Patents

Literature

149results about How to "Easy to rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

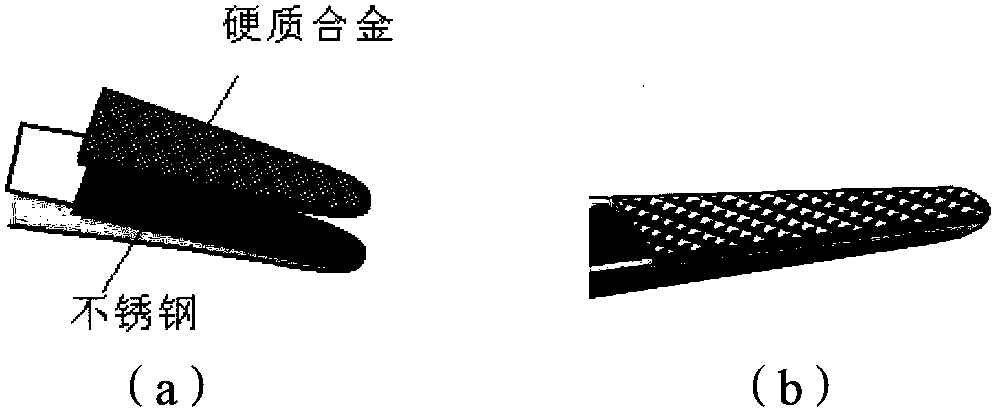

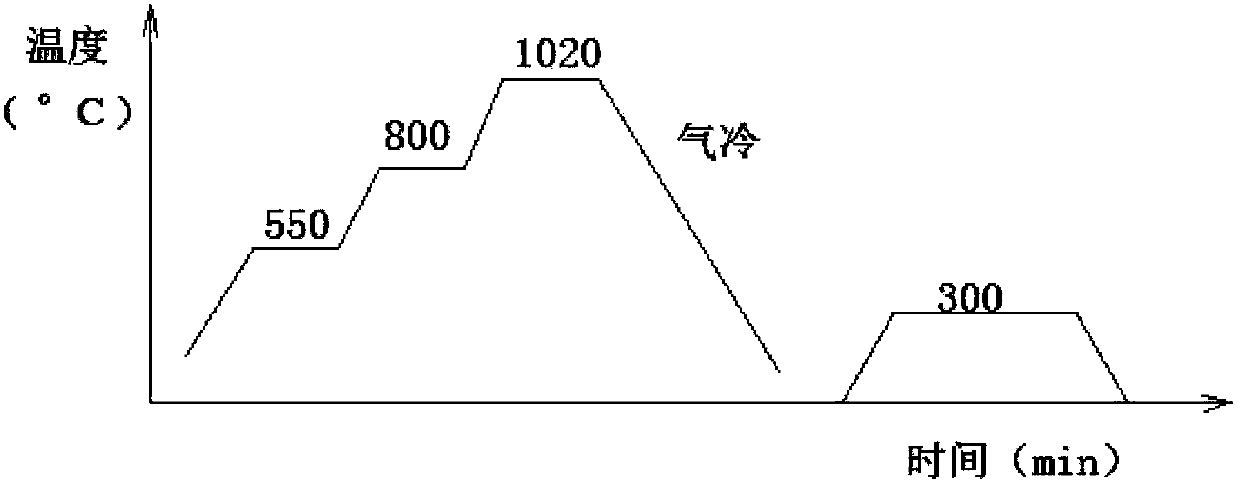

Vacuum brazing and thermal treatment composite process for stainless steel surgical instrument and application of process

InactiveCN103386525AImprove anti-corrosion performanceNot easy to rustSoldering apparatusCemented carbideProduction rate

The invention relates to a vacuum brazing and thermal treatment composite process for a stainless steel surgical instrument and the application of the process. An embedding method is adopted for embedding cemented carbide in the working end of the stainless steel surgical instrument, vacuum brazing and vacuum thermal treatment are adopted for synchronous treatment, the two processes are combined into one process, and on the basis of controlling the vacuum degree, the heating speed, the heating temperature, the brazing temperature, the brazing opportunity and the cooling method, the stainless steel surgical instrument with the working end embedded with the brazed cemented carbide is obtained. The stainless steel surgical instrument has excellent abrasive resistance, anti-slip performance, anti-corrosive performance and the like, the product quality is high, the energy consumption is low, the production rate is high and the operation environment is improved, and quality defects of the original process are overcome. The composite process has great significance in the process of treating stainless steel surgical instruments.

Owner:上海医疗器械(集团)有限公司

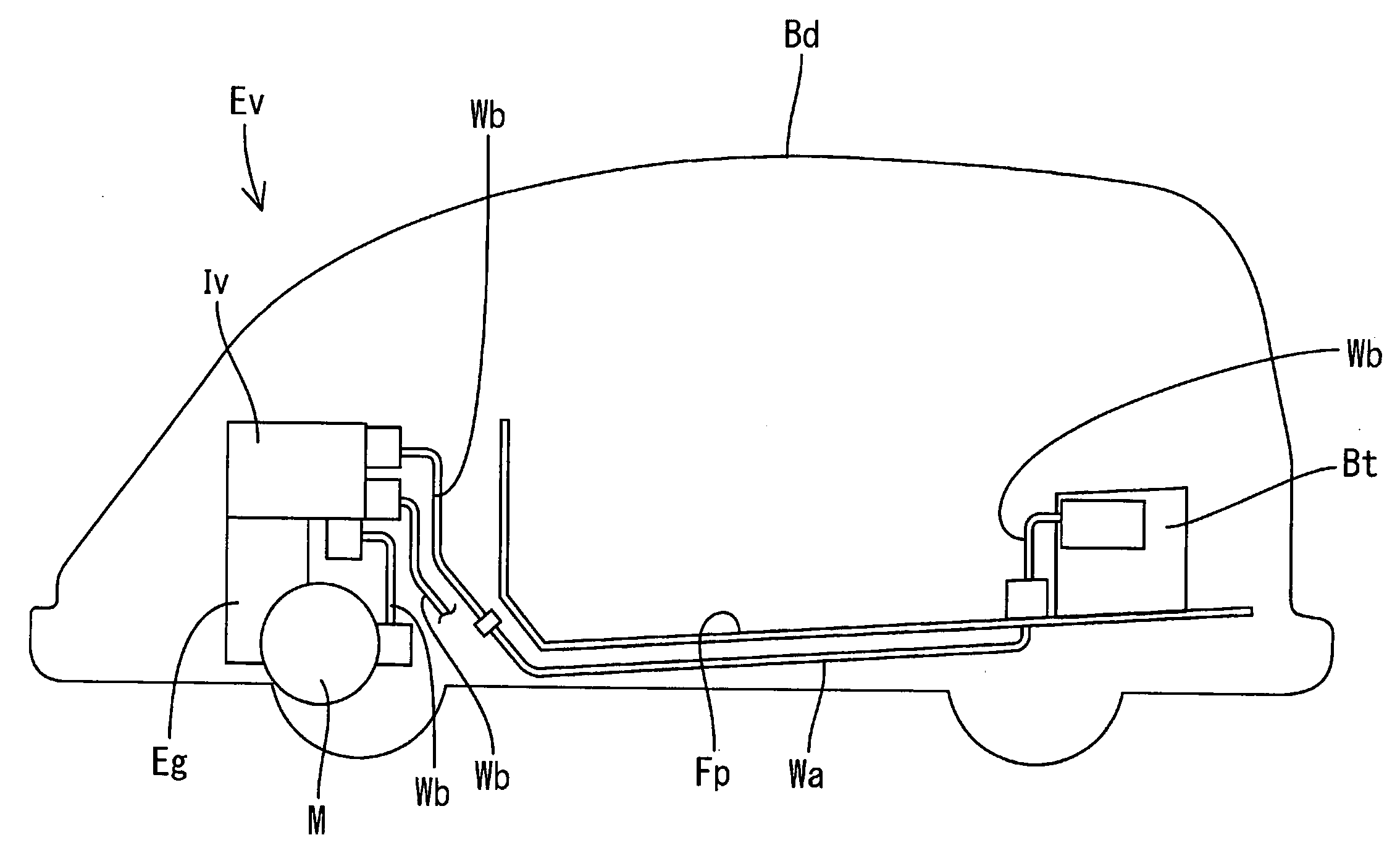

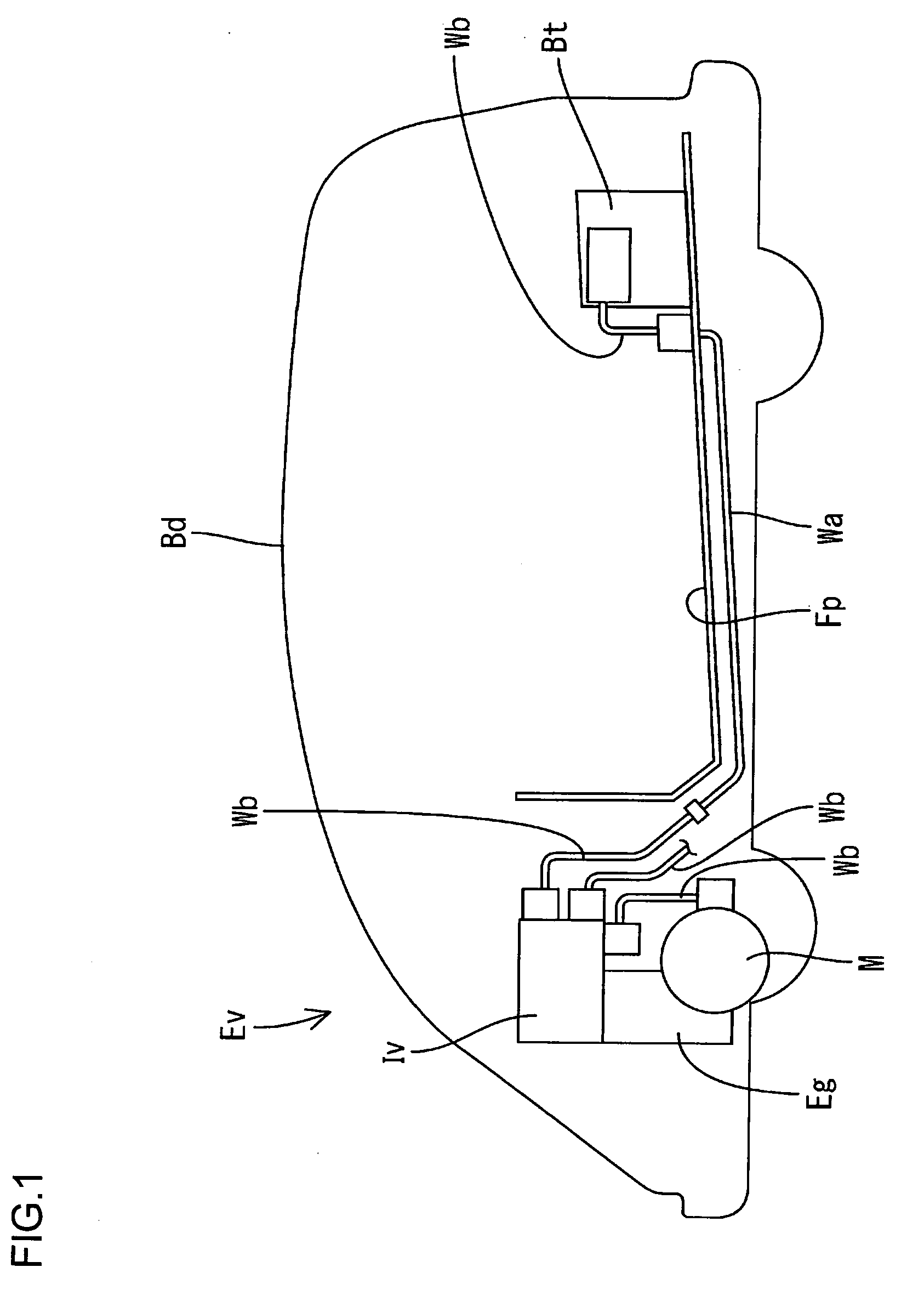

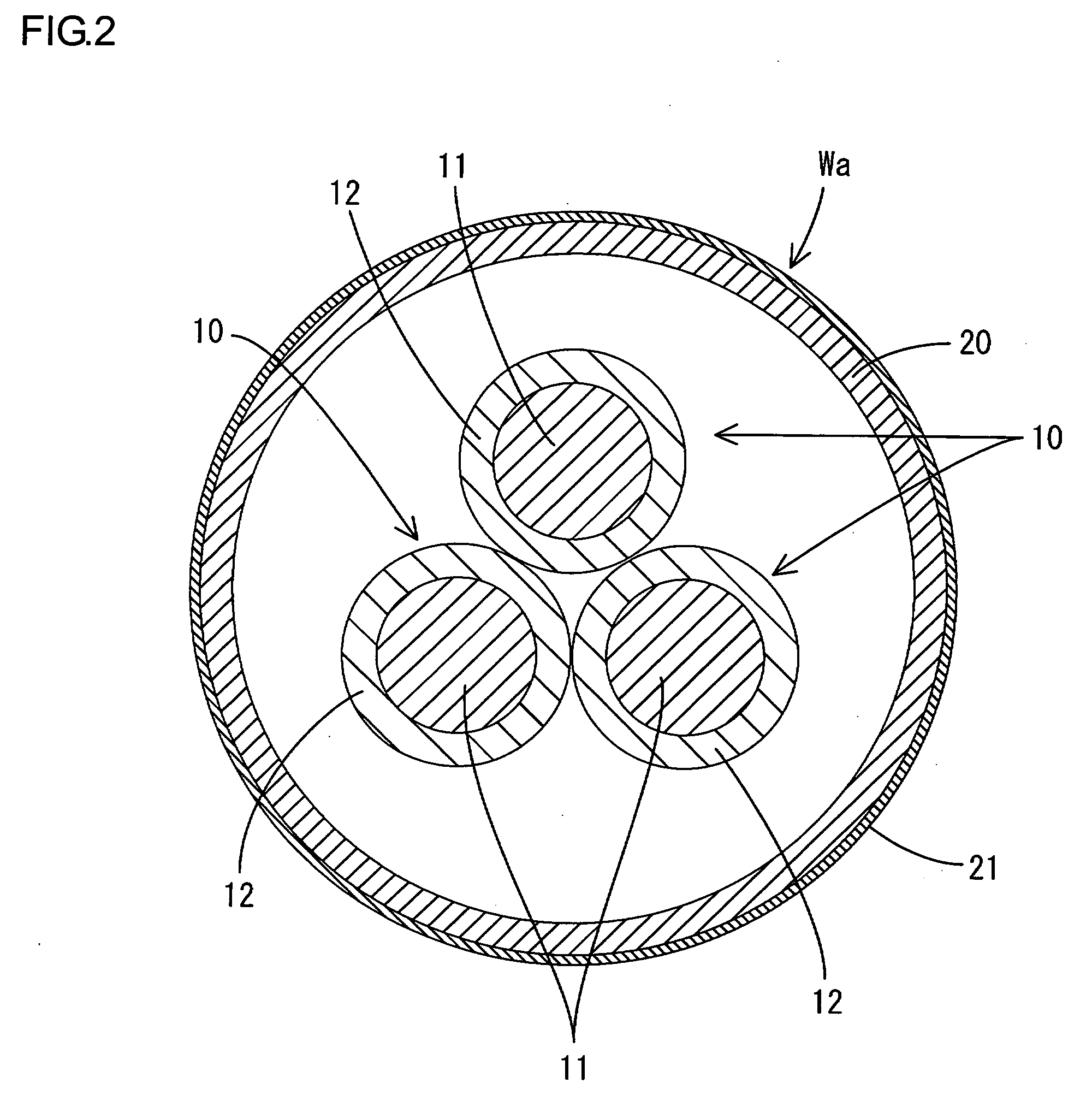

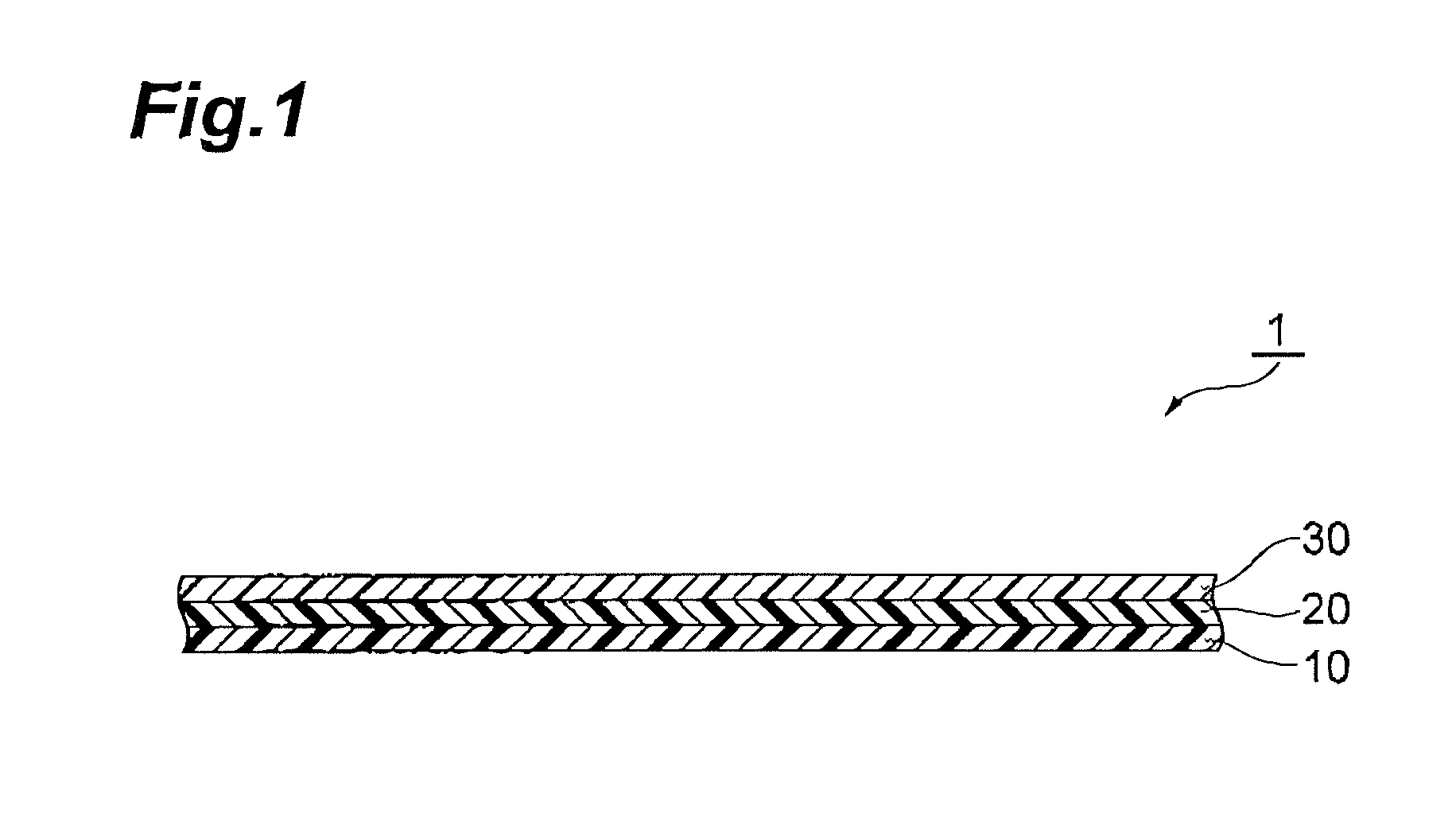

Shielded Conductor for Vehicle

InactiveUS20090107694A1Improve shielding effectEasy to rustRigid-tube cablesPower cables with screens/conductive layersElectrical conductorMetal

Owner:AUTONETWORKS TECH LTD +2

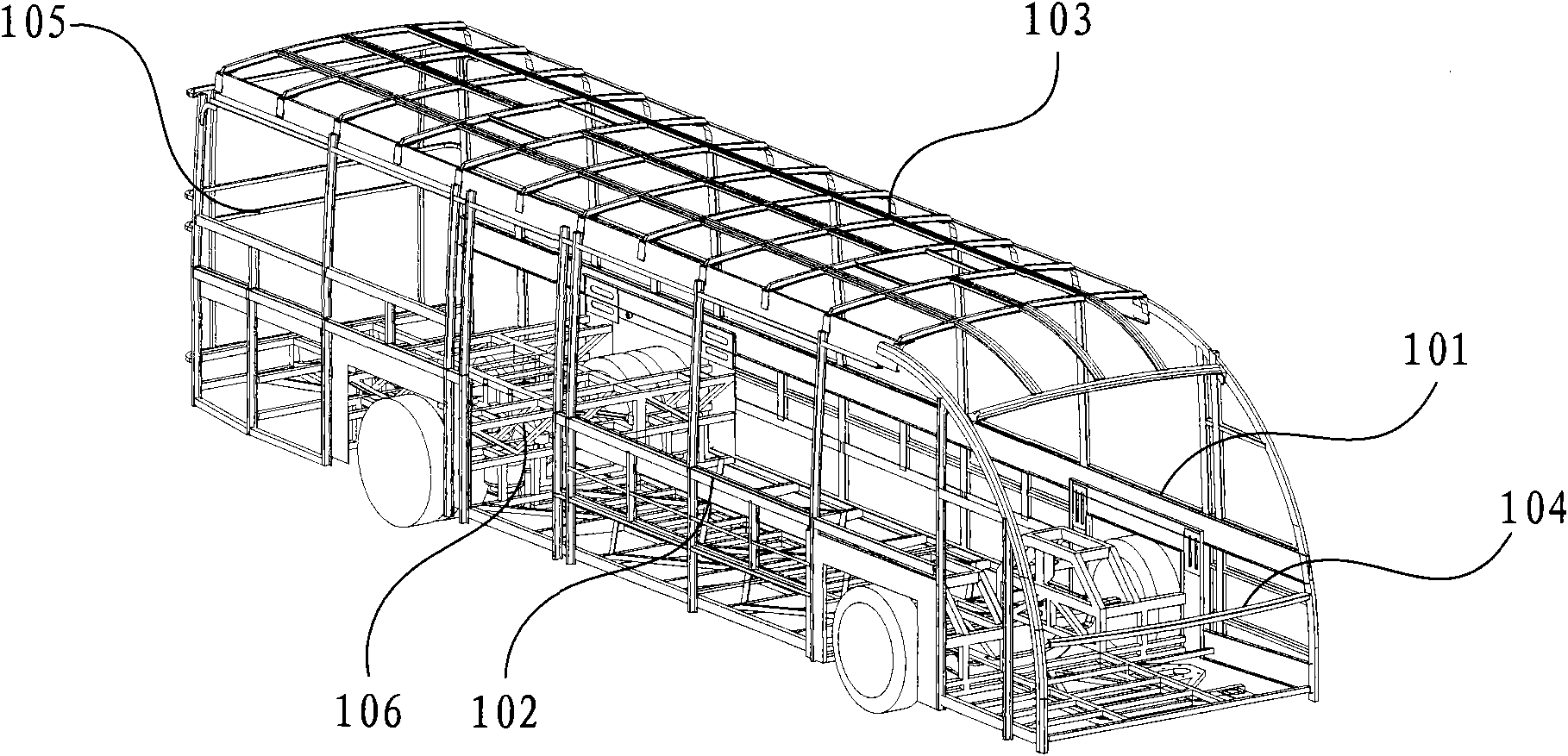

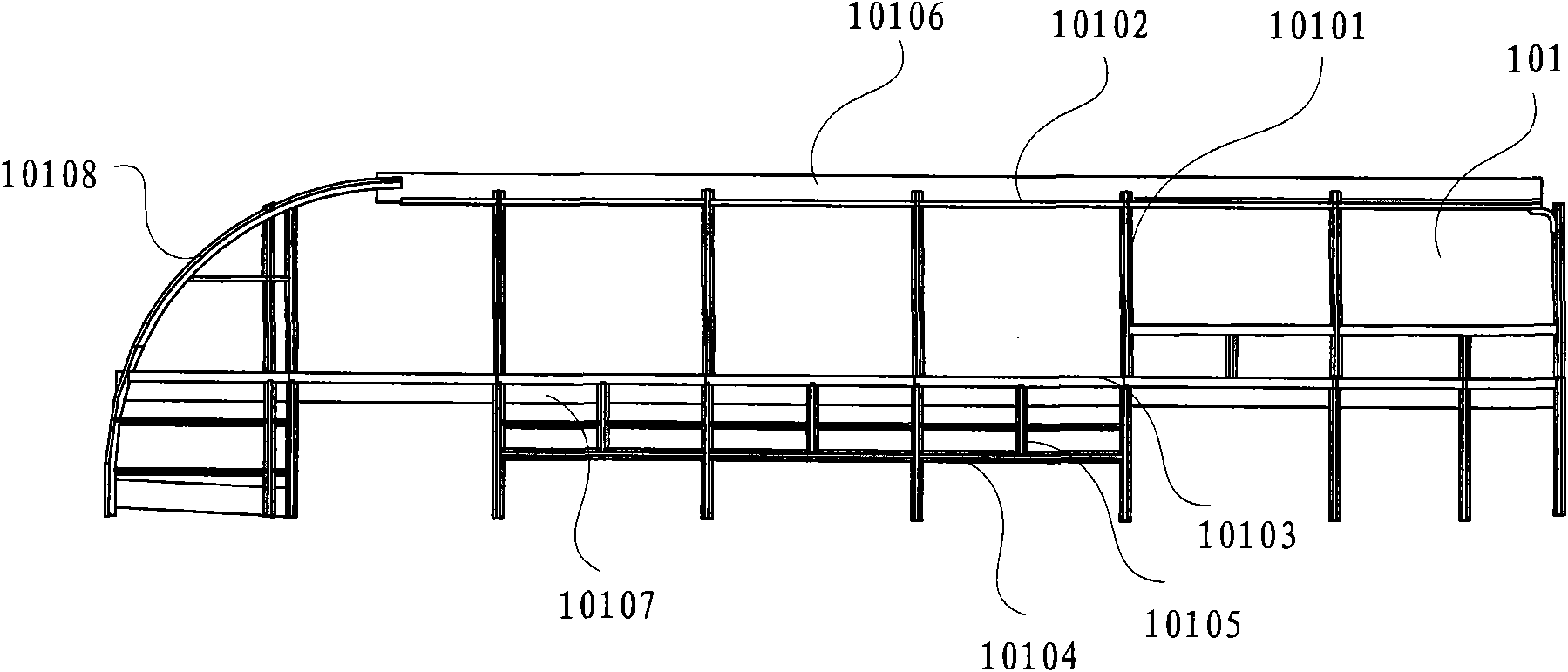

Lightweight total-bearing body frame structure

ActiveCN101863290AReduce weightExtended service lifeSuperstructure connectionsPassenger vehicle superstructuresSteel frameUltimate tensile strength

The invention relates to a lightweight total-bearing body frame structure, which comprises a side wall frame, a roof frame, a front wall frame, a rear wall frame and an interlayer frame. The lightweight total-bearing body frame structure is made of an aluminum alloy or magnesium alloy material, and is riveted with lockbolts so as to ensure that the weight of the body frame is greatly reduced while the whole strength of the body is not lower than the conventional steel body frame. The parts forming the body frame has a unique design, so that well balance between weight reduction and strength maintenance can be achieved. The lightweight total-bearing body frame structure saves more energy than the conventional steel frame.

