Patents

Literature

164 results about "Calcium nitrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium nitrite is an inorganic compound with chemical formula Ca(NO₂)₂. In this compound, as in all nitrites, nitrogen is in a +3 oxidation state. It has many applications such as antifreeze, rust inhibitor of steel and wash heavy oil.

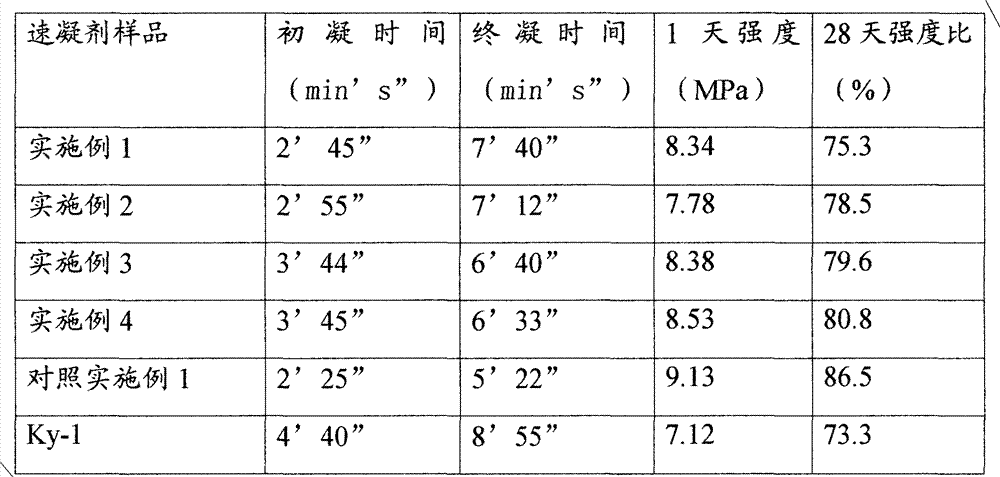

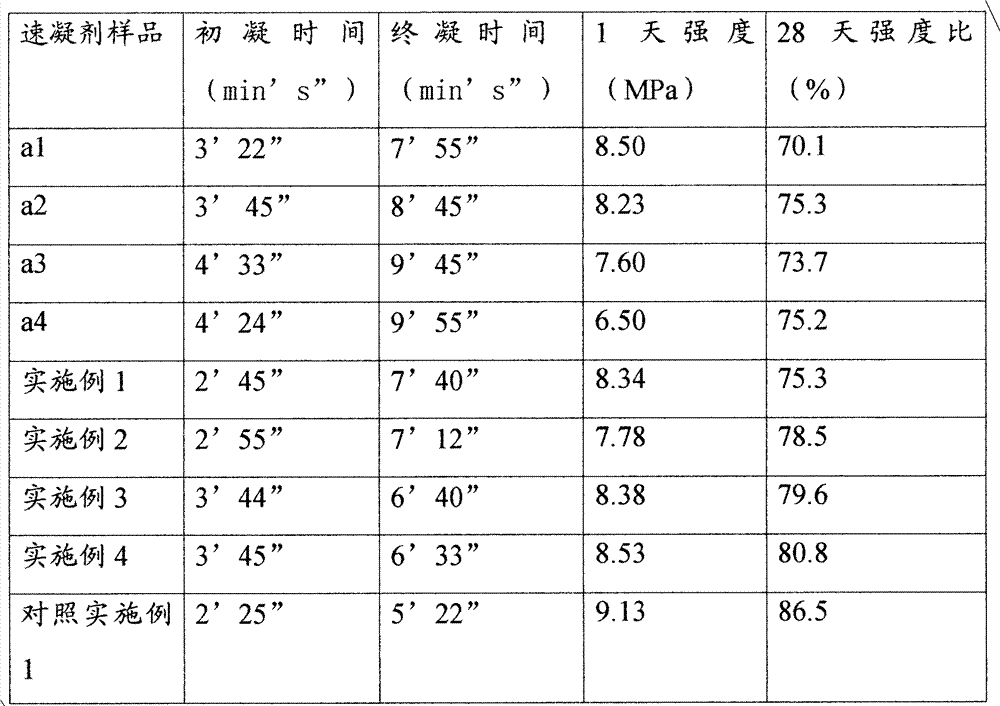

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

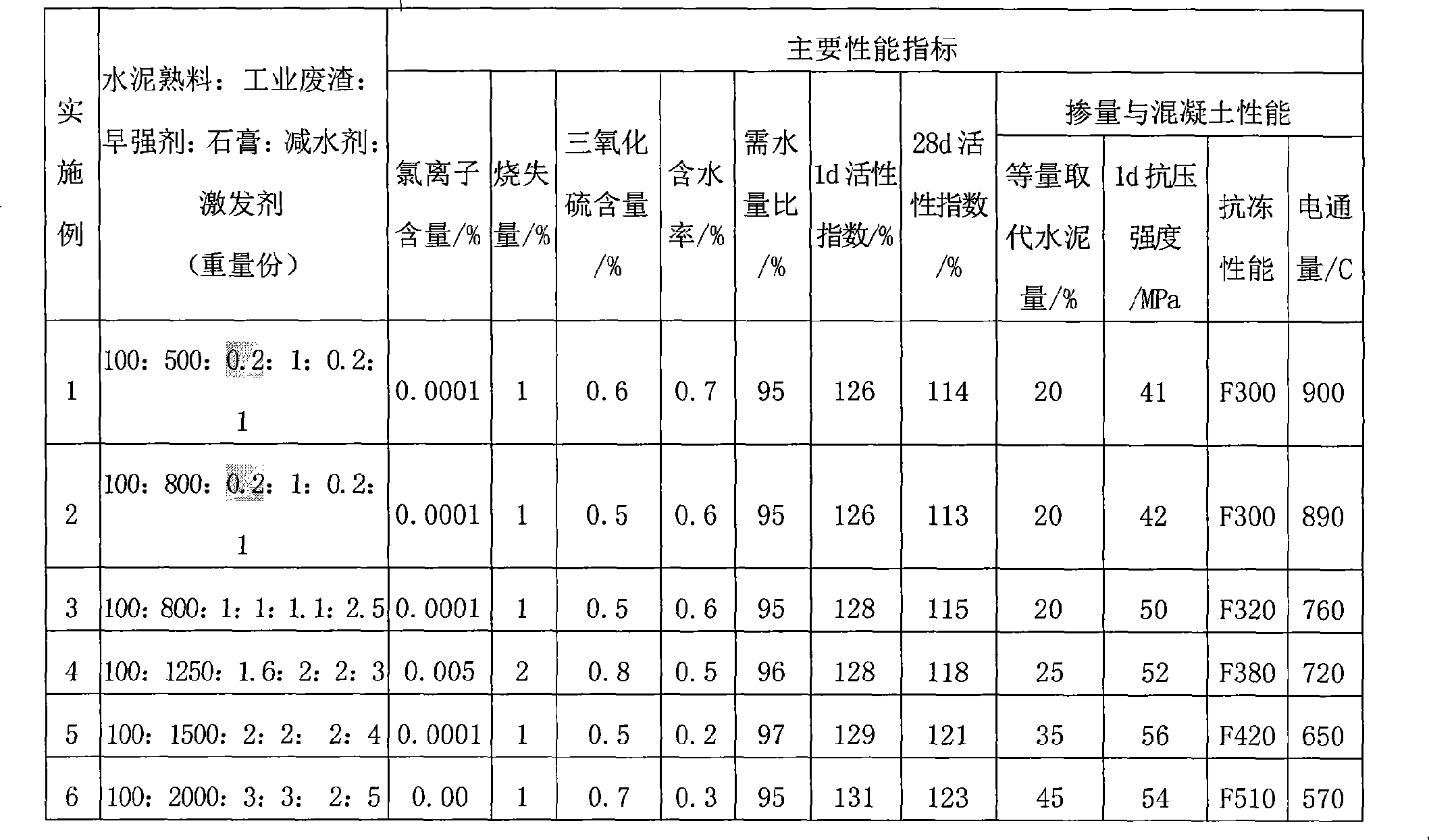

Blending material for high-early-strength concrete

InactiveCN101508557AImprovement of early strength and high strengthReduce dosageSolid waste managementHigh strength concreteCalcium formate

The invention relates to an admixture for high early strength of concrete, characterized in that the admixture is formed by mixing and stirring cement clinkers, industrial residues, early strength agents, plaster, water reducing agents and excitants. The parts by weight of the components are as follows: 100 parts of cement clinkers, 500-2000 parts of industrial residues, 0.2-3 parts of early strength agents, 1-3 parts of plaster, 0.2-2 parts of water reducing agents and 1-5 parts of excitants. The excitant is the mixture of aluminum hydroxide, calcium nitrite and calcium nitrate; wherein, the aluminum hydroxide accounts for 50% of the mixture while the calcium nitrite and the calcium nitrate are in any proportion; the early strength agent is the mixture of trolamine, lithium carbonate and calcium formate, wherein, the trolamine accounts for 50% of the mixture while the lithium carbonate and the calcium formate are in any proportion. The admixture for concrete provided by the invention has high activity index and low content of harmful ions. Adding the admixture can obviously improve the demoulding strength, long-term mechanical property and durability of the concrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Reverse Kleiner method for manufacturing nitrogen dioxide, nitric oxide, nitric acid, metallic ascorbates and alkyl ascorbates of vitamin C

In this invention new chemical reactions, new chemical processes are established, and these chemical reactions, chemical processes can be used with the designed system to produce nitrogen dioxide, nitric oxide and calcium ascorbate or calcium isoascorbate.The reaction vessel contains the aqueous ascorbic acid solution or aqueous isoascorbic acid solution. The temperature in the reaction vessel at the start of the reaction is at temp. 55° C. Into this solution is injected calcium nitrite dissolved in water. The gases generated by the chemical reactions are collected in the gas vessel.Here two sets of chemical reactions take place; one on the surface of the solution that produces the bulk of the gas mixture. In the liquid phase, the reactions go slow; and it gives nitric acid, calcium ascorbate and nitric oxide. Instead of calcium ascorbate one can use isoascorbate, in that case the chemical reactions will go somewhat slower.

