Patents

Literature

36results about How to "Improve production efficiency and yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extraction method for producing baicalin with biological enzyme method

InactiveCN104784254AImprove production efficiency and yieldLow costAntibacterial agentsCosmetic preparationsSolubilityQuality level

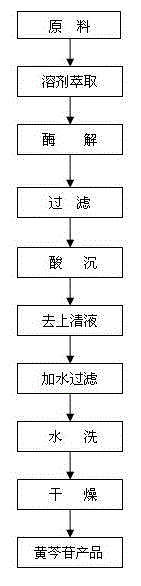

The invention relates to a high-yield technology for producing baicalin from a raw material, namely, baical skullcap roots, with a biological enzyme fermentation technology. According to the technical scheme, the technology comprises steps as follows: reflux extraction of the baicalin is performed on a raw material with boiling water containing a solubilizing agent firstly, a complex enzyme is added to an extract for hydrolysis, after refined filtration, a filtrate is heated to the temperature ranging from 70 DEG C to 100 DEG C, the baicalin precipitates by the aid of hydrochloric acid, is washed with water for acid removal and then is dried, the prepared baicalin content exceeds 85%, the baicalin conforms to national standard requirements, and indexes such as the solubility, the color and the like of the baicalin reach the high-quality level. With the adoption of the technology, the production process of the baicalin is simplified, the yield is increased, the production efficiency is improved, the cost is low, and the technology is suitable for large-scale production.

Owner:宝鸡市虹源生物科技有限公司

Preparation method of thermoplastic polyurethane micro air bag elastomer material

ActiveCN107383854AReduce dicingReduce energy consumptionChemical/physical/physico-chemical stationary reactorsPolymer scienceHigh pressure

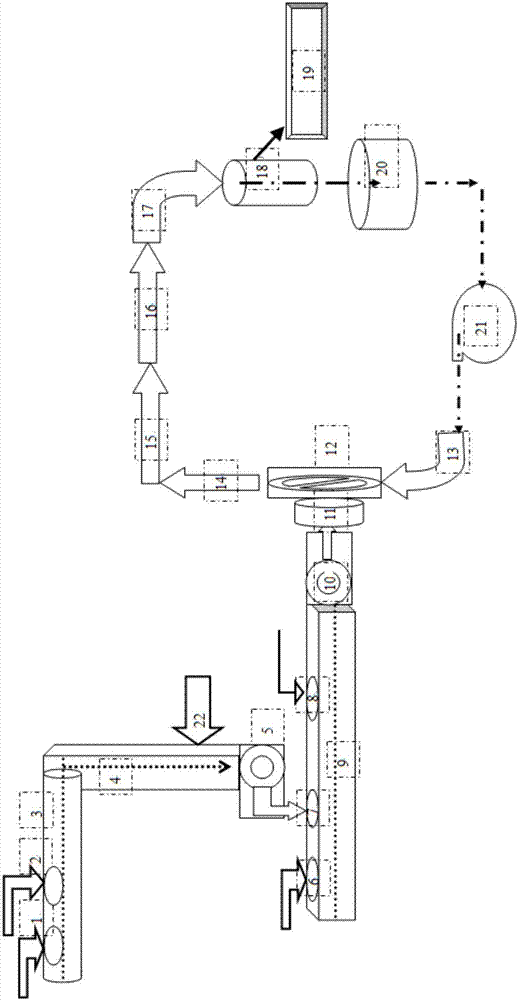

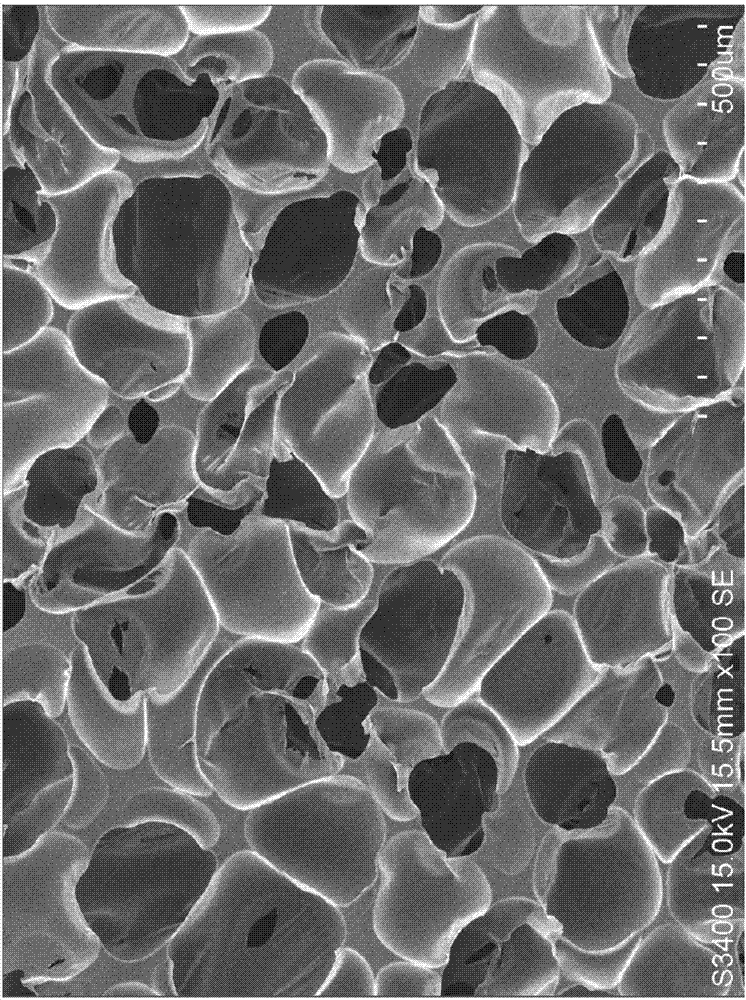

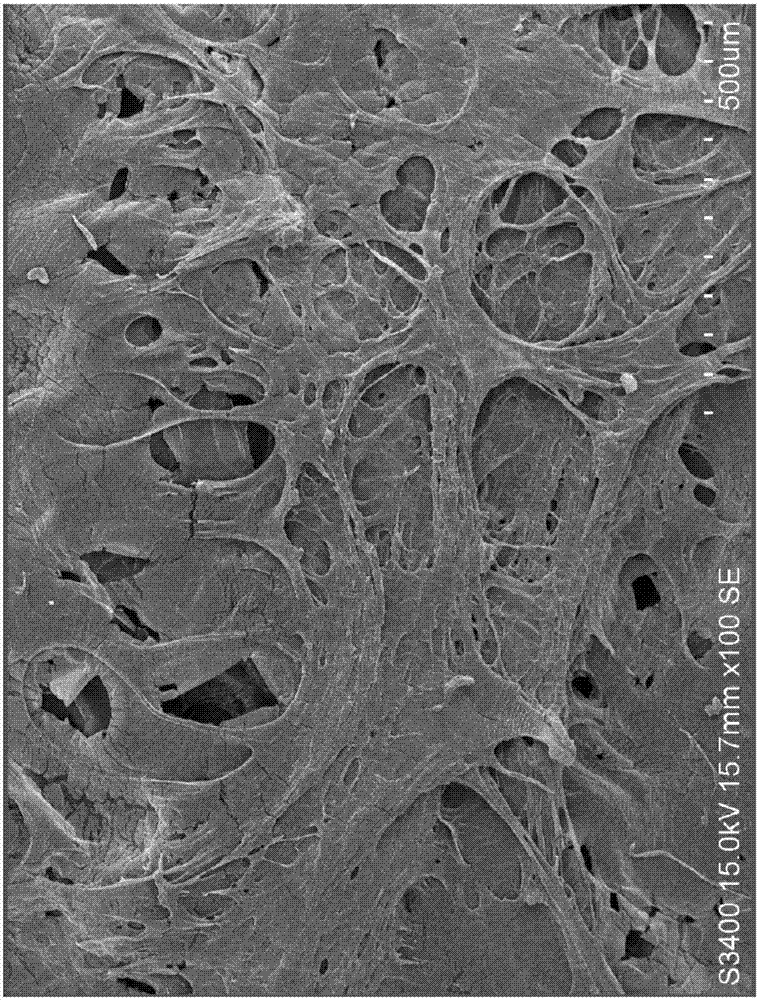

The invention relates to a preparation method of a thermoplastic polyurethane micro air bag elastomer material. The preparation method comprises the following steps of (1) feeding liquid raw materials such as diisocyanate molecules and a solid additive into a twin screw reactor, and carrying out polymerization chain extending reaction to obtain a high molecular weight hot melt; (2) pushing the high molecular weight hot melt into a mixing extrusion molding machine, and carrying out continuous reaction to produce a macromolecular thermoplastic polyurethane melt; (3) continuously adding the obtained macromolecular thermoplastic polyurethane melt, polymer particles and the like in a foaming extrusion molding machine, and then extruding the material from a mold head to an underwater pelletizing chamber in a form of a high-pressure hot melt; and (4) carrying pelletization by process water, sending the pellet-carrying process water to a separation machine by a multi-stage pressure relief and expansion process water pipeline, and carrying out separation, screening and drying to obtain a target product. Compared with the prior art, by adopting the preparation method provided by the invention, the thermoplastic polyurethane elastomer material can be directly prepared from the liquid raw materials such as MDI, so that the energy consumption and the material consumption are greatly lowered, the yield of a product is increased, the production efficiency of the product is improved and the like.

Owner:NANTONG DE NEW MATERIAL CO LTD

Manufacturing process of electronic product glass panel

InactiveCN104252815AReduce production processImprove production efficiency and yieldPhotomechanical exposure apparatusMicrolithography exposure apparatusLean manufacturingActive carbon

The invention discloses a manufacturing process of an electronic product glass panel. The manufacturing process comprises the following steps: imaging transfer; chemical etching; glass edge carving; twice reinforcement; film removal; silk-screen printing; ITO manufacturing; electrode manufacturing; ACF (Active Carbon Fiber) welding; final inspection; package and shipment. On the basis of not damaging the strength of glass, the manufacturing process of the electronic product glass panel is capable of performing various molding and manufacturing on glass, ensuring the precision and effectively improving the production efficiency. The manufacturing process has the following beneficial effects that 1) the production processes can be greatly reduced by virtue of the manufacturing process; 2) the production efficiency and the yield are greatly improved; 3) the production cost is greatly reduced and the processing precision is improved; 4) the chemical tempering strength and bending resistance of glass are improved.

Owner:KUNSHAN RUIYONGCHENG PRECISION EQUIP

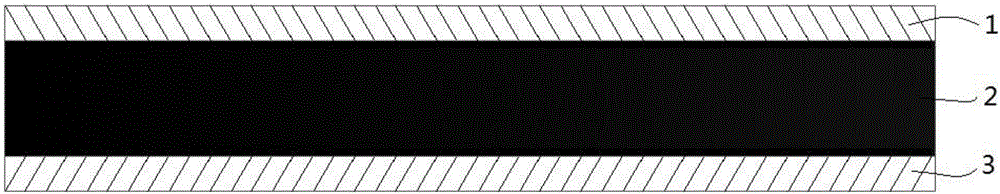

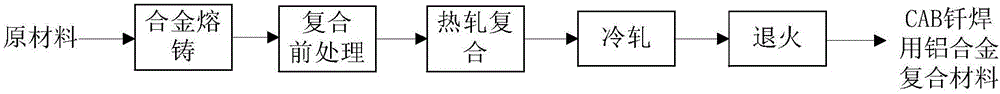

Aluminum alloy, heat exchanger, aluminum alloy composite and preparation method of aluminum alloy composite

InactiveCN106514033AHigh strengthImprove production efficiency and yieldWelding/cutting media/materialsSoldering mediaBrazingAlloy composite

The invention discloses an aluminum alloy, an aluminum alloy composite for CAB brazing, a preparation method of the aluminum alloy composite and a heat exchanger made of the aluminum alloy composite. The aluminum alloy comprises, by mass percentage, 0.1%-0.3% of Mg, 1.0%-1.8% of Mn, 0.01%-1.0% of Si, 0.2%-0.9% of Cu, 0.1%-0.7% of Fe, not larger than 0.02% of Ti, not larger than 0.13% of Zr, and the balance Al and inevitable impurities. The aluminum alloy composite prepared by the novel aluminum alloy as a core material is high in post-welding strength and can be used for CAB brazing.

Owner:YINBANG CLAD MATERIAL

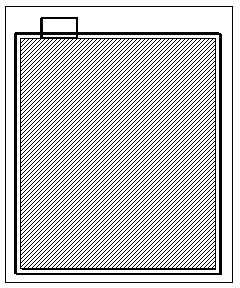

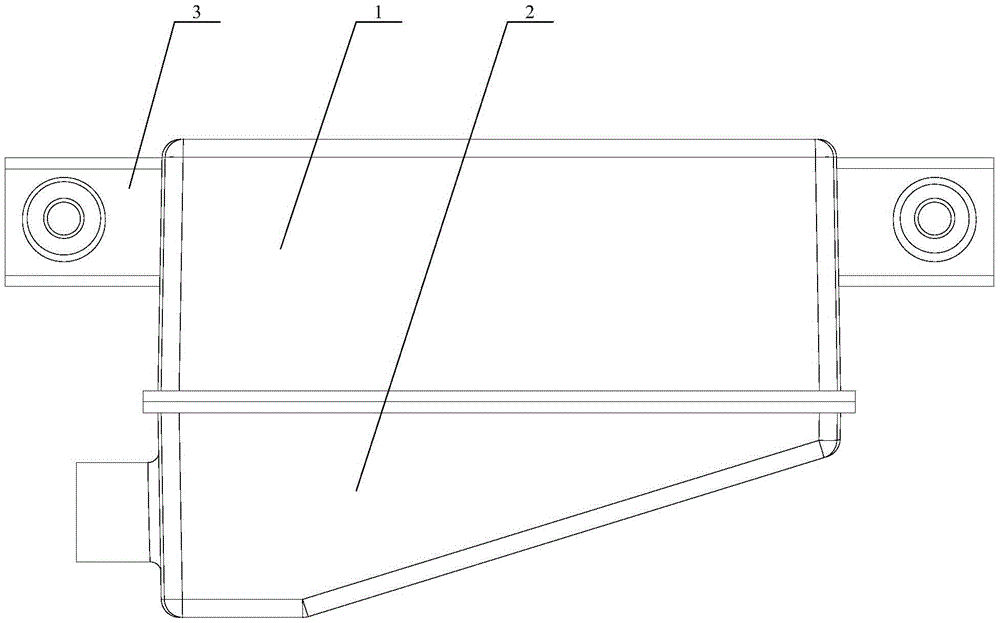

Bag-making type lithium ion battery and preparation method thereof

InactiveCN103094618AImprove production efficiency and yieldImprove sealing and safety performanceFinal product manufactureCell component detailsElectrical batteryLithium electrode

The invention discloses a bag-making type lithium ion battery and a preparation method thereof. The bag-making type lithium ion battery consists of an aluminum plastic package film, a positive electrode lug, a negative electrode lug, an electrode piece and bag-making type electrode pieces, wherein the electrode pieces and upper and lower layers of membranes are manufactured into a bag containing the electrode pieces in an adhesion manner; the bag-making type electrode pieces and counter electrodes are overlapped together layer to layer to form an electrode group; and the positive electrode lug and the negative electrode lug are respectively welded with a positive electrode lug and a negative electrode lug of the electrode group together. With the adoption of the lithium ion battery provided by the invention, the production efficiency and the yield in manufacturing through a battery assembly process can be improved; and the security problem possibly occurring in a process of using the lithium ion battery can be prevented to a certain extent.

