing the end part of the cable is performed by adopting the engraving modules, and the cable isn't wasted. The printing function is provided at the edge of a knife rest of the cable-cutting machine, so that the efficiency is improved, and the use and manufacture cost of materials is reduced. A manner that a number tube or a shrinkable tube sleeves the cable for distinguishing types of cables is avoided. Moreover, V-shaped grooves, arranged on the printing table and distributed along the movement direction of the cable are used for limiting the position of the cable and benefit accurate positioning.

Owner:张晓波

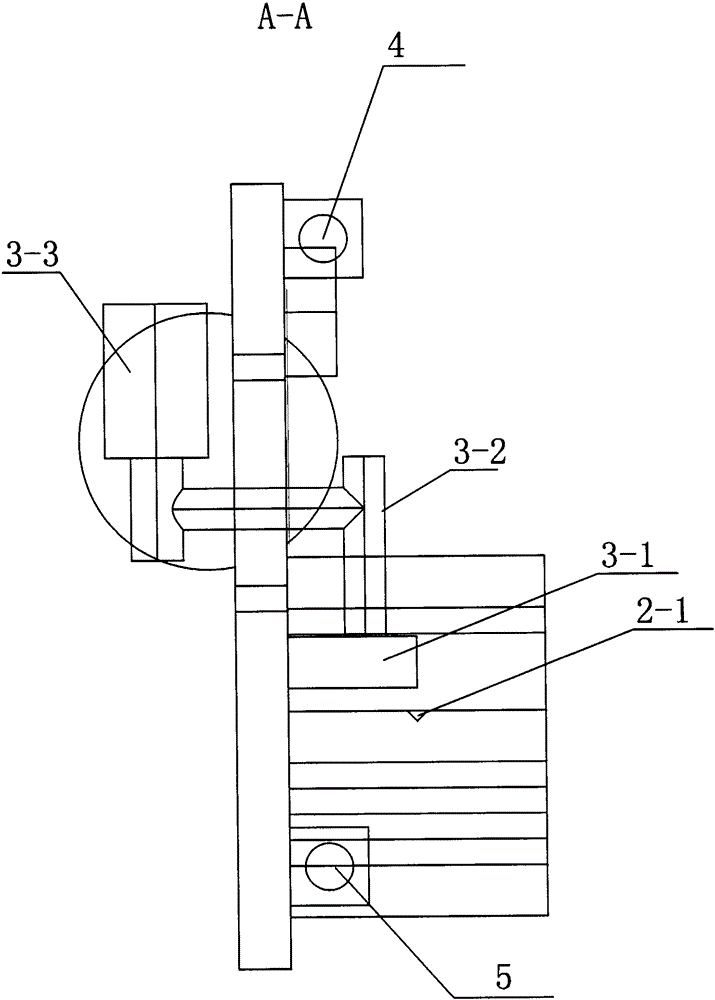

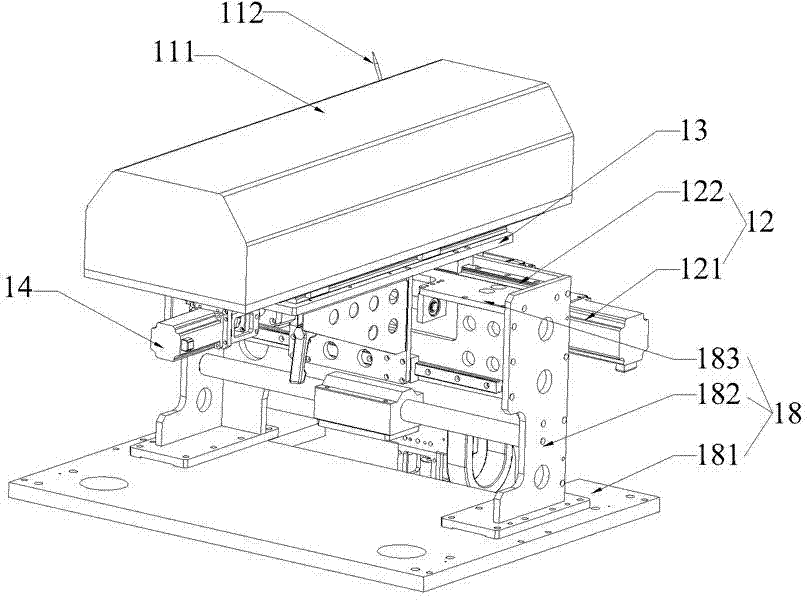

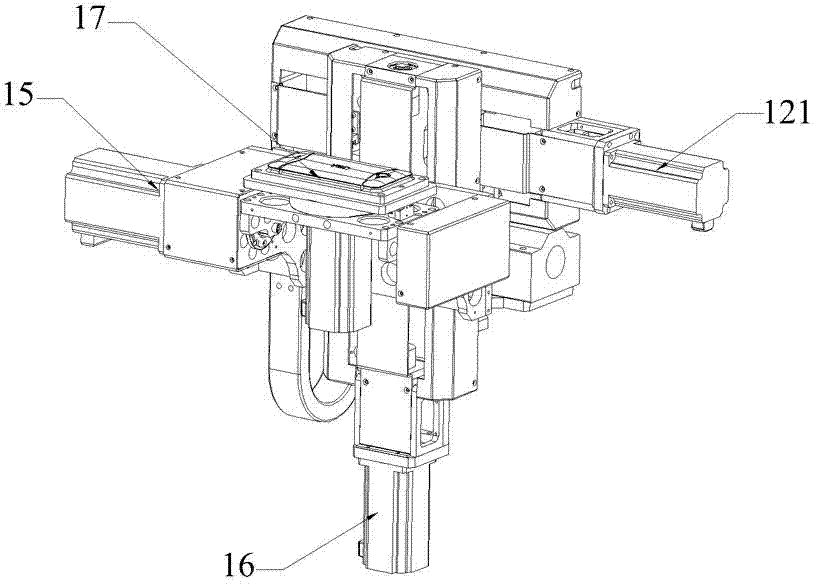

Profiling laser engraving machine and 3D laser engraving method

ActiveCN104493364ARich diversityMeet 3D SculptingLaser beam welding apparatusLaser Device ComponentLaser engraving

The invention discloses a profiling laser engraving machine and a 3D laser engraving method. The profiling laser engraving machine comprises a laser device component, an X-axis horizontal moving driving part, a connecting plate, a Y-axis horizontal moving driving part, an X-axis rotating driving part, a Y-axis rotating driving part, a clamp platform and a truss. The X-axis horizontal moving driving part is fixed to the truss and is connected with the connecting plate; the Y-axis horizontal moving driving part is fixed to the connecting plate and is connected with the laser device component; the X-axis rotating driving part and the Y-axis rotating driving part are fixed to the truss; the X-axis rotating driving part is in driving connection with the clamp platform; and the Y-axis rotating driving part is in driving connection with the clamp platform. According to the profiling laser engraving machine, through one-time clamping, engraving or cutting of five faces of a part can be completed, and different patterns, figures, texts and other contents can be engraved or cut on the different faces; and engraving is more convenient and rapid, working efficiency is higher, and the condition that only the planes can be engraved is changed

Owner:SHENZHEN HADESHENG PRECISION TECH

Wooden furniture polishing and carving machine

InactiveCN108747665AEfficient collectionEasy to clean and maintainProfiling/shaping machinesBark-zones/chip/dust/waste removalPulp and paper industryCarving

The invention discloses a wooden furniture polishing and carving machine. The wooden furniture polishing and carving machine structurally comprises a polishing and carving machine body, a slide rail,a control panel, dust collectors, a polishing roller and a cutting hole, wherein the slide rail is arranged on the top of the polishing and carving machine body; rolling crawler belts are arranged atthe two ends of the slide rail; the bottom of a control device is connected with a laser carving device; the two sides of the laser carving device are both provided with locating and monitoring devices; the dust collectors are arranged on the two sides of the polishing and carving machine body; the cutting hole is formed in the middle of the bottom of the polishing and carving machine body; a cutting knife is arranged at the bottom of the cutting hole; the front and rear sides of the bottom of the polishing and carving machine body are both provided with connecting plates; the polishing rolleris connected to the top of a first connecting rack. The wooden furniture polishing and carving machine drives fans to conduct high-efficiency dust suction through motors, is more accurate in carvingand processing, high in automatic performance, capable of rising and dropping to conduct cutting, more convenient to use and reasonable in design and facilitates polishing front and back during transportation.