Owner:北京绿程锦绣能源科技有限公司

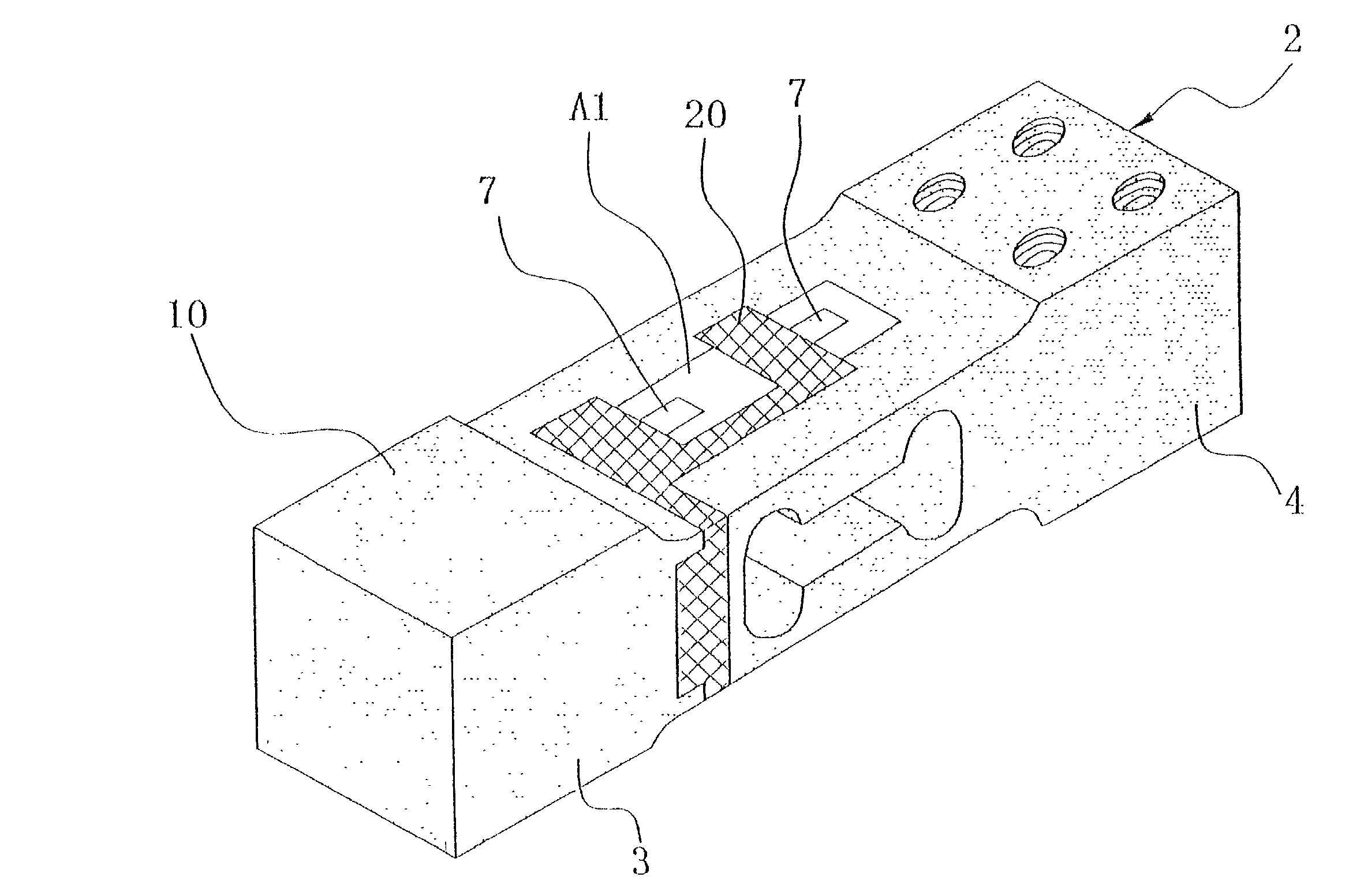

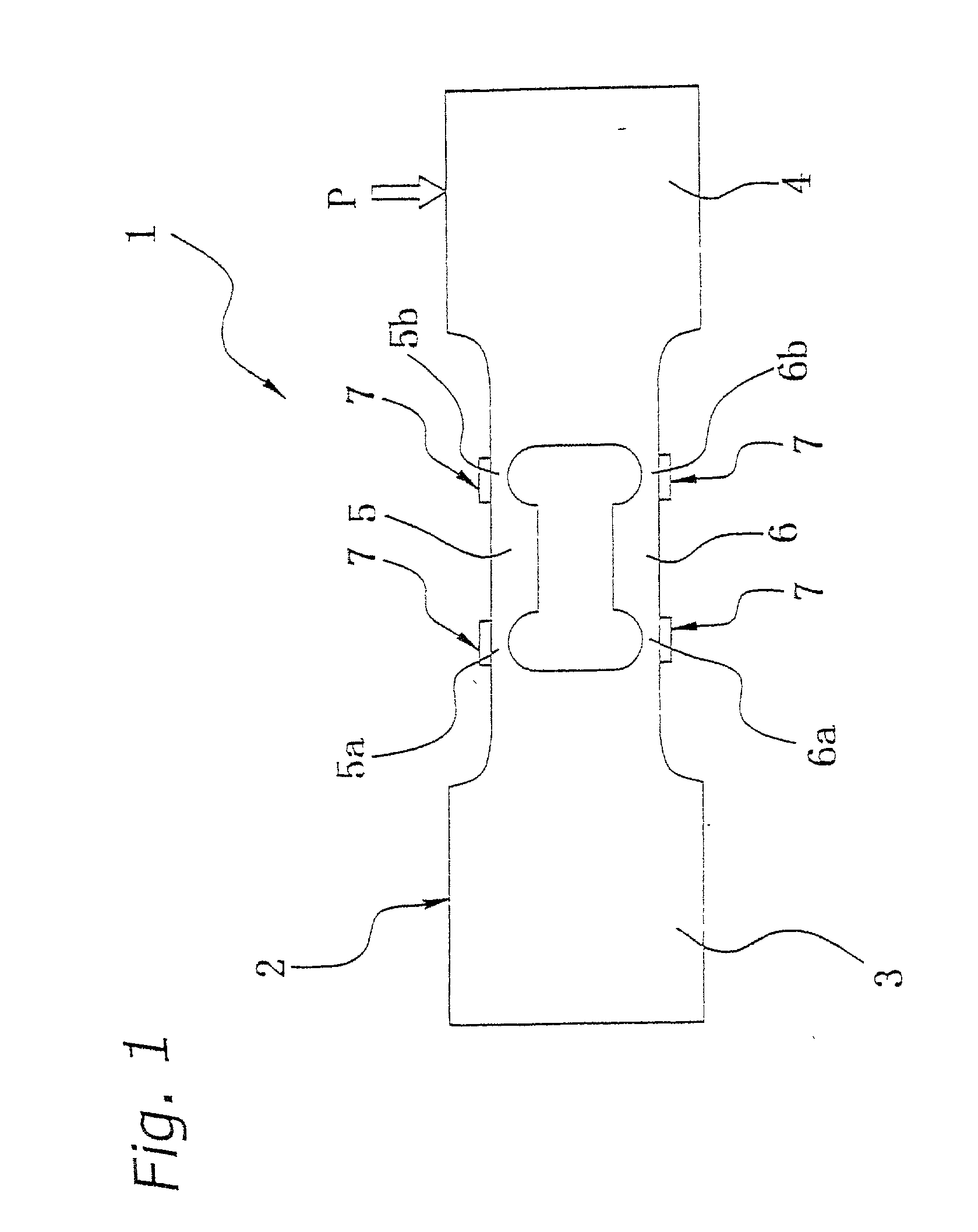

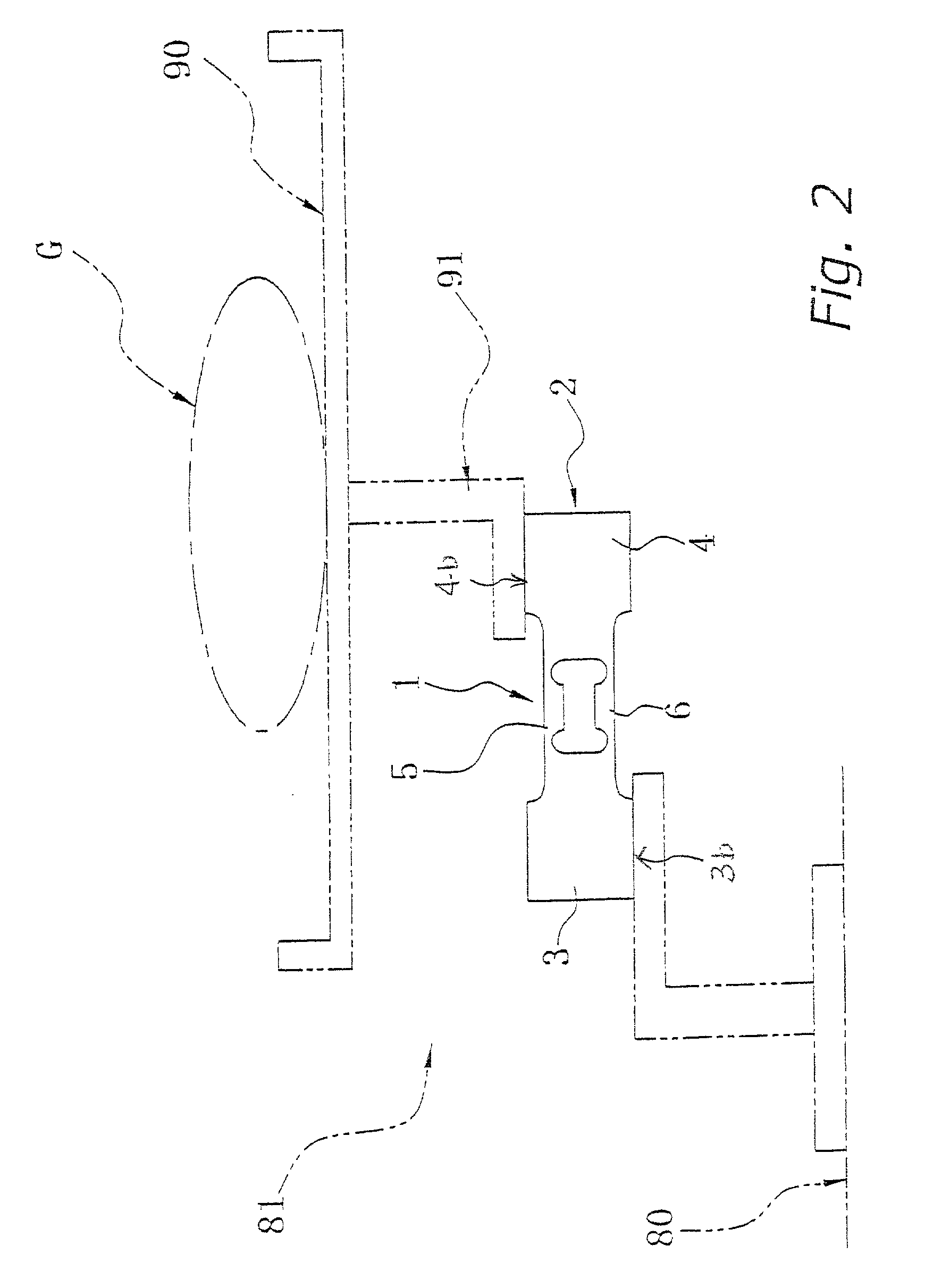

Load cell

InactiveUS20020139203A1Improved resistance to waterEasy to rustWeighing apparatus using elastically-deformable membersApparatus for force/torque/work measurementVitrificationMetallic materials

A load cell 1 includes a strain body 2, a bridge circuit and a coating film 10. The bridge circuit is formed of a strain gauge 7 arranged on the strain body 2. The coating film 10 is formed on the strain body 2, covers at least a portion of the strain body 2 attached to a member made of a metal material dissimilar to the strain body and a strain occurring portion of the strain body 2 except for a portion to be attached to the strain gauge 7, includes a coating layer made of resin having a glass transition temperature of 40° C. or more, and has an electrical insulating property.

Owner:ISHIDA CO LTD

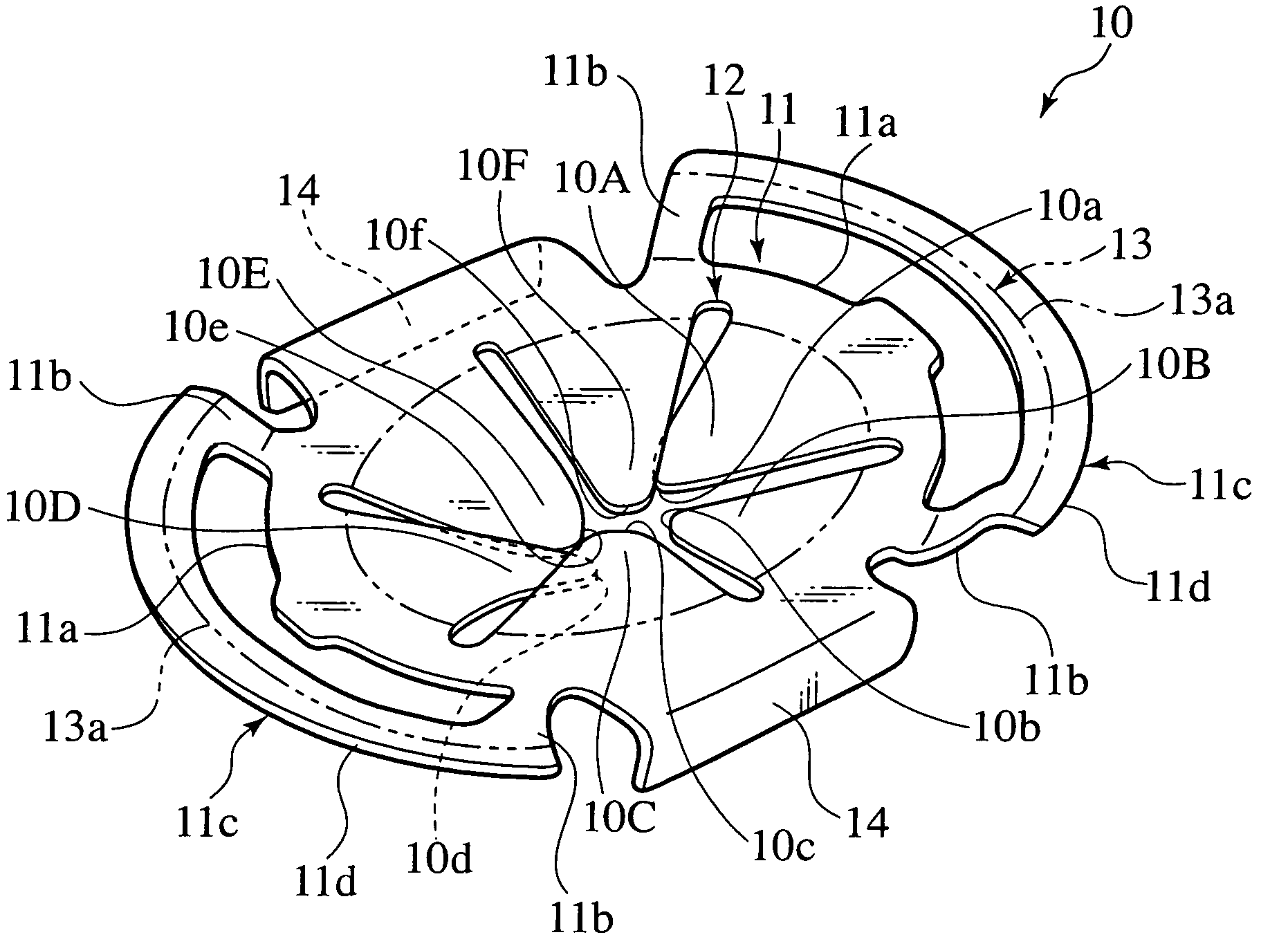

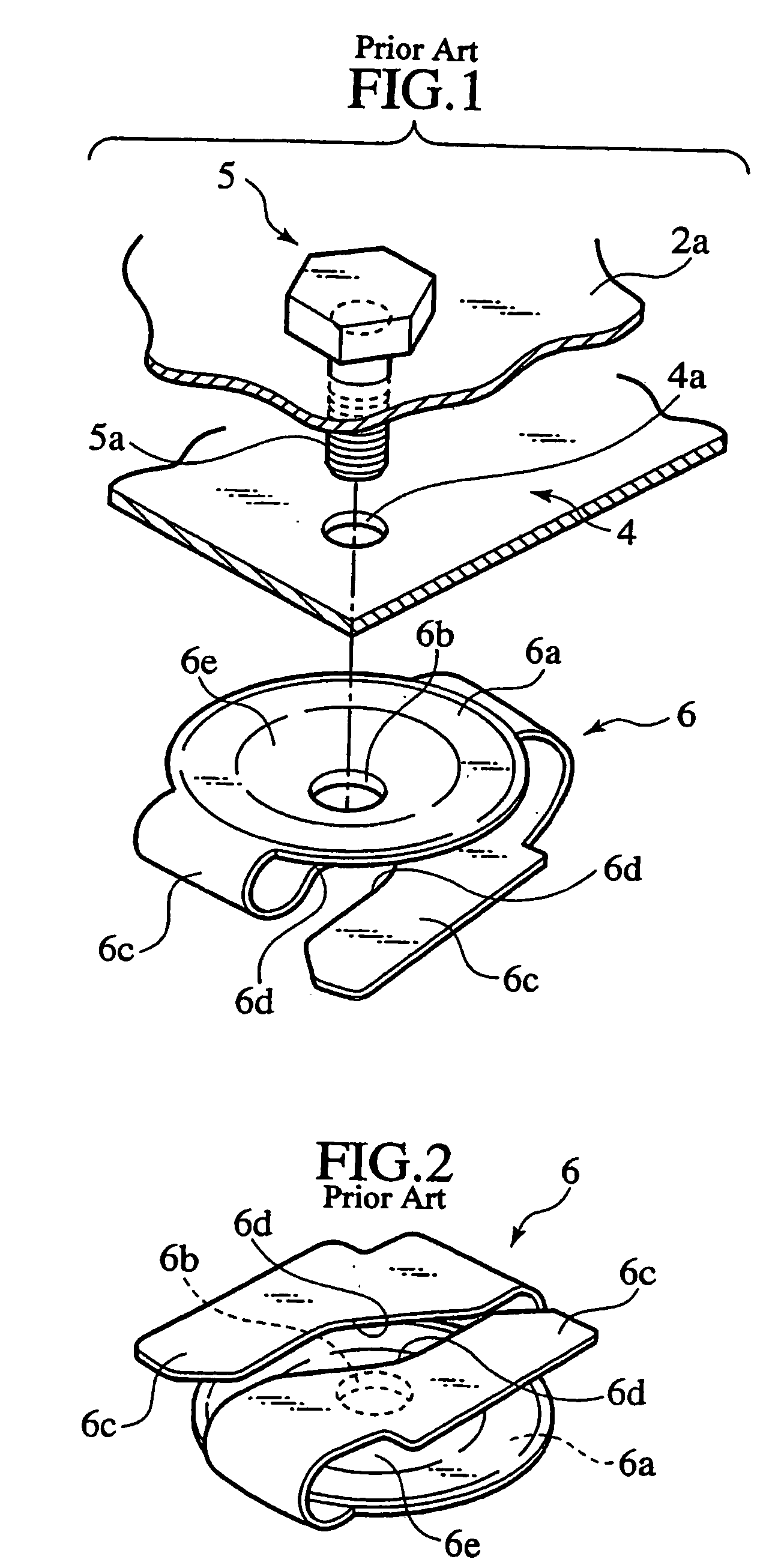

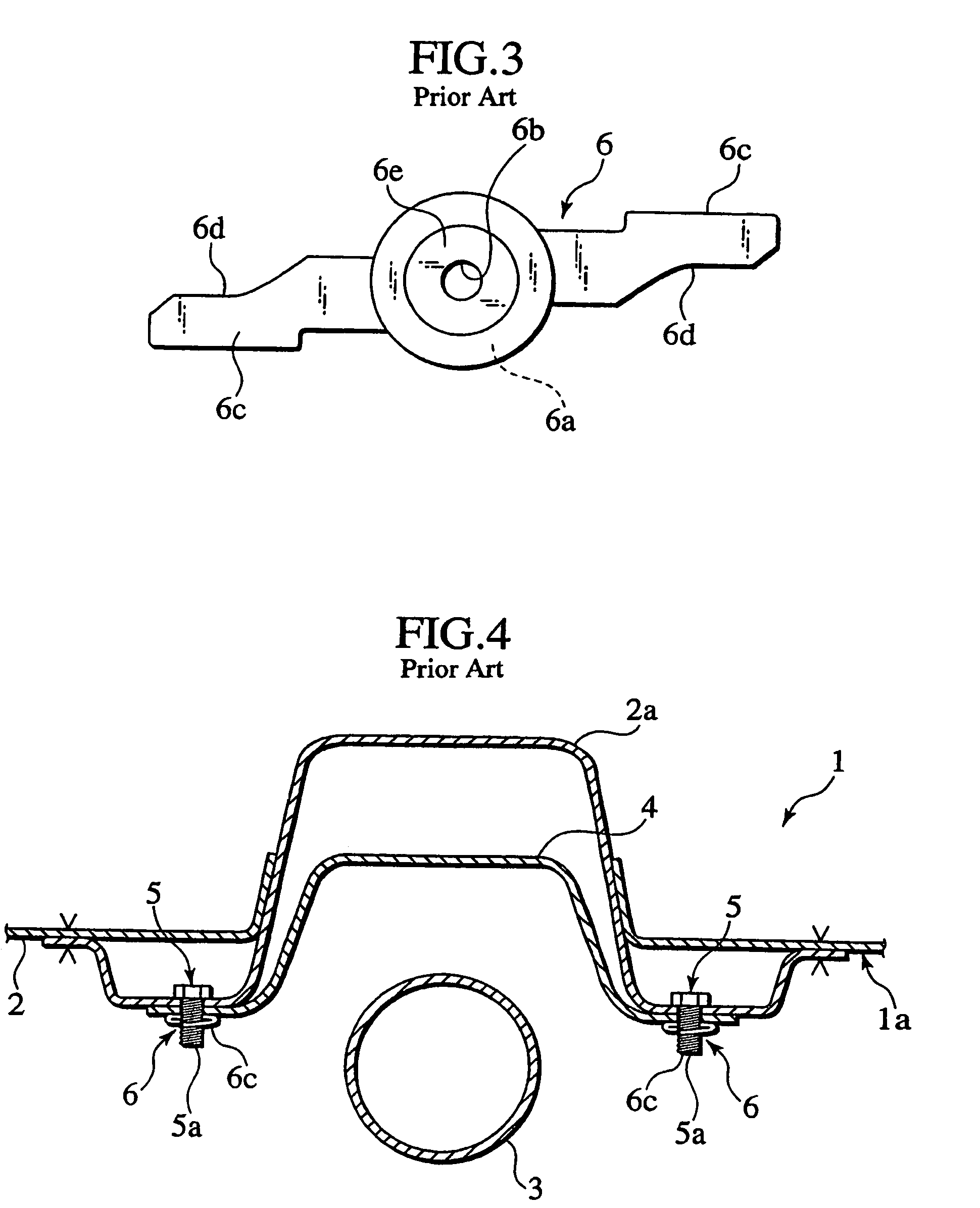

Attachment clip and attachment structure using same

An attachment clip 10 is provided to attach a heat shielding plate 4 to an under-panel 2. The under-panel 2 has a bolt 5 projecting from a floor tunnel 2a. The heat shielding plate 4 has a bolt hole 4a formed to allow passage of a shank 5a of the bolt 5. The attachment clip 10 has a clip body 11 having an abutting part 13 for abutment on the heat shielding plate 4. The abutting part 13 has a shank hole 12 for passage of the shank 5a of the bolt 5. The attachment clip 10 further includes six engagement claws 10A–10F projecting from the inner periphery of the clip body 11 inwardly. The engagement claws 10A–10F have respective engagement tips 10a–10f formed to depart from the clip body 11 along the axial direction of the attachment chip 10, providing a substantial cone-shaped configuration. The engagement claws 10A–10F elastically engage with threads of the shank 5a while urging the heat shielding plate 4 toward the under-panel 2 along the axial direction of the bolt 5.

Owner:NISSAN MOTOR CO LTD

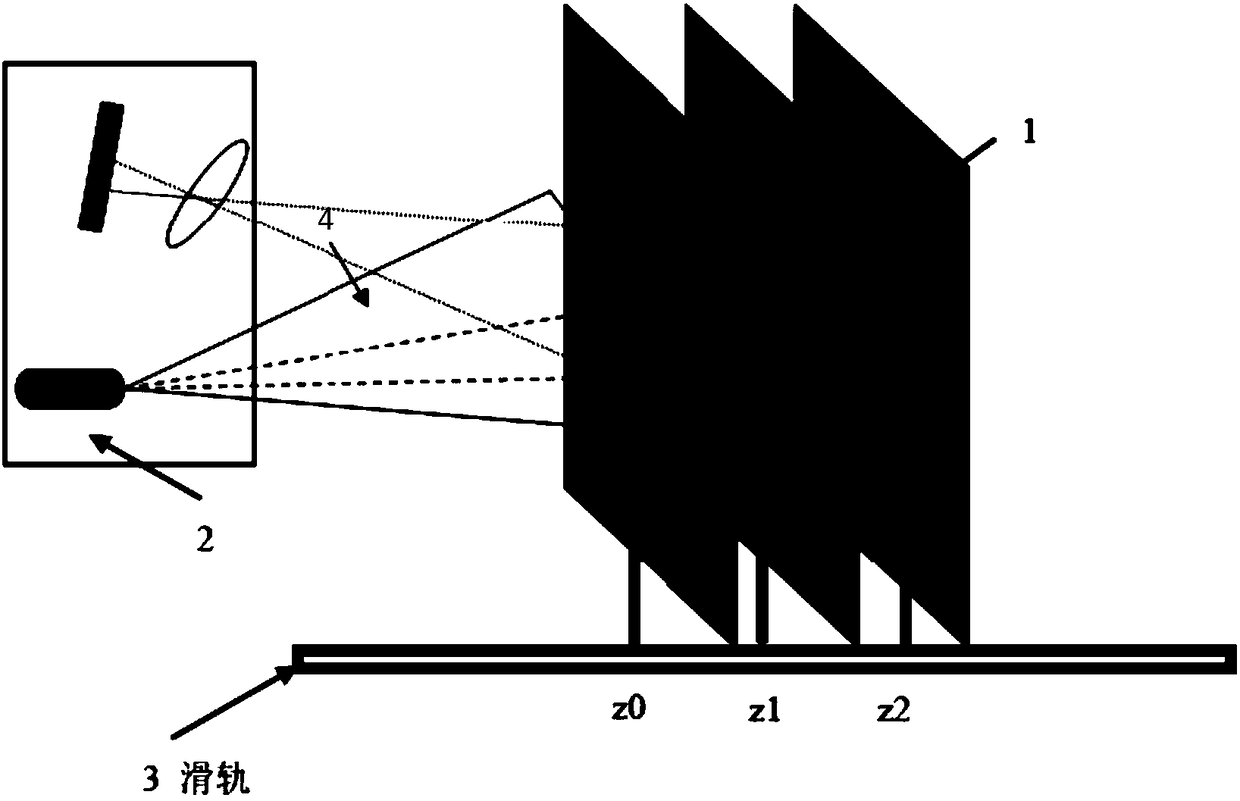

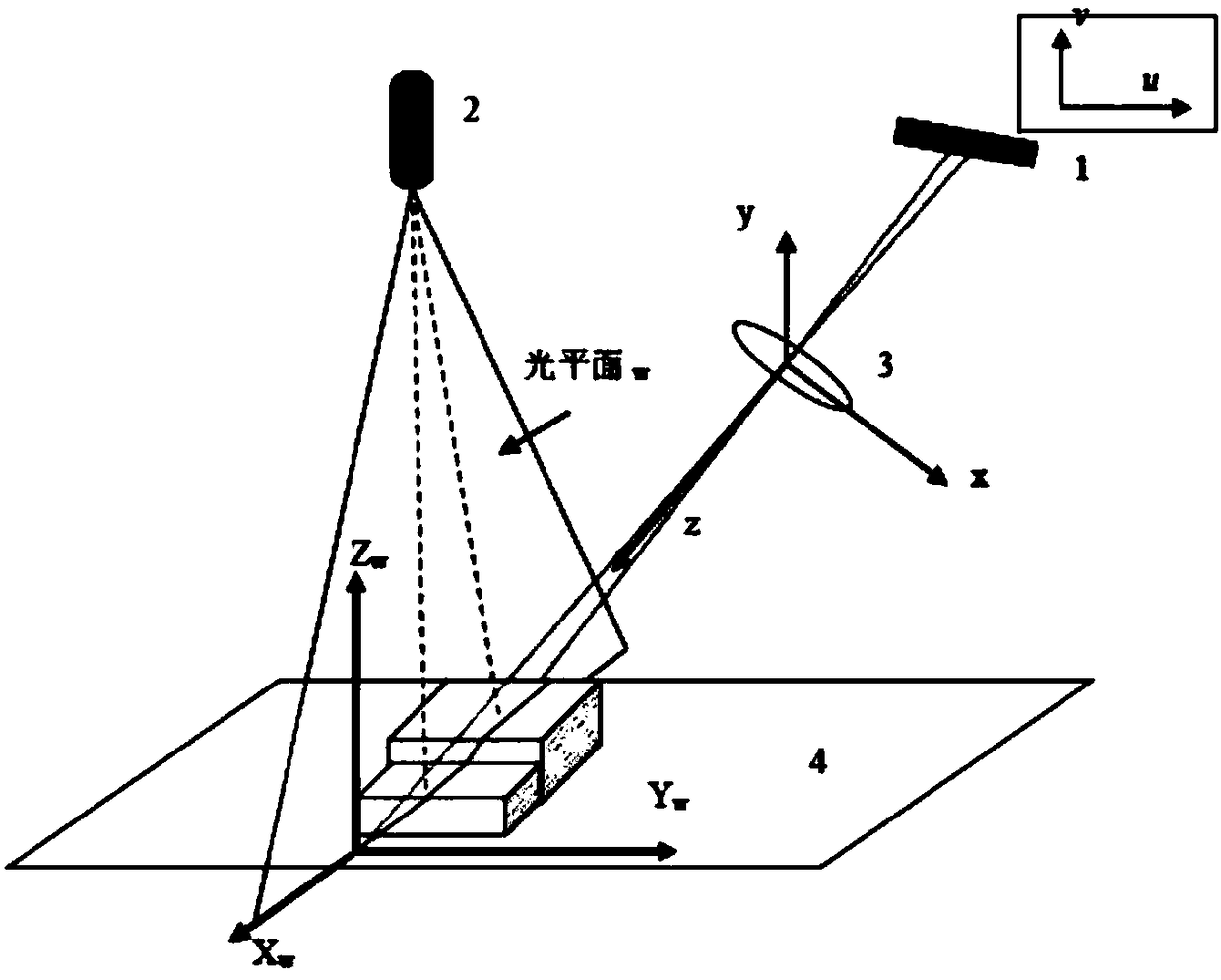

Machine vision technology-based laser structured light automatic calibration method

PendingCN108428251ASolve the complex processing technologySolve the problem of complex processing technology and difficult selection of rigid processing materialsImage enhancementImage analysisMachine visionIntersection of a polyhedron with a line

The invention discloses a machine vision technology-based laser structured light automatic calibration method. The method comprises steps: 1) a calibration board is firstly placed at a clear imaging position; 2) the calibration plate is adjusted to a horizontal position; 3) the distances between a laser line emitted by the laser and cross marks at two sides of the calibration plate are adjusted tobe the minimum; 4) the laser is closed, a backlight source is opened, camera gains and the exposure time are adjusted, a printer marker on the calibration plate is photographed, and an image 1 is acquired; 5) the laser is opened, the backlight source is closed, a laser spot image is photographed, and an image 2 is acquired; and 6) the image 1 and the image 2 are fused to calculate the intersection point between the rectangular edge line of the calibration plate and the laser line.

Owner:深圳市中捷视科科技有限公司

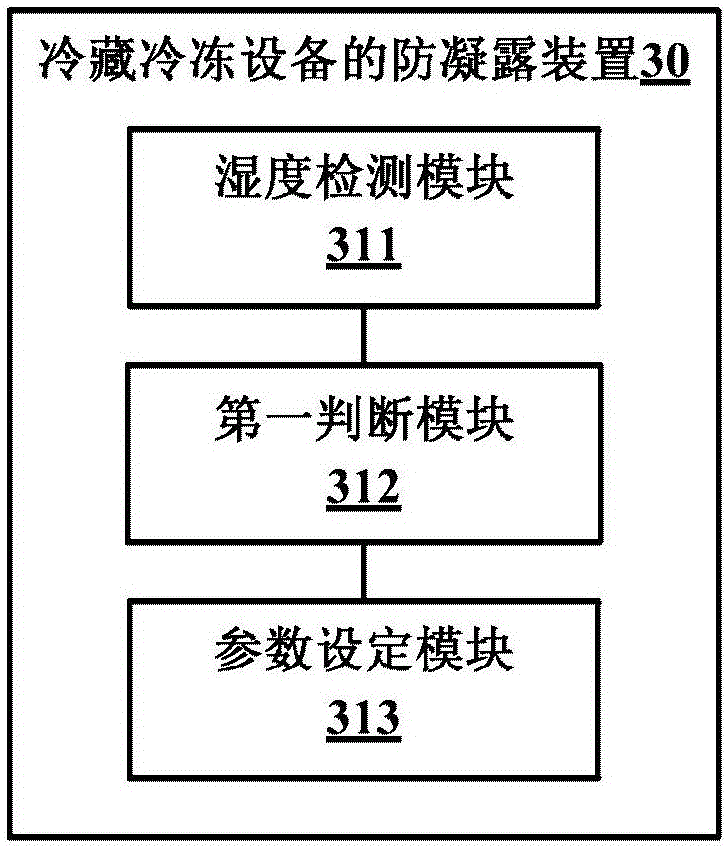

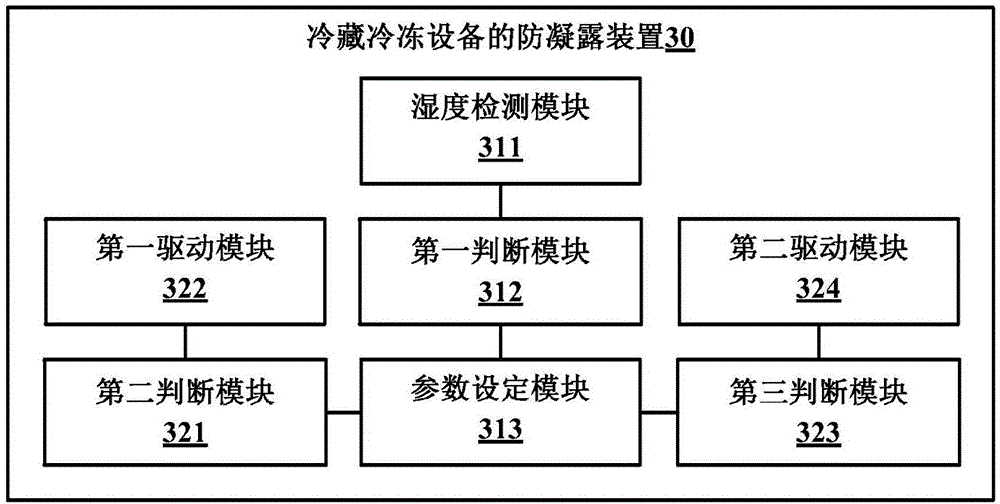

Condensation prevention method and device for refrigeration equipment

ActiveCN106766578AReduce condensation timeAccelerate rustLighting and heating apparatusCooling fluid circulationStop timeCorrosion

The invention provides a condensation prevention method and device for refrigeration equipment. The condensation prevention method comprises the steps: detecting the humidity of the external environment of the refrigeration equipment; judging whether the humidity is less than the preset humidity threshold value or not; if yes, setting the turn-on temperature of a storage room as first turn-on temperature, setting the turn-off temperature of the storage room as first turn-off temperature, and setting the speed of a compressor as first speed; if not, setting the turn-on temperature of the storage room as second turn-on temperature, setting the turn-off temperature of the storage room as second turn-off temperature, and setting the speed of the compressor as second speed. Thus, the refrigeration cycle of a refrigeration system is constant, the operating time of the compressor is prolonged, and the stop time of the compressor is shortened. The condensation prevention method can avoid long-time condensation, thereby overcoming the defects that the paint film of a box body is shed largely, the corrosion of the box body is accelerated, the service life of the refrigeration equipment is shortened, and the refrigeration effect of the refrigeration equipment is influenced.

