Multilayer-injection molding stepped mold device

A step-by-step injection molding technology, applied in the field of plastic injection molds, can solve problems such as poor device movement, inability to observe in time, and inability to solve problems in time, so as to improve yield and production efficiency, facilitate observation and movement, and reduce material and The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

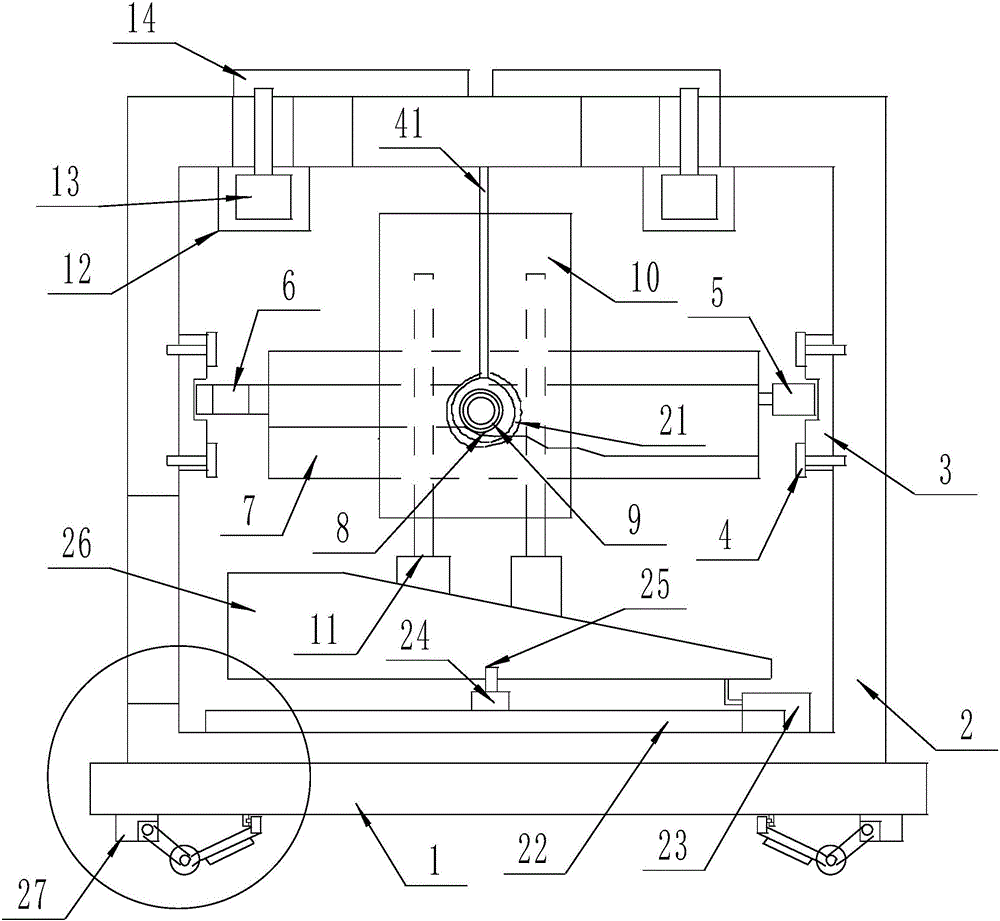

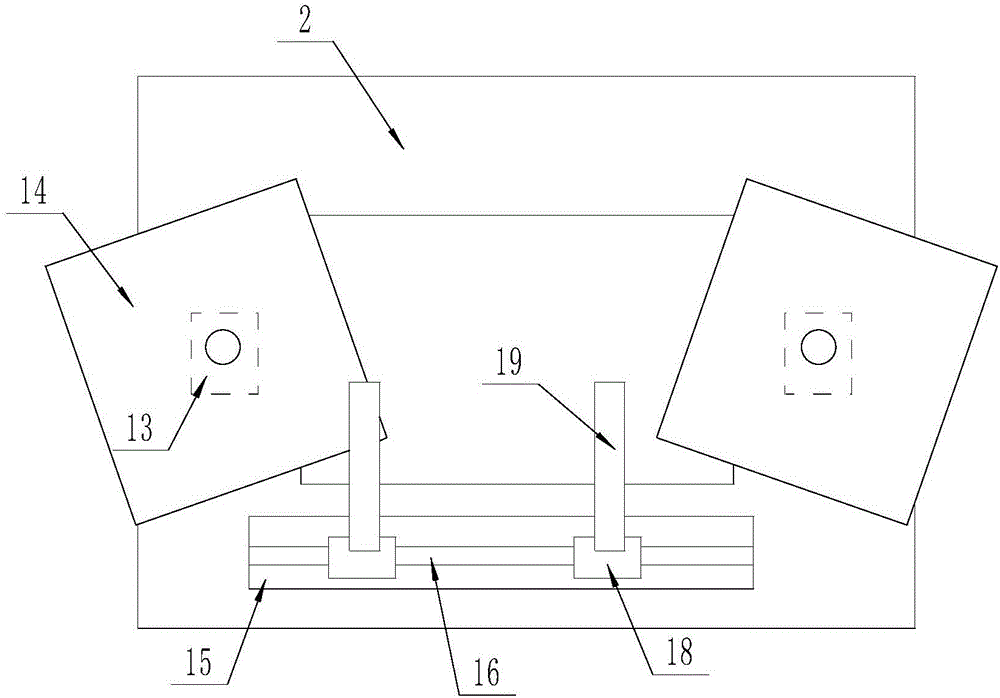

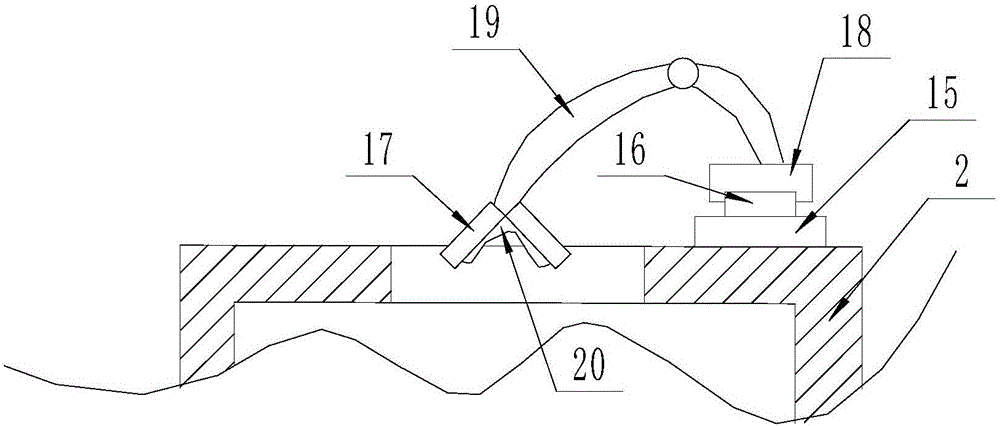

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a stepped mold device for multi-layer injection molding includes a bearing base (1), the upper surface of the bearing base (1) is fixedly connected with a processing box (2), and the processing box (2 ) is provided with a moving mechanism on the inner lower surface, the processing box (2) is provided with an injection molding mechanism connected with the moving mechanism, the lower surface of the bearing base (1) is provided with a walking fixing mechanism, and the processing box ( 2) The upper surface is provided with a clamping and unloading mechanism overlapping with the injection molding mechanism, and the injection molding mechanism is provided on each A plurality of set screws (4) between the rectangular bearing plate (3) and the inner surface of the processing box (2), a plurality of bearing grooves opened at the center of the side surface of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com