Two-component concrete surface modification material, preparation and use method thereof

A technology of concrete surface and modified materials, which is applied in the field of building materials, can solve the problems of discounting the effect of modified materials, etc., and achieve the effects of good implementation effect, easy coating, and reduced surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

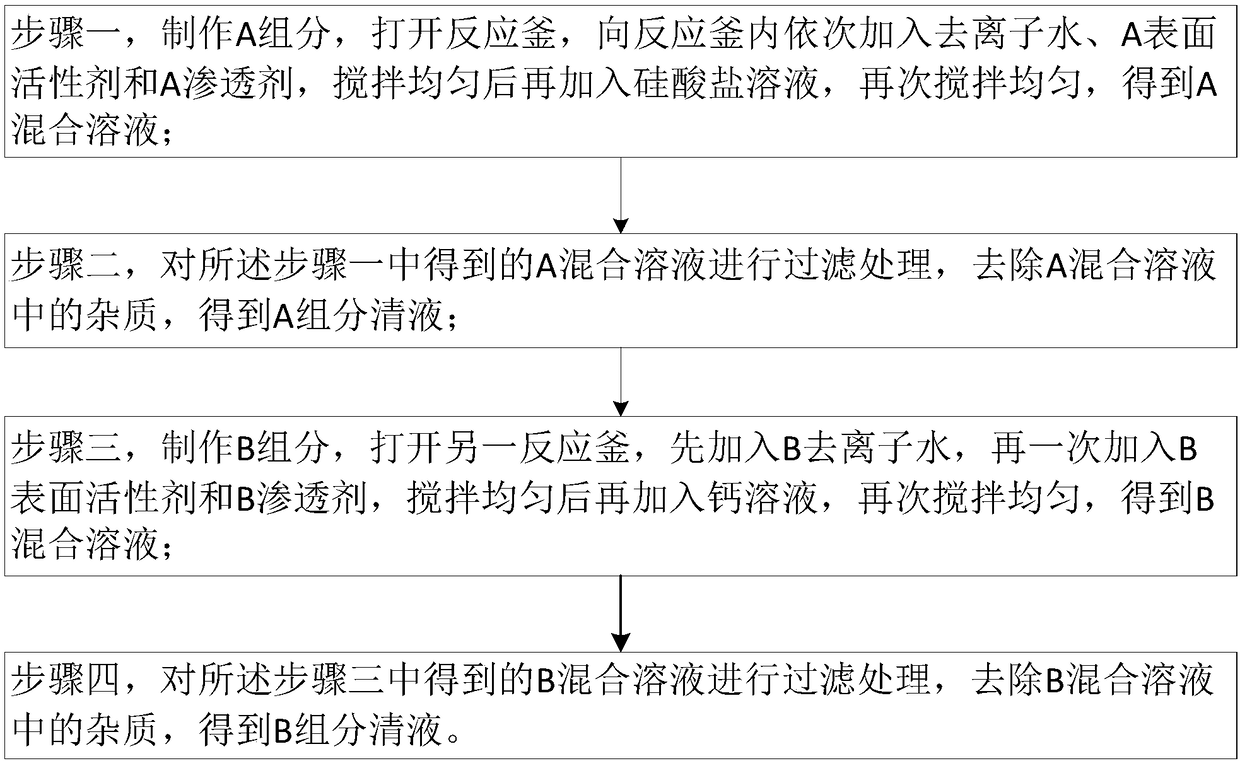

[0037] Such as figure 1Shown, a kind of preparation method of two-component concrete surface modification material comprises the steps:

[0038] Step 1: Make component A, open the reaction kettle, add deionized water, surfactant A and penetrant A into the reaction kettle in sequence, stir evenly, then add silicate solution, stir evenly again, and obtain A mixed solution;

[0039] Step 2, filtering the A mixed solution obtained in the step 1 to remove impurities in the A mixed solution to obtain the A component clear liquid;

[0040] Step 3: Make component B, open another reaction kettle, first add B deionized water, then add B surfactant and B penetrant, stir evenly, then add calcium solution, stir evenly again, and obtain B mixed solution;

[0041] Step 4: Filter the mixed solution of B obtained in step 3 to remove impurities in the mixed solution of B to obtain a clear solution of component B.