Owner:HAIER SMART HOME CO LTD

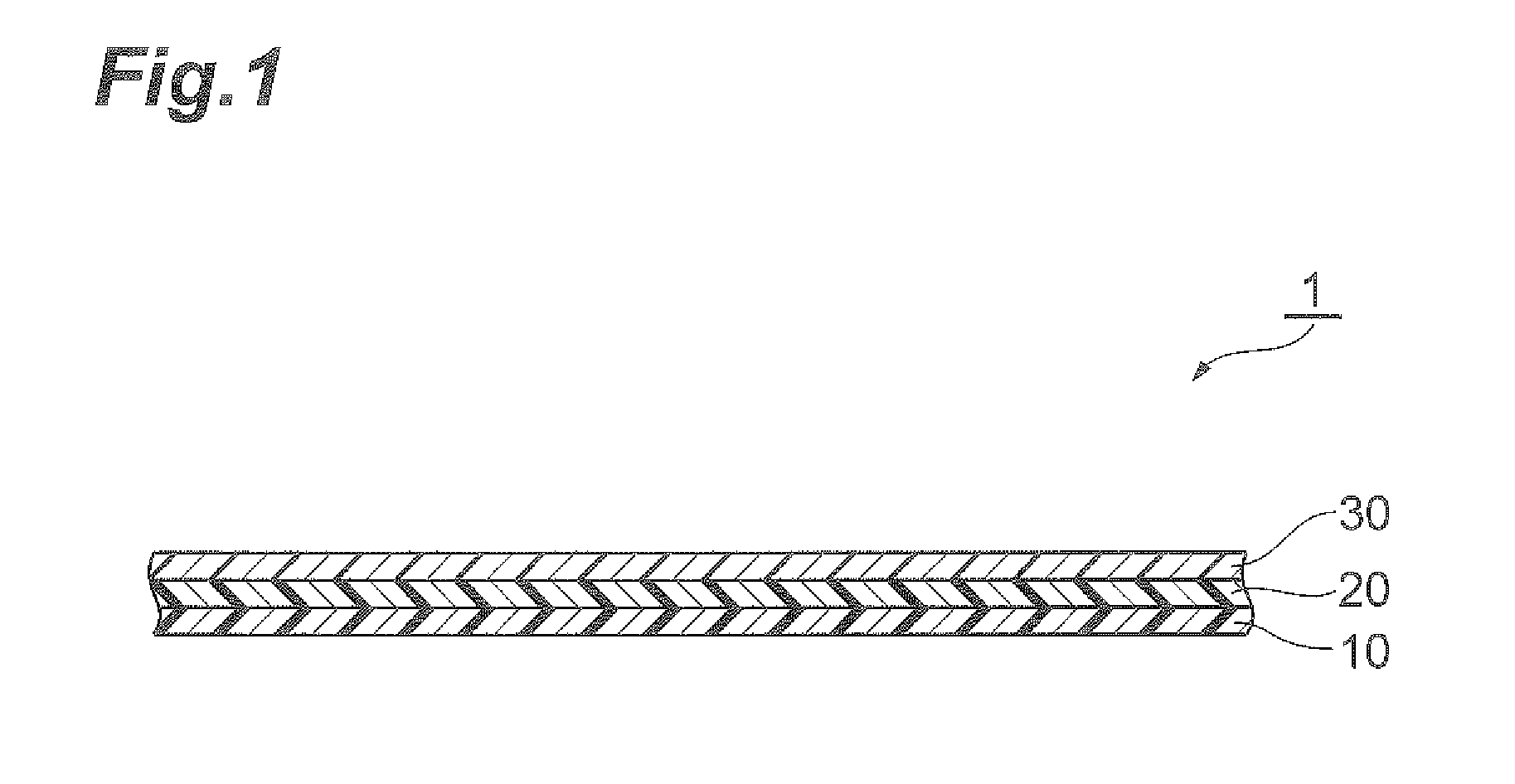

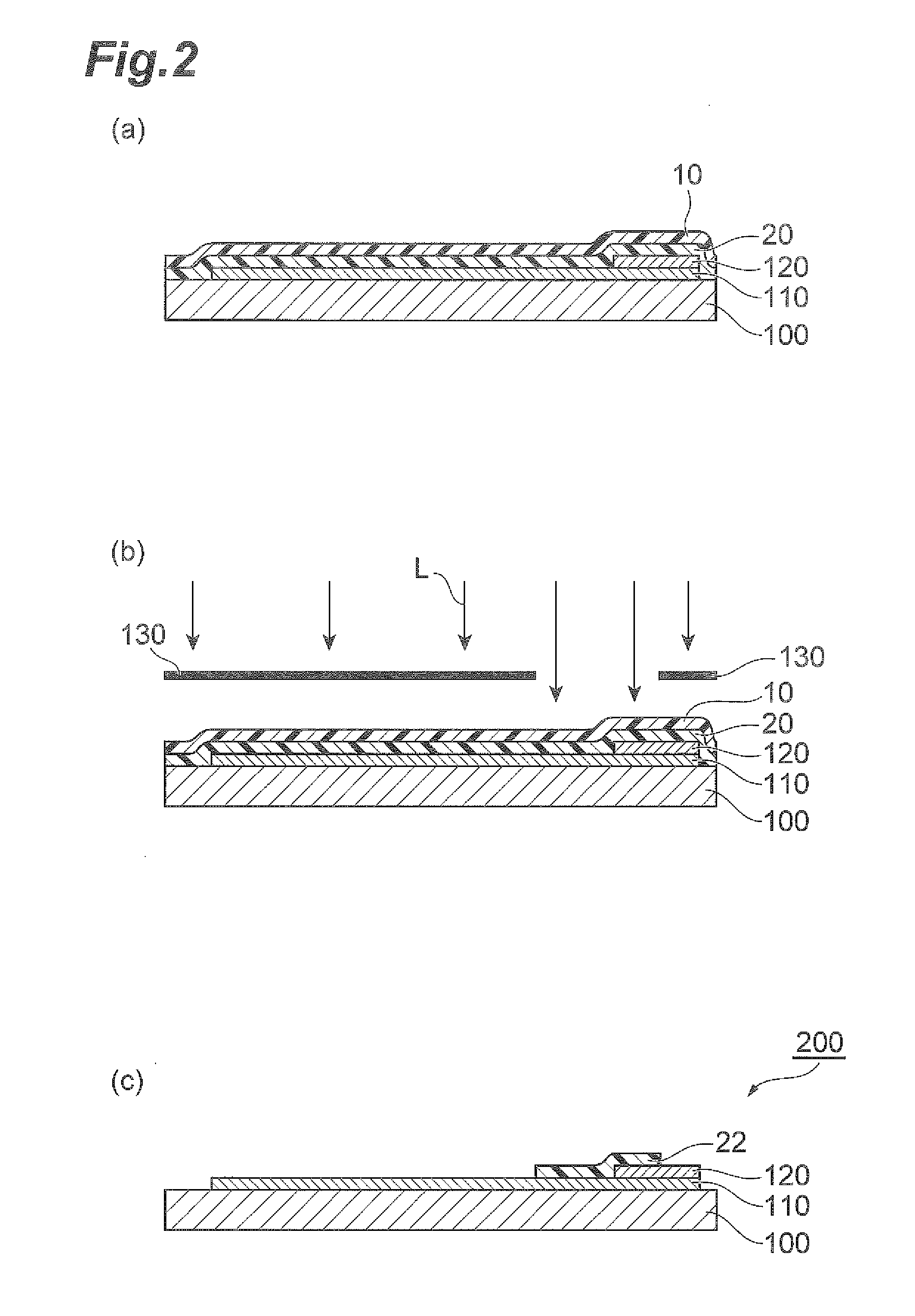

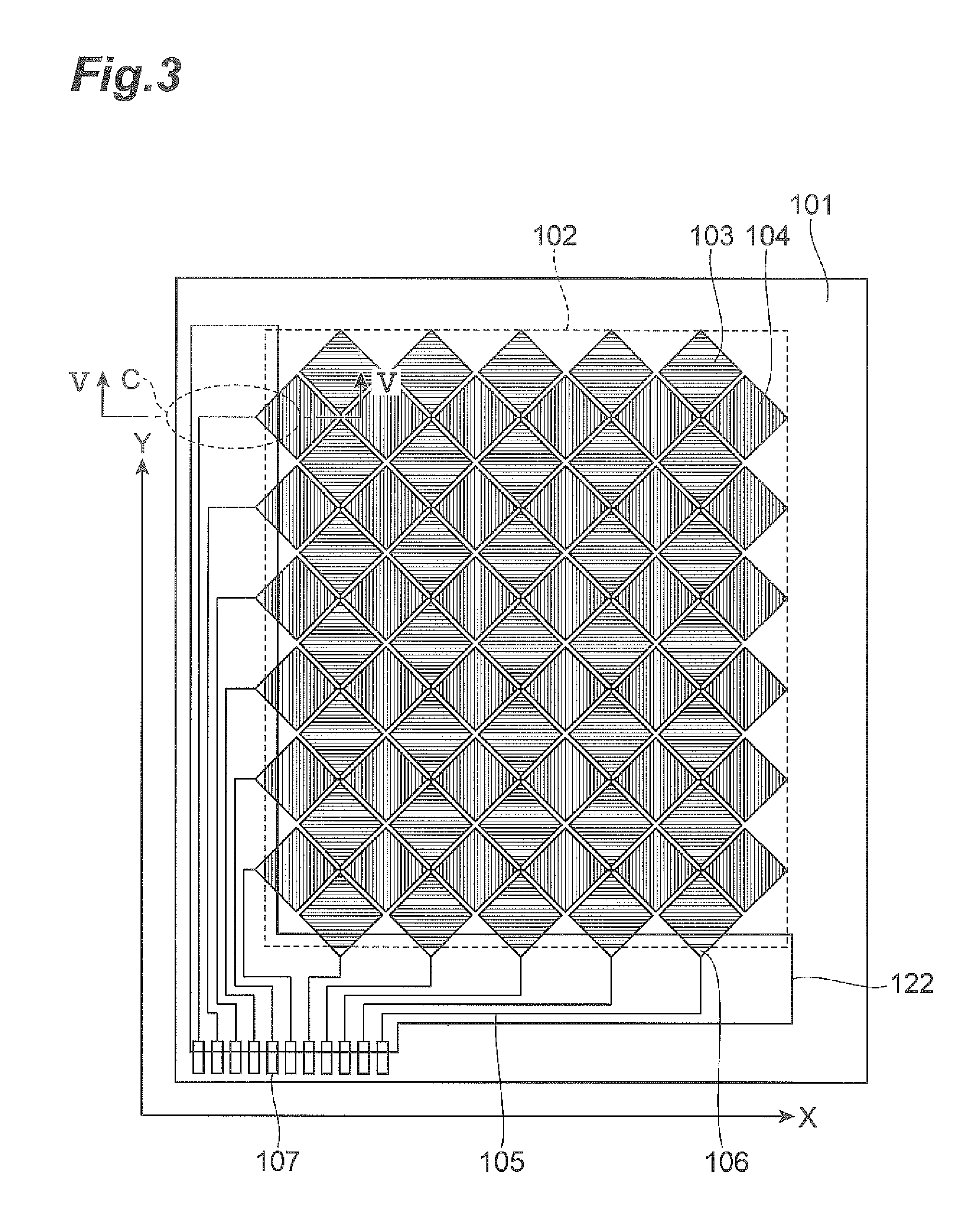

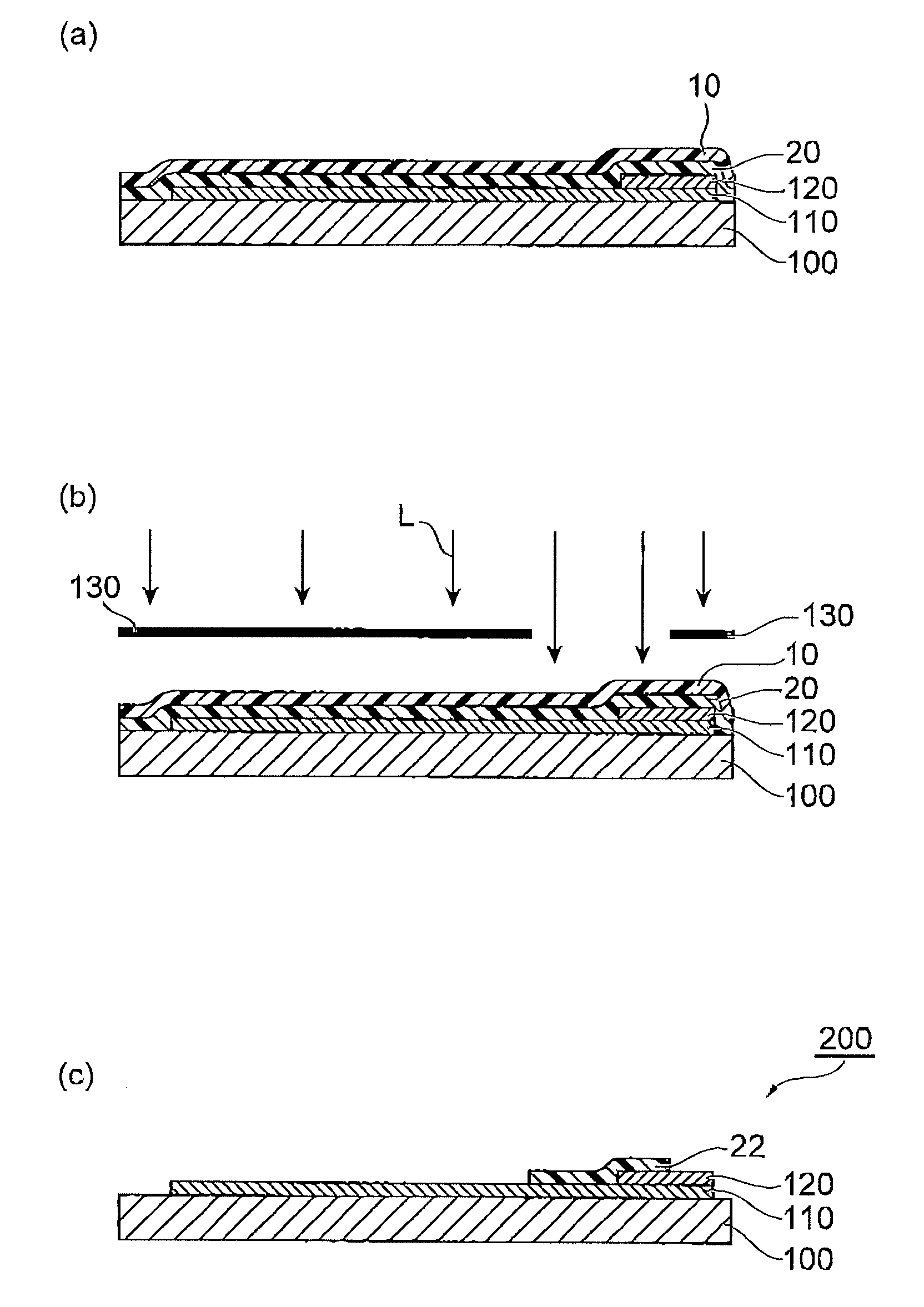

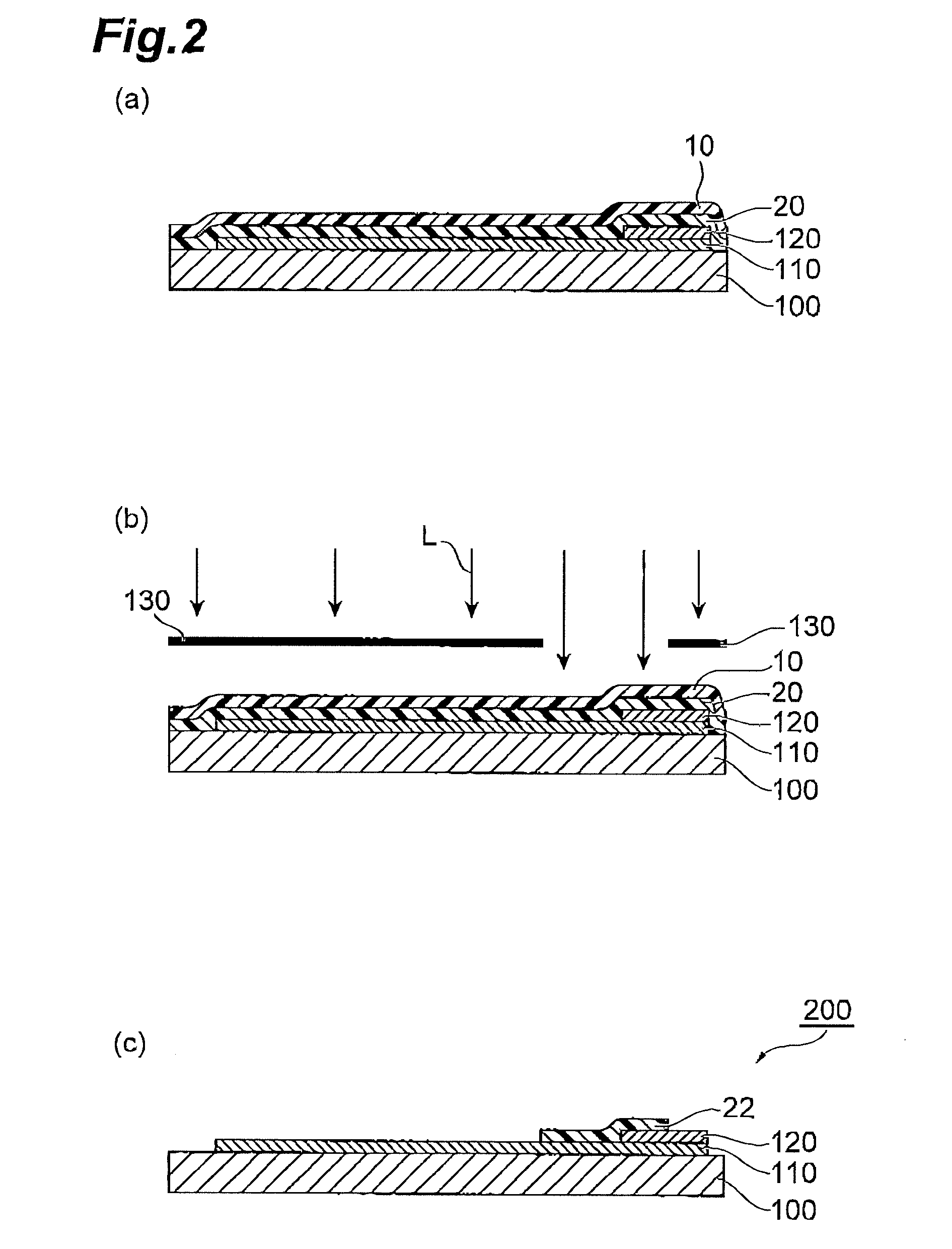

Method of manufacturing transparent substrate provided with cured film, photosensitive resin composition, photosensitive element, and electrical component

InactiveUS20160131974A1Desired film propertySufficient anti-corrosive propertyPhotosensitive materialsLayered productsMeth-Irradiation

The method of manufacturing a transparent base material provided with a cured film according to the present invention is characterized in that a photosensitive layer composed of a photosensitive resin composition containing a binder polymer, a photopolymerizable compound containing at least one (meth)acrylate compound selected from the group consisting of (meth)acrylate compounds having a skeleton derived from ditrimethylolpropane and (meth)acrylate compounds having a skeleton derived from diglycerol, and a photopolymerization initiator is disposed on a transparent base material, a predetermined portion of the photosensitive layer is cured through irradiation with active light rays, and portions of the photosensitive layer other than the predetermined portion are then removed to form a cured film composed of a cured product of the photosensitive resin composition, the cured film coating part or all of the base material.