Owner:KLEINER BELA

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

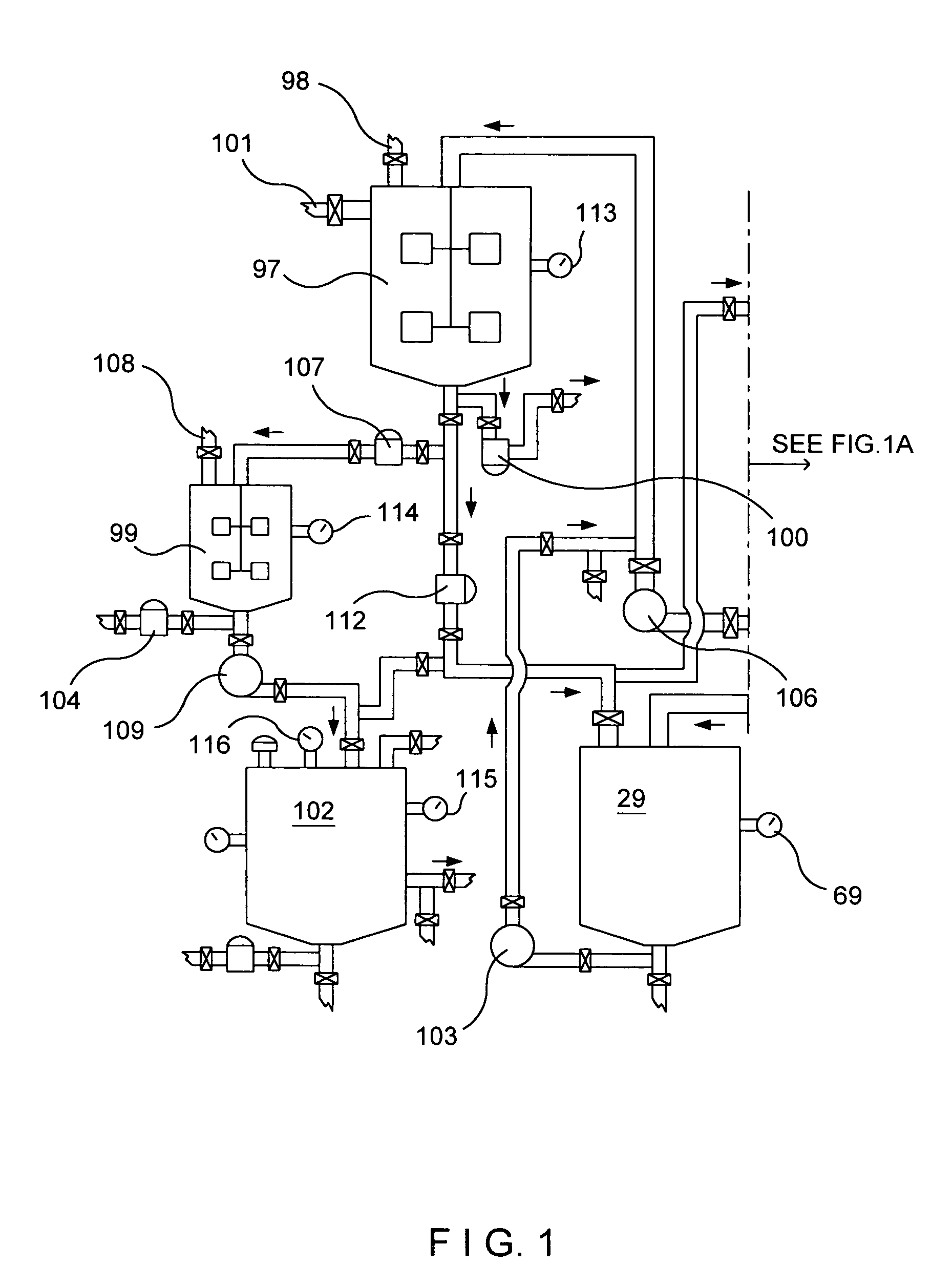

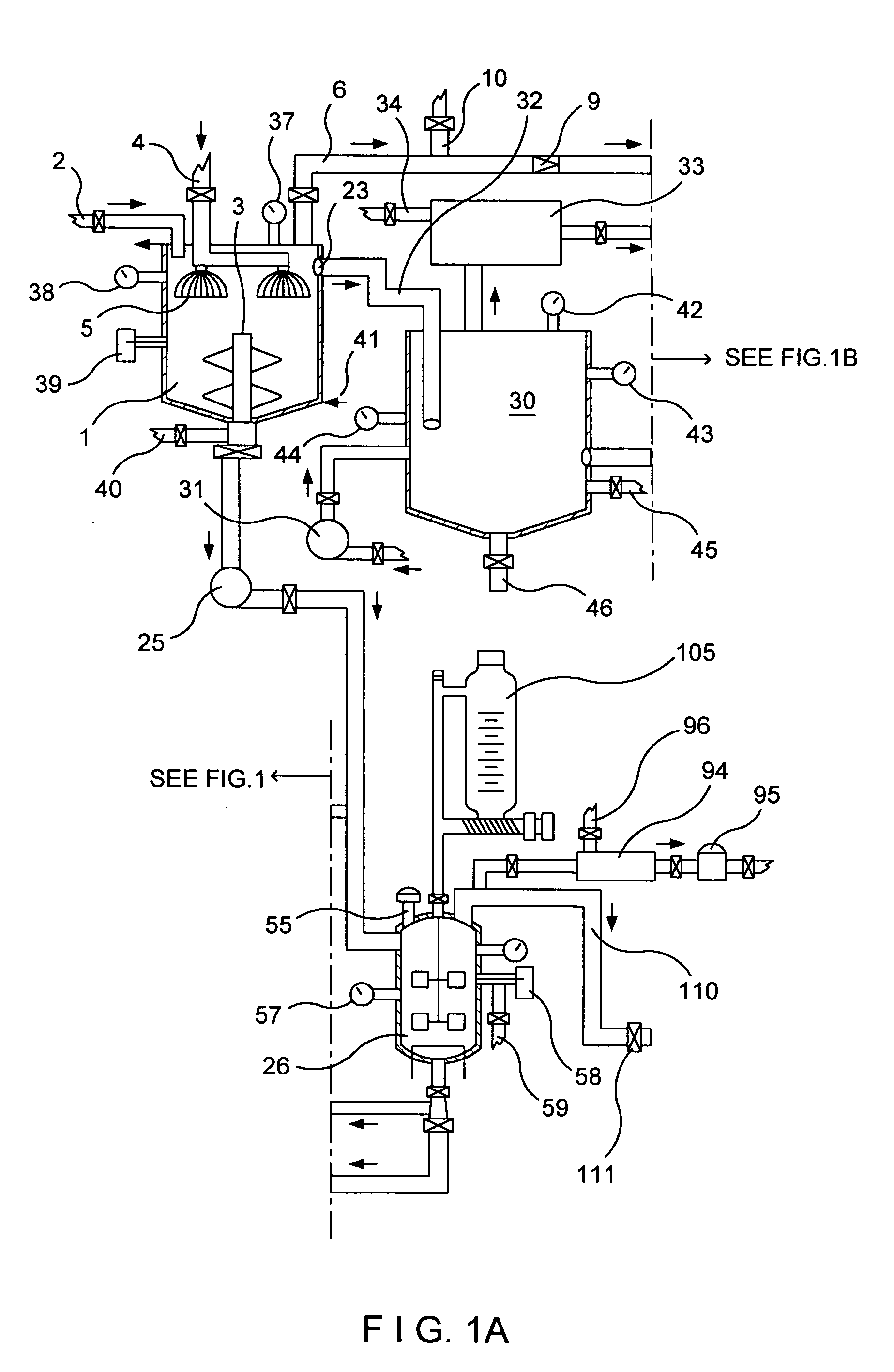

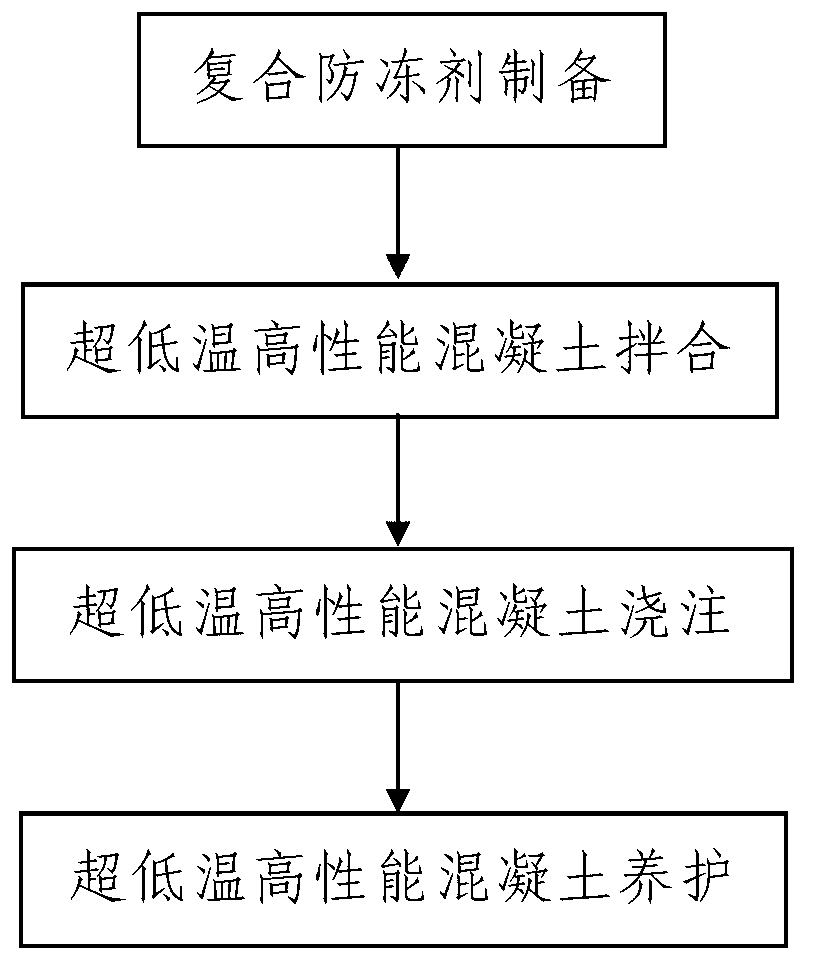

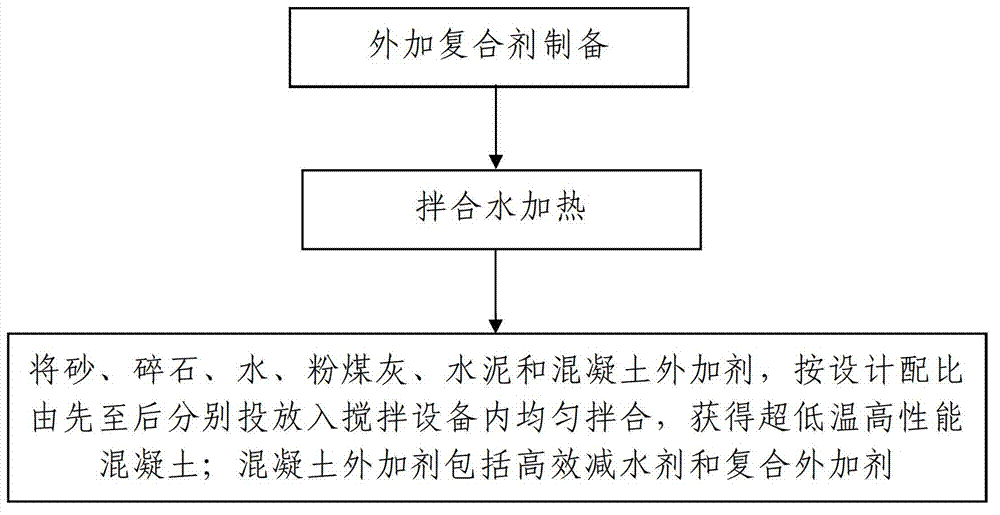

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358AThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

The invention discloses a construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas. The construction technique comprises the steps as follows: A, mixing ultralow-temperature high-property concrete: gelled materials, sand, crushed stone, an efficient water reducing agent, compound antifreeze and water are evenly mixed to obtain the ultralow-temperature high-property concrete; the gelled materials are made by evenly mixing cement and mineral admixtures in the weight ratio of (88-78):(12-22); the weight ratio of the compound antifreeze to the mineral admixtures is (3-6):100; the compound antifreeze comprises 30 to 35 wt% of nitrate, 30 to 33 wt% of organic compound, 0.5 to 1wt% of calcium formate, and water as the rest; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or alcohol; B, pouring the ultralow-temperature high-property concrete; and C, curing the ultralow-temperature high-property concrete. The construction technique has the advantages of reasonable design, simplicity in construction steps, convenience in operation, fast construction progress, low construction cost, and good structural quality of concrete used in construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

Flyash excitant

The flyash excitant has two different compositions. That for no-steel bar concrete consists of mirabilite 10-30 wt%, calcium chloride 10-30 wt%, sodium chloride 10-20 wt%, efficient water reducing agent 10-25 wt%, calcium lignosulfonate 1.5-7.0 wt% and ardealite 5-15 wt% other than carrier material. That for reinforced concrete consists of mirabilite 10-30 wt%, calcium chloride 10-15 wt%, sodium chloride 10-20 wt%, calcium nitrite 20-30 wt% efficient water reducing agent 6-10 wt%, calcium lignosulfonate 2-5 wt% and ardealite 5-15 wt% other than carrier material. The flyash excitant can excite the latent activity of flyash effectively so as to increase the added amount of flyash in concrete and lower the cost of concrete product.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Red-light fluorescent powder and method for making same

InactiveCN101157857AUniform phaseGood chemical stabilityLuminescent compositionsFluorescenceAmmonium metavanadate

The invention provides a red-emitting phosphor. The chemical structural formula of the phosphor material is Ca3(VO4)2:Eu3+. A preparation method of the phosphor is that calcium nitrite, europium nitrate, and citric acid with the mole ratio of 94:6:167-233 are dissolved in deionized water and mixture solution is obtained. Then ammonium metavanadate with proper quantity is added into the mixture and is heated and stirred for a certain time to get viscogel. In the end the hot viscogel is grinded and the product is made. The invention uses a citric acid sol-gel combustion method to prepare the nano Ca3(VO4)2:Eu3+ phosphor. The phosphor is uniform comparatively and has good chemical stability and luminescence with high efficiency. The cost is low. The preparation technology is simple and safe with low production temperature and can save energy.