Owner:TIANJIN ENERGIES

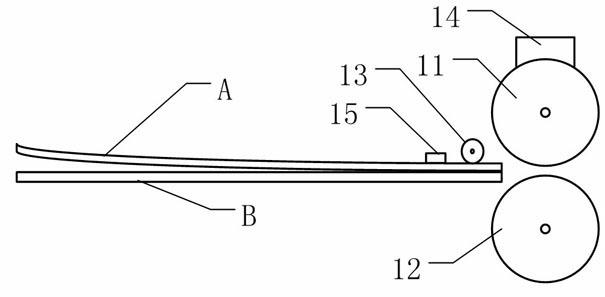

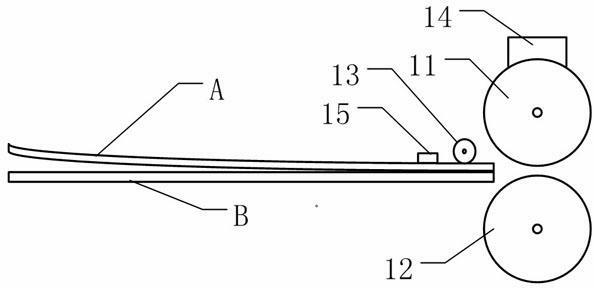

Adhesive tape pasting device

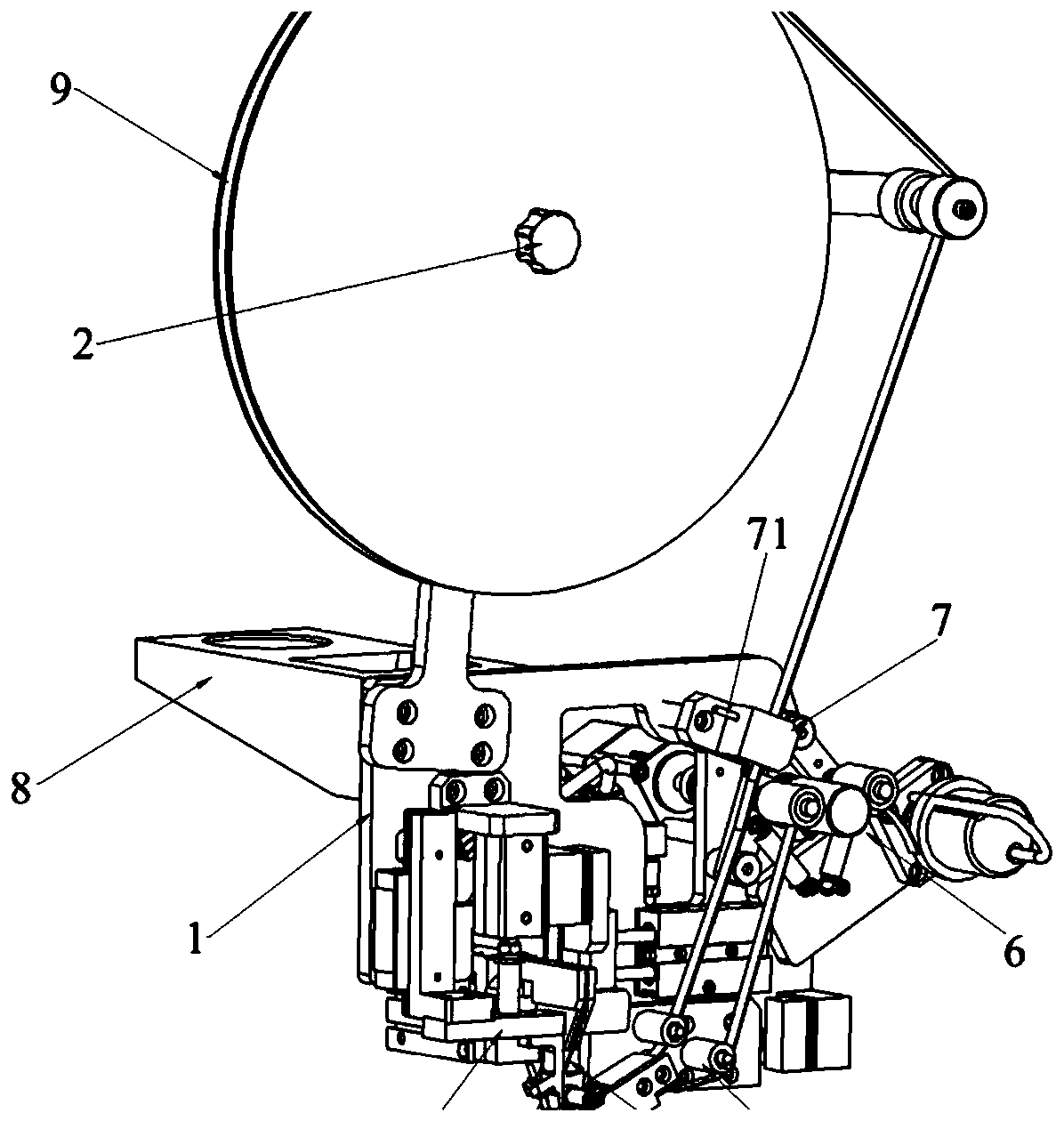

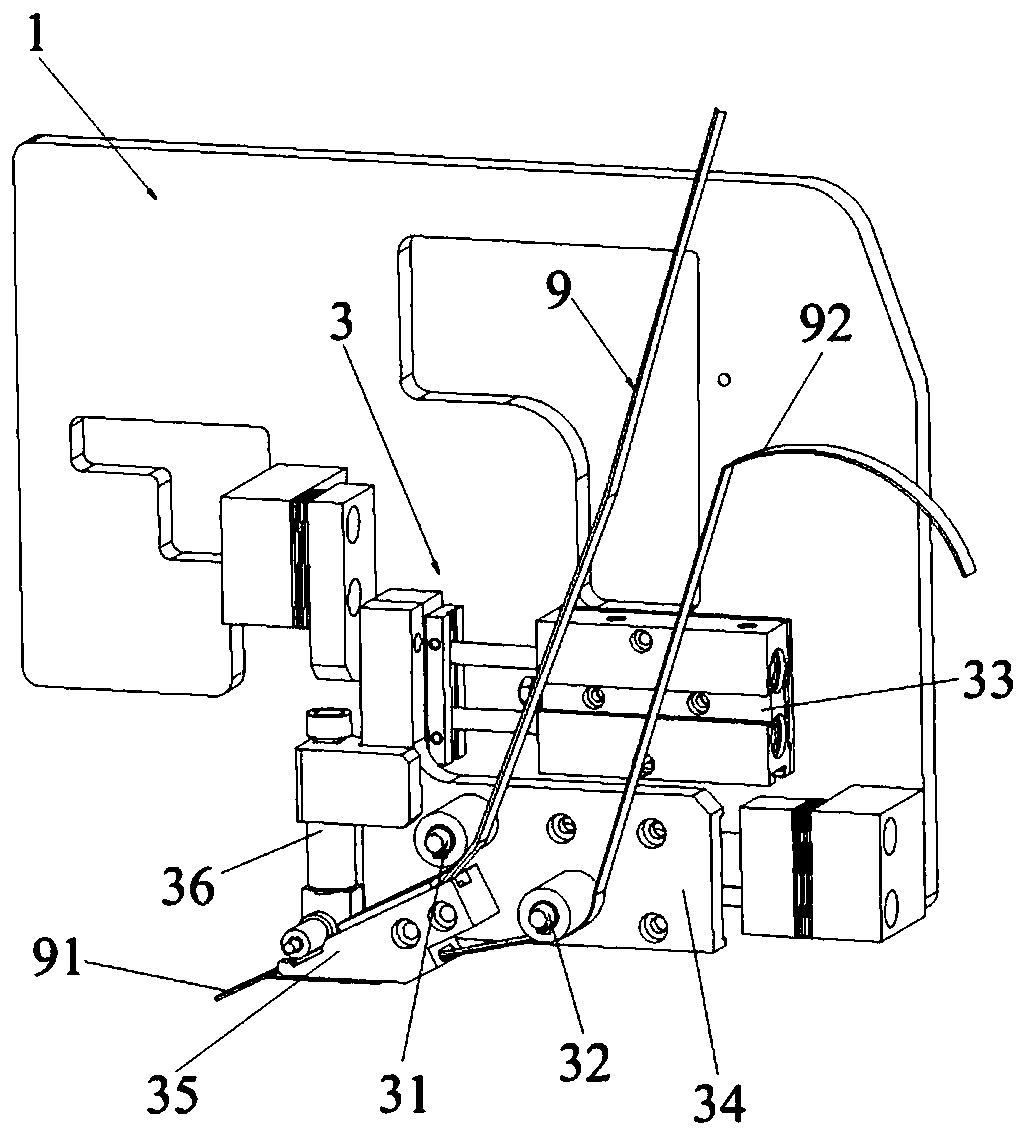

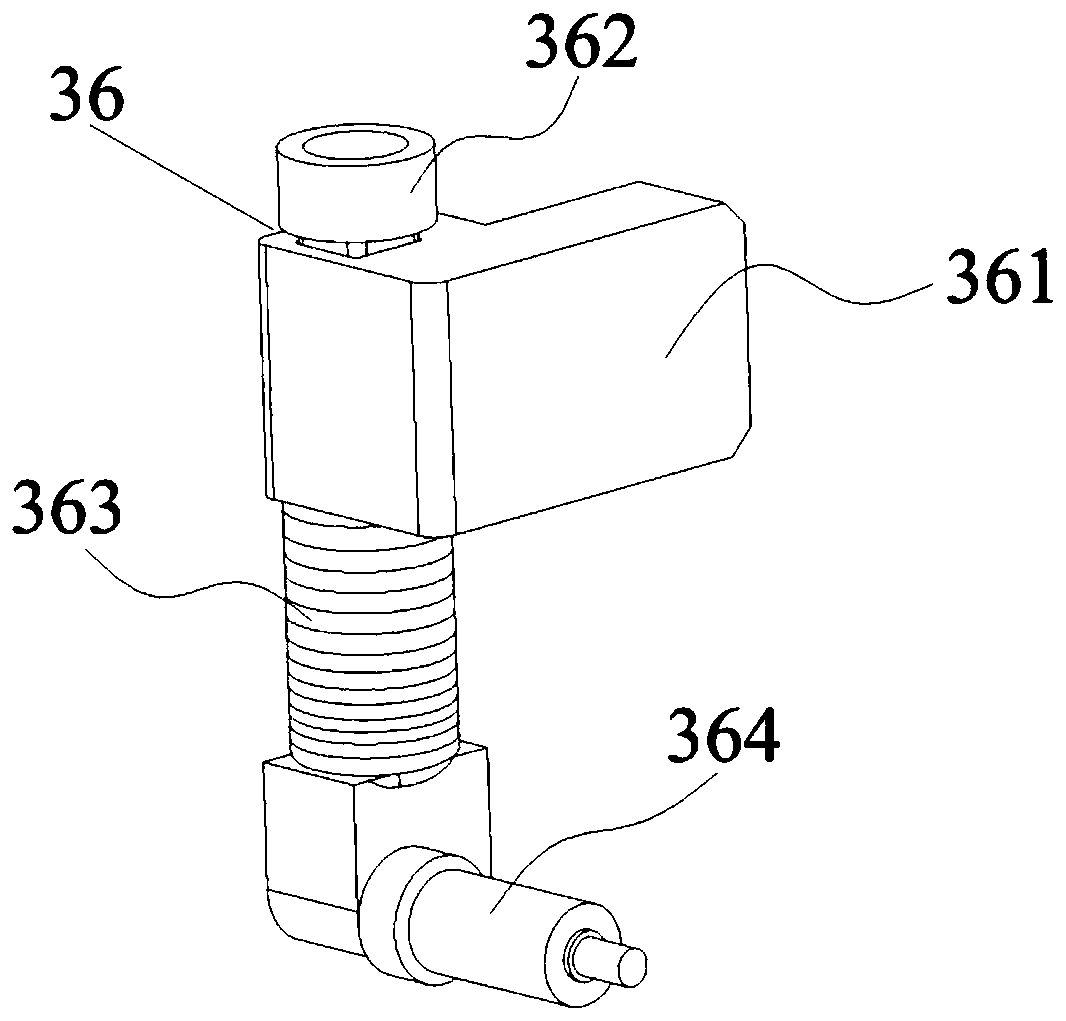

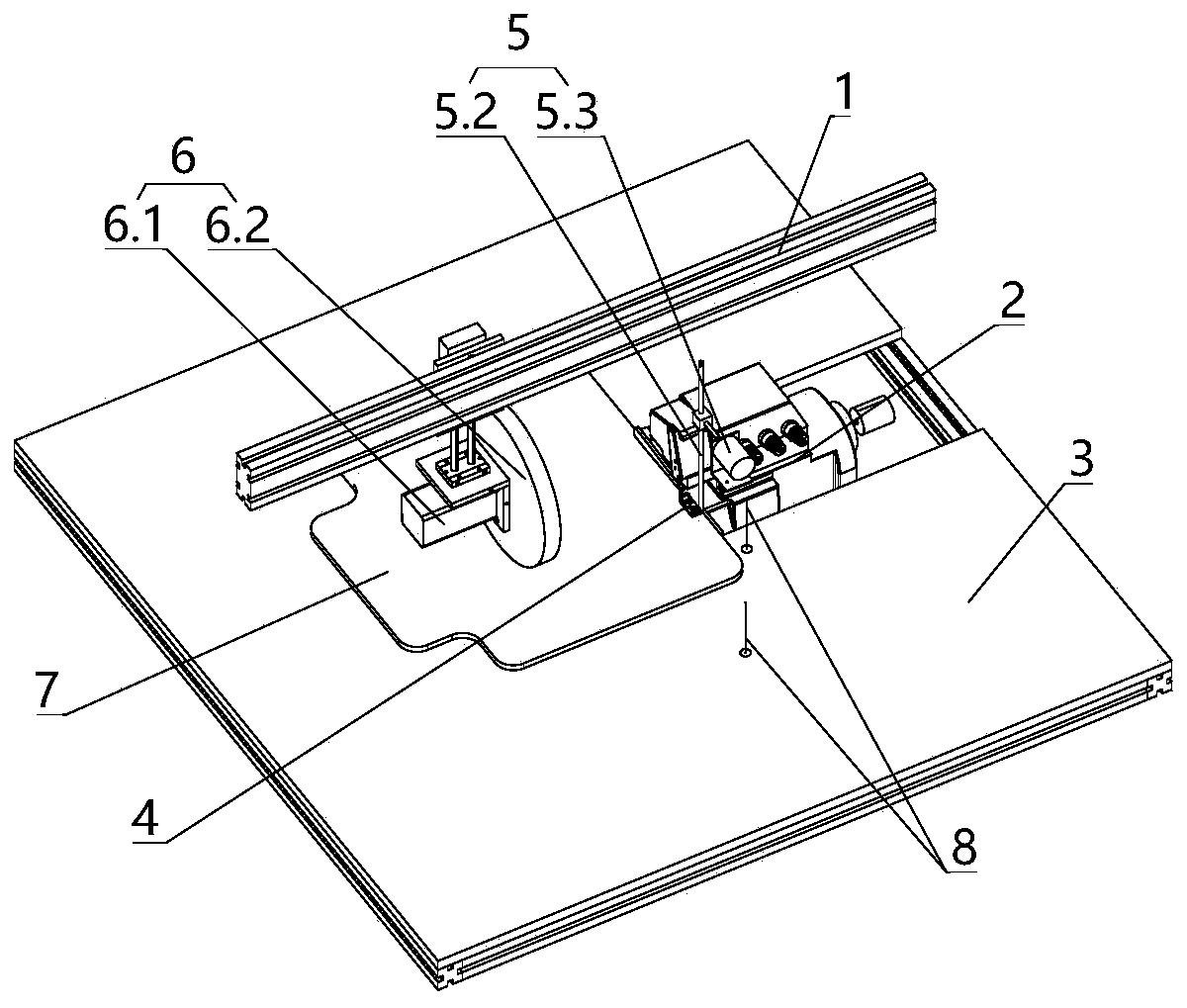

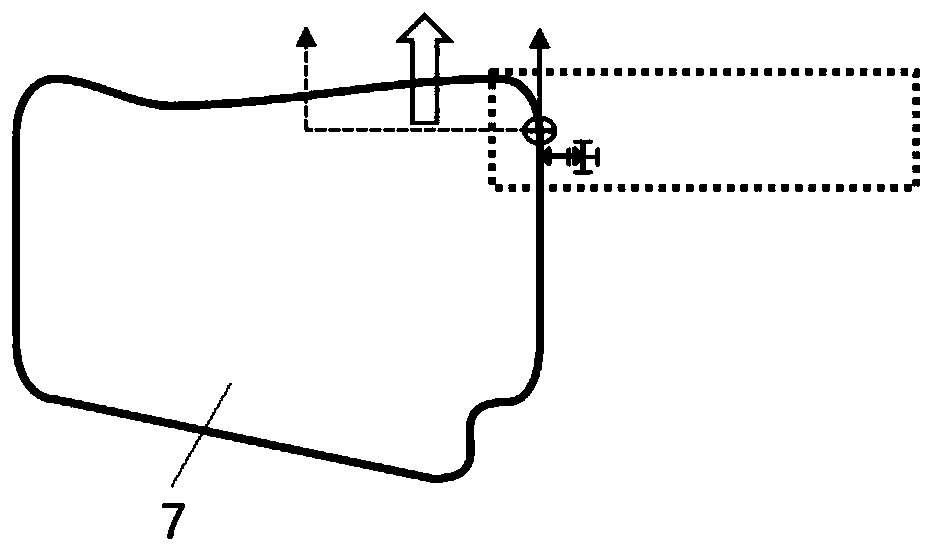

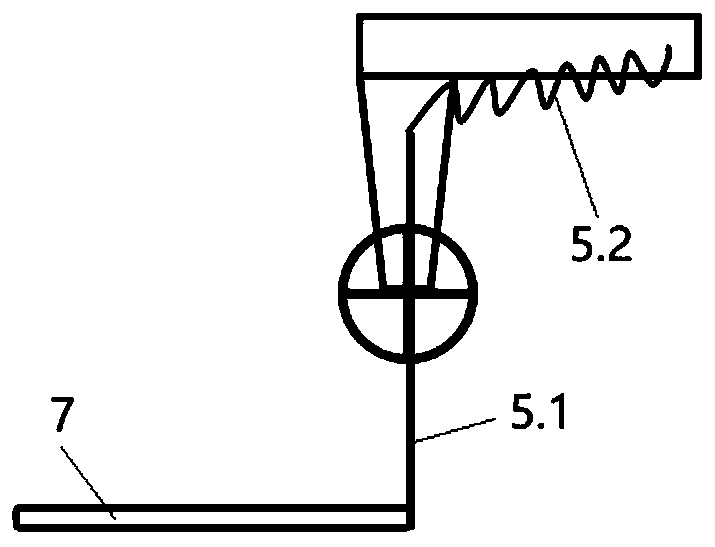

ActiveCN110104496ACompletely separatedImprove production efficiency and yieldArticle deliveryEngineeringMechanical engineering

The invention relates to an adhesive tape pasting device. The adhesive tape pasting device comprises a mounting plate, an adhesive tape unwinding mechanism, an adhesive tape conveying mechanism, an adhesive tape cutting-off mechanism, an adhesive tape pressing mechanism and a release paper collection mechanism, wherein the adhesive tape unwinding mechanism, the adhesive tape conveying mechanism, the adhesive tape cutting-off mechanism, the adhesive tape pressing mechanism and the release paper collection mechanism are arranged on the mounting plate. An induction component is arranged on the adhesive tape pressing mechanism. The adhesive tape conveying mechanism comprises an adhesive tape guide wheel, a release paper guide wheel, a first cylinder, a first sliding plate and a stripping block. The first cylinder drives the first sliding plate to slide leftwards and rightwards on the mounting plate. Adhesive tape is conveyed to the position below the adhesive tape pressing mechanism in thepasting process; after it is induced by the induction component on the adhesive tape pressing mechanism that the adhesive tape is conveyed to the right position, the adhesive tape pressing mechanismis started to press the adhesive tape onto a target accessory; afterwards, the first cylinder retreats, and release paper is wound onto the release paper collection mechanism through the release paperguide wheel; and finally, the adhesive tape is cut off by the adhesive tape cutting-off mechanism. The adhesive tape pasting device starts to work when the adhesive tape is conveyed to the position below the adhesive tape pressing mechanism, and adhesive paper is completely separated from the release paper.

Owner:FUYAO GLASS IND GROUP CO LTD

Automatic edge covering/overlock sewing machine and automatic edge covering/overlock sewing system

ActiveCN110241515AImprove production efficiency and yieldImprove yield rateWork-feeding meansSewing-machine control devicesControl systemDrive wheel

The invention discloses an automatic edge covering / overlock sewing machine and an automatic edge covering / overlock sewing system. The automatic edge covering / overlock sewing machine comprises a machine frame, a sewing machine, a control system, a platen, a contour recognizing device arranged in front of a feed dog of the sewing machine, and a driving unit arranged beside the feed dog of the sewing machine. The driving unit comprises a servo motor electrically connected with the control system, and a driving wheel connected with a driving shaft of the servo motor. The control system transmits real-time contour information through the contour recognizing device to regulate and control the rotating direction and rotating speed of the driving wheel. The driving wheel drives a workpiece to overcome the friction force between the workpiece and a working table and do linear movements or real-time circumference movements around the real-time curvature center under the common effect of the friction force between the driving wheel and the workpiece and the feed dog of the sewing machine. In the whole edge covering or overlock sewing process, the trajectory adjusting and deviation rectifying can be conducted according to the contour of the workpiece in real time, and the yield and production efficiency are greatly improved.

Owner:吴迪 +1

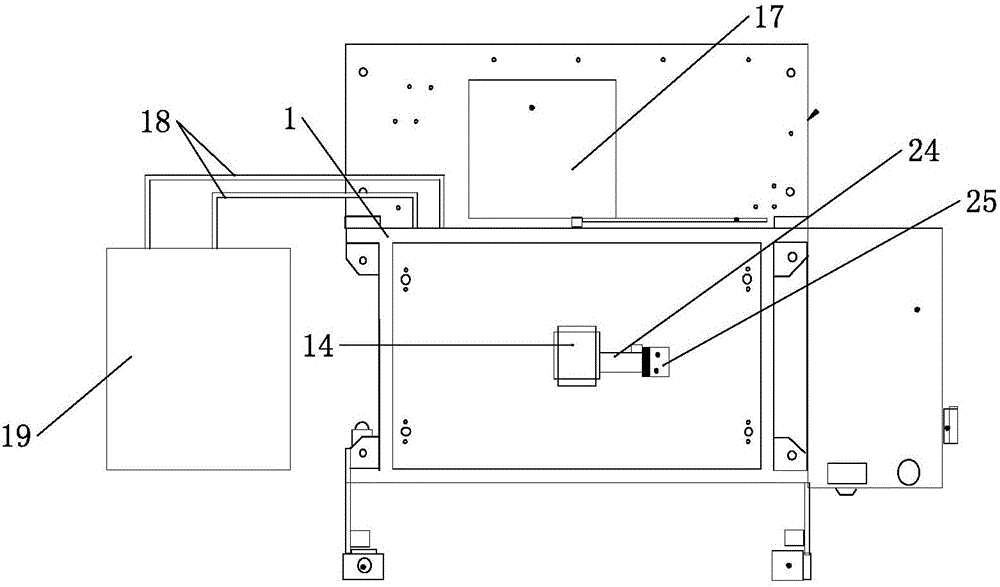

Novel plastic welding equipment

InactiveCN106393701AImprove production efficiency and yieldImprove cooling effectAutomatic controlPlastic welding

The invention discloses novel plastic welding equipment. The novel plastic welding equipment comprises a frame and a control circuit; a welding chamber is arranged on the frame; a positioning support lower mold and a positioning pressing upper mold are arranged below the welding chamber; the positioning support lower mold is provided with a lower positioning mold cavity; the positioning support lower mold is provided with an electromagnetic induction heating copper pipe circuitously arranged around the lower positioning mold cavity; the positioning pressing upper mold is provided with an upper positioning mold cavity; the positioning pressing upper mold is provided with an electromagnetic induction heating copper pipe circuitously arranged around the upper positioning mold cavity; the electromagnetic induction heating copper pipes are connected with an electromagnetic generation device and a cooling water circulating device; and the control circuit includes a programmable controller, a timing module and an operation display module. The novel plastic welding equipment adopts the control circuit with high automation degree to perform automatic control, and adopts circulation of cooling water to effectively cool a welding area so as to improve the product yield and the production efficiency.

Owner:威士茂电子塑胶(珠海)有限公司

Tail-tin-plated type plug power line detecting equipment

InactiveCN110045198AReduce workloadImprove production efficiency and yieldElectrical testingHigh pressureElectrical and Electronics engineering

The invention discloses tail-tin-plated type plug power line detecting equipment, which comprises a rack. A circular conveying line is arranged on the rack; one or more jigs are mounted on the circular conveying line; a feeding mechanism, a tail shaping mechanism, a tail branching mechanism, a high-voltage tester and a discharging mechanism are sequentially arranged on the rack in the conveying direction of the circular conveying line; and a CCD device is further arranged on the high-voltage tester and used for recognizing the position where a triple-phase line is located after branching operation, and inner high-voltage, outer high-voltage, polarity and on-off detection is conducted correspondingly by the high-voltage tester. According to the tail-tin-plated type plug power line detectingequipment, carrying, shaping, branching and detecting operation of plug lines after injection molding can be completed automatically, bent and irregular tail core lines can be shaped and straightened, manual assisting is not needed, the working burden of an operator is greatly reduced, the production efficiency is greatly improved, the yield is greatly increased, and the production cost is saved.