Owner:HITACHI CHEM CO LTD

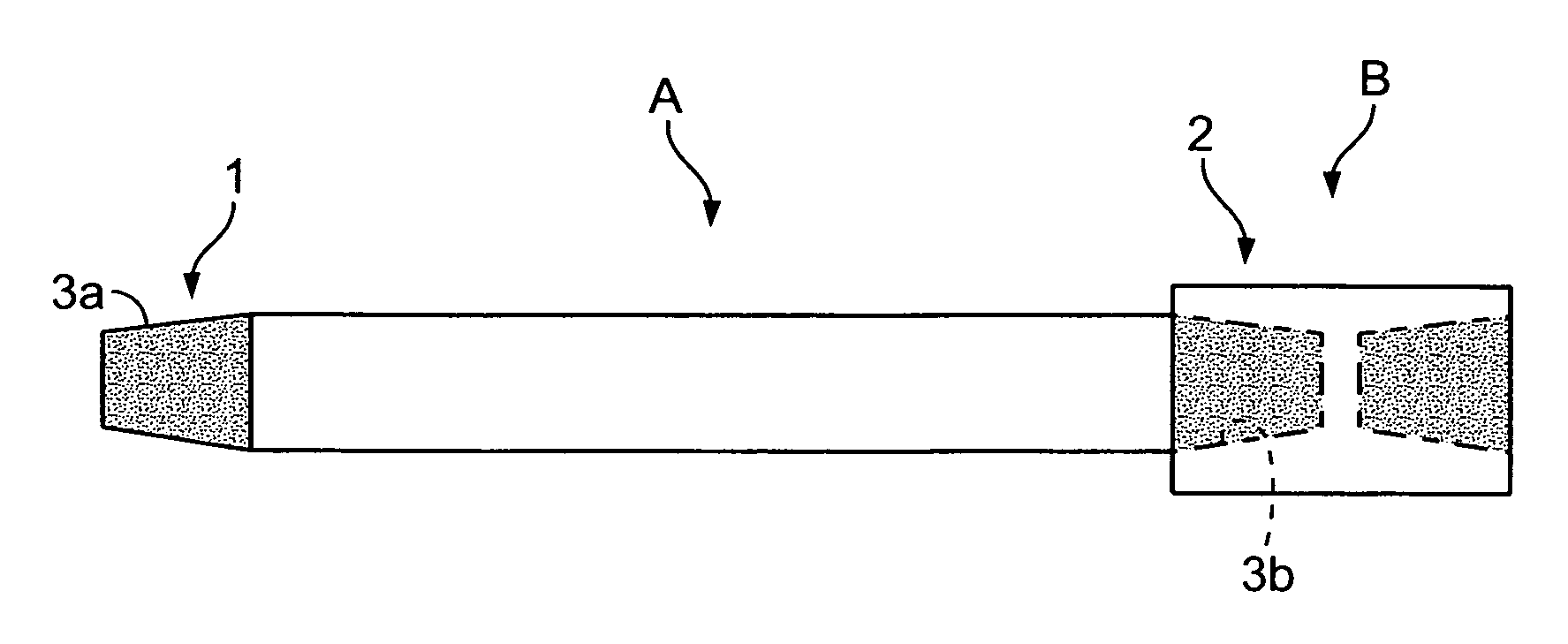

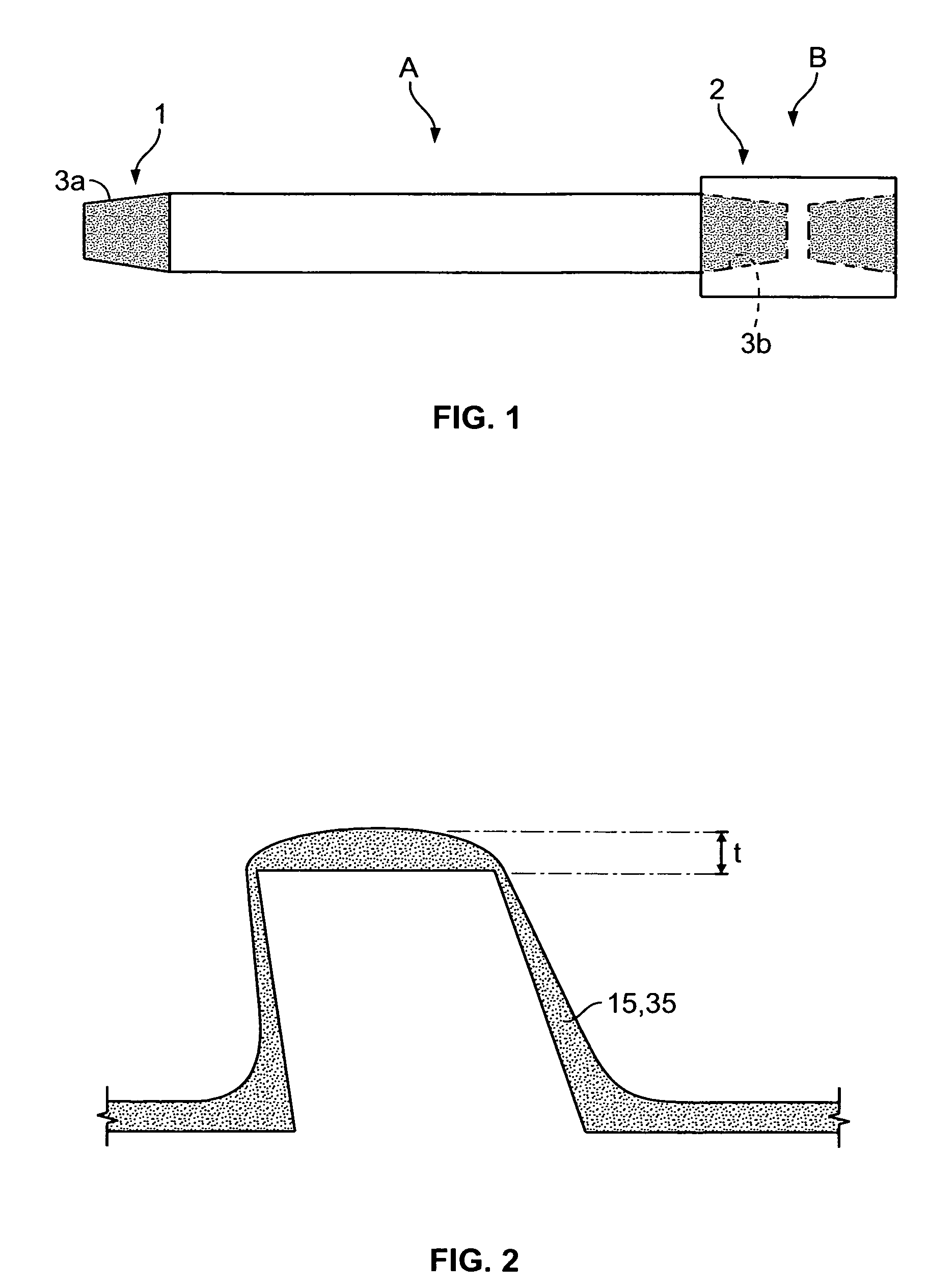

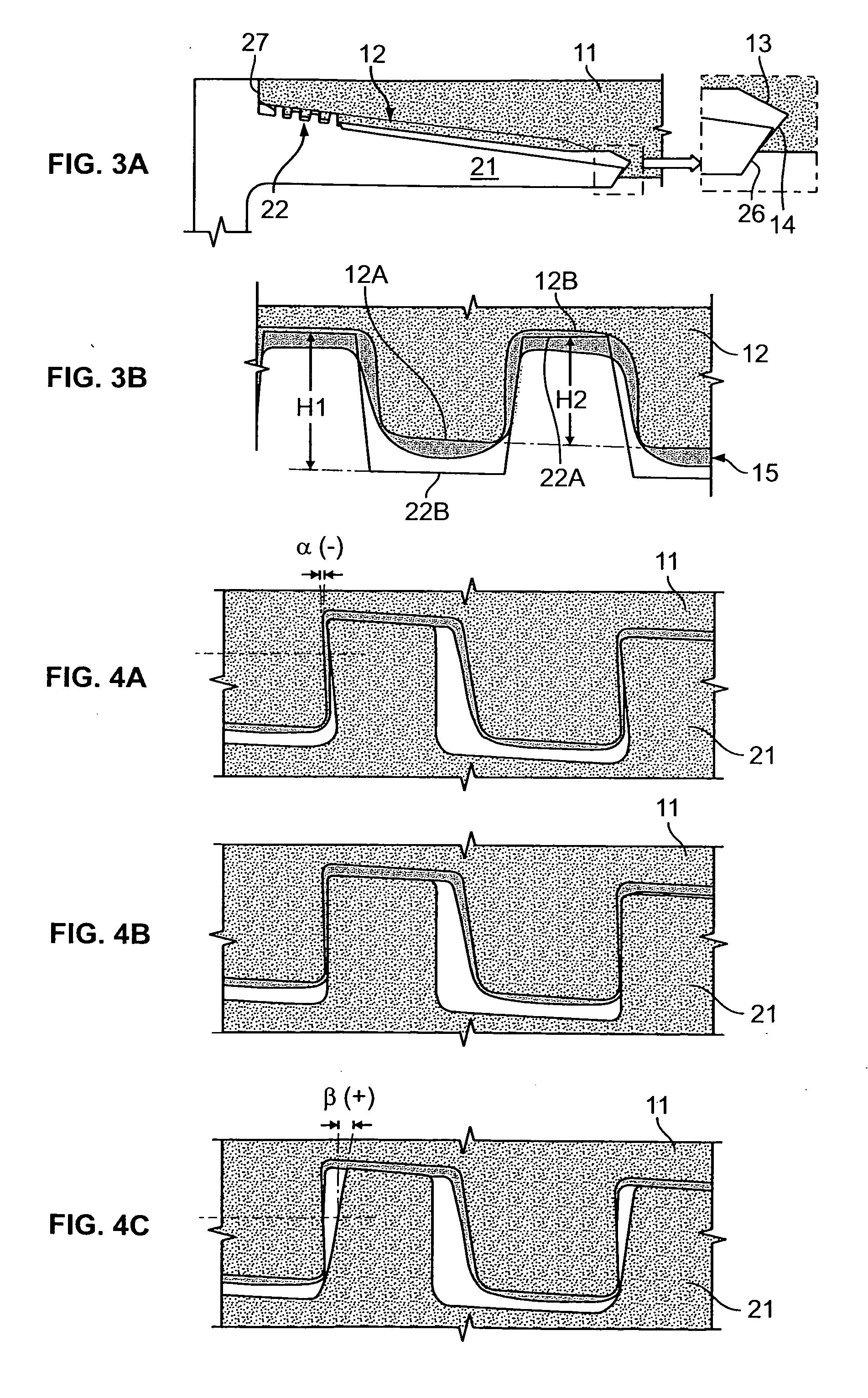

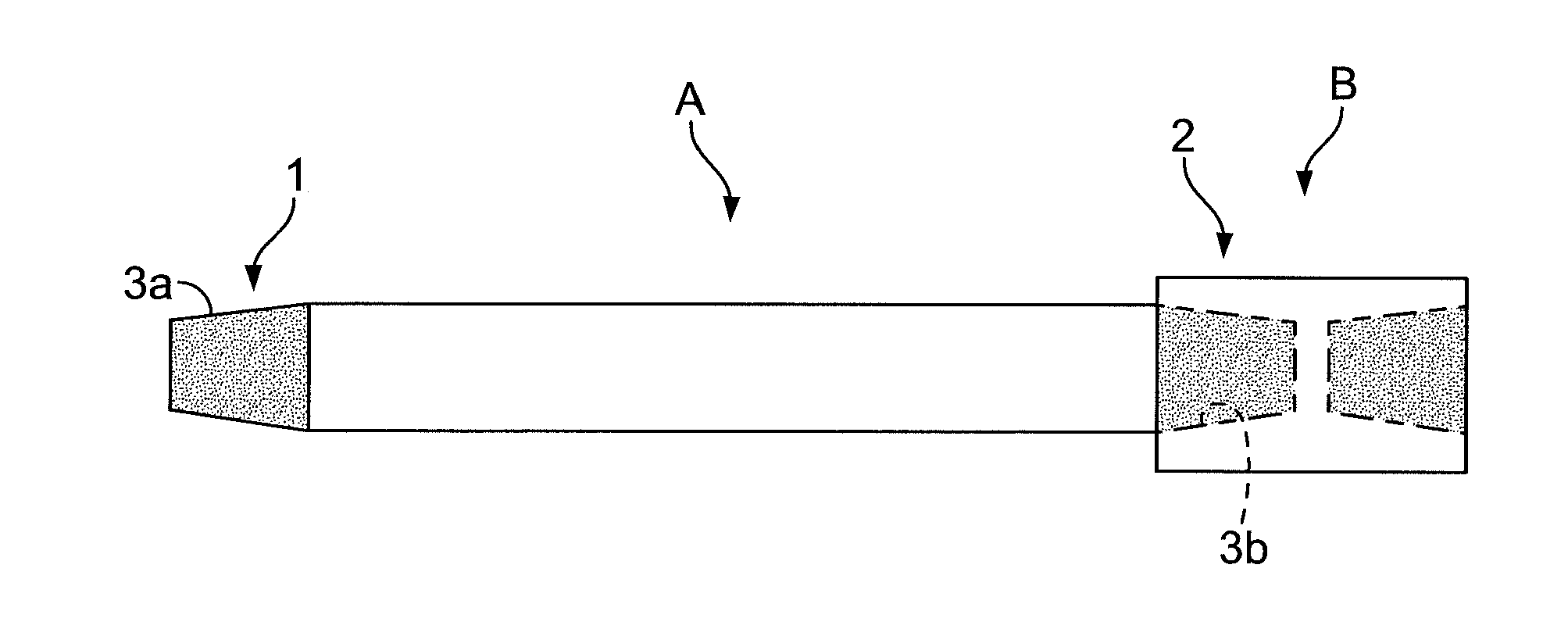

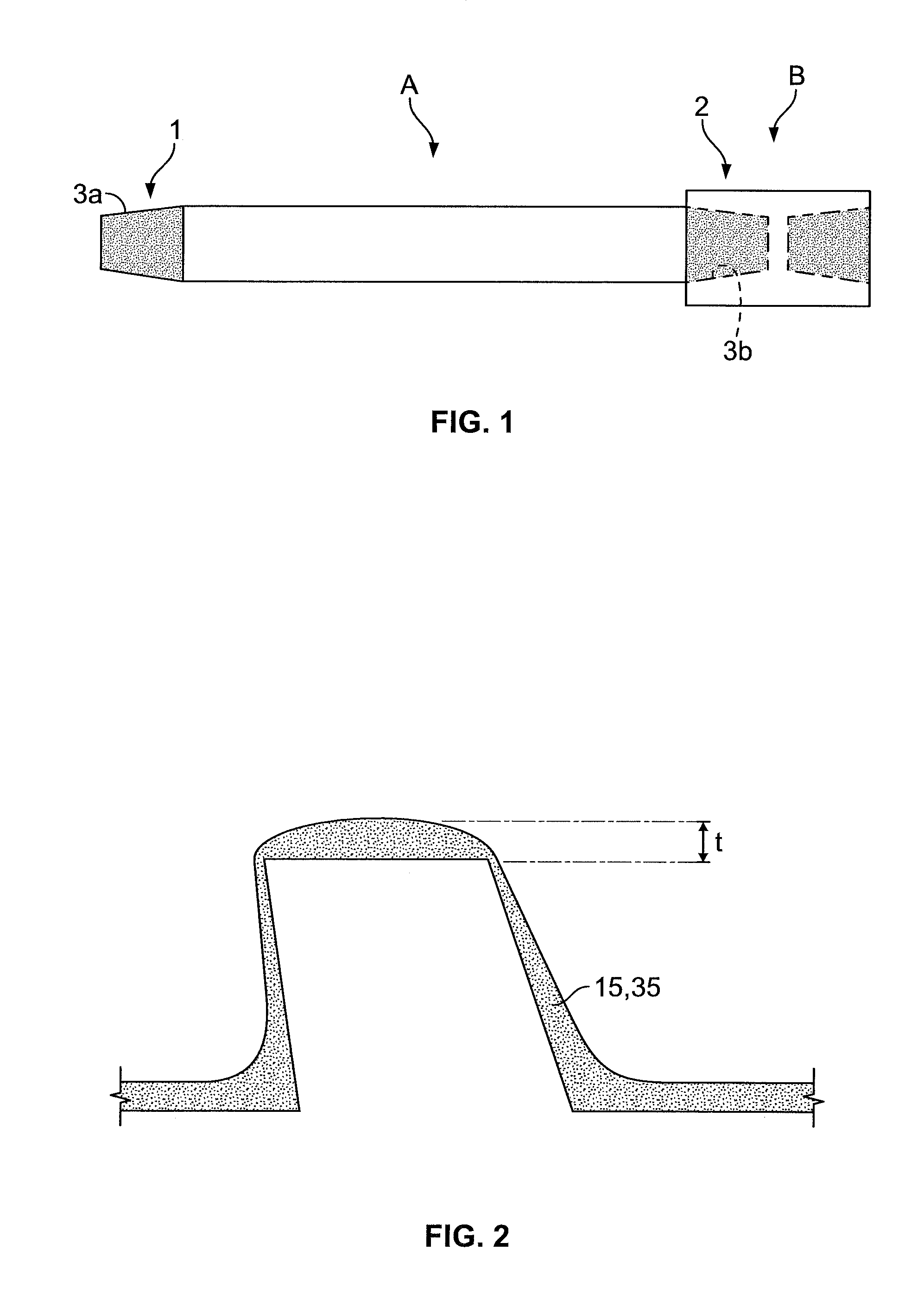

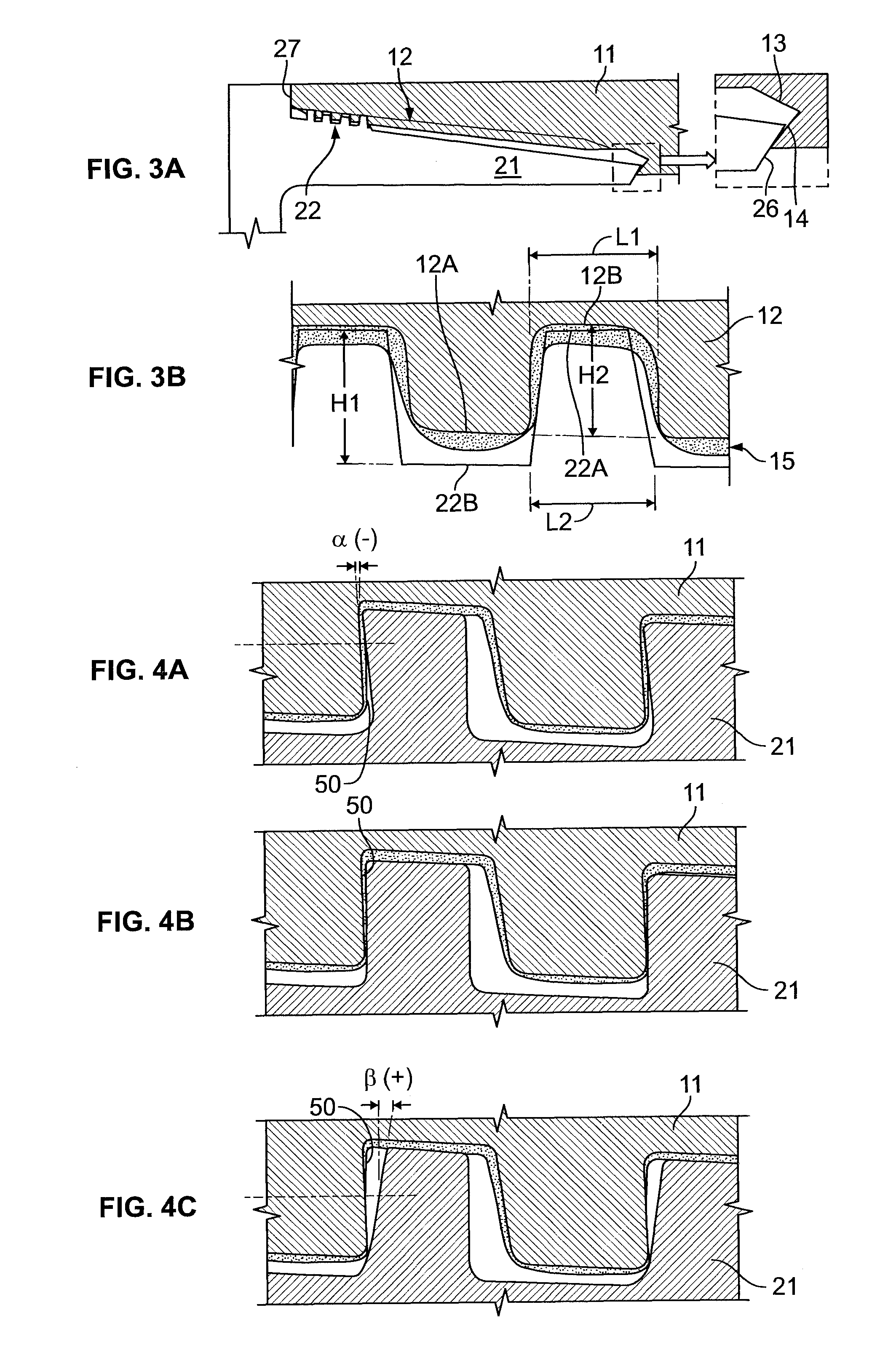

Protector for tubular threaded joint

ActiveUS20100038904A1Decreasing galling resistanceDecreasing resistance corrosionHose connectionsPipe protection against damage/wearScrew threadBiomedical engineering

A protector which prevents damage to a solid lubricating coating on a threaded portion of a threaded joint when the protector is mounted on a pin or a box of a threaded joint for pipes in which at least one of the pin or the box is lubricated with a solid lubricating coating comprises a tubular member having a threaded portion on its inner or outer peripheral surface which threadingly engages with at least a portion and preferably 3-5 complete threads of the threaded portion provided on the pin or the box to be protected. The thread height H1 of the threaded portion of the protector and the thread height H2 of the complete thread of the pin or the box on which the protector is mounted satisfy H1>H2, and the difference between H1 and H2 [=H1−H2] is larger than the maximum coating thickness at the thread crest of the solid lubricating coating which covers the threaded portion of the pin or the box.

Owner:NIPPON STEEL CORP +1

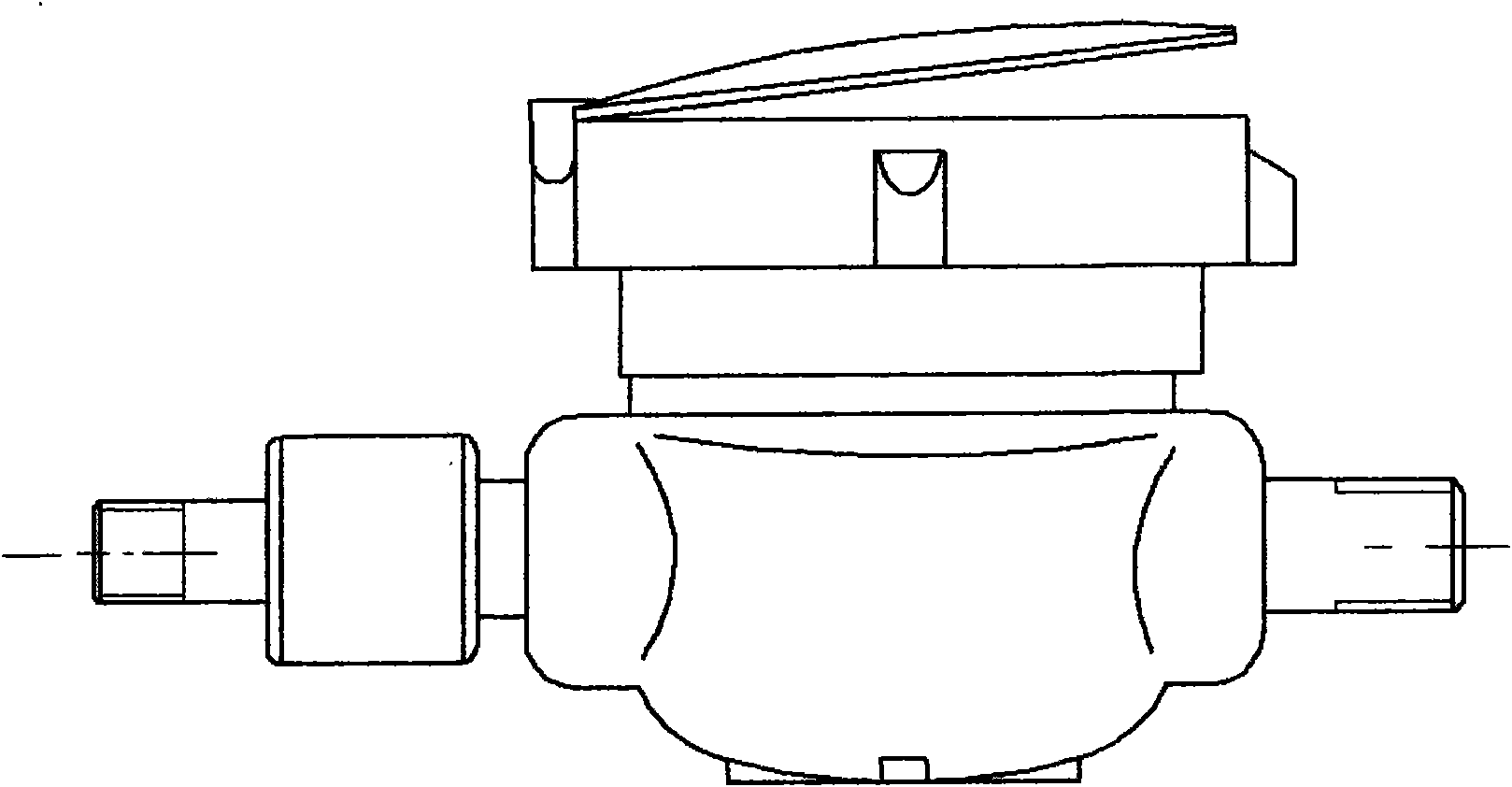

Anti-disassembly, anti-reversion, anti-pulsation, antirust and antidrip energy-saving water meter

InactiveCN101556175APrevent faucets from leakingPrevent being removedVolume/mass flow by mechanical effectsVolume meteringGear transmissionImpeller

The invention relates to an anti-disassembly, anti-reversion, anti-pulsation, antirust and antidrip energy-saving water meter belonging to a measuring instrument for preventing the running water from running away and from being stolen. A pipe connector protective sleeve sleeved on a nut for an inlet pipe connector of the water meter is buckled with a protective sleeve retaining ring to enable meter casings to be connected into a whole, a meter cover protective sleeve is buckled on a meter cover and is used for buckling and hooking the meter cover through an interlocking hook, and a positioning pin is inserted on the meter cover and connected into a whole with the meter casings so as to prevent the water meter from being disassembled and prevent the meter cover from dripping water; an anti-reversion and anti-pulsation structure formed by a check valve is arranged in an inlet of the water meter so as to avoid reversion and pulsation; the transmission between an impeller and a counting device is carried out through an ultra-thin gear transmission shaft and a lip-shaped sealing ring, and an antirust structure for a meter panel can prevent the water from entering in the counting device to cause the meter panel to rust; and symmetrical microflow holes, a recharging hole and a dead weight valve on an impeller case of the water meter and a flow regulation valve on a valve plate form an antidrip structure to avoid a dead angle to affect the accuracy in the rotating process of the impeller and water from dripping, therefore, the invention integrates the five precaution functions into a whole and plays the roles of fair water supply and water saving.

Owner:隋明祥

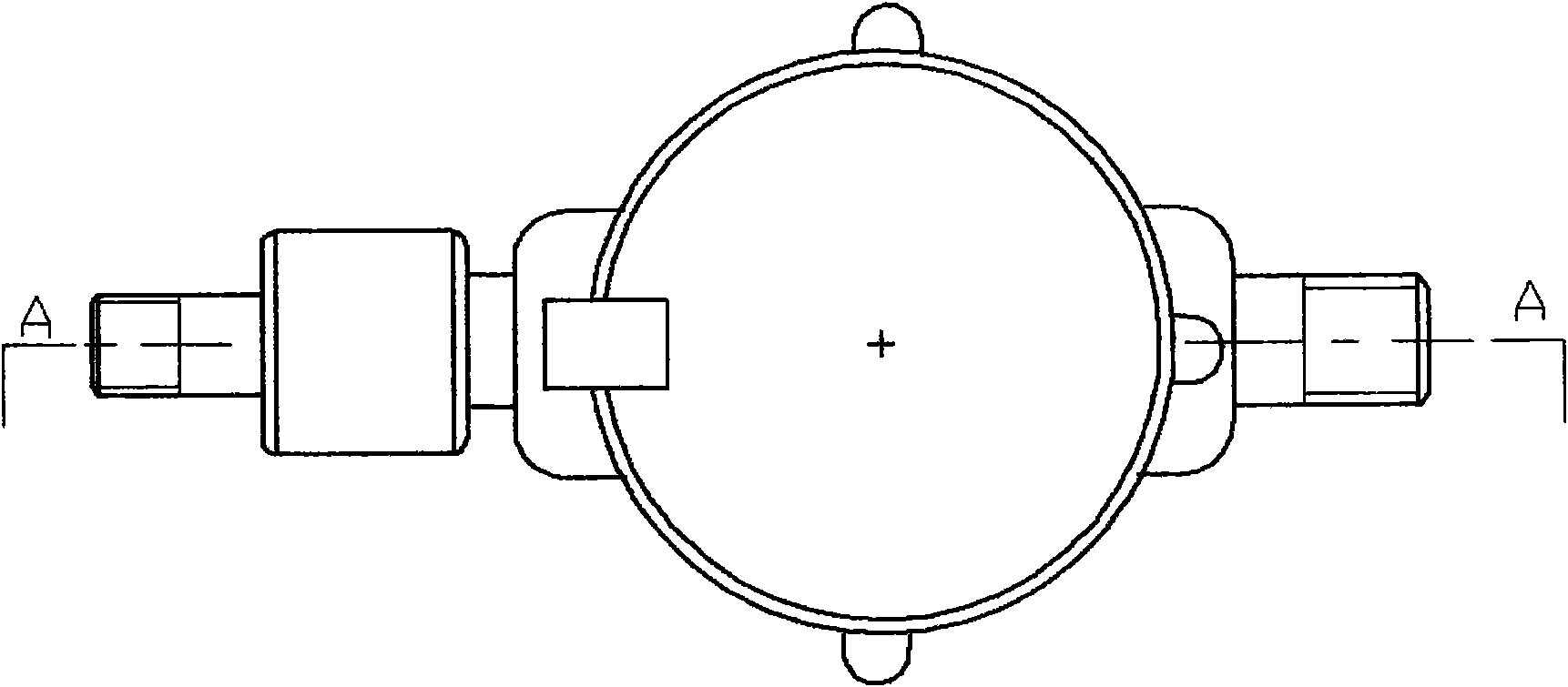

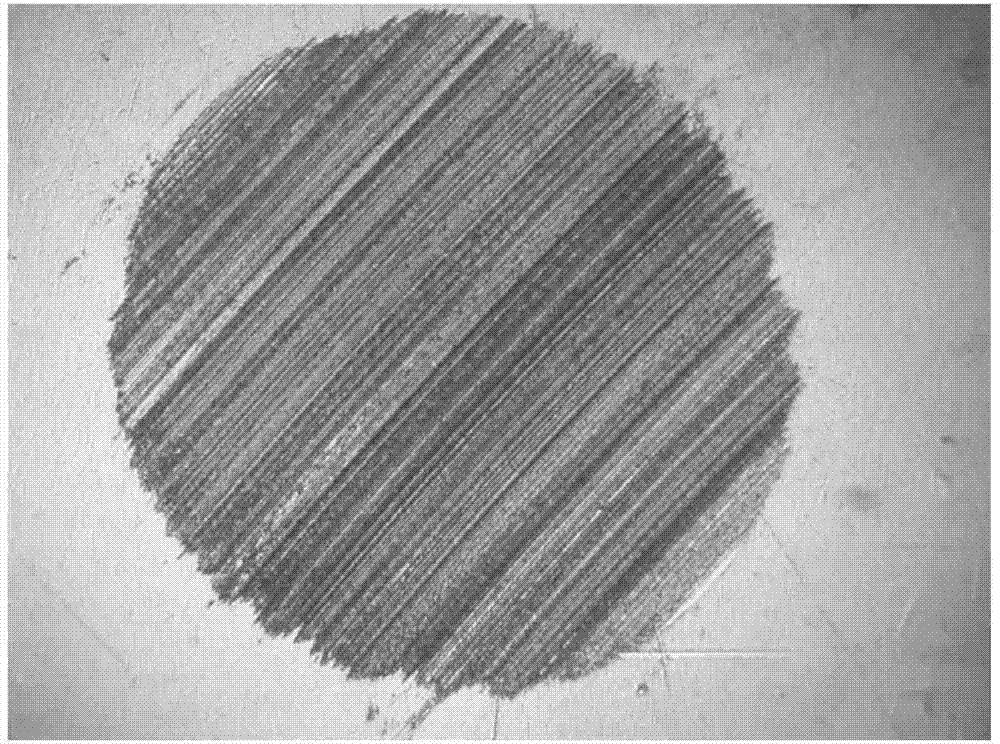

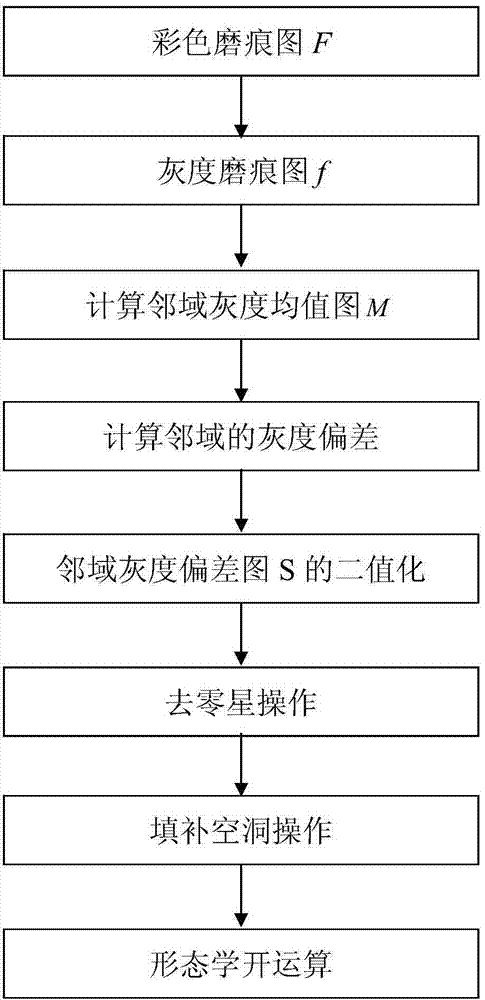

Steel ball grinding crack detection method based on neighborhood gray level similarity

The invention discloses a steel ball grinding crack detection method based on neighborhood gray level similarity. The method specifically includes the following steps that 1, a grinding crack image of a steel ball is acquired and read into a computer; 2, if the acquired grinding crack image is a color image, a step 3 is performed and if the acquired grinding crack image is a gray level image, a step 4 is performed; 3, graying is performed on the color image F; 4, a neighborhood gray level average figure M of the gray level grinding crack image f is calculated; 5, a neighborhood gray level deviation value of pixels is calculated; 6, binaryzation is performed on a neighborhood gray level deviation figure S; 7, fragment removal operation is performed on a neighborhood gray level similar figure L; 8, cavity filling operation is performed on a gray level similarity grinding crack figure D; 9, morphological opening operation is performed. According to the method, a grinding crack area of the steel ball can be detected rapidly, and accordingly the diameter of a grinding crack can be worked out directly.

Owner:CHANGAN UNIV

Heat preservation device with ceramic inner container

The invention provides a heat preservation device with a ceramic inner container, for further improving the heat preservation effect of existing vacuum cups, kettles and drinking cups, and overcoming the defects that stainless steel cups easily precipitate harmful substances and glass inner containers or ceramic inner containers are easily broken. The heat preservation device with the ceramic inner container is better in heat preservation effect, more attractive, unlikely to damage, better in corrosion resistance, easy to clean and good in mouthfeel when being used for accommodating water. The heat preservation device comprises a stainless steel outer container, a stainless steel vacuum inner container and a ceramic coating, wherein the ceramic coating is positioned on the inner wall of the stainless steel vacuum inner container; the ceramic coating is prepared from the following raw materials: 30-40 parts of silica sol, 25-50 parts of silane coupling agent, 2-8 parts of iron ions, 2-8 parts of manganese ions, mixed acid and 50-80 parts of white steel; and the mixed acid comprises acetic acid and acrylic acid. The heat preservation device, which has good attrition, acid, alkali, cold, heat and corrosion resistance, is suitable for popularization and application.

