Heat exchanger for new energy sources

A heat exchanger, new energy technology, applied in the direction of heat exchanger fixing, heat exchange equipment, heat exchanger type, etc., can solve the problems of uneven battery temperature, large battery charge and discharge heat, and electric heating film easy to short circuit. , to achieve the effect of reducing material and processing costs and increasing heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

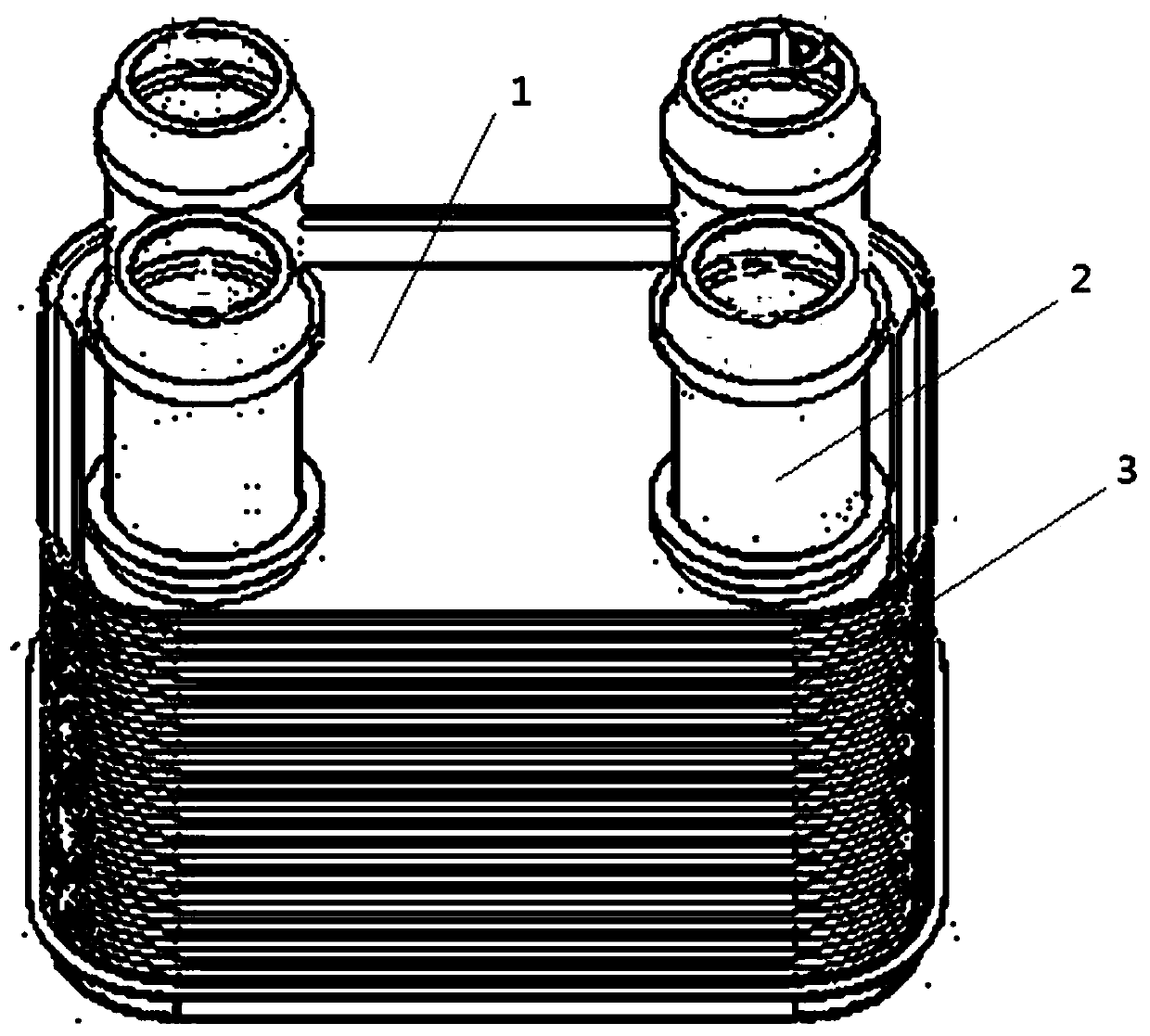

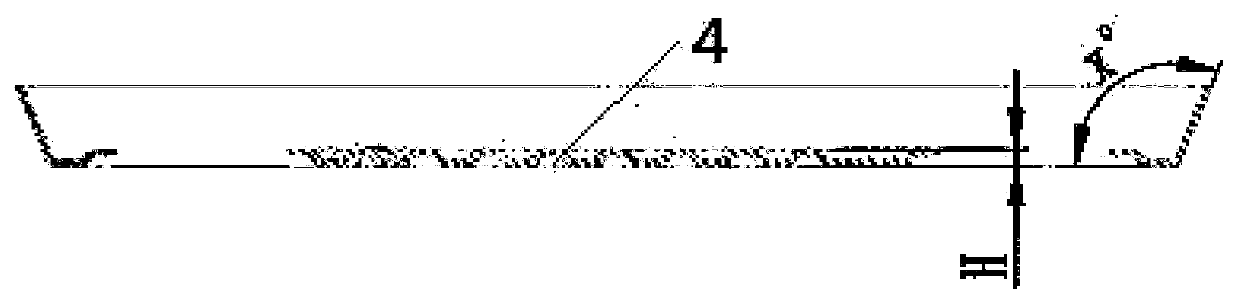

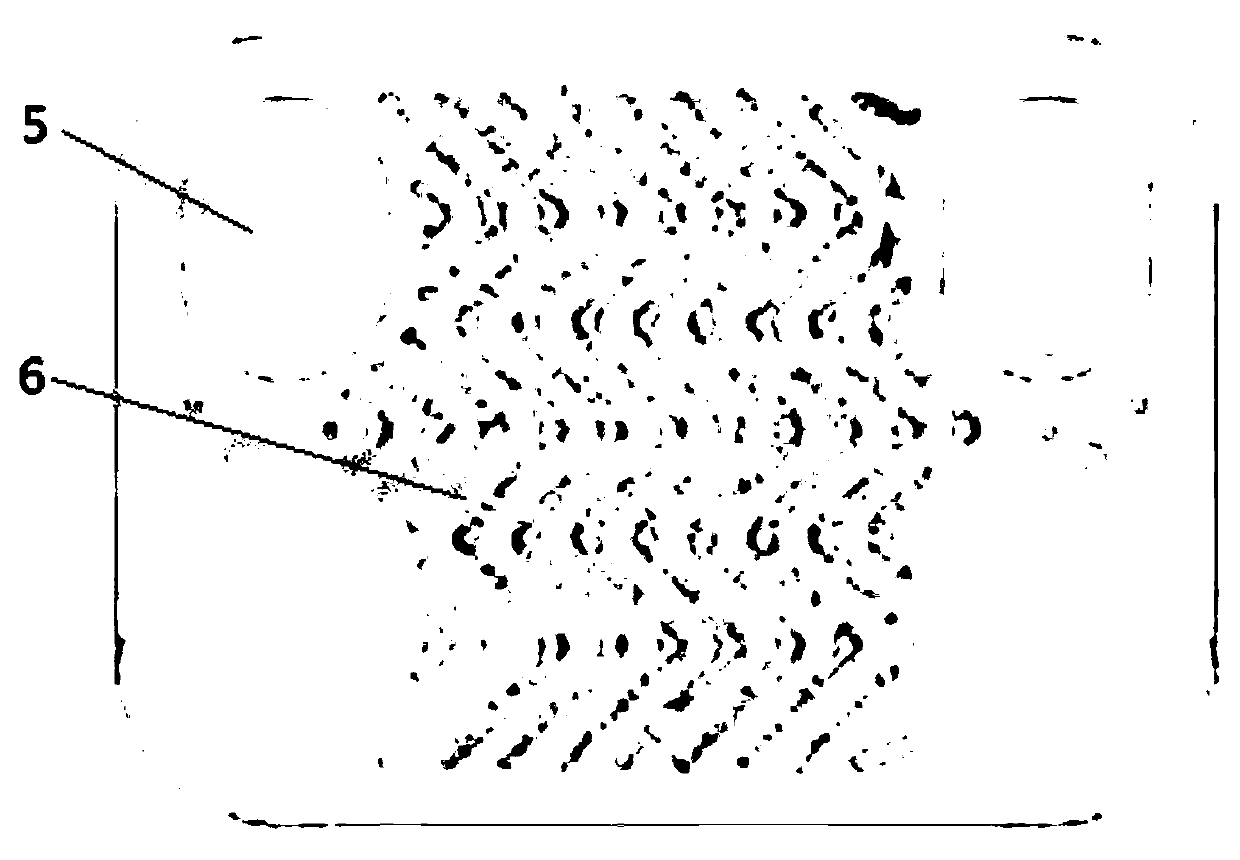

[0025] Such as Figure 1~5 As shown, a heat exchanger for new energy includes an exchanger main body 1 and a liquid collecting pipe 2 formed by stacking a plurality of forming plates 3 left and right; Four liquid collection holes 5 and ribs 4 formed by stamping on the surface of the forming plate 3; the liquid collection holes 5 after the multiple forming plates 3 are stacked left and right form a liquid collection channel, and the liquid collection channel and the liquid collection pipe 2 Sealed connection; the ribs 4 stacked after the plurality of forming plates 3 turn left and right form a flow channel 6 .

[0026] The forming plate 3 is a 0.4mm double composite layer 3-series aluminum plate with a length of 90mm, a width of 65mm and a thickness of 0.3mm.

[0027] The stack height of the heat exchanger main body 1 is 50 mm.

[0028] The height of the rib shape 4 is 0.6mm.

[0029] The sides of the forming plate 3 are inclined to be folded, and the angle of the folded edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com