Owner:BULL GRP CO LTD

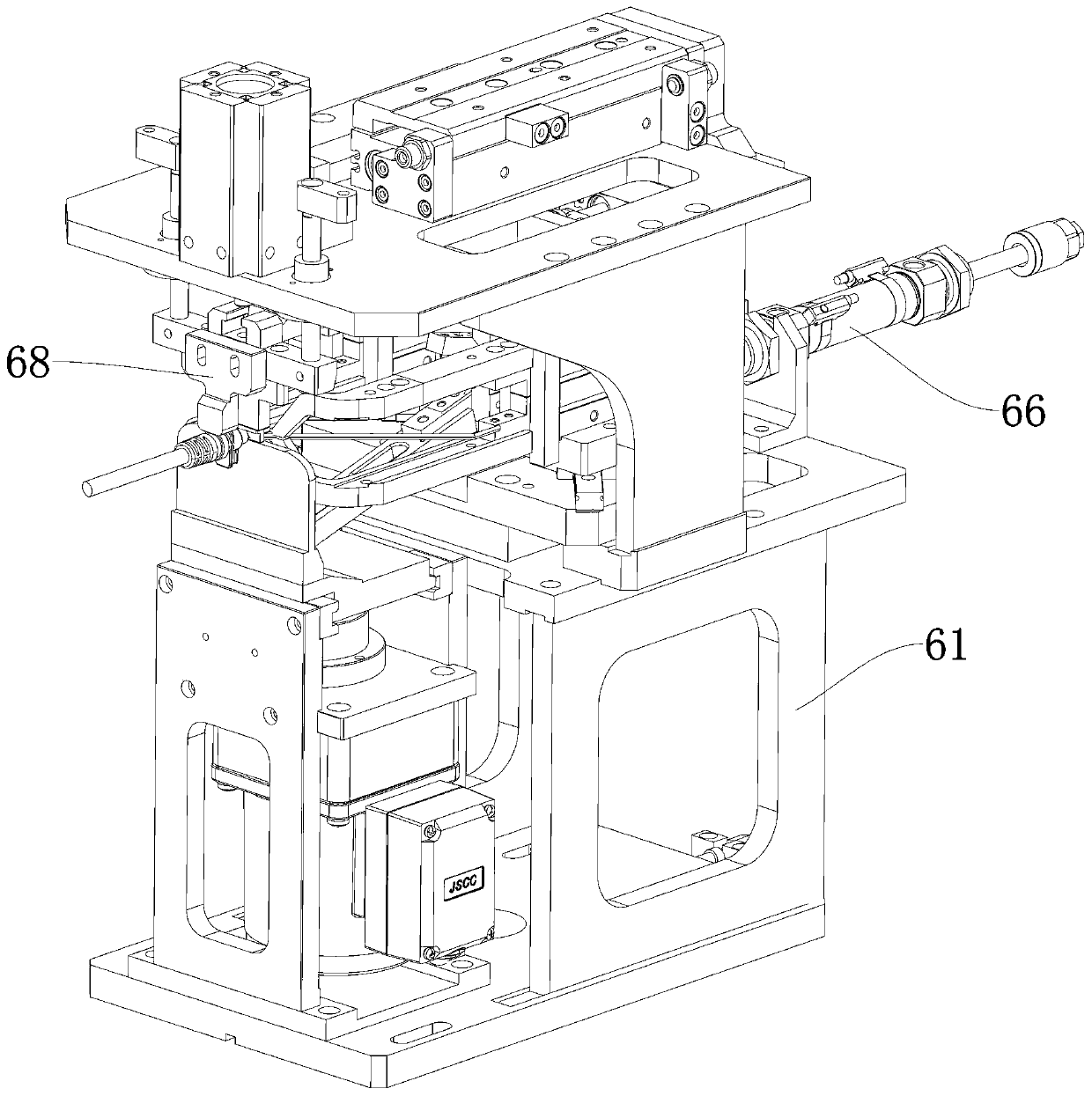

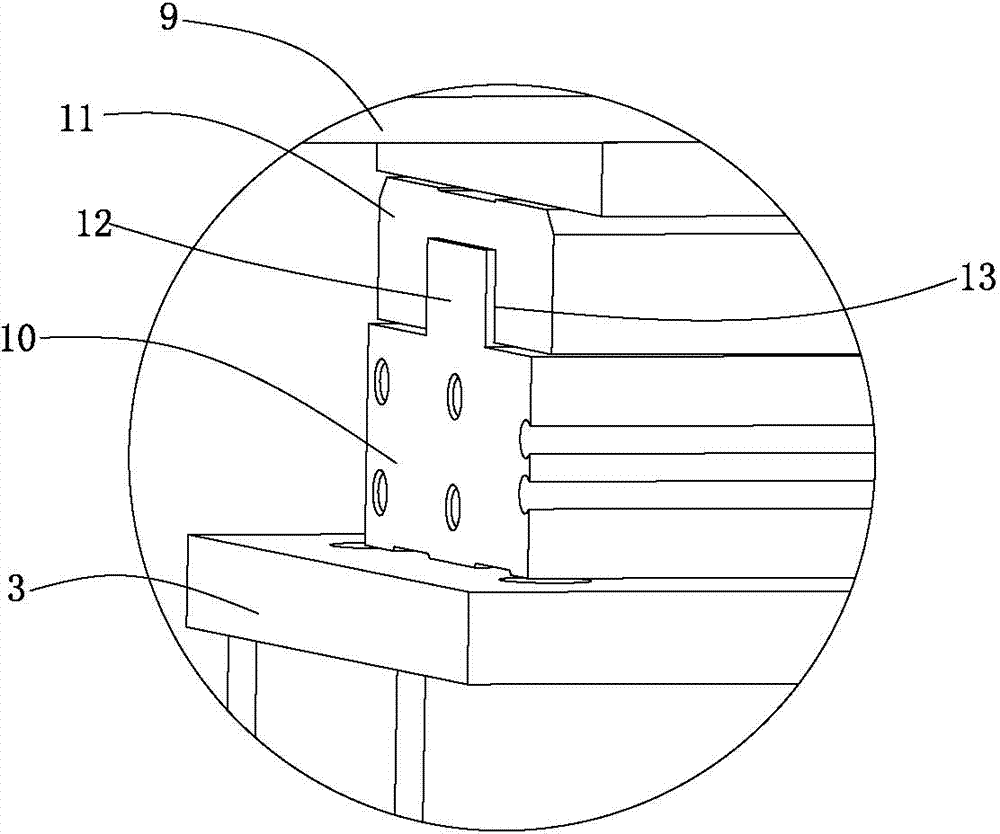

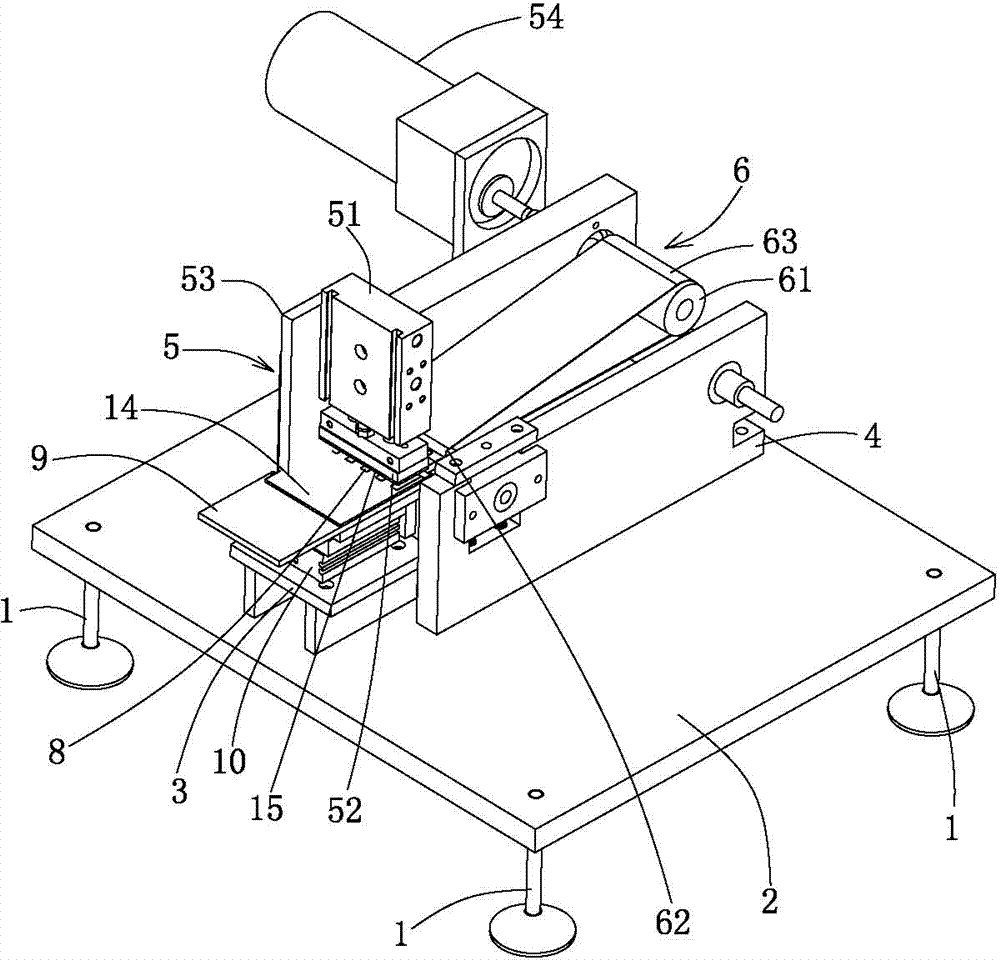

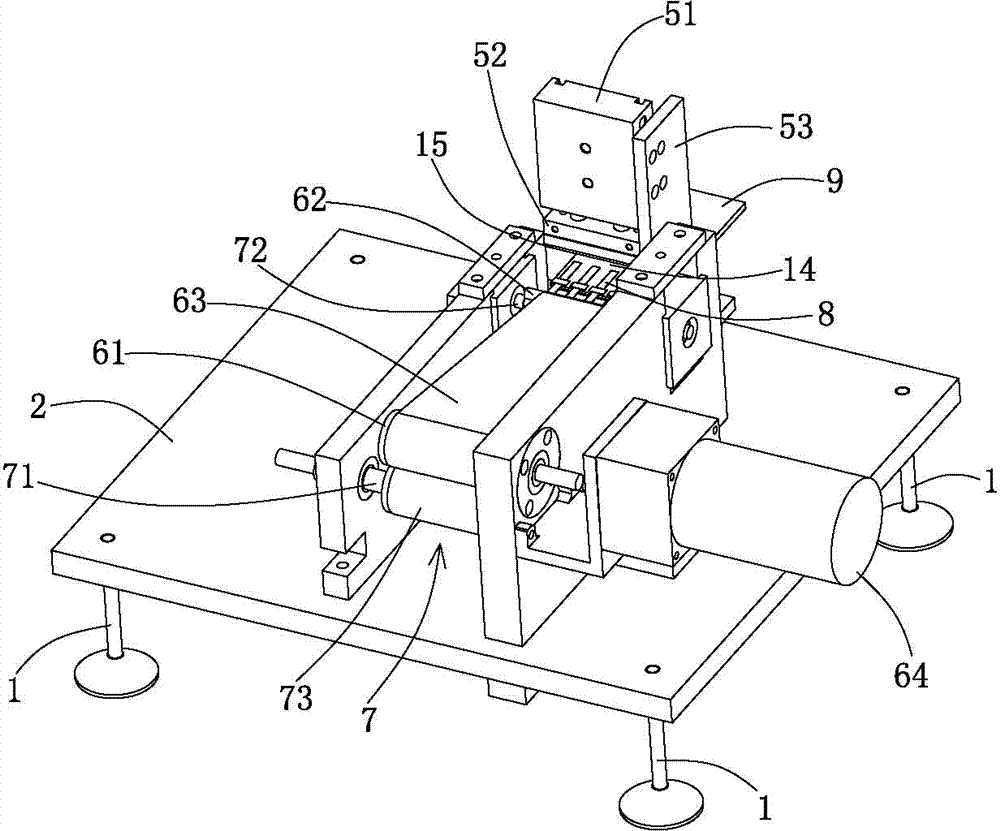

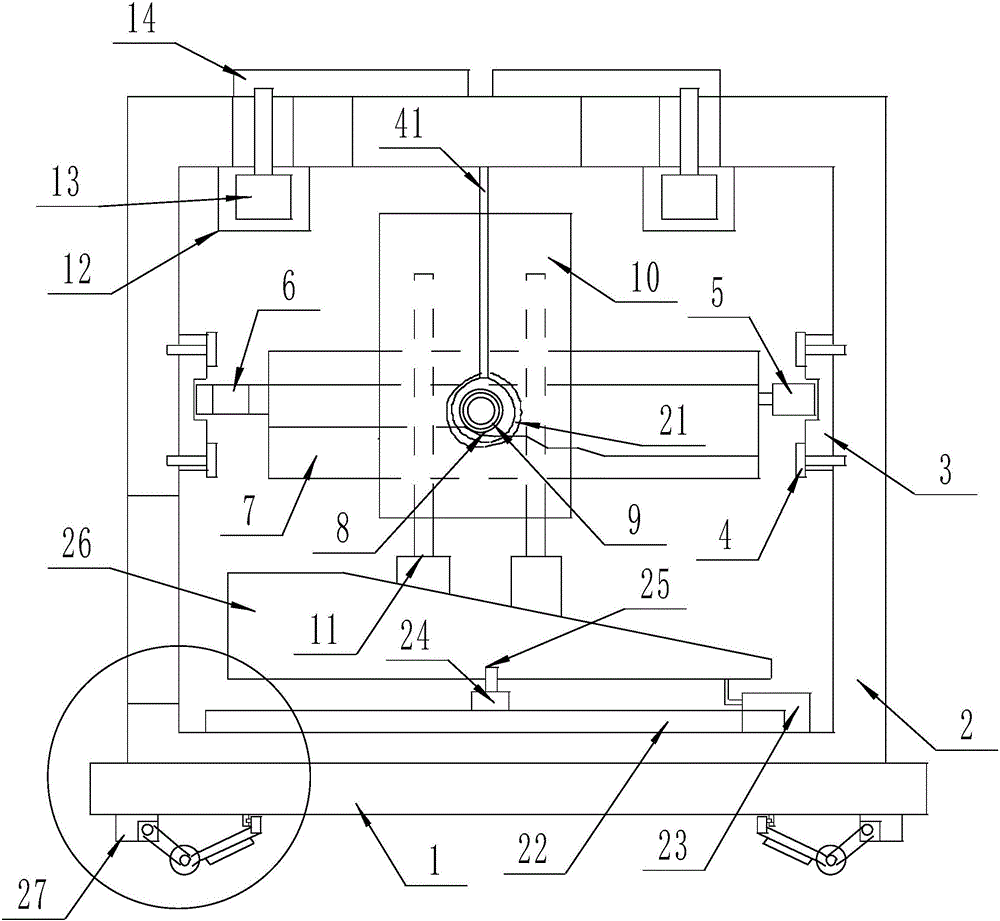

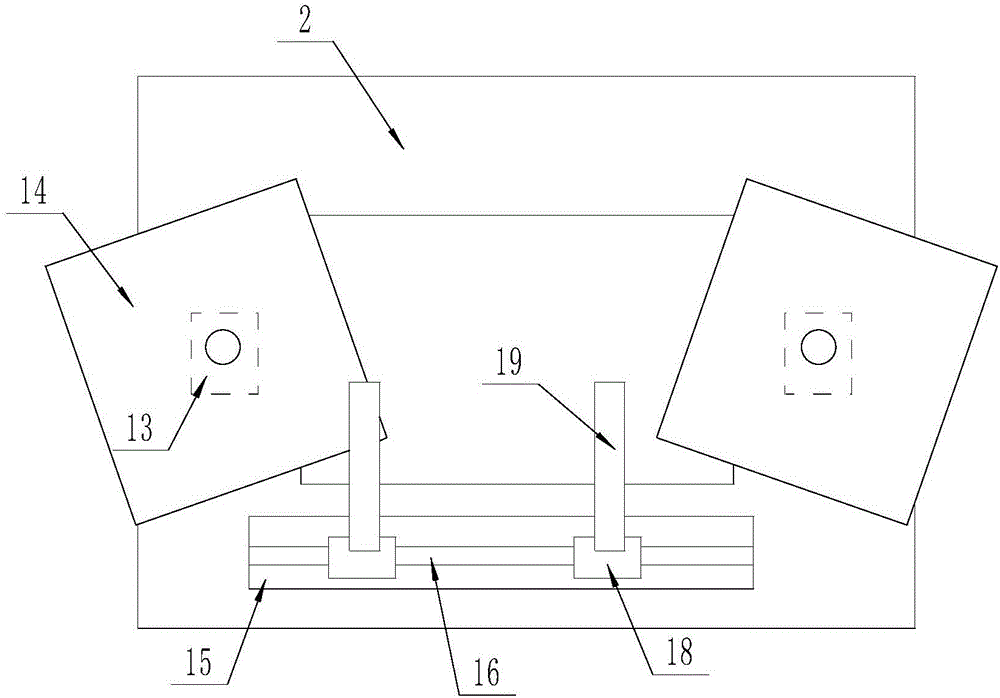

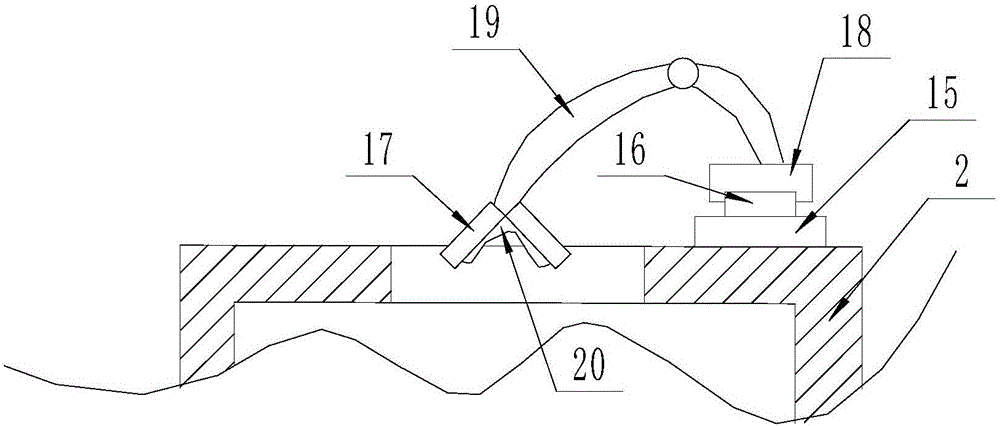

Semi-automatic polishing machine

ActiveCN103029021AImprove production efficiency and yieldPrecise control of grinding thicknessBelt grinding machinesAutomatic controlEngineering

The invention relates to a semi-automatic polishing machine, which comprises a bracket, a table board, a first workbench arranged on the table board and used for fixing a workpiece to be polished, and a second workbench used for polishing, wherein a pressing device used for pressing the workpiece to be polished is arranged above the first workbench, the second workbench is provided with an upper polishing device and a lower polishing device which can be moved circularly, and a gap for the workpiece to be polished to extend in is formed between the upper polishing device and the lower polishing device. The polishing times and the polishing strength can be precisely controlled by the semi-automatic polishing machine, so that the polishing thickness of a metal conducting plate can be controlled, automatic control is adopted by the semi-automatic polishing machine, and the production efficiency and the yield can be improved.