Owner:黄文才

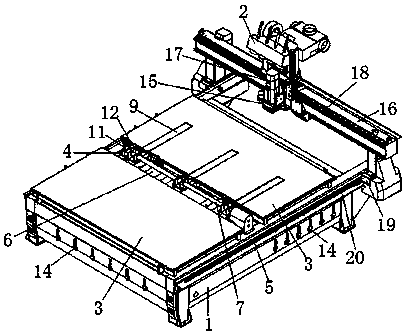

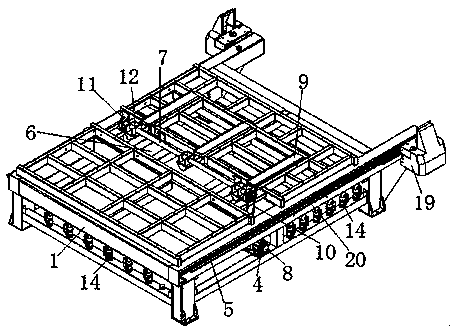

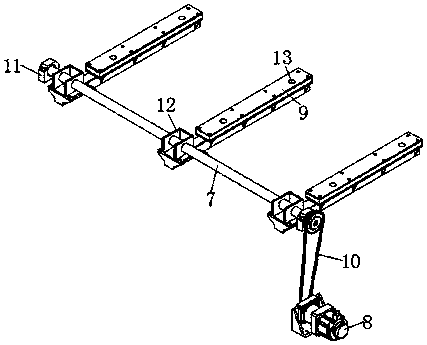

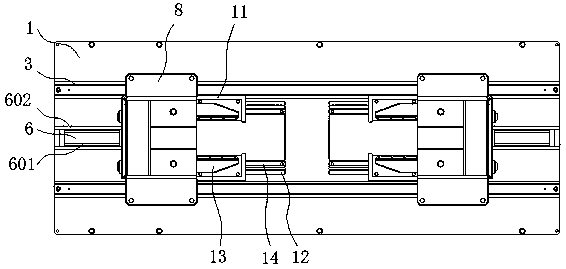

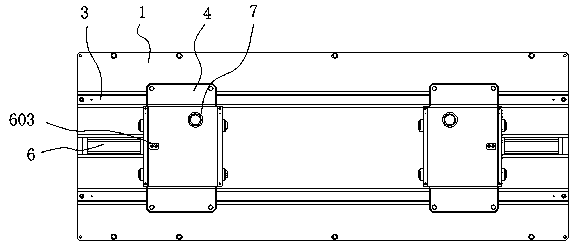

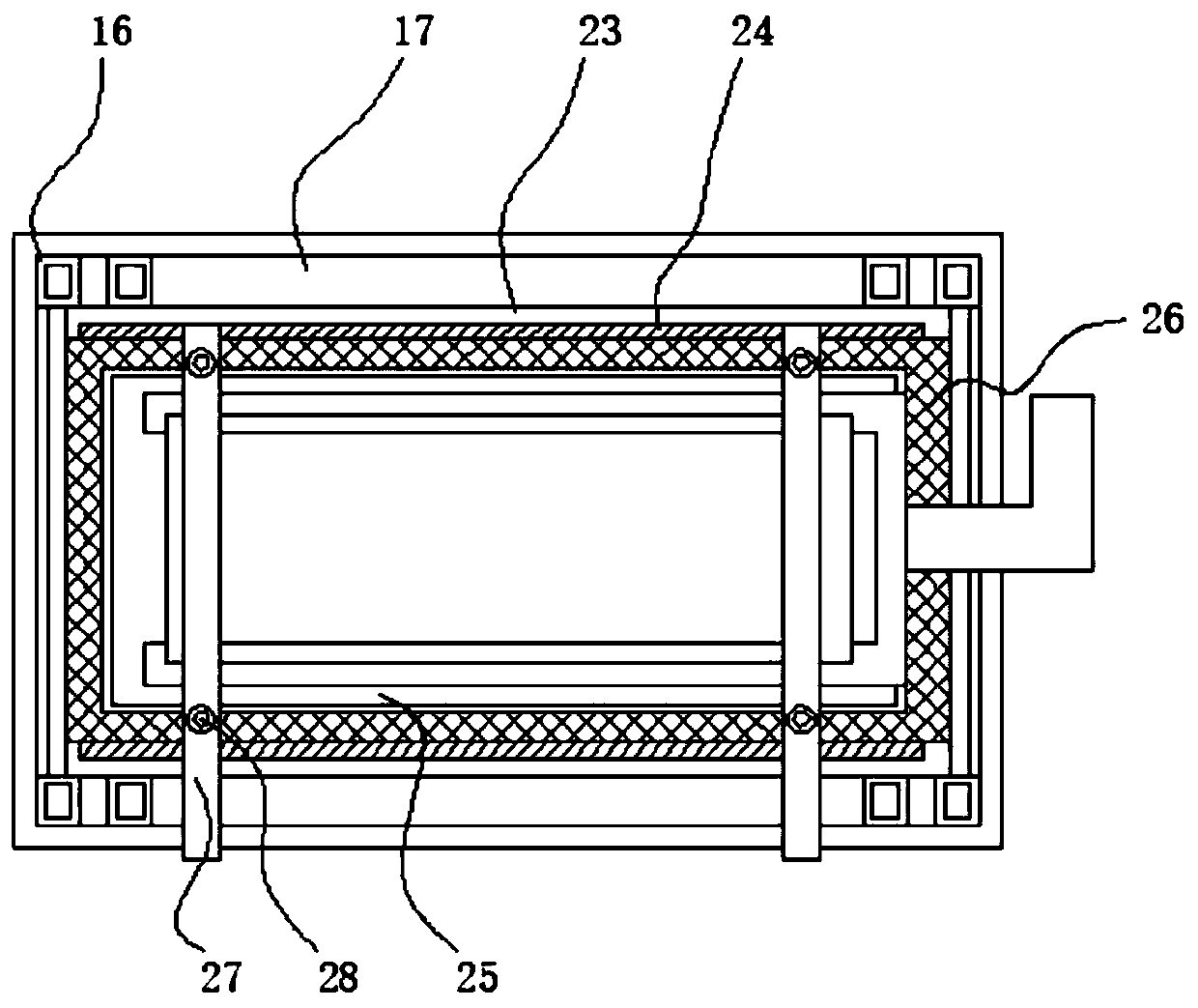

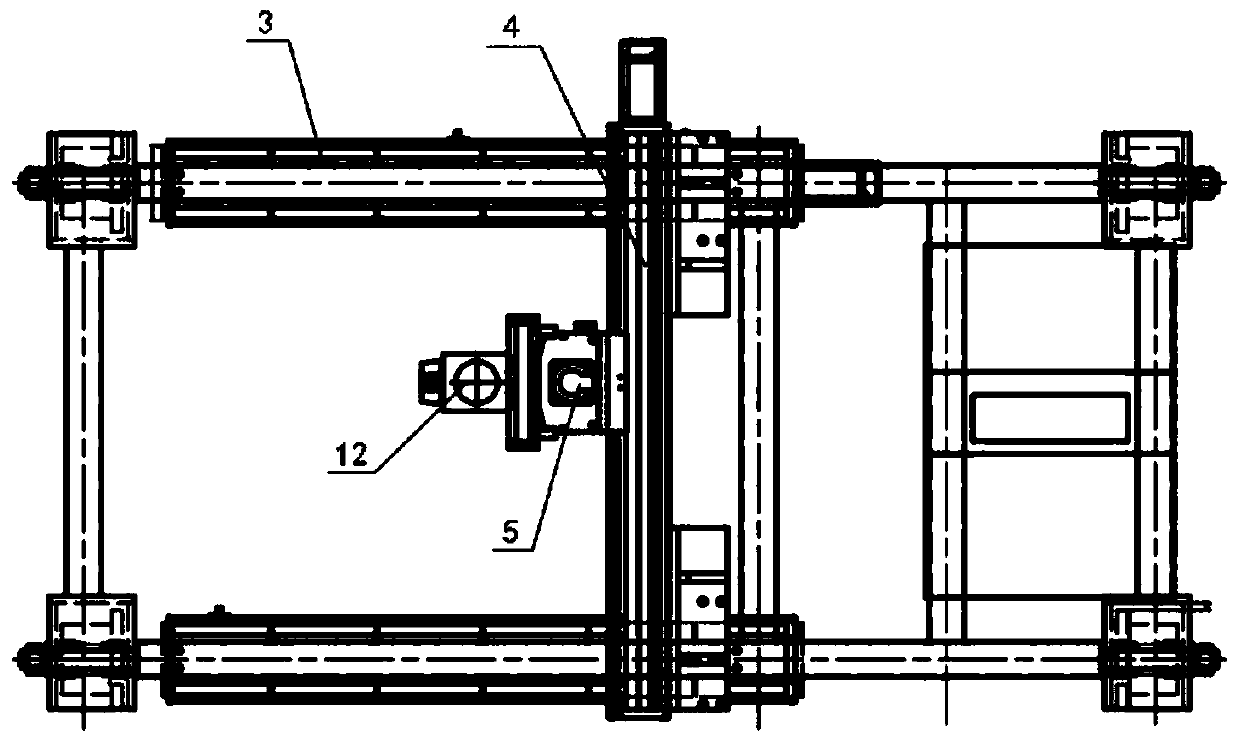

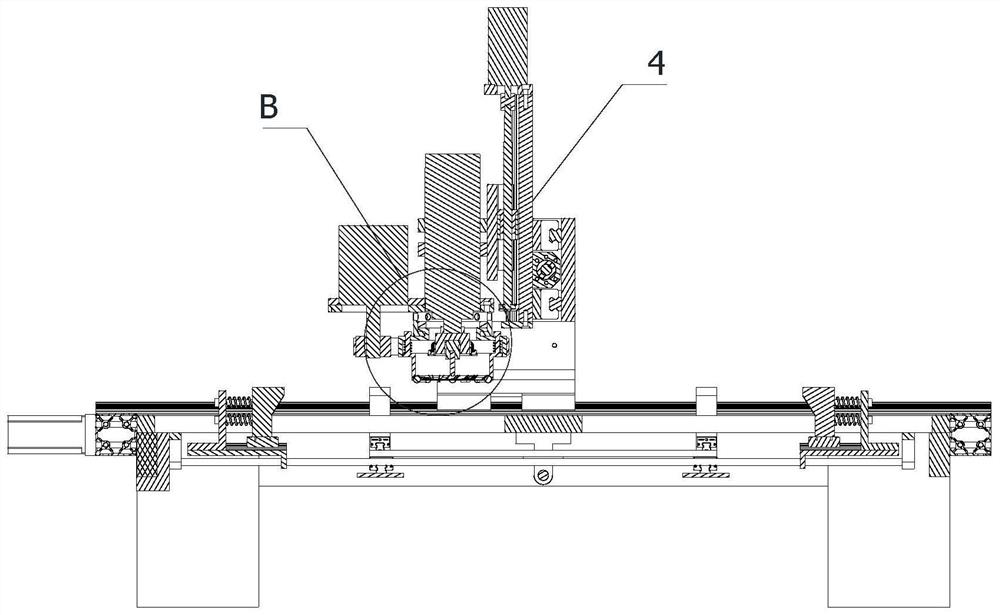

Fully-automatic double-station board turnover device

The invention relates to the field of board turnover devices, in particular to a fully-automatic double-station board turnover device. The fully-automatic double-station board turnover device comprises a board turnover fixing base, a carving machine body and a board turnover unit used for material turnover, wherein sliding devices are arranged on the two sides of the board turnover fixing base, the carving machine body is movably arranged on the board turnover fixing base through the sliding devices, a mounting clearance is arranged in the middle of the board turnover fixing base, and the board turnover unit is arranged in the mounting clearance; and materials are arranged on the two sides of the mounting clearance and located within the rotating radius of the board turnover unit. According to the fully-automatic double-station board turnover device, when people need to process the back side of a board after processing the front side of the board, the board turnover unit can turn the original board directly over to another working table top, the back side of the board can be quickly processed. I the board only needs to be processed on one side, a machine can process two stations inturn, so that the time for the machine waiting for a worker to clamp the materials is saved.

Owner:GUANGZHOU SANTUO METAL PROCESSING MACHINERY CO LTD

Manufacturing process of manually carved furniture

InactiveCN104589452AResilience damageImprove toughnessWood working apparatusPulp and paper industryCarving

The invention provides a manufacturing process of manually carved furniture. The manufacturing process of the manually carved furniture includes the steps of material selecting, cutting, stewing, steaming, drying, carving, grinding, gluing and painting. Peeled wood is stewed, the tenacity of the wood is softened in a stewing mode after temperature rises soon, then the wood is easy to carve, and a steaming method is adopted to prevent the consequence that as damages to the tenacity of the wood are caused by too high stewing temperature, the wood can not be carved any more. Thus, the wood is cooled gradually, the cooling time is saved, the situation that when the wood is directly put in a colder environment, the wood is immediately destroyed is avoided, the tenacity of the wood is increased, the service life is prolonged, and the carving efficiency is improved.

Owner:ANHUI YOUSHUN WOOD IND

Preparation method for landscape bonsai

InactiveCN102248851AEasy access to raw materialsReduce manufacturing costSpecial ornamental structuresMossMaterials science

The invention discloses a preparation method for landscape bonsai, and relates to the field of agroforestry gardening. The preparation method is characterized by: mixing special-type vermiculite, carbonizing rice hull, cement, 108 glue, water and the like according to a ratio of 4:2.5:1:1:3r; or casting the resulting mixture into a die to form a artificial hill; or piling the resulting mixture to solidify into a artificial hill blank, followed by carrying out sculpturing to form the artificial hill. The landscape bonsai provided by the present invention has advantages of easy and available raw materials, low cost, and facilitates the growth of plants and mosses. In addition, the preparation method provided by the present invention can be applicable for preparation of the miniature bonsai or the large-scale landscape.

Owner:梁文荣

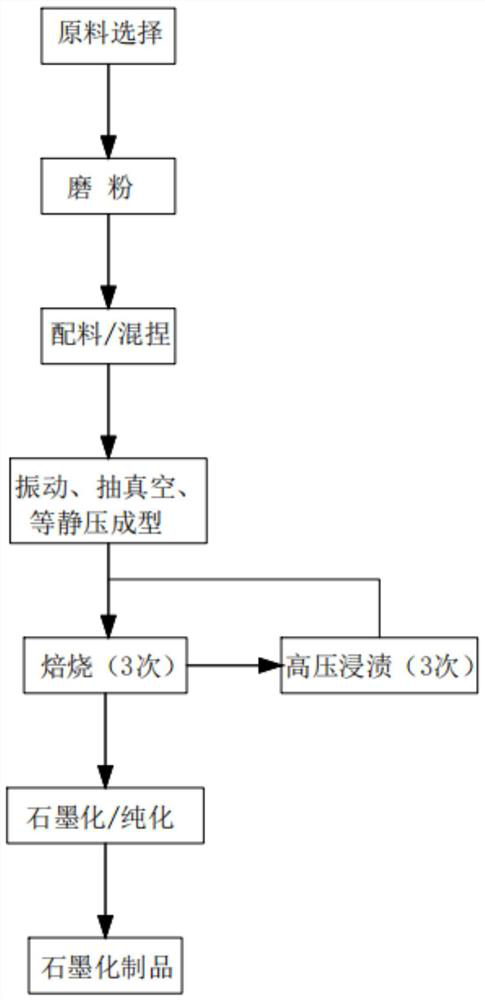

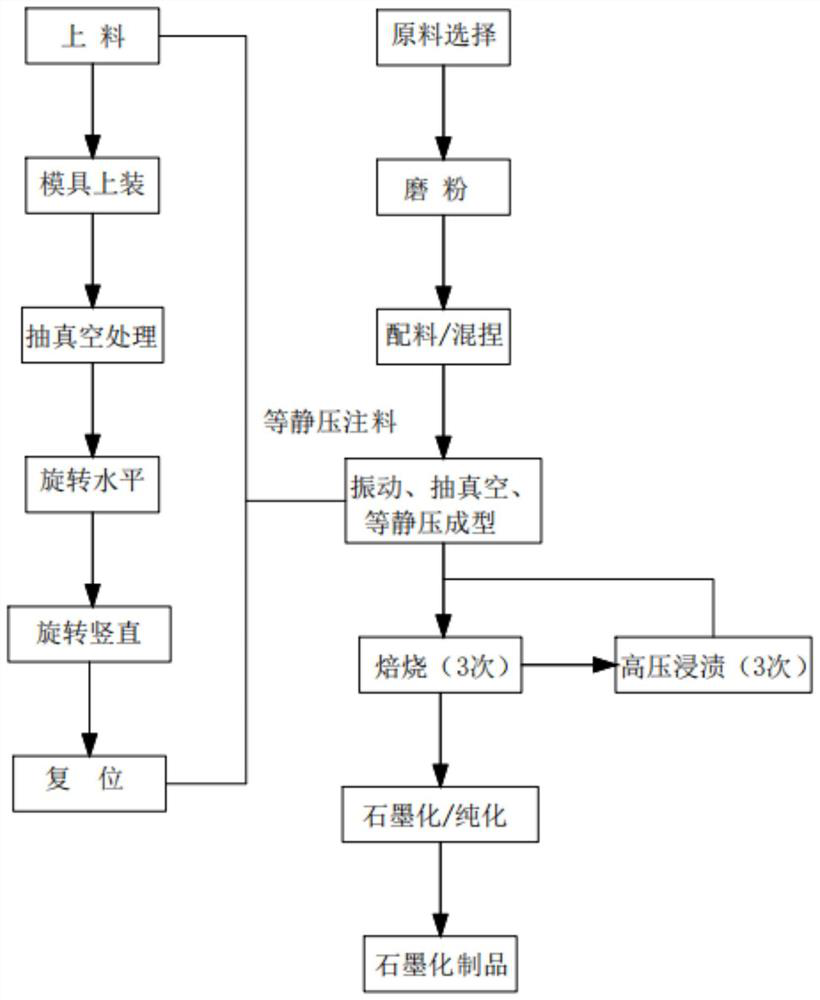

Isostatic graphite preparation process for craft product processing

The invention relates to the technical field of graphite craft product processing, in particular to an isostatic graphite preparation process for craft product processing. The process comprises the following steps: raw material selection, stirring, mixing and kneading, forming, primary roasting, primary dipping, secondary roasting, secondary dipping, tertiary roasting and graphitization / purification. Vibration and vacuumizing treatment are carried out on a kneaded and ground mixture before isostatic compaction, air among powder of the mixture is removed, so influence on the density of a formedgraphite product in the isostatic compaction process is avoided, the density of a formed graphite product is improved, the quality of the formed graphite product is improved, and the technical problem that graphite products cannot be applied to artware processing due to density factors is solved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