Owner:陈守伟 +1

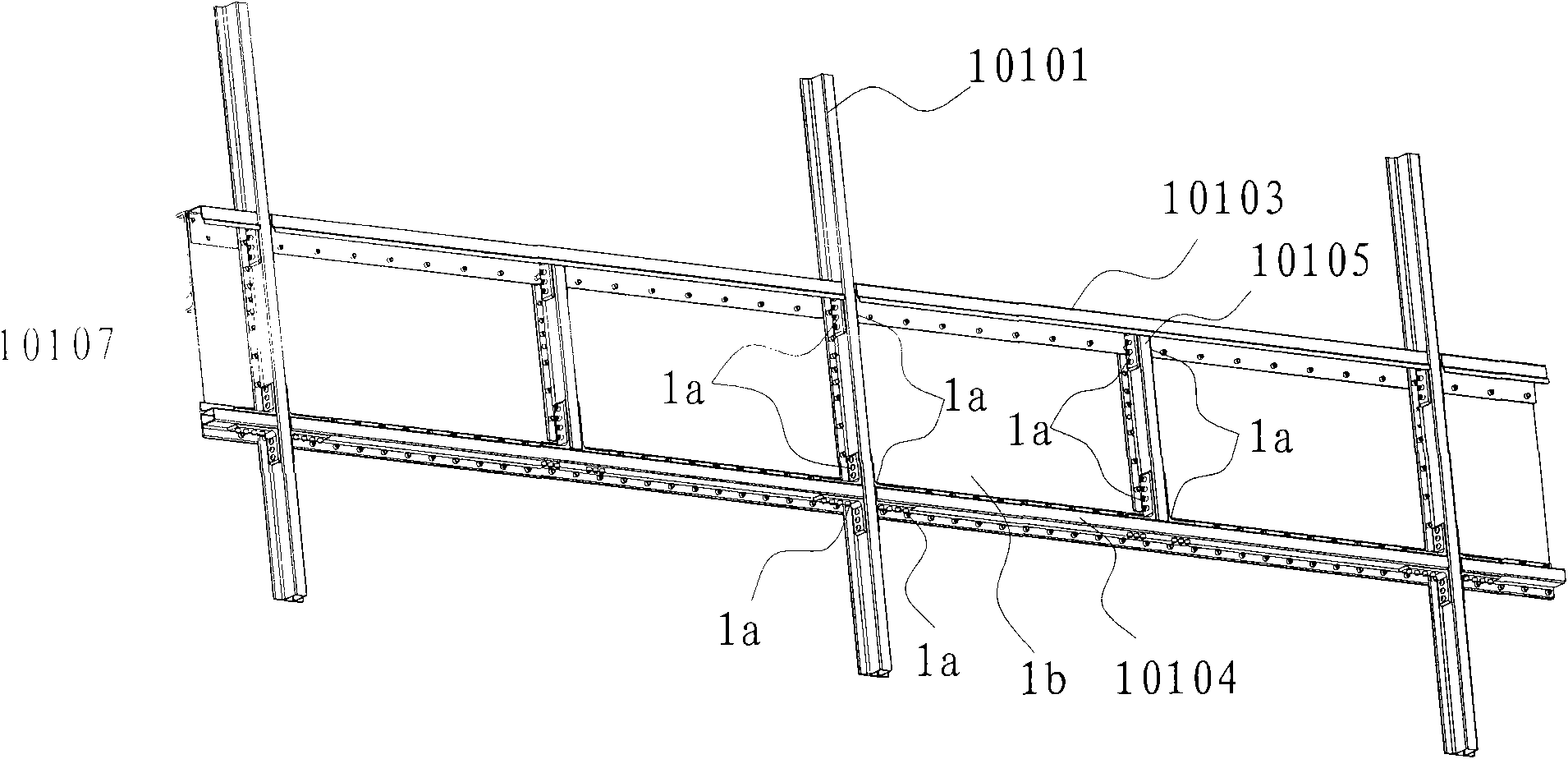

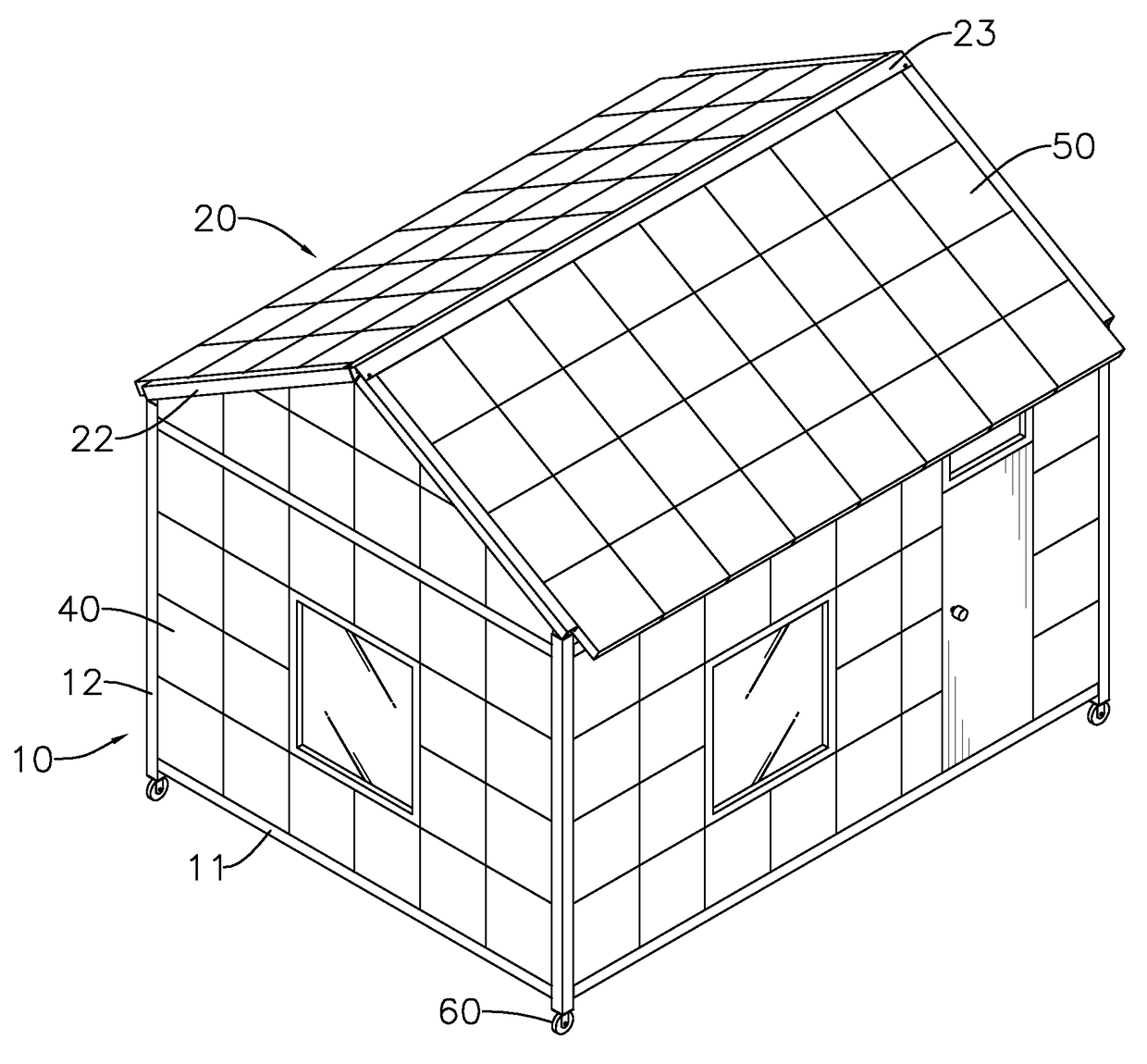

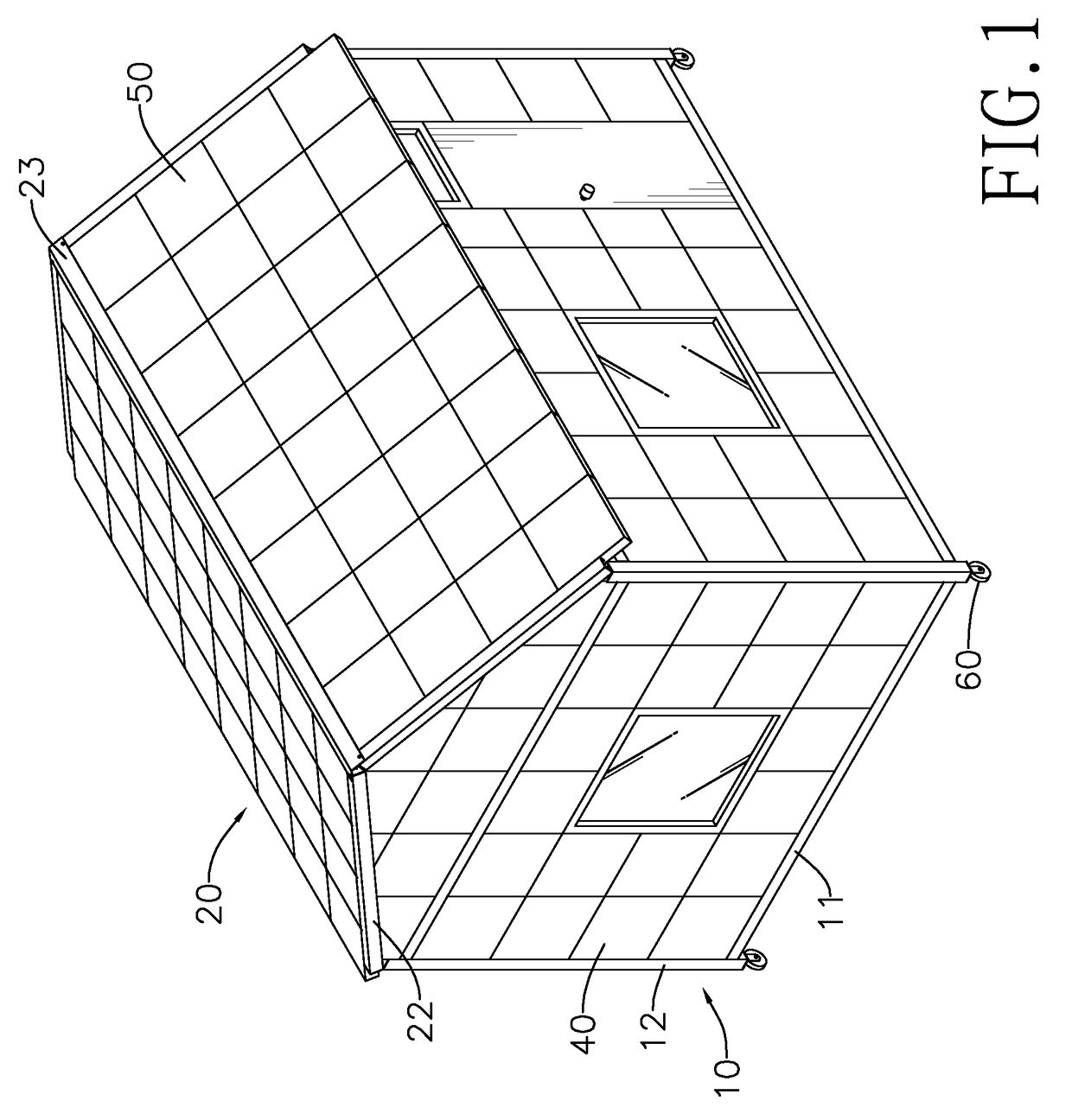

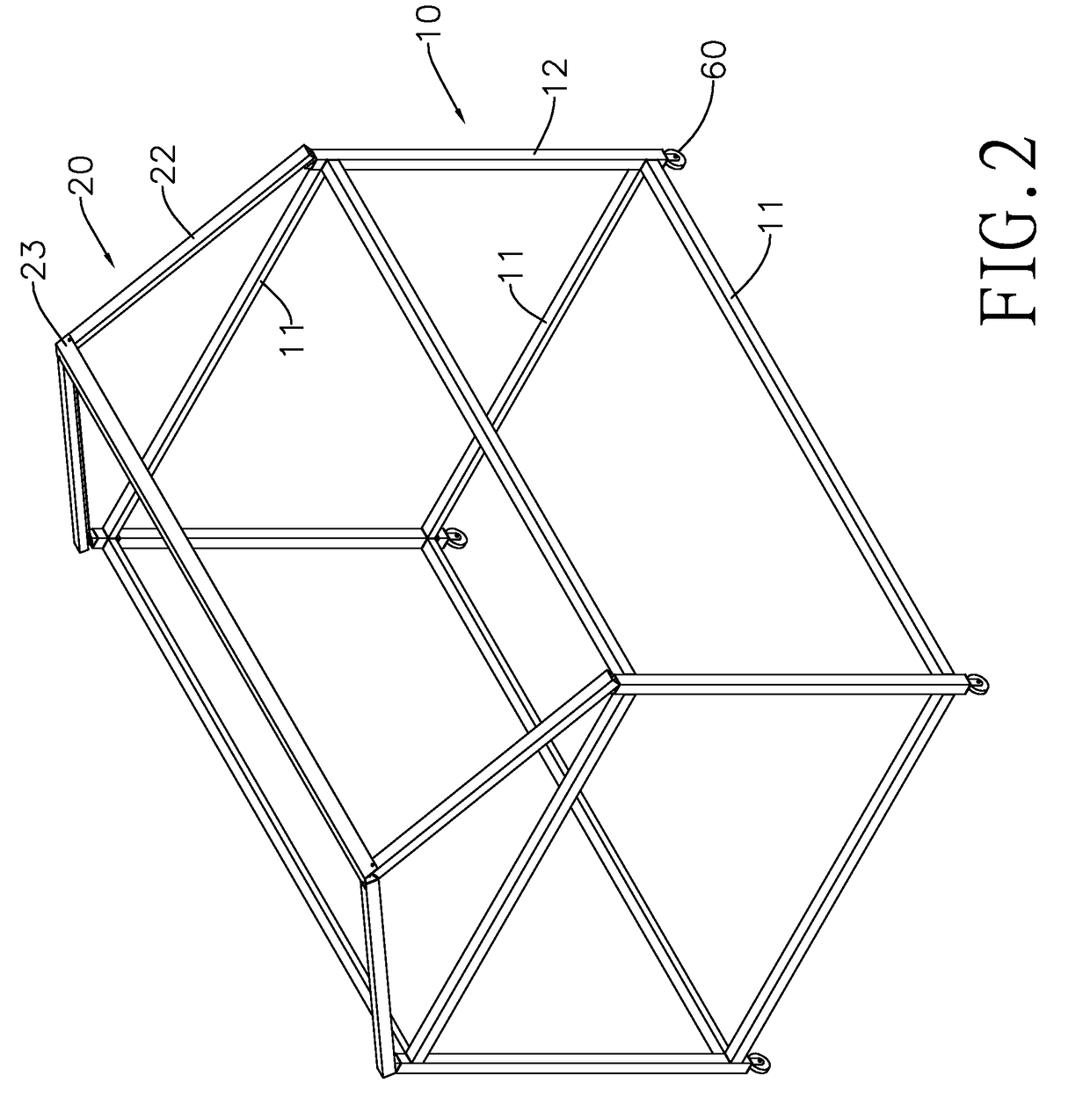

Assembled house

ActiveUS20170145708A1Easy and quick assemblyEasy and fast assemblyBuilding roofsWallsRafterMulti beam

An assembled house has a house framework, a roof framework, wall panels and a roof panel. The house framework has multiple beams, columns, and connectors. The roof framework has multiple rafters. Each one of the connectors is mounted securely in the column, and has multiple screw sleeves mounted securely in a concrete body. Thus, the beam can be connected securely to the column by screws screwed into the screw sleeve of the connector. Welding is not required for assembling the house framework on the site of the assembled house, thereby effectively accelerating the assembling. In addition, the beams and the columns are connected without welding, which eliminates the problem that the welded portions may easily rust. Furthermore, the columns, rafters, and the beams are hollow tubes, which can effectively lower the weight of the whole assembled house.

Owner:CHEN SHENG LIANG

Hub manufacturing method

The invention discloses a hub manufacturing method. An upper air cylinder and a lower air cylinder act, a bottom die and a top die are controlled to get close to a casting hole, a both-way air cylinder acts, each set of oppositely-arranged side dies are controlled to synchronously get close to the casting hole, and the bottom die, the top die and the side dies are mutually pressed to form a hub casting cavity. A casting machine pours liquid molten aluminum into a cavity of a casting die for filling. The lower air cylinder acts, a lower support drives the bottom die to evacuate, a hub supporting rod enters a feeding rail from a walking rail and enters the position below the bottom die from the feeding rail, the top die moves upwards under the action of the upper air cylinder, each set of oppositely-arranged side dies are opened at the same time, and a hub falls onto the hub supporting rod. A water pump conveys cooling water into a circular pipe through a water pipe, the cooling water is sprayed to the outer side edge of the hub through a sprayer on the circular pipe, and the circular pipe reciprocates up and down along a guiding column. After cooling is finished, the hub moves to one end of a discharging rail through the feeding rail along with the hub supporting rod, and the hub is conveyed away through the discharging rail.

Owner:六和轻合金(昆山)有限公司

Method of forming protective film for touch panel electrode, photosensitive resin composition and photosensitive element, and method of manufacturing touch panel

ActiveUS20140377704A1Sufficient rust resistanceImprove conductivityPhotosensitive materialsSemiconductor/solid-state device manufacturingTectorial membraneIrradiation

In the method for forming a protective coat on an electrode for a touch panel according to the invention, a photosensitive layer comprising a photosensitive resin composition containing a binder polymer having a carboxyl group and an acid value of 30 to 120 mgKOH / g, a photopolymerizable compound having at least three ethylenic unsaturated groups, and a photopolymerization initiator, is formed on a base material having an electrode for a touch panel, prescribed sections of the photosensitive layer are cured by irradiation with active light rays and then the sections other than the prescribed sections are removed, to form a protective coat comprising the cured sections of the photosensitive resin composition covering all or a portion of the electrode.

Owner:RESONAC CORP

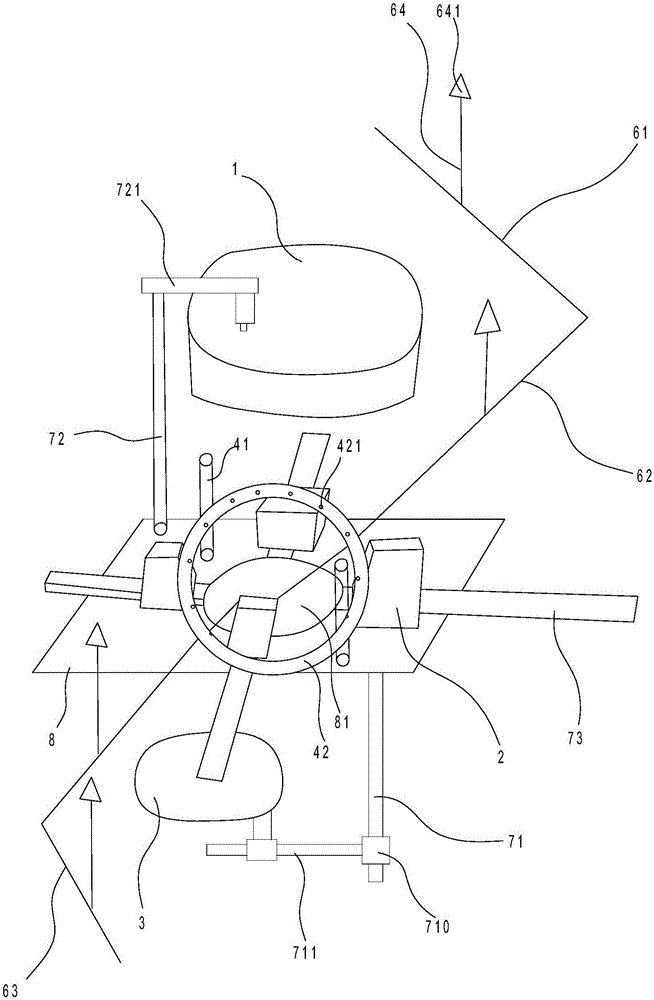

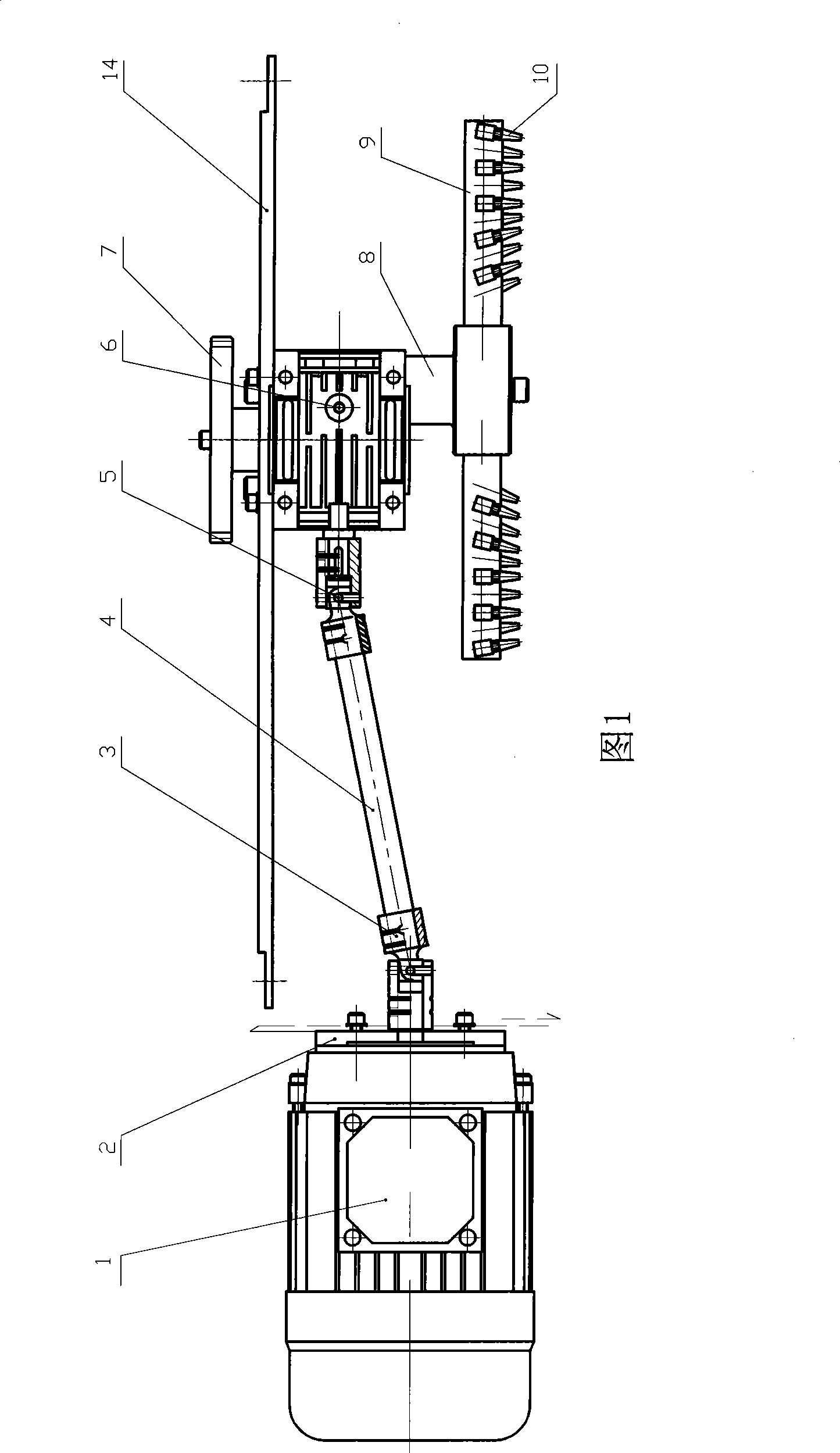

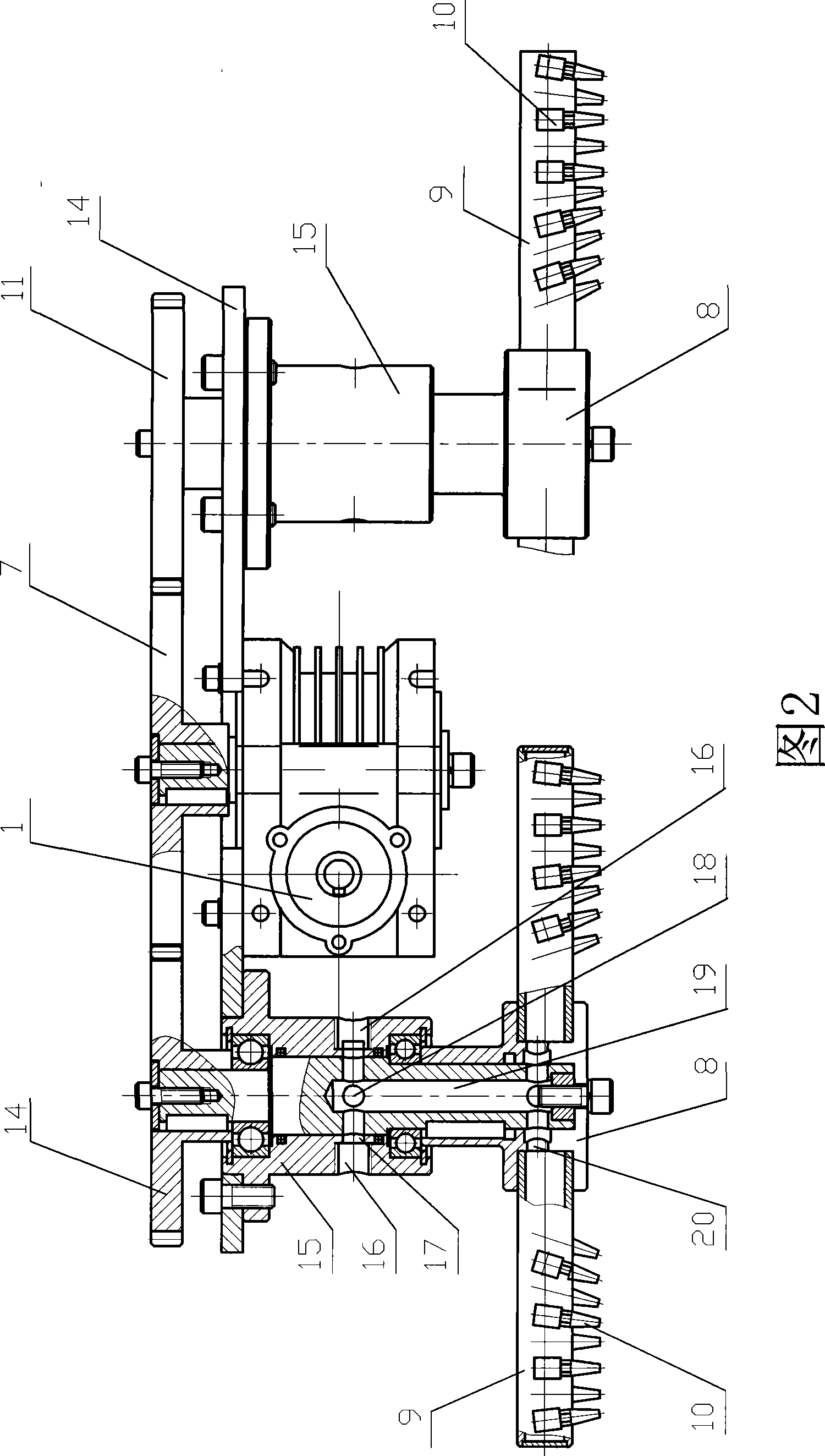

Rotary type hot blast drying device

InactiveCN101419019AReduce air volumeShorten the timeDrying solid materials with heatDrying gas arrangementsHot blastTruck

The invention relates to a rotary type hot blast drying device and belongs to special structural equipment for carrying out cleaning and hot blast drying on parts of a passage train and a freight train in railroad. The rotary type hot blast drying device consists of a motor, a motor output transmission device, a rotator, transmission gears, a rotary head, a wind pipe and blast nozzles. The motor is connected with the motor output transmission device through an output shaft of the motor; the motor output transmission device is connected with the rotator; the output end of the rotator is fixedly provided with a driving gear; a set of the transmission gears is engaged with the driving gear; and each transmission gear is fixed with an input shaft of a rotary head body which is fixed on a disc base and corresponds to the disc base. The front end of the rotary head body is provided with the rotary head; the inside of the rotary head body is provided with a wind channel; the top end of the rotary head is provided with the wind pipe; and a set of the blast nozzles are arranged on the wind pipe. The rotary type hot blast drying device has a reasonable structure, advanced design, high cost performance, good drying effect, high automation degree and strong environmental protection, and can be widely applied to cleaning and drying various parts of railway vehicles.

Owner:大连北方铁路新技术研究所

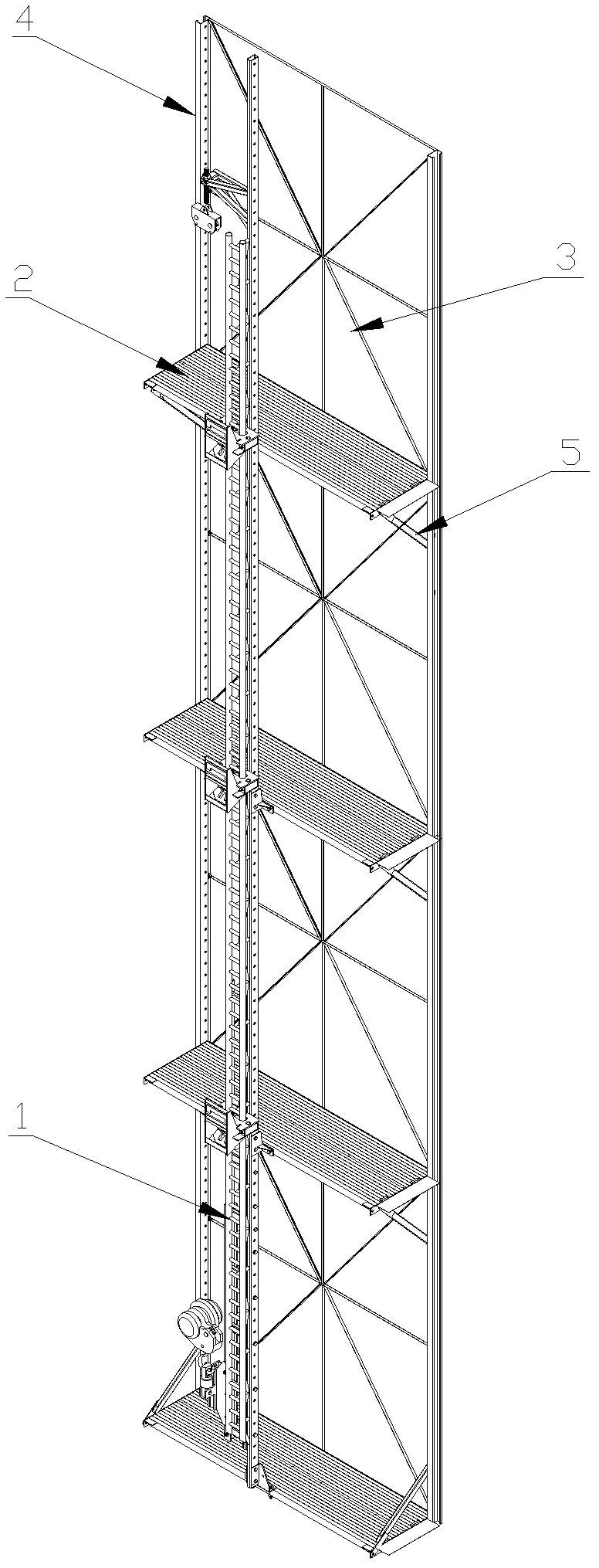

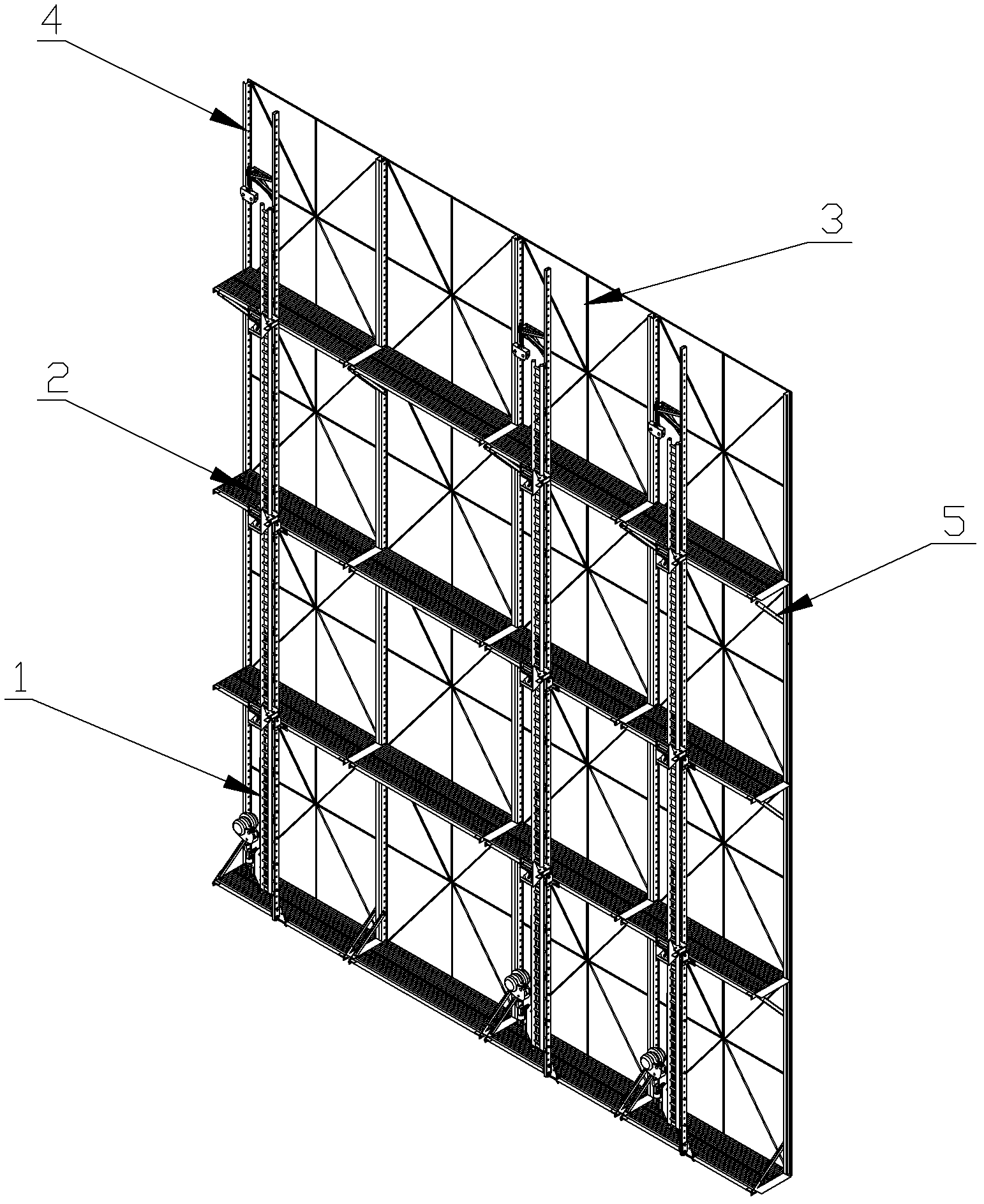

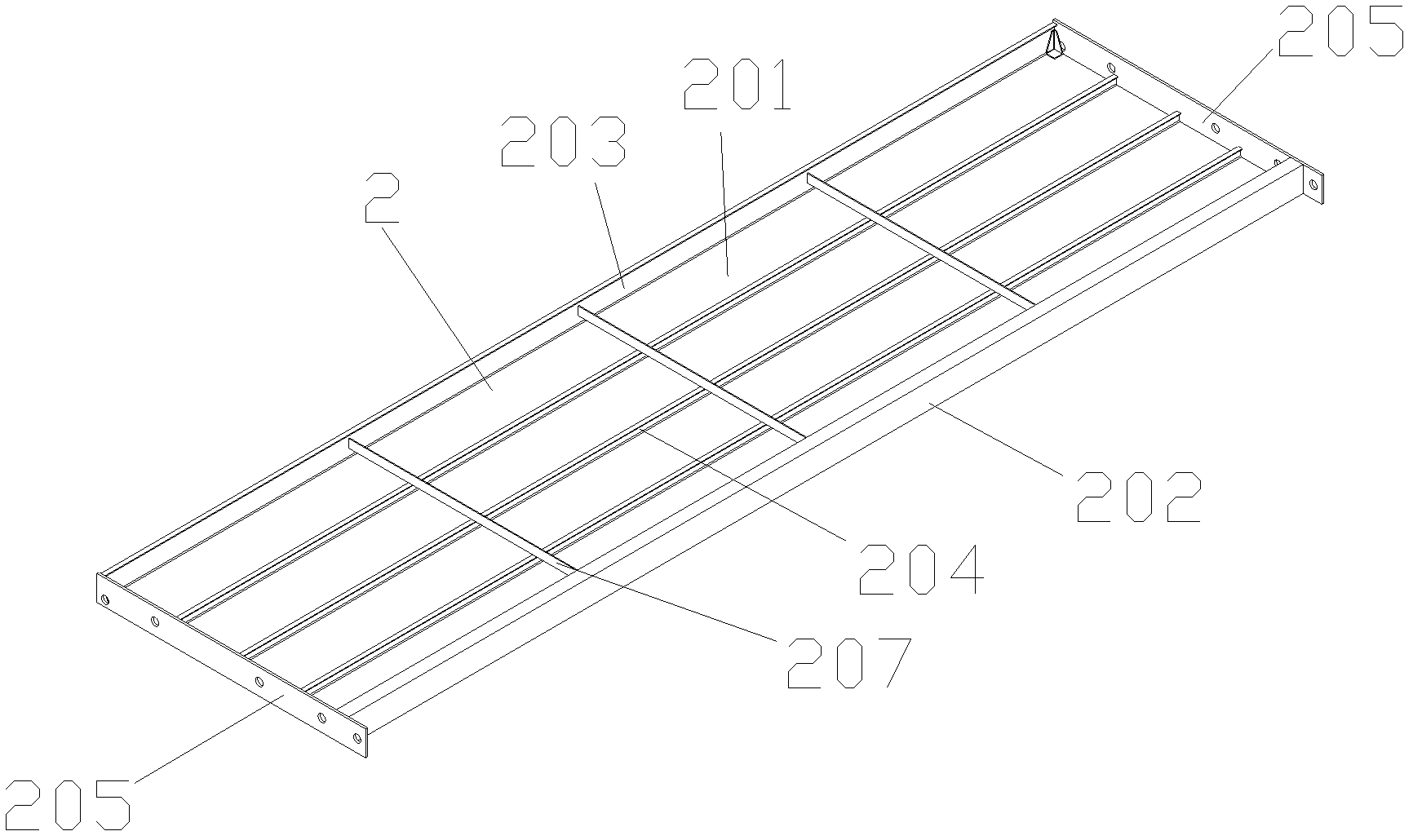

Aluminum alloy lifting scaffold

InactiveCN102635227APlay a protective effectReduce weightBuilding support scaffoldsCorrosionAluminium alloy

The invention relates to an aluminum alloy lifting scaffold which comprises a lifting attaching device (1), protective screens (3), uprights (4) and scaffold floors (2), wherein the scaffold floors (2) are fixed on the uprights (4), the lifting attaching device (1) is fixed on the scaffold floors (2) or uprights (4), the protective screens (3) are fixedly connected with the uprights (4), and the scaffold floors (2) or uprights (4) are made of aluminum alloys. The aluminum alloy lifting scaffold provided by the invention has the advantages of light weight, greatly reduced lifting load, high safety, no corrosion, easiness in maintenance, and high recycling rate.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