Owner:NINGDE AMPEREX TECH

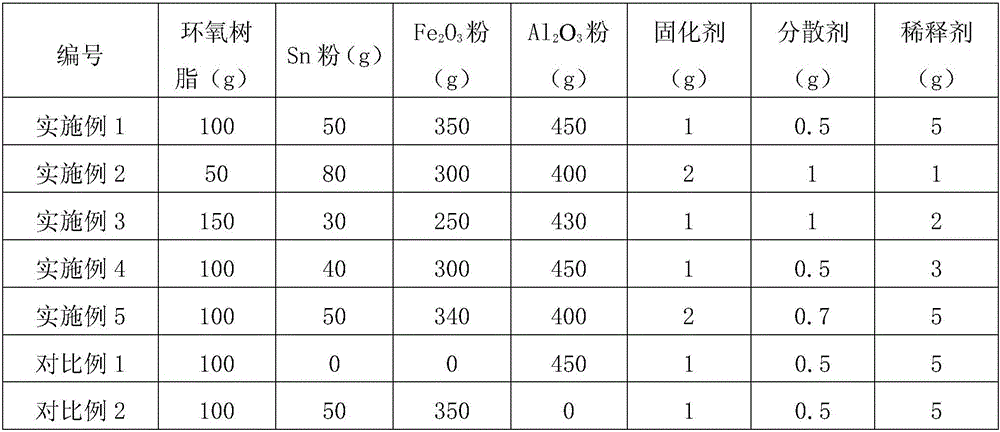

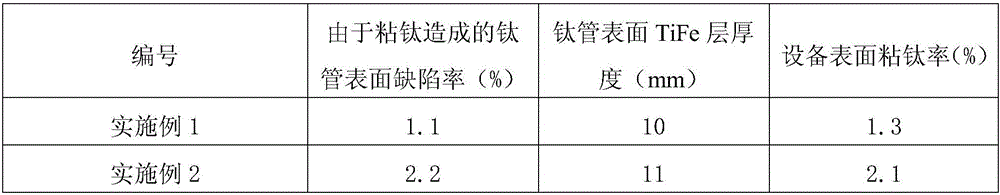

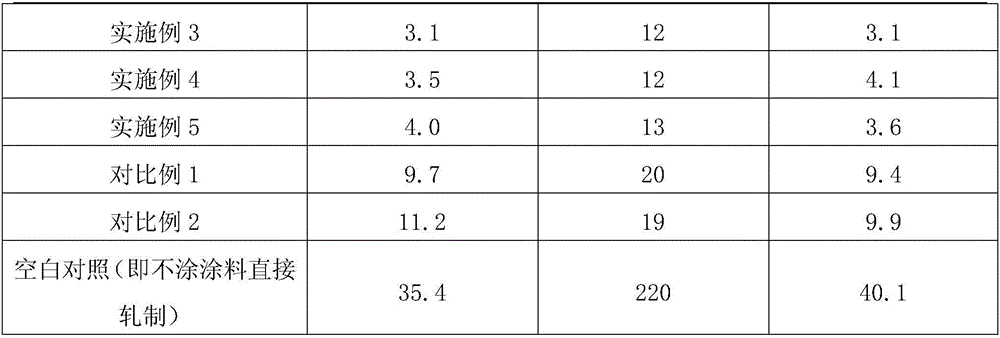

Oil-based high-temperature-resistant anti-bonding titanium coating and application thereof

ActiveCN105969090AImprove product precision size and surface qualityImprove production efficiency and yieldEpoxy resin coatingsTitaniumSesquioxide

The invention relates to an oil-based high-temperature-resistant anti-bonding titanium coating and application thereof and belongs to the technical field of titanium-steel anti-bonding coatings. The oil-based high-temperature-resistant anti-bonding titanium coating is used in titanium tube rolling. The coating is prepared from, by weight, 50-150 parts of oil-based film-forming agent, 30-80 parts of tin powder, 250-350 parts of iron sesquioxide powder and 400-450 parts of aluminum oxide powder. Steel equipment, roller beds and winches are coated with the oil-based high-temperature-resistant anti-bonding titanium coating, a very good isolation layer is formed, it can be guaranteed that a titanium ingot and steel equipment rollers or the winches are not subjected to a bonding reaction in the rolling or piercing process at the temperature of 900 DEG C, the precision size and surface quality of the product are improved, the yield of titanium material machining is increased, the production efficiency of titanium material machining is improved, and the production cost is reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

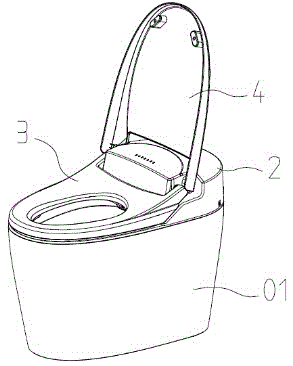

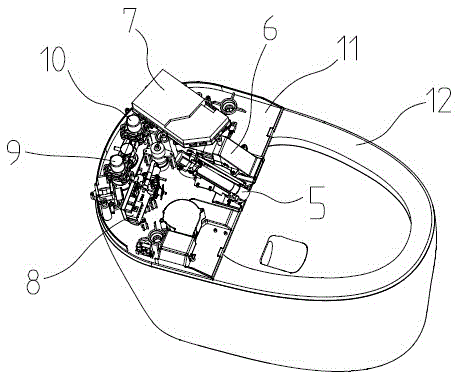

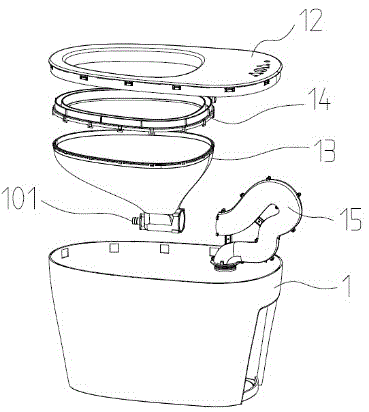

Plastic toilet pan without water tank

InactiveCN107174158AImprove production efficiency and yieldSimple structureBathroom coversEngineeringPlastic materials

The invention discloses a plastic toilet pan without a water tank. The toilet pan comprises a plastic base, a seat ring, a flip cover, an upper cover, a pedestal, a water temperature heater, a water spray rod, a warm wind heating assembly, a control circuit board and a flushing electromagnetic valve, wherein the plastic base is assembled from a base upper cover plate, a base shell, an inner chamber, a water passage frame, a siphon pipe and a connecting rubber pipe. The plastic toilet pan without the water tank adopts the base of a plastic material, avoids the defects of big weight, high defective rate in burning processing and fragility in transportation of a traditional ceramic toilet pan base, and greatly reduces the cost.

Owner:CIXI SANHE INTELLIGENT SANITARY WARE CO LTD

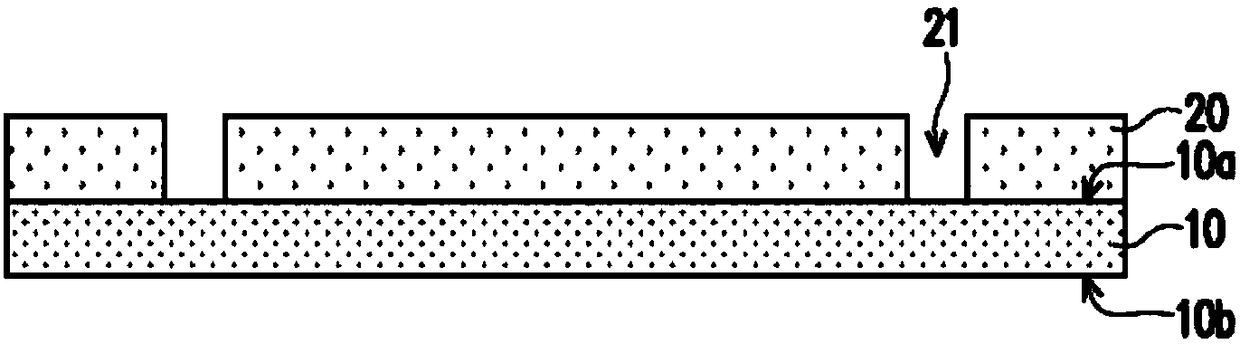

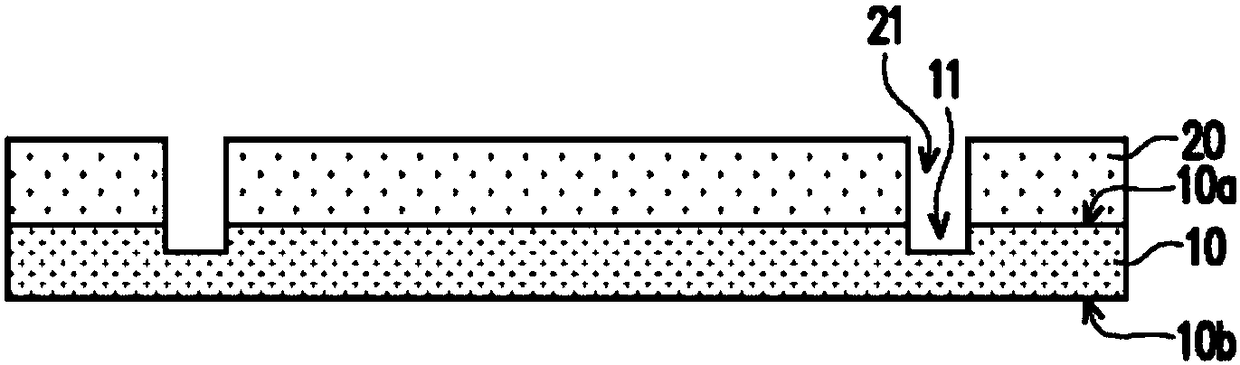

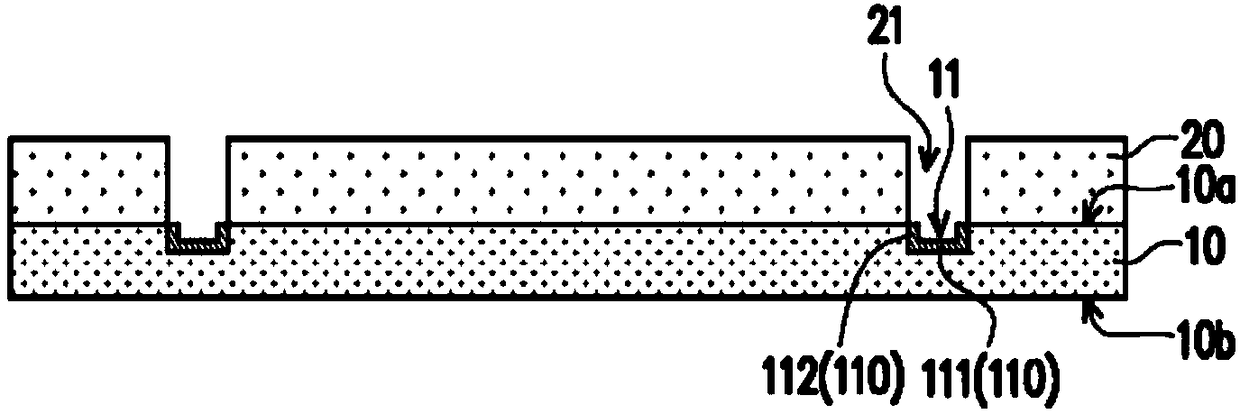

Production method for reducing pinhole short circuit through photoresist insulation according to BM technology

InactiveCN104859327ASolve the short circuit problemImprove production efficiency and yieldOther printing apparatusPrinting after-treatmentPhotoresistLong lasting

The invention discloses a production method for reducing pinhole short circuit through photoresist insulation according to the BM technology. The method comprises the following steps: creating the ITO pattern of an OGS touch screen on a glass substrate in advance according to the conventional yellow light technology and waiting for BM screen printing; conducting blade coating on a BM according to the blade coating screen printing technology, and then putting the treated BM into an oven for baking; conducting screen printing on the BM to form a negative photoresist insulation layer, and then putting the BM with the negative photoresist insulation layer into the oven for baking; carrying out screen printing of via hole carbon paste, and then putting the BM with the via hole carbon paste in the oven for baking; under a yellow light condition, carrying out screen printing and silver paste exposure, and putting the BM with exposed silver paste into the oven for baking; carrying out screen printing to obtain a mirror surface silver icon, carrying out final screen printing of black printing ink, and putting the BM with the black printing ink into the oven for baking; attaching a protecting film on the baked BM. The method has the advantages that the problem of failure of mass production of OGS caused by pinhole short circuit leading poor yield is solved fundamentally; the production efficiency is improved; the labor cost is reduced; the long-lasting problems of high production cost and low yield of an OGS production line are solved.

Owner:晟光科技股份有限公司

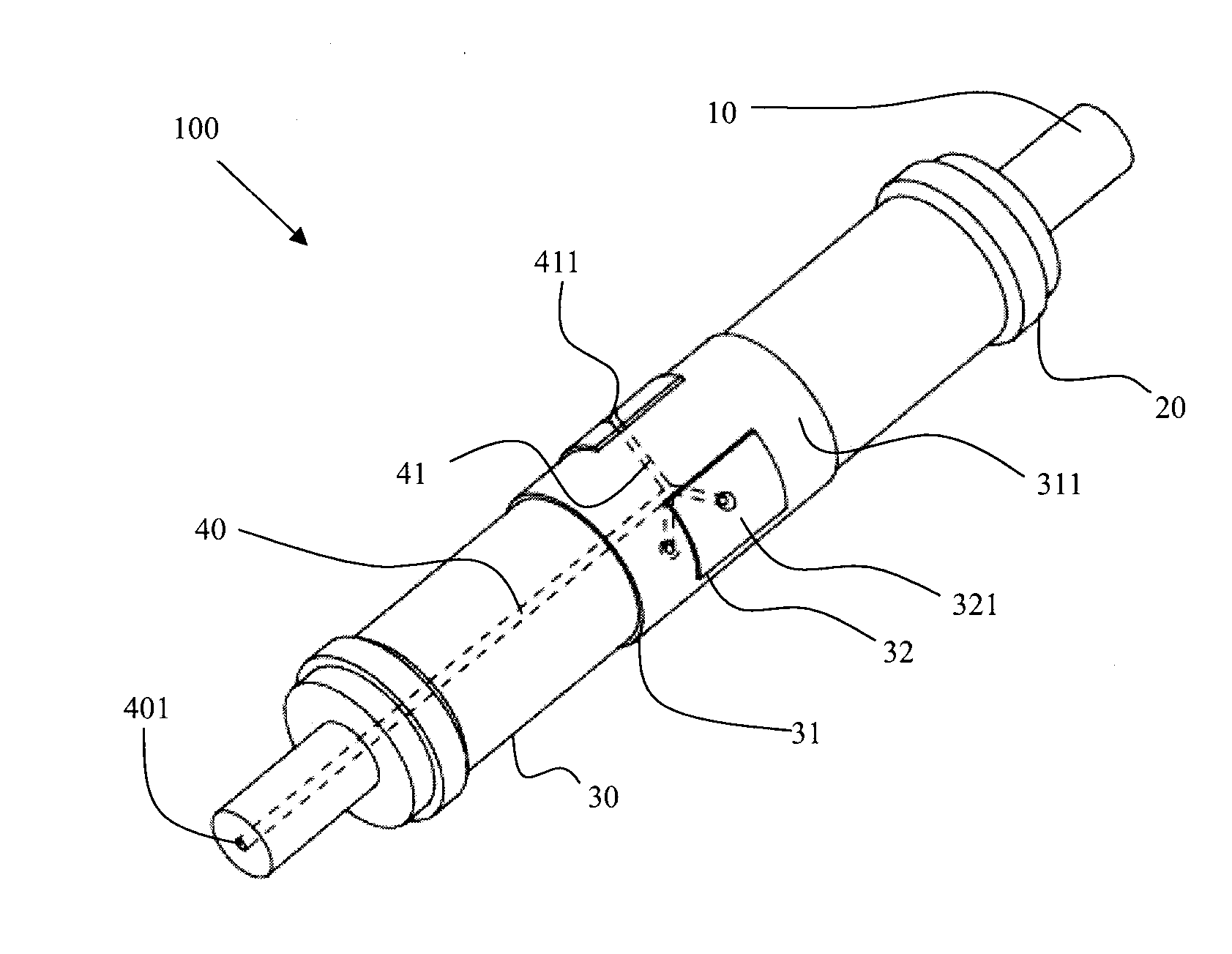

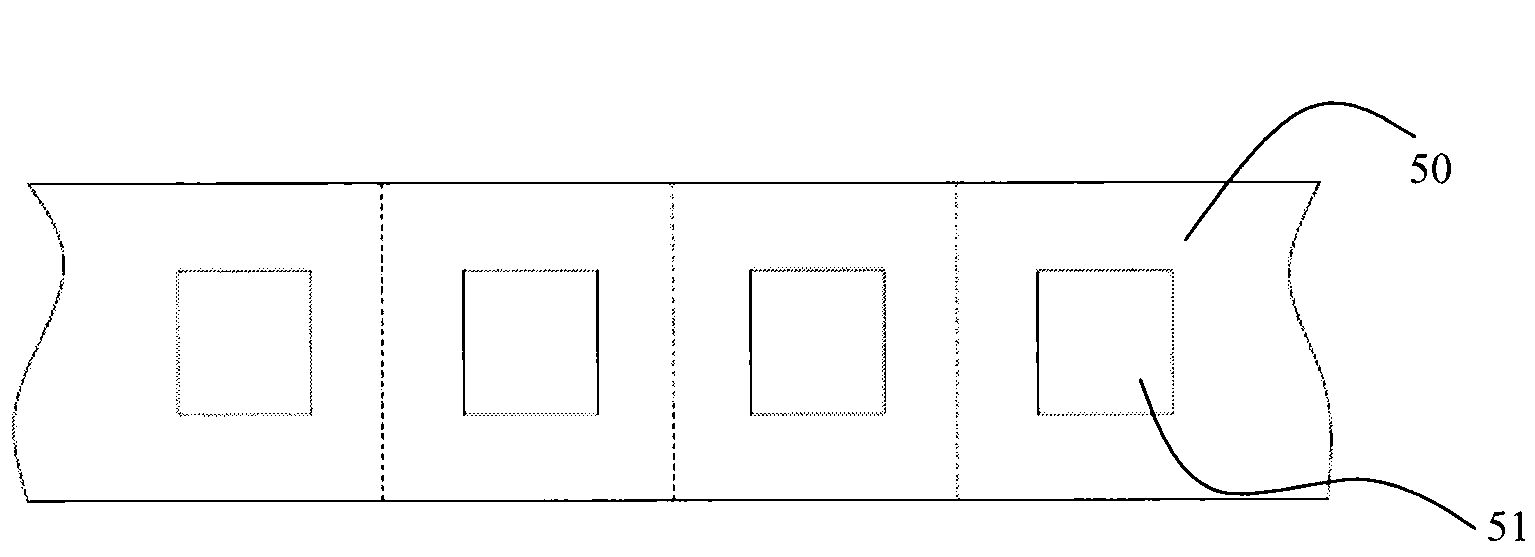

Blowing round roller extraction cutter

InactiveCN103128787AAvoid accumulationImprove production efficiency and yieldMetal working apparatusMain channelEngineering

The invention provides a blowing round roller extraction cutter which comprises a main shaft, a cutter body connected with the main shaft, positioning blocks which are located on the same axis with the main shaft and arranged on the end portions of the two ends of the cutter body, a first protruding stretch part which stretches out of the surface of the cutter body in a protruding mode, and a second protruding stretch part which stretches out of the surface of the first protruding stretch part in a protruding mode. A plurality of auxiliary channels are arranged inside the cutter body, a main channel arranged in a shaft center of the main shaft is arranged inside the cutter body, and the auxiliary channels are mutually communicated with the main shaft. Compressed air is guided into the main channel on the end portion of the main shaft, the extraction cutter is enabled to blow away waste materials by utilization of the compressed air in a waste material ejection process, the waste materials are prevented from being adhered to the protruding stretch parts of the extraction cutter and stacking, the waste material removing effect is improved, and the finished product rate and the production efficiency of a die cutting product are improved.

Owner:SUZHOU YUANDEFU TECH

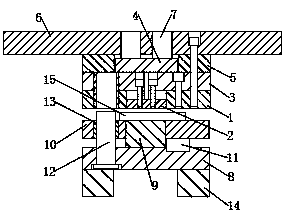

Multilayer-injection molding stepped mold device

ActiveCN106671359AReduce material and tooling costsImprove production efficiency and yieldEngineeringInjection molding machine

The invention discloses a multilayer-injection molding stepped mold device. The multilayer-injection molding stepped mold device comprises a bearing base; the upper surface of the bearing base is fixedly connected with a machining box; a movable mechanism is arranged on the lower surface inside the machining box; an injection molding mechanism connected with the movable mechanism is arranged inside the machining box; a traveling and fixing mechanism is disposed on the lower surface of the bearing base; a clamping and discharging mechanism which is in lap joint with the injection molding mechanism is arranged on the upper surface of the machining box; a group of stretching bars matched with a rotary shaft A are fixedly connected with the upper surface inside the machining box; and the lower end surface of each stretching bar is provided with a fixing round ring connected with the rotary shaft A. The multilayer-injection molding stepped mold device has the beneficial effects that the material cost and the machining cost are effectively reduced, meanwhile, the finished product rate and the production efficiency are greatly improved; and driving is reliable, ejecting is smooth, the size of a mold frame is greatly reduced, the mold space is reasonably utilized, and the mold device is convenient to observe and move.

Owner:QINGDAO JUSTUSE MOLDS TECH

PCB substrate stamping device

InactiveCN103658322APrevent burstImprove production efficiency and yieldShaping toolsEjection devicesReflow solderingEngineering

The invention provides a PCB substrate stamping device. The PCB substrate stamping device comprises a lower die portion and an upper die portion, wherein the lower die portion is fixedly arranged, and the upper die portion moves relative to the lower die portion. The upper die portion comprises a shearing plate, an upper die core and an upper die retreating mechanism. The shearing plate comprises a cavity, and the upper die core is movably arranged in the cavity. The upper die retreating mechanism drives the upper die core to move towards the lower die portion relative to the cavity. By the adoption of the structure, an insulating layer can be prevented from cracking, the rate of finished products and production efficiency are improved, potential quality hazards are eliminated, and the condition that poor high-pressure may occur after reflow soldering is avoided.