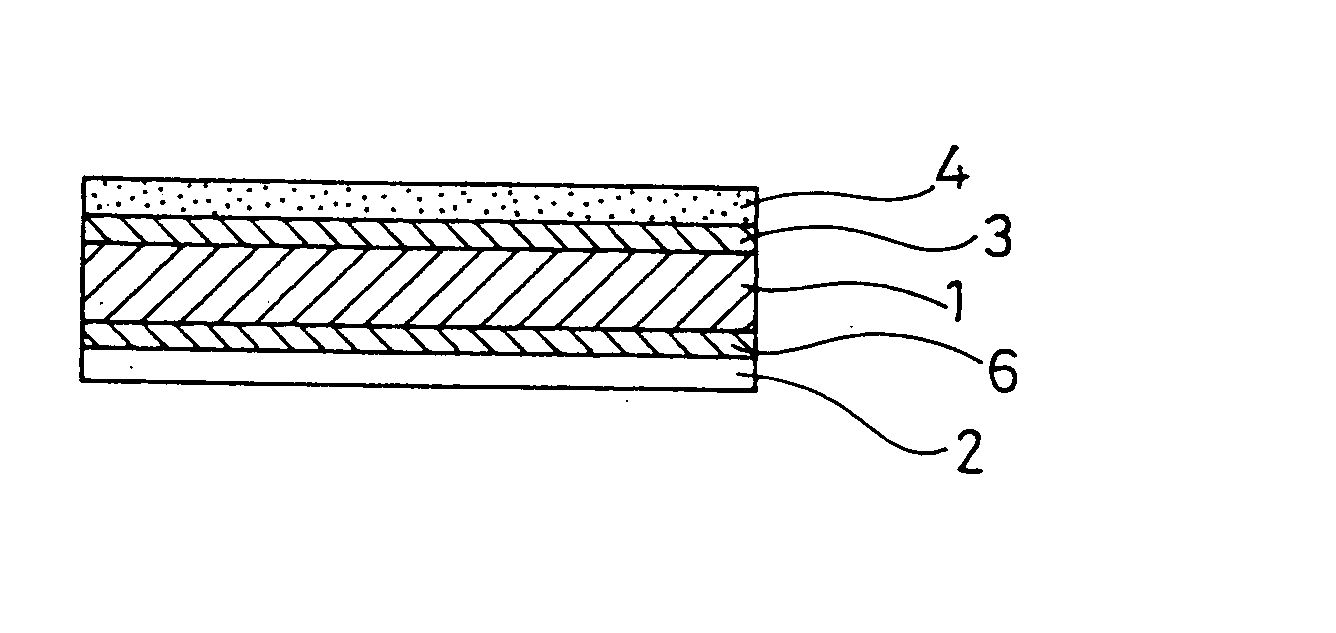

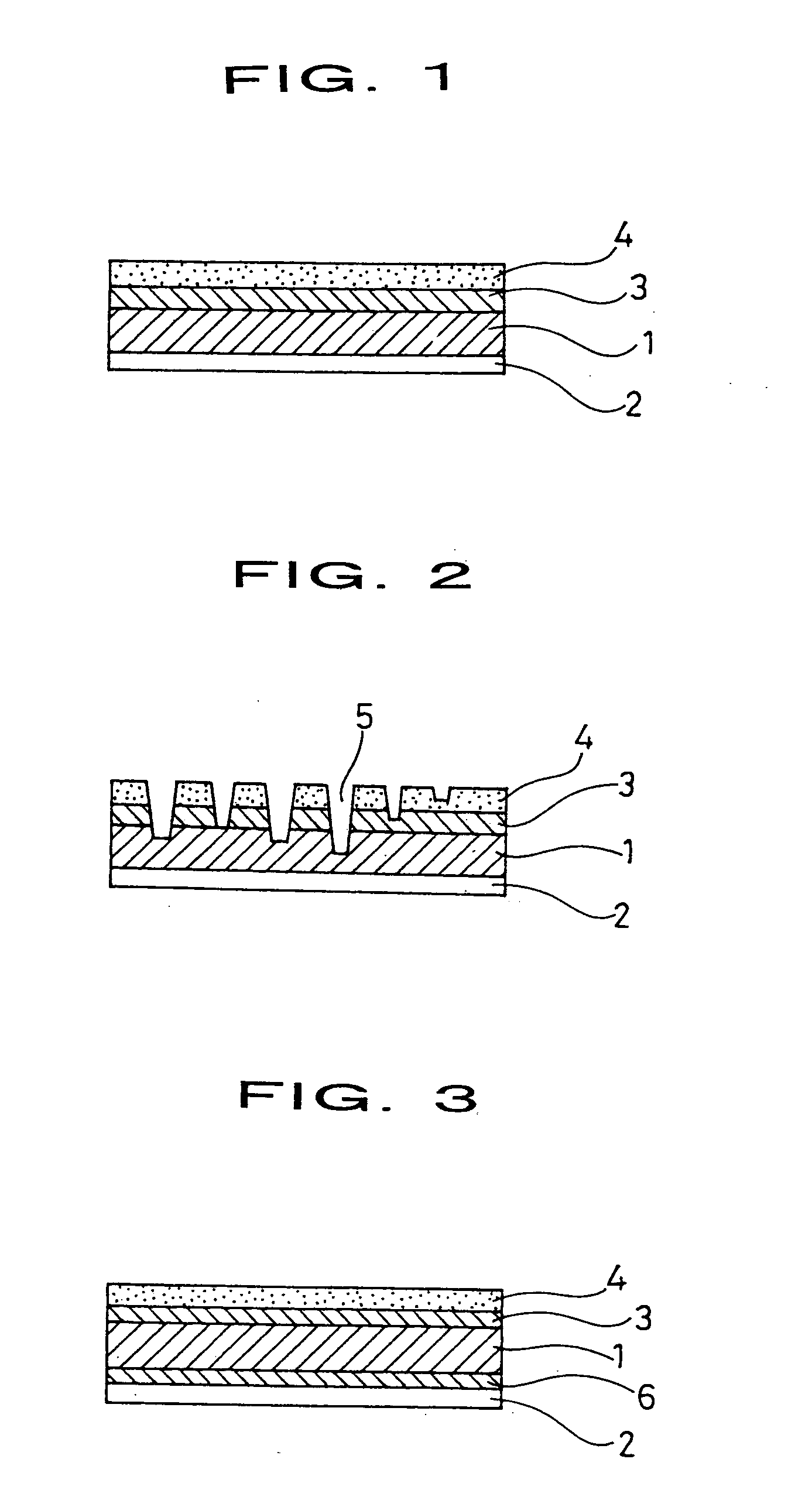

Engraving sheet and method of engraving the same

ActiveUS20040023009A1Not easy to tearDifficult to forgeMechanical working/deformationDecorative surface effectsHigh densityEngineering

An engraving sheet includes a support layer fabricated of biaxially oriented high-density polypropylene, and an engraving layer formed on the support layer and having an opacity of 40%. The engraving sheet is engraved from the engraving layer down to the support layer. The support layer is lower in opacity than the engraving layer with a difference of 20% or more between the opacity of the support layer and the opacity of the engraving layer. The engraving sheet allows a desired pattern, a photograph of the face of an individual, or the like to be engraved thereon, and presents a finger touch similar to that of paper, and is hard to be torn even after it is bound by a sewing machine or a stapler.

