Reflector

A reflective mirror and reflective surface technology, which is applied in the field of light source systems, can solve the problems of high positioning requirements for assembly lighting systems and light source systems, long processing cycles, and low production efficiency, and achieve good light concentration, low processing costs, and flexible use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

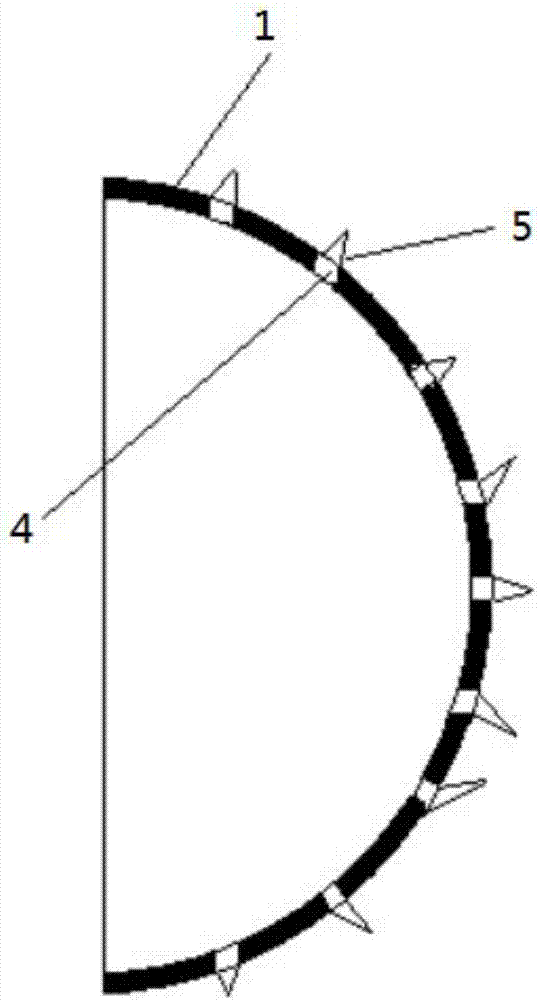

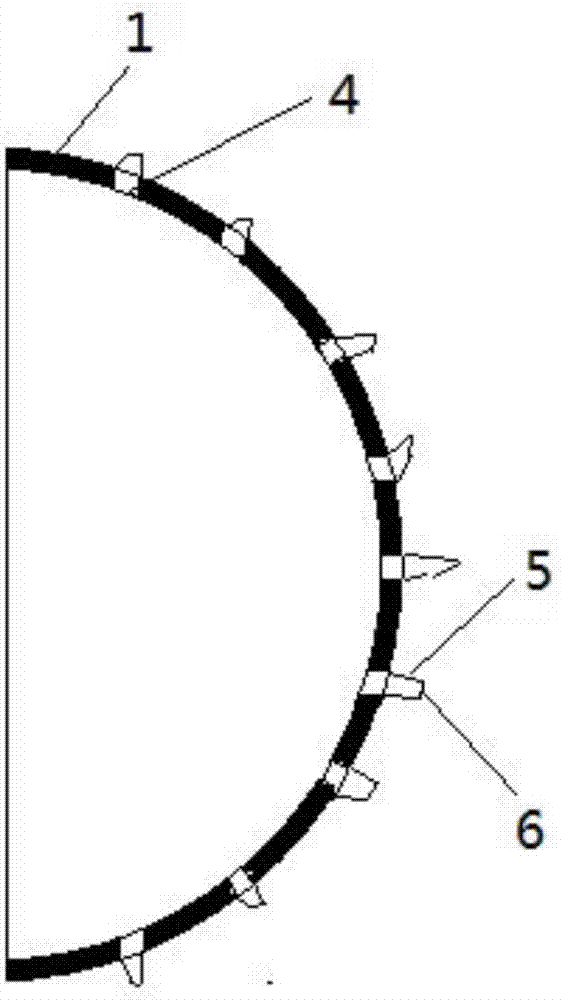

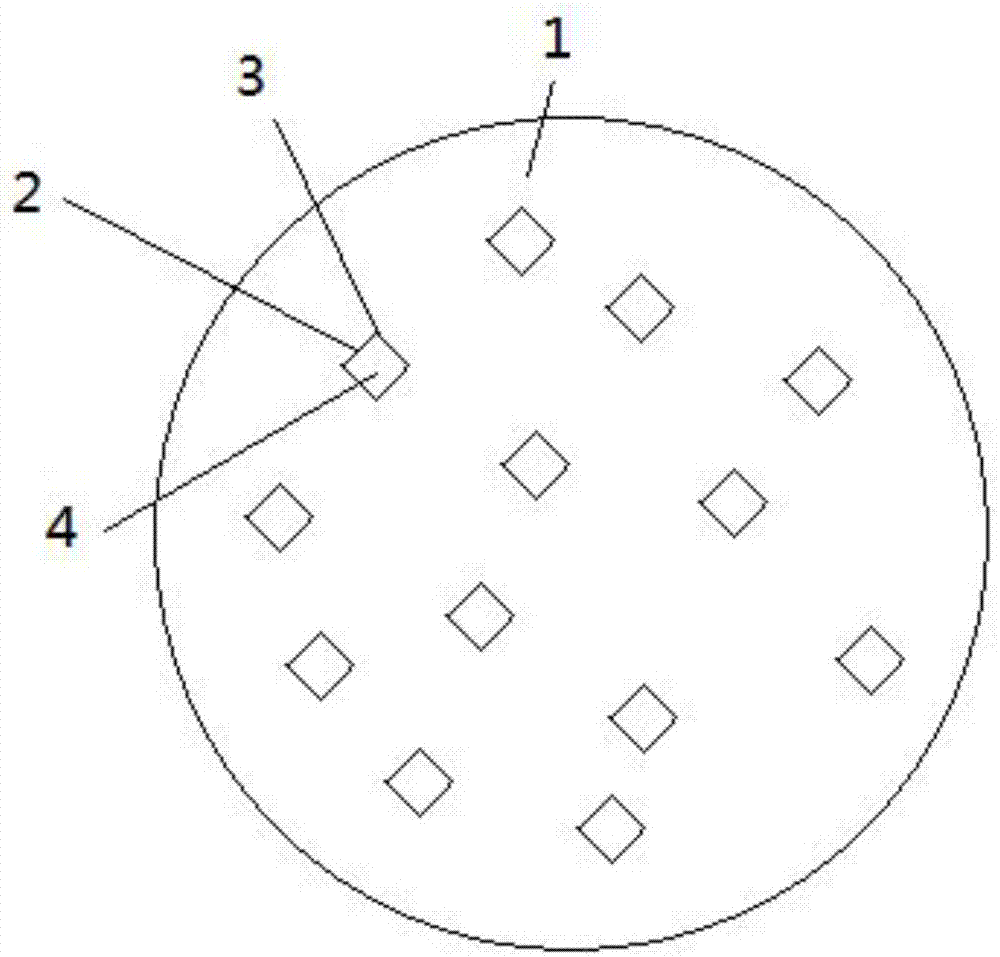

[0021] See Figure 1 ~ Figure 4 , The reflector of the present invention includes a reflecting surface 1, the reflecting surface 1 is provided with a leakage hole 4 formed by connecting a connection point 3 and a straight line 2, and the straight line 2 is provided with an outwardly extending oblique reflection Plane 5, the sides of two adjacent reflection planes 5 are connected to each other, and the ends of each reflection plane 5 are connected to each other;

[0022] The reflecting surface 1 is curved or flat;

[0023] Preferably, the angle α between two adjacent reflection planes 5 is 1 to 179°;

[0024] Preferably, the ends of each reflecting plane 5 are connected by a connecting plane 6;

[0025] Preferably, the equivalent diameter of the leak hole 4 is 0.0000000001 to 100 meters;

[0026] The term "equivalent diameter" is defined as follows. The said equivalent diameter is the sum of the lengths of individual lines divided by the circumference ratio, that is: Equivalent diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com