Owner:恩达电路(深圳)有限公司

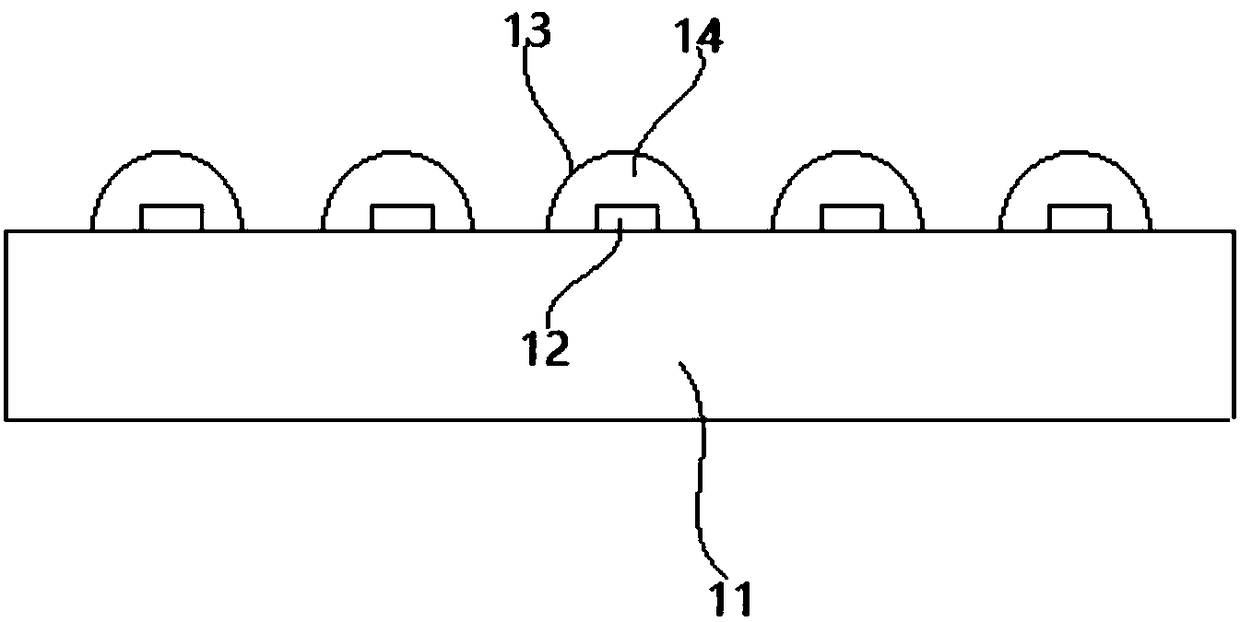

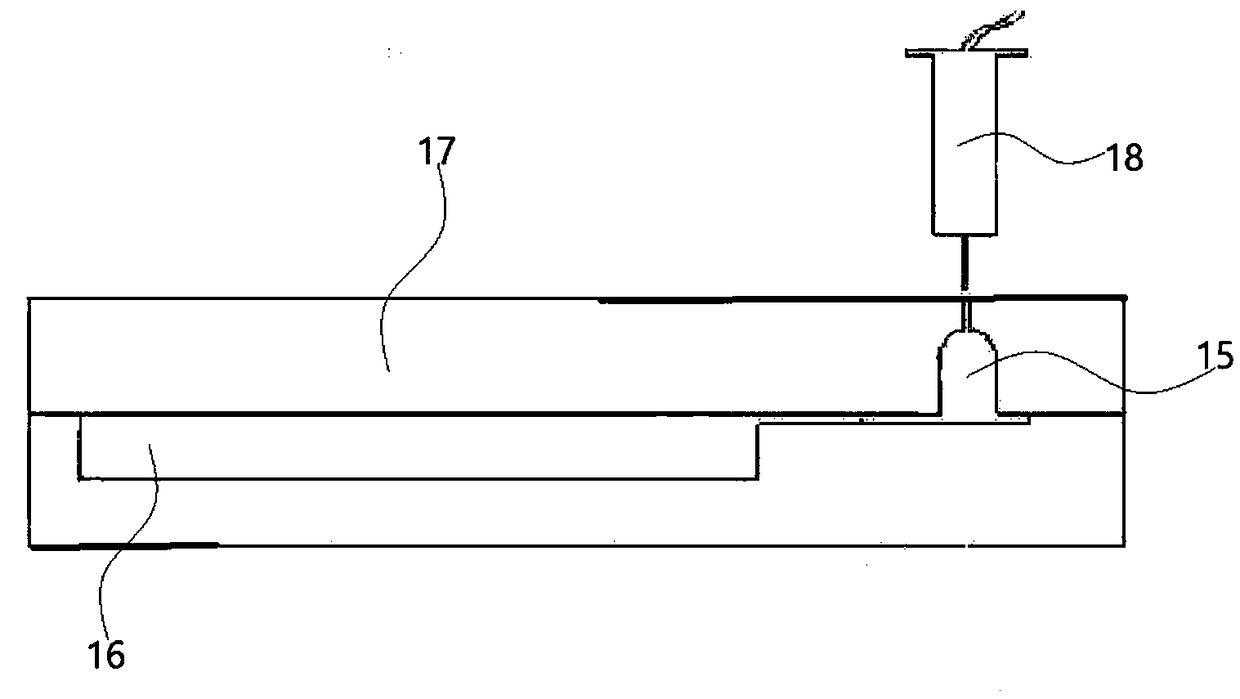

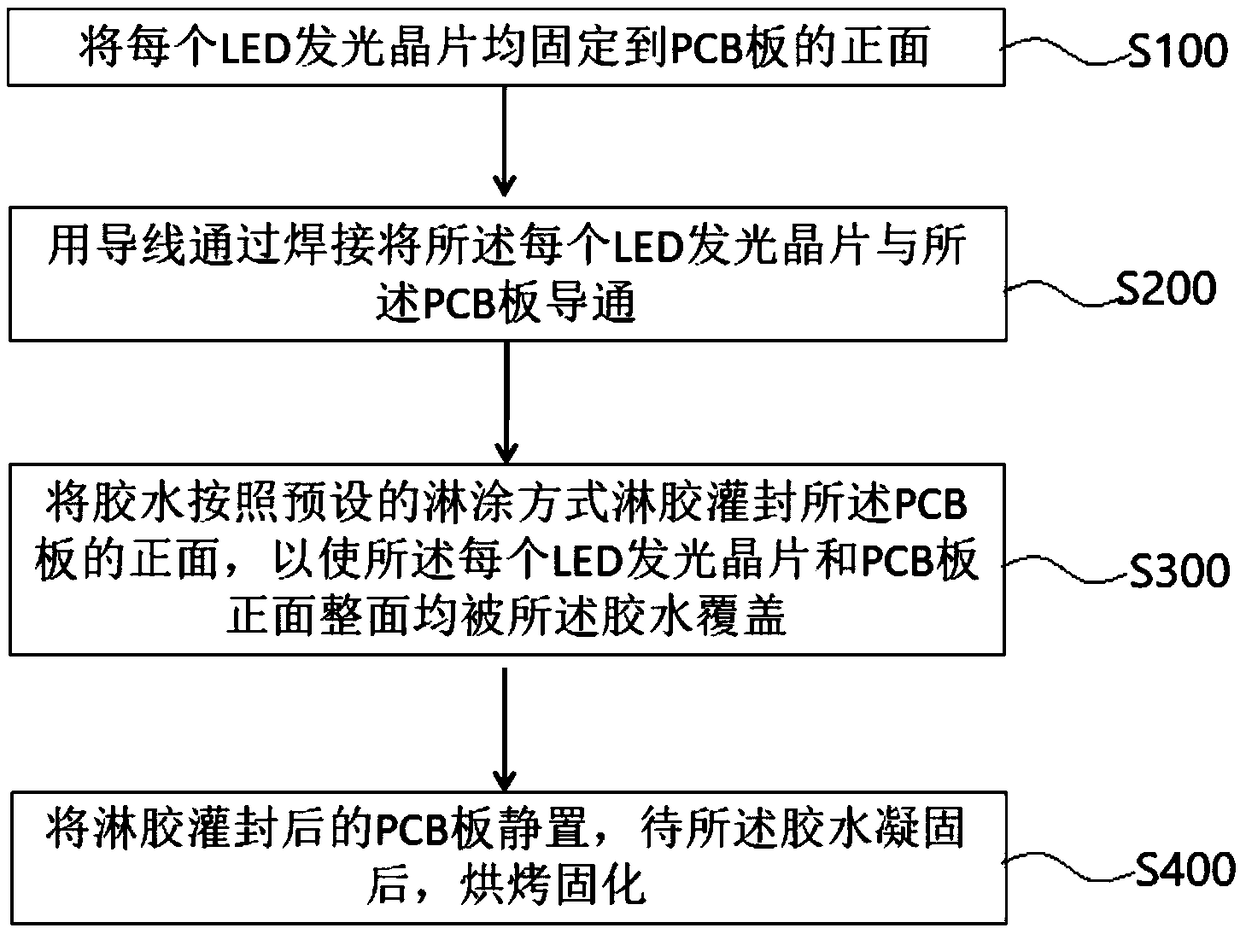

LED COB packaging method and LED packaging module

PendingCN109509826ASimple processImprove production efficiency and yieldSolid-state devicesSemiconductor devicesLed packagingSoldering

The invention discloses a LED COB packaging method and an LED packaging module, which belong to the technical field of LED display screen packaging. The LED COB packaging method comprises the steps of: fixing each LED light-emitting chip to the front side of a PCB; conducting each of the LED light-emitting chips with the PCB through soldering by means of a conductive wire; performing glue sprayingand potting on the front side of the PCB according to a preset shower coating manner, so that each LED light-emitting chip and the whole surface of the front side of the PCB are coated by the glue; and allowing the PCB after glue spraying and potting to stand, and baking and curing the PCB after the glue is solidified. The LED COB packaging method is simple in process, can improve the productionefficiency and the yield of LED display modules, can effectively prevent the LED light-emitting chips from being broken down, and can easily manufacture an LED display screen with dot spacing less than or equal to 1 mm.

Owner:深圳市新光台显示应用有限公司

Back coating type double-station laminating machine and working method thereof

PendingCN110053354AImprove production efficiency and yieldSimple structureTransfer printingPrinting after-treatmentContinuous operationContinuous production

The invention discloses a back coating type double-station laminating machine and a working method thereof. The machine is technically characterized by comprising a paper unwinding unit, a film unwinding device, a coating and laminating unit, a drying box, a stripping unit, a film winding unit, a lustering unit, a backing coating unit, a paper traction unit and a paper winding unit, wherein the paper unwinding unit is used for outputting paper, the film unwinding device is used for outputting films, the coating and laminating unit is used for coating and laminating the paper and the film intocomposite paper, the drying box is used for drying the composite paper, the stripping unit is used for stripping the composite paper dried by the drying box, the film winding unit is used for receiving the stripped film, the lustering unit is used for further processing the composite paper with the film stripped off, and the back coating unit is used for carrying out back coating on the lustered composite paper. According to the machine, the paper unwinding unit and the film unwinding device adopt a double-station zero-speed butt joint material changing technology, the whole machine can realize high-speed continuous production of 200meters / minutes without halt, roll changing does not require speed reduction or halt, continuous operation can be realized at a constant production speed, and the production efficiency and the finished product rate of products are greatly improved.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

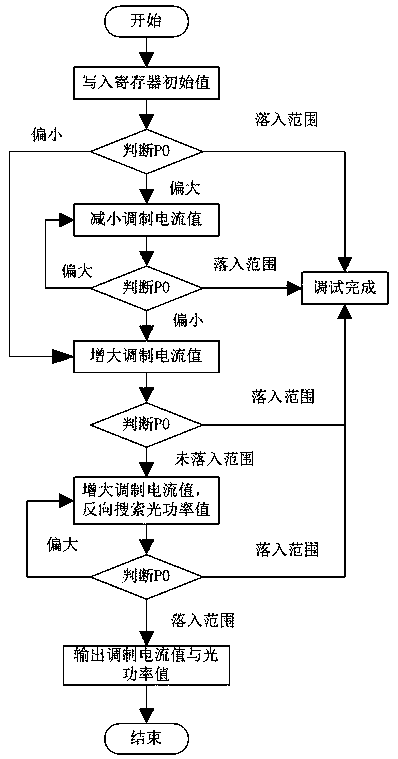

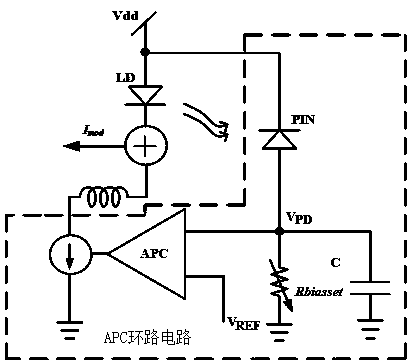

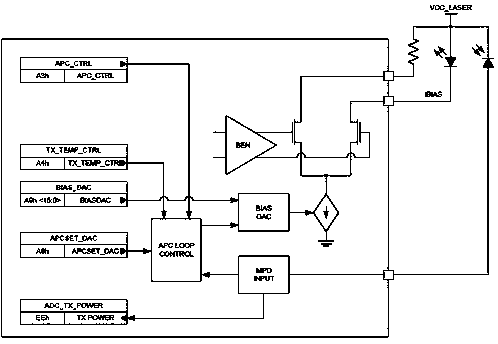

BOB blind debugging technology-based APC anti-noise method for DFB laser

ActiveCN108923252ATroubleshoot debugging failuresImprove production efficiency and yieldLaser optical resonator constructionOptical powerFailure causes

The invention discloses a BOB blind debugging technology-based APC anti-noise method for a DFB laser. The method comprises the steps of writing an initial value of a register; comparing a P0 value with a set value, judging whether an optical power value is within a normal value range or not, if so, completing debugging, if not, judging that the optical power value is larger or smaller, if the optical power value is larger, reducing modulated current, and if the optical power value is smaller, increasing the modulated current; judging whether a DAC is zero or not; increasing a modulated currentvalue, reversely searching the optical power value, comparing the maximum power value with the set value and judging whether the maximum optimal power value is larger or not; and judging whether meanoptical power is within the normal value range, if so, completing debugging and outputting the DAC value and the optical power value. A threshold change caused by a temperature change or laser ageingis overcome, the mean optical power of the laser is kept constant, the problem of an optical power debugging failure caused by board-level noise is solved, the production efficiency and the yield areimproved and the production cost is reduced.

