Parking baseplate assembly of drum-in-disc type parking brake

A parking brake and floor technology, which is applied to brakes, brake components, vehicle parts, etc., can solve the problems of low rust resistance of the parking floor assembly, easy corrosion of metal parts, low production efficiency, etc., so as to shorten the production time. Low cycle, material and processing costs, weight savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

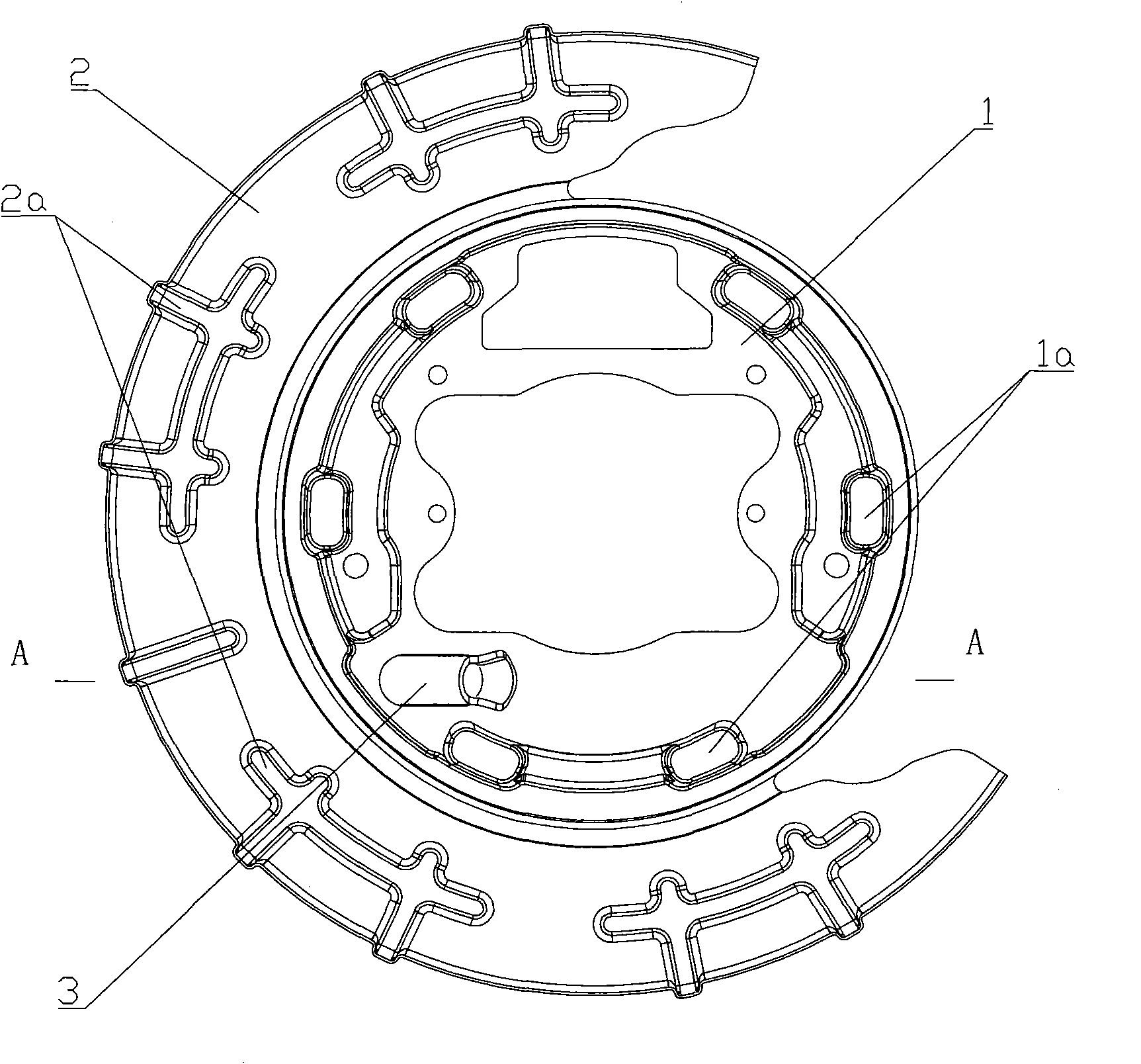

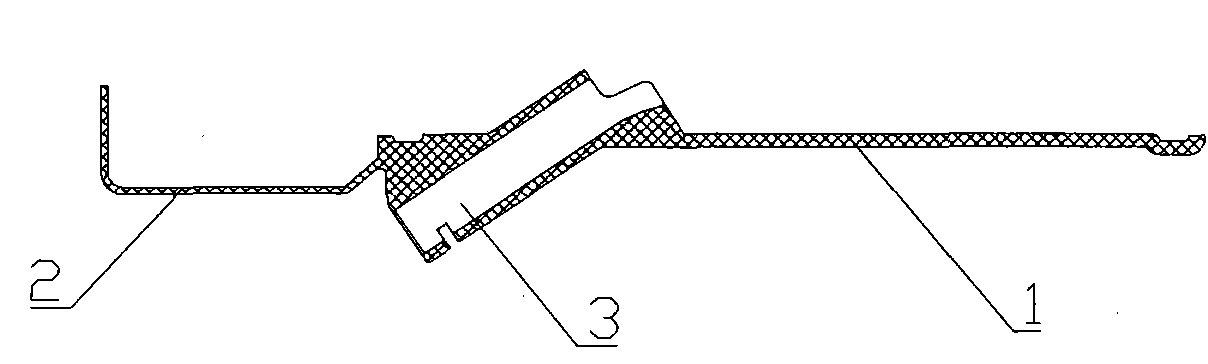

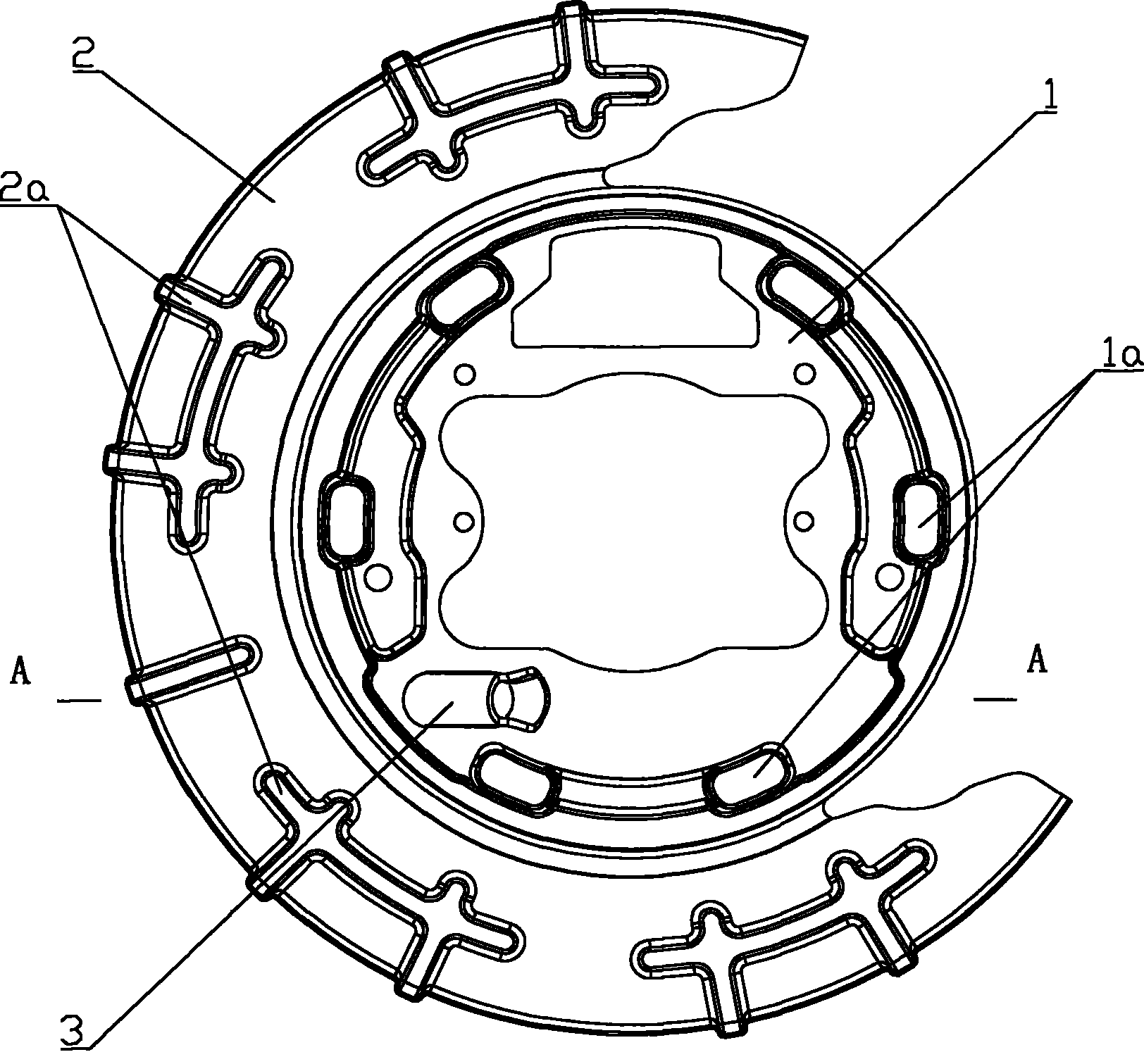

[0014] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A-A sectional view of A-A, as shown in the figure: the parking floor assembly of the drum type parking brake in the present embodiment includes a floor plate body 1, a dust cover 2 and a stay rope guide 3 arranged on the floor plate body 1 , the base plate body 1, the dust cover 2 and the drawstring conduit 3 are made of engineering plastics, because engineering plastics are resistant to high temperature, corrosion-resistant, weather-resistant, and have flame retardancy, compared with those used in the prior art Metal materials, material and processing costs are lower, and the weight of parts is reduced. While effectively meeting the functional and performance requirements of disc drum brakes, it also solves the problem that metal materials are easy to rust. Compared with metal materials, the process of manufacturing parts Processes such as stamping, welding and riveting are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com