Owner:SUZUKI CO LTD Y

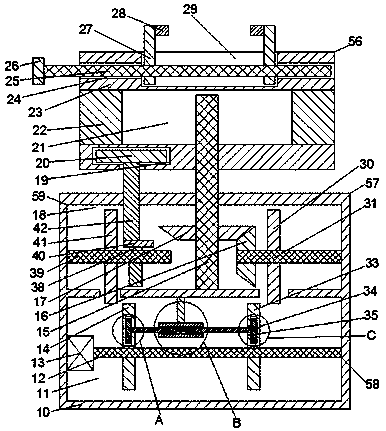

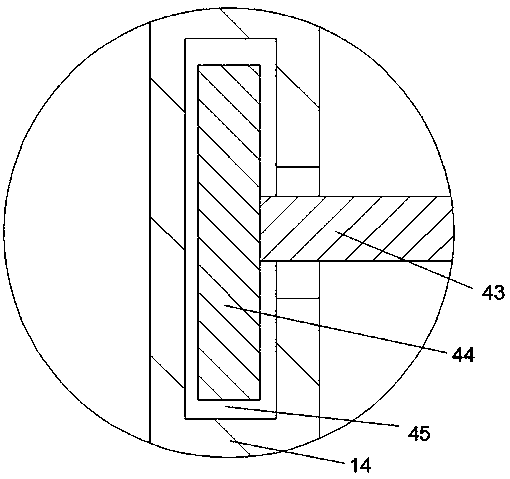

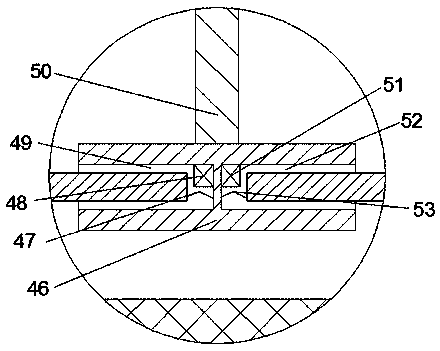

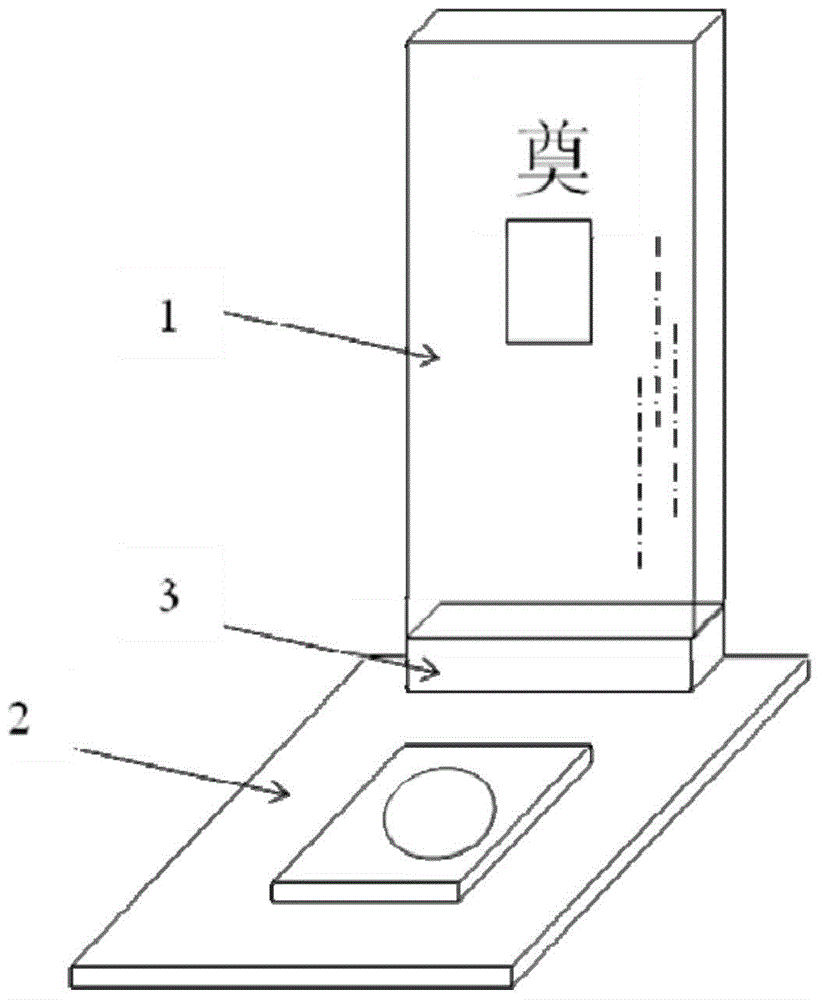

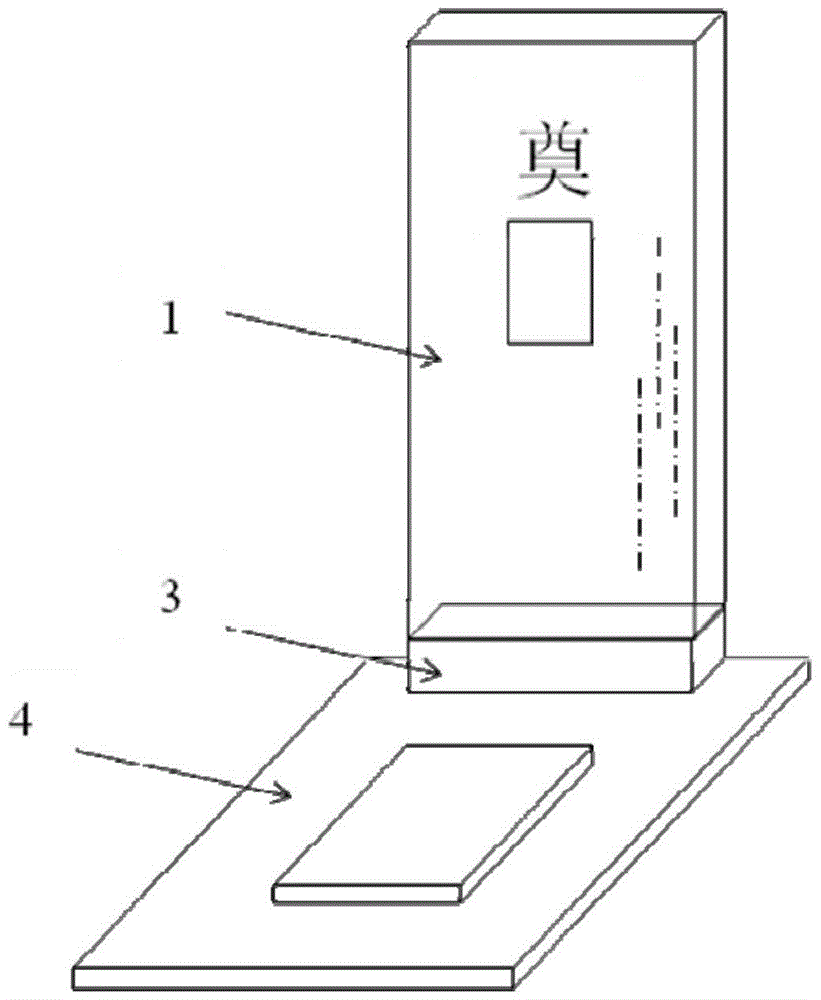

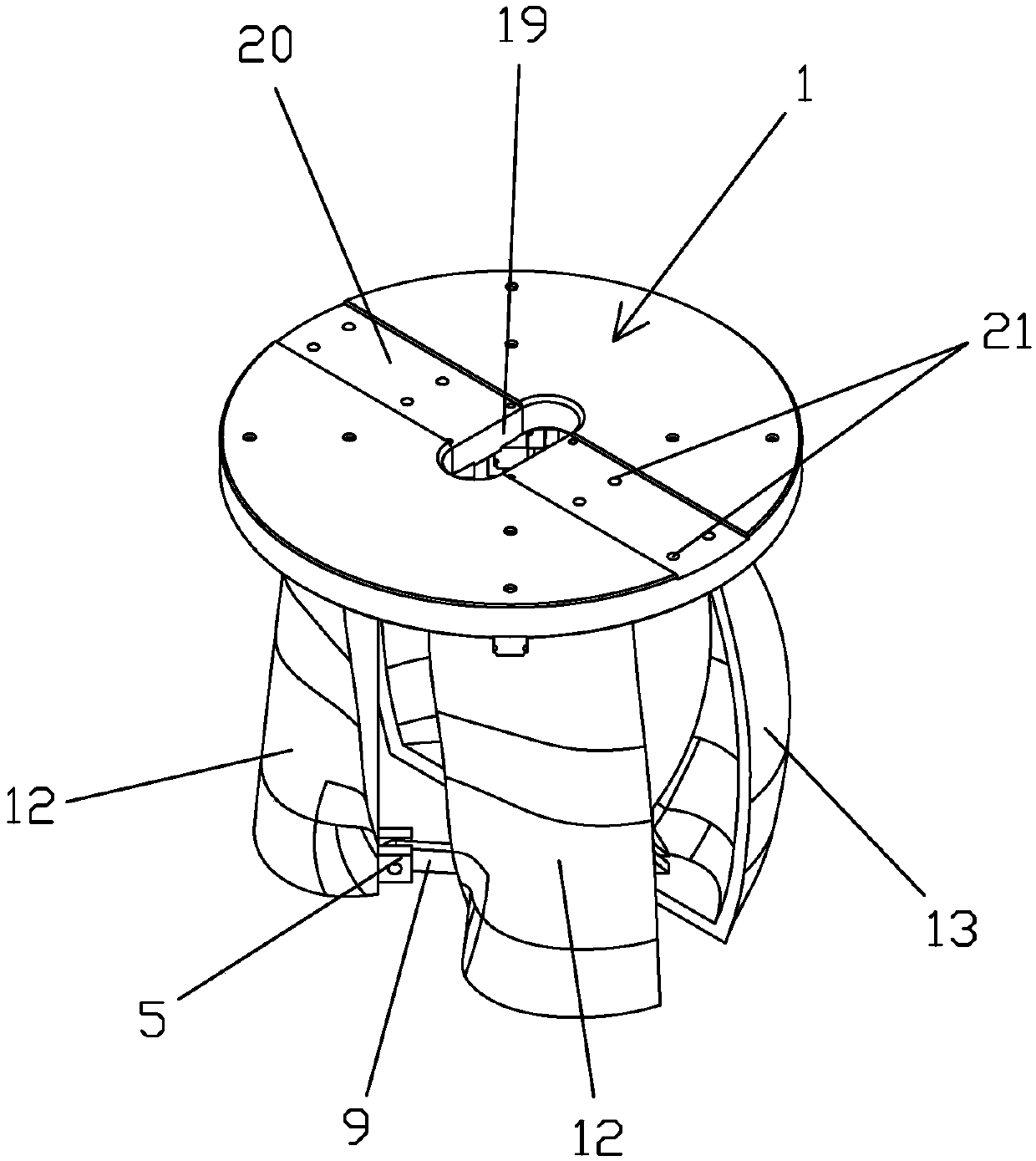

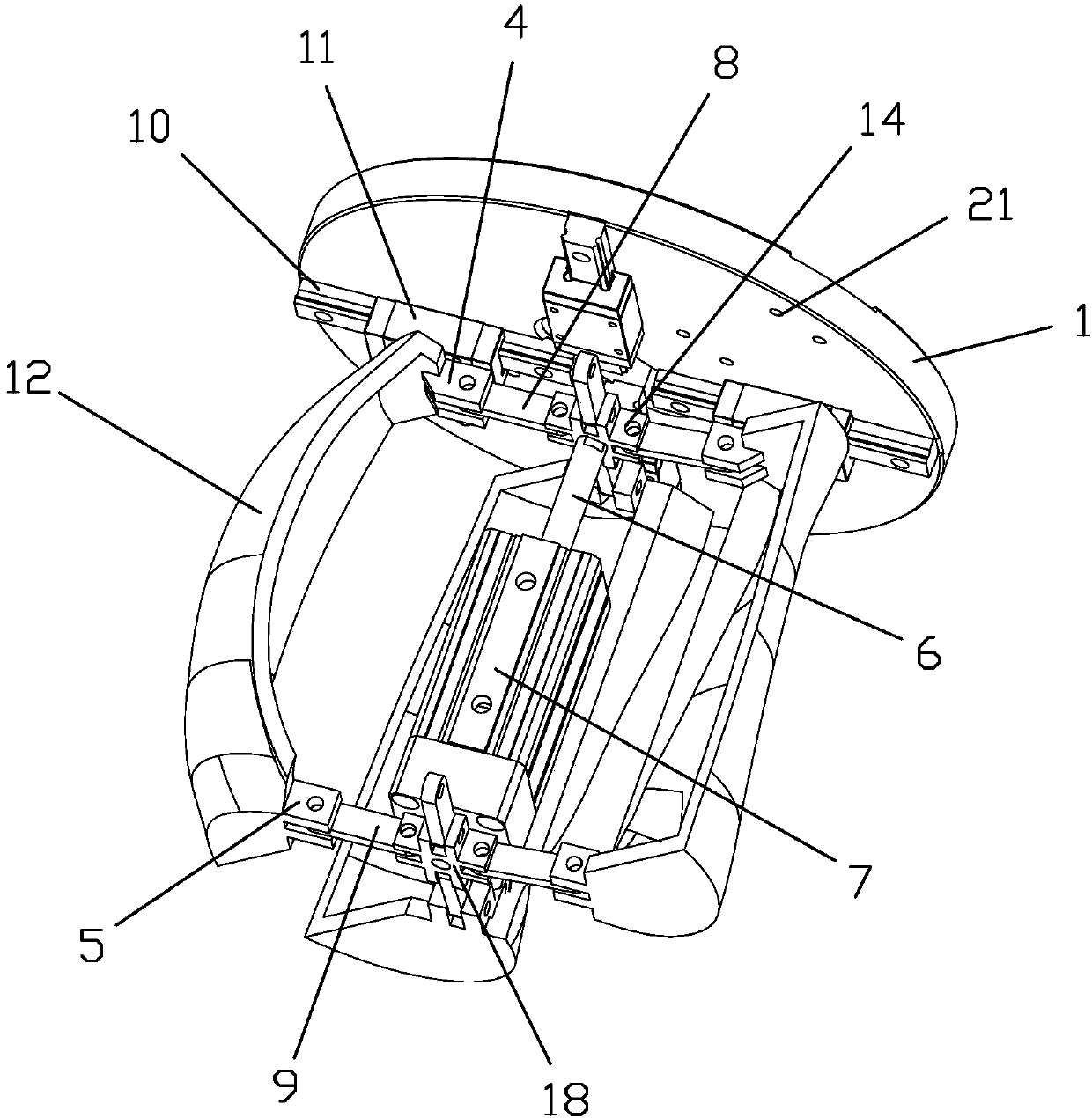

Fixing device for wood carving

ActiveCN110682237ASimple structureEasy to operateLiquid surface applicatorsSpraying apparatusStructural engineeringIndustrial engineering

The invention discloses a fixing device for wood carving. The fixing device mainly comprises a shell, wherein a clamping mechanism for fixing carving raw materials is arranged in the shell, a drivingcavity is arranged in the shell, a rotating mechanism capable of rotating the clamping mechanism is arranged in the driving cavity, a driving mechanism capable of providing power for the device and controlling the device is arranged on the left side of the rotating mechanism, and a lifting mechanism capable of lifting the clamping mechanism is arranged on the left side of the rotating mechanism. When wood needs to be fixed, the wood is placed in the clamping mechanism to be clamped manually, if the wood needs to be lifted, the lifting mechanism is started to lift the fixed wood, if the wood needs to be rotated, the rotating mechanism is started to rotate the fixed wood, the wood does not need to be fixed manually by a person, the fixing stability and the safety are improved, and the lifting and horizontal rotating operations can be carried out when the wood is fixed, and engraving is more convenient.

Owner:安徽省阜南志峰工艺品有限公司

Door core plate production process

InactiveCN104589450ALow thermal conductivityNot easy to splitWood working apparatusMechanical engineeringMaterial selection

The invention discloses a door core plate production process, which comprises the following concrete steps of material selection, material splitting, drying, baking, thickness pressing, edge cleaning, plate splicing, pressing, cutting forming, sanding, polishing, painting, packaging and forming on baked wood plates by a thicknesser. A door core plate produced by the door core plate production process has the advantages that the quality is high, the appearance is attractive, and the like.

Owner:ANHUI ROYAL JOHNNIE WOODEN PROD

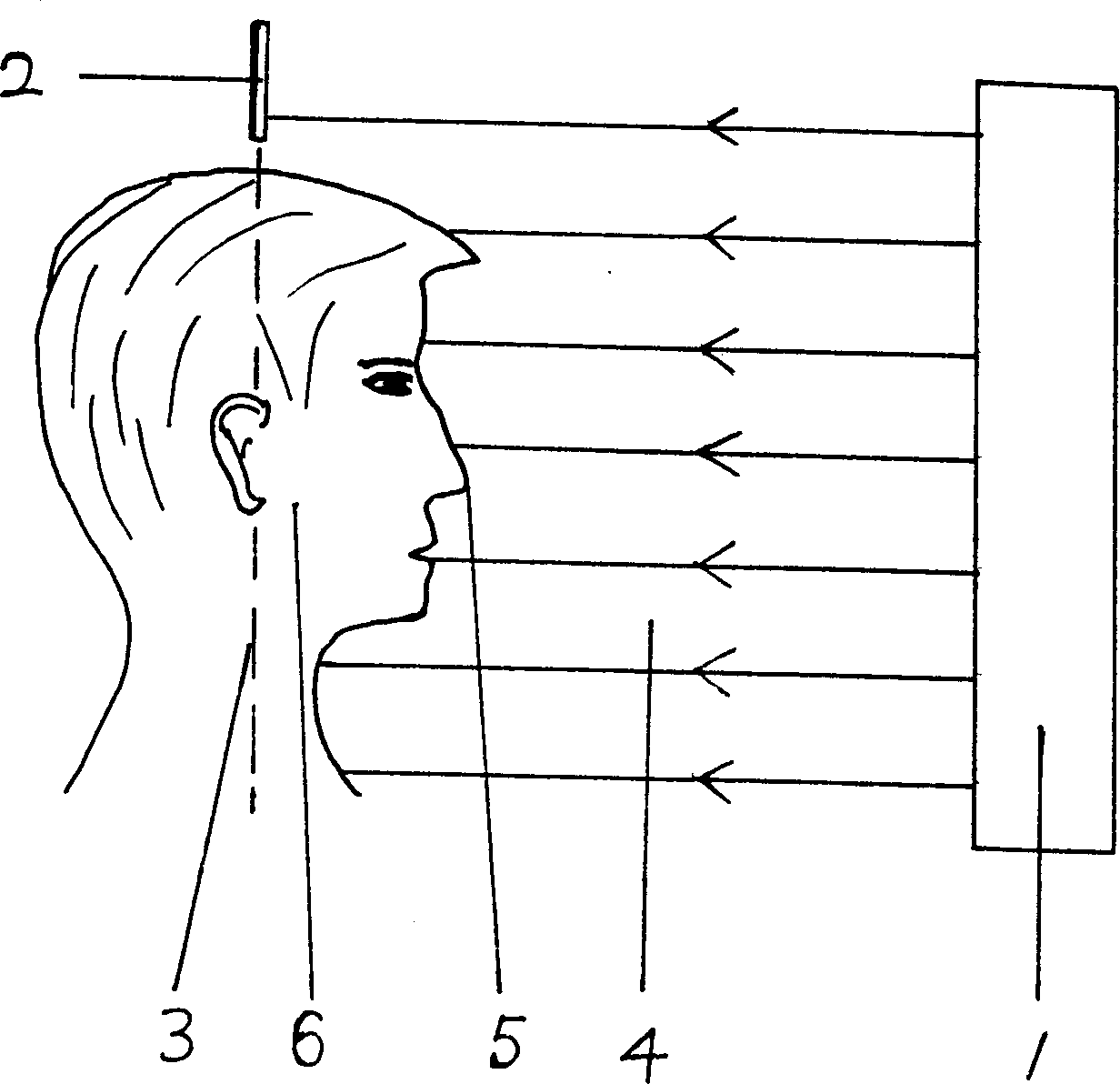

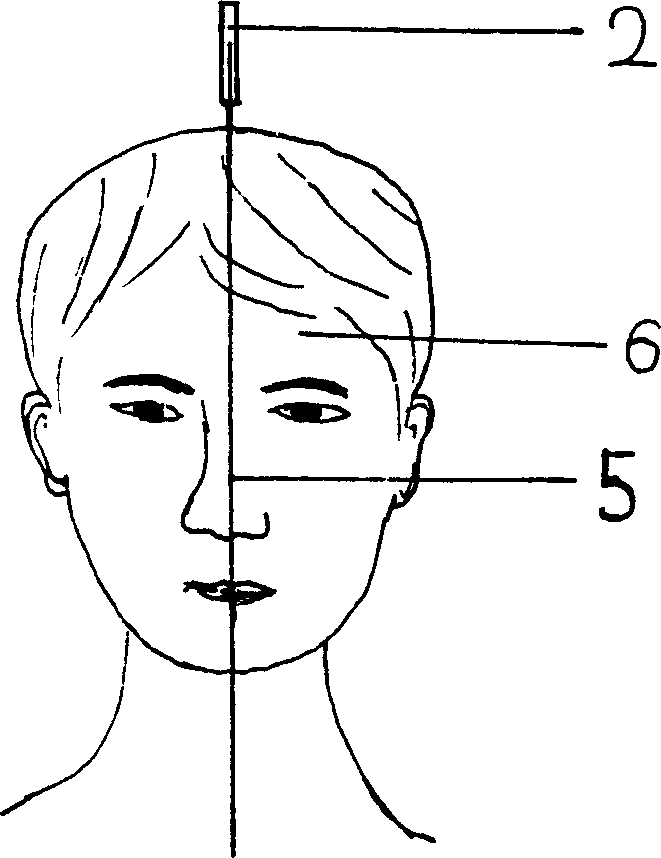

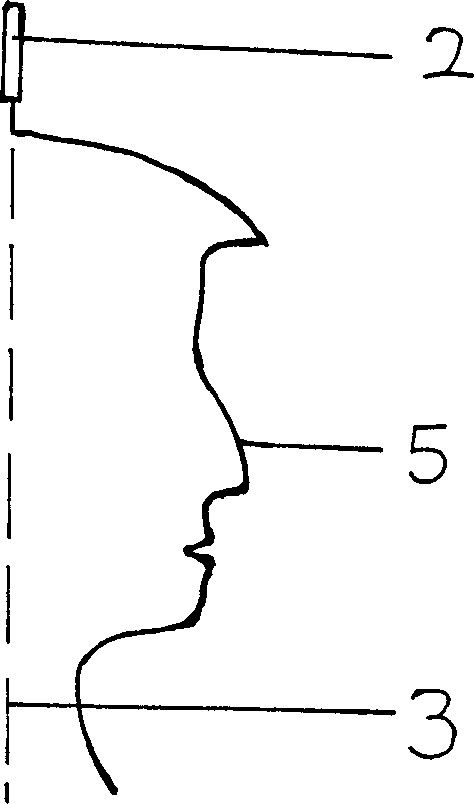

Scanning splitting process and equipment for carving statue

InactiveCN1432481ACarving saves effortEasy to carveTelevision system detailsColor television detailsHuman bodyLongitude

The present invention discloses an automatic computierzed status carving method and equipment. Human body is scanned fast with scanning light; longitude lines and parallels are formed on the surface of human body to represent body's contour; the longitude lines and the parallels are recorded with video camera and fed to computer for processing; and the mechanical carving unit with engraving tool carves the corresponding longitude lines and parallels on one cylindrical blank based on computer commands to form the statue.

