Isostatic graphite preparation process for craft product processing

A technology of isostatic pressing and products, applied in the field of static pressing graphite preparation technology, can solve the problems of handicraft processing and unapplied graphite products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

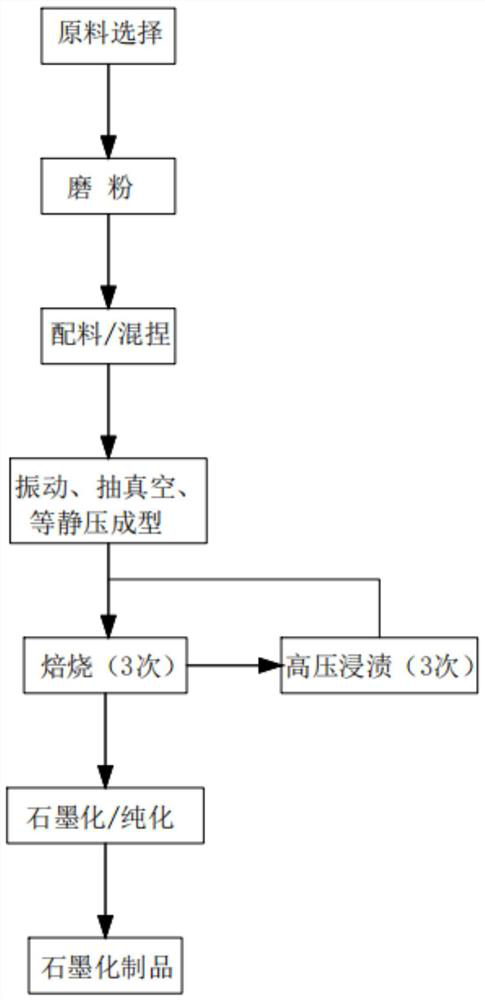

[0101] like figure 1 shown

[0102] 1. Raw materials: 65 parts by weight of petroleum coke with an average diameter of 10 μm and 35 parts by weight of pitch.

[0103] 2. Preparation method:

[0104] Step 1. Raw material selection

[0105] Choose from petroleum coke and pitch.

[0106] It mainly consists of the following raw materials and performance indicators:

[0107] Petroleum coke: fixed carbon content ≥99%, ash content ≤0.5%, boron B, gadolinium Gd less than 0.1ppm, samarium Sm, europium Eu, cadmium Cd and lithium Li less than 0.5ppm, moisture ≤0.2%, sulfur content ≤ 0.2%;

[0108] Asphalt: ash content ≤0.2%, volatile content 40-70%, coking value 40-70%, softening point 160-200°C, quinoline insoluble content 20-25%, toluene insoluble content 25-55% ;

[0109] Step 2, ingredients, kneading

[0110] Put the petroleum coke and pitch into the kneader, the temperature is 350°C, and the kneading time is 150min.

[0111] Step three, isostatic pressing

[0112] Place th...

Embodiment 2

[0126] like figure 1 shown

[0127] 1. Raw materials: 60 parts by weight of petroleum coke with an average diameter of 8 μm and 40 parts by weight of pitch.

[0128] 2. Preparation method:

[0129] Step 1. Raw material selection

[0130] Choose from petroleum coke and pitch.

[0131] It mainly consists of the following raw materials and performance indicators:

[0132] Petroleum coke: fixed carbon content ≥99%, ash content ≤0.5%, boron B, gadolinium Gd less than 0.1ppm, samarium Sm, europium Eu, cadmium Cd and lithium Li less than 0.5ppm, moisture ≤0.2%, sulfur content ≤ 0.2%;

[0133] Asphalt: ash content ≤0.2%, volatile content 40-70%, coking value 40-70%, softening point 160-200°C, quinoline insoluble content 20-25%, toluene insoluble content 25-55% ;

[0134] Step 2, ingredients, kneading

[0135] Put petroleum coke and pitch into a kneader, the temperature is 250°C, and the kneading time is 200min.

[0136] Step three, isostatic pressing

[0137] Place the mixtu...

Embodiment 3

[0151] like figure 1 shown

[0152] 1. Raw materials: 40 parts by weight of petroleum coke with an average diameter of 5 μm and 60 parts by weight of pitch.

[0153] 2. Preparation method:

[0154] Step 1. Raw material selection

[0155] Choose from petroleum coke and pitch.

[0156]It mainly consists of the following raw materials and performance indicators:

[0157] Petroleum coke: fixed carbon content ≥99%, ash content ≤0.5%, boron B, gadolinium Gd less than 0.1ppm, samarium Sm, europium Eu, cadmium Cd and lithium Li less than 0.5ppm, moisture ≤0.2%, sulfur content ≤ 0.2%;

[0158] Asphalt: ash content ≤0.2%, volatile content 40-70%, coking value 40-70%, softening point 160-200°C, quinoline insoluble content 20-25%, toluene insoluble content 25-55% ;

[0159] Step 2, ingredients, kneading

[0160] Put the petroleum coke and pitch into the kneader, the temperature is 400°C, and the kneading time is 175min.

[0161] Step three, isostatic pressing

[0162] Place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com