Anti-corrosion admixture for oceanic concrete

A marine concrete and anti-corrosion technology, applied in the field of concrete admixtures, can solve problems such as unsatisfactory effects and single mechanism of action

Inactive Publication Date: 2010-08-25

NANJING UNIV OF TECH

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(2) Formation of corrosion cells

However, the existing various measures have a single mechanism of action, and the effect is not very satisfactory.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

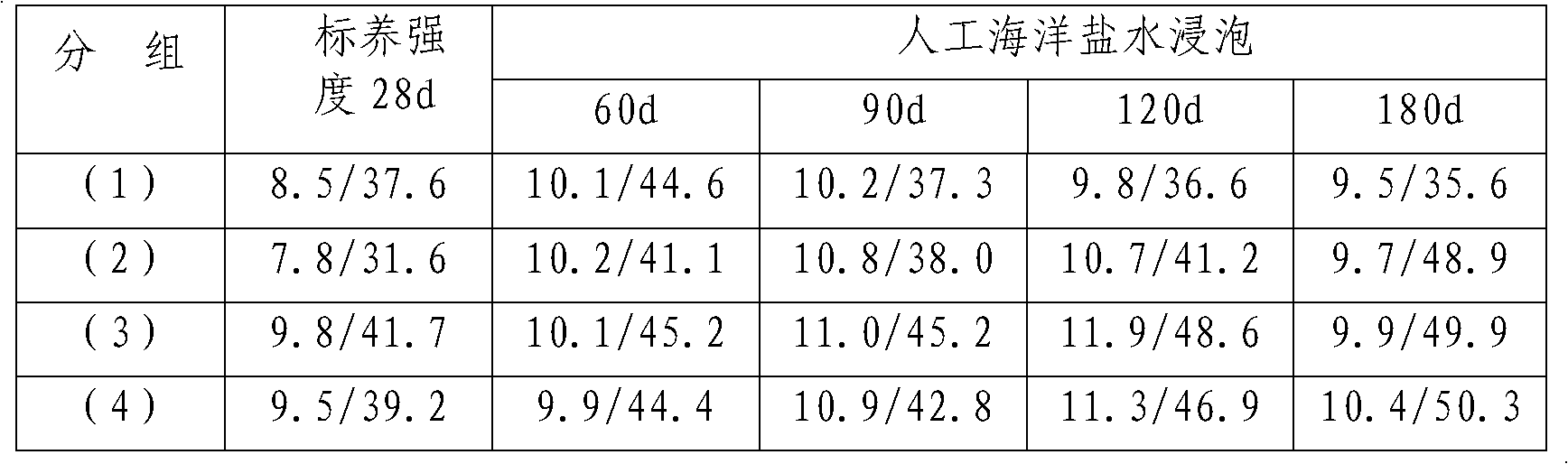

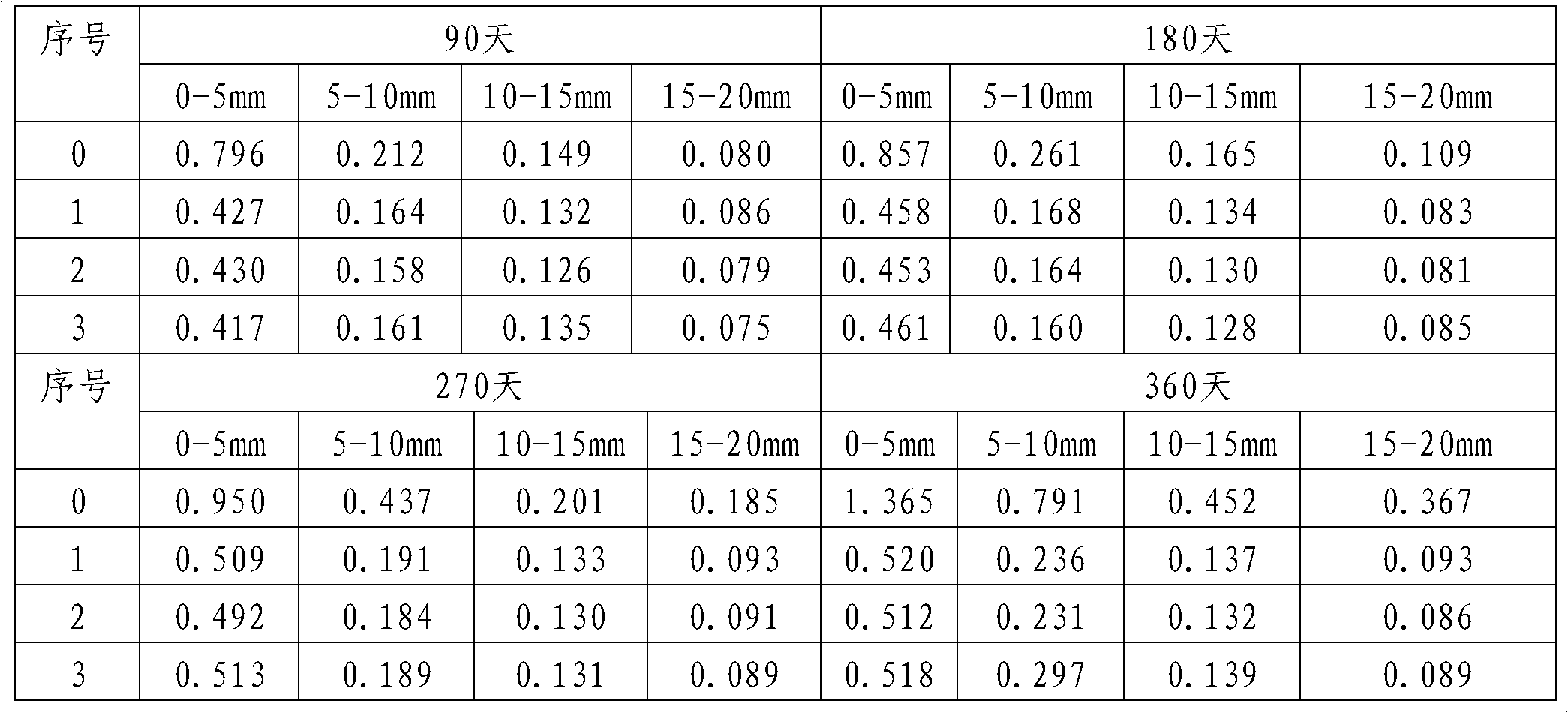

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an anti-corrosion admixture for oceanic concrete, which can enhance the anti-corrosion capability of the oceanic concrete by using a plurality of anti-corrosion mechanisms. The anti-corrosion admixture for the oceanic concrete comprises the following components by weight percent: 20-30% of calcium nitrite, 15-20% of calcined gypsum, 5-10 % of laminated soluble sodium silicate, 3-5% of hexamethylenetetramine, 1-3% of sodium tripolyphosphate, 0- 20% of water reducing agent, 0-0.4% of air entraining agent and the balance of coal ash. In a preferred scheme of the invention, the the calcined gypsum is obtained by calcining at 600-800 DEG C, and the modulus of the laminated soluble sodium silicate is from 2.1 to 2.3. In the invention, the novel anti-corrosion admixture for the oceanic concrete is formed by combining a corrosion resisting agent of reinforcing steel bars with activators of concrete admixtures (coal ash and grounded furnace slag), thereby the anti-corrosion capability of the oceanic concrete is greatly enhanced.

