Ultralow-temperature high-performance concrete for railway construction in severe cold regions and preparation technique thereof

A high-performance concrete and ultra-low temperature technology, which is applied in the field of high-performance concrete preparation, achieves the effects of low investment cost, convenient optimization, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

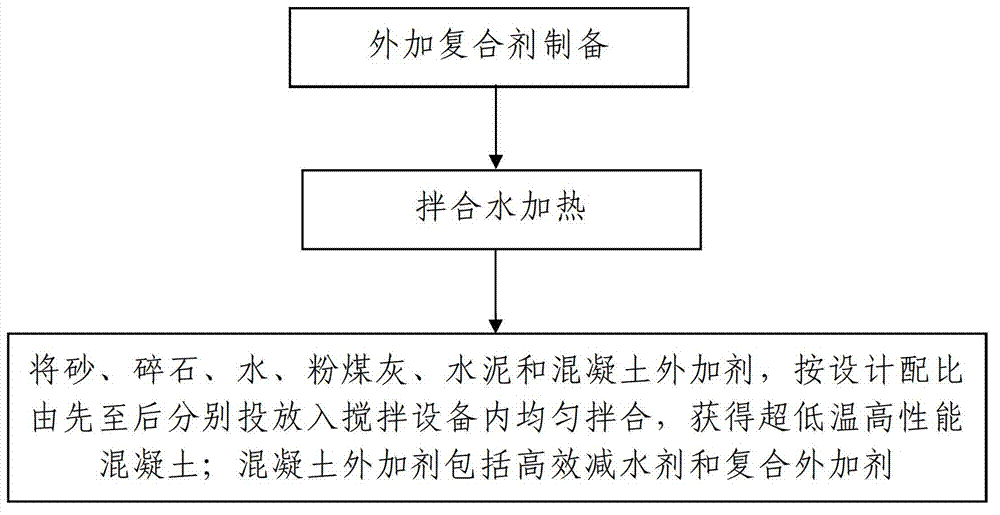

Method used

Image

Examples

Embodiment 1

[0033] The ultra-low temperature high-performance concrete prepared by the present invention is uniformly mixed with cementitious material, sand, gravel, high-efficiency water reducer, composite antifreeze and water, and the volume density of the ultra-low temperature high-performance concrete is 2350kg / m 3 ~2450kg / m 3 , and the maximum water-binder ratio and sand ratio of the ultra-low-temperature high-performance concrete are designed according to the design drawings of the concrete structure to be constructed, and are designed according to the mix ratio design method of concrete for railway construction.

[0034]The cementitious material is uniformly mixed with cement and mineral admixture in a weight ratio of 15-20:85-80. In actual use, the mineral admixture is coal fly ash or ground slag powder. In this embodiment, the mineral admixture is coal fly ash.

[0035] The water reducing rate of the superplasticizer is not less than 25%, and the weight ratio of the superplasti...

Embodiment 2

[0115] In this example, the difference between the mixed ultra-low temperature high-performance concrete and Example 1 is that the water-binder ratio of the ultra-low temperature high-performance concrete is 0.3, the weight ratio of sand to cementitious material is 1.4-1.5, and the sand rate is 32%, the weight ratio of cement and fly ash in the cementitious material is 88:12, the weight ratio of the composite antifreeze to the cementitious material is 4:100, and the weight ratio of the superplasticizer to the cementitious material is 0.8:100 The composite antifreeze used is different from Example 1: the composition of the composite antifreeze is by weight: 35% nitrate, 30% organic compound, 0.5% calcium formate, and the balance is water.

[0116] In this example, the proportion of other components of the ultra-low temperature high-performance concrete used, as well as the process steps and process parameters of its preparation process are the same as those in Example 1.

Embodiment 3

[0118] In this example, the difference between the mixed ultra-low temperature high-performance concrete and Example 1 is that the water-binder ratio of the ultra-low temperature high-performance concrete is 0.4, the weight ratio of sand to cementitious material is 1.7-1.8, and the sand rate is 38%, the weight ratio of cement and fly ash in the cementitious material is 78:22, the weight ratio of the composite antifreeze to the cementitious material is 5:100, and the weight ratio of the superplasticizer to the cementitious material is 1:100 The composite antifreeze used is different from Example 1 in that the composition of the composite antifreeze is by weight: 32% nitrate, 32% organic compound, 0.8% calcium formate, and the balance is water.

[0119] In this example, the proportion of other components of the ultra-low temperature high-performance concrete used, as well as the process steps and process parameters of its preparation process are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com