Owner:SICHUAN TIANYI COMHEART TELECOM

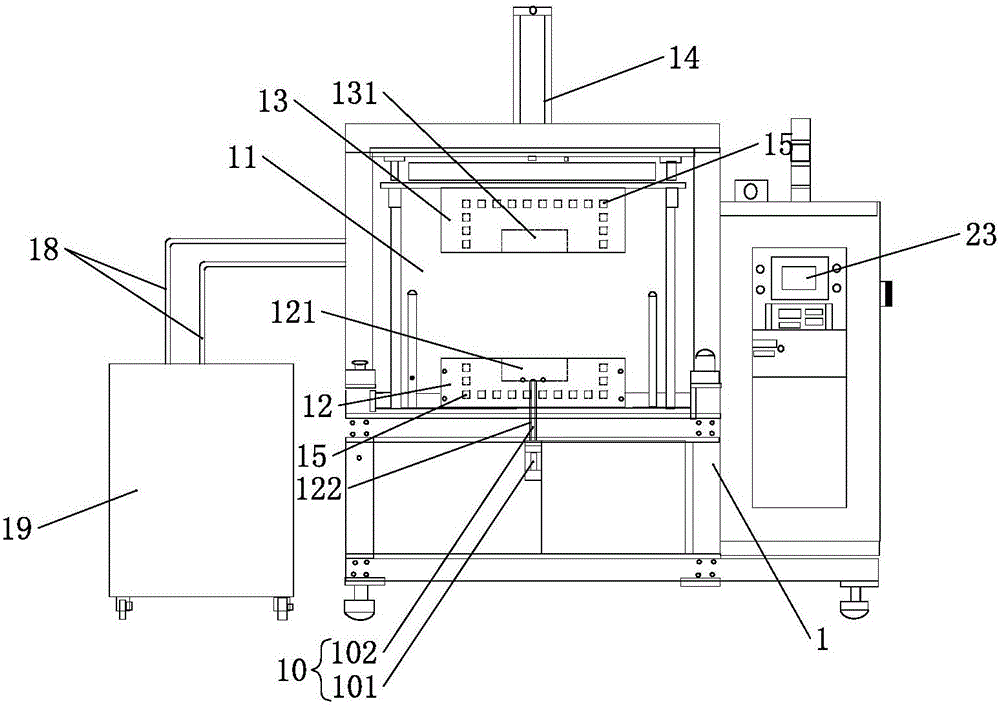

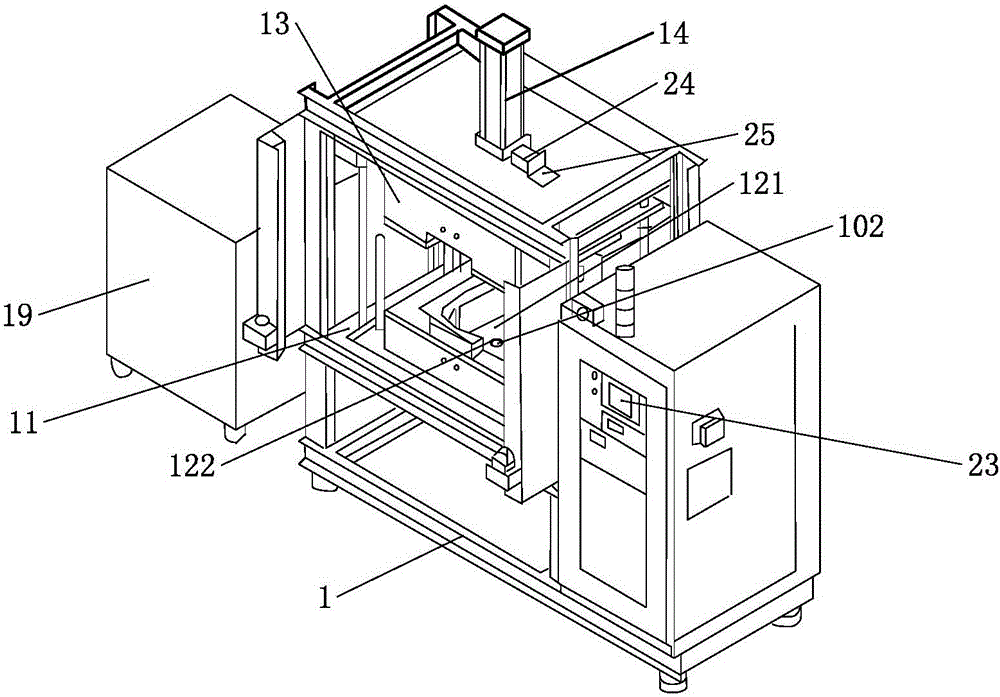

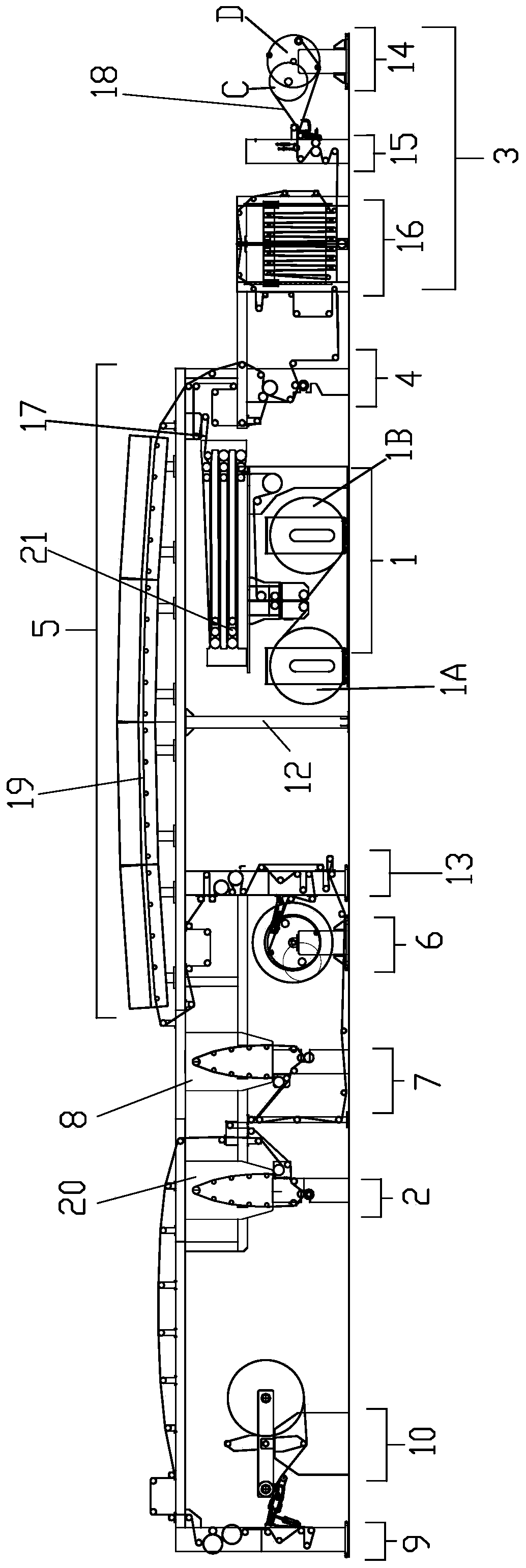

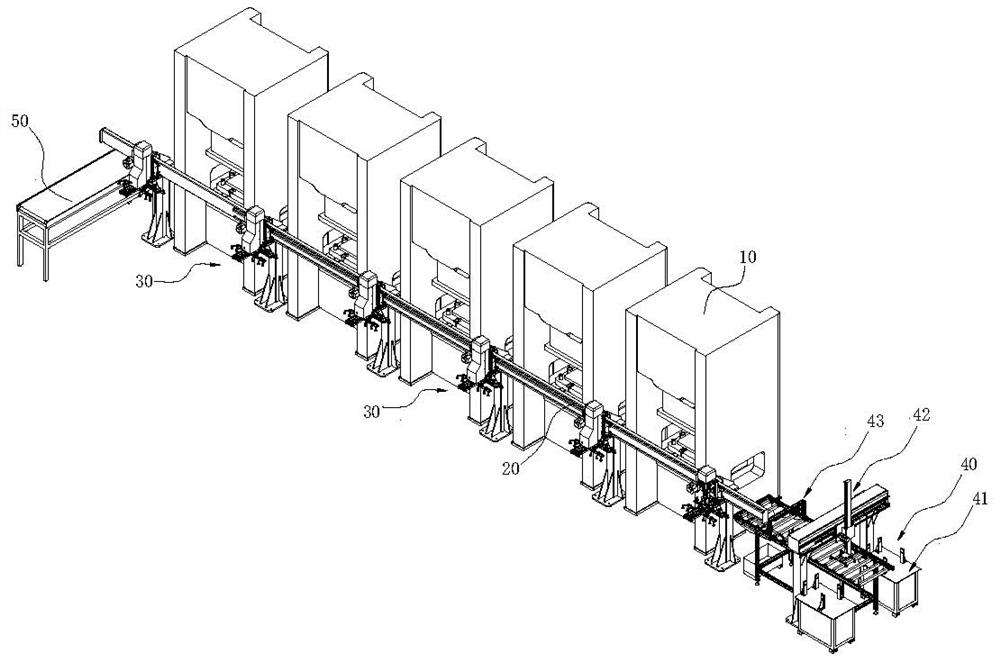

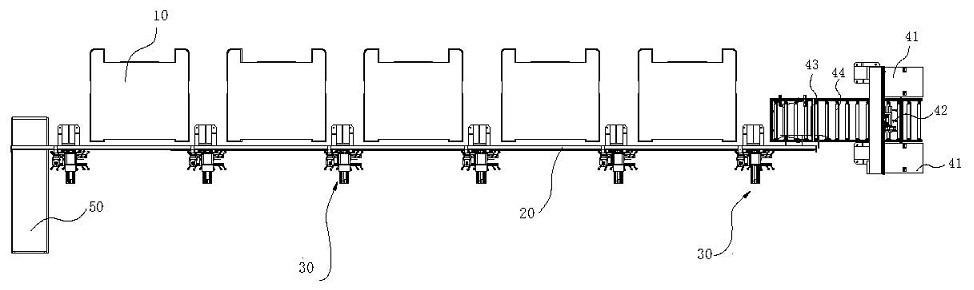

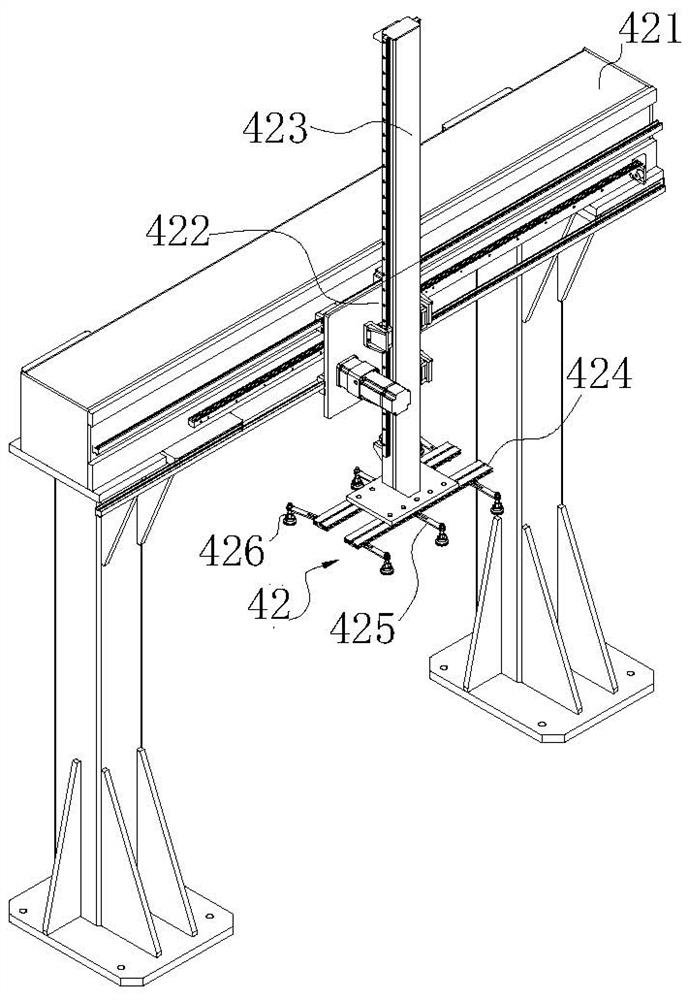

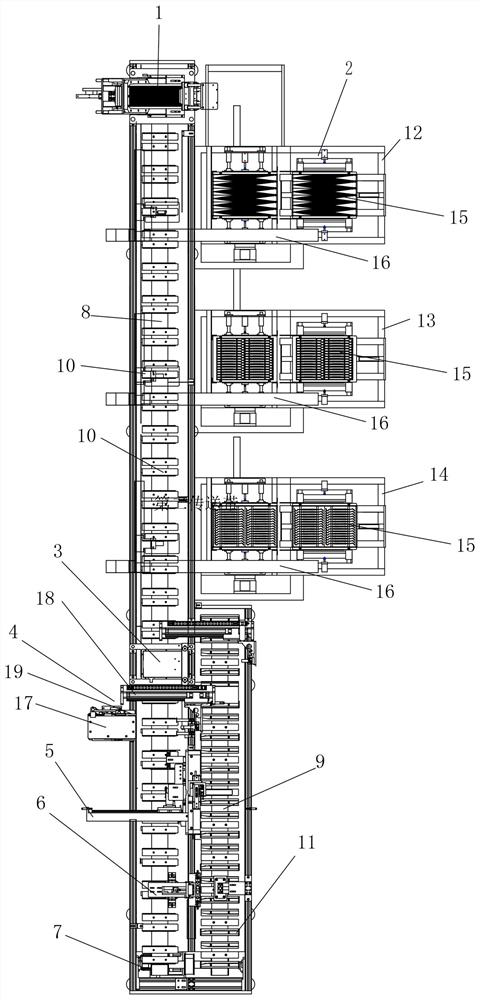

Automatic production equipment for internal cover plates

InactiveCN111872255ARealize automated productionImprove production efficiency and yieldShaping toolsMetal-working feeding devicesTransfer mechanismProcess engineering

The invention relates to automatic production equipment for internal cover plates. The automatic production equipment comprises a conveying line for conveying plate materials, stamping devices for forming the plate materials are arranged on a conveying path of the conveying line at intervals, and a material transfer mechanism is arranged between every two adjacent stamping devices; and a feeding mechanism used for supplying the plate materials is arranged at the head end of the conveying line, and a discharging device used for discharging the formed products is arranged at the tail end of theconveying line. According to the automatic production equipment, an improvement is made on the basis of an existing manual material transferring implementation scheme, and therefore implementation ofthe stamping devices is kept consistent with that of existing stamping devices. By additionally arranging the conveying line, the transfer mechanism, the feeding device and the like, automatic production of the cover plates is achieved, and the production efficiency and the yield are improved.

Owner:HEFEI ZHIDE IND & TRADE

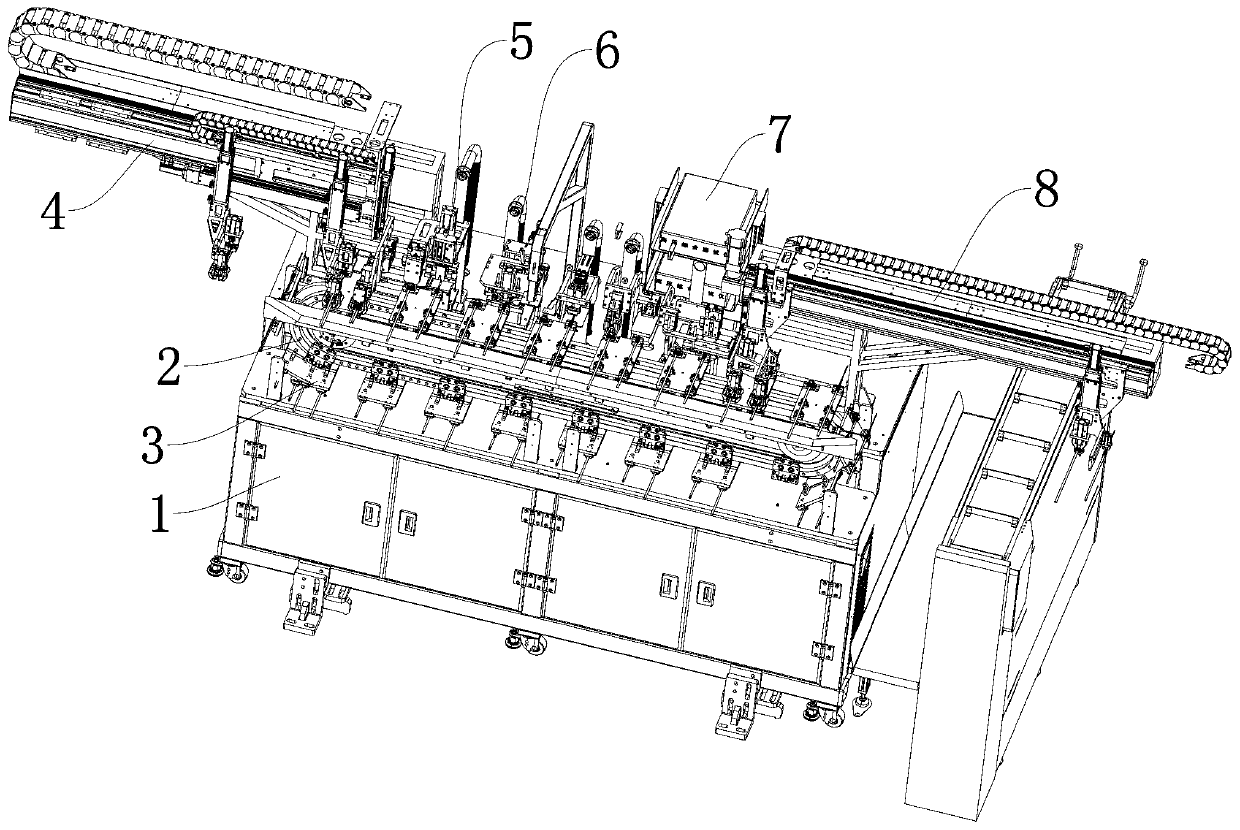

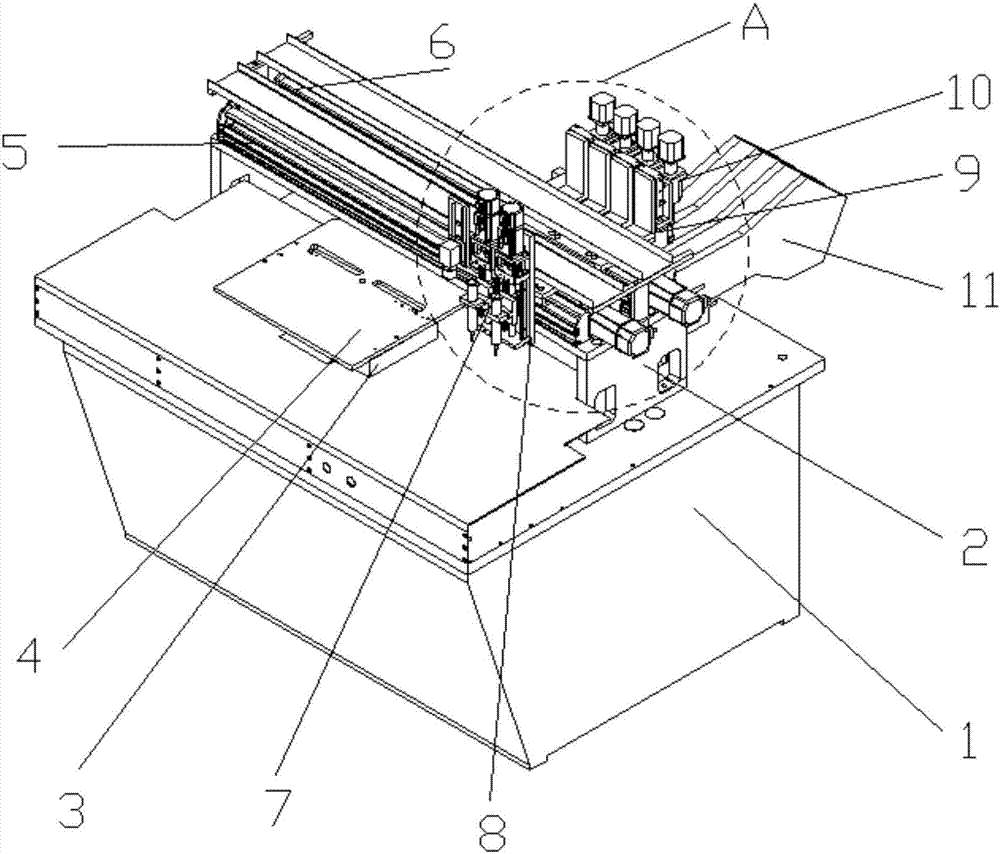

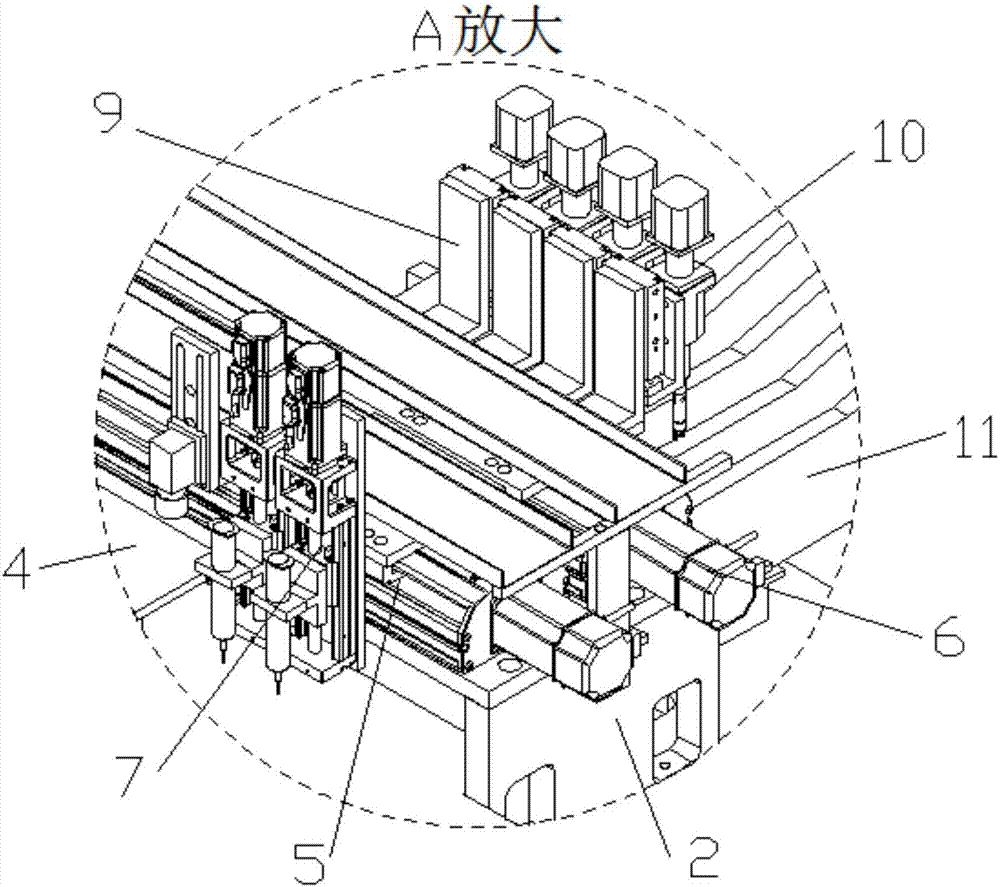

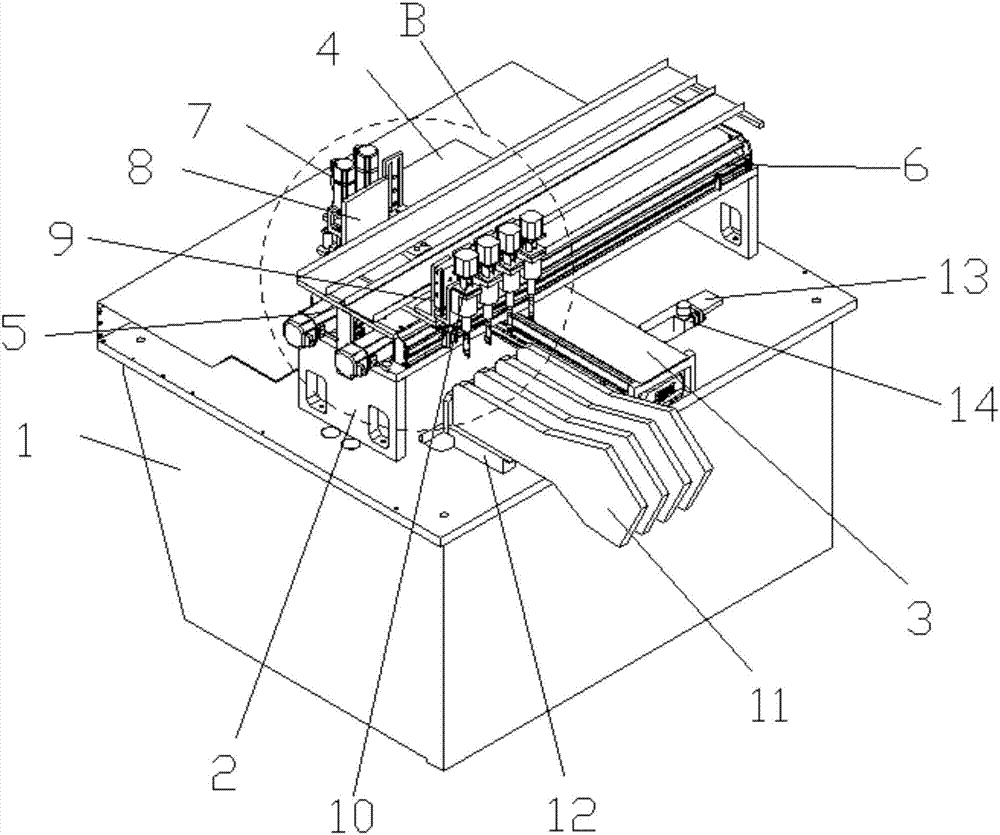

Full-automatic dispensing and LED lamp mounting equipment for flexible circuit board

ActiveCN107249262AReduce manual alignment stepsImprove production efficiency and yieldPrinted circuit assemblingPrinted circuit aspectsLED lampComputer engineering

The invention relates to the technical field of circuit board processing machinery, and specifically relates to full-automatic dispensing and LED (Light Emitting Diode) lamp mounting equipment for a flexible circuit board. The equipment comprises a base, a sliding table seat, a platform transfer sliding table, a platform, a dispenser sliding table, a lamp mounter sliding table, a dispenser, a dispenser installation plate, a lamp mounter installation plate, a lamp mounter, a lamp feeder, a feeder seat, a camera connecting seat and an LED lamp camera; the sliding table seat is transversely installed at the upper part of the base; the platform transfer sliding table is longitudinally installed on the base; the platform is installed on a sliding block of the platform transfer sliding table; the dispenser sliding table is installed inside the sliding table seat; the lamp mounter sliding table is installed outside the sliding table seat; the dispenser is fixed on the dispenser sliding table via the dispenser installation plate; the lamp mounter is fixed on the lamp mounter sliding table via the lamp mounter installation plate; the feeder seat is installed on the base at the lower part of the lamp mounter; the lamp feeder is installed on the feeder seat; the camera connecting seat is installed on the sliding table seat; and the LED lamp camera is installed in the camera connecting seat. The equipment can greatly improve the lamp mounting efficiency of the circuit board.

