Method for determining calcium oxide and magnesium oxide in iron slag grains

A method of determination, the technology of calcium oxide, is applied in the direction of material analysis by observing the influence of chemical indicators, the preparation of test samples, and the analysis by making materials undergo chemical reactions. Easy to filter, wide measurement range, and short analysis process due to cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation and calibration of standard solution:

[0028] 1A. Preparation of 0.01mol / L EDTA standard solution: Weigh 3.75g analytically pure EDTA (tetraethylamine disodium oxalate) into a 500ml beaker, add about 200ml of water, heat to 60-70℃ to dissolve, cool, Dilute to 1000ml, set aside after 1 week.

[0029] 1B. Preparation of calcium oxide standard solution: accurately weigh 1.0009g of calcium carbonate (mass fraction of 99.995%) which has been dried at 105°C for 2 hours and cooled to room temperature in a desiccator, placed in a 250ml beaker, added 50ml of water, and covered the surface Add 20ml of 1:1 (hydrochloric acid to water volume ratio 1:1) from the mouth of the cup, and heat to dissolve it, boil for 1-2 minutes, cool to room temperature, transfer to a 1000ml volumetric flask, dilute with water to Scale, the concentration of this calcium oxide standard solution is 0.01mol / L.

[0030] 1C. Calibration: Draw three portions of 20ml 1B in a 250ml beaker, add water...

Embodiment 2

[0059] 1. Preparation and calibration of standard solution: the same as Example 1

[0060] 2. Preparation of the solution to be tested:

[0061] Accurately weigh 0.2500g of vanadium-titanium ore grain iron slag sample, and prepare the filtrate to be tested in the same steps as in Example 1.

[0062] 3. Titration of calcium oxide:

[0063] Pipette 50ml filtrate into a 250ml beaker, adjust the volume to about 100ml with water, add 5ml 1:1 triethanolamine (volume ratio of triethanolamine to water=1:1), adjust pH ≥12 with 20% sodium hydroxide, add calcium carboxylic acid With a little indicator, titrate with 1A EDTA standard solution until the solution turns from red to pure blue as the end point. Note that the consumption of EDTA standard solution is 5.85ml.

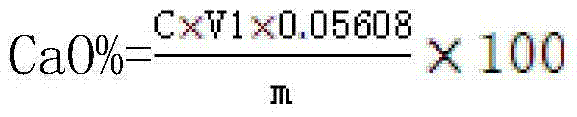

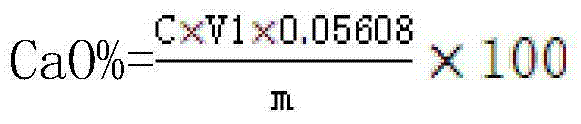

[0064] Calculation of calcium oxide content Ca 0 % = C X V 1 X 0.05608 m X 100

[0065] In this embodiment, m is 0.05 g, and the calculated mass fraction of calcium oxide is 6.56%.

[0066] 4. Titrati...

Embodiment 3

[0070] 1. Preparation and calibration of standard solution: the same as Example 1

[0071] 2. Preparation of the solution to be tested:

[0072] Accurately weigh 0.2500g of iron ore granular iron slag sample, and the steps are the same as in Example 1 to prepare the filtrate to be tested.

[0073] 3. Titration of calcium oxide:

[0074] Pipette 50ml filtrate into a 250ml beaker, adjust the volume to about 100ml with water, add 5ml 1:1 triethanolamine (volume ratio of triethanolamine to water=1:1), adjust pH ≥12 with 20% sodium hydroxide, add calcium carboxylic acid With a little indicator, titrate with 1A EDTA standard solution until the solution turns from red to pure blue as the end point. Note that the consumption of EDTA standard solution is 18.20ml.

[0075] Calculation of calcium oxide content Ca 0 % = C X V 1 X 0.05608 m X 100

[0076] In this embodiment, m is 0.05 g, and the calculated mass fraction of calcium oxide is 20.41%.

[0077] 4. Titrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com