Owner:李小平

Clamping equipment with anti-skid grain engraving for pincers machining

InactiveCN110640503APlay a shock absorption and anti-slip effectStable center of gravityWork benchesLarge fixed membersStructural engineeringOpen hole

The invention relates to clamping equipment with anti-skid grain engraving for pliers machining. The clamping equipment comprises a base and lower bearing platforms, wherein anti-skid pads are fixed to the periphery of the bottom of the lower end of the base, sliding rails are welded to two sides of the upper end of the base, the lower bearing platforms are movably connected to the tops of the sliding rails, sliding blocks are welded at the joints between the lower bearing platforms and the sliding rails, pulling structures are fixed at the rear ends of the lower bearing platforms, transmission structures are arranged in the middles of the lower bearing platforms, the tops of the lower bearing platforms are provided with upper bearing platforms, and open holes are formed in the peripheriesof the interiors of the upper bearing platforms. According to the clamping equipment, clamping structures are arranged, the clamping structures are provided with lower die platforms, the sizes of thelower die platforms are mutually matched with formed hole grooves and the size shape of pliers so that the lower die platforms can exert effective supporting force on the pliers, meanwhile, detachable structures are adopted between embedded blocks on the two sides of the lower die platforms and mounting platforms, then a user can effectively disassemble the lower die platforms according to the use requirements of the user, and the use by the user is facilitated.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Manufacturing process of artistic safety solid-wood door

The invention belongs to the technical field of door appliances and particularly relates to a manufacturing process of an artistic safety solid-wood door. The invention discloses the manufacturing process of the artistic safety solid-wood door, and the manufacturing process comprises the following steps of A selecting timbers; B preliminarily processing the timbers; C contrastively detecting the precision of all points of a wood plate, and then repairing and sanding to make the wood plate smooth; D manufacturing a door framework by adopting a metallic material; E brushing a layer of color paint on the surface of a solid-wood door after cooling, transmitting the solid-wood door to an oil-spraying machine by an assembly line, so that the solid-wood door is sprayed with a layer of gloss oil, and then drying. The manufacturing process has the beneficial effects that various graphs, characters and the like can be carved on the solid-wood door, so that the style of the solid-wood door is diversified, and the solid-wood door has more attractiveness on the bases of firmness and durability.

Owner:涂兴家

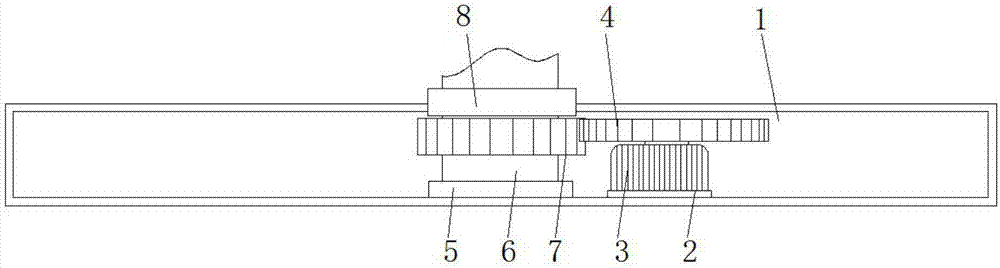

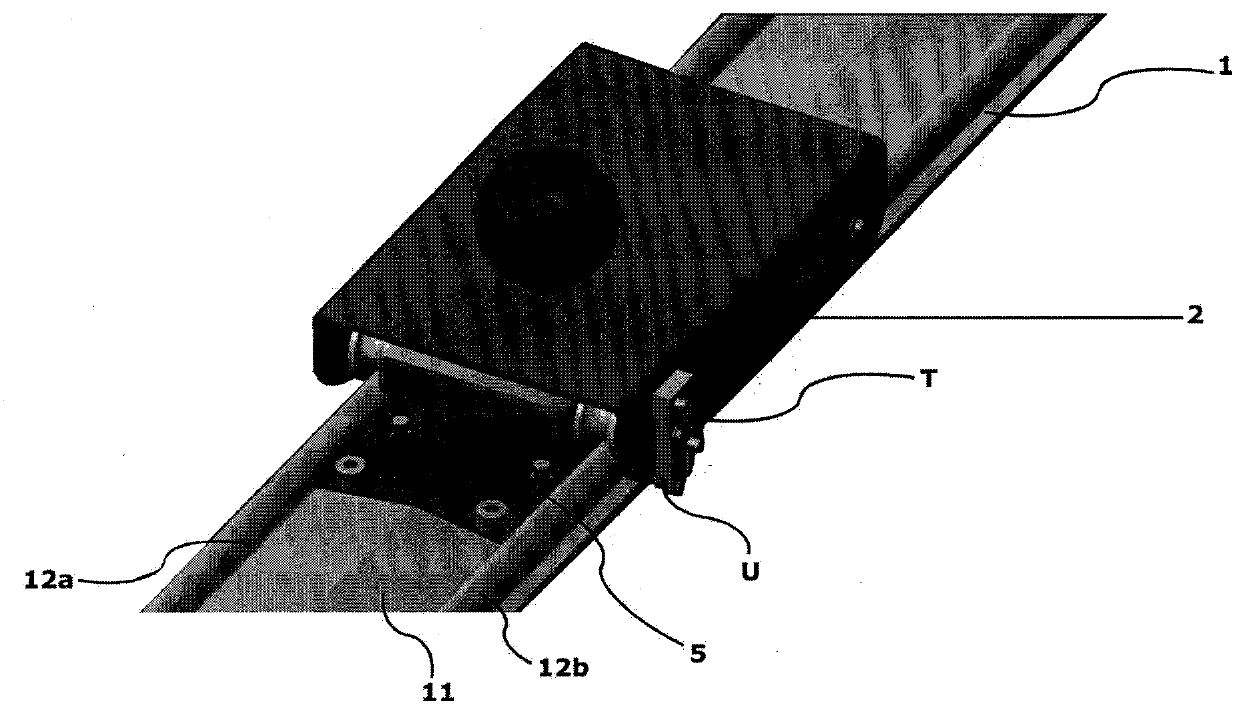

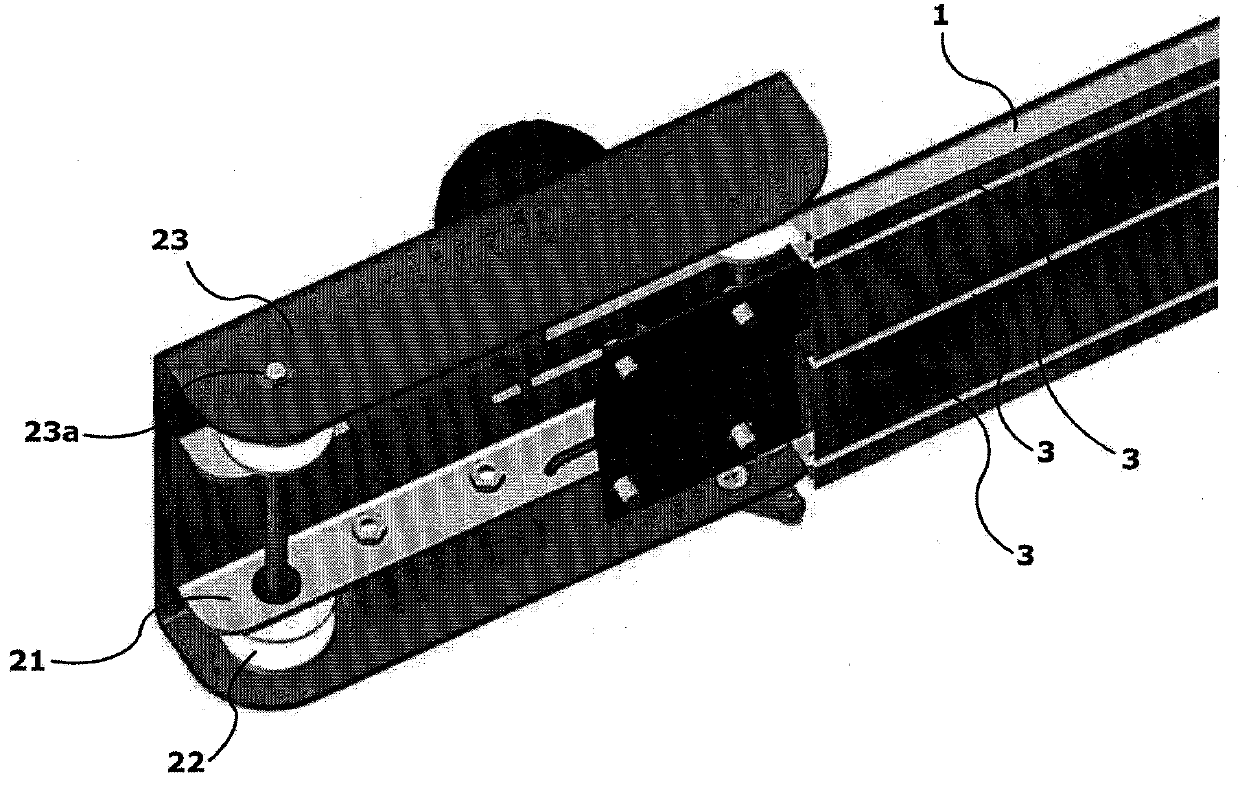

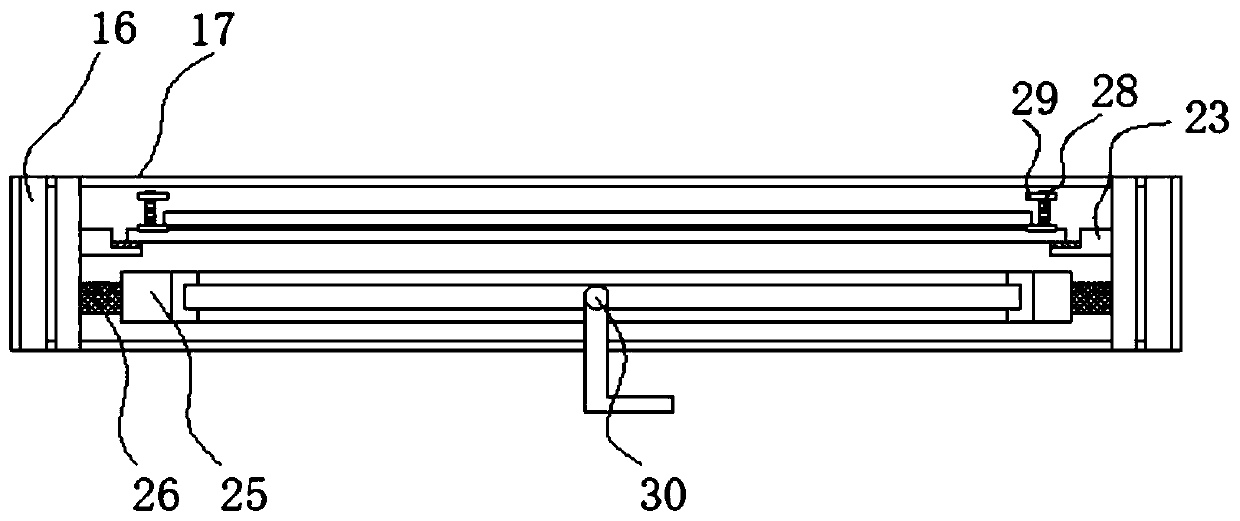

Simplified Router with Straight Guide Rod

The present invention relates to a simplified engraving machine with straight guide rods. Engraving machine for flat panels comprising a straight guide bar (1) and a carriage (2) mounted in a free sliding manner along said straight guide bar (1), said carriage (2) carrying an engraving tool (U) , wherein, the lower surface of the straight guide rod (1) is provided with a deformable support device made of high friction material (3), and the engraving tool (U) is integrated with the pressure plate (23), the pressure The plate (23) is mounted displaceably relative to the frame (21) of said carriage (2), having at least one component of displacement perpendicular to said lower surface, opposite the elastic means (24).

Owner:BREVETTI MONTOLIT

Forming and processing method for fine ceramic accessories

The invention discloses a forming and processing method for fine ceramic accessories. The forming and processing method comprises the following steps of firstly, grinding fine ceramic main materials into nano-scale powder; then, designing a mould according to dimensions and shapes of to-be-processed accessories; adding a binder into the main materials, stirring by an injection molding machine, and injection-molding into the mould, de-molding after cooling and forming to obtain formed blank, and soaking in aviation kerosene and then drying in air; degreasing and biscuiting the dried blank in a degreasing furnace at 500-600 DEG C; sintering at a low temperature of 1000-1200 DEG C; carving and modeling on the formed blank according to a designed shape to obtain formed accessories; and finally, sintering at a high temperature of 1250-1500 DEG C to obtain the fine ceramic accessories. The forming and processing method disclosed by the invention realizes application of the fine ceramic in accessories by controlling hardness of the fine ceramic.