Owner:SHANDONG UNIV

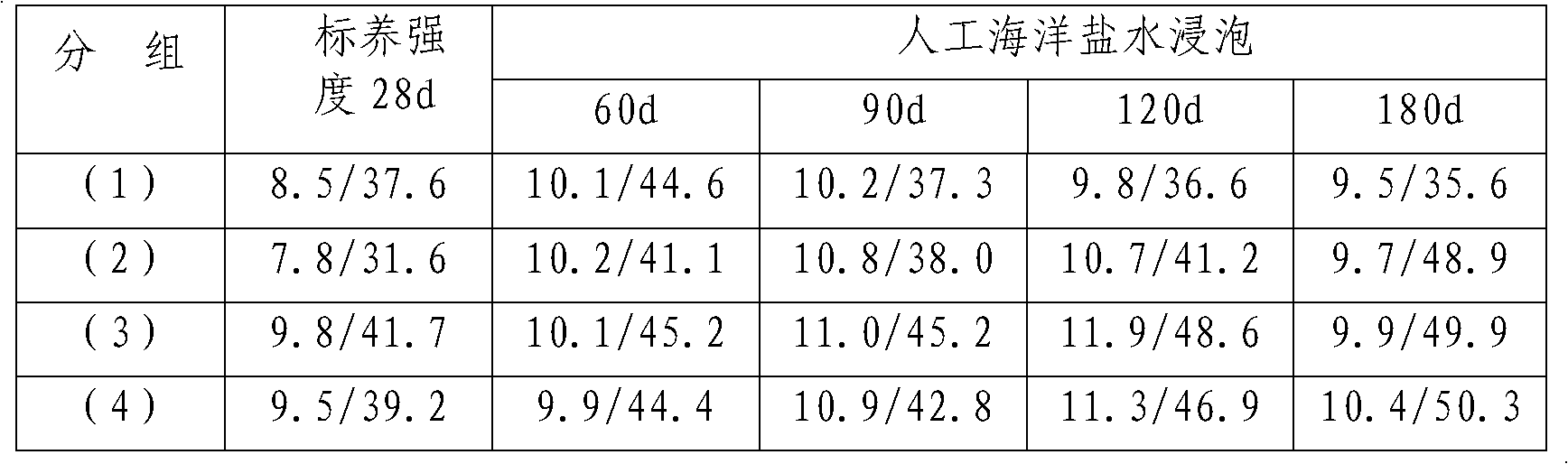

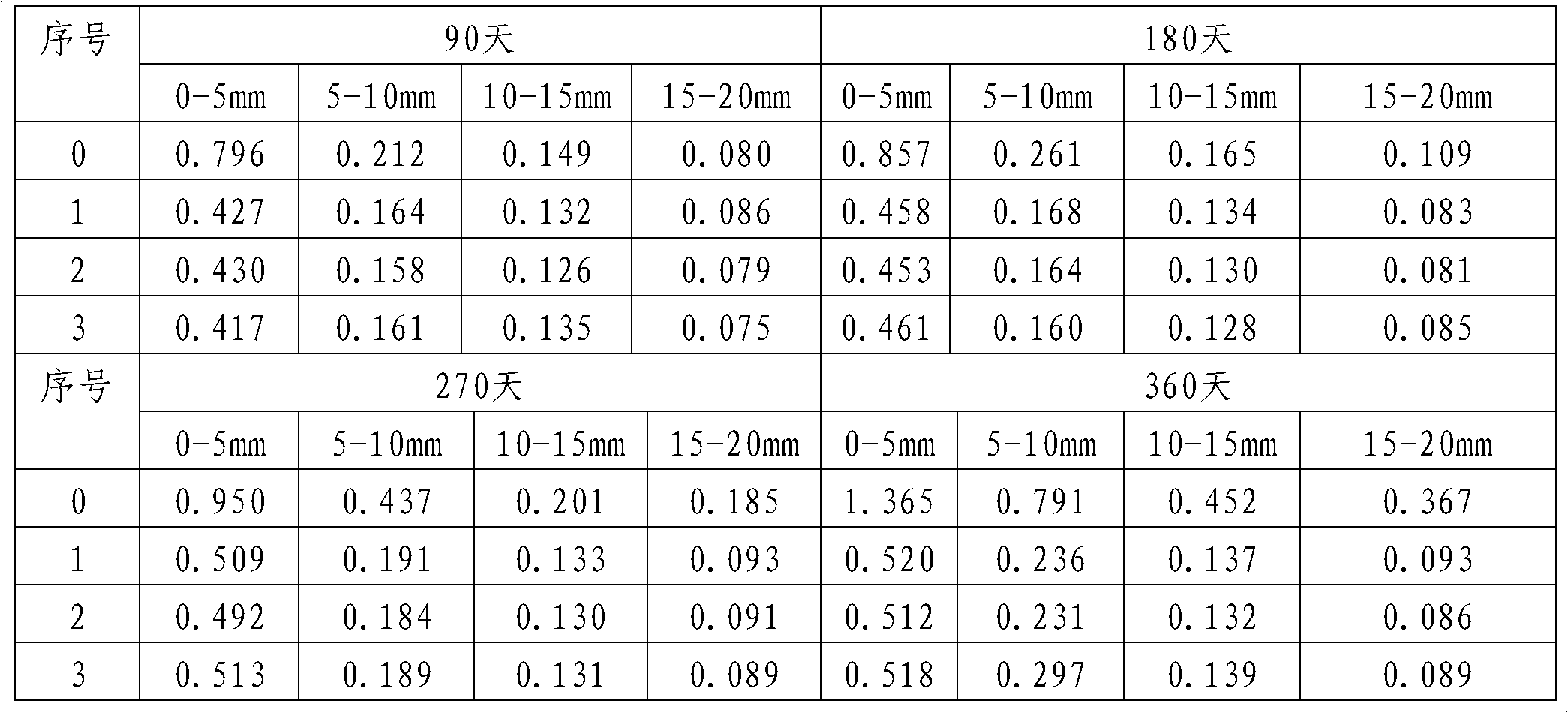

Anti-corrosion admixture for oceanic concrete

The invention relates to an anti-corrosion admixture for oceanic concrete, which can enhance the anti-corrosion capability of the oceanic concrete by using a plurality of anti-corrosion mechanisms. The anti-corrosion admixture for the oceanic concrete comprises the following components by weight percent: 20-30% of calcium nitrite, 15-20% of calcined gypsum, 5-10 % of laminated soluble sodium silicate, 3-5% of hexamethylenetetramine, 1-3% of sodium tripolyphosphate, 0- 20% of water reducing agent, 0-0.4% of air entraining agent and the balance of coal ash. In a preferred scheme of the invention, the the calcined gypsum is obtained by calcining at 600-800 DEG C, and the modulus of the laminated soluble sodium silicate is from 2.1 to 2.3. In the invention, the novel anti-corrosion admixture for the oceanic concrete is formed by combining a corrosion resisting agent of reinforcing steel bars with activators of concrete admixtures (coal ash and grounded furnace slag), thereby the anti-corrosion capability of the oceanic concrete is greatly enhanced.

Owner:NANJING UNIV OF TECH

Ultralow-temperature high-performance concrete for railway construction in severe cold regions and preparation technique thereof

ActiveCN102815901AThe preparation process steps are simpleEasy to operateHigh performance concreteCalcium nitrite

The invention discloses an ultralow-temperature high-performance concrete for railway construction in severe cold regions and a preparation technique thereof. The concrete is prepared by evenly mixing cementing material, sand, gravel, high-efficiency water reducing agent, composite antifreezing agent and water, wherein the cementing material is prepared by evenly mixing cement and mineral admixture in a weight ratio of (15-20):(85-80); the water reducing rate of the high-efficiency water reducing agent is not less than 25%; the composite antifreezing agent comprises 30-35 wt% of nitrate, 30-33 wt% of organic compound, 0.5-1 wt% of calcium formate and the balance of water; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or ethanol. The preparation technique comprises the following steps: 1. preparing the composite antifreezing agent; and 2. evenly mixing to obtain the ultralow-temperature high-performance concrete. The preparation technique disclosed by the invention is simple to operate and has the advantages of simple steps and favorable use effect; and the workability of concrete, and the mechanical properties and endurability after curingcan satisfy the design requirements.

Owner:CHINA RAILWAY 20 BUREAU GRP

Environment-friendly waterproof dry-mixed mortar

A disclosed environment-friendly waterproof dry-mixed mortar is prepared from the following raw materials in parts by weight: 20-45 parts of Portland cement, 7-16 parts of quartz sand, 11-16 parts of gypsum, 4-8 parts of latex powder, 4-7 parts of wood fiber, 2-6 parts of cellulose ether, 6-10 parts of nanometer silicon dioxide powder, 6-9 parts of hollow alloy bead, 5-9 parts of PP fiber, 10-20 parts of fly ash, 3-7 parts of barium sulfate, 5-8 parts of polymer glue, 15-25 parts of high alumina cement and 3-7 parts of calcium nitrite. The provided environment-friendly waterproof dry-mixed mortar is large in tensile strength, low in cost, thermal-insulating, energy-saving, waterproof, seepage-resisting, reduced in hollow, foaming and cracking phenomena, and strong in adhesive force.

Owner:QINGDAO CHENQING INFORMATION TECH

Addition for concrete of road for enhacing anti-bending strength

InactiveCN1559966AReduce dosageReduce the water-binder ratioSolid waste managementRebarPrecast concrete

The invention relates to a road concrete additive of improving folding strength, prepared of benzene solfonic acid formaldehyde condensation compound, lignin calcium sulfonate, sugar calcium, sodium calcium sulphate, ferrous sulphate, calcium nitrite and powder coal ashes. It can reduce the water dosage of concrete by above 18%, enhances the early strength of concrete by a large margin and increase the 28 d pressive strength, obviously enhance the folding strength of concrete, thus on condition of less dosage of cement, able to make the folding strength of concrete up to the requirements for above secondary roads (folding strength above 4.5 MPa), and simultaneously able to improve the durability of concrete. It can be widely applied to road concrete and simultaneously applied to the constructions (structures) of reinforced concrete, precast concrete, steam cured concrete, etc.