Owner:无锡市莱科自动化科技有限公司

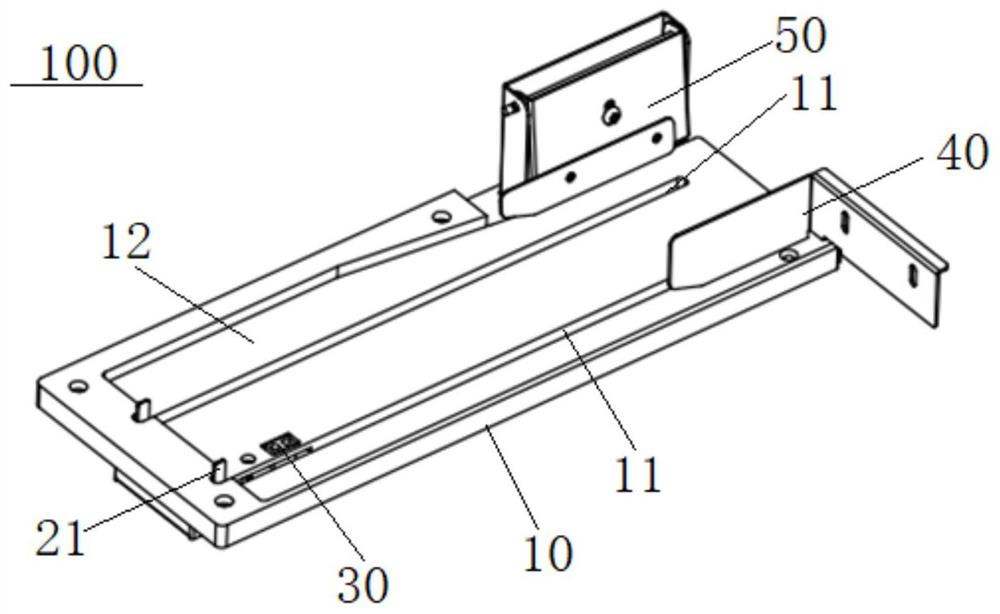

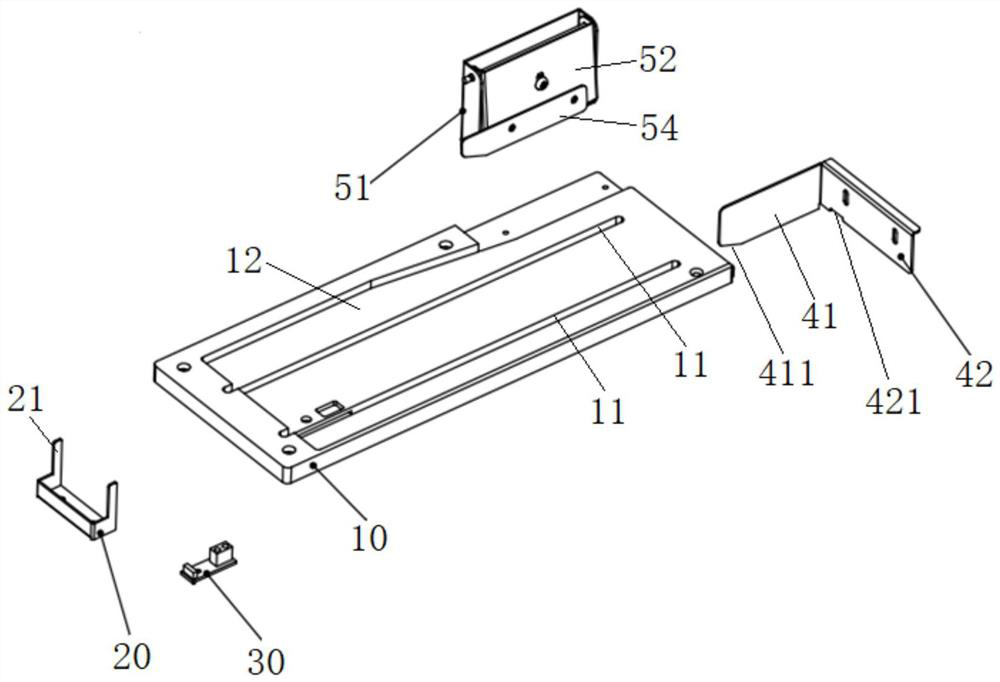

Guiding correction device of temporary identity card making machine

PendingCN114282628AImprove production efficiency and yieldSave human resourcesConveying record carriersEngineeringMechanical engineering

The invention discloses a guiding and correcting device of a temporary identity card making machine, which comprises a guide groove plate, the guide groove plate is provided with a guide surface for conveying a to-be-corrected piece, the guide surface is provided with a guide groove extending along the conveying direction, and the width of the first side of the guide surface is larger than that of the second side of the guide surface; the push plate is arranged at the first end of the guide groove plate; the sensor is arranged on the guide surface; the first guide piece is arranged at the second end of the guide groove plate; and the second guide piece is arranged at the second end of the guide groove plate, and the first guide piece, the second guide piece and the guide groove plate are matched to form a conveying track of the piece to be corrected. According to the guiding and correcting device, automatic alignment, guiding and overlapping of the transparent film and the temporary identity card base card can be achieved, it is guaranteed that the transparent film and the temporary identity card base card can be completely overlapped together, the yield and production efficiency of temporary identity card manufacturing are effectively improved, and manpower resources are reduced.

Owner:GUANGZHOU PRESTIGE TECH

Semiconductor packaging structure and manufacturing method thereof

InactiveCN108630555ASimple processImprove production efficiency and yieldSemiconductor/solid-state device detailsSolid-state devicesProtection layerDielectric layer

The present invention provides a semiconductor packaging structure including a circuit board, at least one chip, and a packaging layer. The circuit board includes a dielectric layer, a plurality of conductive pillars, a circuit layer, and a plurality of protective layers. The conductive pillars extend through the dielectric layer. Each of the conductive pillars has opposing first and second end portions. The second end portion protrudes from the dielectric layer. The circuit layer is disposed on the dielectric layer. The circuit layer is connected to the first end portion. The protective layers coat the second end portions of the conductive pillars. The material of the protective layers is different from the material of the conductive pillars. The chip is disposed on the dielectric layer.The chip and the circuit layer are located on the same side of the dielectric layer. The chip is electrically connected to the circuit layer. The packaging layer is disposed on the dielectric layer and coats the chip. A method for manufacturing the semiconductor packaging structure is also provided.

Owner:POWERTECH TECHNOLOGY

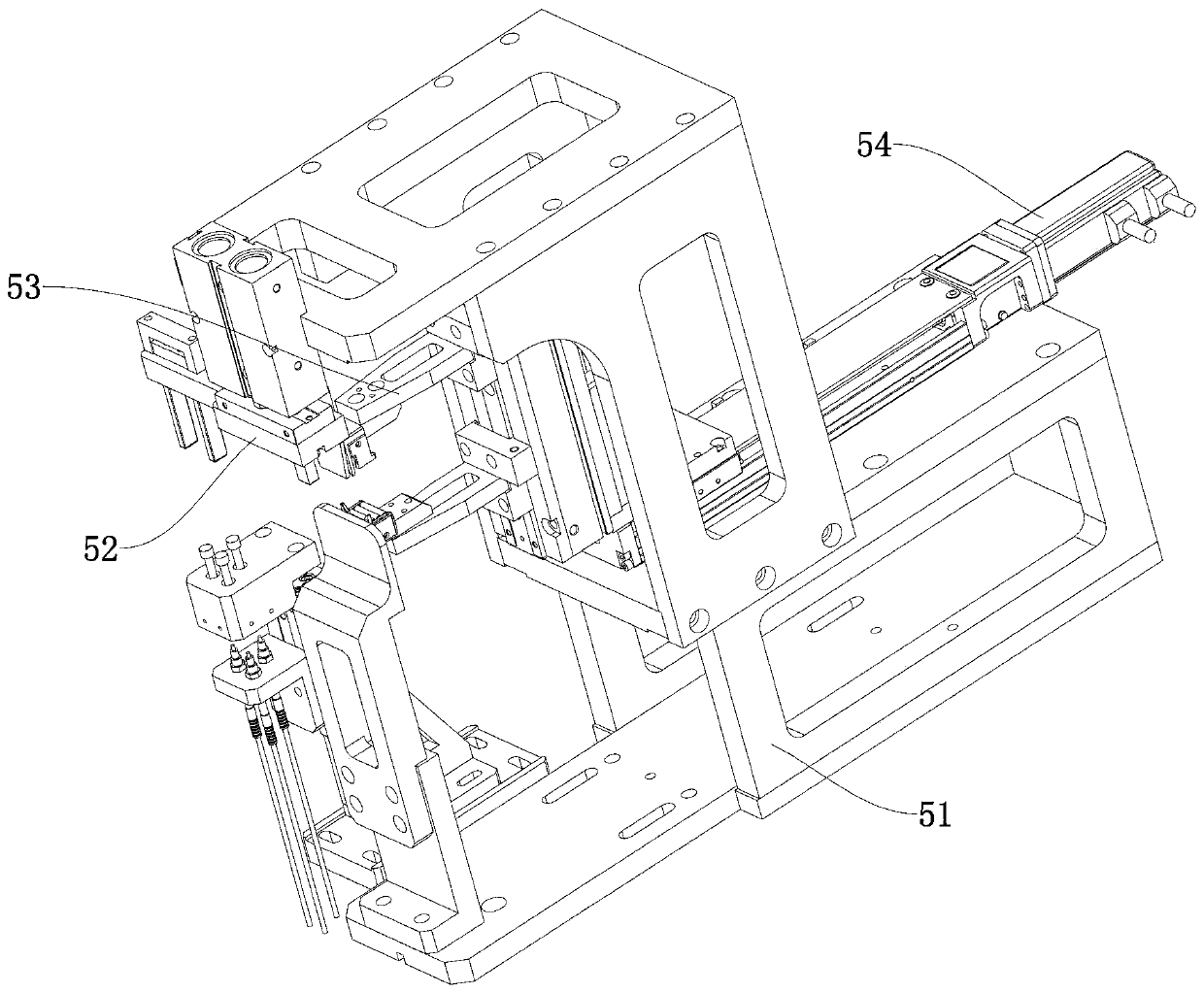

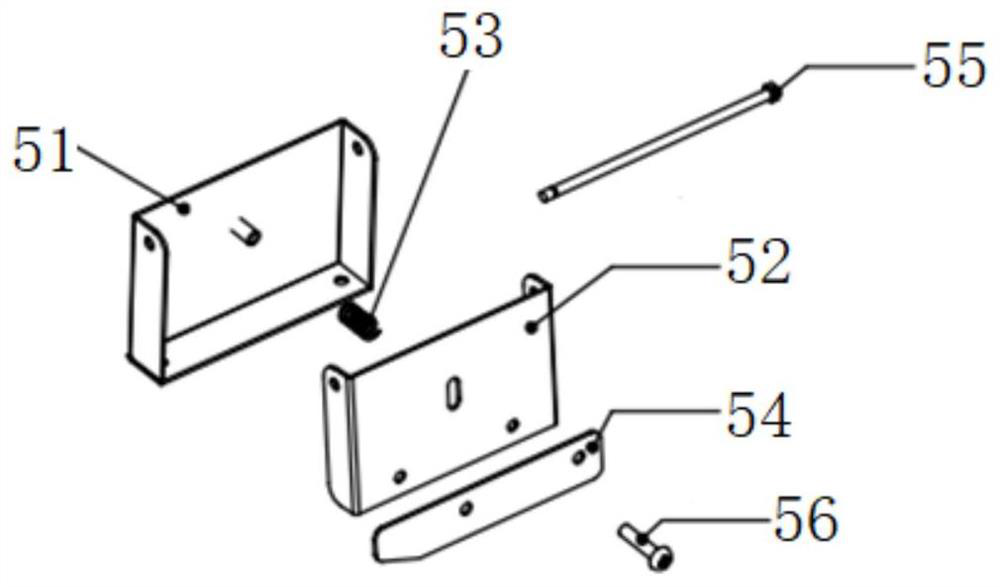

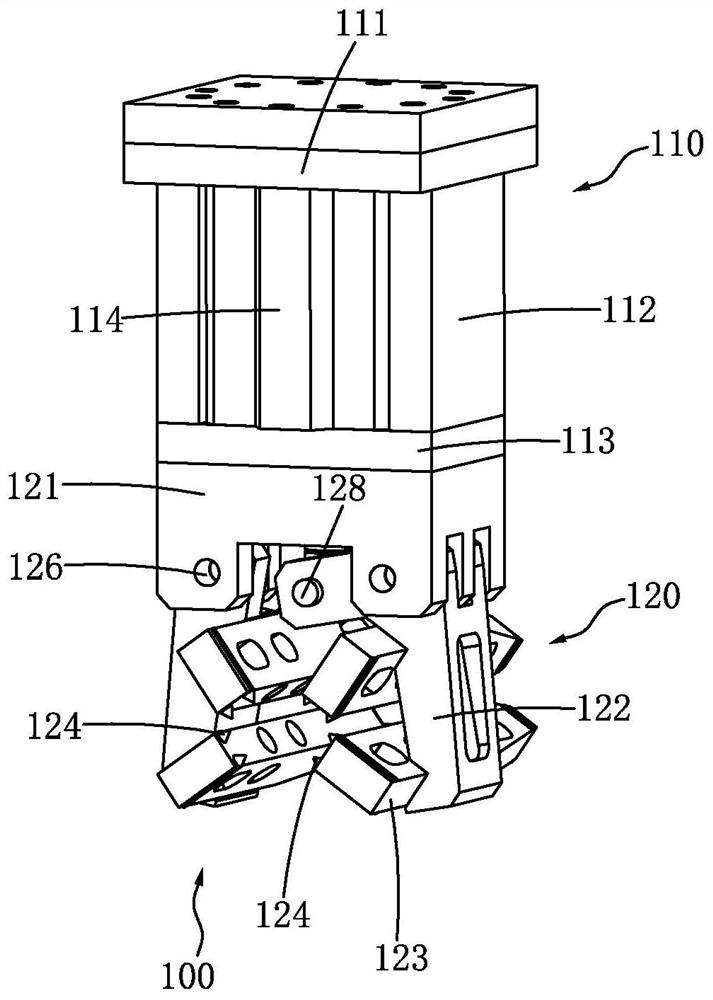

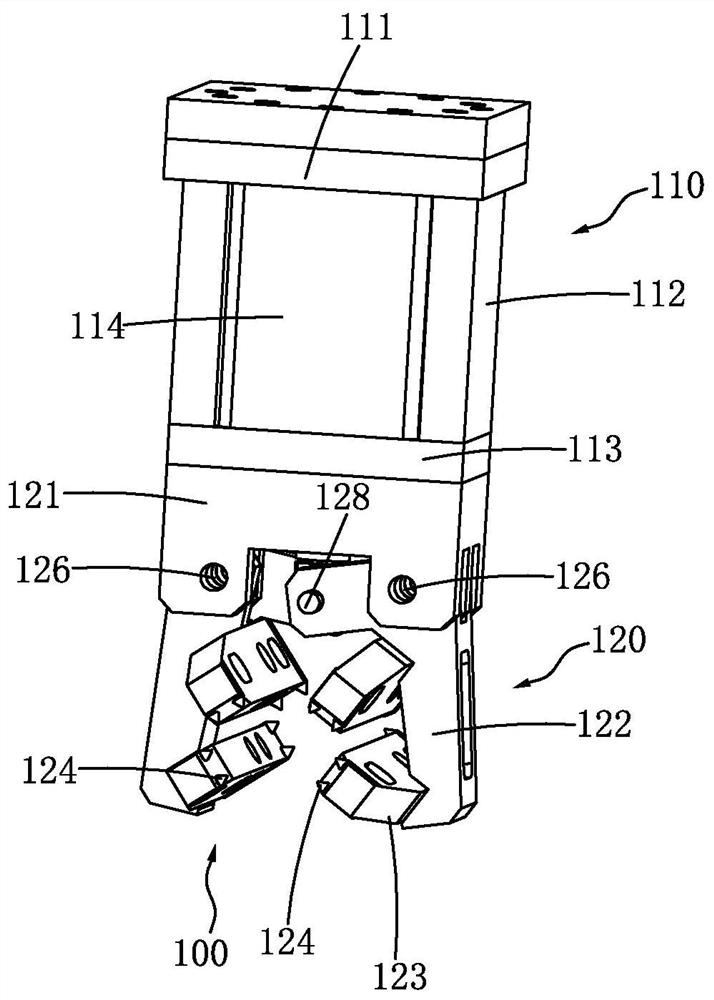

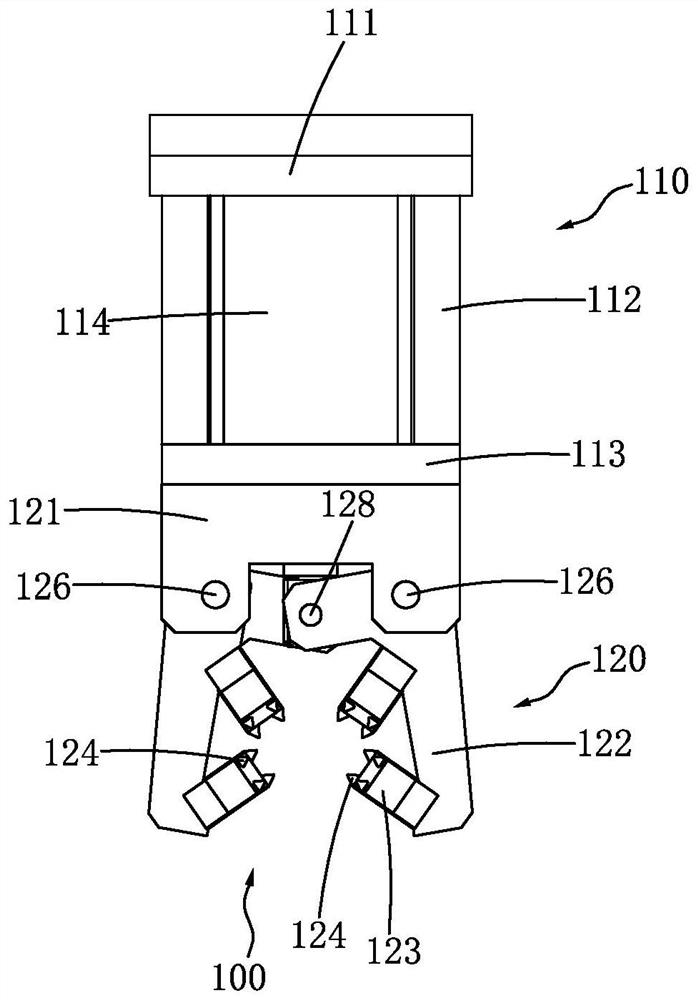

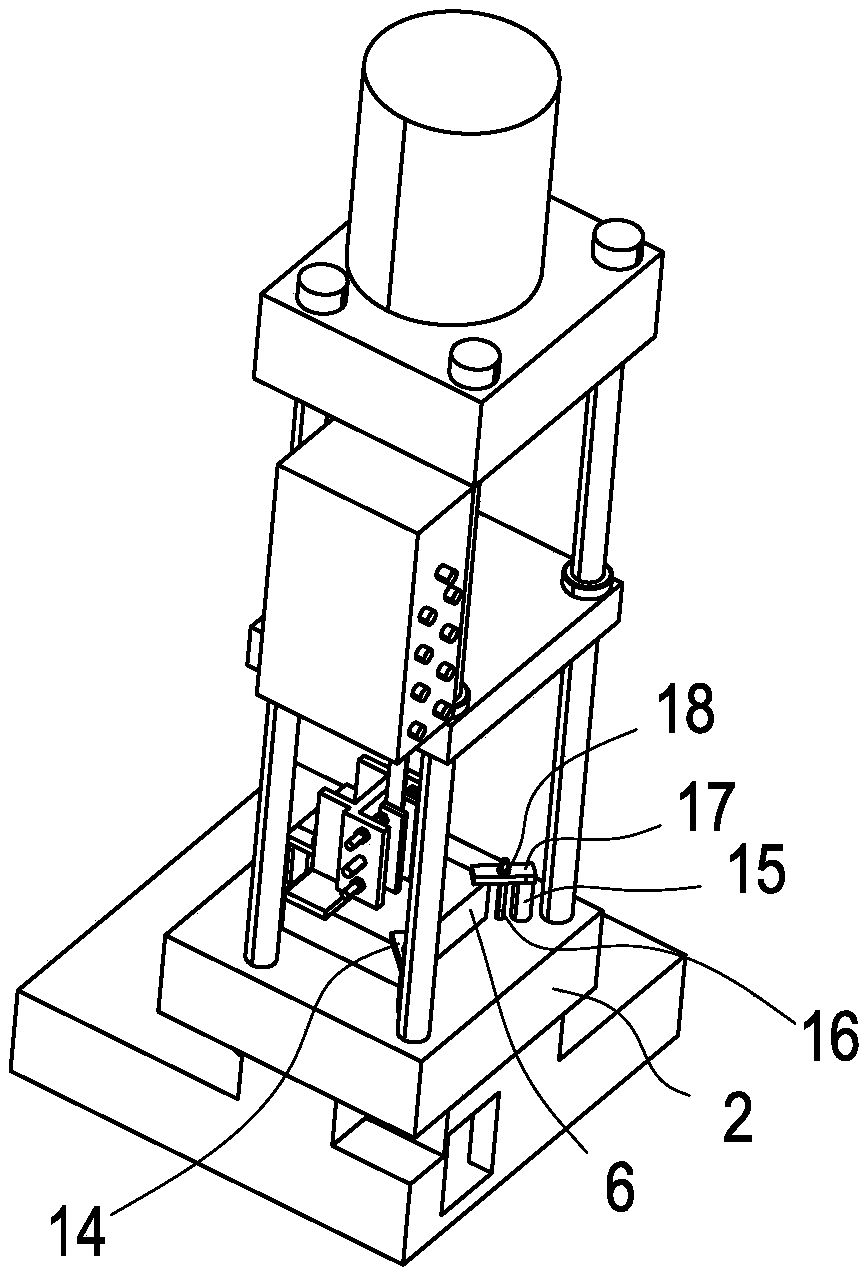

Ejection product taking-out device

PendingCN113119417AEnsure location consistencyImprove production efficiency and yieldSharp toothManufacturing engineering

The invention relates to an ejection product taking-out device which comprises a fixing mechanism, a clamping mechanism and a control unit. The fixing mechanism is arranged on a horizontal plane and comprises a bottom plate, side plates, a fixing plate and an air cylinder. The clamping mechanism is arranged below the fixing mechanism and comprises a base, hinge structures, connecting blocks and sharp tooth structures. The control unit is electrically connected with the air cylinder. By means of the ejection product taking-out device, the problems that due to a clamp, products slip, fall and are scrapped, the product position accuracy is poor, and the product quality is reduced are solved, the position consistency of the products in the automatic production process is guaranteed, and the yield of the products and the production efficiency are greatly improved.