Description

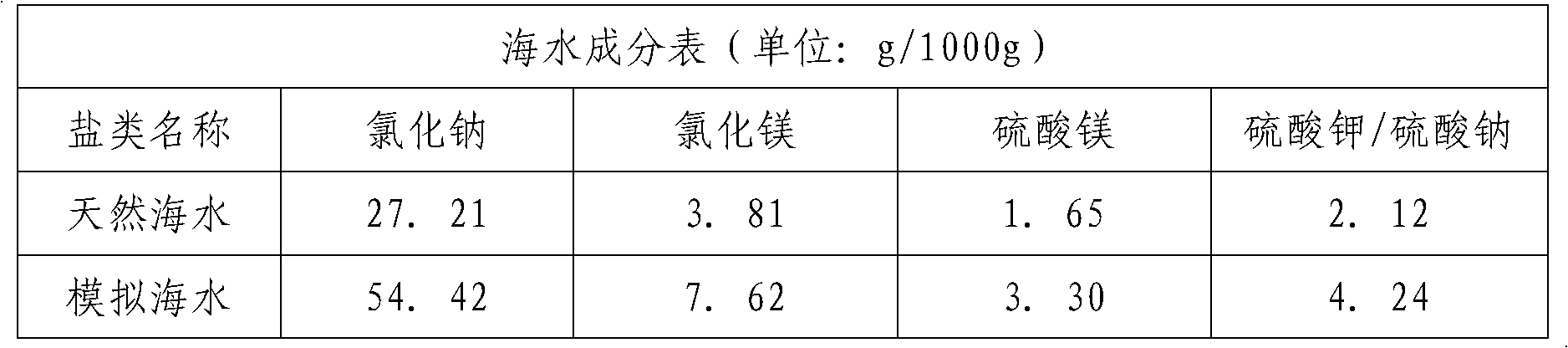

technical field The invention relates to a concrete admixture, in particular to a marine concrete anti-corrosion admixture. Background technique The 21st century is the ocean century. Our country is a large ocean country, and it is in a period of rapid economic development. Many important buildings costing a lot of money, such as cross-sea bridges, submarine tunnels, offshore oil production platforms, seaports, offshore projects, etc. have been or are under construction. The durability of structures has naturally become the focus of attention in civil engineering circles. In order to ensure the durability of marine concrete structures such as cross-sea bridges and subsea tunnels, some super-large projects in China have even adopted a 100-year design reference period. The concrete engineering adopts a comprehensive durability technology plan centered on high-performance concrete technology. The ocean is the main source of chloride ions, and seawater usually contains about ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/12C04B24/30C04B11/028C04B103/61

CPCC04B2111/24C04B40/0039C04B2103/61C04B11/02Y02W30/91C04B12/04C04B18/08C04B22/085C04B22/143C04B22/16C04B24/10C04B24/121C04B24/226C04B28/02C04B2103/302C04B2103/304

Inventor 张伟姚晓旷鹏

Owner NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com