Patents

Literature

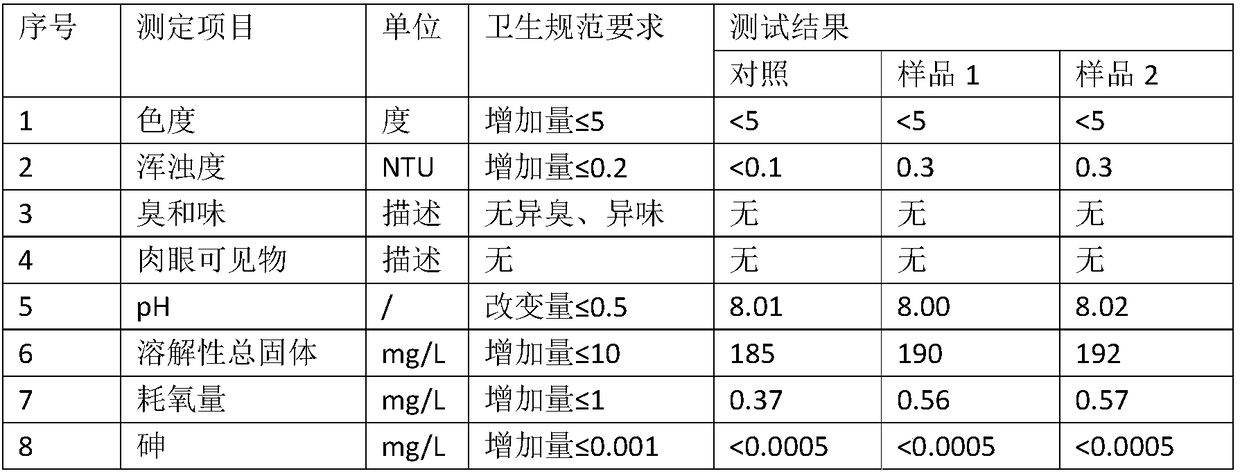

88results about How to "Avoid falling powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

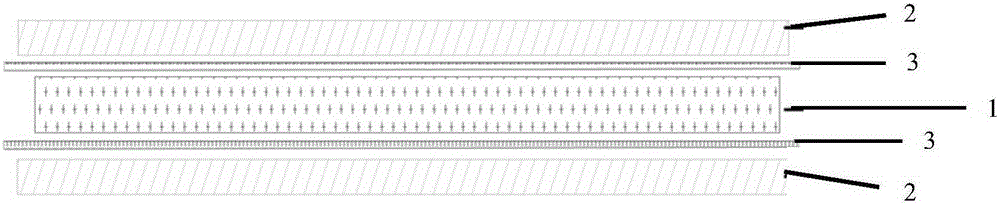

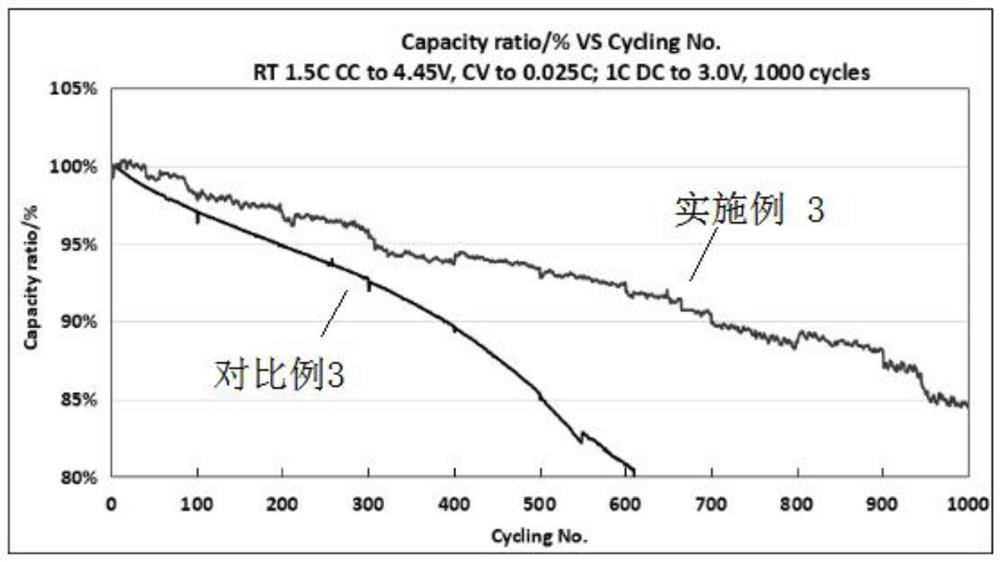

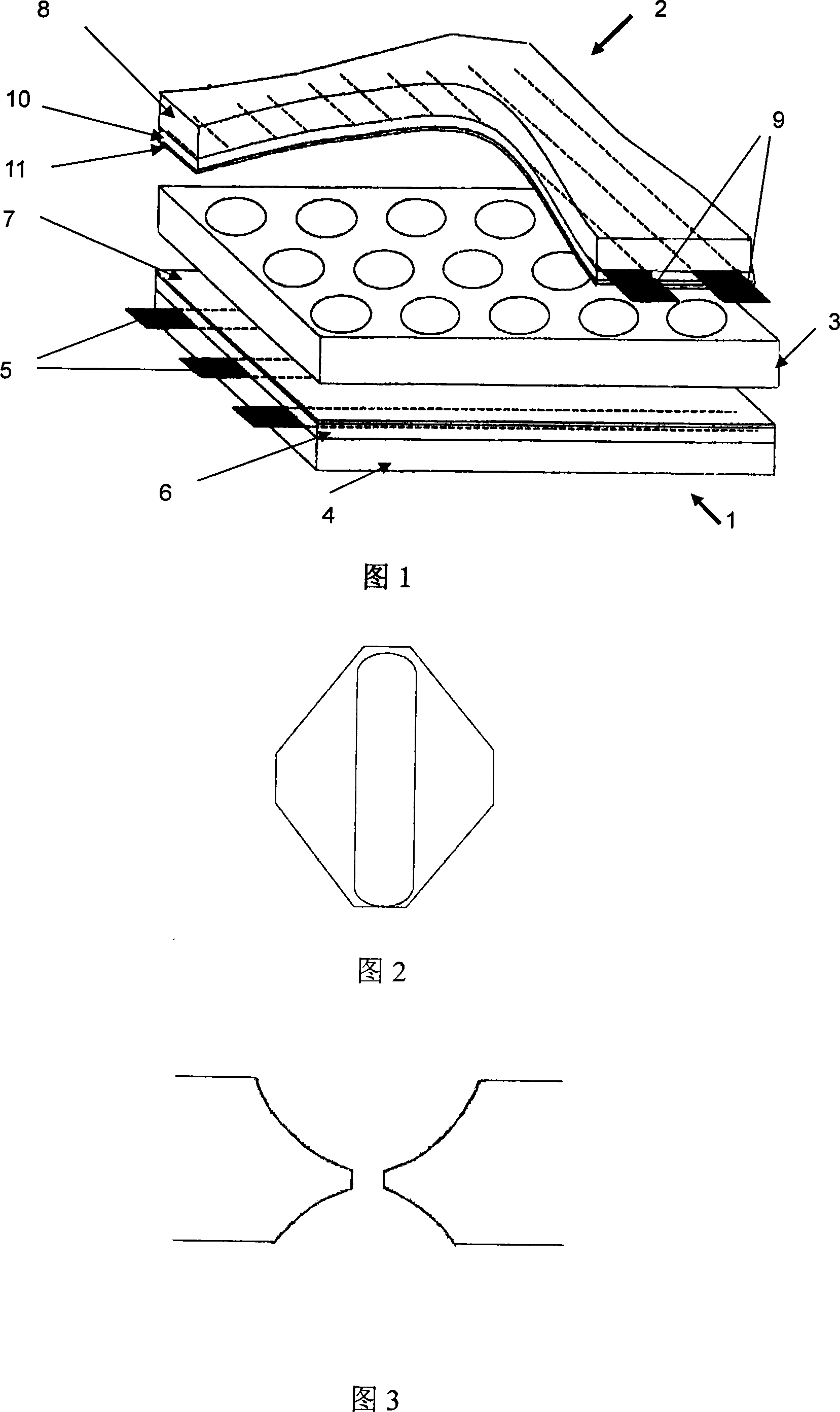

Lithium ion battery lamination unit, battery cell, battery cell preparing method and lithium ion battery

InactiveCN105336976AIncrease productivityAvoid misalignmentLarge-sized flat cells/batteriesFinal product manufactureElectrical polarityEngineering

The invention relates to a lithium ion battery lamination unit, a battery cell, a battery cell preparing method and a lithium ion battery and belongs to the technical field of lithium ion batteries. The lithium ion battery lamination unit comprises an inner electrode slice, membranes and outer electrode slices, wherein the polarity of the inner electrode slice and the polarity of the outer electrode slices are opposite, the membranes are attached to the two side faces of the inner electrode slice respectively through a binder, and the outer electrode slices are attached to the outer side faces of the membranes through the binder. According to the lithium ion battery lamination unit, on one hand, dislocation of the membranes relative to the electrode slices can be prevented, and a short circuit between a positive plate and a negative plate can not be formed; on the other hand, during battery cell manufacturing, due to the fact that part of procedures of clamping membranes in the electrode slices are omitted, battery cell manufacturing time is shortened greatly, and the production efficiency of the lithium ion battery is improved.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

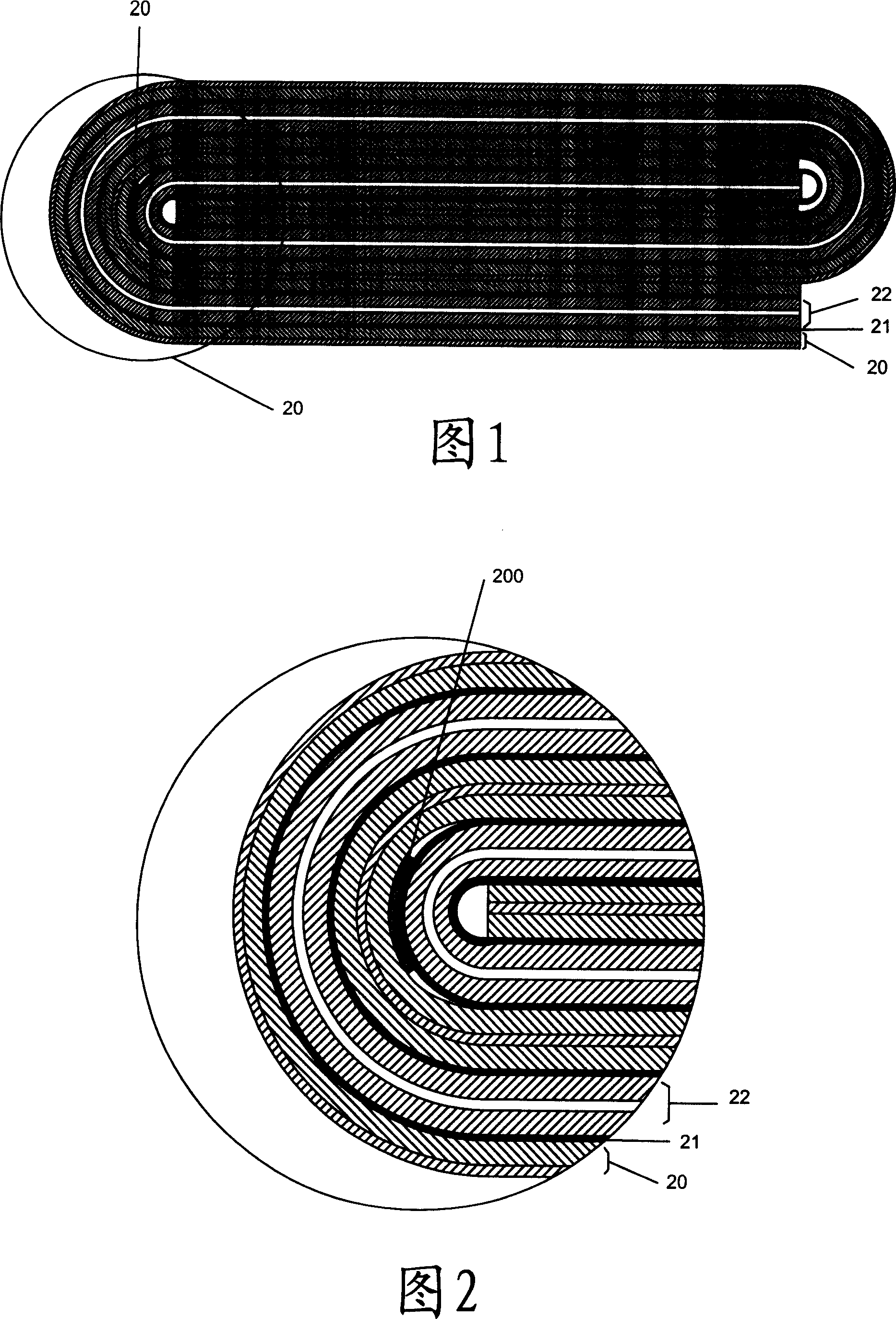

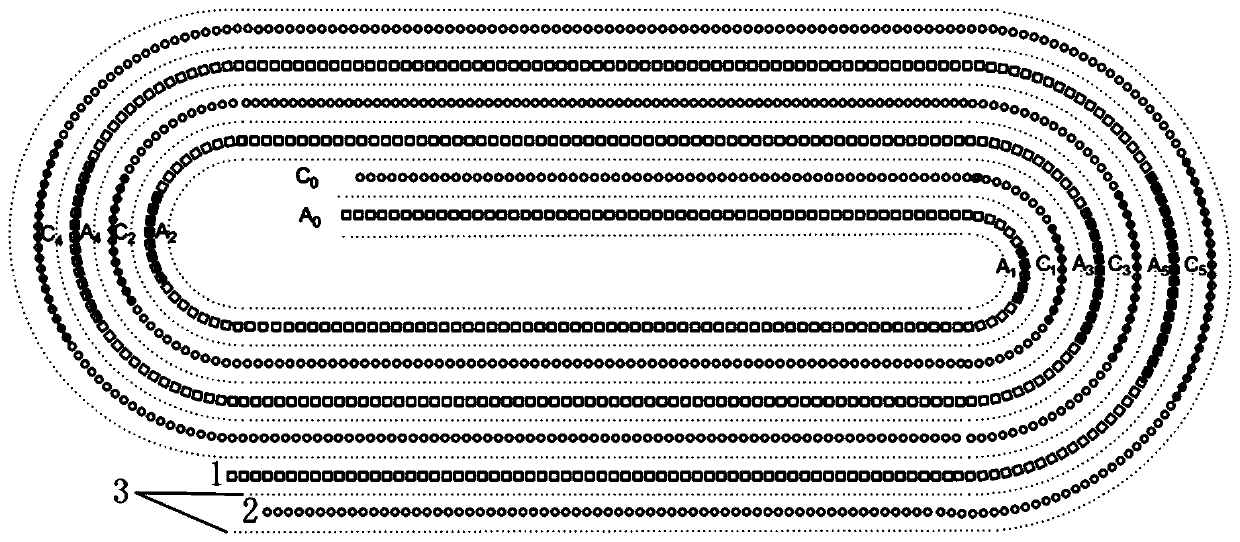

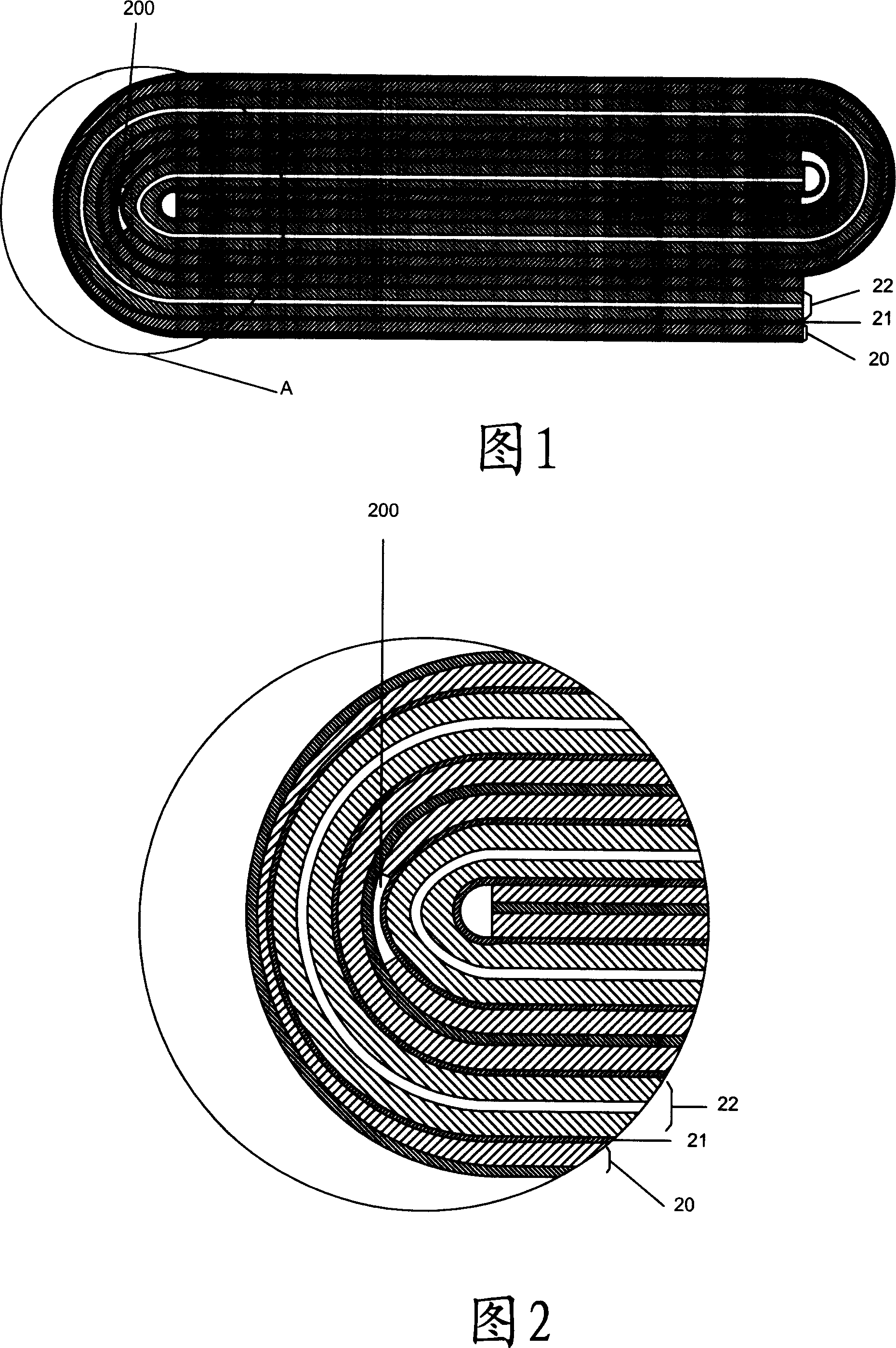

A coiling lithium secondary battery

InactiveCN101150183AAvoid the phenomenon of micro-short circuitImprove yield rateFinal product manufactureActive material electrodesProtection layerLithium-ion battery

This invention provides a kind of winded Li-secondary cells including a shell, a core winder and electrolyte in the shell, in which, the core winder is formed by winding positive pole plates, membranes and negative pole plates characterizing in setting a protection layer inside of the pole plates at the bending place of the winder to avoid that active substance at the inside of the pole plates at the bending place falls off from a collector effectively and fall off substance will not move around due to the protection of glue paper so as to avoid micro-short-circuit in the cell.