Owner:廖文宏

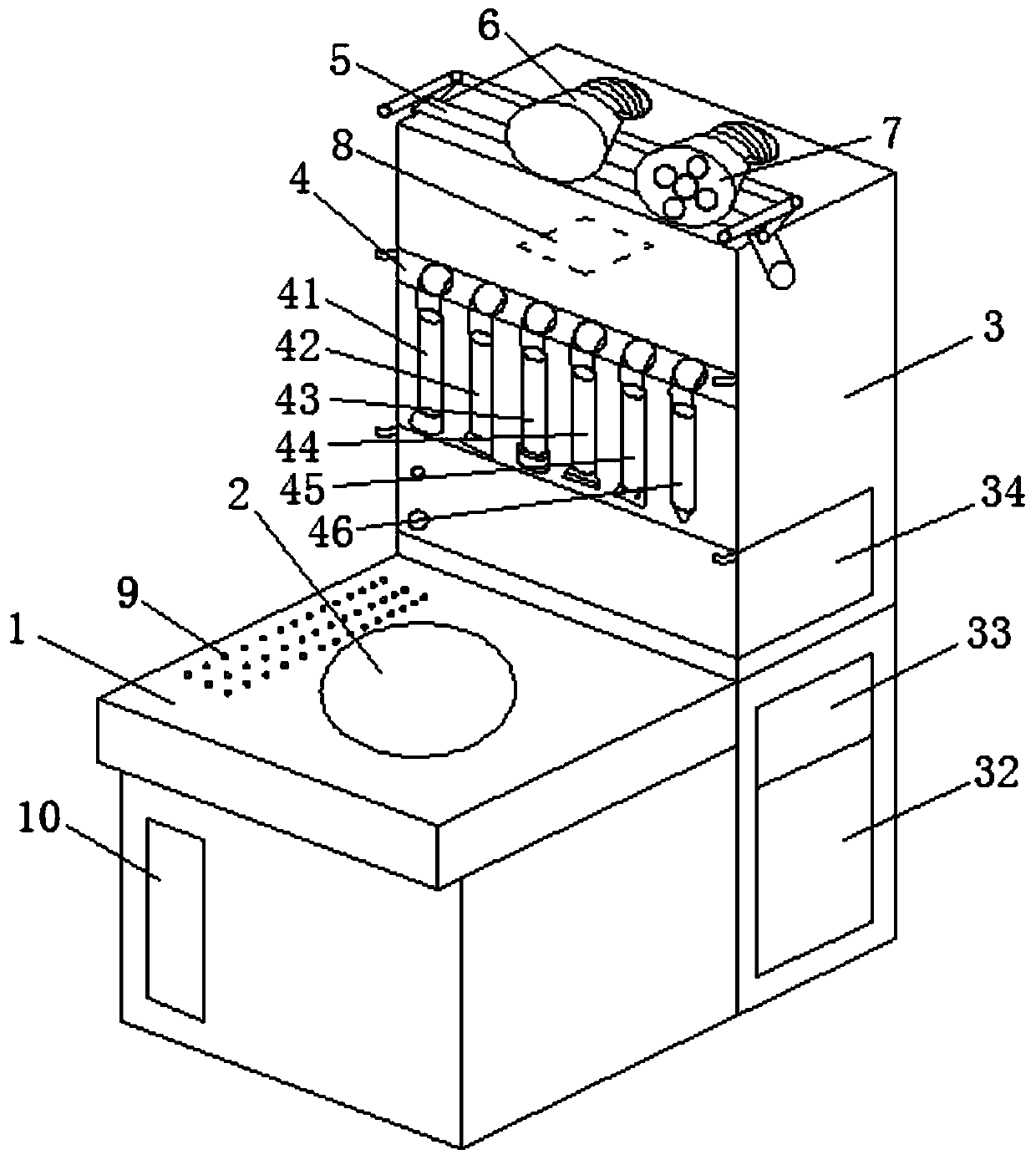

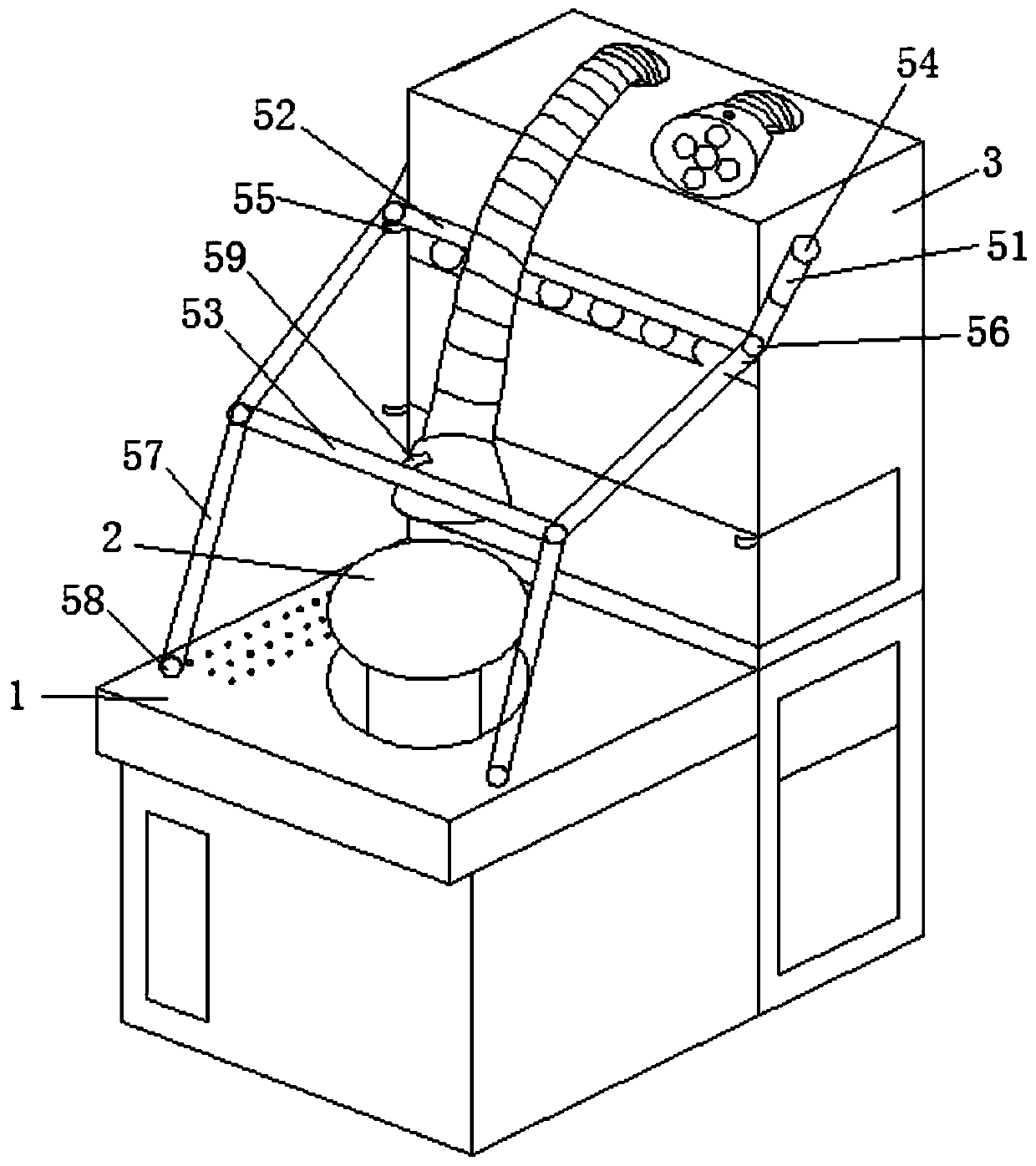

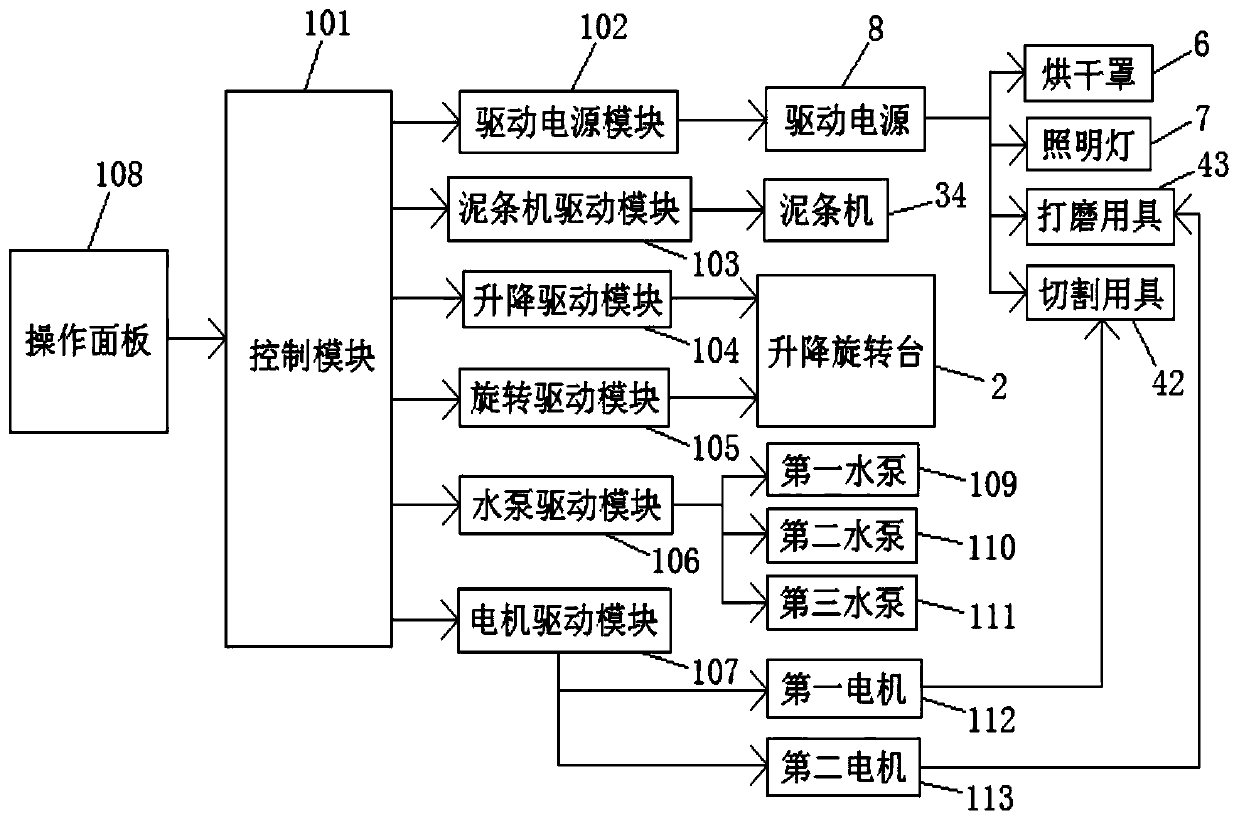

Multi-functional ceramic weaving and carving machine and control system thereof

The invention provides a multi-functional ceramic weaving and carving machine and a control system thereof. The multi-functional ceramic weaving and carving machine comprises a workbench, a lifting rotation table embedded in the middle of the workbench, and a machine body erected behind the workbench; the left side of the bottom of the machine body is provided with a water box, the right side of the bottom of the machine body is provided with a glaze box and a color box, and the middle of the machine body is provided with a mud strip machine; the front side surface of the upper portion of themachine body is provided with a tool frame, and the tool frame is connected with a water spray head, a cutting tool, a polishing tool, a fettling knife, a glaze discharging gun and a coloring spray gun from left to right in sequence; and the top of the machine body is provided with a push-pull hanging rack, a push-pull drying cover and a push-pull illumination lamp. The control system comprises acontrol module, a driving power module, a mud strip machine driving module, a lifting driving module, a rotation driving module, a water pump driving module, a motor driving module and an operation panel. According to the multi-functional ceramic weaving and carving machine and the control system thereof, on the premise that the procedure requirements of ceramic weaving work are met, the occupiedspace of the ceramic weaving work can be decreased, and the multi-functional ceramic weaving and carving machine and the control system thereof are suitable for beginners to use.

Owner:郑都英

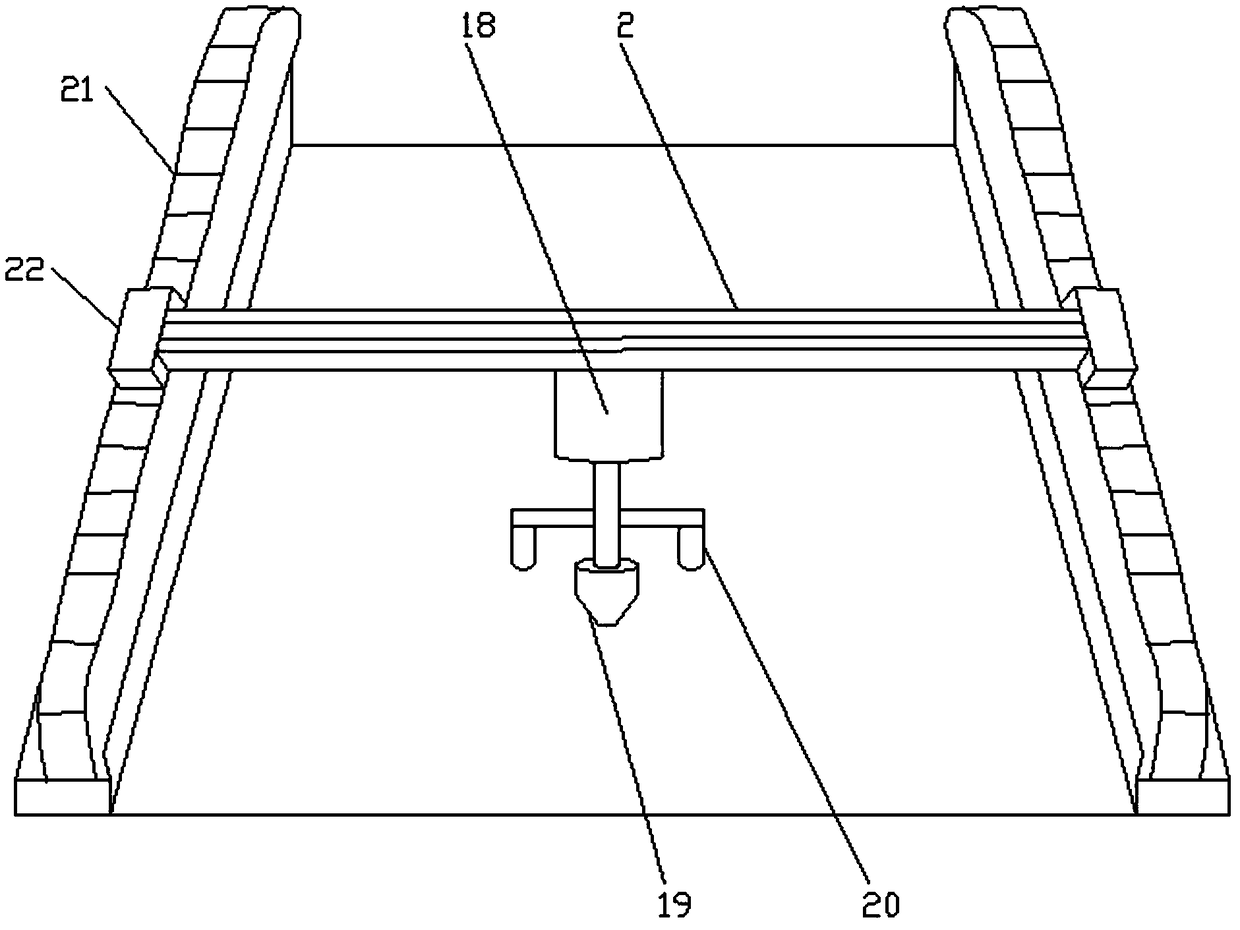

An intelligent engraving device that can be interconnected and can engrave from multiple angles

ActiveCN109278454BImprove functionalityAvoid instabilityOther artistic work equipmentsModel makingEngravingStructural engineering

The invention discloses intelligent carving equipment capable of networking and multi-angularly carving, and relates to the technical field of intelligent carving equipment. The intelligent carving equipment capable of networking and multi-angularly carving concretely comprises a base and a bottom plate, wherein support rods are fixed to the left side and the right side of the upper part of the base; vertical slide rails are arranged on the inner sides of the support rods; the support rods and the base are fixedly welded; network cable ports are formed in the outer sides of the vertical sliderails; a second spring is connected to the bottom part of the bottom plate; and the bottom plate is located on the bottom part of the middle on the upper part of the base. According to the intelligentcarving equipment capable of networking and multi-angularly carving, through arranging the base, the whole device can move conveniently; the support rods and the base are fixedly welded, so that thestability of the device can be improved, and the overall structure is prevented from being unstable; meanwhile, through arranging the network cable ports, the equipment can be networked through the network cable ports; through the threaded connection between a screw cap and a screw rod, a pressing plate can move; and through enabling the pressing plate to move downwards, the functionality of the pressing plate is improved.