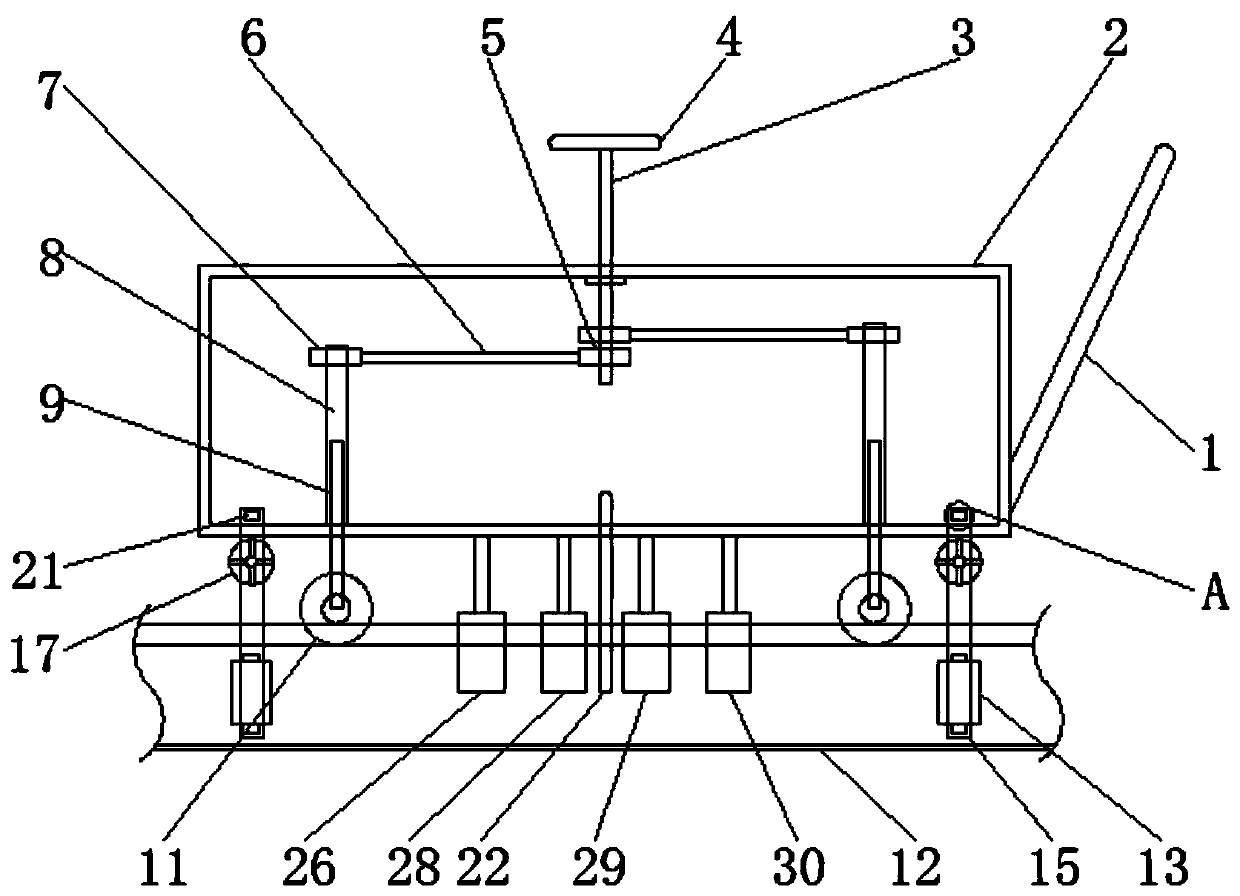

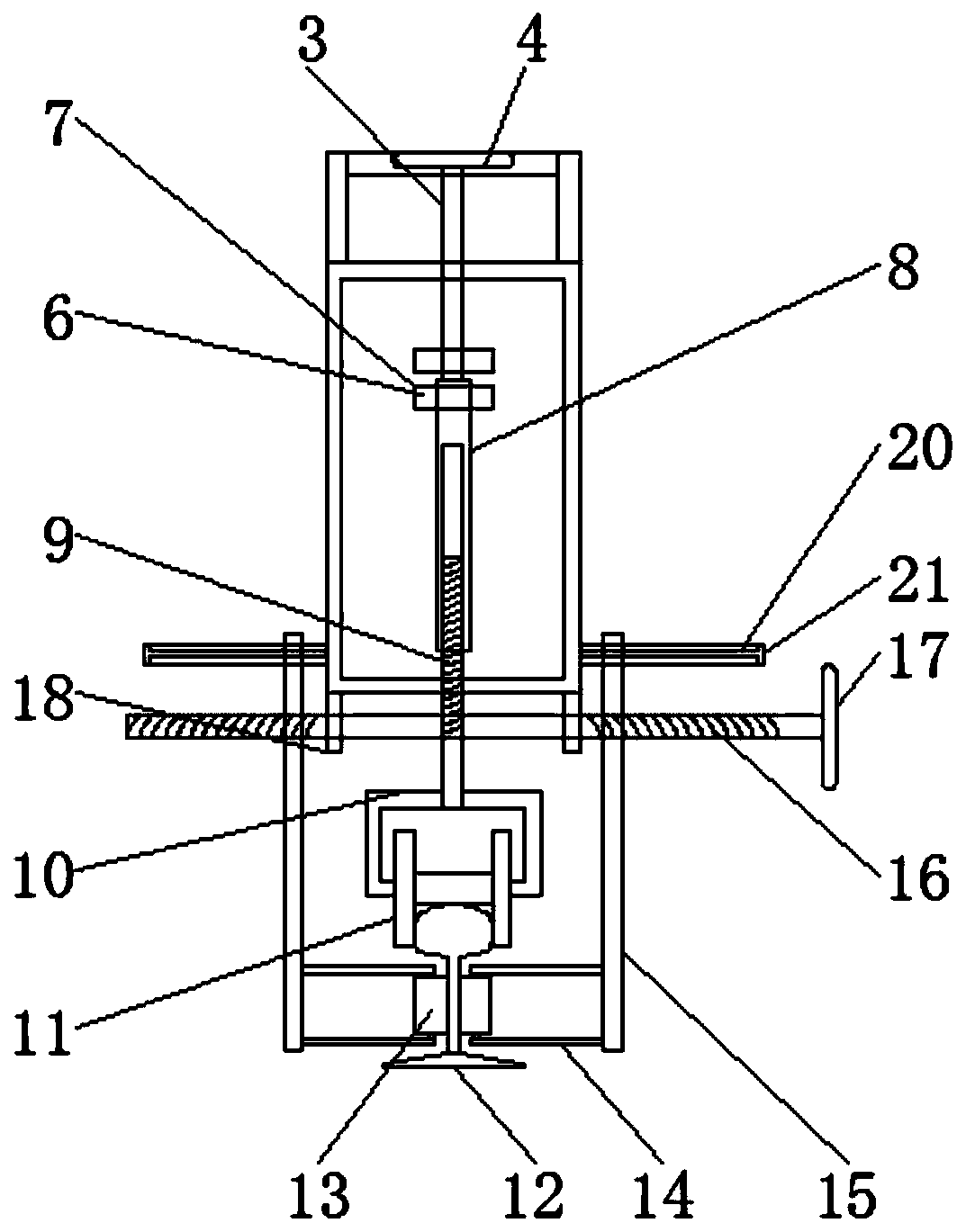

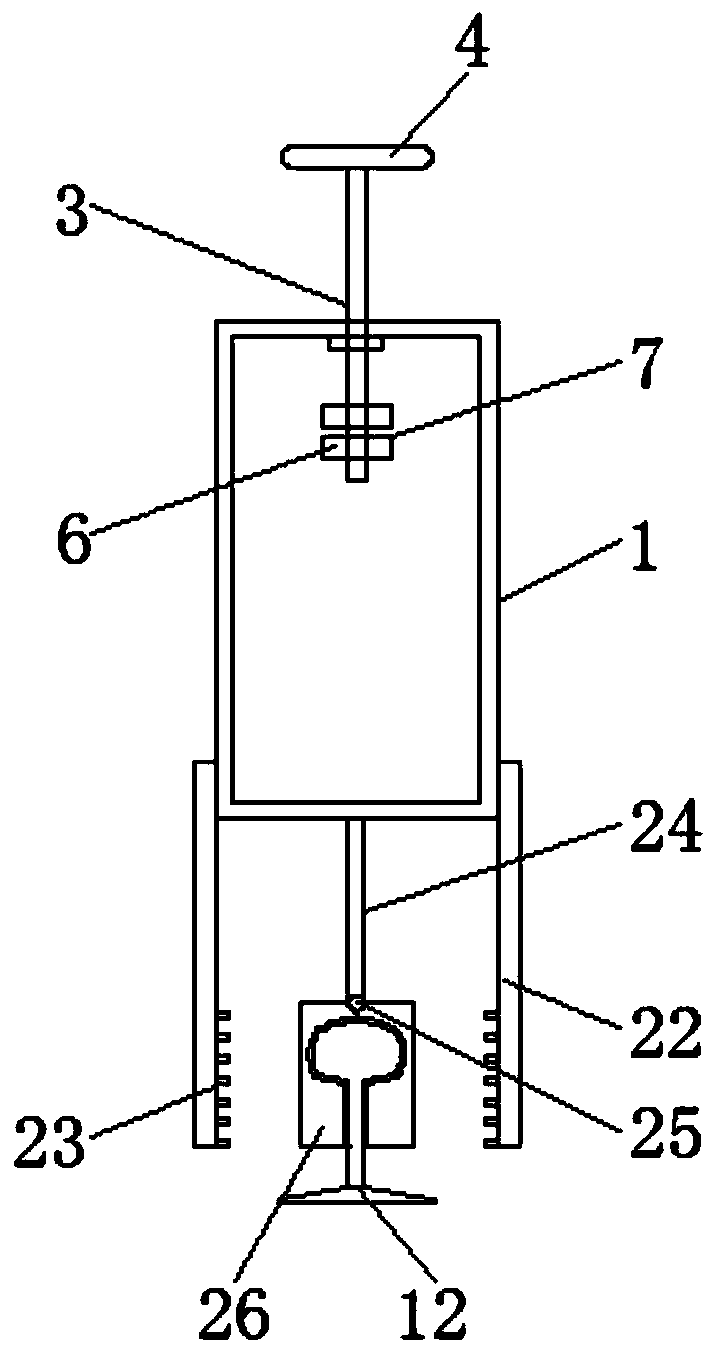

Railway track maintenance device

ActiveCN110029543AEasy to installEasy to disassembleRailway track constructionEngineeringThreaded rod

The invention discloses a railway track maintenance device. The railway track maintenance device comprises a handle, a water pipe and a second connecting rod. A box body is fixed to one end of the handle, a rotating rod is connected to the top of the box boxy, and a first rotating handle is fixed to one end of the rotating rod; a first rotating shaft is connected to the side, away from the first rotating handle, of the rotating rod in a sleeving mode; and belts are connected to one side of the first rotating shaft, and second rotating shafts are connected to the sides, away from the first rotating shaft, of the belts. The railway track maintenance device is provided with two-way threaded rods capable of rotating by rotating second rotating handles, so that sliding rods are driven to be slidably connected conveniently when the two-way threaded rods rotate, and sliding blocks can be driven to rotate when the sliding rods are slidably connected, so that the sliding blocks move and slideswith sliding grooves; and the sliding rods move to drive the first connecting rod to move, the first connecting rod moves to drive fixing wheels to move, and the fixing wheels move to fix rails, so that the maintenance device is conveniently moved and fixed and does not fall.

Owner:中铁隧道集团一处有限公司

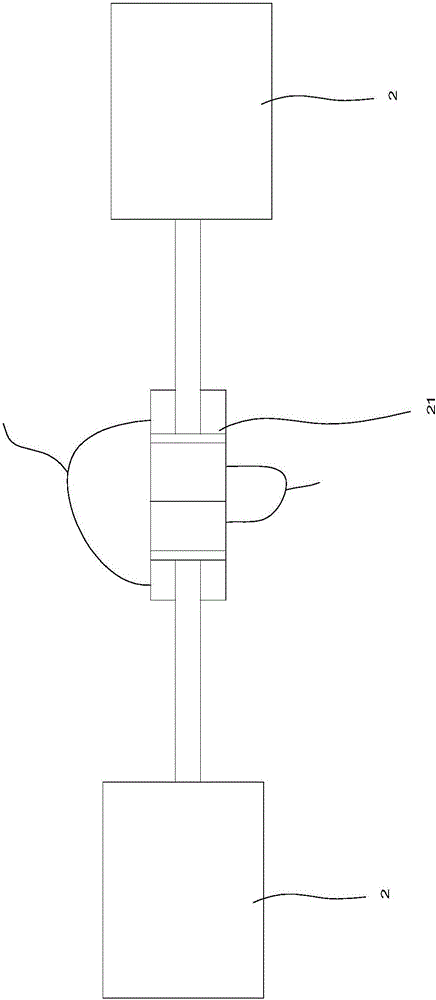

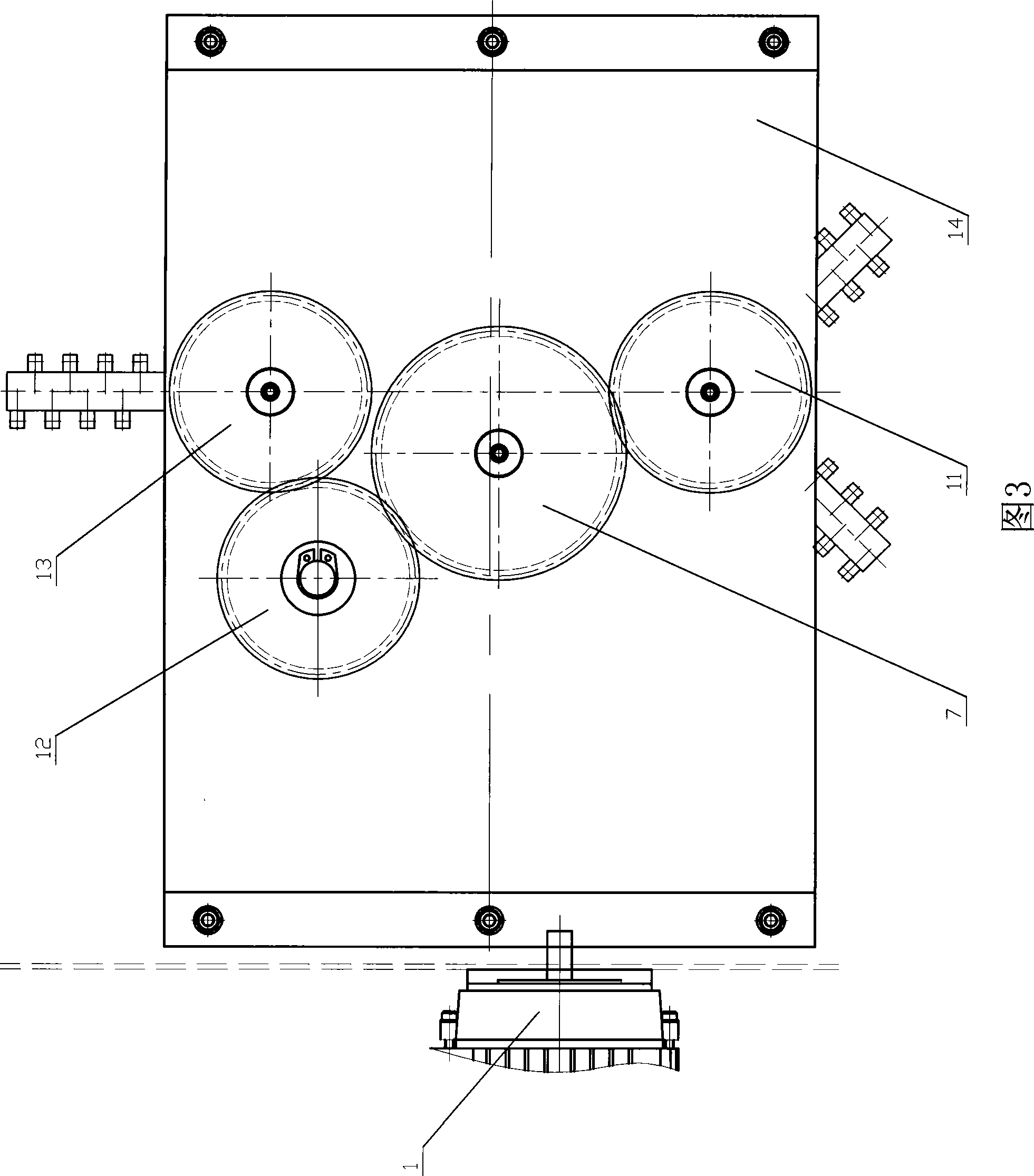

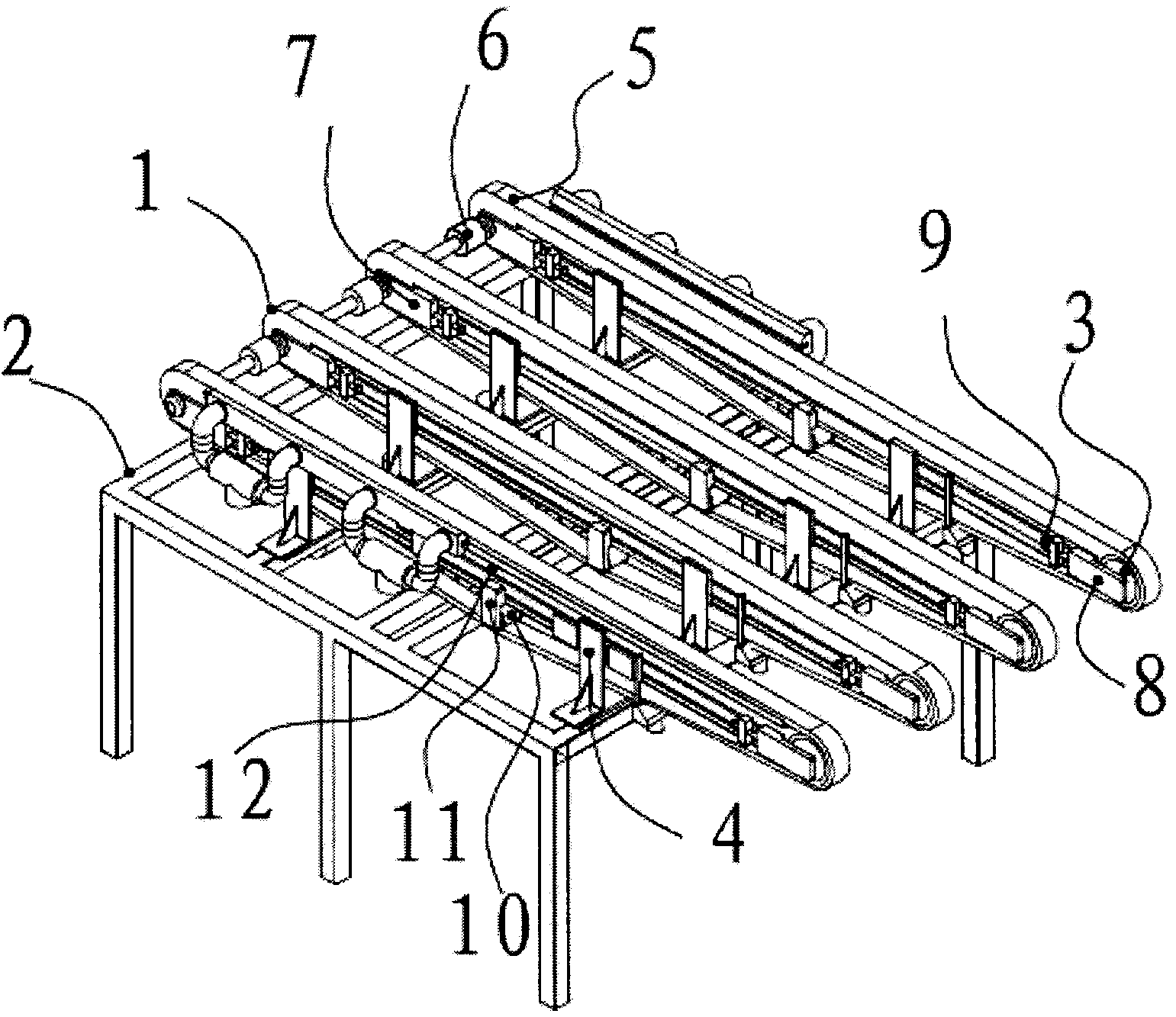

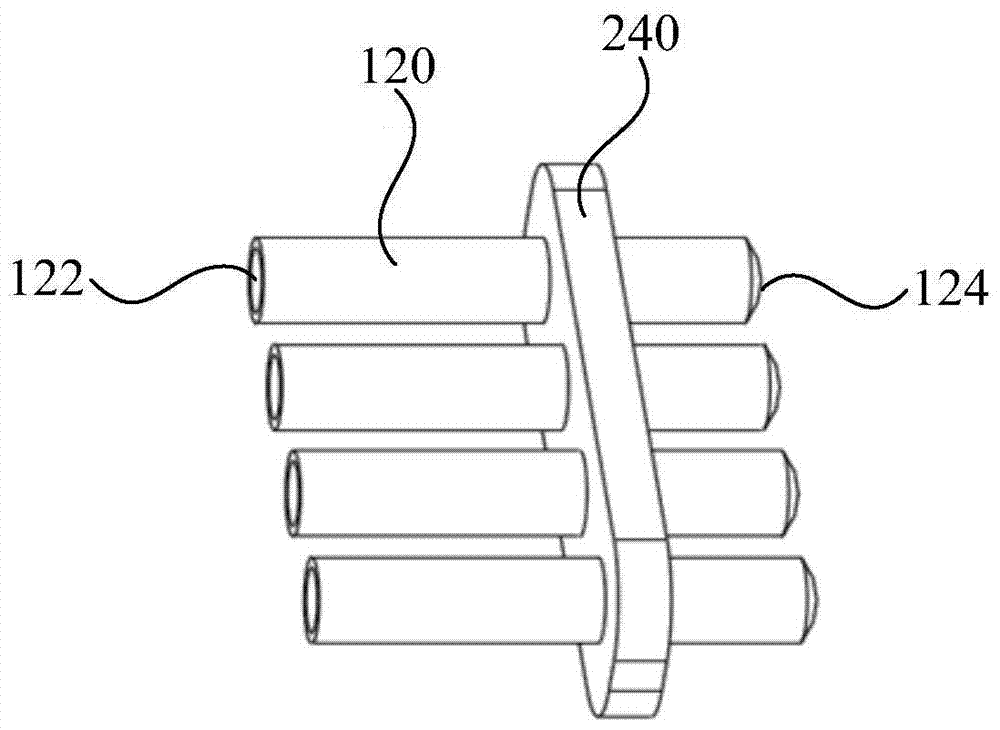

Synchronous wheel conveying mechanism

InactiveCN103449180AHigh conveying precisionHigh precisionConveyorsCharge manipulationLiquid-crystal displayEngineering

The invention discloses a synchronous wheel conveying mechanism, which is provided with a synchronous wheel mechanism and a hair brush belt, and conveying of LCD (Liquid Crystal Display) glass substrates is realized by driving the hair brush belt with the synchronous wheel mechanism. Moreover, a tension device is further arranged to control the tightness of the hair brush belt so as to ensure safe and stable conveying. The synchronous wheel conveying mechanism has the advantages of increase in equipment accuracy, increase in product yield and reduction in the production cost.

Owner:SUZHOU HUIQIAO AUTOMATION EQUIP CO LTD

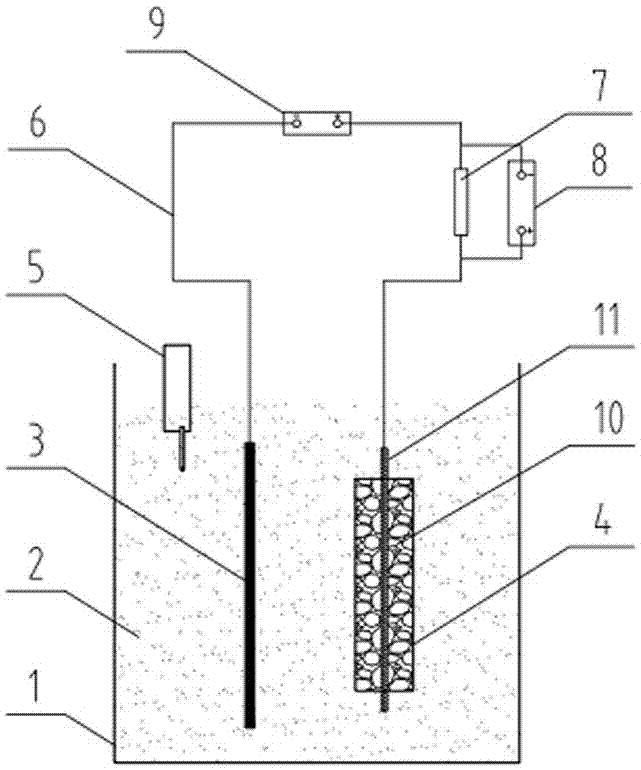

Electrified accelerated corrosion reinforced concrete test device and method

InactiveCN107328706ALarge sand sizeLarge particle sizeWeather/light/corrosion resistanceElectrical resistance and conductanceReinforced concrete

The invention relates to an electrified accelerated corrosion reinforced concrete test device and method. An electrolyte (2) in the device is placed in a box (1); a cathode (3) is placed in the electrolyte (2) and connected with the negative pole of a direct-current power supply (9) through a wire (6); a reinforced concrete test piece (4) is composed of concrete (10) and a steel bar (11) and placed in the wooden box (1); the steel bar (11) is connected with the positive pole of the direct-current power supply (9) through a wire (6) and serves as an electrified anode; a probe of a humidity monitor (5) is placed in the electrolyte (2); a resistor (7) is connected with wire (6) in a welded mode and connected with the steel bar (11) and the direct-current power supply (9) in series; a data recorder (8) is connected with the two ends of the resistor (7) through a wire (6). The method comprises the following steps that the reinforced concrete test piece is prepared and subjected to an electrified accelerated corrosion test. The feasibility and practicability of the test device and method are comprehensively evaluated through electrified corrosion efficiency calculation and steel bar corrosion product determination.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