Owner:SHENZHEN BAK BATTERY CO LTD

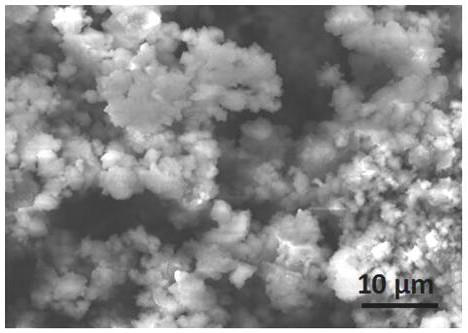

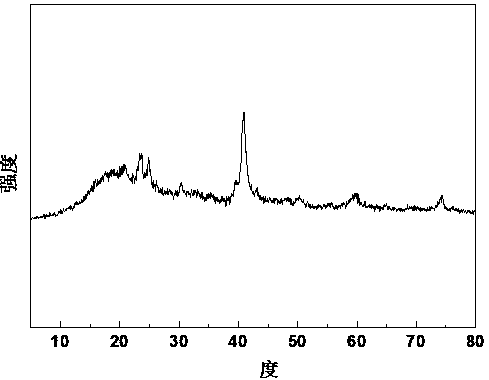

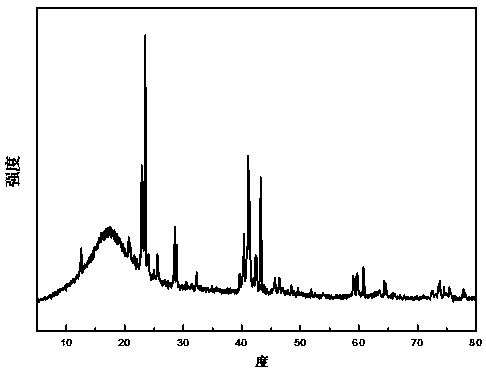

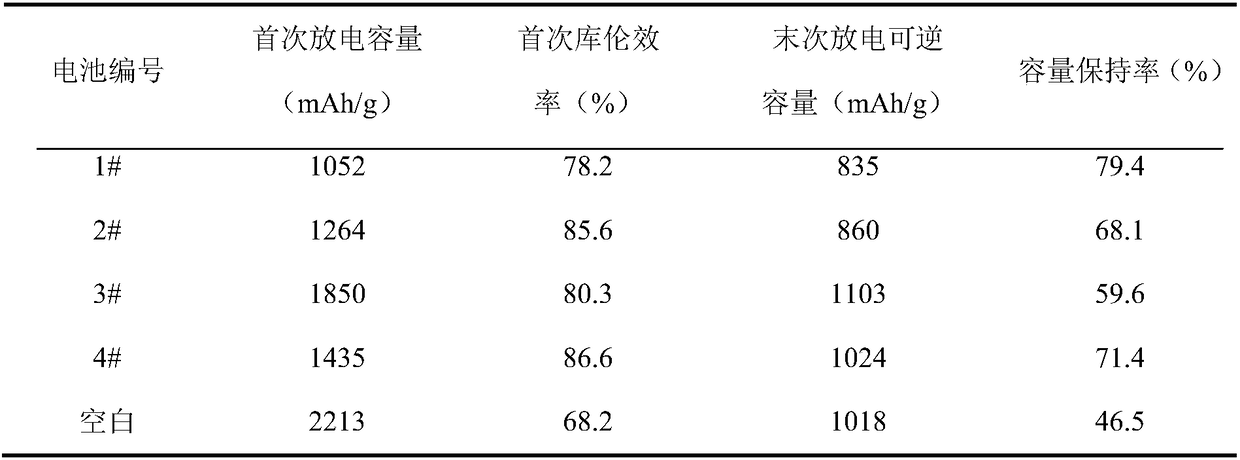

Preparation method of high-efficiency negative active material for lithium ion secondary battery

ActiveCN109786670AImprove first week coulombic efficiencyImprove electrochemical cycle stabilityCell electrodesSecondary cellsSilicon alloyHigh energy

The invention relates to a preparation method of a high-efficiency negative active material for a lithium ion secondary battery. Lithium-silicon alloys Li4.4Si, Li3.25Si and Li1.71Si are prepared by high-energy ball milling. The preparation method is simple, pollution-free and high in safety. At the same time, a suitable solvent is added in the high-energy ball milling to serve as a lubricant, thereby greatly improving the efficiency of an alloying reaction. A composite material is prepared from a lithium-silicon alloy together with pre-ball-milling silicon powder, graphite and carbon has a unique structure, which inhibits the volume expansion of materials during charging and discharging. Moreover, LixSi has high capacity and higher conductivity than pure silicon, and contains lithium, which can inhibit the formation of an SEI film in the first week and improve the first week coulombic efficiency of materials. Secondly, the experimental results of the invention show that the synthesized LixSi can be transformed into amorphous silicon after lithium removal, thereby effectively alleviating the volume change during charging and discharging, and exhibiting cycle performance far exceeding that of crystalline silicon. The high-efficiency negative active material is environmentally friendly, simple and feasible in preparation method and instrument and equipment, high in safety, and suitable for industrial production.

Owner:NANKAI UNIV

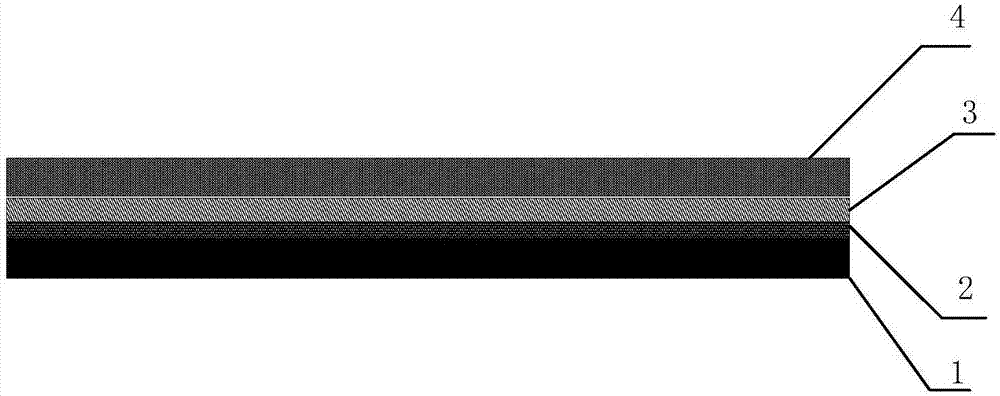

Lithium battery diaphragm for power battery and preparation method thereof

InactiveCN106935772AExcellent heat shrinkage resistanceAvoid large area short circuitLi-accumulatorsCell component detailsElectrospun nanofiberElectrical battery

The invention provides a lithium battery diaphragm for power vehicles. The diaphragm has four layers, the layers are respectively from bottom to top a base diaphragm, a nanometer flame retarding layer, an electrospun nanofiber layer and a thermal closed layer, wherein the base diaphragm is a PET nuclear pore membrane with a thickness of 5 microns-20 microns, the nano meter flame retardant layer is a flame retardant ceramic slurry with a thickness of 0.5 micron-10 microns, the thickness of the electrospun nano-fiber layer is 2 microns-5 microns, and the heat closed layer is a heat-resistant epoxy resin with a thickness of 5 microns-10 microns. The invention also provides a preparation method of the lithium battery diaphragm; the heat-resistance and shrinkage performance of the prepared lithium battery diaphragm can be greatly improved, the thermal stability and thermal closed property are significantly improved, and the security is very good.

Owner:湖南中智优库科技有限公司

Winding cell and battery

InactiveCN110364769APrevent precipitationAvoid safety hazardsFinal product manufactureSecondary cellsLithiumElectrical battery

The invention discloses a winding cell and a battery. The winding cell comprises electrode pieces, a separator and an adhesive tape, wherein the electrode pieces comprise a positive electrode piece and a negative electrode piece; the separator is arranged between the positive electrode piece and the negative electrode piece; the adhesive tape is attached to the surface of the positive electrode piece and is attached to a corner position of the positive electrode piece; the adhesive tape can also be attached to the surface of the negative electrode piece and is attached to a corner position ofthe negative electrode piece; and one side, or, both sides, of the electrode piece is bonded with the adhesive tape. By a bonding mode, safety hazards caused by cracking occurring during the hot pressing process of the electrode piece can be effectively avoided, precipitation of metal lithium is prevented, and the safety performance of the winding cell is improved.

Owner:REPT BATTERO ENERGY CO LTD +1

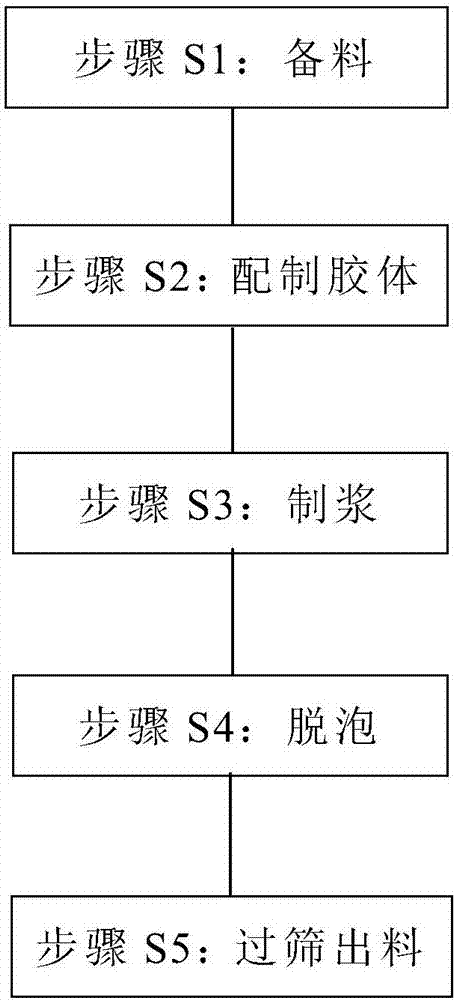

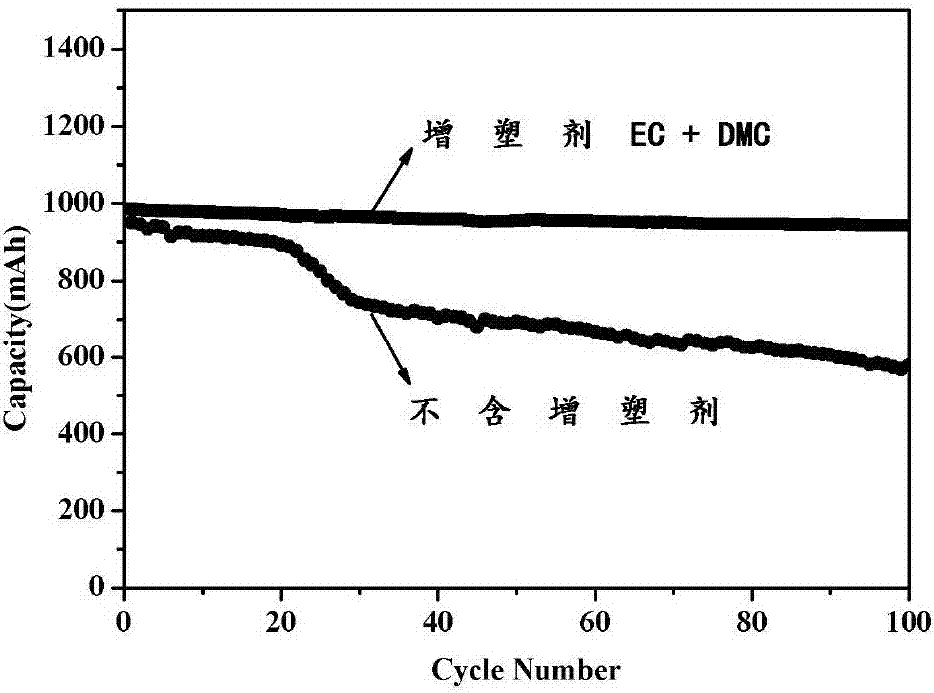

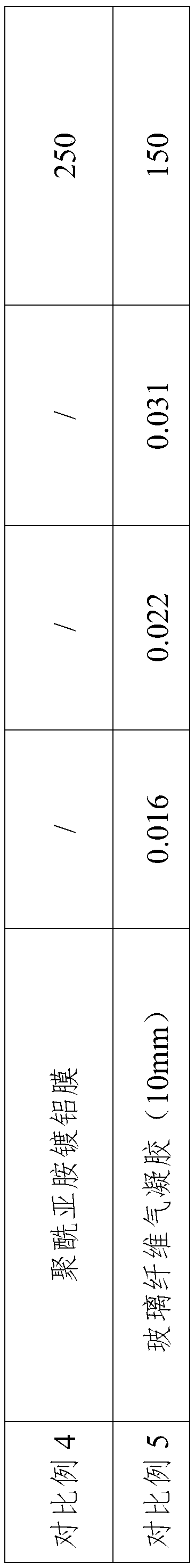

Sodium ion battery negative electrode slurry, preparation method thereof, and negative electrode plate

InactiveCN107170957AImprove plasticityReduce stressElectrode manufacturing processesSecondary cellsSlurrySodium-ion battery

The invention provides a sodium ion battery negative electrode slurry. The slurry comprises a negative electrode active substance, a conductive agent, a binder, a plasticizer and a solvent. Plasticizer molecules are inserted among polymer molecular chains in order to weaken the stress among the polymer molecular chains, reduce the crystallization degree of the polymer molecular chains and increase the plasticity of a polymer. The plasticizer is added to improve the dry brittleness and bulky edge problems of a coating, increase the flexibility of an electrode plate, avoid the powder dropping of the electrode plate and obviously enhance the processing performance of the electrode plate. The invention also provides a preparation method of the sodium ion battery negative electrode slurry, used for preparing the negative electrode slurry. The invention further provides a sodium ion battery negative electrode plate.