Owner:KUNSHAN HANDING PRECISION METAL CO LTD

A Preforming Die for Machining Straight and High Cylindrical Forgings

InactiveCN102284662AImprove production efficiency and yieldLow costForging/hammering/pressing machinesEngine componentsStructural engineeringForging

The invention relates to a die, in particular to a pre-forming die for processing straight-height cylindrical forgings, which belongs to the field of bearing parts processing equipment. In the preforming die used for processing straight-height cylindrical forgings provided by the present invention, the V-shaped opening is formed by two side baffles; the V-shaped opening is 112°, and the blank ring is finally formed into a circular frustum, and the inclination angle of the circular frustum is 3°, the blank ring does not move outwards and moves inwards, which solves the problems of rolling end face depressions and burrs, improves the yield and production efficiency, and reduces the cost of the product.

Owner:WAFANGDIAN GUANGYANG BEARING GRP

Tap water separator lifting hole machining equipment and water separator lifting hole machining method

PendingCN108097820AImprove production efficiency and yieldIncrease productivityFixed frameMachining process

The invention provides tap water separator lifting hole machining equipment and a water separator lifting hole machining method, and belongs to the technical field of valve part machining. The equipment comprises a stand, and a pressing table arranged on the stand; the pressing table is provided with a press with an output shaft capable of axially reciprocating, and is detachably provided with a water separator fixed frame; an output shaft of the press is connected with a cylindrical pressing rod; and the position of the pressing rod is corresponding to the water separator fixed frame. The equipment gets rid of milling and polishing procedures needed by a traditional machining process, adopts once pressing molding to obtain qualified lifting holes, saves the polishing process, generates noruins, and synchronously improves the production efficiency and the yield.

Owner:ZHEJIANG GAOAO SANITARY WARE CO LTD

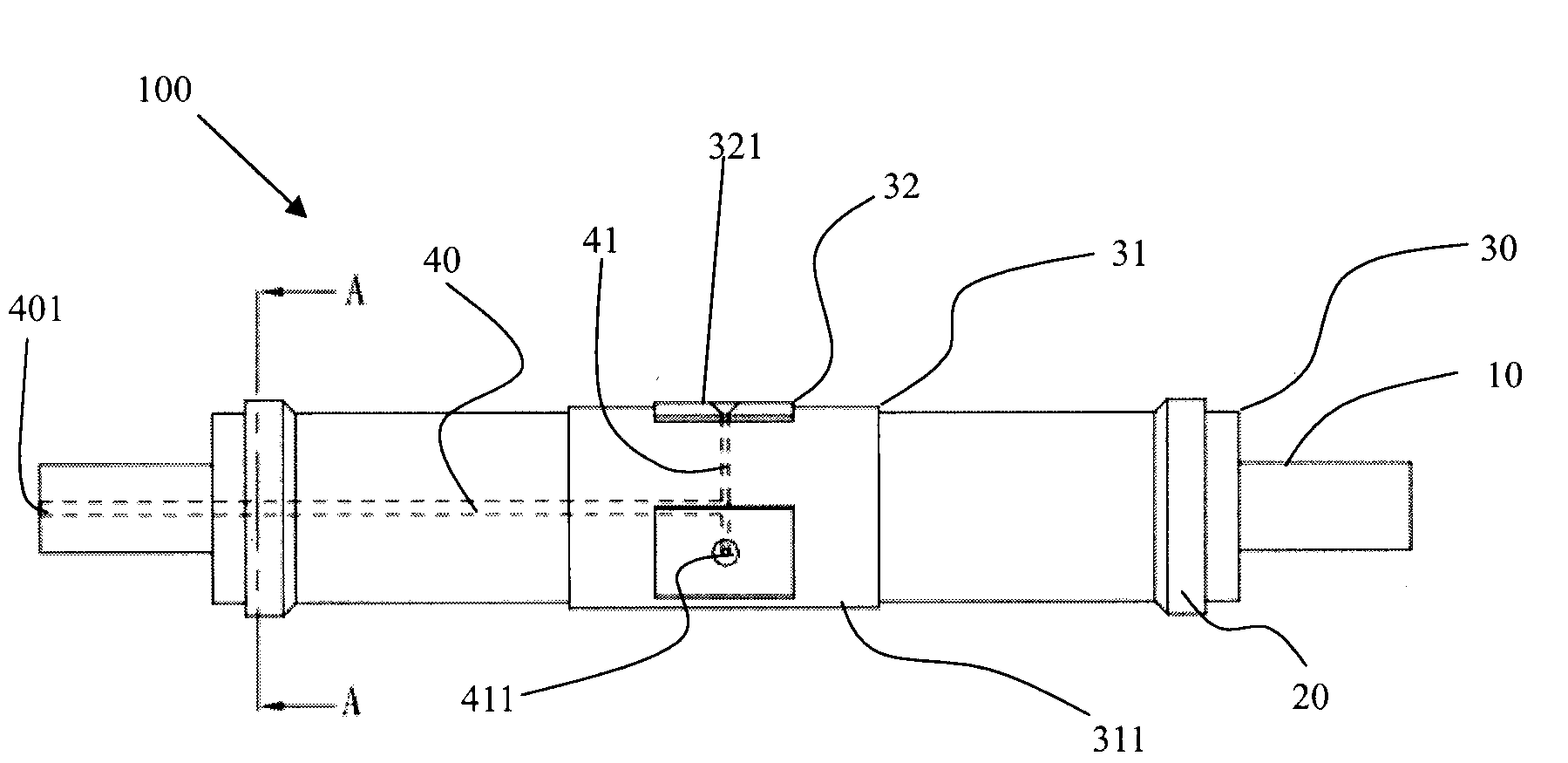

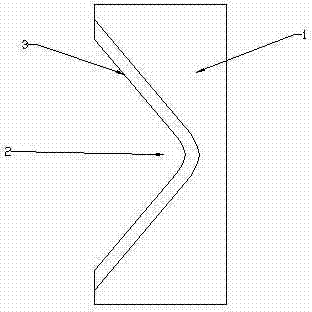

Car, resonant cavity and manufacturing method of resonant cavity

InactiveCN105569890AImprove production efficiency and yieldSolve the problem of low yieldMachines/enginesIntake silencers for fuelResonant cavityClassical mechanics

The invention discloses a resonant cavity. The resonant cavity comprises a shell, the shell is provided with an air inlet, a resonant cavity body is formed in the shell, and the air inlet is communicated with the resonant cavity body; the shell comprises an upper shell body and a lower shell body, the upper shell body and the lower shell body are buckled for forming the shell, the upper shell body is provided with a first cavity, the lower shell body is provided with a second cavity, and the first cavity and the second cavity form the resonant cavity body when the upper shell body and the lower shell body are buckled. By dividing the resonant cavity body into the split structure of the upper shell body and the lower shell body, the production efficiency and the yield of the resonant cavity can be improved through the split optimization design compared with the original integrated structure of existing products, the problem that the original yield is low can be solved, and the production efficiency and the yield can be improved. The invention further discloses a car comprising the resonant cavity and a manufacturing method of the resonant cavity.

Owner:力帆科技(集团)股份有限公司

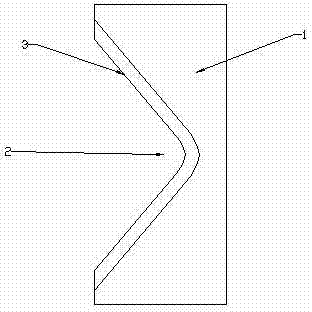

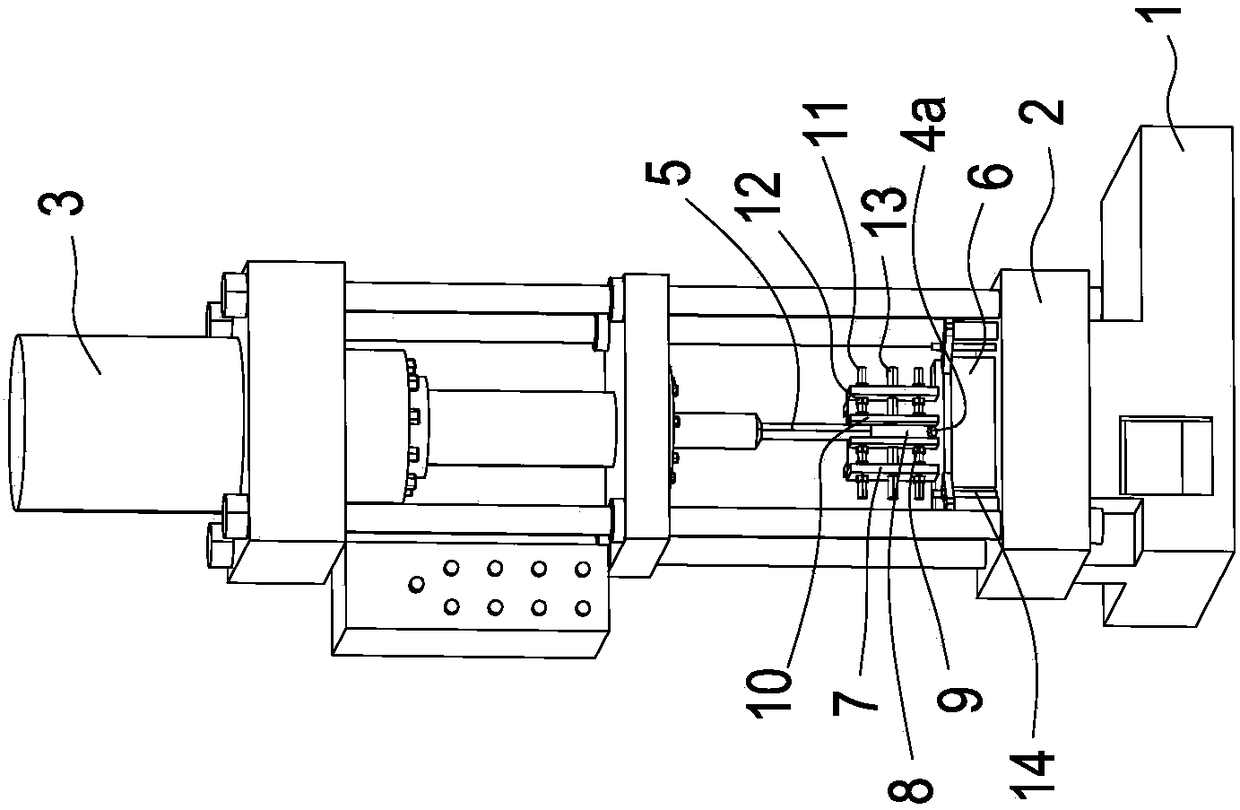

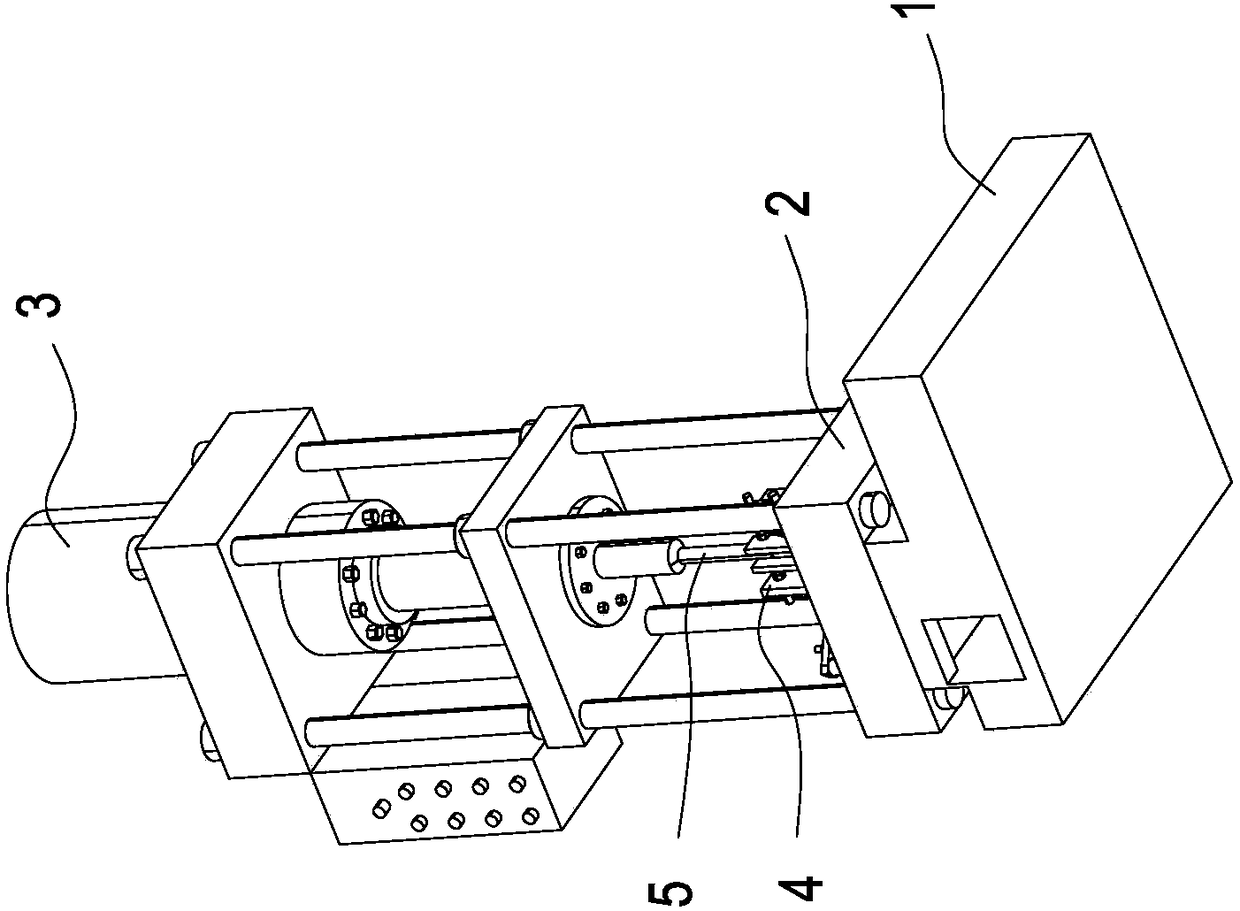

Position guiding compaction device for rolling mill

InactiveCN102248010AEliminates tension and torsionImprove production efficiency and yieldGuiding/positioning/aligning arrangementsEngineeringRaw material

The invention discloses a position guiding compaction device for a rolling mill. The rolling mill is provided with an upper press roll and a lower press roll which are used for compounding two metal sheets, wherein a worktable which is used for the horizontal sliding of raw material sheets before compounding is arranged between the two press rolls. The device is characterized in that: the position guiding compaction device is a roller which is arranged in front of the two press rolls, which are opposite to the sliding direction of the raw material sheets, on the worktable; the roller is suspended above the surface of the worktable; and the suspension height is greater than the overall thickness of the raw material sheets in a leveled stacking state. The position guiding compaction device reduces and eliminates the torque force and the tensile force which are generated on alloy sheets, ensures that the compounding production of double metals is steadily performed, greatly improves the production efficiency and the yield, and also saves production cost.

Owner:张家港市宏翔金属制品有限公司

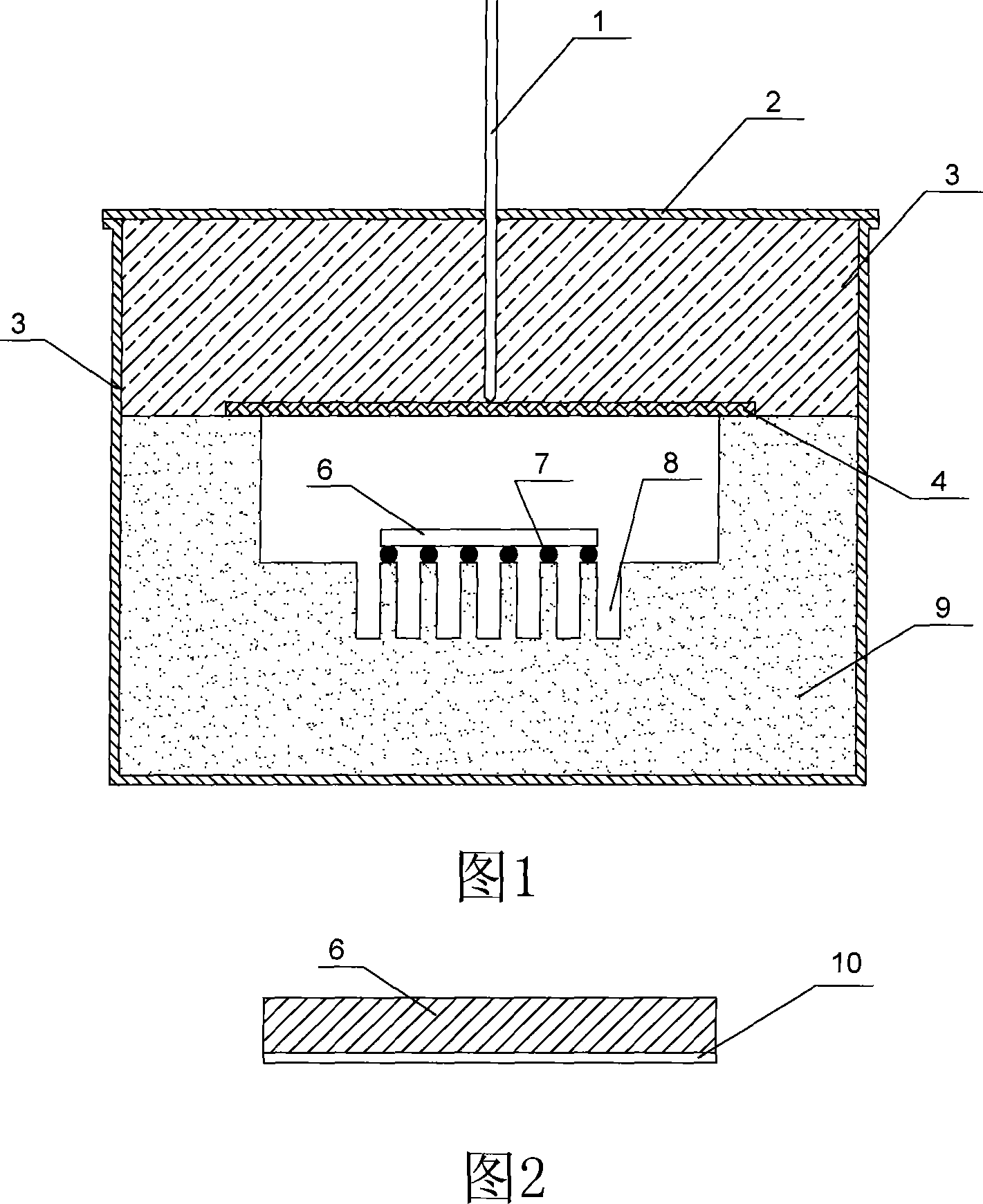

Compound blue crystal underlay substrate and method for producing the same

The invention relates to a blue crystal substrate, in particular to a compound blue crystal substrate and the manufacture method thereof. The compound blue crystal substrate comprises a blue crystal wafer (alpha-SiO2), and a layer of lithium silicate (gamma-Li2SiO2) compounded on the surface of the blue crystal wafer (alpha-SiO2). The invention is prepared through vapor transport equilibration technique; the compound blue crystal substrate (Li2SiO2 / alpha-SiO2) overcomes the disadvantages of high price, high hardness and processing difficulty of traditional blue crystal substrate (Li2AlO2 / alpha-Al2O3), and yield of scribing is about 90%.

Owner:ZHEJIANG SINGBEE LIGHTING TECH

Oral instrument box packaging and feeding device

PendingCN114872992AImprove production efficiency and yieldLow manufacturing costPackaging by pressurising/gasifyingIndividual articlesPhysicsPulley

The invention discloses a packaging and feeding device for oral instrument boxes. The device comprises a tray distribution mechanism, a plurality of oral instrument feeding mechanisms, a bag film clamping and conveying mechanism, a scarf clamping and conveying mechanism, a bag opening and box pushing mechanism, an air suction sealing mechanism and a conveying mechanism. The conveying mechanism comprises a synchronous belt wheel, a first conveying belt and a second conveying belt. The second conveying belt is arranged on one side of the tail part of the first conveying belt in parallel; the synchronous pulley is respectively connected with the tail parts of the first conveyor belt and the second conveyor belt; the tray distributing mechanism is connected to the front end of the first conveying belt, and the oral instrument feeding mechanisms are sequentially located on one side of the first conveying belt. The bag film clamping and conveying mechanism, the scarf clamping and conveying mechanism, the bag opening and box pushing mechanism and the air suction and sealing mechanism are sequentially arranged at the front end of the second conveying belt and on the first conveying belt from front to back.

Owner:SHANGHAI SHENGDA MEDICAL HEALTH STOCK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com