Owner:TONGJI UNIV

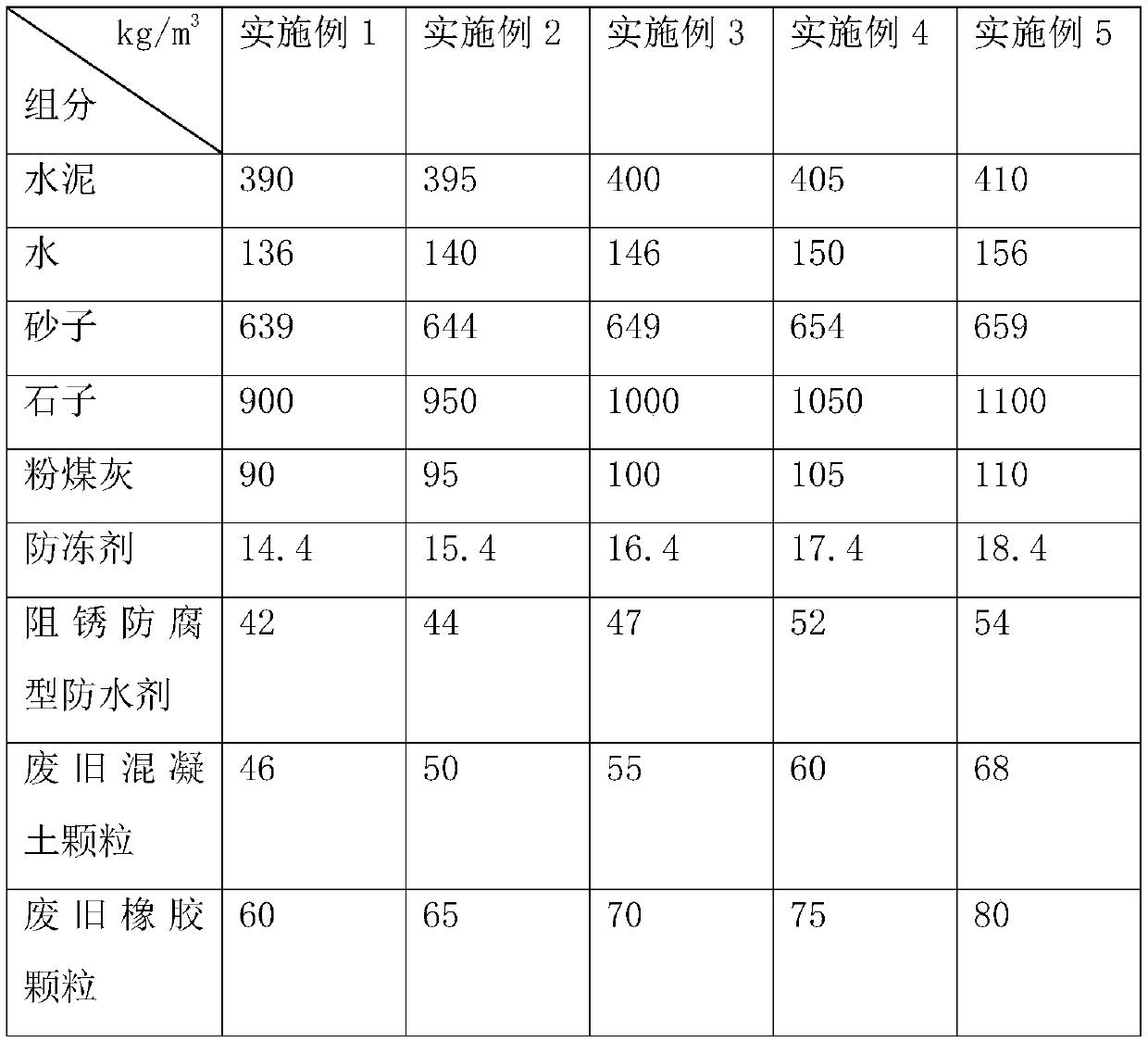

High-strength impermeable anti-freezing concrete and preparation method thereof

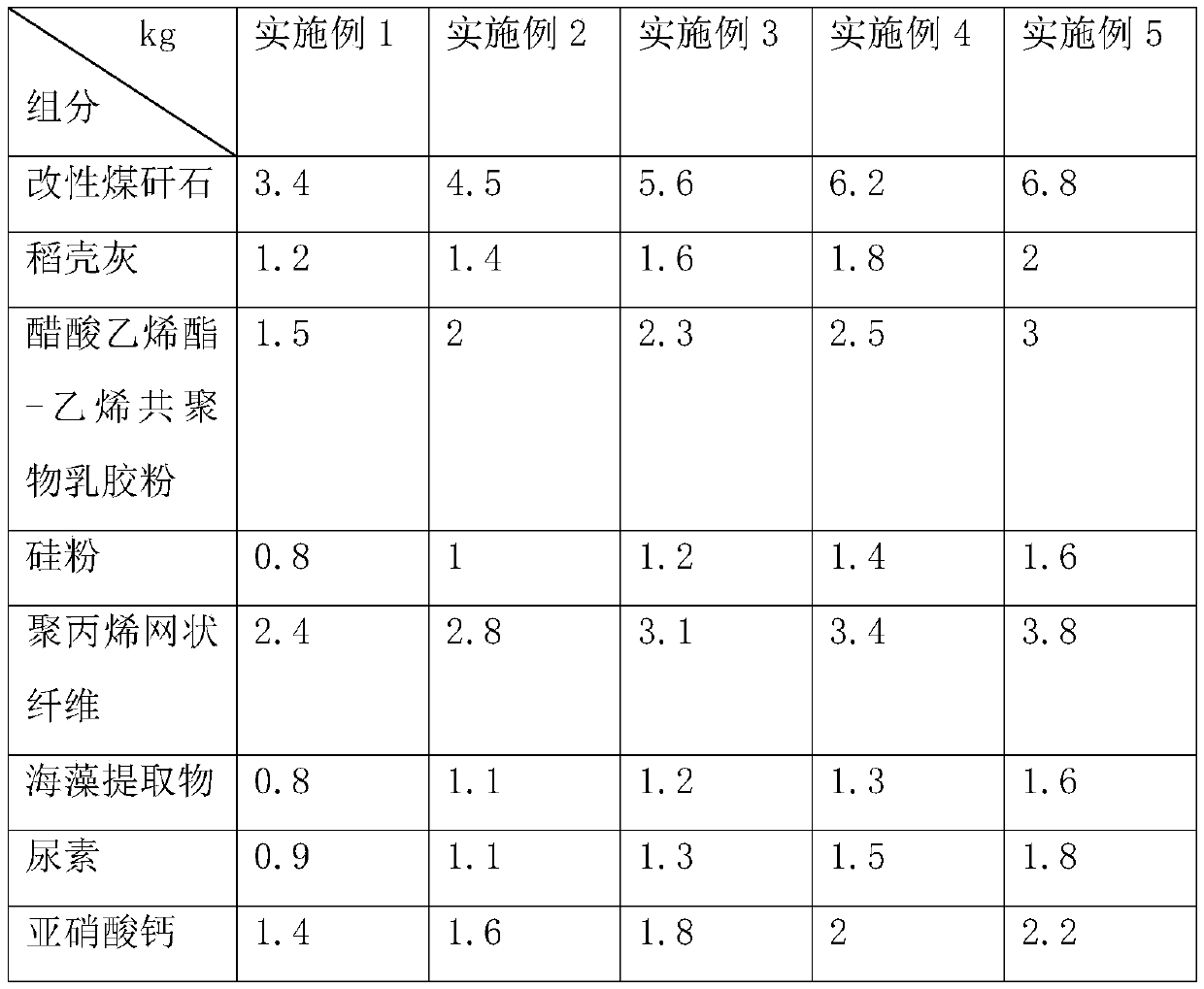

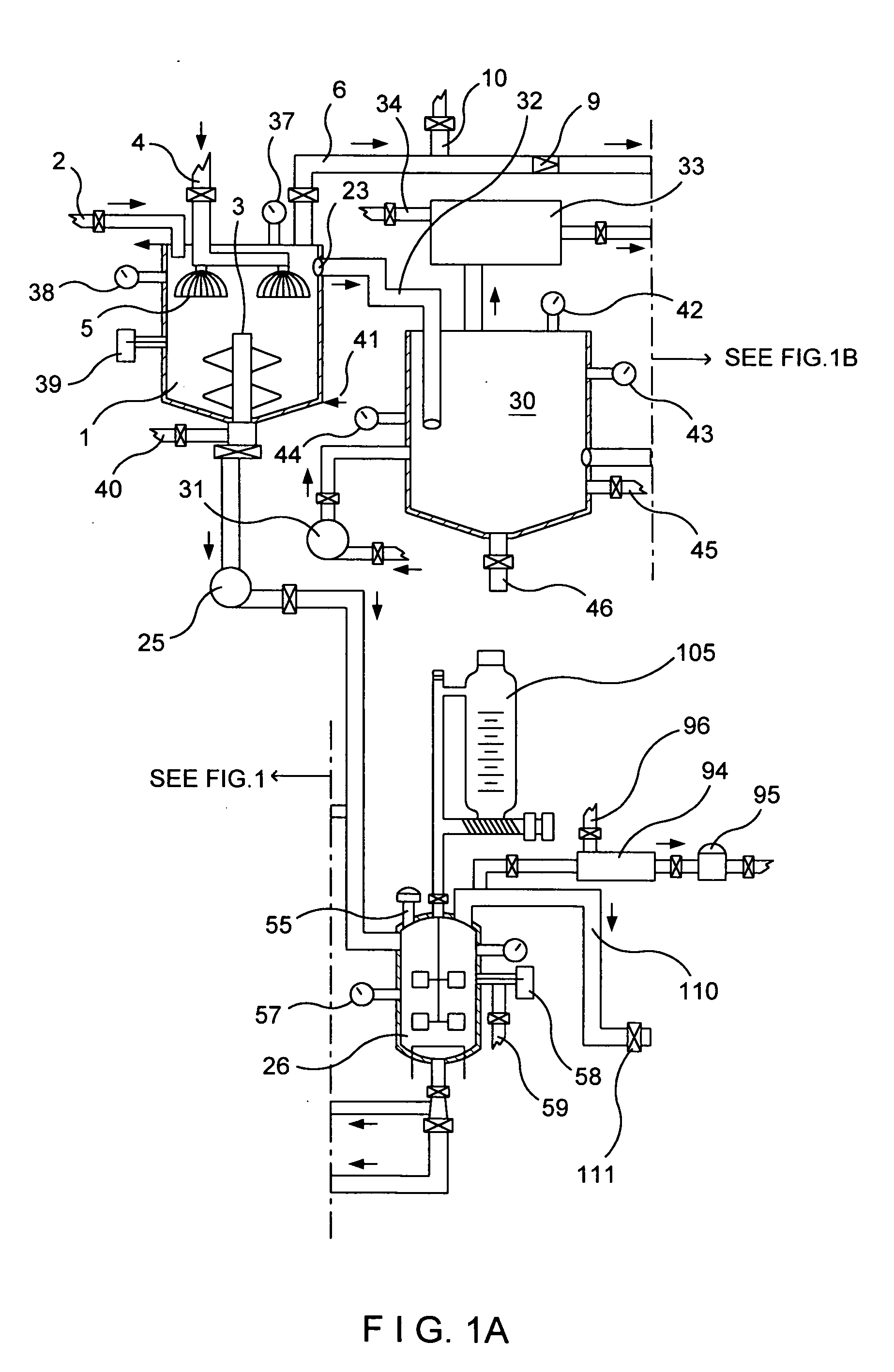

The invention discloses high-strength impermeable anti-freezing concrete and a preparation method thereof. The high-strength impermeable anti-freezing concrete is prepared from the following raw materials: cement, water, sand, stones, fly ash, an anti-freezing agent, a rust-inhibiting anti-corrosion waterproof agent, waste concrete particles and waste rubber particles. The anti-freezing agent is prepared from the following components in parts by weight: 3.4 to 6.8 parts of modified coal gangue; 1.2 to 2.0 parts of rice hull ash, 1.5 to 3 parts of vinyl acetate-ethylene copolymer latex powder;0.8 to 1.6 parts of silicon powder; 2.4 to 3.8 parts of polypropylene reticular fiber; 0.8 to 1.6 parts of seaweed extract; 0.9 to 1.8 parts of urea; 1.4 to 2.2 parts of calcium nitrite and 10 to 20 parts of water. The high-strength impermeable anti-freezing concrete has the advantages of effective utilization of waste materials, strong freeze-thaw resistance and mechanical properties, reduction of freeze-thaw diseases of concrete in cold regions, and purification of automobile exhaust.

Owner:青岛兴业商砼有限公司

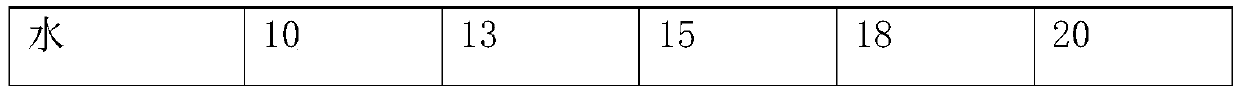

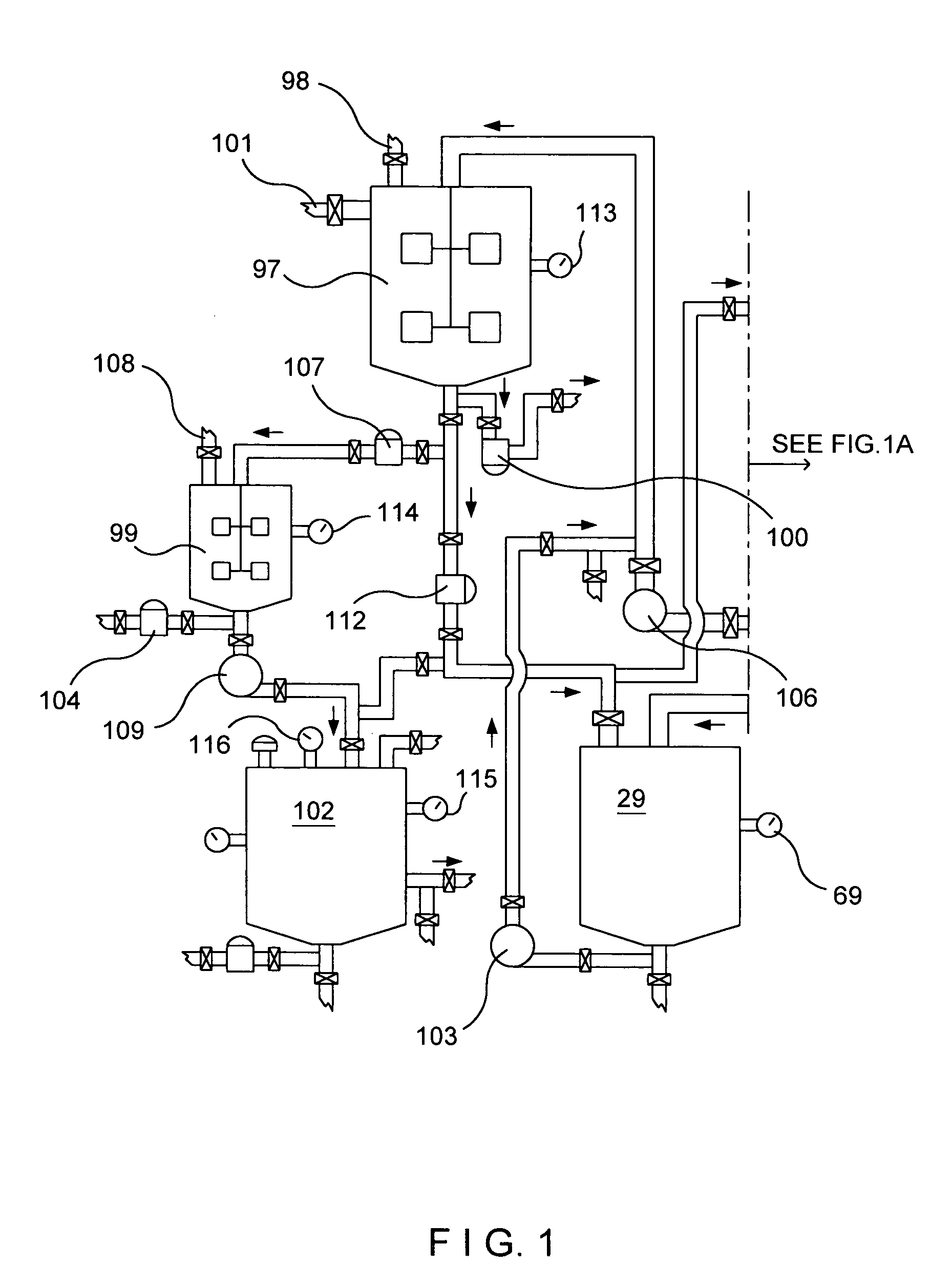

Reverse Kleiner method for manufacturing nitrogen dioxide, nitric oxide, nitric acid, metallic ascorbates and alkyl ascorbates of vitamin C

In this invention new chemical reactions, new chemical processes are established, and these chemical reactions and chemical processes can be used with the system designed to produce nitrogen dioxide, nitric oxide, nitric acid as well as metallic ascorbates or alkyl ascorbates, either as main or as secondary products. Ascorbic acid solution is reacted at room temperature or at elevated temperature with either sodium nitrite or potassium nitrite or calcium nitrite or alkyl nitrite such as isobutyl nitrite or barium nitrite or silver nitrite solution. All the second reactants except alkyl nitrites such as isoamyl nitrite or isopropyl nitrite or isobutyl nitrite, as well as the first reactant, ascorbic acid, are in aqueous solutions. The reaction vessel contains the ascorbic acid solution; into this solution, under, certain pressure, is delivered the choosen aqueous nitrite solution. Gas mixture of nitrogen dioxide and nitric oxide is produced by addition of the choosen nitrite solution. The generated and collected gas mixture is then mixed with oxygen, thus the nitric oxide in the gas mixture converts—by reacting with oxygen—into nitrogen dioxide, then this homogeneous gas is dissolved in water, thus giving us nitric acid. In this chemical reaction system two sets of chemical reactions take place; one on the surface of the solution(s) that produces the main part of the gas mixture, and this is the major part of the chemical reaction system. In the liquid phase of the reaction processes form the metallic ascorbates as well as the alkyl ascorbates. All the same can be done with isoascorbic acid; the chemical reactions will go somewhat slower.