Owner:中国电子新能源(武汉)研究院有限责任公司

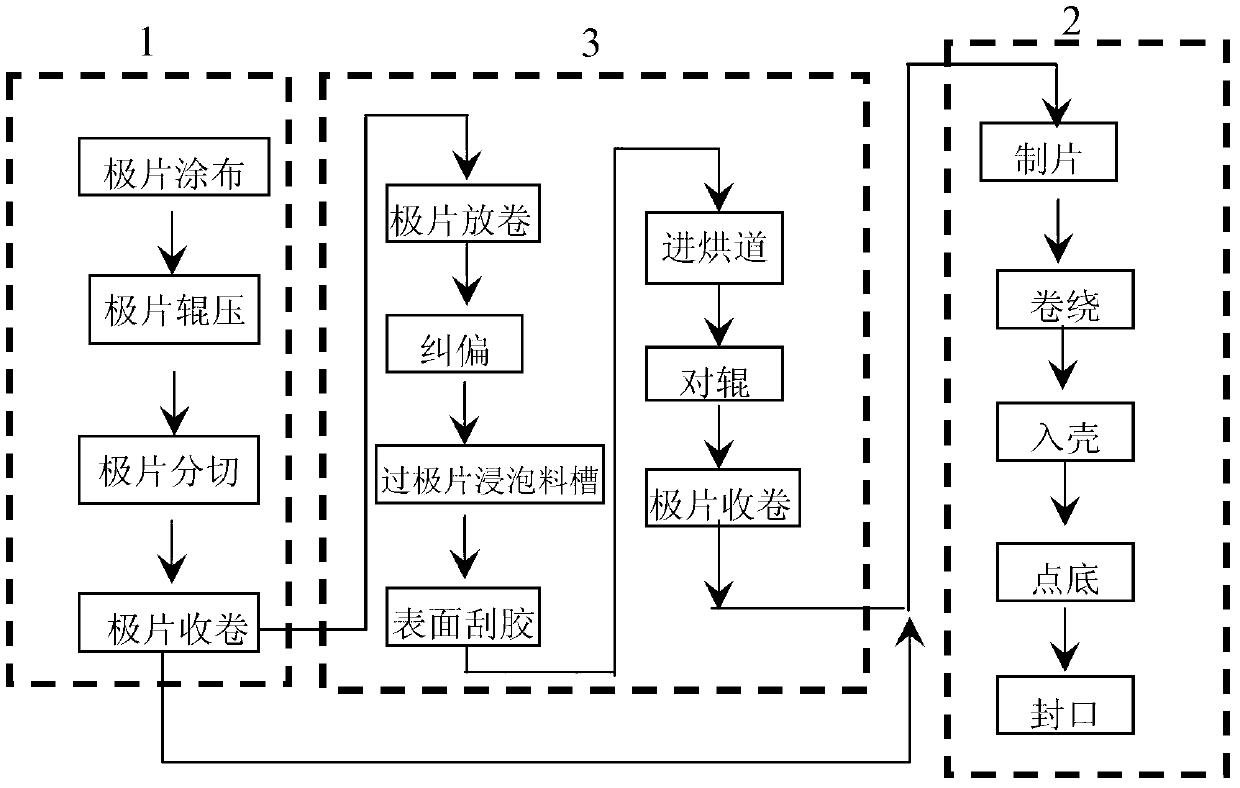

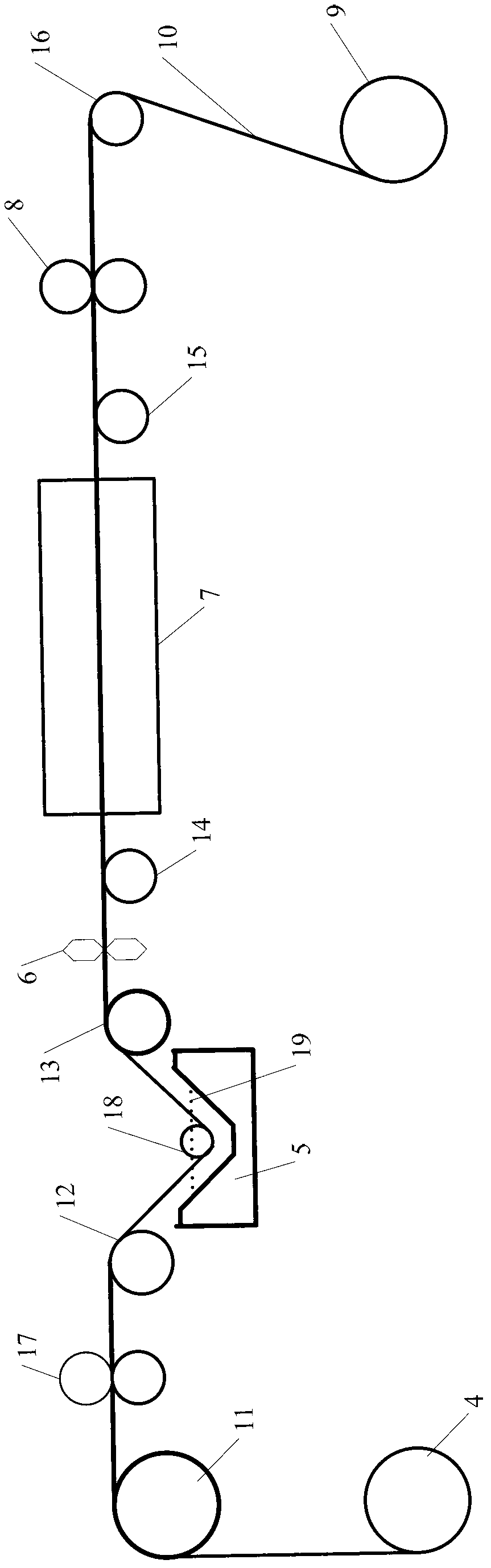

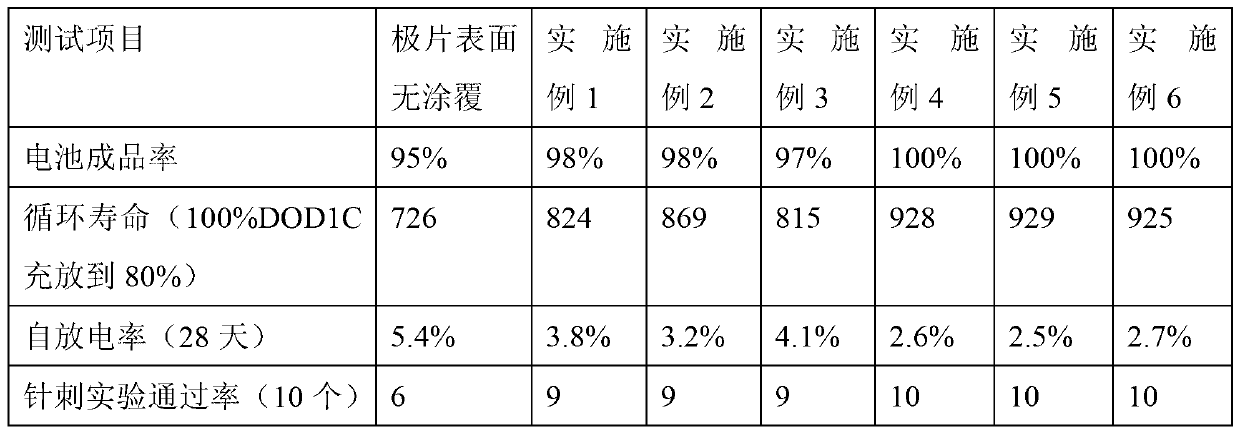

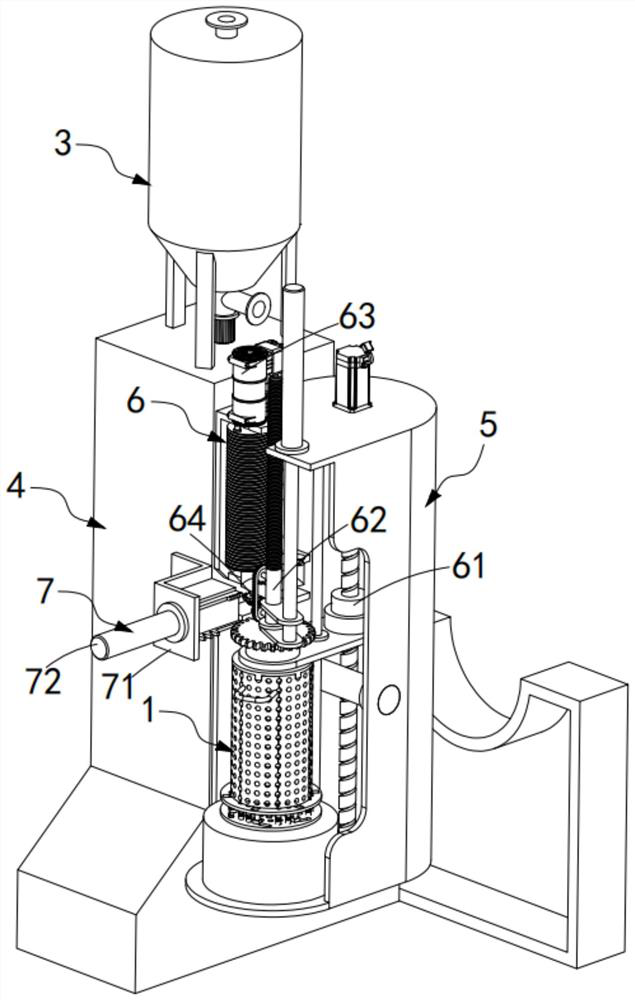

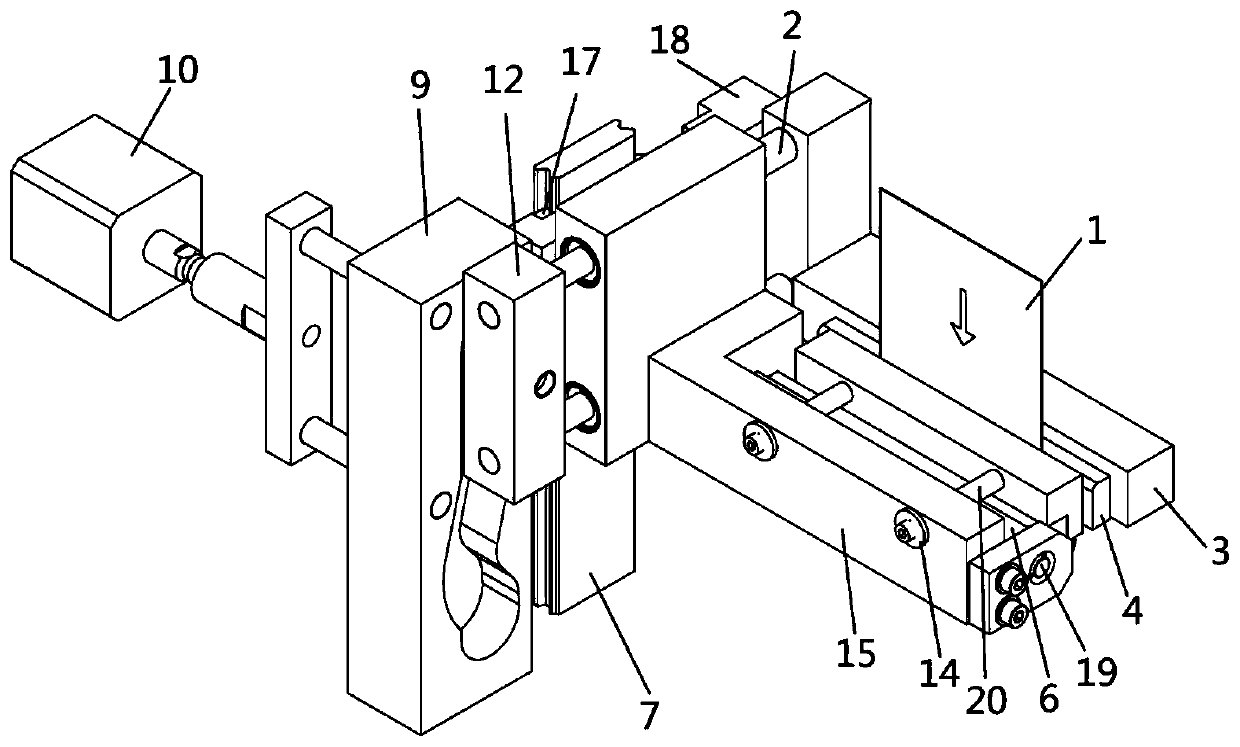

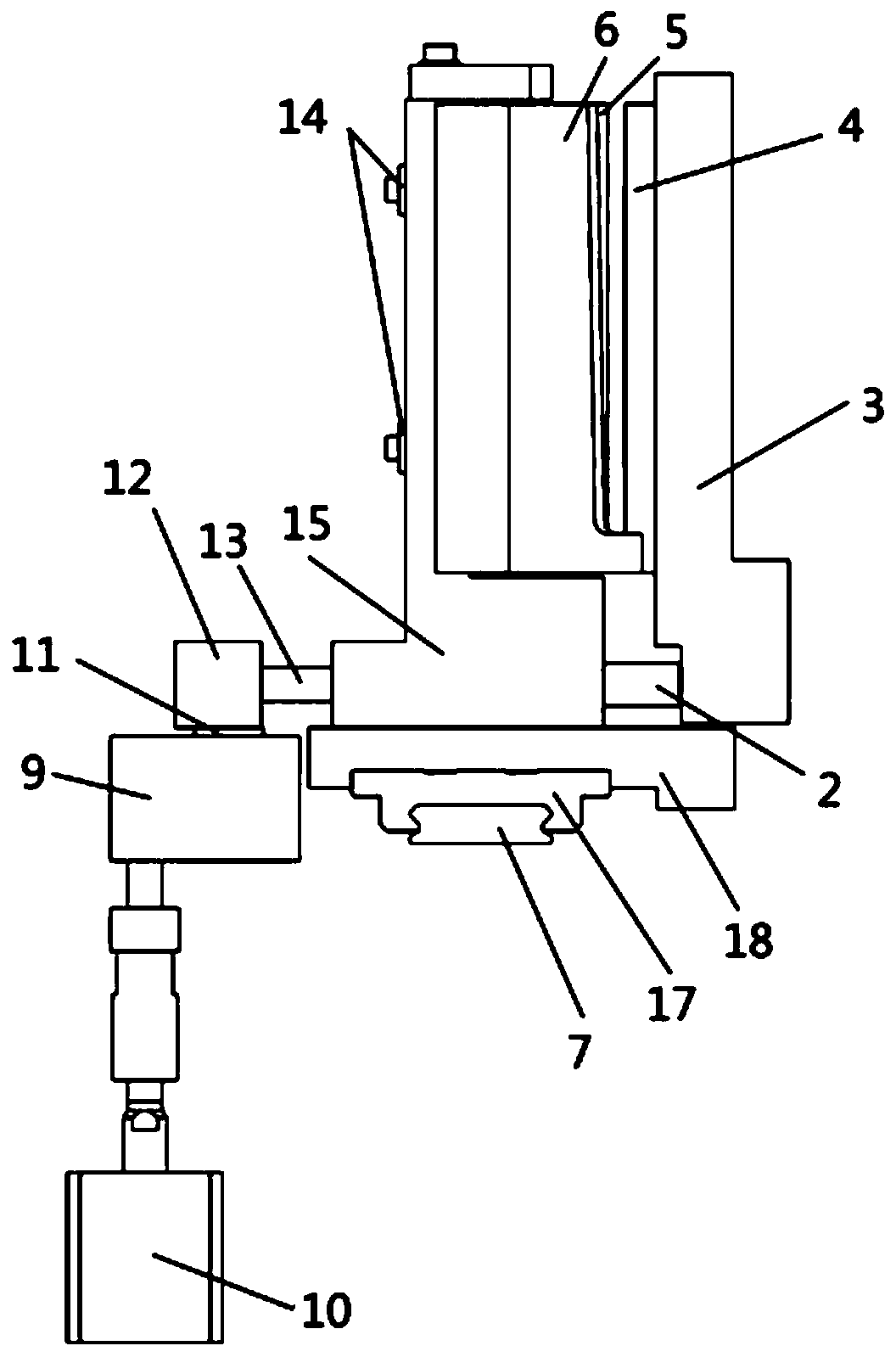

Lithium ion battery pole sheet making method and lithium ion battery pole sheet surface treatment device

InactiveCN103137945AImprove adhesionImprove cycle lifeCell electrodesElectrical batteryLithium electrode

The invention discloses a lithium ion battery pole sheet making method. The method comprises: a pole sheet coating slitting operation; a pole sheet surface treatment operation comprising a step of immersing a coat-slitted pole sheet in an aqueous high-polymer treatment liquid, and a step of drying to obtain a high-polymer film on the surface of the pole sheet; and a made sheet packaging operation. The method which allows the pole sheet surface treatment operation to be increased and the high-polymer film to be formed on the surface of the pole sheet can effectively prevent the powder fall of the lithium ion battery pole sheet, reduce the floatation powder generated in the making process of a battery, improve the bonding force of active substances, and improve the comprehensive electrochemical performances of the lithium ion battery. The invention also discloses a surface treatment device of the lithium ion battery pole sheet. The device comprises, sequentially arranged, an unreeling wheel, a pole sheet immersion material tank, a spreading knife, a drying tunnel, roller machines and a reel wheel, and can automatically and efficiently complete the surface treatment of the pole sheet, so the industrialized continuous production is convenient.