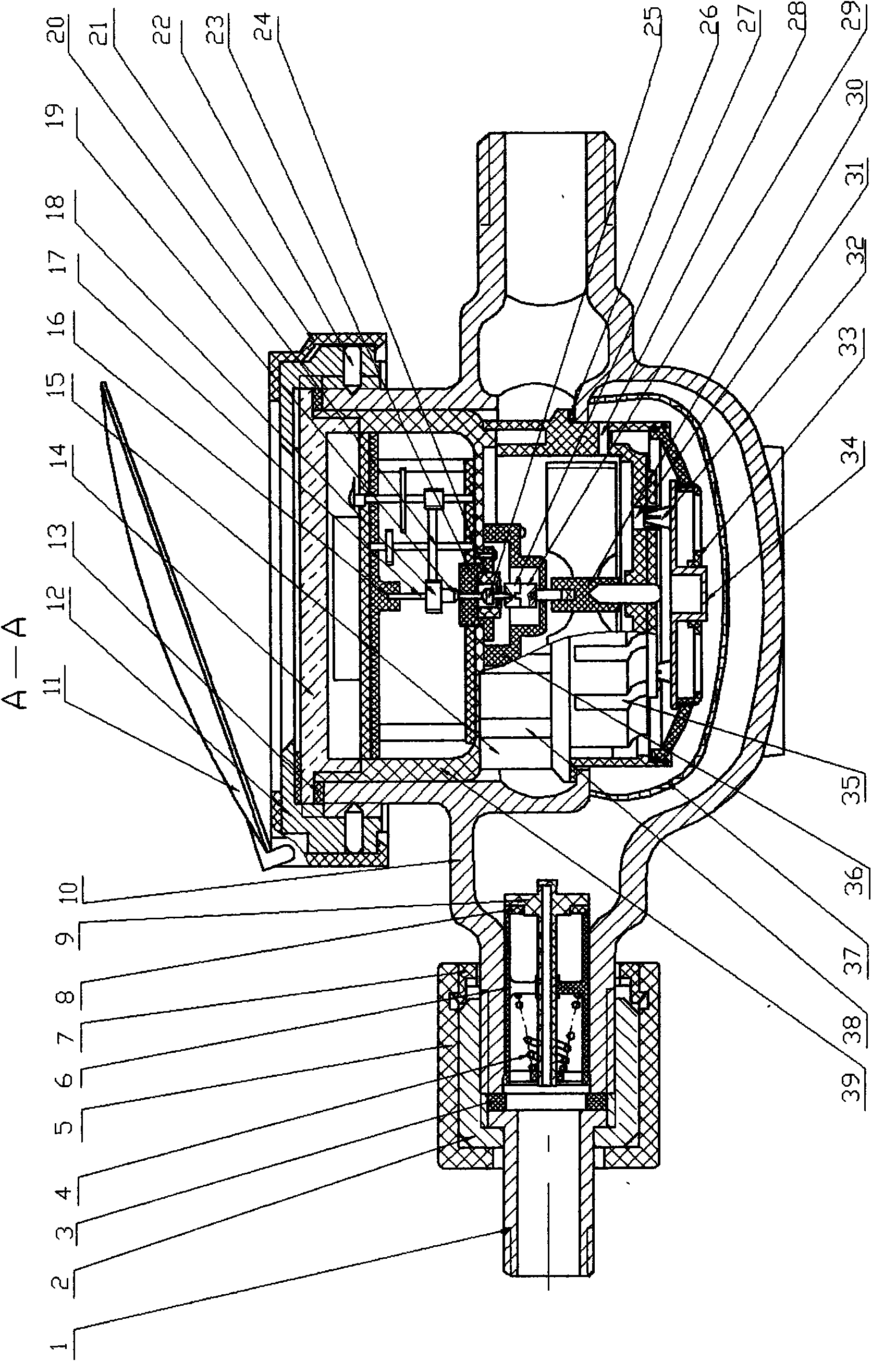

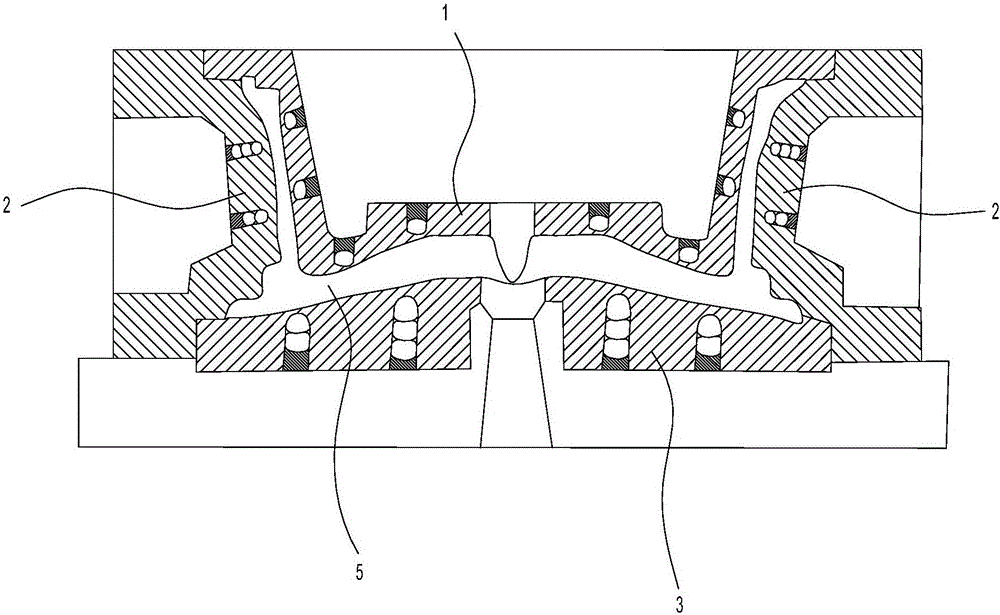

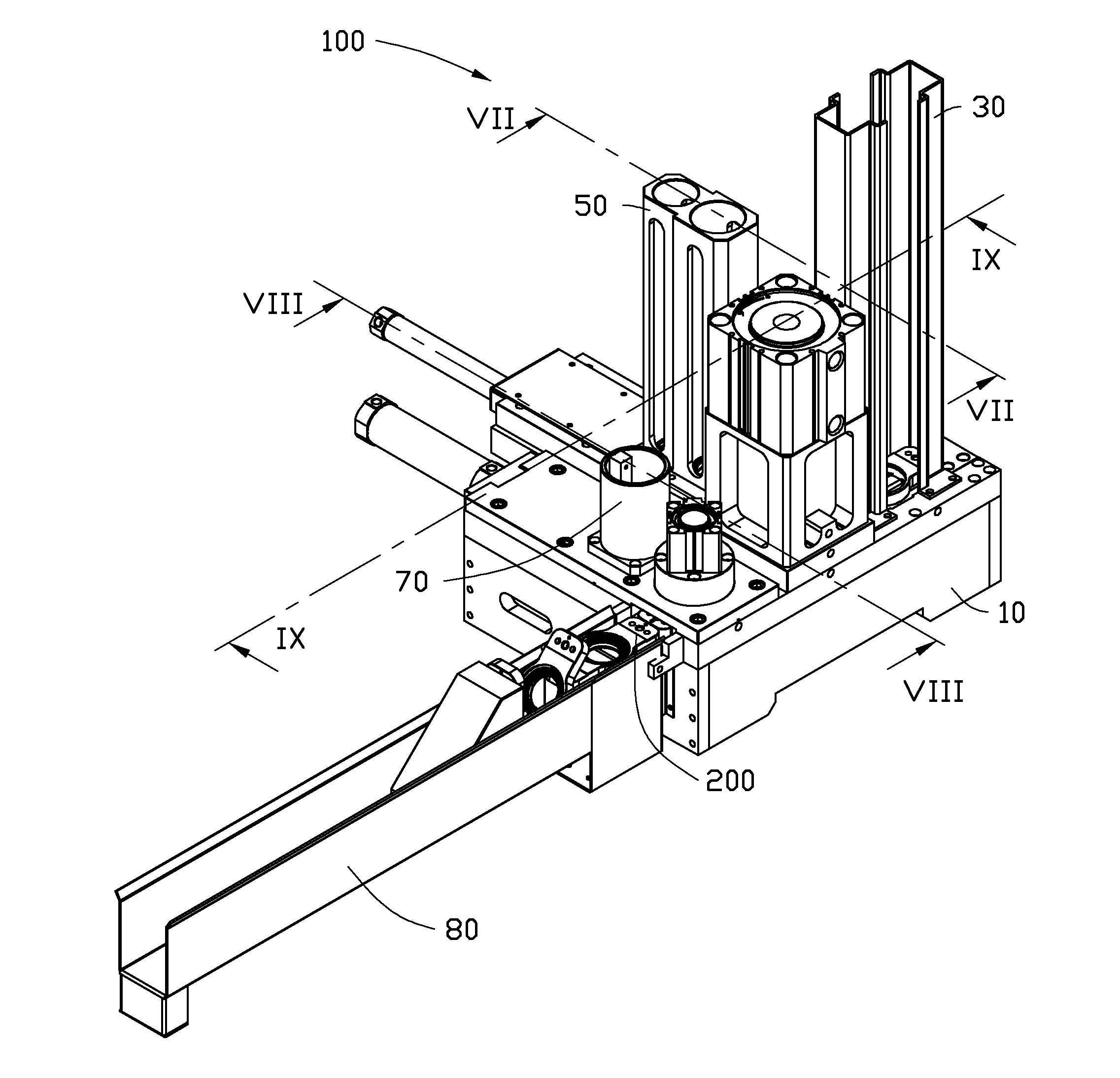

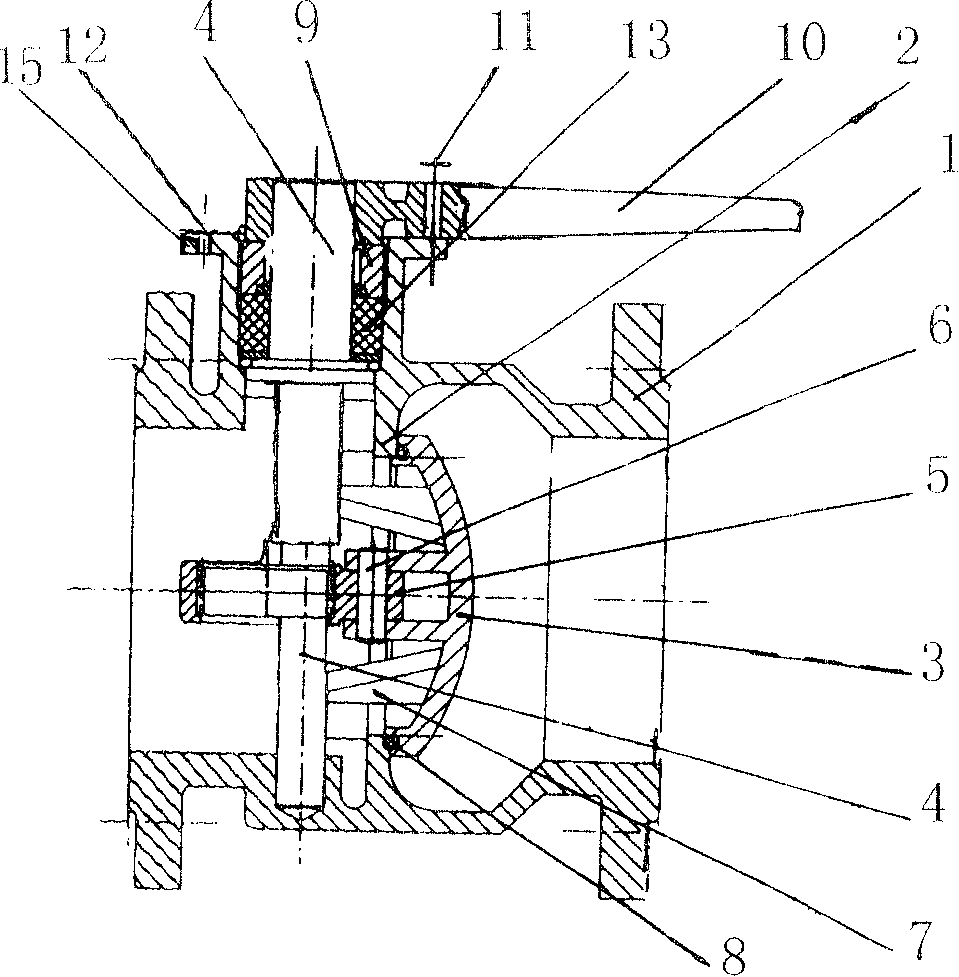

Assembly apparatus for bearing assembly

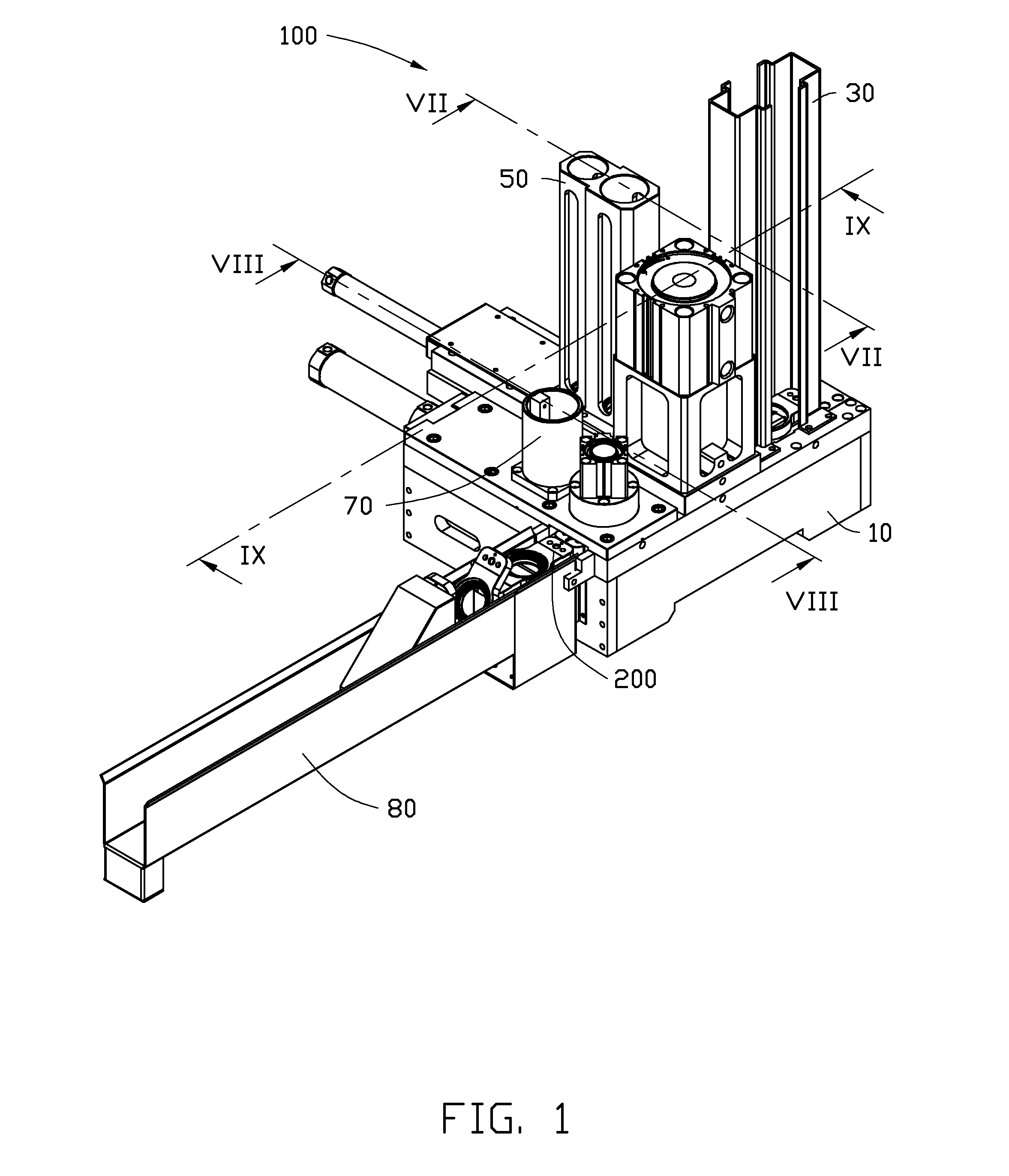

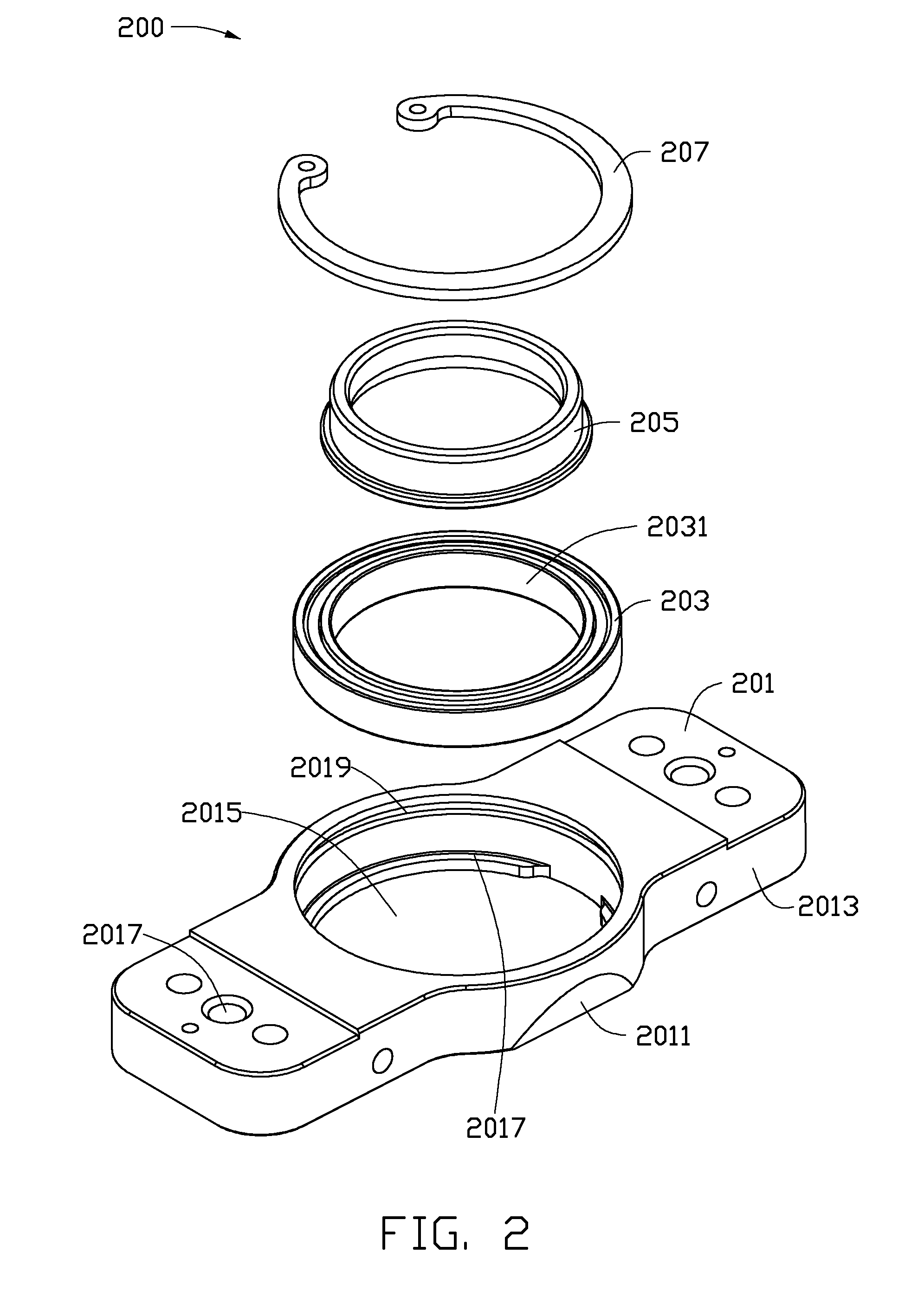

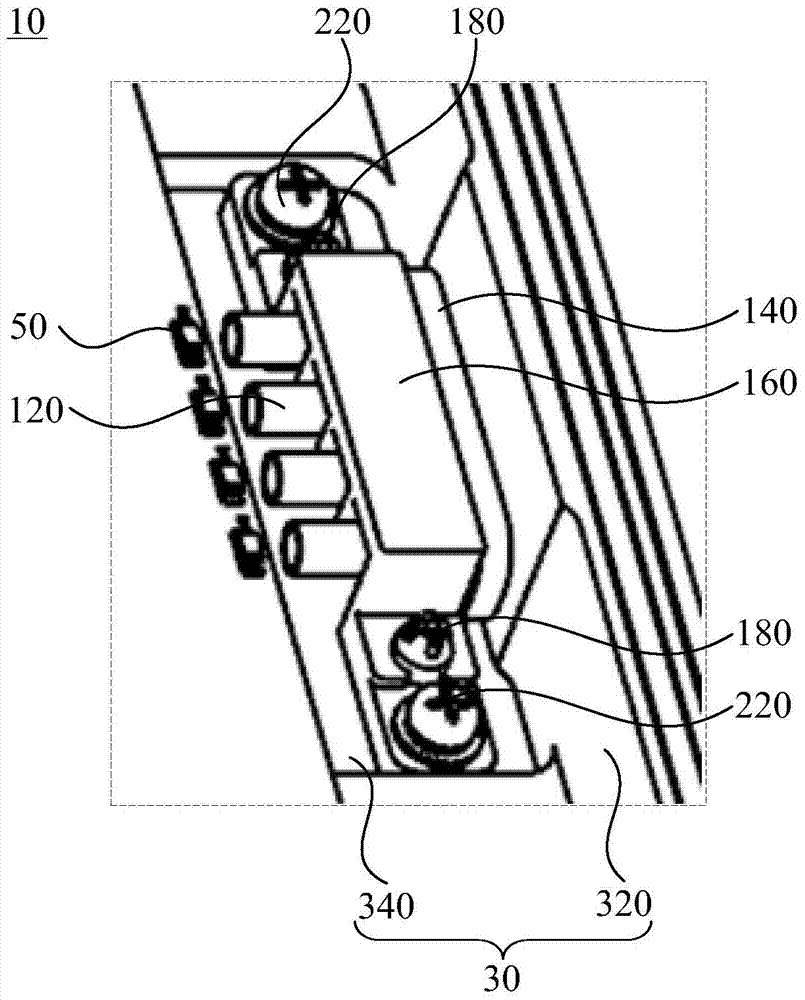

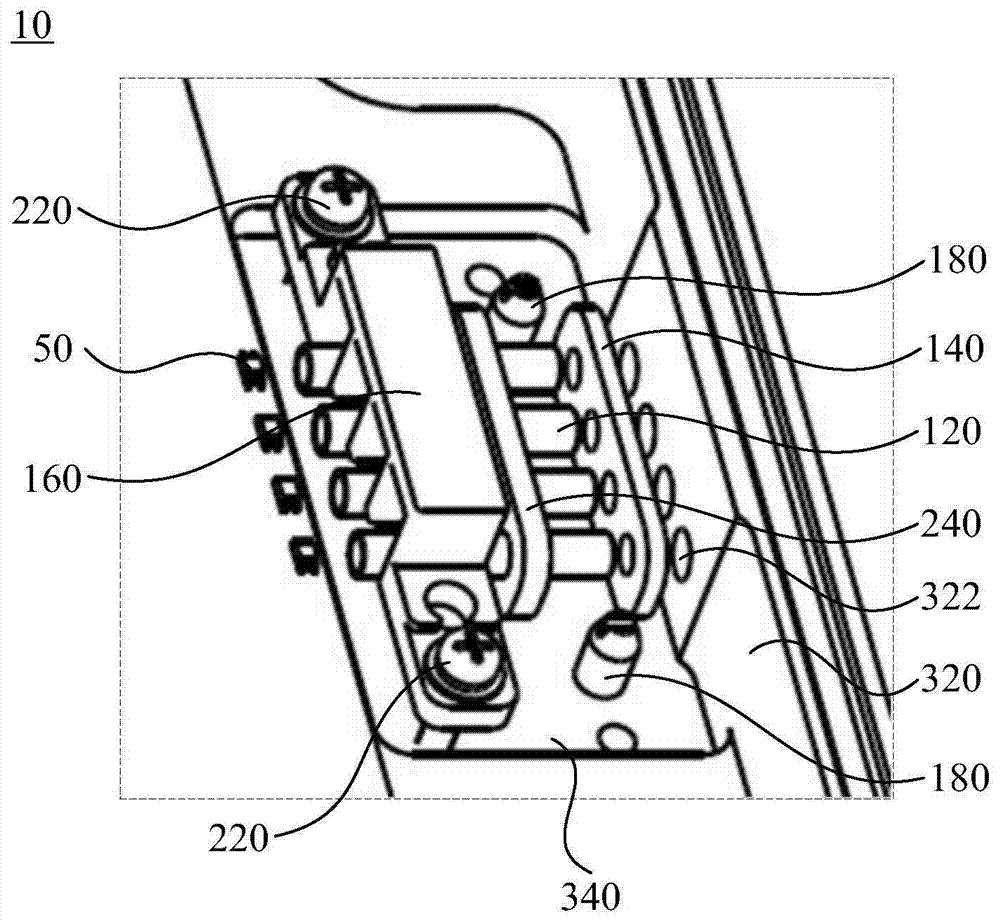

InactiveUS20130212850A1Low efficiencyEasy to rustBearing assemblyShaft assemblyEngineeringTransfer mechanism

An assembly apparatus for automatically assembling a bearing assembly includes a base, a transferring mechanism, a first assembly mechanism, and a second assembly mechanism. The transferring mechanism is movably mounted on the base, for transferring and positioning the bearing seat. The first assembly mechanism is mounted on the base adjacent to the transferring mechanism, for installing the bearing and the bushing into the mounting hole of the base. The second assembly mechanism is mounted on the base adjacent to the first assembly mechanism, for installing the latching ring into the latching groove of the bearing seat.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Communication equipment and indicating lamp mounting structure thereof

InactiveCN106939982AFirmly connectedThe installation is firmLighting applicationsMechanical apparatusLight guideMechanical engineering

The invention relates to communication equipment and an indicating lamp mounting structure thereof. The indicating lamp mounting structure comprises light guide columns, a sealing piece and a pressing plate; one end surface of each light guide column is a light inlet surface, and the other end surface of each light guide column is a light outlet surface; each light guide column is inserted into a via hole in a side wall of a shell; the light outlet surfaces are exposed out of the shell; the sealing piece is provided with through holes matched with the light guide columns in shape; the sealing piece sleeves the light guide columns through the through holes, and is in tight fit with the light guide columns; one side of the sealing piece abuts against the side wall; the pressing plate is connected to the bottom surface of the shell; and the pressing plate extrudes the other side of the sealing piece, so that the sealing piece seals a gap between the light guide columns and the side wall. The indicating lamp mounting structure is positioned in the shell, and is reliable in structure connection, excellent in sealing effect, simple in structure and low in cost, and the conditions that screws are liable to get rusty due to be exposed out of the equipment and the sealing piece is liable to failure due to being exposed to external environment in a long time are avoided, so that the waterproof performance, the corrosion resistance and the reliability are improved.

Owner:ZTE CORP

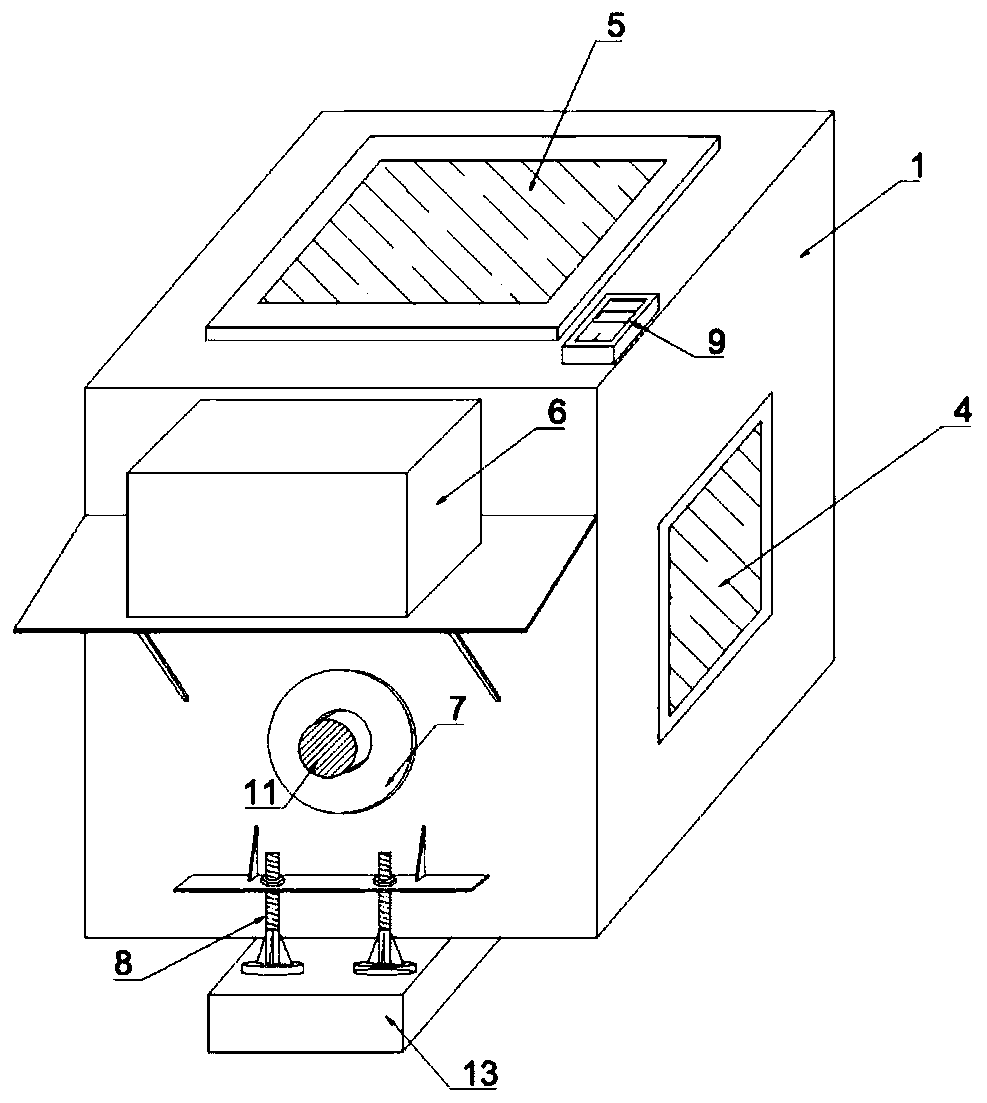

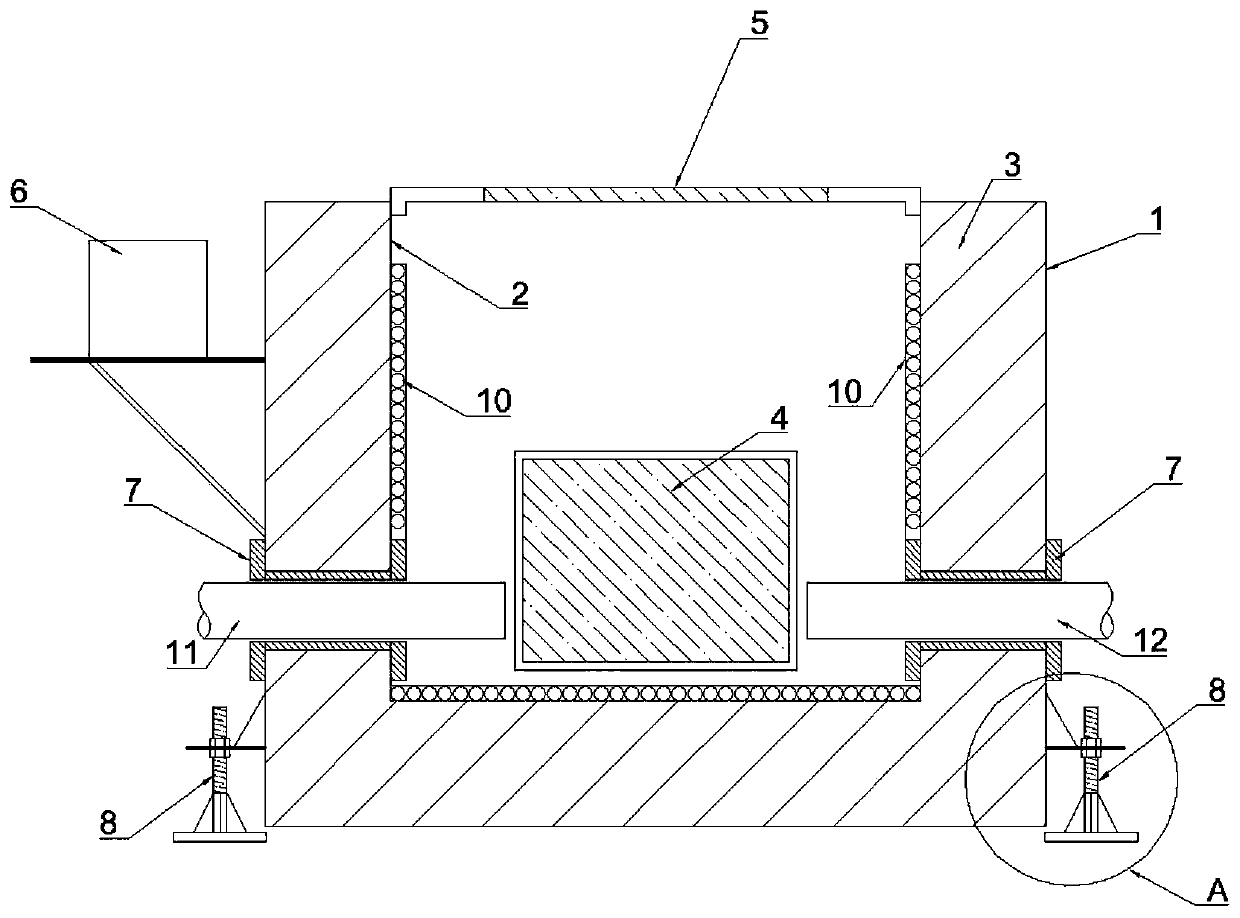

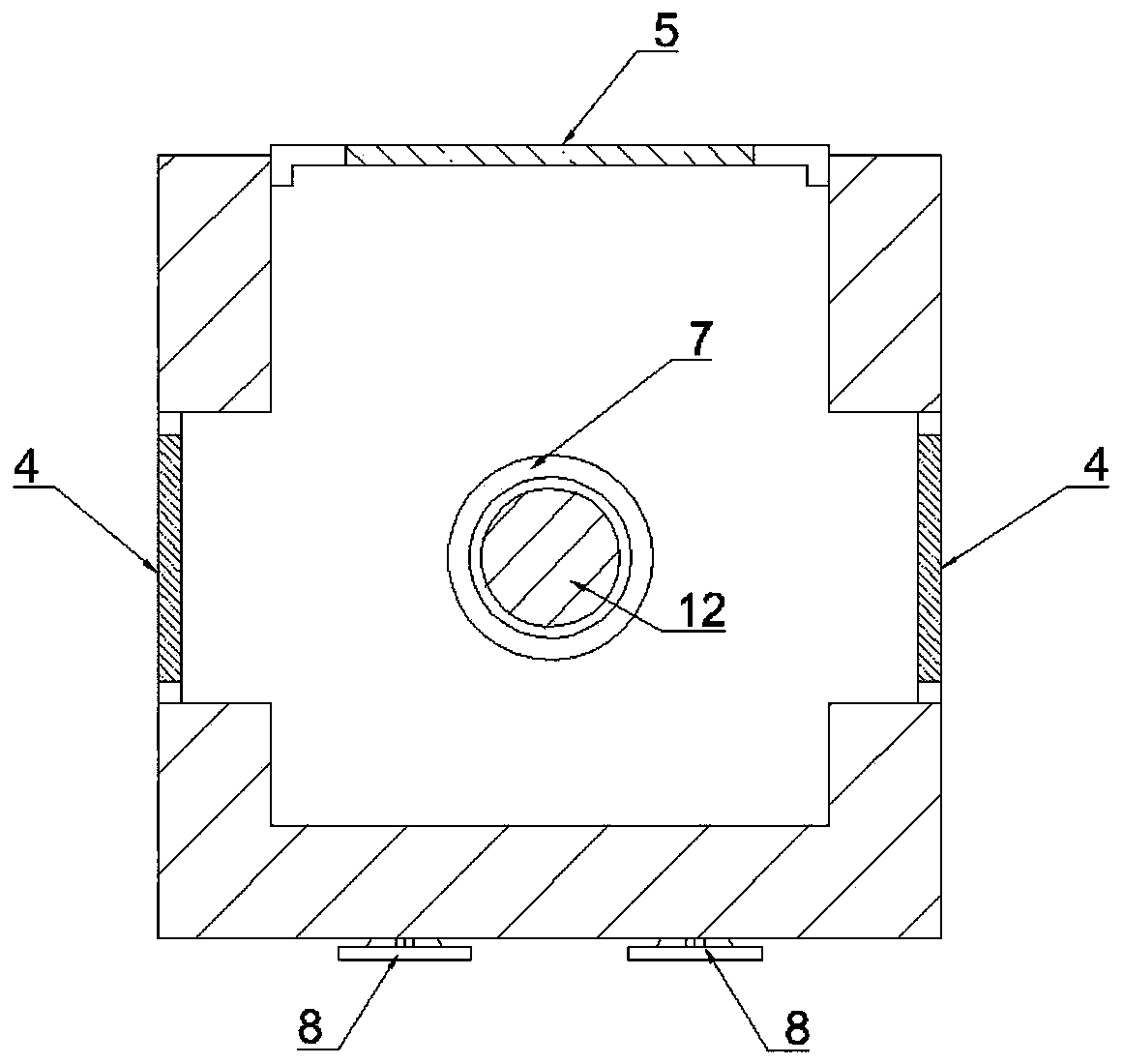

Low-temperature environmental chamber used for performing Hopkinson bar experiment on ice material

InactiveCN110763576AImprove securityMature and reliable technologyMaterial strength using single impulsive forceThermal insulationControl system

The invention belongs to the technical field of experimental facilities used for testing dynamic mechanical properties of a material in a low-temperature environment and in particular relates to a low-temperature environmental chamber used for performing a Hopkinson bar experiment on an ice material. The low-temperature environmental chamber comprises a thermal insulation system, a refrigeration temperature control system and an experiment and observation system; a thermal insulation material fills a gap between an outer chamber body and an inner chamber body, a polytetrafluoroethylene sealingpart is arranged at the periphery of each of left and right rod holes; a compressor and a cooling fan are mounted on a platform outside a chamber body; a refrigeration pipe and an aluminum plate aremounted on the bottom surface and the left and right inner walls of the cavity of the inner chamber body; a temperature sensor is composed of a display screen and a temperature measuring probe, the temperature measuring probe is mounted in an experimental cavity, and the display screen is mounted outside the chamber body; and high-transparency glass observation windows are mounted in front, on theback and at the upper part of the chamber body. The low-temperature environmental chamber provided by the invention selects Freon as a refrigerant, a technology is mature and reliable, and cost is low, so that an experimental temperature can be maintained to be stable for a long time. The observation windows are formed in three directions respectively, so that illumination and image acquisition are facilitated in an experiment process.