Owner:江苏元骋智能科技有限公司

Glass processing device for improving attractiveness of glass

InactiveCN110948715AImprove aestheticsEasy to fixWorking accessoriesStone-like material working toolsCarvingComposite material

The invention provides a glass processing device for improving the attractiveness of glass, and relates to the field of glass processing. The glass processing device for improving the attractiveness of glass comprises a base and a glass body. A fixing device is welded to the top of the base. The fixing device comprises two negative pressure boxes, the bottoms of the two negative pressure boxes arewelded to the two sides of the top of the base correspondingly, through pipes are inserted into the tops of the negative pressure boxes; a lifting rod is inserted into the inner side of each throughpipe, and the bottoms of the lifting rods penetrate through the through pipes and extend into inner cavities of the negative pressure boxes. When the device is used, the lifting rods drive air pressure blocks to move downwards to make negative pressure generated in the inner cavities of the negative pressure boxes, so that an air suction pipe and an air inlet pipe suck air located on the inner side of a rubber suction cup into the inner cavities of the negative pressure boxes, the rubber suction cup generates adsorption force, the rubber suction cup can firmly adsorb the glass body, the glassbody is fixed more firmly in the carving process, and shaking of the glass body is avoided.

Owner:林长辉

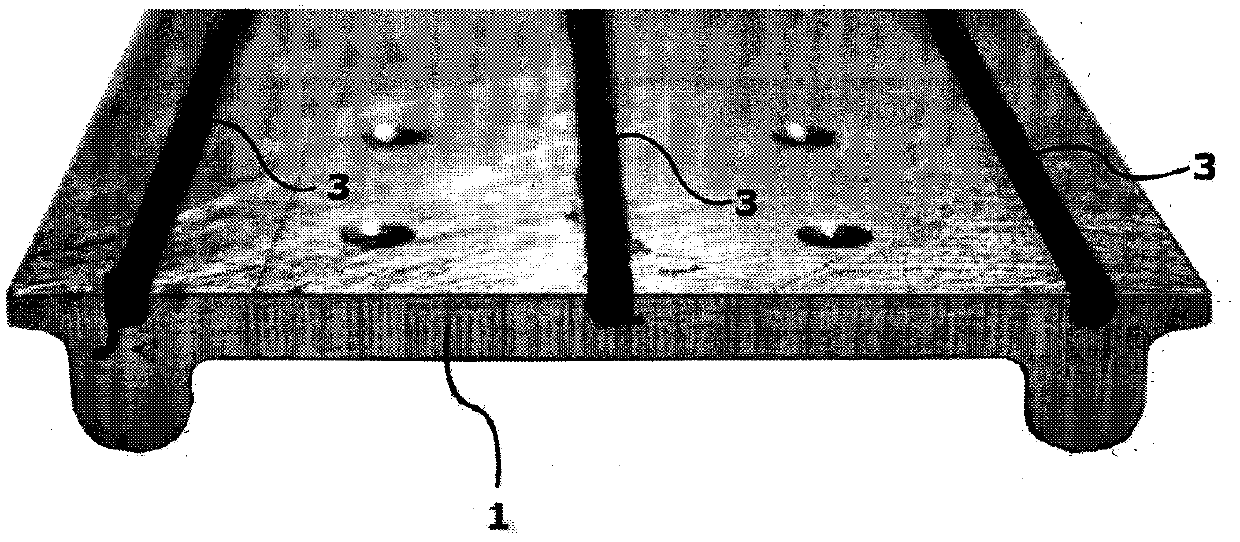

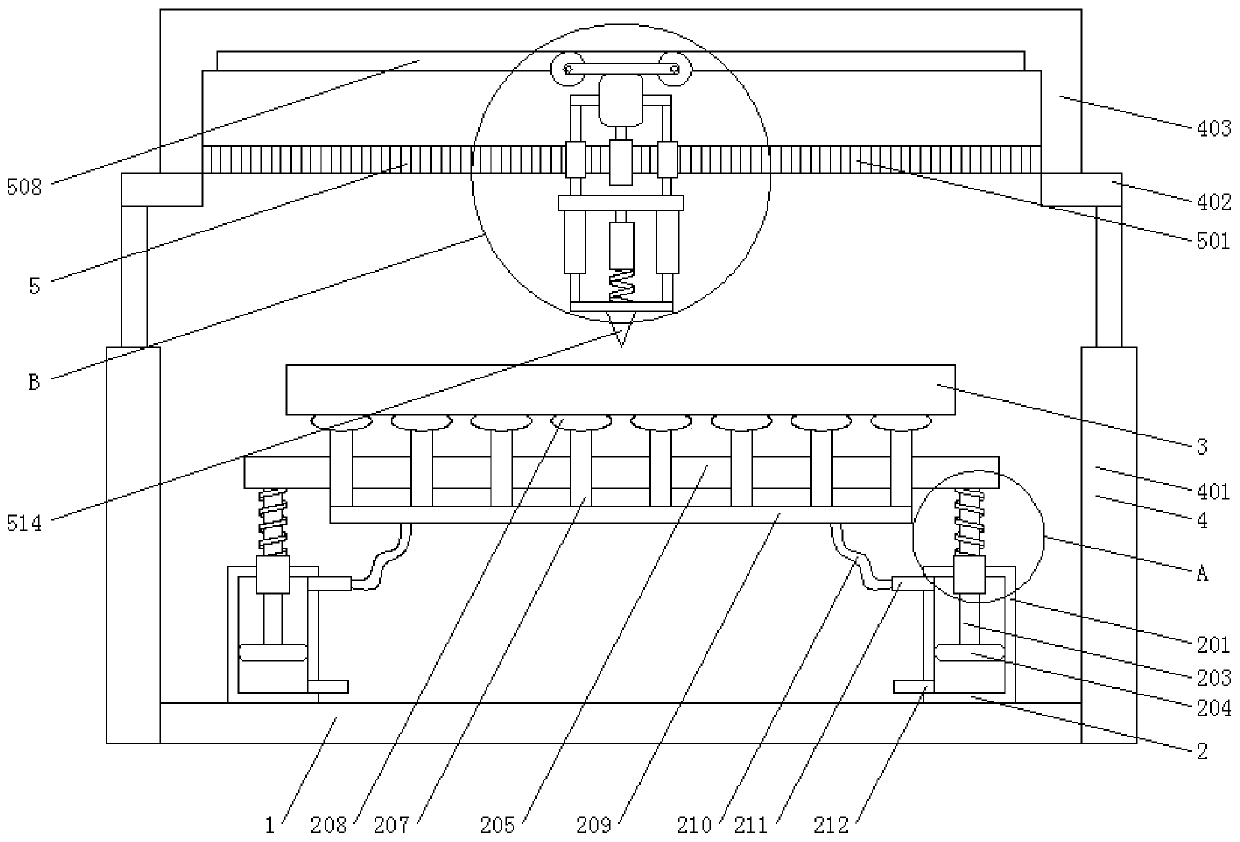

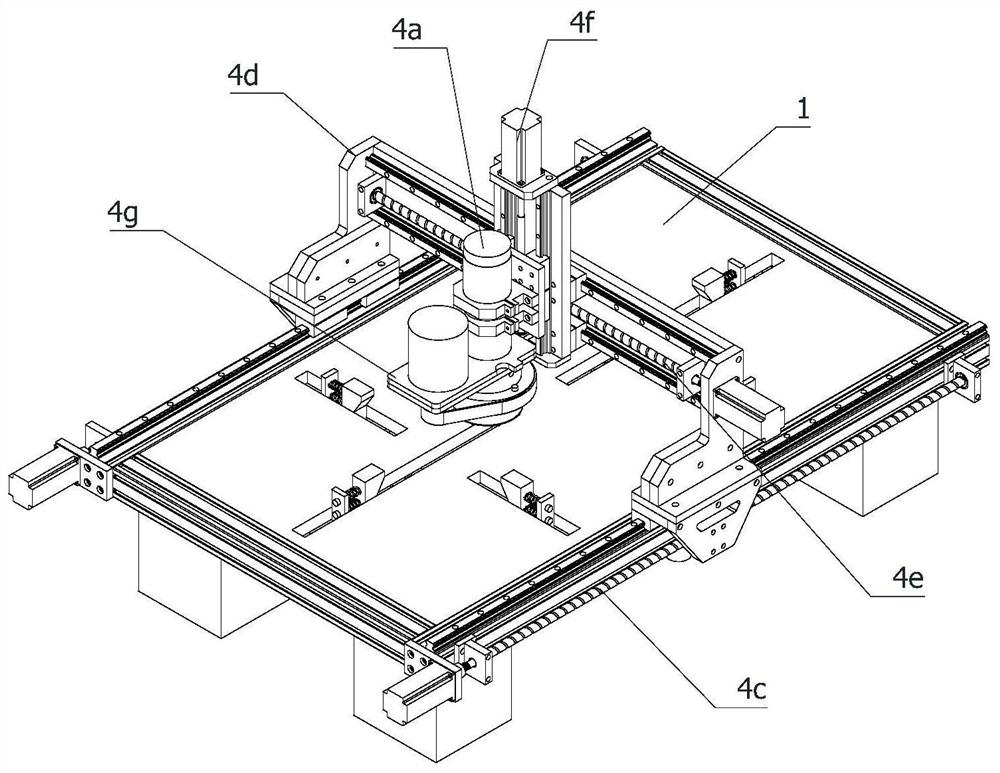

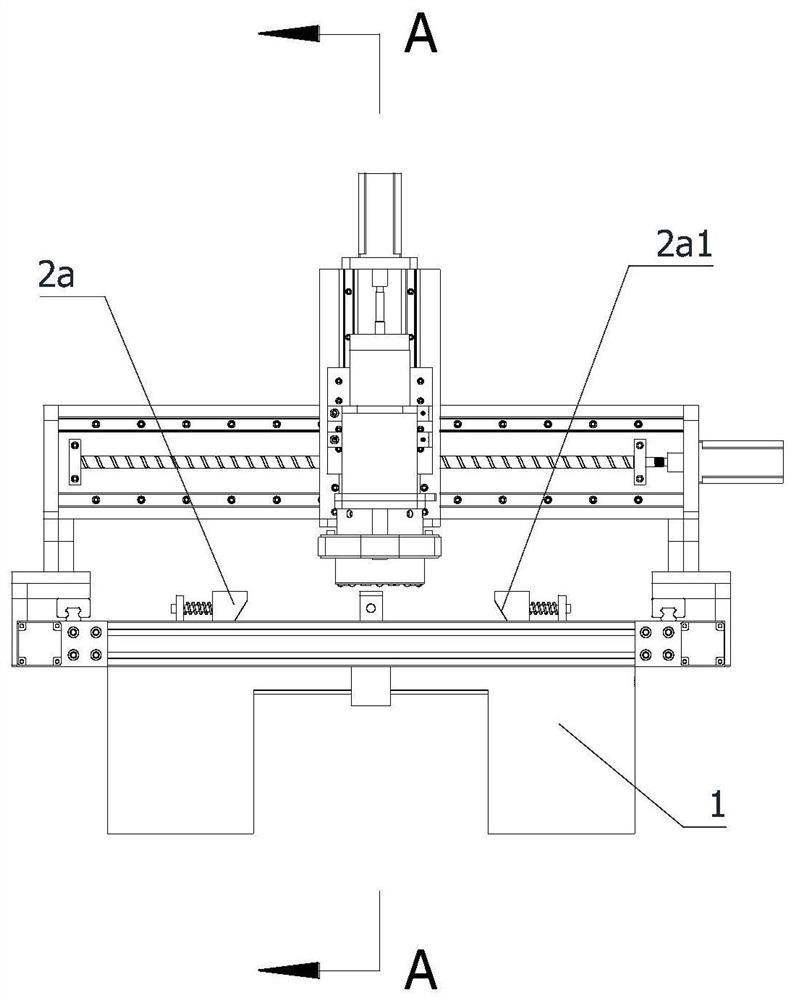

High speed rail line concrete track plate engraving machine and engraving method

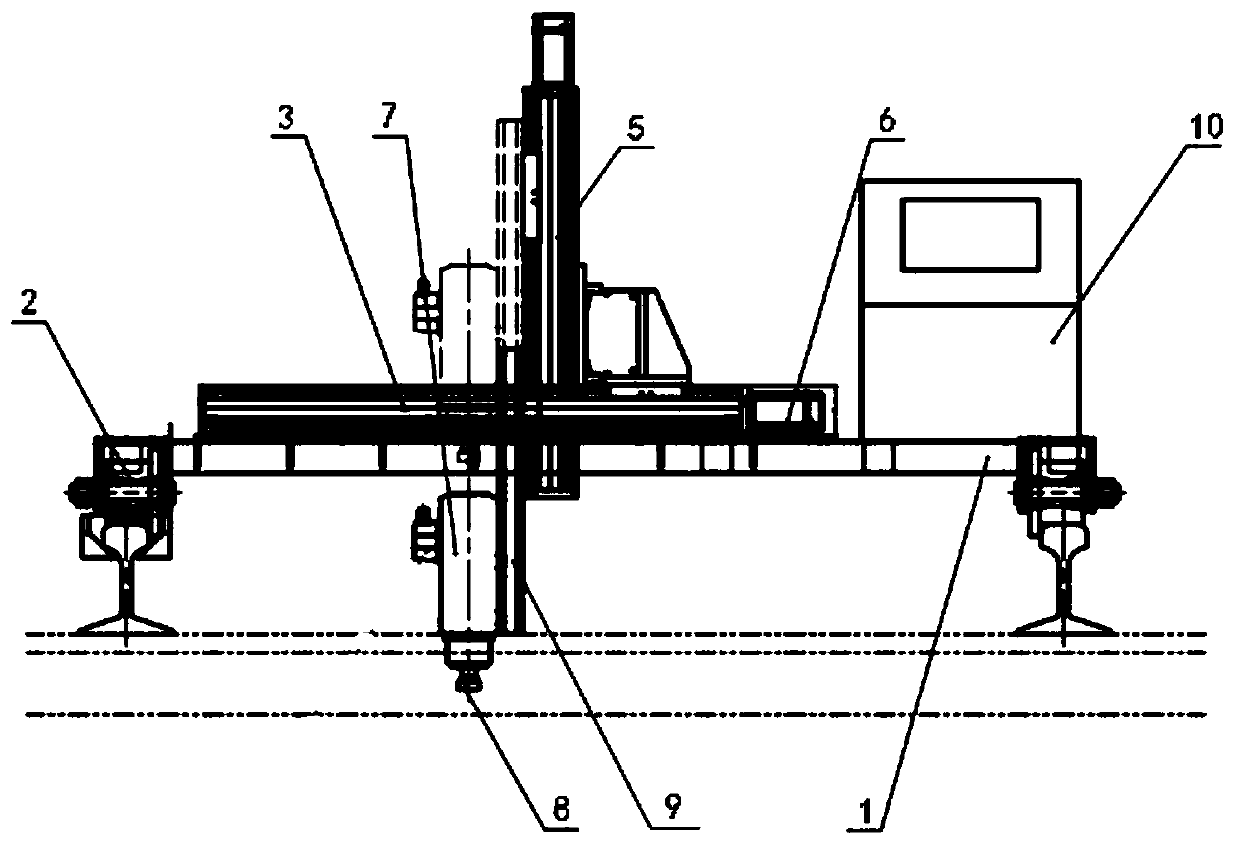

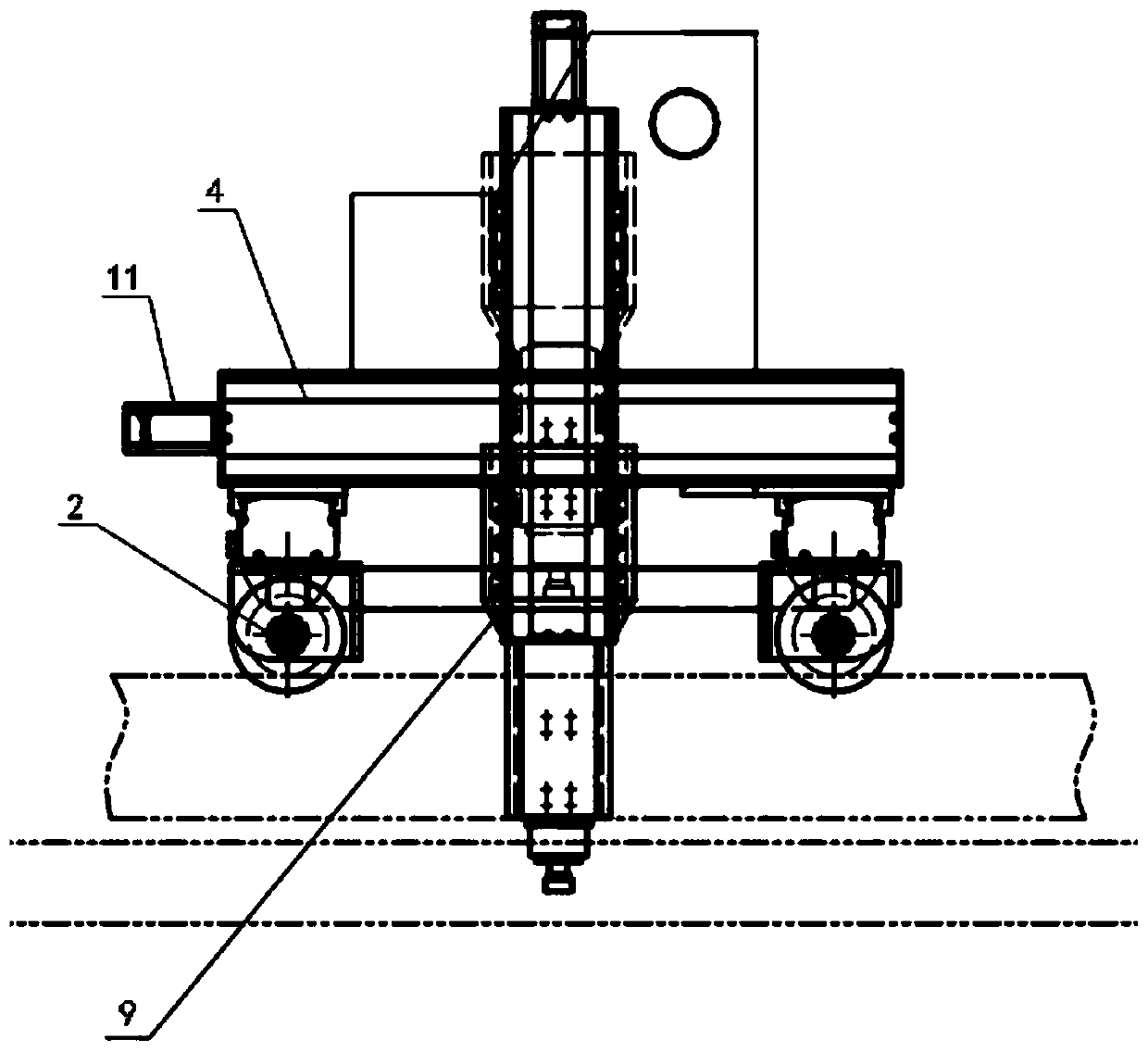

PendingCN110027122AImprove stabilityHigh degree of automationWorking accessoriesStone-like material working toolsEngravingControl system

The invention provides a high speed rail line concrete track plate engraving machine and an engraving method. The high speed rail line concrete track plate engraving machine comprises a rack, a wheelset, a three-axis linkage mechanism, an engraving mechanism, a cooling system and a control system, wherein the rack moves on a track through the wheel set; and after a moving trail of the engraving mechanism is pre-programmed, the control system controls the three-axis linkage mechanism so as to drive to engraving mechanism to run according to the moving trail, so that permanent engraving is accomplished. The high speed rail line concrete track plate engraving machine provided by the invention is stable in performance, simple to operate, and capable of permanently marking concrete.

Owner:CHINA RAILWAY SCI & IND GRP RAIL TRANSPORTATION EQUIP LIMITED

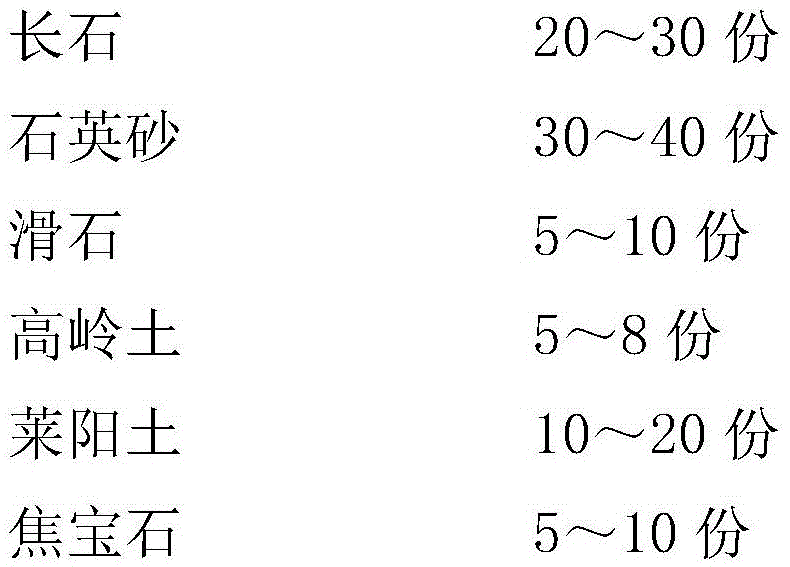

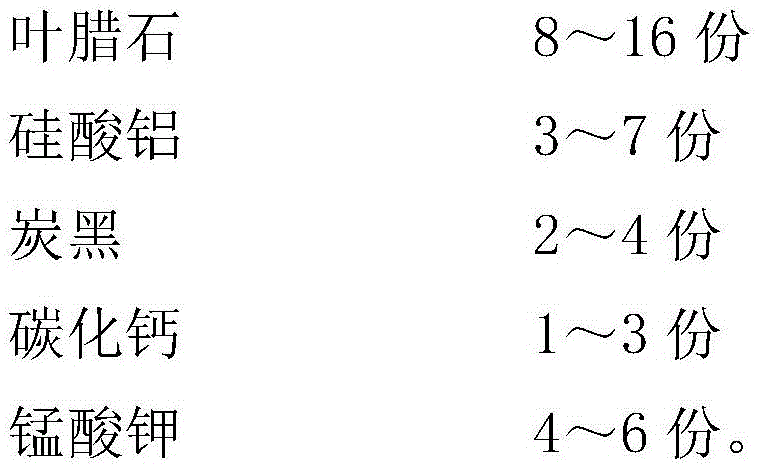

Black ceramic and preparation method thereof

The invention relates to black ceramic and a preparation method thereof, and relates to the technical field of ceramics. The black ceramic is prepared from the raw material components of, by weight, 20-30 parts of feldspar, 30-40 parts if quartz sand, 5-10 parts of talc, 5-8 parts of kaolin, 10-20 parts of Laiyang clay, 5-10 parts of flint clay, 8-16 parts of pyrophyllite, 3-7 parts of aluminum silicate, 2-4 parts of carbon black, 1-3 parts of calcium carbide and 4-6 parts of potassium manganite. The method comprises the following steps: slurry preparation is carried out, wherein the raw materials are blended according to the formula; and ball milling, sieving, iron removing and pond storage steps are carried out, such that a slurry is obtained; a mold is prepared; cast molding is carried out, wherein grouting and blowing are carried out with a plaster mold; demolding is carried out; and blank trimming is carried out, such that a semi-finished product blank is produced; and sintering is carried out, wherein a spray-glazed semi-finished product is subjected to high-temperature firing in a kiln, such that a product is obtained, wherein the sintering time is 17-20h, and a sintering temperature is 1210-1290 DEG C; and examination is carried out. The black ceramic has the advantages of high strength, low brittleness, cracking resistance, easy carving, and pure color. According to the preparation method, glaze spraying is not needed.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

Crystal tombstone and manufacturing method thereof

InactiveCN105696841AFast processingImprove machining accuracyBurial vaultsMonumentsTransmittanceEngineering

