Multiple composite corrosion inhibitor and preparation method thereof

A multi-component composite and corrosion inhibitor technology, applied in the field of water treatment, can solve problems such as poor corrosion inhibition performance, and achieve strong oxidation resistance, convenient use, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

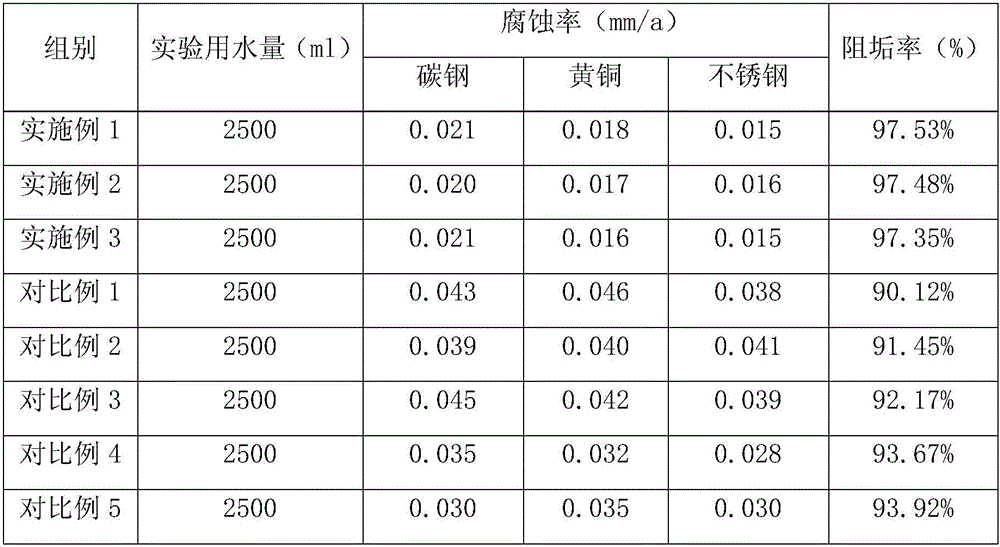

Examples

Embodiment 1

[0021] A multi-component composite corrosion inhibitor, made of the following raw materials in parts by weight: 5 parts of polyepoxysuccinic acid, 6 parts of benzotriazole, 8 parts of calcium gluconate, 5 parts of sodium silicate, secondary alkylsulfonic acid 4 parts of sodium, 1 part of sodium alginate, 1.5 parts of zinc sulfate, 2.5 parts of sodium borate, 1 part of sodium citrate, 2 parts of stearyl polyoxyethylene ether, 3 parts of dimethyl ketoxime, 4 parts of ethylene glycol ether part, 3 parts of ethylenediamine, 0.6 part of tea saponin, 0.8 part of bactericide, 1.0 part of chelating agent, 0.3 part of calcium nitrite, 6 parts of glycerol, 8 parts of ethanol, 30 parts of deionized water; the bactericide is guanidine Class bactericide, the chelating agent is potassium sodium tartrate;

[0022] The preparation method comprises the following steps:

[0023] (1) prepare materials respectively according to the consumption of each component;

[0024] (2) Add deionized water...

Embodiment 2

[0029] A multi-component composite corrosion inhibitor, made of the following raw materials in parts by weight: 9 parts of polyepoxysuccinic acid, 6 parts of benzotriazole, 6 parts of calcium gluconate, 8 parts of sodium silicate, secondary alkylsulfonic acid 2 parts of sodium, 0.5 parts of sodium alginate, 2 parts of zinc sulfate, 2.5 parts of sodium borate, 1.0 part of sodium citrate, 2.5 parts of stearyl polyoxyethylene ether, 2 parts of dimethyl ketoxime, 4 parts of ethylene glycol ether part, 2 parts of ethylenediamine, 0.8 part of tea saponin, 1.5 parts of bactericide, 0.6 part of chelating agent, 0.4 part of calcium nitrite, 6 parts of glycerin, 5 parts of ethanol, 40 parts of deionized water; Class bactericide, the chelating agent is potassium sodium tartrate;

[0030] The preparation method comprises the following steps:

[0031] (1) prepare materials respectively according to the consumption of each component;

[0032] (2) Add deionized water to the configuration t...

Embodiment 3

[0037]A multi-component composite corrosion inhibitor, made of the following raw materials in parts by weight: 6 parts of polyepoxysuccinic acid, 9 parts of benzotriazole, 8 parts of calcium gluconate, 5 parts of sodium silicate, secondary alkylsulfonic acid 2 parts of sodium, 1.5 parts of sodium alginate, 1 part of zinc sulfate, 1 part of sodium borate, 2 parts of sodium citrate, 2 parts of stearyl polyoxyethylene ether, 3 parts of dimethyl ketoxime, 2 parts of ethylene glycol ether part, 3 parts of ethylenediamine, 0.8 part of tea saponin, 1.2 parts of bactericide, 1.8 parts of chelating agent, 0.3 part of calcium nitrite, 8 parts of glycerol, 6 parts of ethanol, 35 parts of deionized water; Class bactericide, the chelating agent is potassium sodium tartrate;

[0038] The preparation method comprises the following steps:

[0039] (1) prepare materials respectively according to the consumption of each component;

[0040] (2) Add deionized water to the configuration tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com