Electrified accelerated corrosion reinforced concrete test device and method

A reinforced concrete, accelerated corrosion technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of not being able to simulate the natural corrosion of steel bars well, reduce the stress of concrete caused by corrosion products, and the corrosion products are easy to dissolve with the solution Exudation and other problems, to achieve the effect of preventing excessive moisture, large void ratio, and large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

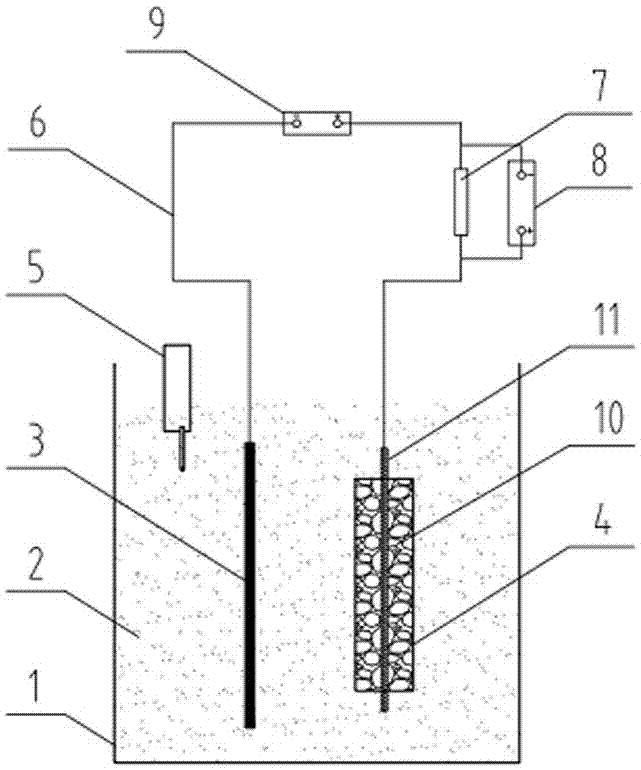

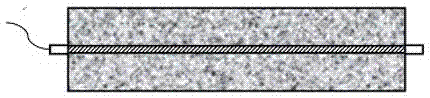

[0013] The present invention is a test device and test method for accelerated corrosion of reinforced concrete with electricity, such as figure 1 , figure 2 , image 3 As shown, the energized accelerated corrosion reinforced concrete test device of the present invention includes a casing 1, an electrolyte 2, a cathode 3, a reinforced concrete specimen 4, a humidity monitor 5, an electric wire 6, a resistor 7, a data recorder 8, and a DC power supply 9 , concrete 10, steel bars 11, the box 1 is a wooden box; the electrolyte 2 is wet salt sand, placed inside the box 1; the cathode 3 is placed vertically inside the electrolyte 2, and the DC power supply is connected to the The negative poles of 9 are connected; the reinforced concrete specimen 4 is made up of concrete 10 and steel bars 11, and the whole is vertically placed in the wooden box 1; the steel bars 11 are connected with the positive pole of the DC power supply 9 through electric wires 6, as energized anodes; Humidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com