Seawater and sea sand-based anticorrosive additive for producing marine high-performance concrete

A high-performance concrete, anti-corrosion technology, applied in the field of anti-corrosion admixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

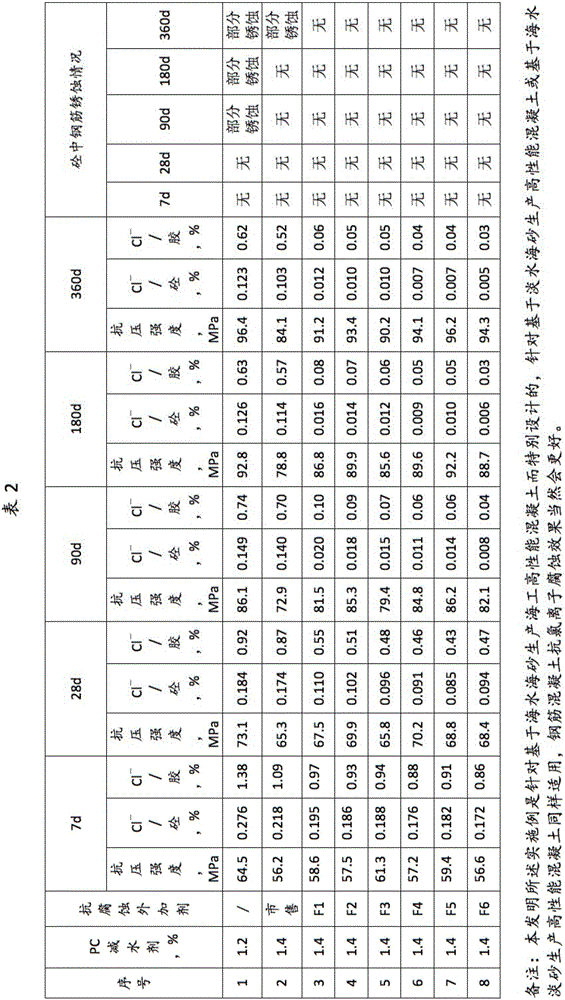

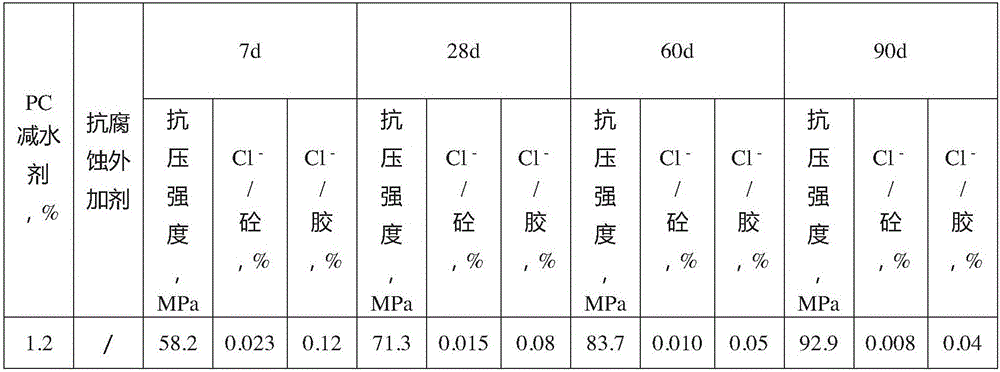

Examples

Embodiment Construction

[0011] The manufacturers and models of the substances involved in all of the following embodiments are as follows:

[0012] Calcium nitrite, industrial grade, produced by Shandong Luguang Chemical Factory;

[0013] Sodium carbonate, industrial grade, produced by Shandong Haihua Co., Ltd. Soda Ash Factory;

[0014] Sodium sulfate, industrial grade, produced by Zibo Huayan Chemical Co., Ltd.;

[0015] Chitosan, industrial grade, produced by Shandong Laizhou Haili Biological Products Co., Ltd.;

[0016] Triethanolamine, 85% concentration, produced by Shandong Hongyi Technology Co., Ltd.;

[0017] Triisopropanolamine, 85% concentration, produced by Nanjing Hongbaoli Co., Ltd.;

[0018] Ethylene glycol monoisopropanolamine, 85% concentration, produced by Nanjing Rongfeng Environmental Protection Technology Co., Ltd.;

[0019] Fly ash hollow microspheres, produced by Huichang Floating Pearl Factory in Xingtai City, Hebei Province;

[0020] Zeolite molecular sieve (molar ratio 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com