Owner:湖南三迅新能源科技有限公司

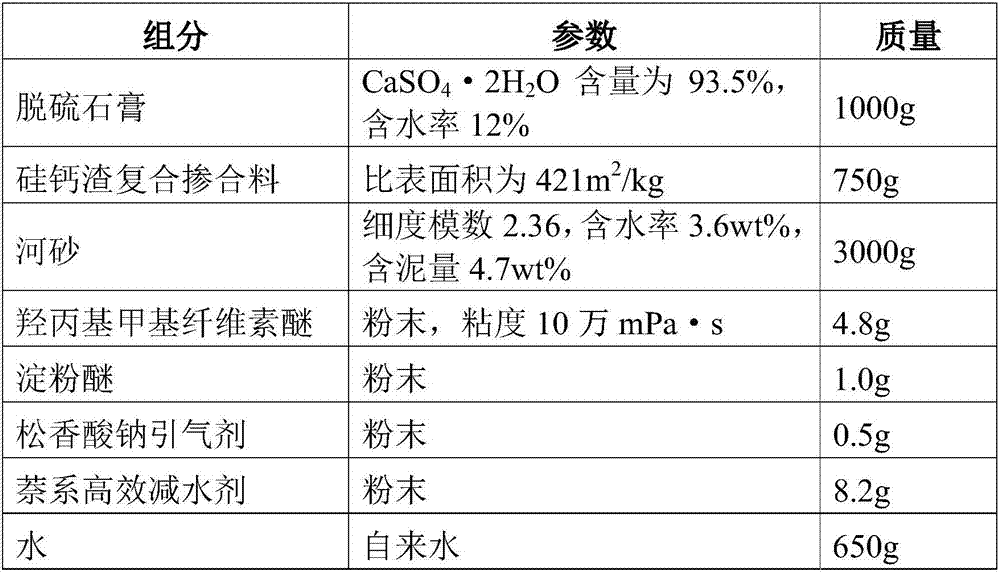

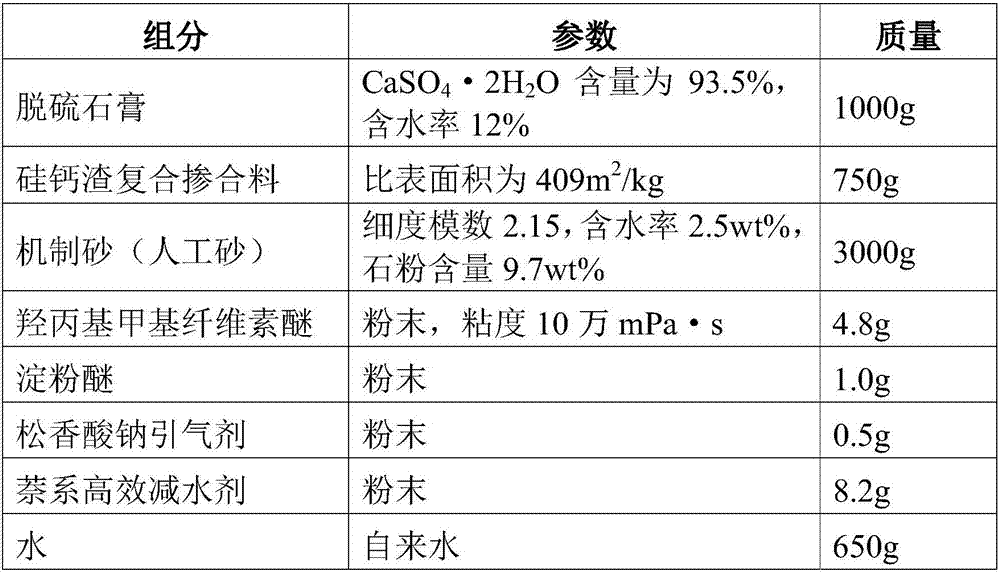

Cement-free desulfurized gypsum plastering mortar and preparation method thereof

The invention provides a cement-free desulfurized gypsum plastering mortar and a preparation method thereof. The cement-free desulfurized gypsum plastering mortar comprises the following components in parts by weight: 15-20 parts of desulfurized gypsum, 15-20 parts of silicon-calcium slag composite admixture, 60-70 parts of aggregate, 0.2-0.3 part of additive and 10-15 parts of water. The silicon-calcium slag composite admixture is composed of the following components in parts by weight: 40-50 parts of silicon-calcium slag, 1-5 parts of desulfurized gypsum, 30-35 parts of fly ash, 15-25 parts of granulated blast-furnace cinder and 0.05-0.08 part of grinding aid. The cement-free desulfurized gypsum plastering mortar is free of any cement and directly adopts the desulfurized gypsum, silicon-calcium slag and other industrial solid wastes as the basic components, so that the prepared cement-free desulfurized gypsum plastering mortar can satisfy requirements in related standards, and does not need to perform drying, calcination, milling and other processes on the desulfurized gypsum, thereby lowering the energy consumption and pollution in the desulfurized gypsum plastering mortar working process.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Heat insulation composite board and preparation method thereof

ActiveCN111823681ASimple molding processEasy to operateClimate change adaptationSynthetic resin layered productsCalcium silicateInsulation layer

The invention belongs to the technical field of heat insulation, and discloses a heat insulation composite board and a preparation method thereof. The heat insulation composite board comprises a firstpanel layer and a heat insulation layer, and the heat insulation layer and the first panel layer are integrally formed; the first panel layer is a fiber reinforced resin-based composite sheet, a metal plate, a cement plate, a calcium silicate plate or a gypsum plate, and the heat insulation layer is a fiber reinforced aerogel felt. The preparation method comprises the following steps of: (1) flatly laying a fiber-reinforced aerogel felt; (2) paving the first panel layer on the upper surface of the fiber reinforced aerogel felt; and (3) carrying out hot press molding treatment to obtain the heat insulation composite board. The heat insulation composite board provided by the invention can implement a thermal insulation scheme on scenes like pipes, walls and box bodies, and has the advantages of convenient operation, simplicity, feasibility and the like.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

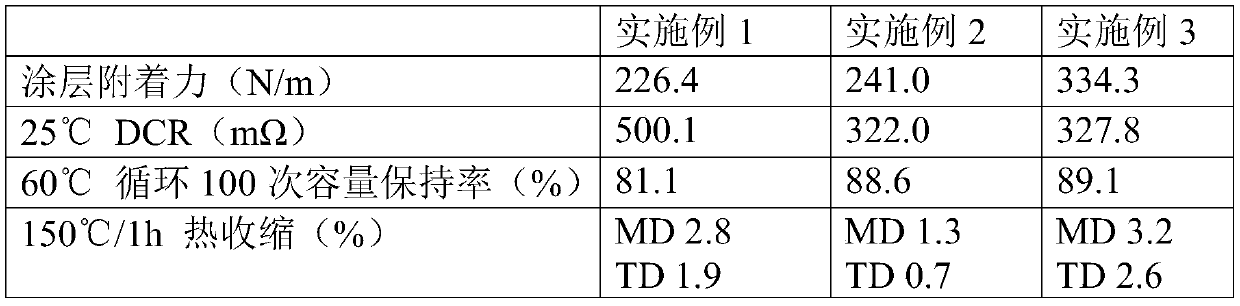

Diaphragm, preparation method and lithium ion battery comprising diaphragm

InactiveCN111384345AImprove bindingAvoid falling powderSecondary cellsCell component detailsPorous substrateCeramic coating

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD

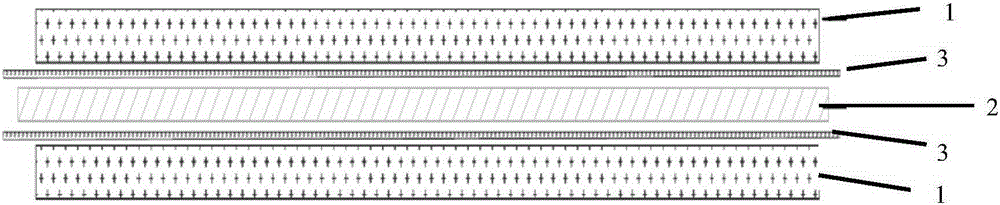

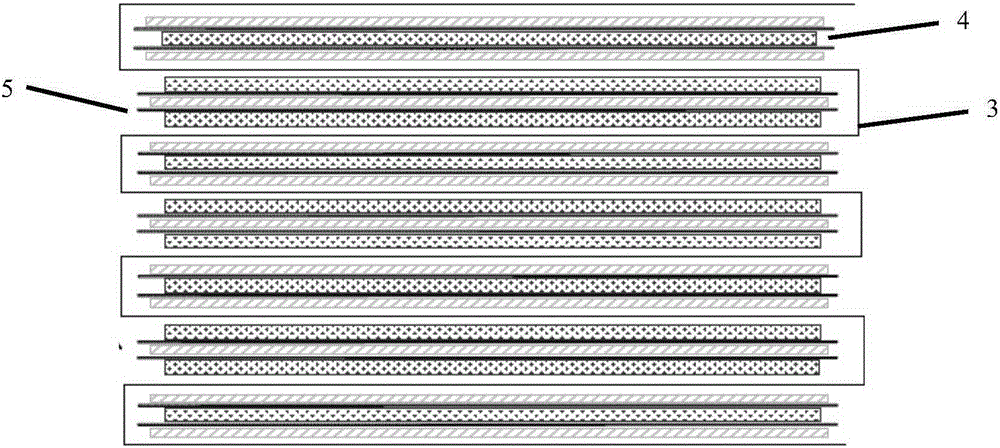

Bag-making type lithium ion battery and preparation method thereof

InactiveCN103094618AImprove production efficiency and yieldImprove sealing and safety performanceFinal product manufactureCell component detailsElectrical batteryLithium electrode

The invention discloses a bag-making type lithium ion battery and a preparation method thereof. The bag-making type lithium ion battery consists of an aluminum plastic package film, a positive electrode lug, a negative electrode lug, an electrode piece and bag-making type electrode pieces, wherein the electrode pieces and upper and lower layers of membranes are manufactured into a bag containing the electrode pieces in an adhesion manner; the bag-making type electrode pieces and counter electrodes are overlapped together layer to layer to form an electrode group; and the positive electrode lug and the negative electrode lug are respectively welded with a positive electrode lug and a negative electrode lug of the electrode group together. With the adoption of the lithium ion battery provided by the invention, the production efficiency and the yield in manufacturing through a battery assembly process can be improved; and the security problem possibly occurring in a process of using the lithium ion battery can be prevented to a certain extent.