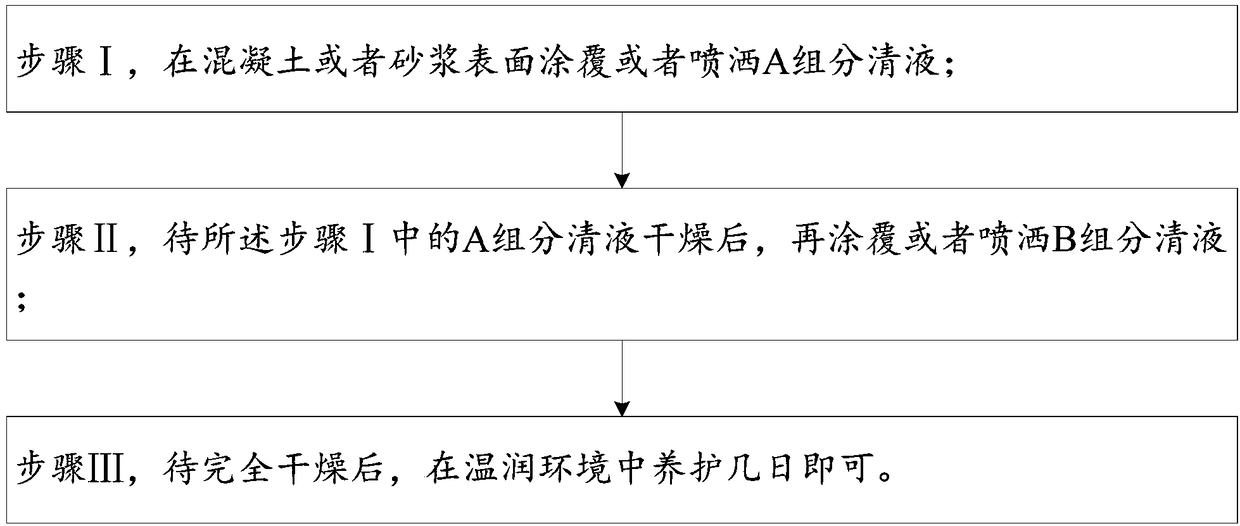

[0042] figure 2 It is a flowchart of a method for using a two-component conc...

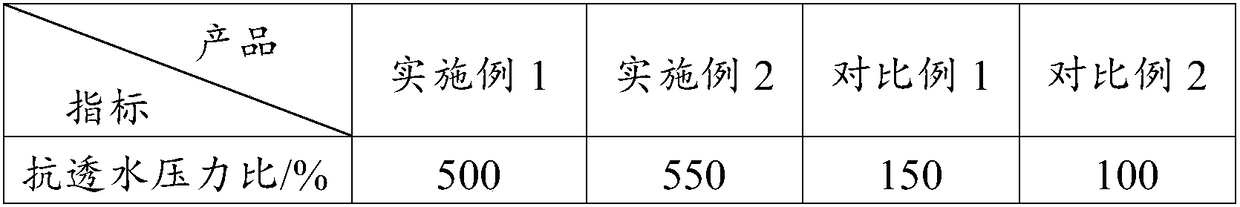

Embodiment 1

[0051] (1) Embodiment 1: (A component: sodium silicate solution 40%, sodium dodecylbenzenesulfonate 0.1%, glycerol 1%, deionized water 58.9%; B component: calcium nitrite solution 30%, sodium dodecylbenzenesulfonate 0.03%, glycerol 0.5%, deionized water 69.47%)

[0052] Preparation of component A: measure by weight, add 58.9kg of deionized water to the reactor in sequence, then add 0.1kg of sodium dodecylbenzenesulfonate and 1kg of glycerin, stir well and then add 40kg of sodium silicate solution, Stir evenly again to obtain a mixed solution of A, and filter the mixed solution of A to remove impurities in the mixed solution of A to obtain about 100 kg of the clear liquid of component A.

[0053] Preparation of component B: measure by weight, add 69.47kg of deionized water to the reaction kettle in turn, add 0.03kg of sodium dodecylbenzenesulfonate and 0.5kg of glycerin again, stir well and then add 30kg of calcium nitrite solution , Stir evenly again to obtain the B mixed sol...

Embodiment 2

[0055] (2) Embodiment 2: (A component: sodium silicate solution 50%, sodium dodecylbenzenesulfonate 0.12%, glycerol 1.3%, deionized water 48.58%; B component: calcium nitrite solution 40%, sodium dodecylbenzenesulfonate 0.04%, glycerol 0.8%, deionized water 59.16%)

[0056] Preparation of component A: measure by weight, add 48.58kg of deionized water to the reactor in turn, then add 0.12kg of sodium dodecylbenzenesulfonate and 1.3kg of glycerol, stir well and then add 50kg of sodium silicate solution , Stir evenly again to obtain the A mixed solution, filter the A mixed solution to remove impurities in the A mixed solution, and obtain about 100 kg of the A component clear liquid.

[0057] Preparation of component B: measure by weight, add 59.16kg of deionized water to the reaction kettle in turn, add 0.04kg of sodium dodecylbenzenesulfonate and 0.8kg of glycerin again, stir well, and then add 40kg of calcium nitrite solution , Stir evenly again to obtain the B mixed solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com