Owner:KLEINER BELA

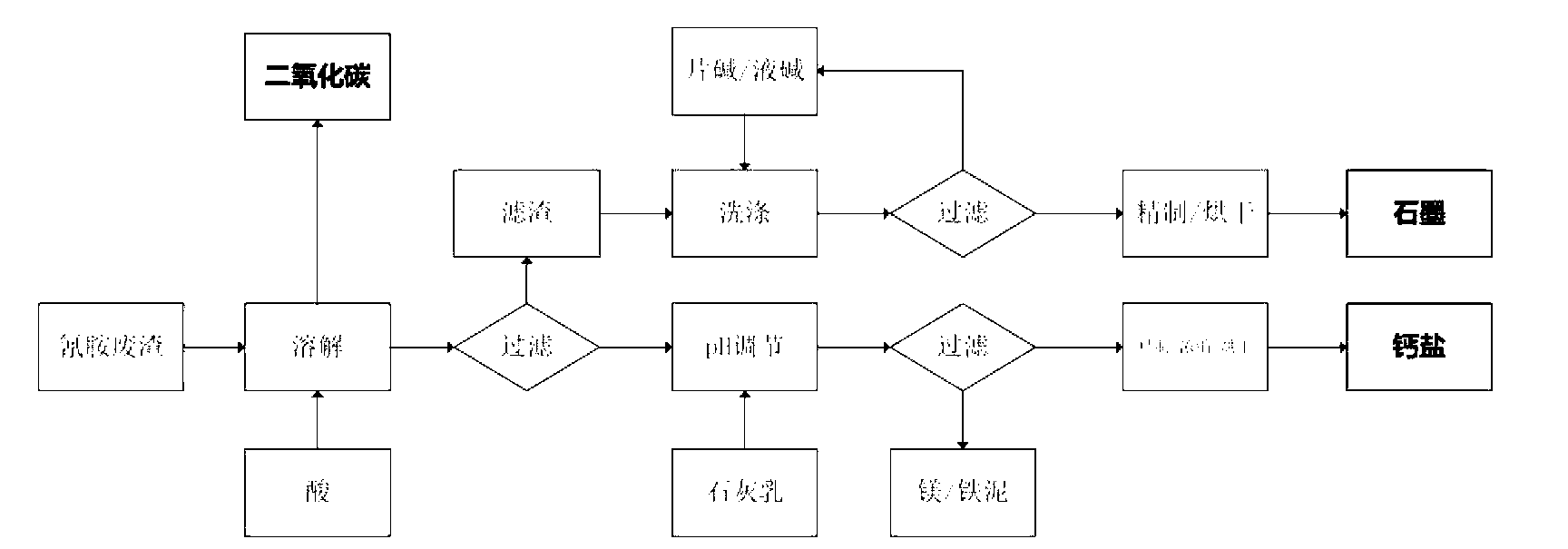

Comprehensive utilization method of cyanamide waste residue

InactiveCN103011161AAchieve reuseSimple processCalcium/strontium/barium chloridesCarbon compoundsCalcium formateNuclear chemistry

The invention relates to a comprehensive utilization method of a cyanamide waste residue. The comprehensive utilization method of the cyanamide waste residue comprises the following steps: firstly, adding an acid into the cyanamide waste residue for reaction, collecting carbon dioxide gas generated in the reaction, and filtering a reacted solution to obtain a filter residue A and a filtrate A; heating the filtrate A to 30-100 DEG C; regulating pH to 7.0-9.0 by using lime milk; filtering again; and evaporating for concentrating, crystallizing and drying an obtained filtrate Bto obtain a calcium salt. Through effective treatment of the cyanamide waste residue, inorganic calcium salts (such as calcium chloride, calcium nitrate and calcium nitrite) or organic calcium salts (such as calcium formate, calcium acetate and amino calcium sulfonate), graphite powder and carbon dioxide can be prepared, thus achieving recycle of industrial wastes; the comprehensive utilization method is simple in whole technical process and low in treatment cost; and the added valve of the product is greatly improved.

Owner:宁夏兴平精细化工股份有限公司

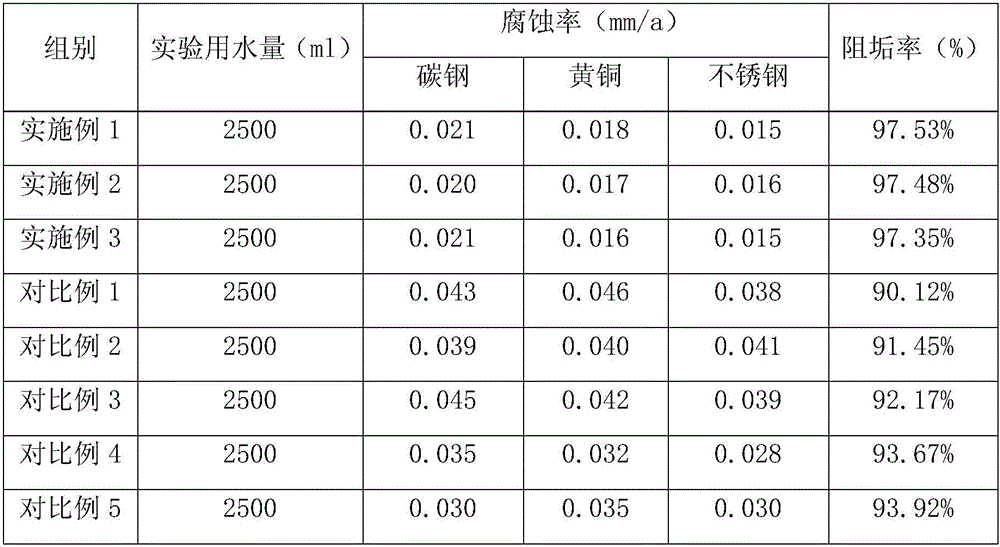

Multiple composite corrosion inhibitor and preparation method thereof

InactiveCN105753183AGood corrosion inhibitionImprove antioxidant capacitySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsAlkaneEthylenediamine

The invention relates to a multiple composite corrosion inhibitor and a preparation method thereof.The multiple composite corrosion inhibitor is made from the following materials according to parts by weight: 5-10 parts of polyepoxysuccinic acid, 5-10 parts of calcium gluconate, 5-10 parts of sodium silicate, 1-5 parts of secondary alkane sodium sulfonate, 0.5-2 parts of sodium alginate, 0.5-3 parts of zinc sulfate, 0.5-3 parts of sodium borate, 1-3 parts of sodium citrate, 1-3 parts of octadecanol polyoxyethylene ether, 1-5 parts of dimethylketoxime, 1-5 parts of ethylene glycol ethyl ether, 1-5 parts of ethylenediamine, 0.5-1 parts of tea saponin, 0.5-2 parts of a bactericide, 0.5-2 parts of a chelating agent, 0.1-0.5 part of calcium nitrite, 5-10 parts of glycerol, 5-10 parts of ethyl alcohol, and 20-50 parts of deionized water.The multiple composite corrosion inhibitor is widely applicable to carbon steel, stainless steel, aluminum and copper equipment; the corrosion inhibiting capacity meets the provisions in GB50050-2007 design standard for industrial circulating water, and the inhibitor of the invention has the advantages of no phosphorus, environment friendliness, high oxidation resistance, convenience of use and the like.

Owner:安徽马钢和菱实业有限公司

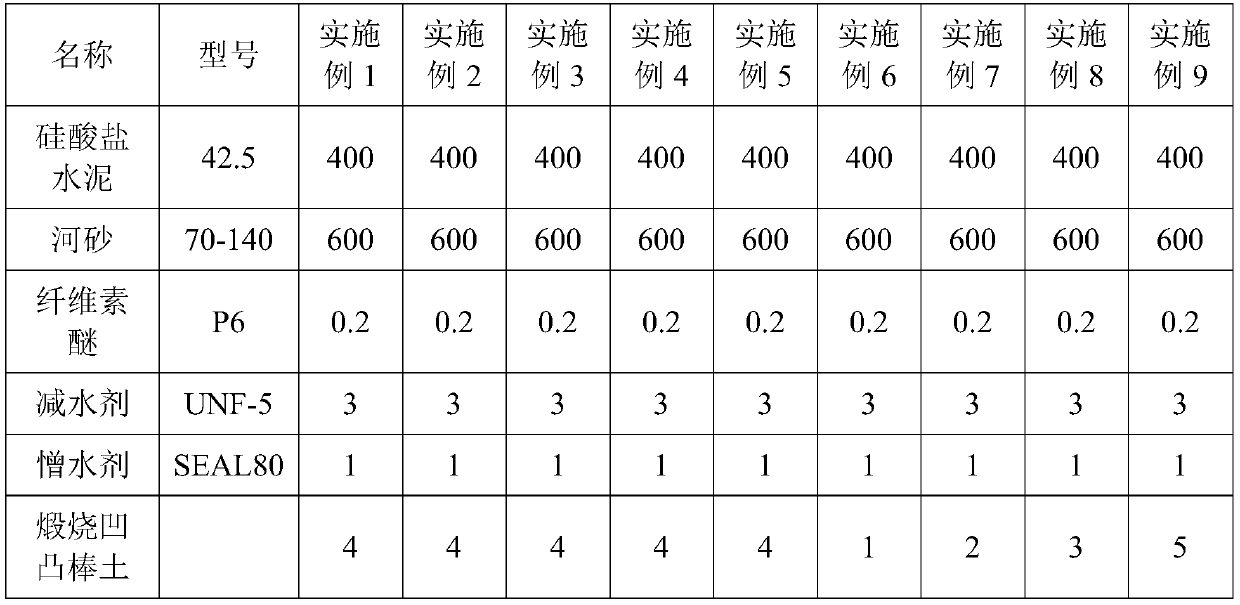

Quick-setting agent and quick-setting polymer cement waterproof slurry and preparation method thereof

The invention discloses a quick-setting agent and a quick-setting polymer cement waterproof slurry and a preparation method thereof. The quick-setting agent comprises: 2-10 parts by weight of hydrofluoric acid, 1-5 parts by weight of aluminum hydroxide, 4-20 parts by weight of aluminum sulfate, 1-5 parts of melamine, 1-5 parts of calcium nitrite, 1-5 parts of lithium sulfate, 1-5 parts by weight of polyol amine, 10-20 parts by weight of sodium silicate and 50-100 parts by weight of water. The invention solves the problems that the existing waterproof slurry cannot carry out the next process quickly because of the slow setting speed, cannot be used for the quick repair project and the time limit project, and the waterproof slurry produced with the fast hardening cement in the market has theadvantages of fast setting speed and short construction time. The quick-setting polymer cement waterproof slurry has the advantages of fast curing, high early strength, good impermeability, good waterproofing effect, long operable construction time, construction at low temperature, mildew prevention, alkali resistance, weather resistance, non-toxicity, harmlessness, pollution-free, and the like.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD

Steel smelt additive and processing technology thereof

The invention relates to an additive in the process of smelting iron and steel, which comprises the following parts: 10%-15% sodium peroxide, 15%-25% sodium per chlorate, 5%-10% calcium chloride, 20%-28% borax, 5%-15% calcium nitrite, 5%-8% sodium methylol fibre, 5%-8% sodium perborate, 10%-20% polyacrylamide. The manufacturing technique comprises the following steps: (1) adding every part sequentially according to the weight and mixing mechanically; (2) mixing and heating; (3) filtering; drying and finishing the product. The invention improves the insufficient places of the original additive product, which develops a new additive; reduces the cost of smelting iron; adds the benefit.

Owner:刘钧

Early-concreting anchoring mortar

The early setting anchoring mortar consists of cement 20-35 weight portions, quartz sand 35-50 weight portions, latex powder adhesive 2-5 weight portions, waterproof latex powder adhesive 1-2 weight portions, methyl cellulose 0.1-0.8 weight portion, heavy calcium carbonate 8-10 weight portions, calcium sulphoaluminate 1.5-3 weight portions, calcium chloride 0-2 weight portions, calcium sulfate 0-3 weight portions, early strength air entraining agent 0-0.3 weight portion, lignin 0-0.5 weight portion, and calcium nitrite 0-1.5 weight portions except essential water. It is applied for adhering heat insulating material to wall firmly.