Owner:TIANJIN ENERGIES

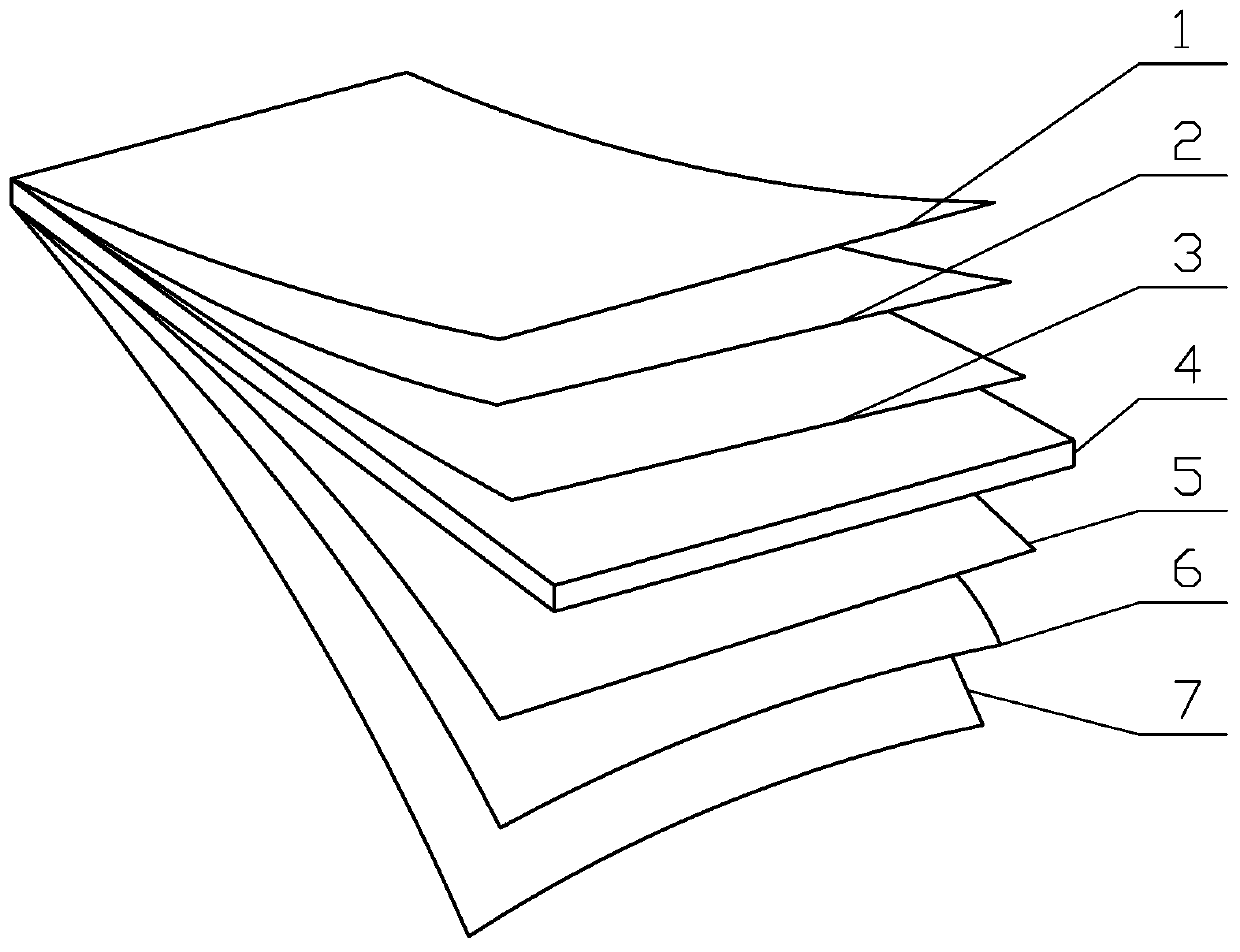

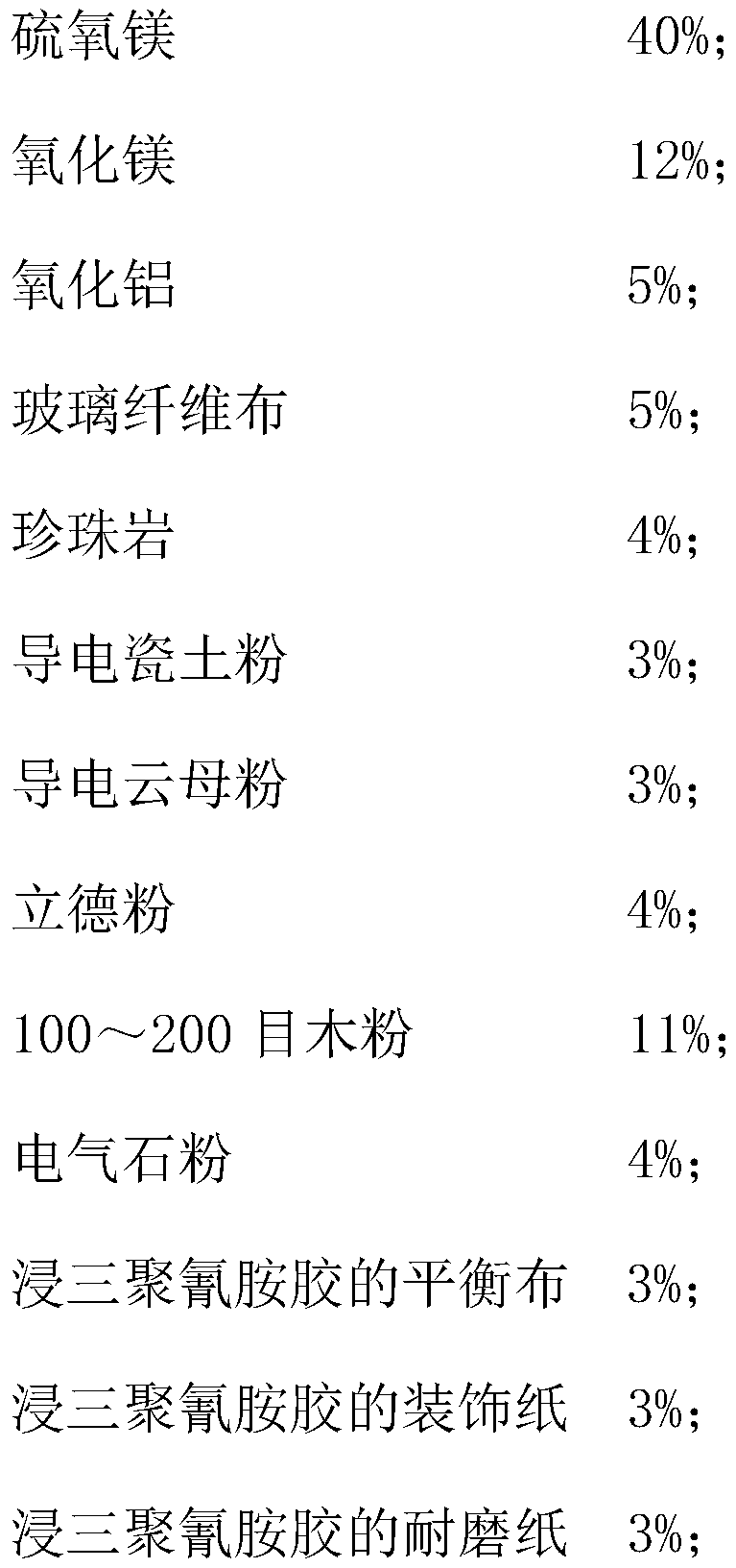

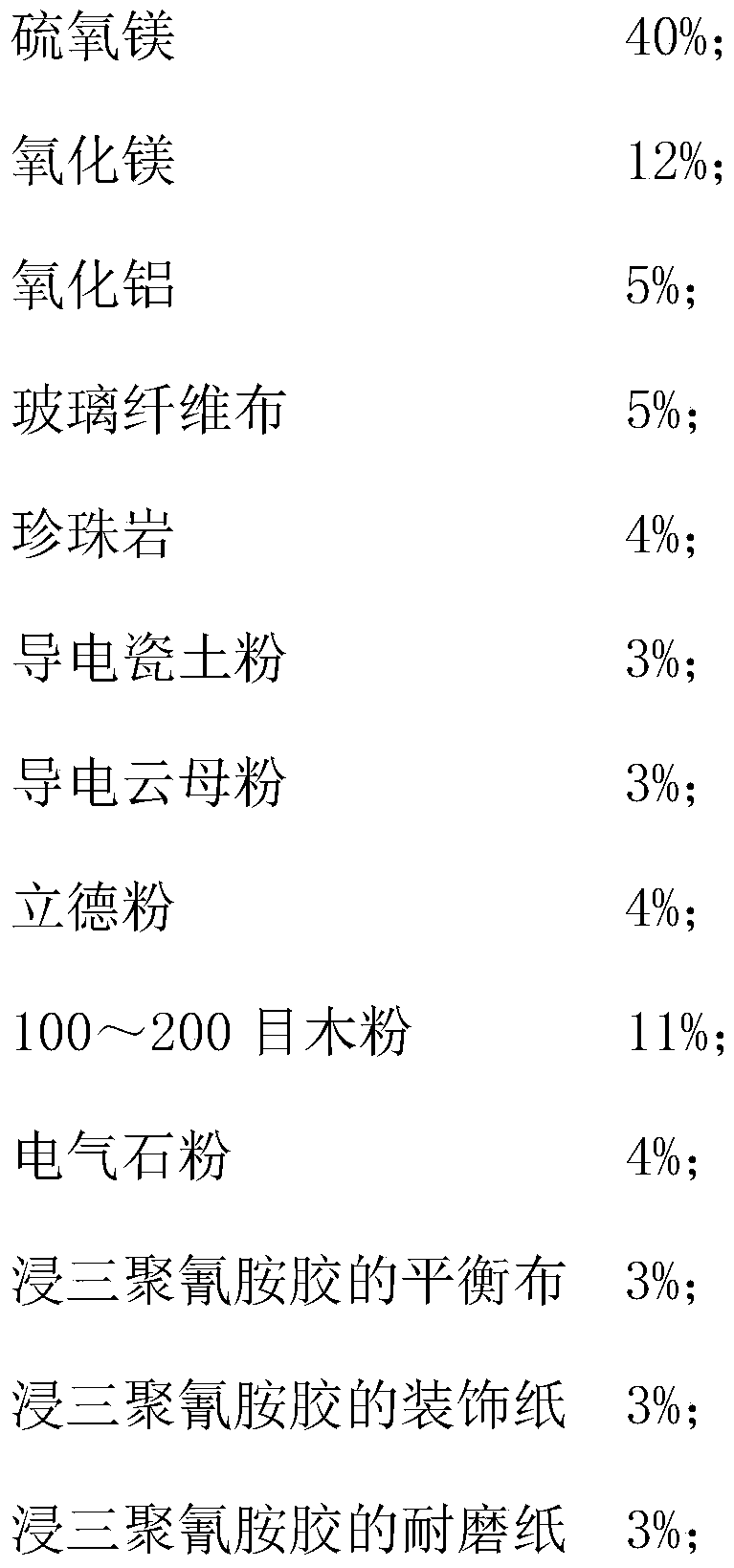

Magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board and production method thereof

PendingCN110091570AImprove insulation performanceStrong weather resistanceCovering/liningsLaminationThermal insulationWear resistant

The invention particularly relates to a magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board and a production method thereof, wherein the raw materialscomprise: 40% of magnesium oxysulfate, 12% of magnesium oxide, 5% of alumina, 5% of a glass fiber cloth, 4% of perlite, 3% of electric-conduction procelain clay powder, 3% of electric-conduction micapowder, 4% of lithopone, 11% of 100-200 mesh wood powder, 4% of tourmaline powder, 3% of a balance cloth immersed with a melamine glue, 3% of decoration paper immersed with a melamine glue, and 3% ofwear-resistant paper immersed with a melamine glue. The production method comprises: 1) preparing a magnesium oxysulfate substrate having a fine pore structure; 2) respectively spreading both surfaces of the magnesium oxysulfate substrate with a balance cloth immersed with a melamine glue, decoration paper immersed with a melamine glue, and wear-resistant paper immersed with a melamine glue; and3) carrying out hot pressing molding. According to the present invention, the magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board has advantages of light weight, smooth surface, high hardness, good fireproof performance, good moisture proof performance, good temperature-difference resistance, strong water resistance, no moisture absorption halogenaccumulation, good thermal insulation effect and wide application range, and does not contain asbestos, formaldehyde and harmful radioactive elements.

Owner:山东凯勒蓝房家居文化发展有限公司

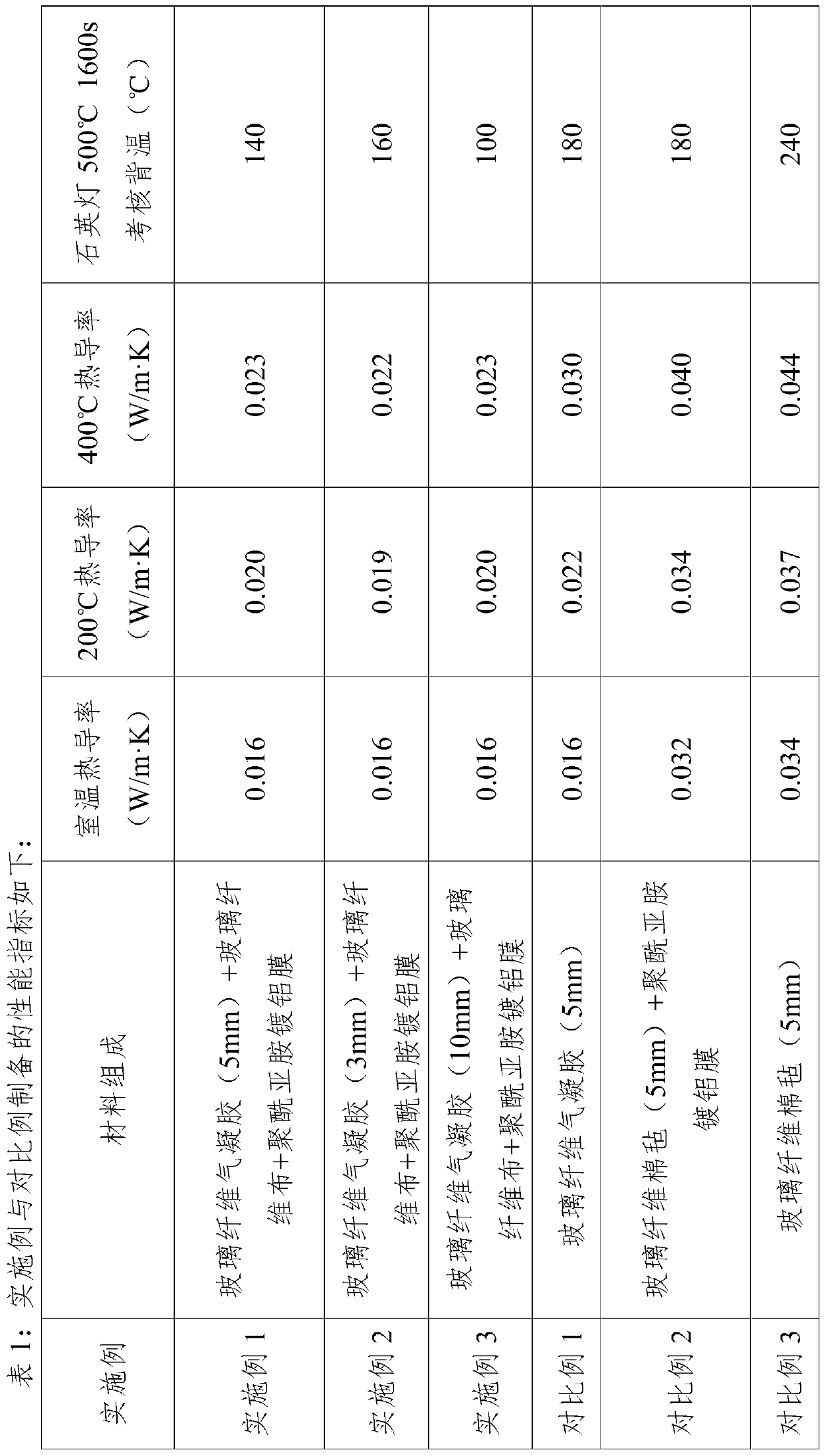

Light high-efficiency multilayer heat insulation material and preparation method thereof

ActiveCN110406135AAvoid falling powderImprove integritySynthetic resin layered productsVehicle componentsFiberThermal insulation

The invention relates to a light high-efficiency multilayer heat insulation material and a preparation method thereof. The method comprises the following steps: (1) impregnating a fiber preform with sol to prepare an aerogel composite material; (2) wrapping and sewing the aerogel composite material prepared in the step (1) by using fiber cloth to obtain a thermal insulation material preform; and (3) bonding a reflection film on the surface of the thermal insulation material preform obtained in the step (2) to prepare the light high-efficiency multilayer thermal insulation material. The invention also provides the light high-efficiency multilayer heat insulation material prepared by the preparation method, and the material can carry out high-efficiency heat insulation protection on a targetstructure at room temperature -500 DEG C. The light high-efficiency multilayer heat insulation material and the preparation method thereof have simple preparation process and low cost, and are expected to be popularized and applied in the fields of low-temperature heat insulation and civil heat insulation in aerospace.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A coiling lithium secondary battery

InactiveCN101150184AAvoid falling powderAvoid micro-short circuit inside the batteryFinal product manufactureActive material electrodesMembrane configurationElectrolyte

This invention discloses a winded Li-secondary cell including a shell and a core winder and electrolyte in the shell, in which, the winder is formed by winding positive pole plates, membranes and negative pole plates characterizing in not coating active substance inside of the pole plates at the bending place of the winder to prevent fall off of powder so as to avoid micro-short-circuit in the cell caused by fall off active substance breaking the membrane and increase the quality.

Owner:SHENZHEN BAK BATTERY CO LTD

Method for forming aqueous super capacitor

InactiveCN101656156AAvoid falling powderShort formation cycleElectrolytic capacitorsHybrid/EDL manufactureInternal resistanceSupercapacitor

The invention provides a method for forming an aqueous super capacitor. In the method, quantitative electrolyte is added by a vacuum injection method, and the aqueous super capacitor is charged and discharged for activation through different current values in multiple stages. Therefore, the method effectively improves the powder dropping phenomena of pole pieces in the process of formation and enhances the product properties of current leakage and internal resistance of the super capacitor. Meanwhile, the method has the advantages of greatly shortening the forming period and improving the production efficiency.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

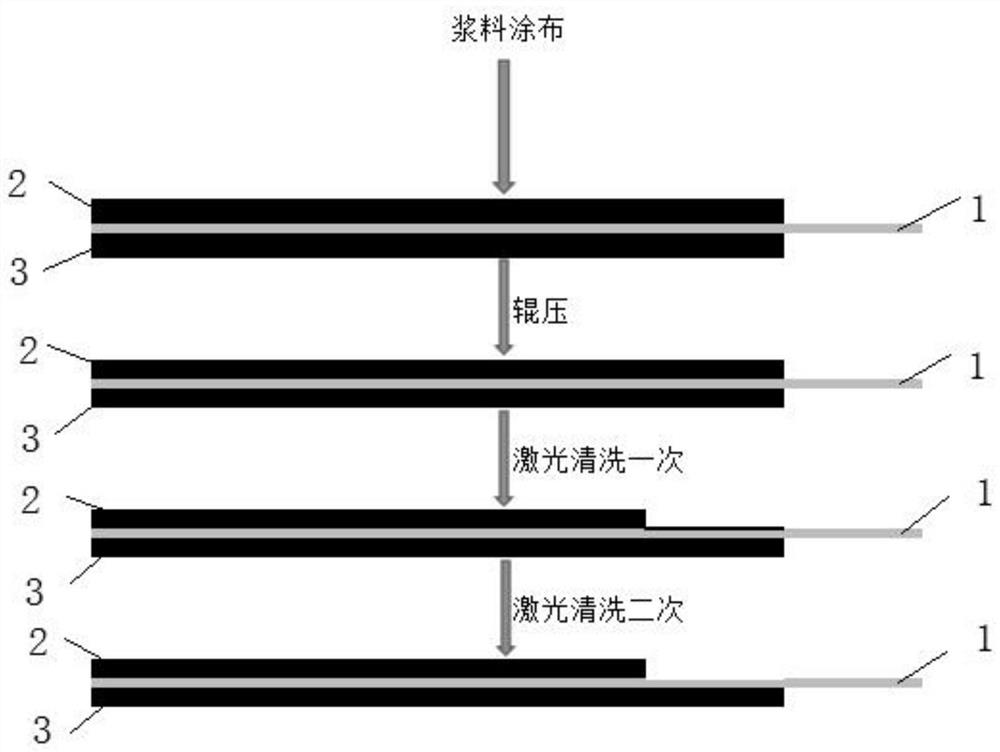

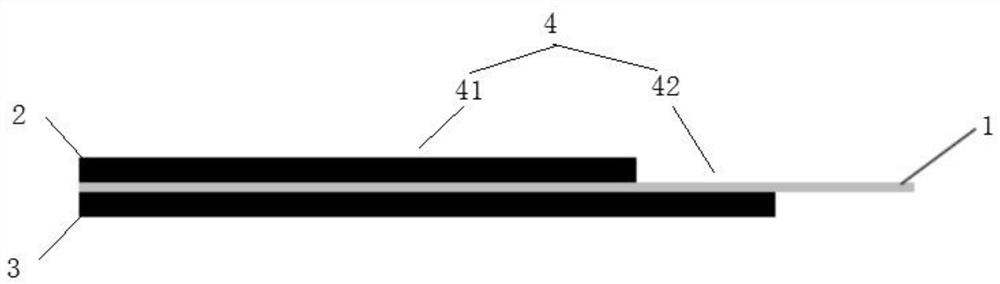

Preparation method of fast charging type lithium ion battery pole piece, pole piece and lithium ion battery

InactiveCN112582583AConsistent thicknessConsistent stressElectrode rolling/calenderingSecondary cellsFast chargingPhysical chemistry

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a fast charging type lithium ion battery pole piece. The method comprises thefollowing steps of coating slurry with active substances on the two surfaces of a current collector to obtain the pole piece with a first active substance layer and a second active substance layer which are symmetrically arranged; rolling the two surfaces of the pole piece; and cleaning the redundant first active material layer to obtain the fast charging type lithium ion battery pole piece witha double-sided coating area and a single-sided coating area. According to the preparation method of the fast charging type lithium ion battery pole piece, the rolling thickness of the single-side coating area of the pole piece after rolling is consistent with that of the double-side coating area, and the compression degree of active substance layers at the two sides of the pole piece can be effectively ensured to be consistent during rolling; and the failure problems of powder falling, lithium precipitation and the like of the single-side coating area in the subsequent charging and dischargingprocess due to different thicknesses of the single-side coating area and the double-side coating area of the pole piece and different compression degrees when the pole piece is rolled to pass througha roll gap in the traditional process, are effectively avoided.