The invention discloses a crystal tombstone and a manufacturing method thereof. The crystal tombstone is manufactured through artificial crystals. A tombstone body of the crystal tombstone is solid. The surface of the tombstone body of the crystal tombstone is provided with a plane and / or three-dimensional colored or colorless patterns and / or characters, wherein the plane is carved through a laser carving machine and / or a rotating carving machine. The surface of the tombstone body is further provided with a colored or colorless departed saint picture carved through the laser carving machine. According to the crystal tombstone, a traditional stone or artificial stone tombstone is replaced with artificial crystal glass, the tombstone body is completely transparent and can reflect sunlight, a fashionable sunny tombstone group with the modern characteristics and the innovated idea is made, the visual impact, the good light transmittance, the whole shocking sense and the obvious image are achieved, a deep impression is given to people, the people will feel conspicuous, and a forerunner path is developed for the future funeral and interment industry. The patterns, the characters and the picture can be carved on the tombstone body and never fade, the crystal tombstone is exquisite and is like artware, the personal character is demonstrated, and people are made to be reluctant to leave.

Owner:段然

Clamp for clamping pants

The present invention provides a clamp for clamping pants, which belongs to the technical field of clamps. The clamp solves the technical problems that the precision of carving and the beautiful appearance of the patterns may be affected because the surfaces of the pants clamped by the existing clamp may jitter during the working process. The lower surface of the substrate of the clamp is radiallyprovided with linear sliding rails on which sliders are slidably arranged, each slider is connected with a supporting plate, the inner side of each supporting plate is provided with an upper hinge portion at the upper end portion and a lower hinge portion at the lower end portion, the other end of a first connecting rod hinged with the upper hinge portion is hinged with the upper end part of a piston rod of a cylinder arranged centrally, the other end of a second connecting rod hinged with the lower hinge portion is hinged with the lower end portion of the cylinder of the cylinder. The clampsupports the pants through the supporting plates sliding along the sliding rails to achieve the fixing of the pants, and the outer shapes of the supporting plates simulate the shapes of human buttocksand abdomen so that the supporting plates can be more fitted with the pants to facilitate the carving of the pants.

Owner:ZHEJIANG DOSO SEWING MACHINE

Metal engraving machine for aluminum plate forming

InactiveCN113102810AAvoid injuryPrecise positioningFeeding apparatusMilling equipment detailsEngravingMaterials science

The invention relates to the technical field of metal engraving equipment, in particular to a metal engraving machine for aluminum plate forming. The machine comprises a workbench, a first elastic abutting assembly, a second elastic abutting assembly, a three-axis machining mechanism, an engraving knife body and a negative pressure dust moving mechanism. A first sliding chute and a second sliding chute are formed at the top end of the workbench; the elastic abutting assemblies are arranged at the bottom of the workbench, the working end of the first elastic abutting assembly comprises abutting blocks which slide on the first sliding chute in an opposite or back-to-back manner, and the opposite sides of the abutting blocks are provided with inclined planes which are inclined downwards; and the three-axis machining mechanism is arranged at the top of the workbench and comprises a first servo motor with the working end vertically facing downwards, and a three-pin positioning assembly is coaxially arranged on an output shaft of the first servo motor. An inserting column is arranged at the top end of the engraving knife body; and the negative pressure dust moving mechanism is arranged at the working end of the three-axis machining mechanism and comprises an elastic rotating cover, balls are arranged at the bottom end of the elastic rotating cover, and turbine blades are further evenly distributed at the bottom end of the interior of the elastic rotating cover along the axis. The metal engraving machine can automatically engrave an aluminum plate, and waste chips can be prevented from being accumulated to affect the precision.

Owner:欧阳丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com