Owner:ZHEJIANG SHUNJIE CONSTR GROUP +1

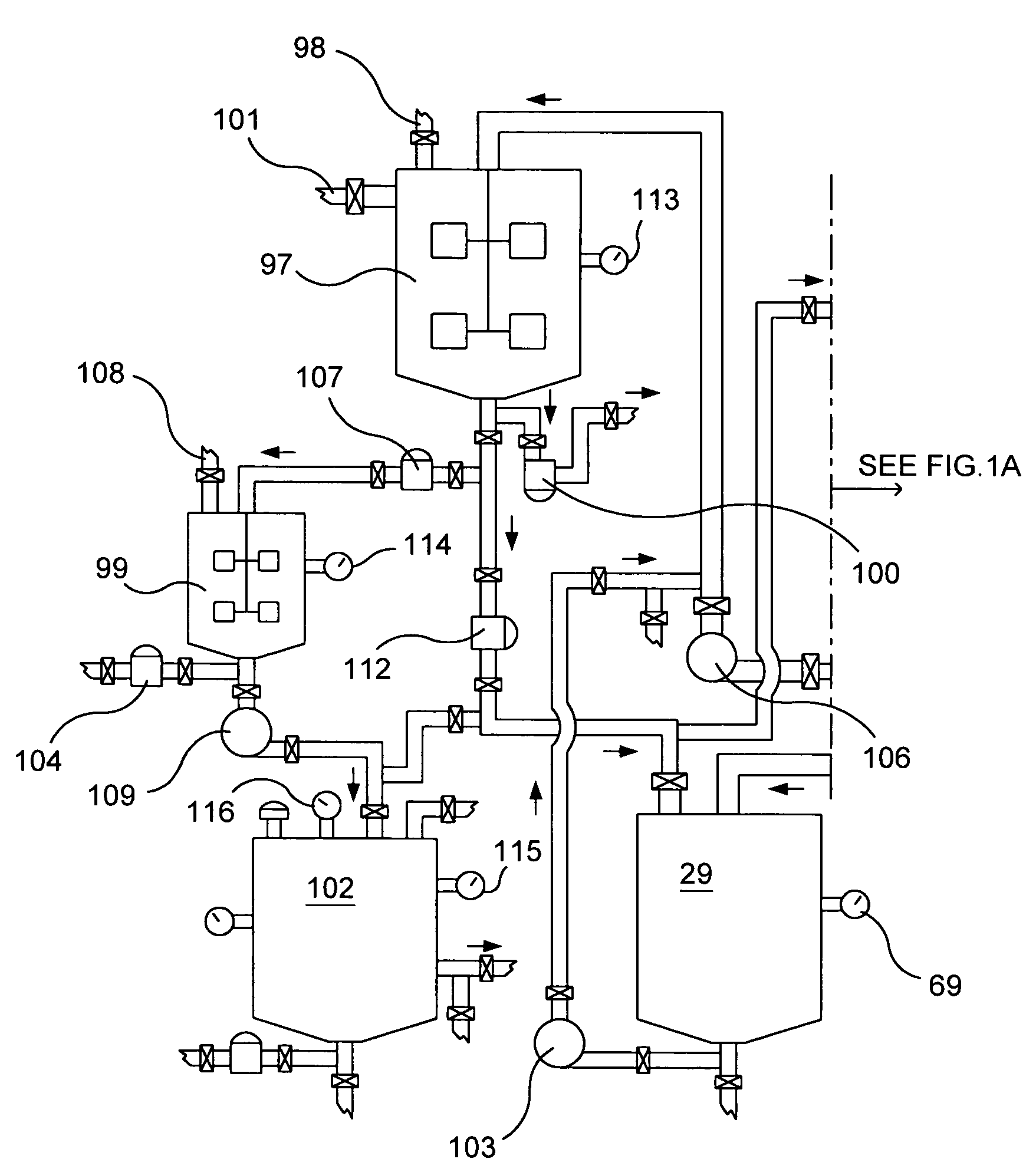

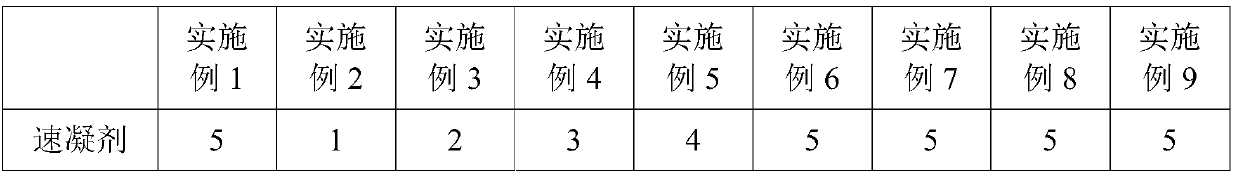

Low-temperature fume oxidizing and denitration method and system

InactiveCN104437037ARealize recyclingSolve processing problemsDispersed particle separationNitrous acidChlorine dioxideReaction temperature

The invention relates to a low-temperature fume oxidizing and denitration method and system. The method is characterized in that chlorine dioxide and low-temperature fume to be purified are subjected to gas-gas mixing in a fume channel and then are fed into an oxidizing tower; NO is oxidized into NO2 and NaO3 by chlorine dioxide in the oxidizing tower, and the reaction is performed under a temperature of 50 to 80 DEG C; the oxidizing and denitration are performed in the oxidizing tower, and the oxidizing reaction costs 1 to 2 seconds; the oxidized fume enters a spraying absorbing section and then is sprayed with a calcium oxide liquid at a mass concentration being 5 to 8%, and calcium nitrate and calcium nitrite liquids are generated after spraying and absorbing; and the calcium nitrite liquid is saturated and then is sequentially processed by impurity removing, evaporating, concentrating, crystallizing and purifying to obtain calcium nitrite. According to the low-temperature fume oxidizing and denitration method, ClO2 is selected and fully mixed with the fume to achieve denitration under a low temperature of 50 to 80 DEG C, and therefore, the problem of wastewater treatment can be solved; and meanwhile, the resource can be recycled; the denitration efficiency is up to more than 85%.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

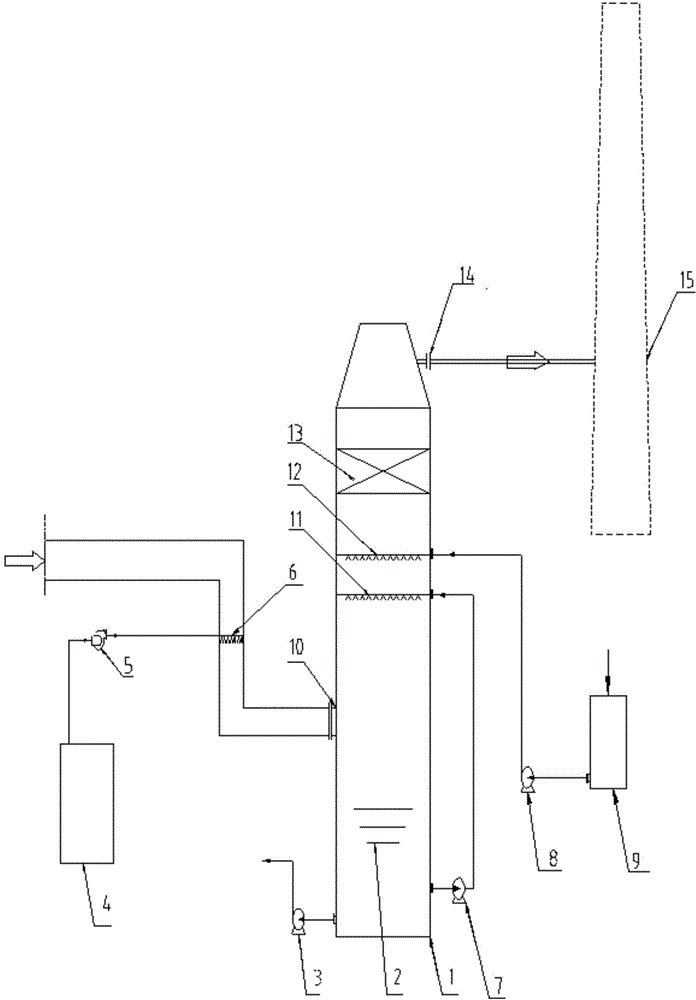

Process method for converting dry-method desulfurized fly ash into desulfurized gypsum

InactiveCN111348853ARealize the purpose of treating waste with wasteSolve conversion problemsCalcium/strontium/barium sulfatesDistillationDistilled water

The invention belongs to the technical field of solid waste treatment, and particularly relates to a process method for converting dry-method desulfurized fly ash into desulfurized gypsum. The processmethod comprises the following steps: step 1, adding water and dry-method desulfurized fly ash into an oxidation tower, and stirring to obtain a dry-method desulfurized fly ash solution; step 2, introducing the dry-method desulfurized fly ash solution into sintering machine flue gas under a stirring condition for reaction; 3, after the reaction is completed, carrying out solid-liquid separation on the solution; step 4, returning the solution prepared by solid-liquid separation to an oxidation tower, and feeding a separated solid into a distillation device; step 5, carrying out solid-liquid separation in a distillation device, returning distilled water vapor to the oxidation tower, and taking the left solid as desulfurized gypsum; a precipitation method can be adopted to remove calcium chloride and calcium nitrite in the solution prepared through solid-liquid separation further. According to the method, the temperature of the flue gas of a sintering machine head and the sulfur dioxidemedium in the flue gas are fully utilized to realize conversion of calcium sulfite in the dry-method desulfurization fly ash, and meanwhile, the problem of secondary pollution caused by calcium chloride and calcium nitrite is solved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Traditional Chinese medicine residue heat preserving mortar and preparation method thereof

The invention discloses traditional Chinese medicine residue heat preserving mortar. The traditional Chinese medicine residue heat preserving mortar is characterized by being prepared from the following raw materials in parts by weight: 300 to 360 parts of white portland cement, 150 to 180 parts of barium carbonate residue, 190 to 210 parts of calcium bentonite, 70 to 90 parts of traditional Chinese medicine residue, 8 to 11 parts of urea, 10 to 13 parts of calcium hydroxide, 30 to 50 parts of nanometer titania, 90 to 110 parts of calcium carbonate powder, 90 to 130 parts of straw sorghum, 8 to 13 parts of calcium nitrite, 9 to 11 parts of nylon fiber, 7 to 9 parts of milled profiled steel fiber, and 3 to 7 parts of assistants. The heat preserving mortar added with the traditional Chinese medicine has anti-bacterial and anti-mildew performances, and other assistants added are used in match with the raw materials, so that the heat preserving mortar has the advantages of being waterproof, resistant to crack, and high in adhering performance; because of the same service life as a building, the heat preserving motor can be directly used as a plastering mortar layer for an inner wall and an outer wall; in addition, the heat preserving mortar is small in volume weight, so that the thickness of the wall surface in construction is reduced, and the construction is saved on the premise that the heat preserving performance of a wall body is ensured.

Owner:安徽众凯架业有限责任公司

Freeze-thaw resistant cement hollow brick and preparation method thereof

InactiveCN105967585AImprove freeze-thaw resistanceHigh mechanical strengthSolid waste managementSodium acetateBrick

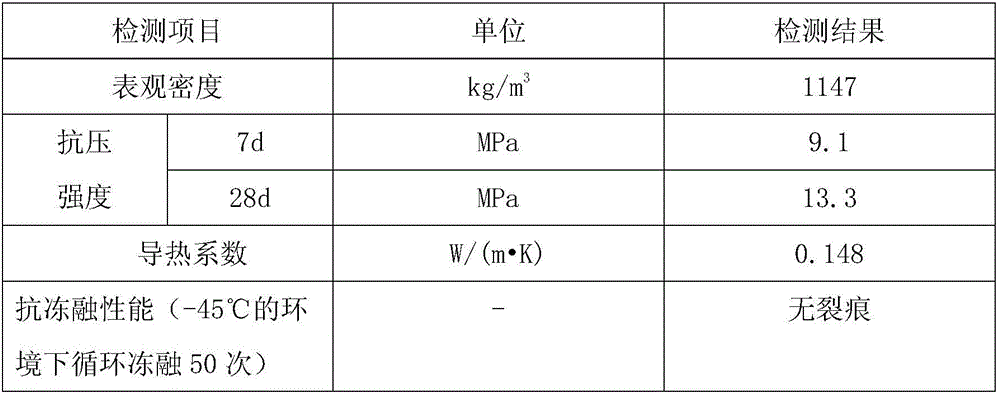

The invention discloses a freeze-thaw resistant cement hollow brick and a preparation method thereof. The brick of the invention is prepared from the following raw materials (by weight): 42-54 parts of ordinary Portland cement, 22-28 parts of construction waste residue, 16-22 parts of mountain sand, 8-14 parts of sulfur fixation ash, 5-10 parts of hornblende, 10-15 parts of silica powder, 3-6 parts of barium carbonate, 8-12 parts of halloysite slag, 4-8 parts of copper ore tailings, 7-11 parts of coal gangue, 9-14 parts of electrolytic manganese residue, 5-10 parts of boric sludge, 6-12 parts of loess, 2-4 parts of calcium nitrite, 3-5 parts of urea, 2-3 parts of sodium acetate, 1-2 parts of 1,3-propylene glycol, 4-8 parts of calcium hydrophosphate, 6-9 parts of hydroxypropyl methyl cellulose and a proper amount of water. By compounding of raw materials including calcium nitrite, urea, sodium acetate, 1,3-propylene glycol and the like, freeze-thaw resistance of the cement hollow brick is enhanced, and the brick will not crack after 50 times of frozen-thaw cycles in an environment of minus 45 DEG C.