Owner:东莞维科电池有限公司

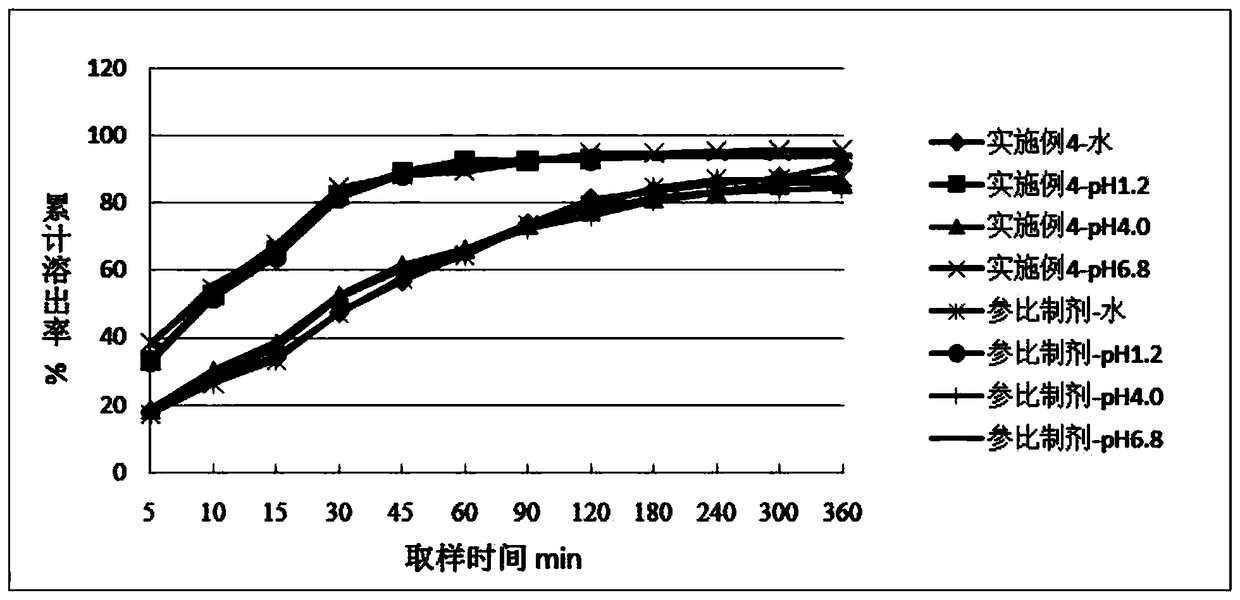

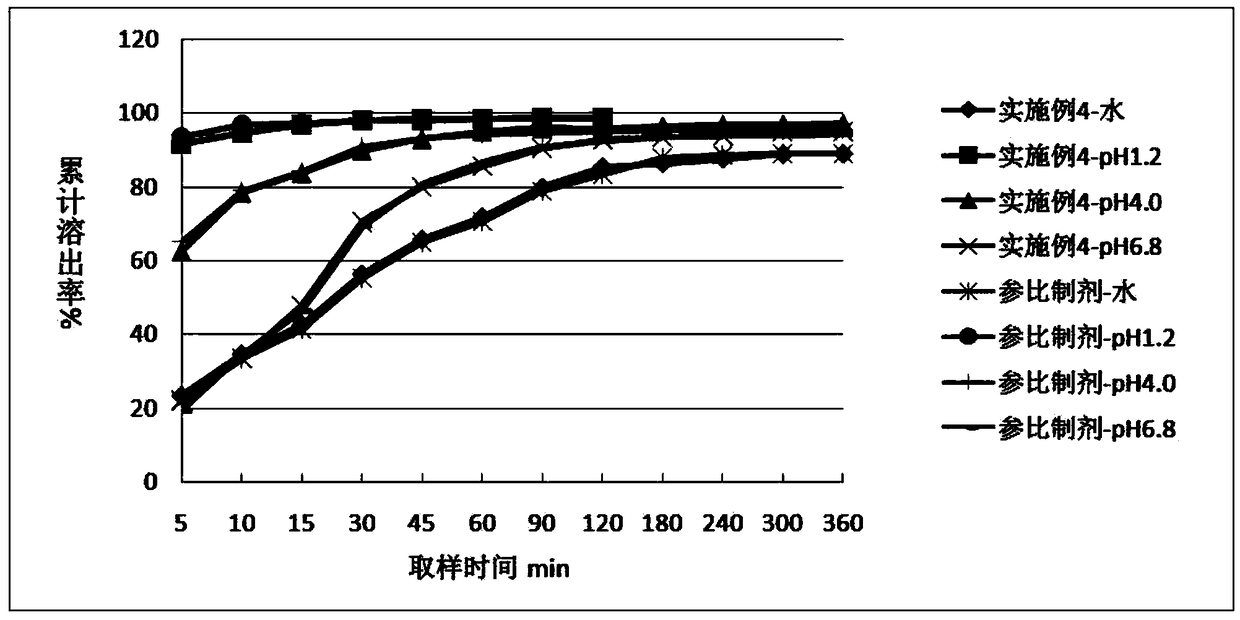

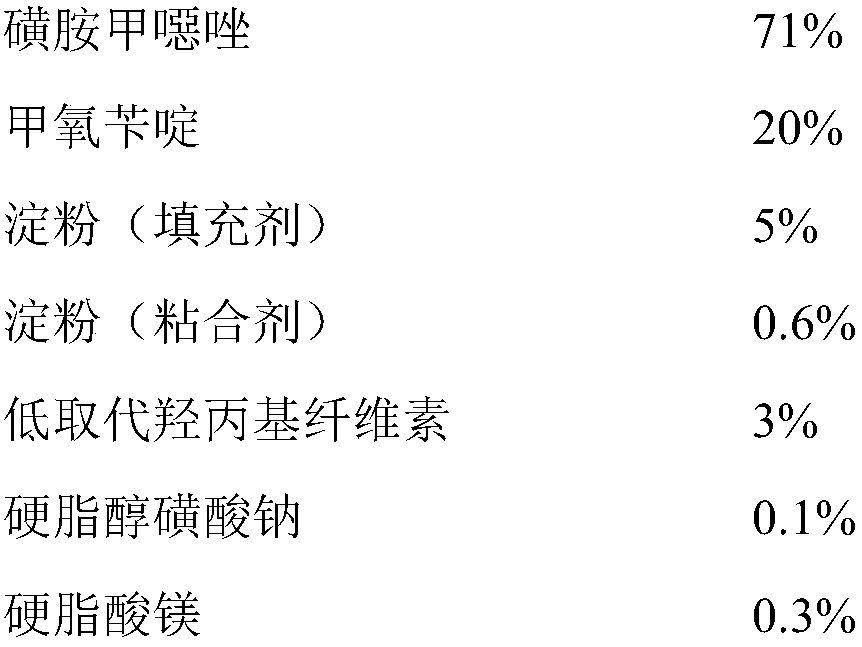

Compound sulfamethoxazole tablet and preparation method thereof

InactiveCN108743552AReduce the amount addedAvoid loose flakesAntibacterial agentsOrganic active ingredientsAdhesiveTrimethoprim

The invention discloses a compound sulfamethoxazole tablet and a preparation method of the compound sulfamethoxazole tablet. The compound sulfamethoxazole tablet takes sulfamethoxazole and trimethoprim as the main drugs, and is added with a filler, an adhesive, a disintegrating agent, a surfactant, a lubricant and a coating agent; and the compound sulfamethoxazole tablet is prepared through the steps of mixing, pelletizing, drying, tableting, coating and the like. The obtained compound sulfamethoxazole tablet composition effectively avoids the condition that the solid compound sulfamethoxazolepreparation is loosened because of weak granule viscosity, the dissolution of the preparation is obviously improved, the stability of the preparation is guaranteed, the product quality of the preparation is improved, the quality and the treatment effect of the preparation are guaranteed, and the compound sulfamethoxazole tablet has an excellent application prospect.

Owner:ZHENGZHOU MINGZE MEDICAL TECH

Method for preparing sintering-free coating of polycrystalline silicon ingot crucible

InactiveCN104561963AHigh viscosityImprove adhesionPolycrystalline material growthSolid/suspension decomposition chemical coatingSilicon nitridePolycrystalline silicon

The invention discloses a method for preparing a sintering-free coating of a polycrystalline silicon ingot crucible. The method comprises the following steps: after uniformly mixing silica sol with water, adding silicon nitride and nanosilicon dioxide, and stirring uniformly to obtain a slurry; polishing the inner wall of the crucible with a scouring pad, blowing with compressed air after polishing, then preheating the crucible, and raising the corner temperature of the crucible to 70-80 DEG C; spraying the inner wall of the crucible with the slurry, during spraying, controlling the corner temperature of the crucible at 60-70 DEG C and spraying thickness at 0.8-0.9mm, and after spraying, baking the crucible at 60-70 DEG C for 20-30 minutes. Compared with the prior art, the method can prevent the coating from peeling and dusting, and meanwhile, avoids the crack of the polycrystalline silicon ingot.

Owner:无锡荣能半导体材料有限公司

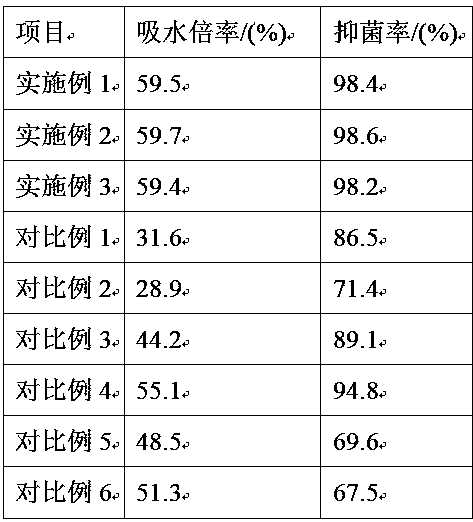

Method for preparing strong-absorption antibacterial paper diaper

InactiveCN110090110AImprove antibacterial propertiesImprove water absorptionSanitary towelsBaby linensSoaking skinNonwoven fabric

The invention mainly relates to the technical field of hygiene products and discloses a method for preparing a strong-absorption antibacterial paper diaper. The method comprises the steps of surface layer preparation, Ag-activated carbon composite fiber layer preparation, water-absorption cotton preparation, water-absorption non-woven fabric preparation, core layer water-absorption layer preparation, bottom water-proof layer preparation and paper diaper preparation. By adopting the method for preparing the strong absorption antibacterial paper diaper, the paper diaper has strong hygroscopicity, achieves instant absorption, can prevent moisture of urine from soaking skin, is breathable and antibacterial, keeps skin to be dry and fresh, avoids generating the allergic phenomenon, and ensuressafety and health; the surface non-woven fabric is prepared by mixing fibers and performing spunlacing and is prepared from chitosan fibers, composite water-absorbent resin fibers, nano-antibacterialbioprotein fibers and silk fibers, so that the surface non-woven fabric can instantly absorb urine after contacting the urine and prevents itching and red rash since the urine contacts skin.

Owner:安徽舒源妇幼用品有限公司

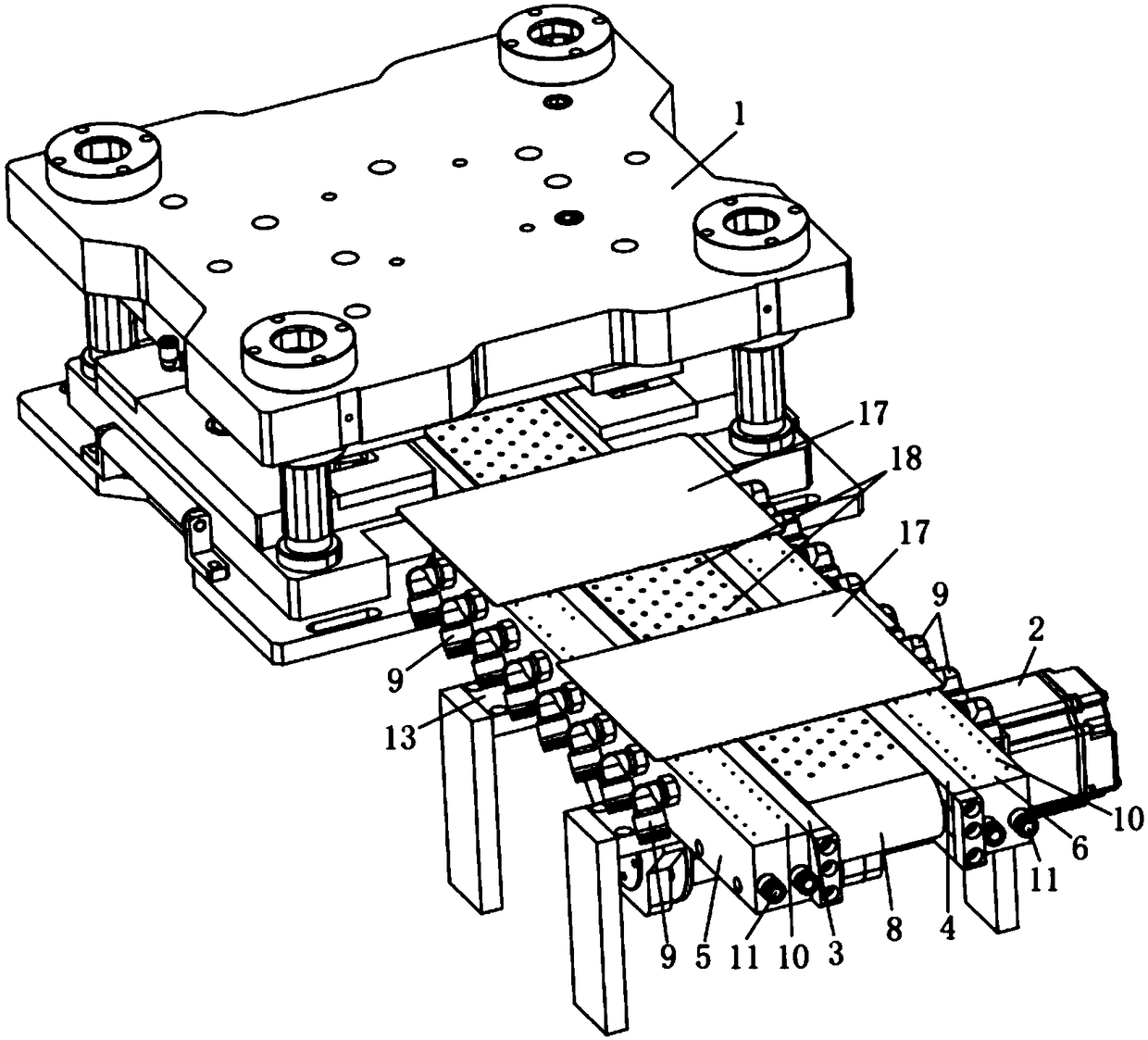

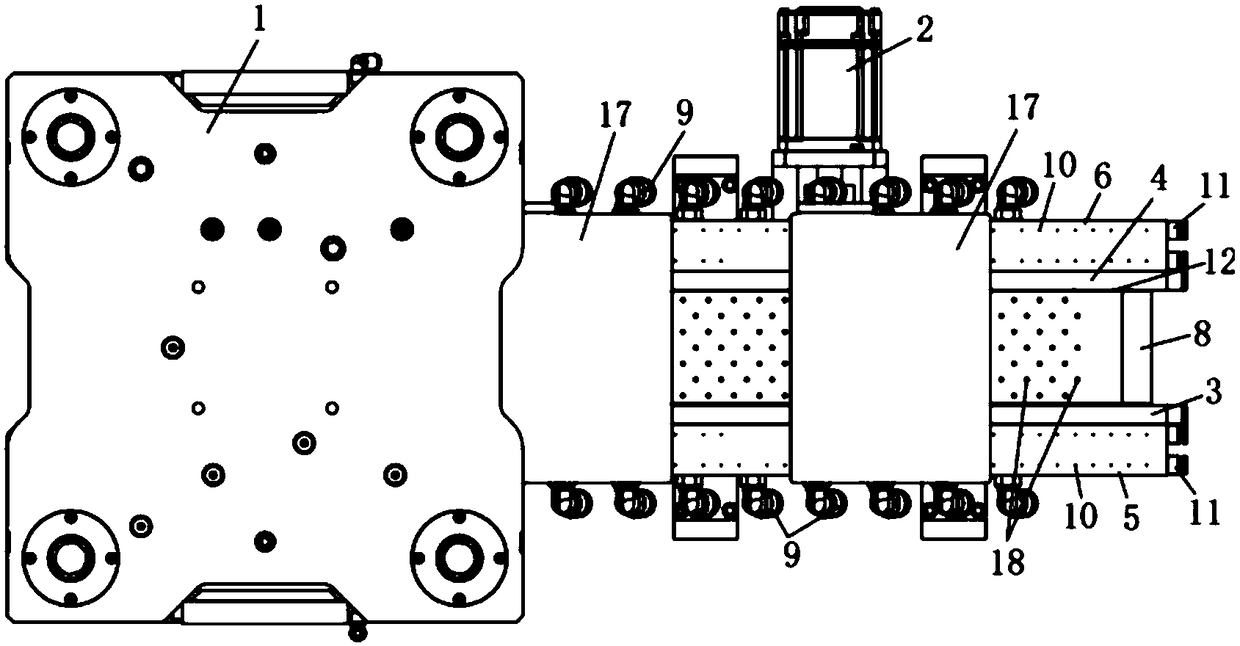

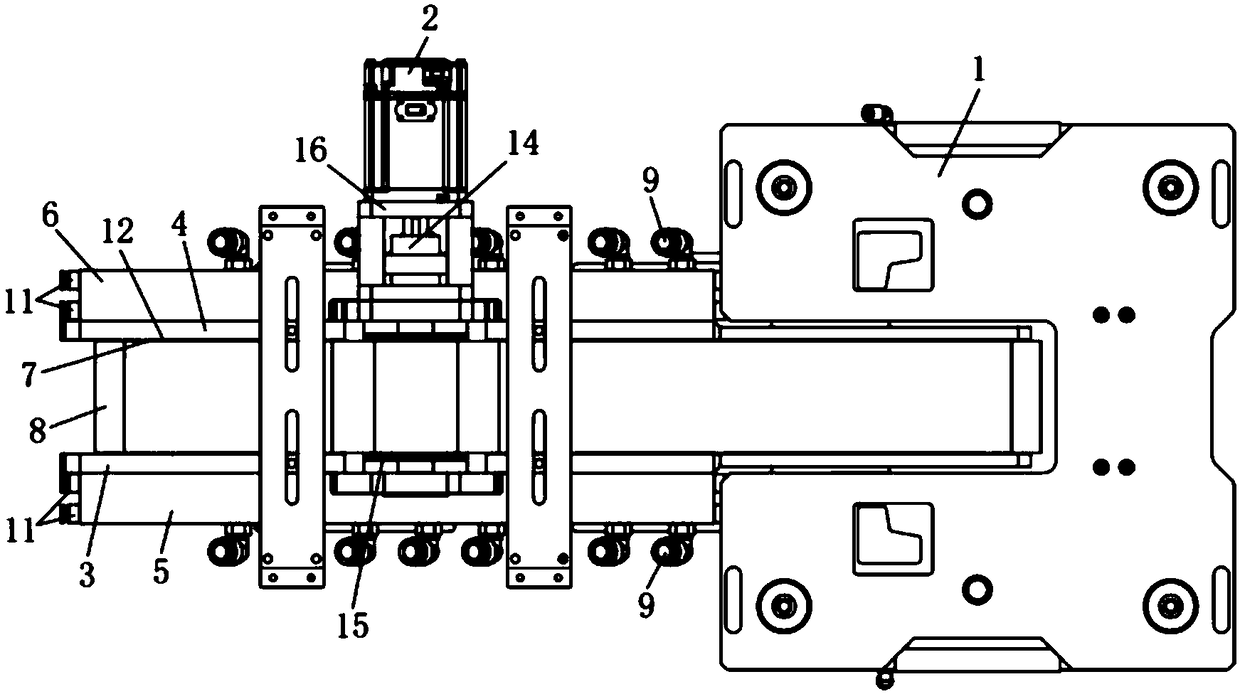

Entering air-flotation type belt conveying mechanism

The invention relates to the technical field of conveying mechanisms, in particular to an entering air-flotation type belt conveying mechanism. The conveying mechanism comprises a tab punching mold, avacuum belt conveying mechanism, a servo motor in driving connection with the vacuum belt conveying mechanism, a left belt side plate, a right belt side plate, a left pole piece flotation plate and aright pole piece flotation plate; the front end of the vacuum belt conveying mechanism is arranged below the tab punching mold; the vacuum belt conveying mechanism comprises a vacuum cavity, a belt and negative-pressure gas suction pipe joints; negative-pressure holes are formed in the upper part of the vacuum cavity and the belt; ventilation cavities are formed inside the left pole piece flotation plate and the right pole piece flotation plate; a plurality of blowing holes are formed in the upper part of the left pole piece flotation plate and the upper part of the right pole piece flotationplate; and blowing end gas pipe joints are arranged at the ends of the left pole piece flotation plate and the right pole piece flotation plate. By the aid of the conveying mechanism, the phenomenonthat the front ends of pole pieces or the single edges of the pole pieces scratch the surface of the belt can be prevented, powder falling of the edges of the pole pieces can be avoided, then the polepiece quality in the pole piece forming technology can be guaranteed, and the yield and the safety of pole piece production can be improved.