Owner:HARBIN ENG UNIV

Composite magnetic material and process for production thereof

ActiveUS20130136933A1Excellent direct superposition propertyImprove corrosion resistanceInorganic material magnetismInductances/transformers/magnets manufactureShell moldingMetal

A composite magnetic material manufactured by mixing a metal magnetic powder with an insulating binder to produce a mixed powder, press-molding the mixed powder to produce a molded product, and heat-treating the molded product in an oxidizing atmosphere at not lower than 80° C. and not higher than 400° C. to form an oxide film on a surface of the molded product. The metal magnetic powder includes Si, Fe, and component A, and the composition thereof satisfies 5.5%≦Si≦9.5%, 10%≦Si+component A≦13.5%, and the remainder is Fe, where % denotes weight %. The component A includes at least one of Ni, Al, Ti, and Mg.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

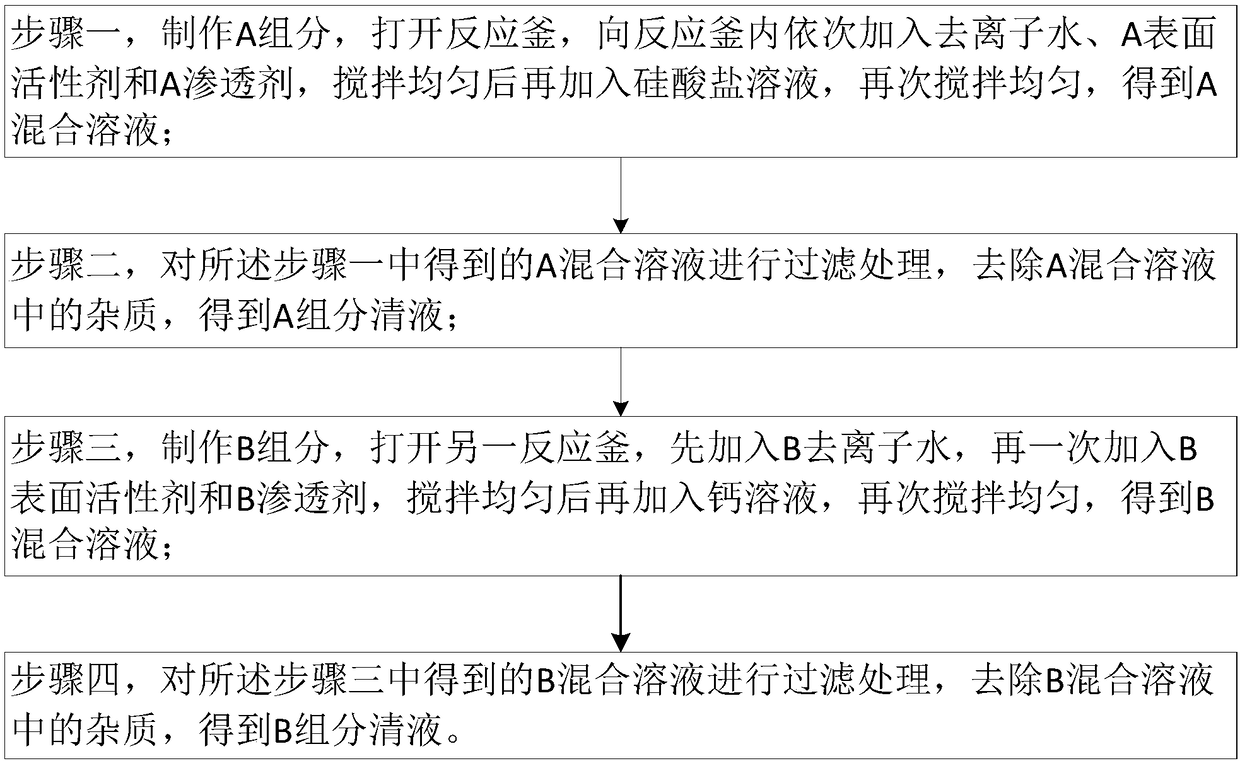

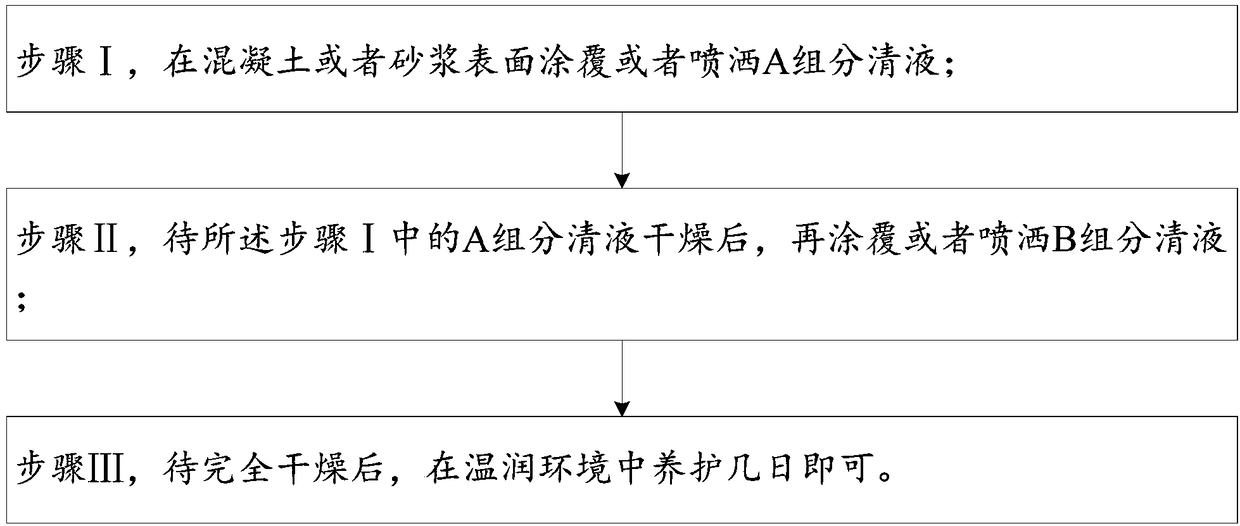

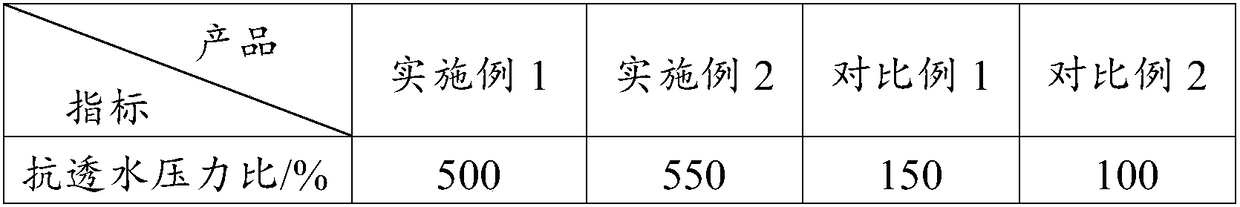

Two-component concrete surface modification material, preparation and use method thereof

Relating to the technical field of building materials, the invention discloses a two-component concrete surface modification material, a preparation method and use method thereof. The two-component concrete surface modification material comprises a component A and a component B, by weight percentage, the component A comprises 30-60% of a silicate solution, 0.05-0.15% of a surfactant A, 0.5-1.5% ofa penetrant A, and 38.35-69.45% of deionized water A, and the component B comprises 20-50% of a calcium solution, 0.01-0.05% of a surfactant B, 0.3-1.0% of a penetrant B, and 48.95-79.69% of deionized water B. According to the invention, the component A serves as the reactant, the component B serves as the assistant, calcium nitrite ions enter concrete in an aqueous solution form, meet the steelbar, react with iron ions when encountering a steel bar to generate a passivation film again to protect the steel bar and prevent rusting of the steel bar, the calcium solution is added into the component B and solves the problem of few calcium ions in concrete or mortar, and for concrete or mortar with large porosity or seriously carbonized surface layer, more calcium silicate crystals can be produced to fill the pores so as to reach a best modification effect.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

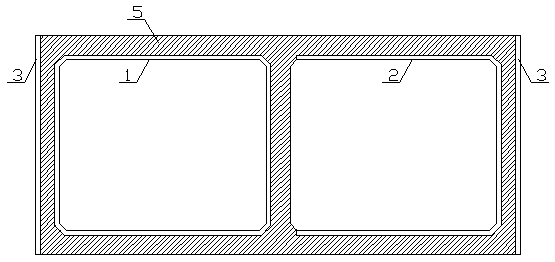

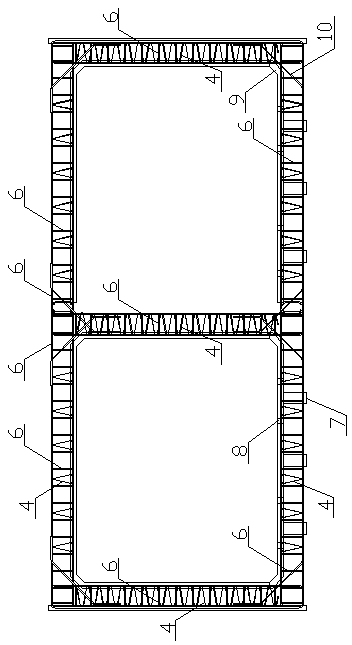

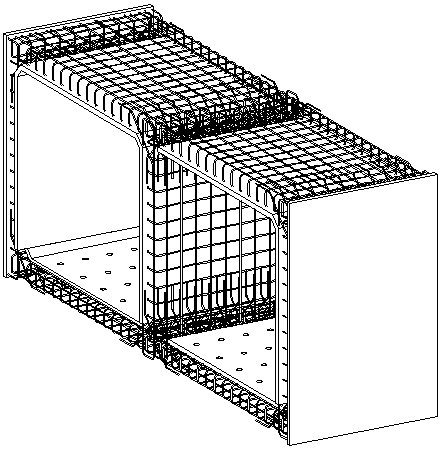

Combined integral assembly superposed box culvert and construction method

PendingCN108049318AEasy to rustAvoid secondary pollutionArtificial islandsGround-workRoad surfaceRebar

The invention provides a combined integral assembly superposed box culvert and a construction method. An existing integral prefabricated box culvert is high in weight, the model of a site crane is large, the requirement for hardening conditions of a pavement at the crane position is high, box culverts are connected by adopting a dry method, and the requirement for the connection accuracy is high.The combined integral assembly superposed box culvert is composed of an annular inner wall (1), a C-shaped inner wall (2) and a supporting outer wall (3), the annular inner wall, the C-shaped inner wall and the supporting outer wall and all prefabricated concrete layers, a steel reinforcement framework is a box culvert steel reinforcement framework, the box culvert steel reinforcement framework isa double-layer double-way steel reinforcement integral framework composed of a box culvert top plate, an internal wall, an external wall and a bottom plate, the annular inner wall is connected with the supporting outer wall through lattice rebars (4), the C-shaped inner wall is connected with the supporting outer wall through the lattice rebars (4) as well, and cast-in-place concrete (5) is poured into the superposed part of cavities, the top plate and the bottom plate, wherein the the cavities are formed between the annular inner wall and the C-shaped inner wall, the annular inner wall and the supporting outer wall as well between the C-shaped inner wall and the supporting outer wall. The utility model is applied to the combined integral assembly superposed box culvert.

Owner:湖北宇辉中工建筑产业化有限公司

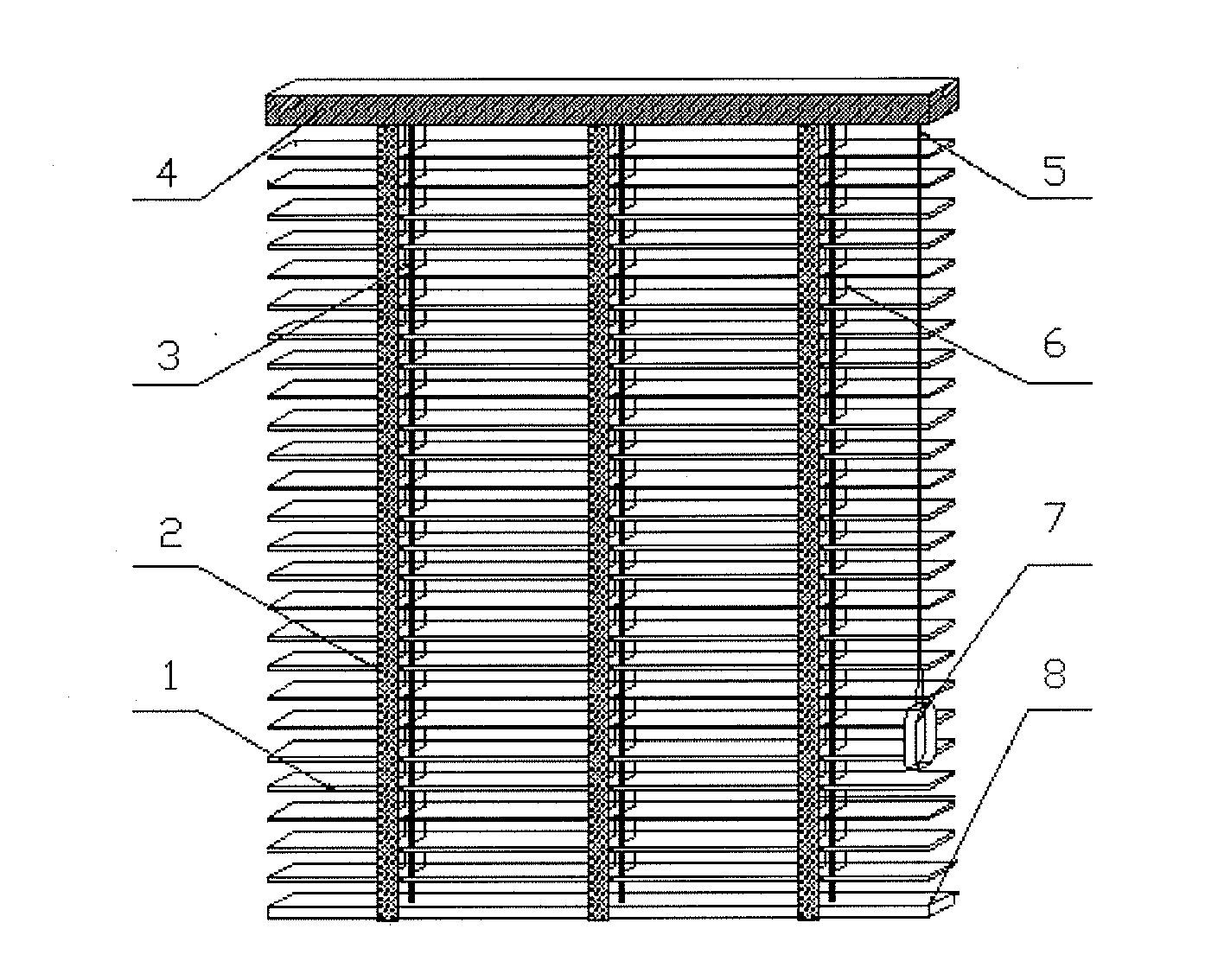

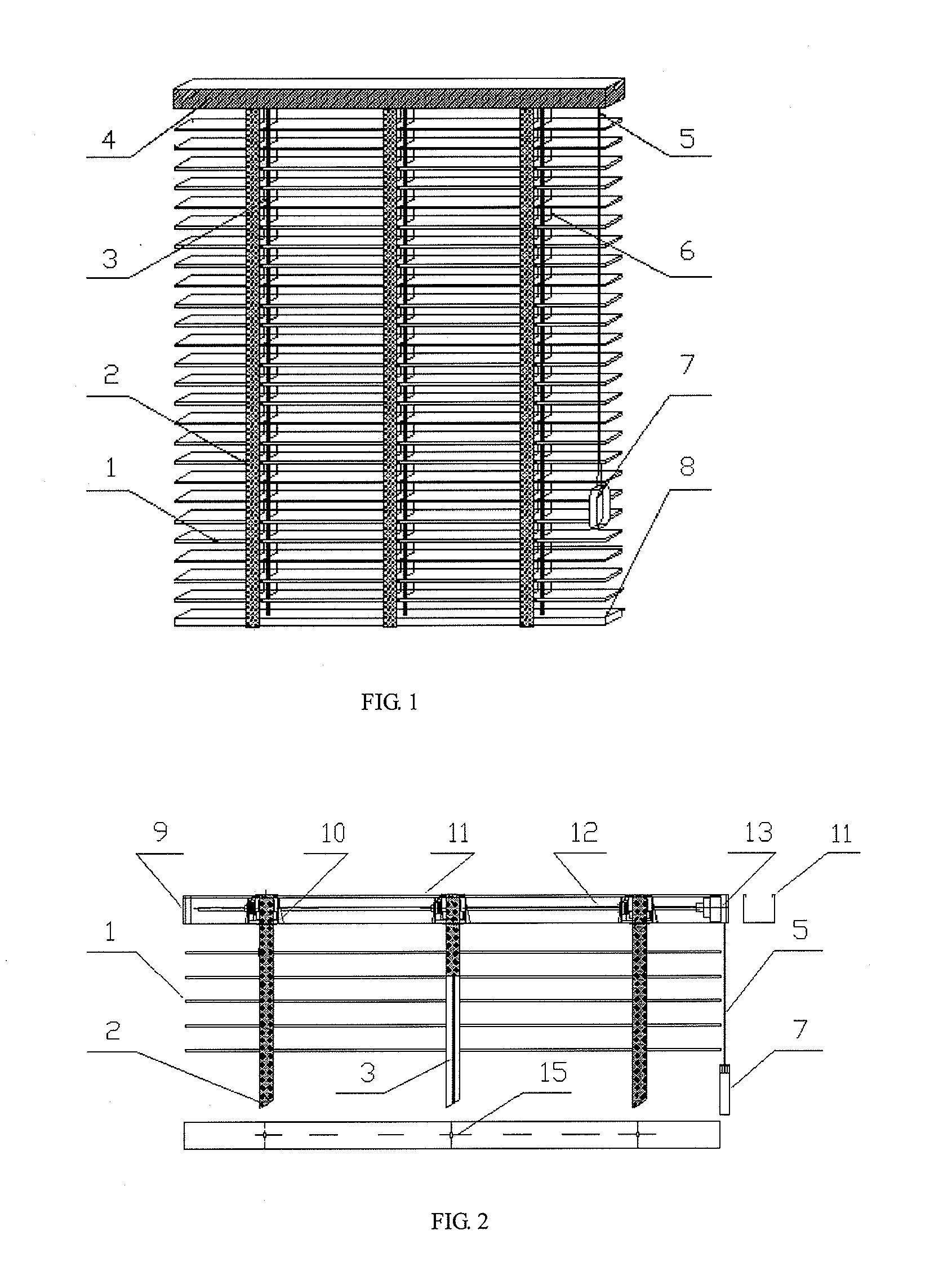

Lifting type venetian blind

A lifting Venetian blind having a rope lock device is equipped at an end of a head rail, a side cover is equipped at another end of the head rail, a piece of transverse shaft is equipped in a head rail assembly system, an end of the piece of transverse shaft is loaded in the rope lock device, and another end of the piece of transverse shaft is equipped with elevator components, which include an elevator connection seat, a ladder belt cover wheel brake shaft, a cloth wheel stop bit elastic device, a ladder belt cover wheel, a bearing block, a bearing, and an elevator belt rotating wheel. It solves a problem of light leaking through a hole on a blind slat to the greatest extent possible. When the blind is raised or lowered, an elevator belt is easily on and off and not mutually winding knot without noise.

Owner:LANDER IND (ZHEJIANG) CO LTD

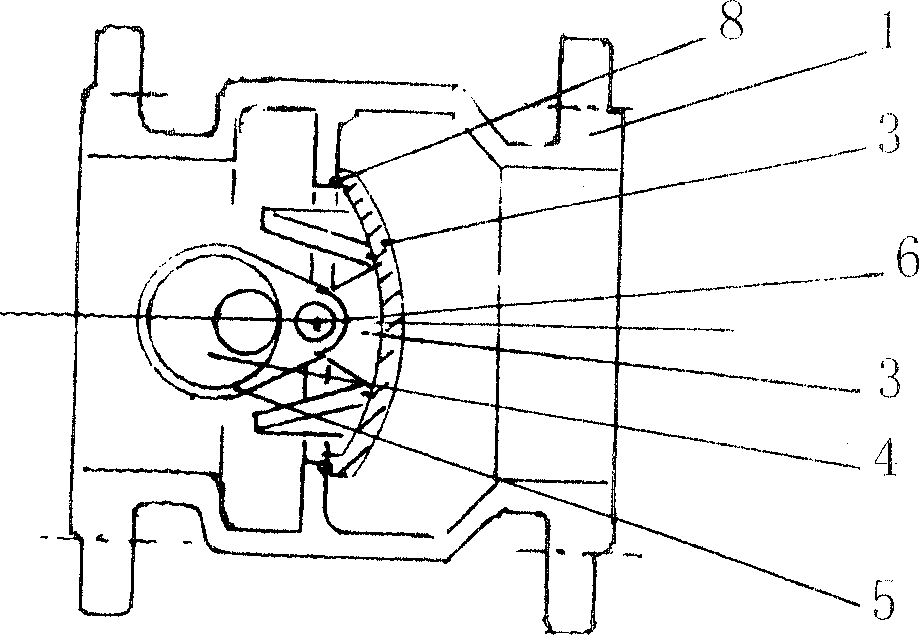

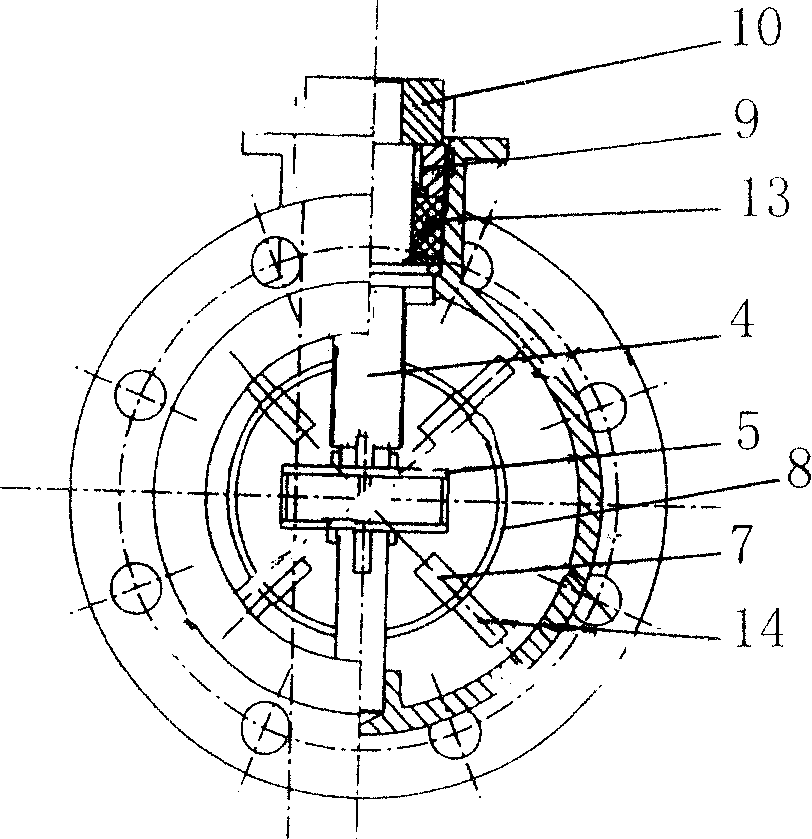

Cam valve

InactiveCN100398883CEasy to rustImprove airtightnessOperating means/releasing devices for valvesLift valveEngineeringCam

Owner:常殿林

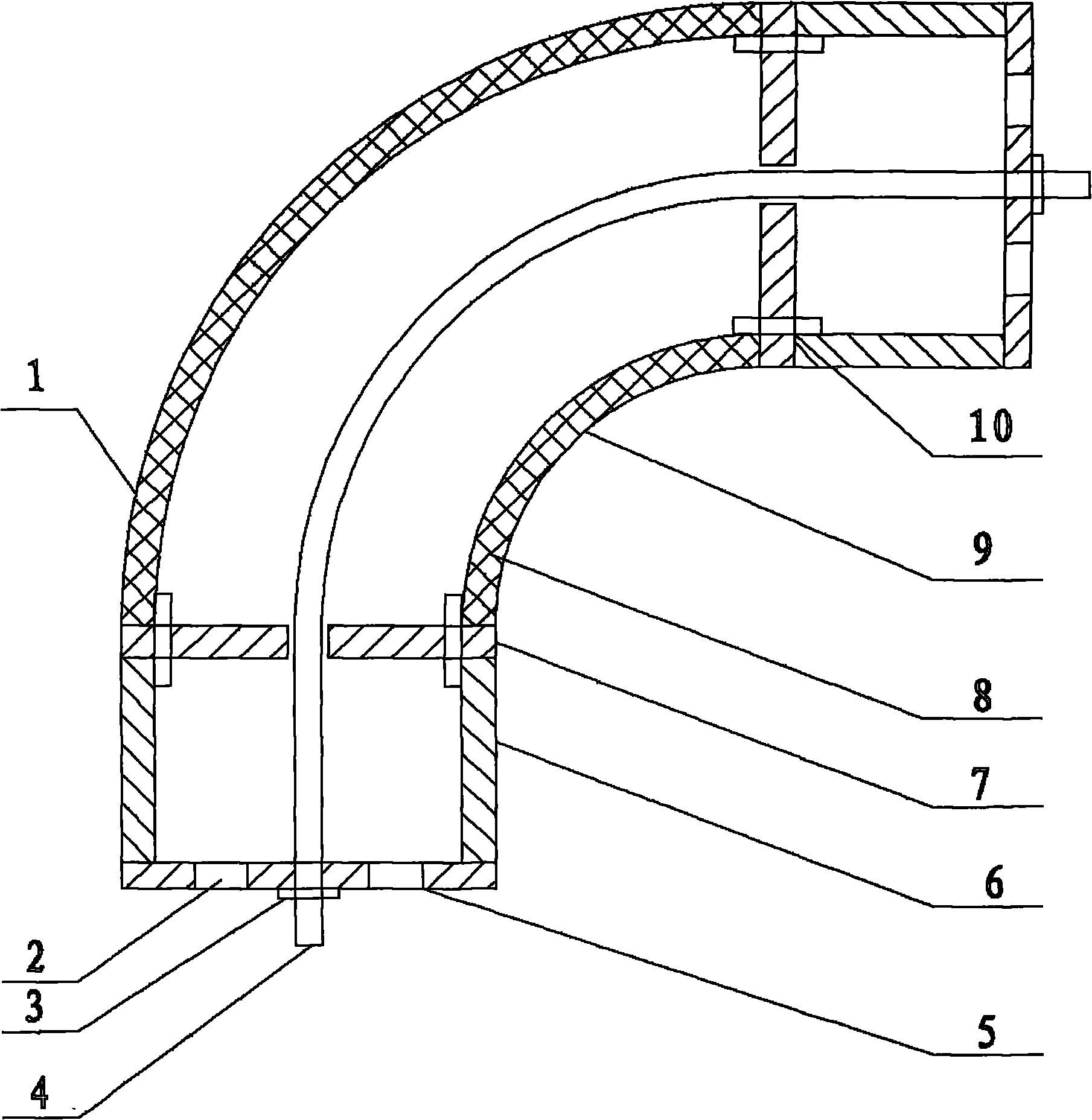

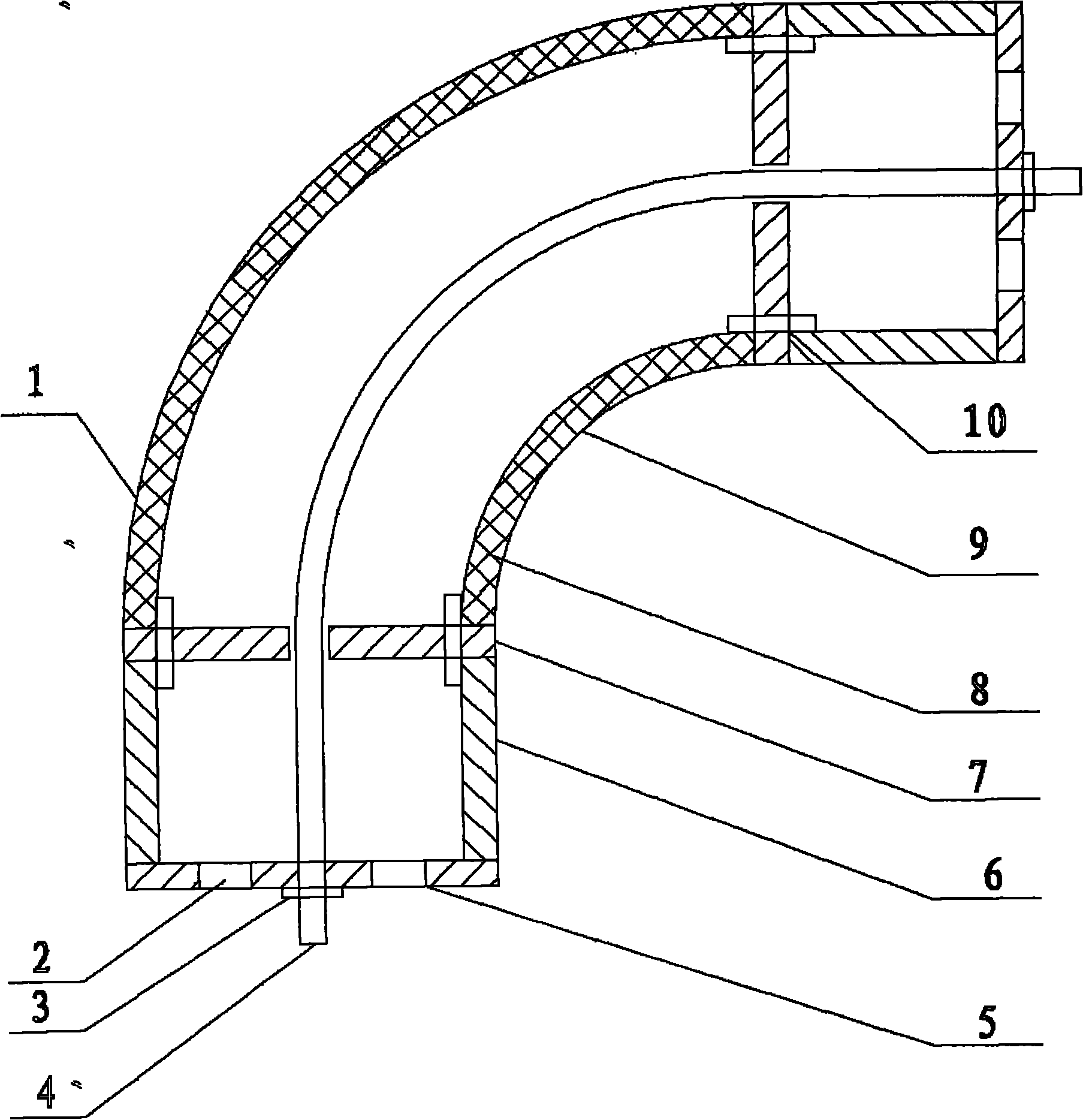

Glass reinforced plastic elbow die and manufacturing method thereof

InactiveCN102145519ASave materialMeet the requirements of hand lay-up processDomestic articlesProduction ratePlastic materials

The invention relates to a glass reinforced plastic elbow die and a manufacturing method thereof. The die comprises an end cover, a connection section die, an elbow die body, an intermediate plate and a pull rod. The elbow die body consists of an elbow inner template and an elbow outer template which are made of glass reinforced plastic material. The lengths of arc seams at both sides, which are butted in a matching mode, are at least 10mm. The connection section die is one of a straight tube connection section die, a butting connection section die, a socket connection section die and a lap joint flange connection section die. The manufacturing method of the elbow die body comprises the following steps of: 1, making a scraper; 2, making a cement die; 3, duplicating a glass reinforced plastic die; 4, carrying out machining; and 5, carrying out surface polishing treatment. The glass reinforced plastic elbow die and the manufacturing method solve the problem that the steel is easy to rust, are easy to repair, have the advantages of simple structure, high precision, high quality, high productivity and low manufacturing cost and are easy to demould. A product produced by the elbow die has a smooth inner wall, good seepage prevention performance and attractive appearance. The materials are saved. Due to the adoption of the elbow die, not only can the requirement of a hand lay-up process be met, but also the requirements of a mechanical winding process can be met.

Owner:奉玉贞

Protector for tubular threaded joint

A protector which prevents damage to a solid lubricating coating on a threaded portion of a threaded joint when the protector is mounted on a pin or a box of a threaded joint for pipes in which at least one of the pin or the box is lubricated with a solid lubricating coating comprises a tubular member having a threaded portion on its inner or outer peripheral surface which threadingly engages with at least a portion and preferably 3-5 complete threads of the threaded portion provided on the pin or the box to be protected. The thread height H1 of the threaded portion of the protector and the thread height H2 of the complete thread of the pin or the box on which the protector is mounted satisfy H1>H2, and the difference between H1 and H2 [=H1−H2] is larger than the maximum coating thickness at the thread crest of the solid lubricating coating which covers the threaded portion of the pin or the box.

Owner:NIPPON STEEL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com