Owner:ANHUI XINRUN NEW MATERIALS

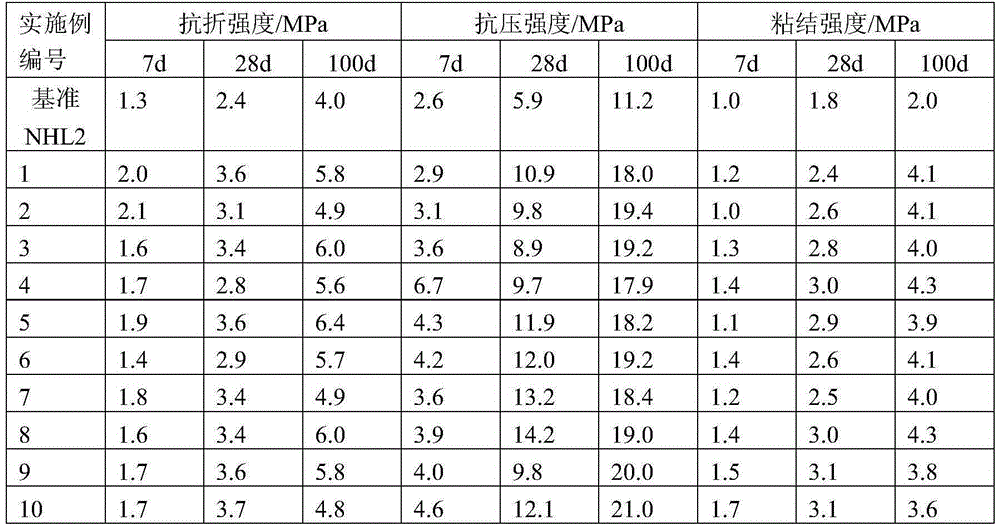

Modified hydraulic lime based material and preparation method thereof

The invention discloses a modified hydraulic lime based material and a preparation method thereof and belongs to the technical field of building materials. The modified hydraulic lime based material comprises components of raw materials in percentage by weight as follows: 40%-80% of hydraulic lime, 5%-50% of ground mineral powder (S95level), 1%-5% of calcium nitrite, 1%-3% of lithium carbonate, 0.5%-2% of sodium gluconate, 0.5%-2% of a viscous resisting agent, 0.5%-2% of an adhesion resisting agent, 1%-3% of a thixotropy resisting agent, 1%-3% of an anti-crack resisting agent and 0.5%-1.5% of a water reducer, wherein the water reducer is an ShiJiXingYuan XY-4 type Qingdao naphthalene water reducer. The preparation method comprises steps as follows: the components are uniformly mixed in proportion and put in a grinding machine to be ground, and a mixture is obtained. The raw materials are easy to obtain, a preparation process is simple, and the modified hydraulic lime based material is simple to cure; compared with ordinary hydraulic lime, the hydraulic lime has higher crush resistance, fracture resistance and adhesion strength, has good water resistance, acid resistance, alkali resistance and ultraviolet resistance and can be well used for repairing work of antiques.

Owner:BEIJING GUOWENYAN CULTURAL HERITAGE CONSERVATION CENT LTD

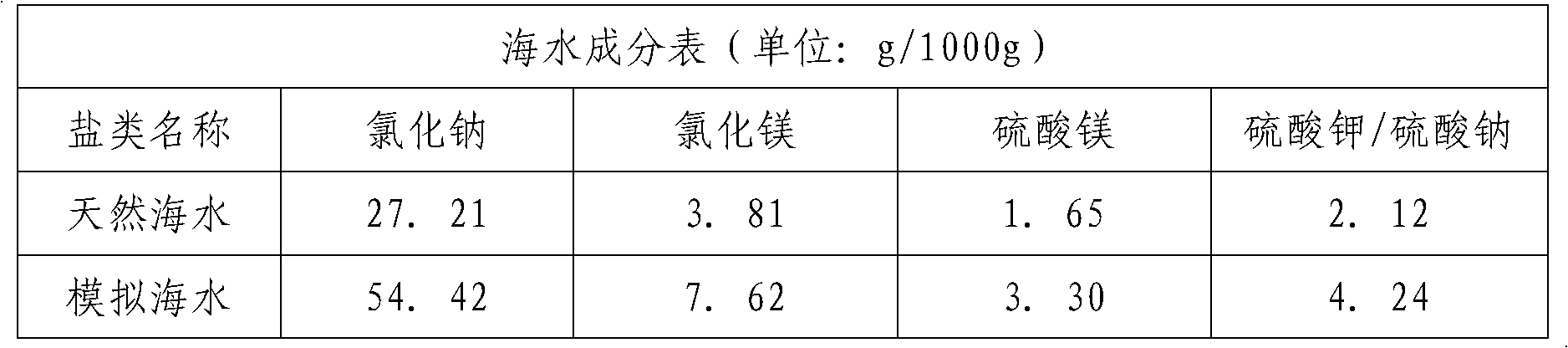

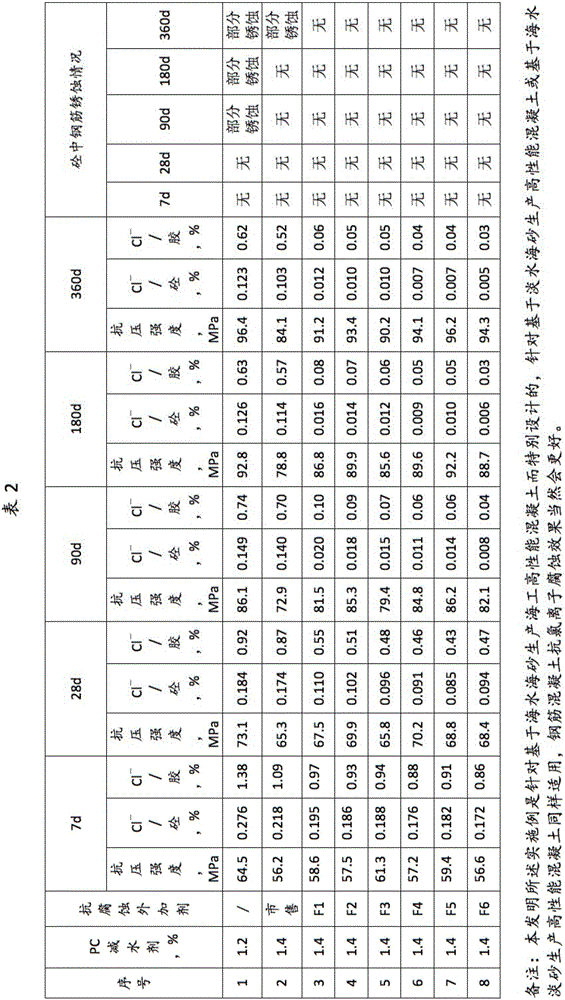

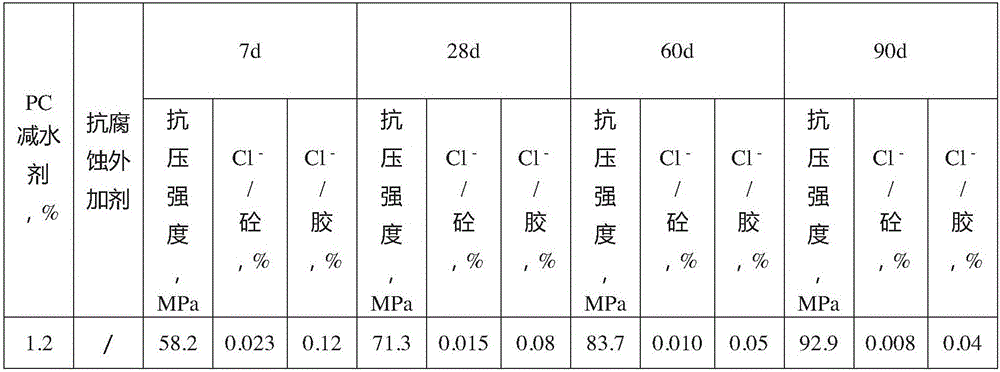

Seawater and sea sand-based anticorrosive additive for producing marine high-performance concrete

The invention relates to a seawater and sea sand-based anticorrosive additive for producing marine high-performance concrete. The anticorrosive additive is prepared from the following components by mass percent: 10 to 20 percent of calcium nitrite, 3 to 5 percent of sodium carbonate, 3 to 5 percent of sodium sulfate, 1 to 5 percent of chitosan, 0.6 to 1.0 percent of alcohol-amine compounds, 20 to 40 percent of coal ash hollow microbeads, 5 to 10 percent of zeolite molecular sieves, 3 to 5 percent of nanoscale silicon dioxide powder, and the balance of metakaolin, wherein the molar ratio of SiO2 / Al2O3 in the zeolite molecular sieve is 25 to 30. Accordingto the seawater and sea sand-based anticorrosive additive for producing themarine high-performance concrete,the durability of the concrete is improved by the synergistic effect of various ways, and the content of water-soluble chlorine ions in the marine high-performance concrete is gradually decreased in 7 days, 28 to 90 days and is stable for a long term after 90 days, so that the structural safety and durability of marine reinforced concrete is guaranteed.

Owner:SHANDONG HARBOR ENG GRP

Quenching phosphorated fluid for metal comprehensive processing

InactiveCN101671769ANo pollution in the processHigh degree of phosphatingMetallic material coating processesQuenching agentsPhosphateSurface-active agents

Owner:SHANDONG TENGDA STAINLESS STEEL PRODS

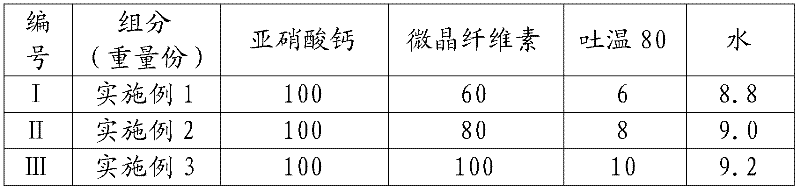

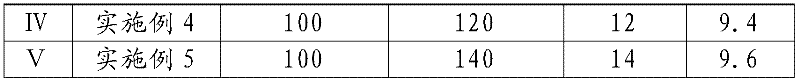

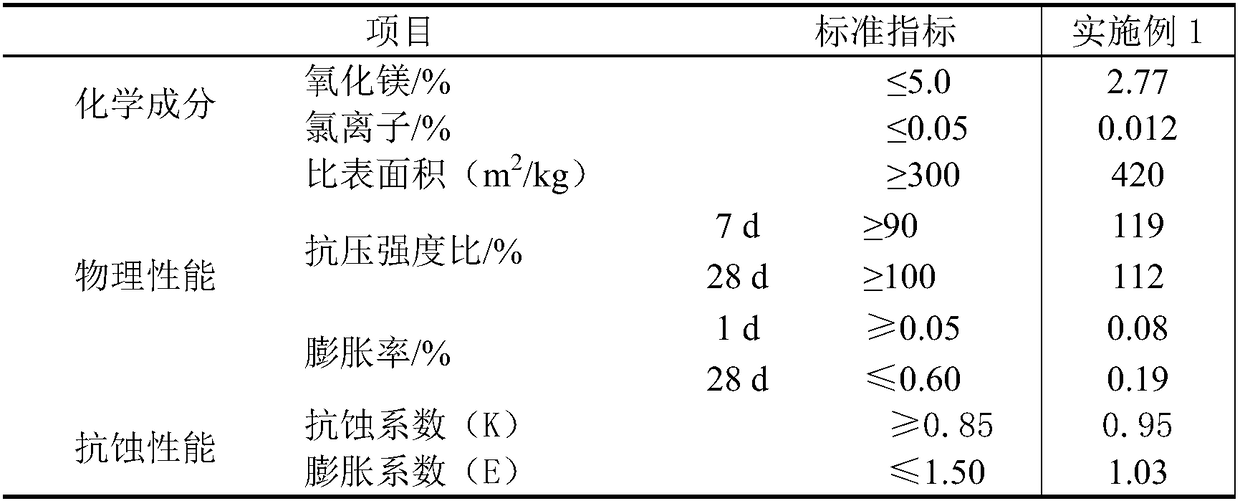

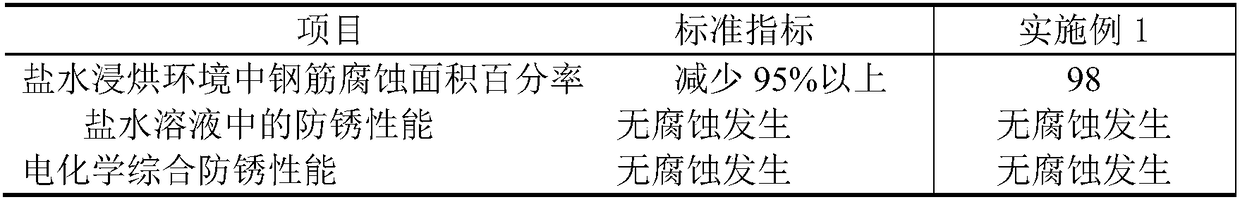

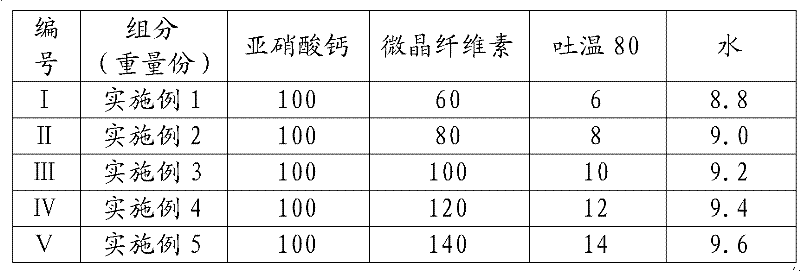

Ethyl cellulose type calcium nitrite corrosion inhibitor and preparation method thereof

ActiveCN102517587AImprove stabilityControlled optimization of release rateAdditive ingredientCalcium nitrite

The invention discloses an ethyl cellulose type calcium nitrite corrosion inhibitor and a preparation method thereof. The shape of the ethyl cellulose type calcium nitrite corrosion inhibitor is a capsule, the capsule comprises a capsule core and a coating; the ingredients of the capsule core comprise calcium nitrite, microcrystalline cellulose and Twin 80; and the coating is made from ethyl cellulose aqueous dispersion. According to the invention, the calcium nitrite microcapsule corrosion inhibitor coated by the ethyl cellulose aqueous dispersion has good stability, and the mass ratio of the capsule core material to the coating material is changed to guarantee controllable release speed, long validity period, good antirust effect and environmental friendliness for the microcapsule.