Owner:GUANGDONG SUNIVE INTELLIGENT EQUIP CO LTD

Novel green environmentally-friendly anti-scaling filtering material and preparation method thereof

InactiveCN108609752AStrong water absorptionStrong adsorptionSeawater treatmentSpecific water treatment objectivesIonSeawater

The invention provides a novel green environmentally-friendly anti-scaling filtering material and a preparation method thereof. The novel green environmentally-friendly anti-scaling filtering materialcomprises 30-50wt.% of powdered attapulgite with 200-600 meshes, 35-45wt.% of powdered humic acid with 200-600 meshes, 5-10% of powdered montmorillonite with 200-600 meshes, 10-15wt.% of powdered zeolite, and 40-60wt.% of a liquid adhering agent. According to the novel green environmentally-friendly anti-scaling filtering material, the raw materials collaborate with each other, so that the novelgreen environmentally-friendly anti-scaling filtering material is free from phosphorus, nontoxic, and nuisanceless, can be completely biologically degraded, is high in adhesion capacity, shows extremely high chelating capacity to ions, and is high in corrosion inhibition function, anti-scaling function, bacteria inhibiting function, smell removing function and other performance; powder is hard tofall off and dissolving is greatly prevented during use; the strength is high; and the novel green environmentally-friendly anti-scaling filtering material can be widely applied to the fields of industrial water treatment, seawater desalting, and the like; the environment is protected; and the cost is low.

Owner:QUANZHOU WANLIDE ENERGY SAVING TECH

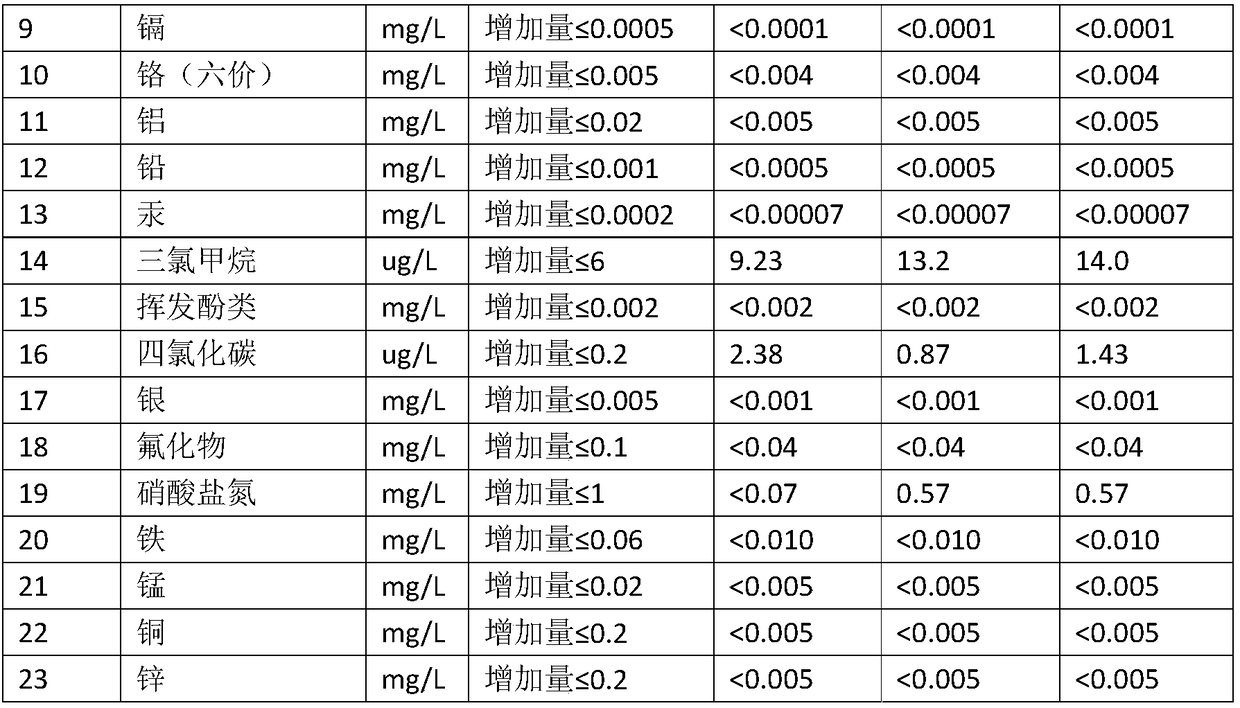

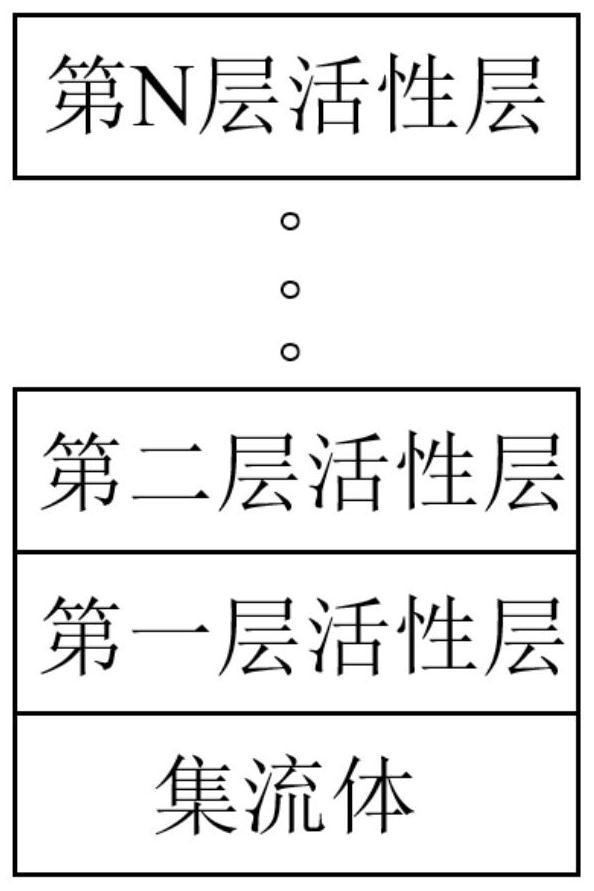

Negative plate as well as preparation method and application thereof

InactiveCN111613774AIncrease energy densityAvoid falling powderSecondary cellsNegative electrodesPhysicsChemistry

The invention provides a negative plate as well as a preparation method and application thereof. On the first aspect, the invention provides a negative plate. The negative plate comprises a current collector and N active layers, wherein the active layer comprises a carbon material and a silicon material, the layer number set of the active layers is recorded as S={1, 2,..., i-1, i,..., N}, N is greater than or equal to 2, and the direction from the first active layer to the Nth active layer is the direction gradually far away from the current collector; and the mass of the silicon material in the (i-1)th active layer is greater than the mass of the silicon material in the ith active layer, and the mass of the carbon material in the (i-1)th active layer is less than the mass of the carbon material in the ith active layer. According to the negative plate provided by the invention, through a mode that the mass of the silicon material is gradually reduced layer by layer and the mass of thecarbon material is gradually increased layer by layer, powder falling of the negative plate in a circulation process can be effectively prevented, the volume expansion rate of the negative plate is reduced, and the circulation performance of the negative plate is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

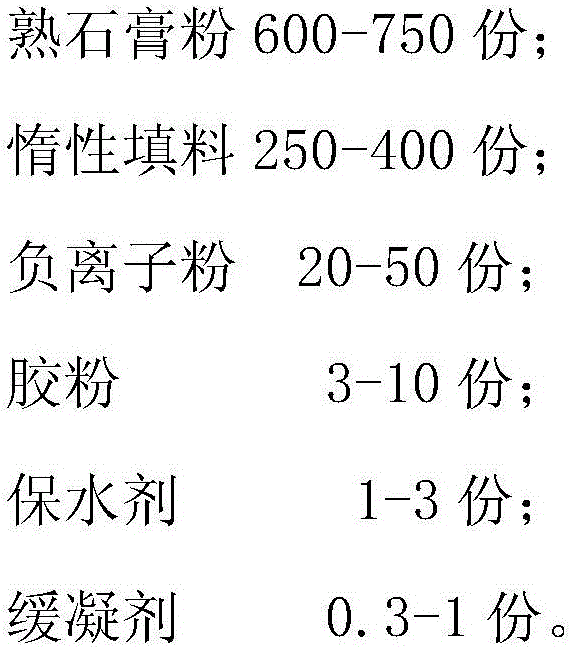

Negative ion gypsum-based putty powder and preparing method

ActiveCN105906294AHigh bonding strengthSmall shrinkage deformationUltimate tensile strengthLiving environment

Negative ion gypsum-based putty powder and a preparing method are disclosed and belong to the field of building wall decoration materials. The putty powder comprises 600-750 parts by weight of powder of plaster of Paris, 250-400 parts by weight of an inert filler, 20-50 parts by weight of negative ion powder, 3-10 parts by weight of glue powder, 1-3 parts by weight of a water retaining agent and 0.3-1 part by weight of a retarder. The putty powder has characteristics of high adhesion strength, low shrinkage deformation, capability of preventing peeling, powder dropping and cracking, good workability, excellent construction properties, environment protection, and the like, and is suitable for puttying treatment of various walls. Negative ions can be effectively released through the negative ion powder, thus meeting desire for enjoying nature flavor for people and fundamentally changing the present living environment. The putty powder and the method have good development significance.

Owner:湘乡金联建材有限公司

Fluorescent powder slurry materialfor plasma display and forming method on shadow mask

InactiveCN101159214AGood dispersionGood suspensionTube/lamp screens manufactureDischarge tube luminescnet screensOrganic solventMetallurgy

The invention relates to a fluorescent powder slurry for plasma display and the formation method on shadow mask, belonging to the technical field of flat panel TV set. The inventive slurry consists of fluorescent powder, organic resin, organic solvent and nanopowder, wherein the fluorescent powder accounts for 40-50 percent of the total weight, the organic resin accounts for 3-6 percent of the total weight, the organic solvent accounts for 45-55 percent of the total weight, and the nanopowder accounts for 0.5-3 percent of the total weight. The proper amount of nanopowder (0.5-3 percent) added into the fluorescent powder slurry can effectively improve the dispersion and the suspension properties of the fluorescent powder in the slurry and can well improve the thixotropy of the fluorescent powder slurry so as to ensure that the slurry viscosity decreases during printing to obtain adequate feeding amount and also ensure that the slurry can rapidly regain the high viscosity and settle at the periphery of small holes other than flowing out when the slurry is printed to the holes of the shadow mask. Meanwhile, the slurry can be oven-dried and sintered after the printing process such that the nanopowder is filled into the gap between particles of fluorescent powder, thereby well bonding the fluorescent powder particles and preventing powder loss resulting from insufficient bonding force of the fluorescent powder.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

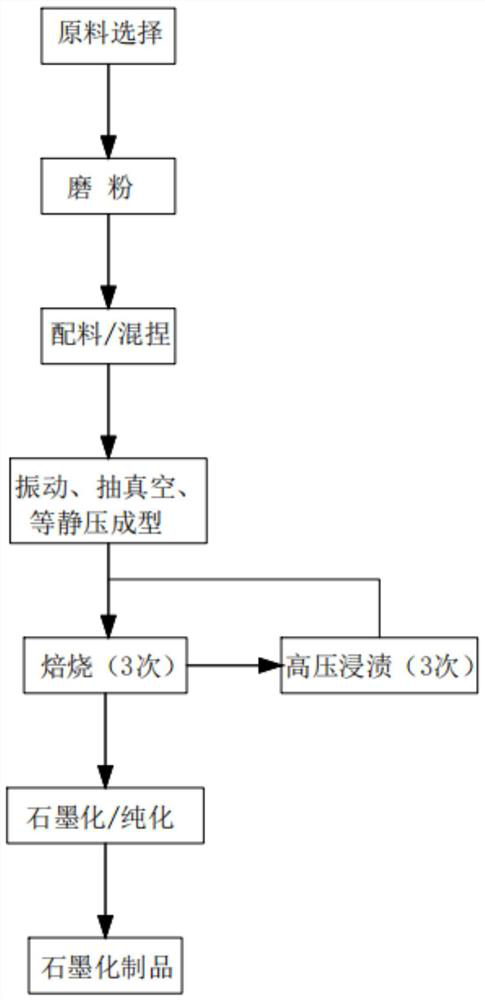

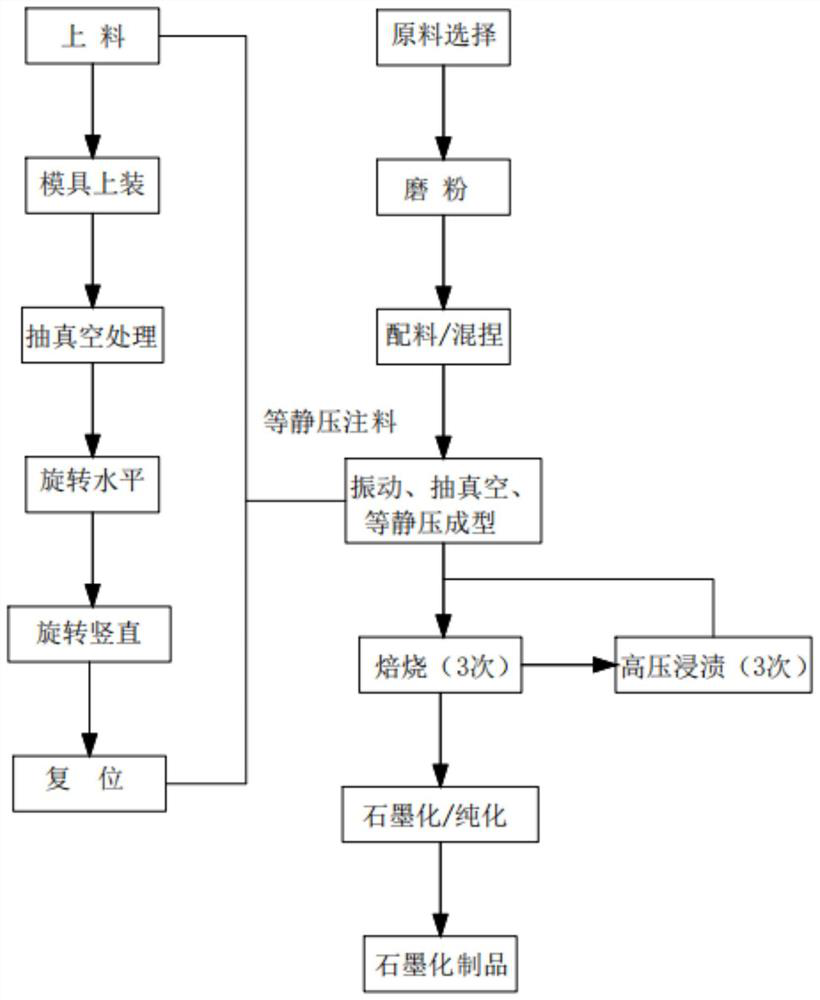

Isostatic graphite preparation process for craft product processing

The invention relates to the technical field of graphite craft product processing, in particular to an isostatic graphite preparation process for craft product processing. The process comprises the following steps: raw material selection, stirring, mixing and kneading, forming, primary roasting, primary dipping, secondary roasting, secondary dipping, tertiary roasting and graphitization / purification. Vibration and vacuumizing treatment are carried out on a kneaded and ground mixture before isostatic compaction, air among powder of the mixture is removed, so influence on the density of a formedgraphite product in the isostatic compaction process is avoided, the density of a formed graphite product is improved, the quality of the formed graphite product is improved, and the technical problem that graphite products cannot be applied to artware processing due to density factors is solved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

High wearing feature sticking magnetic stripe

InactiveCN1622127AGood dispersionIncrease packing densityOther chemical processesRecord carriers used with machinesSolventAntistatic agent

The present invention relates to magnetic bar, and is especially one kind of adhesive magnetic bar with high wear resistance. The magnetic bar consists of adhering layer, base belt, magnetic layer and protecting layer, and features the protecting layer comprise ternary polymer 5-90 (in weight portions, the same below), polyurethane 5-100, assistant 2-30, antistatic agent 3-30, grinding agent 1-20, dispersant 0.1-10, curing agent 2-20 and solvent 400-1400. The recipe makes the magnetic bar possess the features of high hardness, high wear resistance, good heat resistance, high brightness, high antistatic performance, good flexibility and high tensile stability, as well as low material consumption, low cost and long service life.