Owner:SHENZHEN UNIV

Snow melting agent

InactiveCN111748319APromote environmental protectionFast ice and snow removalCalcareous fertilisersMagnesium fertilisersSODIUM METAPHOSPHATESodium phosphates

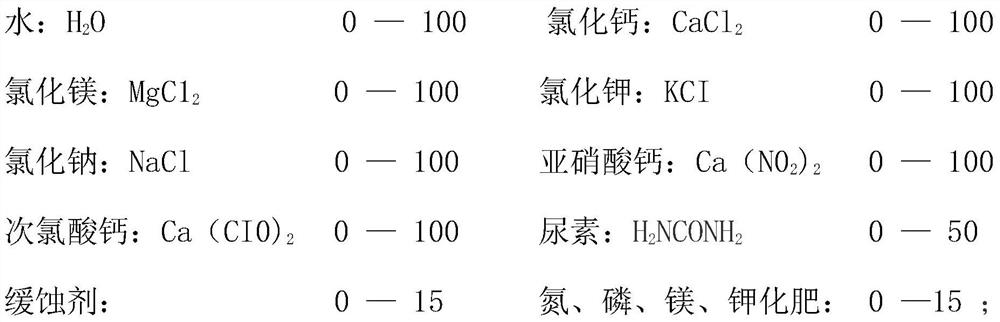

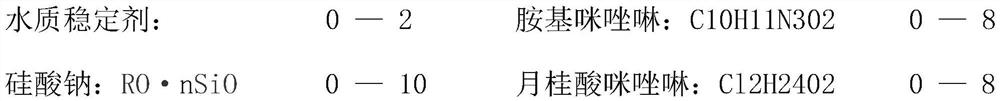

The invention discloses a snow melting agent, and belongs to the technical field of composite salt. Water and one, two, three, four, or five of calcium chloride, magnesium chloride, potassium chloride, sodium chloride, calcium nitrite, calcium hypochlorite, and urea chemical raw materials, a a water quality stabilizer, one, two, three, four, or five of sodium citrate, sodium hexametaphosphate, sodium gluconate, polyaspartic acid and other chemical materials as a corrosion inhibitor, one, two, three, four, or five of chemical fertilizers for promoting plant growth, potassium fulvate for improving a soil aggregate structure, and sodium chloride and activator urea for alleviating pavement thermal shock are used for forming the snow melting agent according to respective attributes. The snow melting speed is high, the use amount is small, and the effect is good; both solid and liquid exist and the snow melting agent can be used at the temperature of over 35 DEG C; corrosion to metal and concrete can be effectively reduced; the plant growth is promoted; the snow melting agent has functions of bleaching, sterilization, disinfection, skid resistance, road surface cleaning and the like on water obtained after ice and snow melting; the snow melting agent, is suitable for mechanical throwing or spraying operation.

Owner:杨毅男

Concrete anticorrosive rust inhibitor for cast-in-place piles

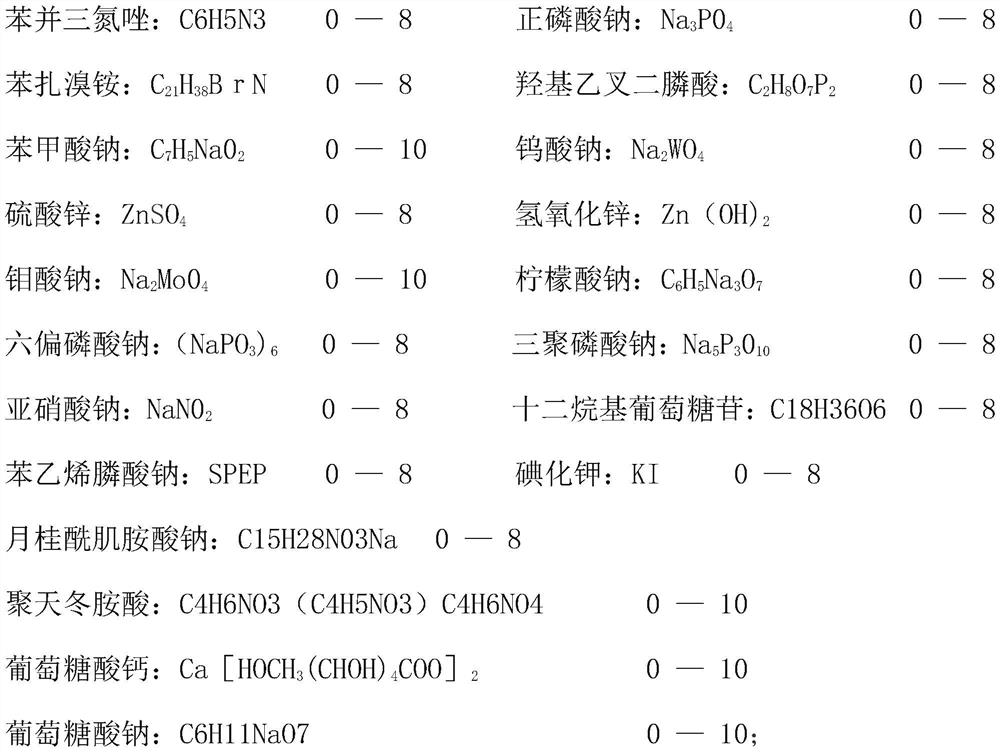

The invention discloses a concrete anticorrosive rust inhibitor for cast-in-place piles. The concrete anticorrosive rust inhibitor is formed by mixing and stirring the following components by mass: 20-30% of calcium nitrite, 20-30% of silica fume, 30-40% of fly ash, 8-10% of finely ground expansive clinker, 1-1.5% of a powder plasticizer and 0.2-0.8% of an air entraining agent. The concrete anticorrosive rust inhibitor has no significant effect on working performance of concrete under appropriate dosage, improves age strength of the concrete, increases compactness of the concrete by certain self-expansion, forms a dense protective layer on a surface of a reinforcing bar, and effectively improves sulfate corrosion resistance of the concrete and erosion resistance of the reinforcing bar.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

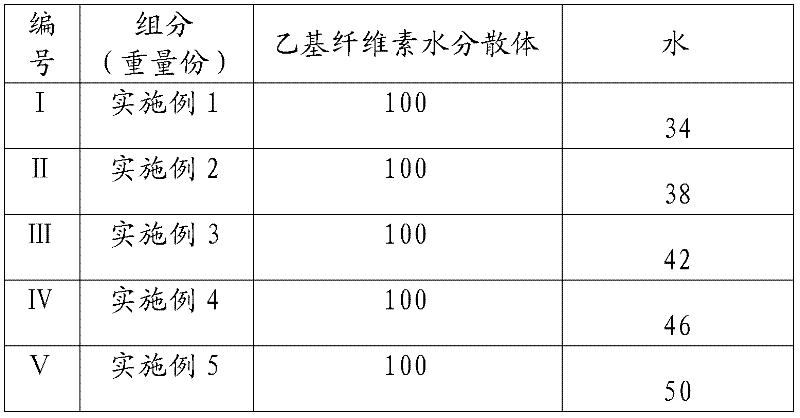

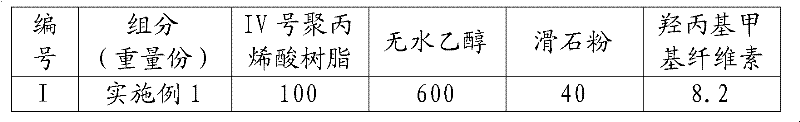

Polyacrylic acid type calcium nitrite corrosion inhibitor and preparation method thereof

The invention discloses a polyacrylic acid type calcium nitrite corrosion inhibitor and a preparation method thereof. The polyacrylic acid calcium nitrite corrosion inhibitor has a capsule form, the capsule comprises a core and a coating, the core comprises calcium nitrite, a microcrystalline cellulose and tween 80, and the coating comprises a polyacrylic resin, talc, and hydroxypropyl methyl cellulose. The polyacrylic resin wrapped calcium nitrite corrosion inhibitor of the invention has a good stability, and the release rate of the microcapsule can be controllably optimized by changing the mass ratio between the core material and the coating material, so defects of easy loss and easy oxidation of the calcium nitrite corrosion inhibitor are effectively solved; and the polyacrylic acid type calcium nitrite corrosion inhibitor of the invention has the advantages of long valid period, good corrosion inhibition effect, and environmental protection.

Owner:SHENZHEN UNIV

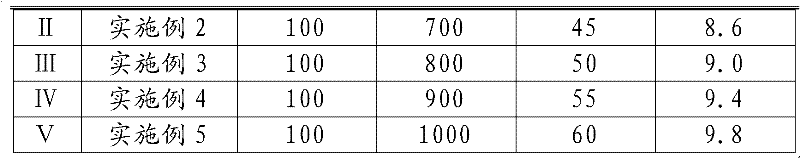

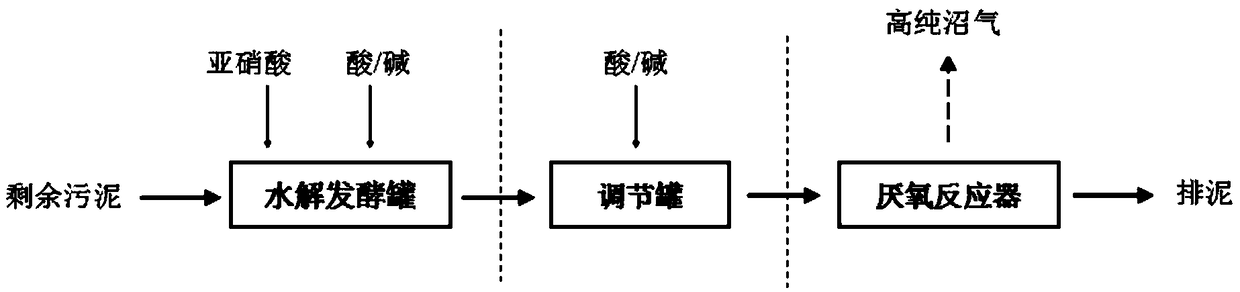

Method for improving methane purity in sludge anaerobic digestion generated biogas

ActiveCN108793656AImprove methane production efficiencyFacilitated releaseWater treatment parameter controlSludge treatment by oxidationLysisHydrogen

The invention provides a method for improving methane purity in a sludge anaerobic digestion generated biogas. The method comprises the following steps: concentrating organic sludge till a solid content is 20-40g / L; adding an additive, and controlling a pH value to 4.0-6.0, and carrying out a hydrolytic acidification reaction at 35-39 DEG C; adjusting the pH value of the sludge after hydrolytic acidification to 6.0-6.5, carrying out an anaerobic digestion reaction, and collecting a biogas. By adopting the method, calcium nitrite is adopted as the additive, so that sludge lysis and hydrolysis acidification can be improved, the anaerobic acid generation velocity of the sludge is greatly increased, furthermore, the sludge anaerobic digestion efficiency is improved; due to the addition of thecalcium nitrite, a function of blocking carbon is also achieved, the concentration of carbon dioxide in the biogas is also reduced, and the purity of methane is improved; as the pH value is adjusted twice, both acidic hydrolysis of the sludge under the action of the calcium nitrite is improved, and growth of hydrogen type methanogens in an anaerobic methanogenesis period is facilitated, the potential that the carbon dioxide is in reaction with hydrogen to generate the methane is improved, and the purity of the methane in the biogas is further improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com