Owner:CHINA LUCKY FILM CORP

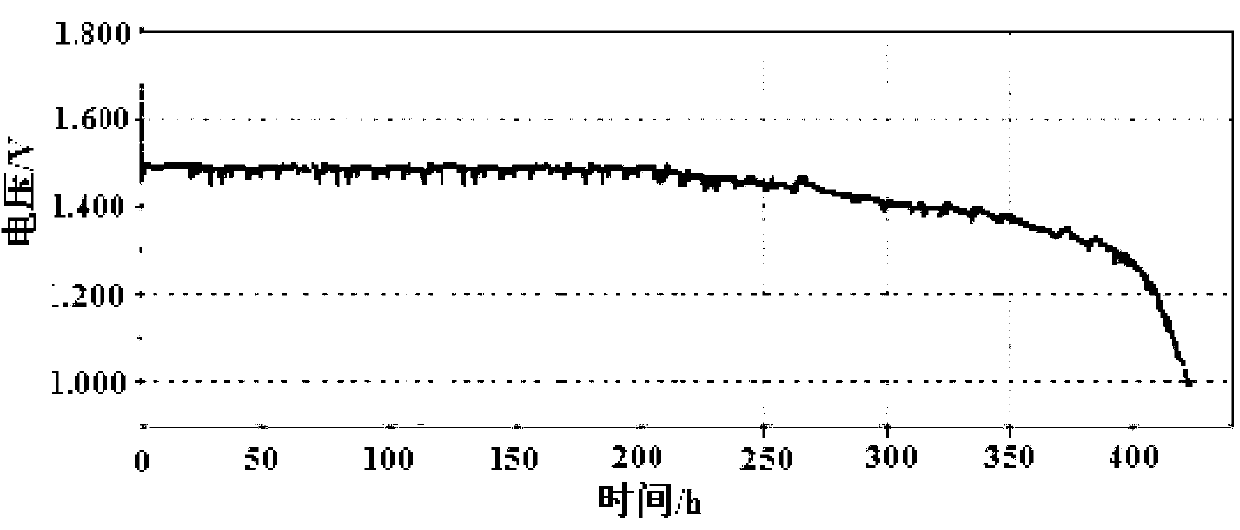

Method for preparing positive plate of lithium-iron button battery

ActiveCN103280550AHigh specific surface areaHigh specific capacityElectrode manufacturing processesSlurryMixed materials

The invention discloses a method for preparing a positive plate of a lithium-iron button battery. The method is capable of producing a high-energy and pollution-free lithium-iron button battery, and comprises the following steps of: placing an iron disulfide positive pole material which is pre-treated at high temperature into a ceramic ball mill for ball-milling, and sieving through a 150-mesh sieve; adding a sieved mixed material of iron disulfide and a conductive agent into the ceramic ball mill for the ball-milling in a mass ratio of 96:(1-3), and sieving through the 150-mesh sieve; adding the mixed material of the iron disulfide and the conductive agent into a stirring drum of a planetary stirrer, adding pre-prepared deionized water boiling at the temperature of 100 DEG C, adding a polytetrafluoroethylene (PTFE) solution, starting the planetary stirrer, continuously stirring, and separating slurry from the deionized water to form pasty slurry; taking the pasty slurry out from the stirring drum, and laying the pasty slurry in a porcelain dish; placing a positive pole material into the ceramic ball mill, and performing ball-milling through a ceramic milling ball with the diameter of 2 to 5cm; brushing the positive pole material into foamed nickel through a brush; and rolling the positive plate to obtain the positive plate of the lithium-iron button battery.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

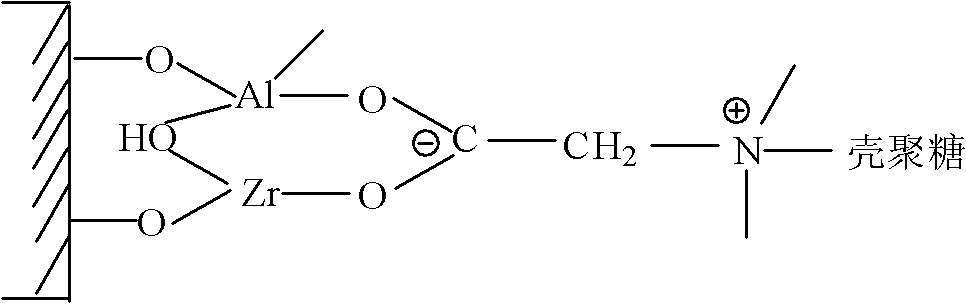

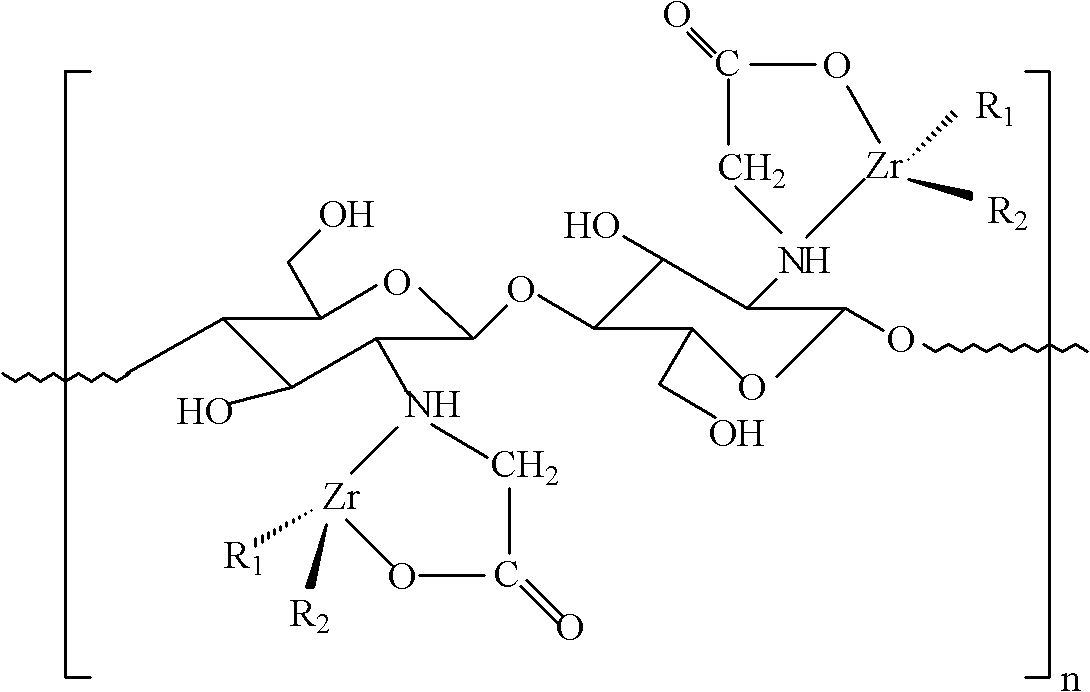

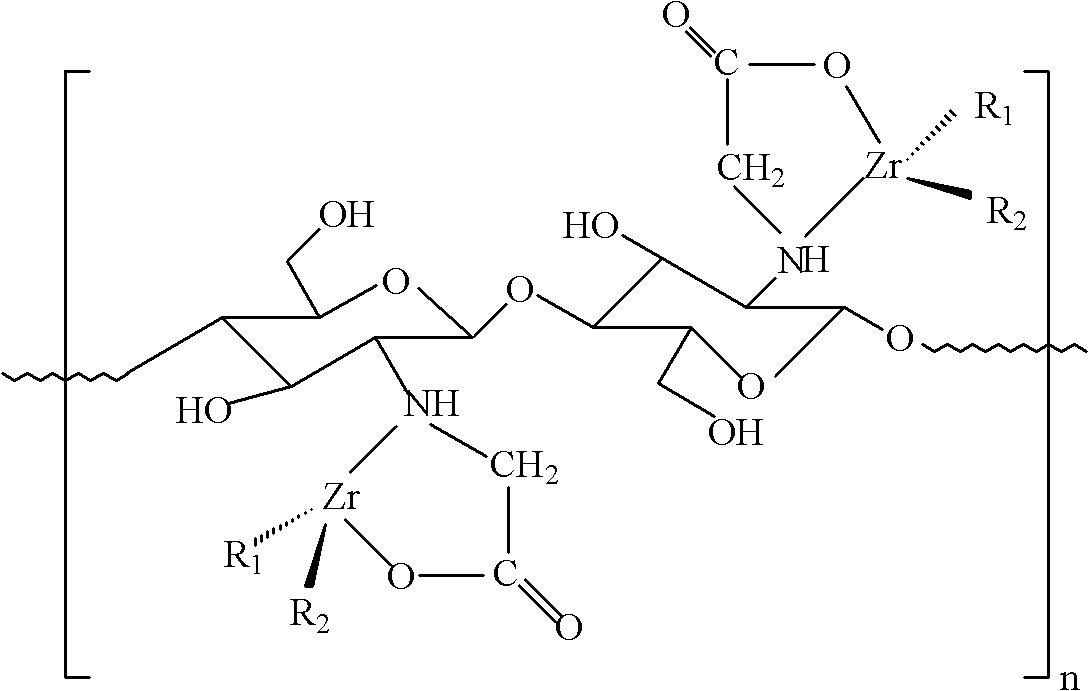

Cultural paper surface sizing agent

InactiveCN101974867ALow costPrevent hair lossWater-repelling agents additionPhysical chemistrySalt solution

The invention discloses a cultural paper surface sizing agent. The raw material of the cultural paper surface sizing agent comprises the following main components in percentage by weight: 0.3 to 0.5 percent of carboxymethyl chitosan, 20 to 25 percent of zircon salt, 2 to 5 percent of acid solution and the balance of deionized water. In preparation, solution of carboxymethyl chitosan is prepared first by dissolving the carboxymethyl chitosan in the acid solution; then solution of zircon salt is prepared by dissolving the zircon salt in the deionized water; and finally, the solution of carboxymethyl chitosan is dripped into the solution of zircon salt slowly, the mixed solution is stirred uniformly, and thus, the cultural paper surface sizing agent is obtained. The paper made by using the cultural paper surface sizing agent of the invention is insusceptible to picking and duslting, low in cost and environmentally friendly.

Owner:SHAANXI UNIV OF SCI & TECH

Graphene-modified copper foil electrode used for power battery with silica-based cathode

ActiveCN108288714AIncrease contact areaLower migration barrierElectrode carriers/collectorsSecondary cellsPower batteryInternal resistance

The invention discloses a graphene-modified copper foil electrode used for a power battery with a silica-based cathode. The copper foil electrode includes a copper foil base body, and the copper foilbase body is sequentially provided with a graphene buffering layer and an active material layer; the graphene buffering layer is formed on the copper foil base body and forms a flow gathering layer along with the copper foil base body; the active material layer is a silica-based alloy cathode coating layer, and the silica-based alloy cathode coating layer includes compound ingredients including C,Si, GeP5 and GeS, wherein the mass ratio of the compound ingredients including C, Si, GeP5 and GeS is (1-10):(1-10):(1-10):(1-10). The graphene-modified copper foil electrode has the advantages thatthe contact area between the flow gathering layer and the active materials is enlarged, and electronic migration potential barriers and interface internal resistance are reduced; the compatibility andbonding strength between the active materials and flow gathering bodies are enhanced; the physical, chemical and electrochemical properties are stable, and the stability of copper foil under an electrochemical condition and the battery safety are improved.

Owner:深圳名飞远科技有限公司

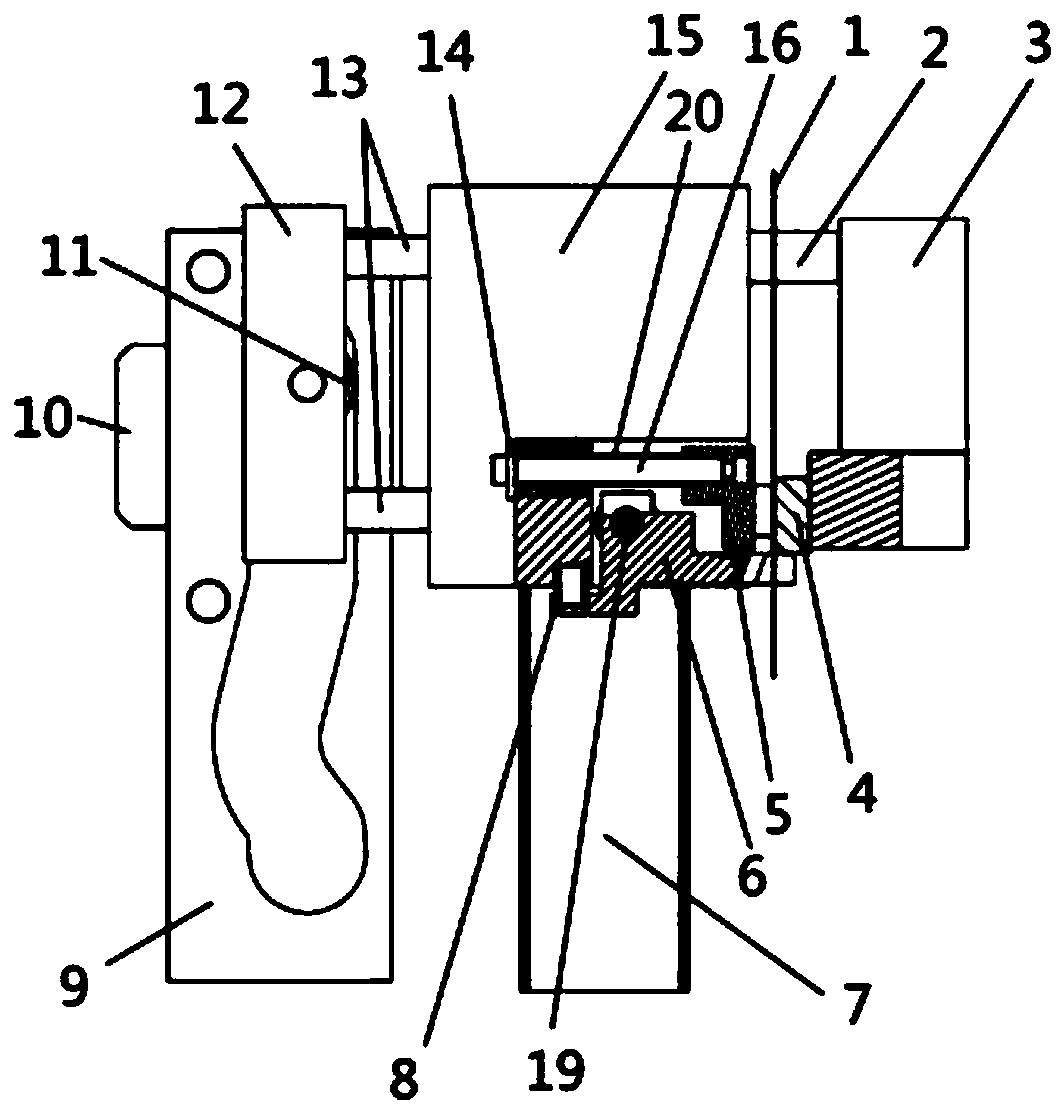

Cutting device of lithium battery pole piece

InactiveCN110227852AAvoid falling powderGuaranteed cutting qualityElectrode manufacturing processesShearing machinesRelative displacementOptical axis

The invention discloses a cutting device of a lithium battery pole piece. The cutting device of the lithium battery pole piece comprises a fixing cutter rest, a movable cutter rest and a driving device, wherein a pressing block, a first polished shaft, a first compression spring and a fixing cutter are arranged on the fixing cutter rest, the first compression spring sleeves the first polished shaft, the two ends of the first spring abut against the fixing cutter rest and the pressing block correspondingly, the side face, facing the pressing block, of the movable cutter on the movable cutter rest is an extrusion surface, and a cutting edge is arranged at the bottom of the extrusion surface; and a gap for the pole piece to pass is formed between the pressing block and the fixing cutter and amovable cutter, the driving device is used for controlling the movable cutter to move, when the movable cutter moves towards the direction of the pressing block until the pole piece is pressed on thepressing block through the extrusion face, the pole piece is cut off under the action of the cutting edge of the movable cutter and the fixing cutter. The movable cutter and the pressing block of anelastic structures can ensure that the pole piece is clamped without generating relative displacement, additionally, the shear type cutter point is formed between the cutting edge of the movable cutter and the fixing cutter, so that the cutting quality of the pole piece can be guaranteed while the pole piece can be effectively prevented from dusting.

Owner:CHANGDE TOBACCO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com