Sulphur-resisting acid-proof food can inner wall paint and preparation method thereof

A technology for food cans and coatings, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of low safety and sanitation, poor salt resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, the embodiment of the present invention also provides a method for preparing a coating for the inner wall of a sulfur-resistant and acid-resistant food can with easily controlled conditions. The method can be used to prepare the above-mentioned anti-sulfur and acid-resistant food tank inner wall coating, specifically, the method comprises the following steps:

[0045] S01. Prepare the first solution of epoxy resin 1009: add epoxy resin 1009 into an organic solvent, and reflux at a constant temperature of 90° C. to 100° C. for 1 hour until the epoxy resin 1009 is completely dissolved to obtain epoxy resin 1009. organic solution;

[0046] S02. Mix the organic solution of epoxy resin 1009 with the remaining components: disperse the pigment into the organic solution of epoxy resin 1009 prepared in step S01 and then grind it, then add blocked isocyanate 3175 and additives , and the remaining organic solvent for dispersion treatment, or add blocked isocyanat...

Embodiment 1

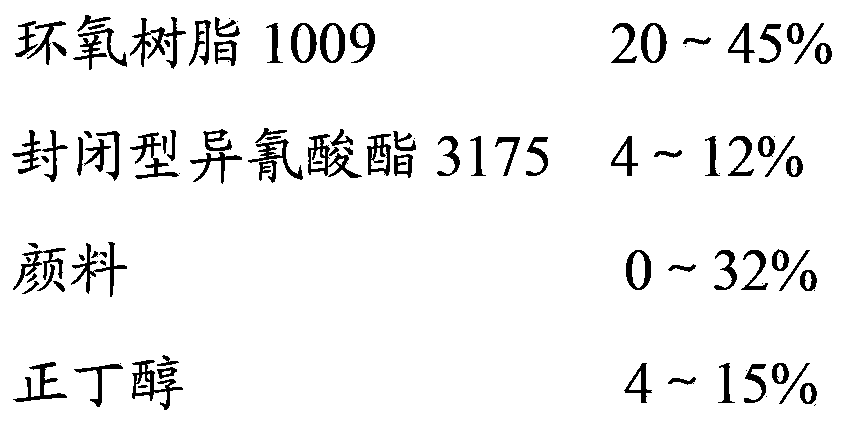

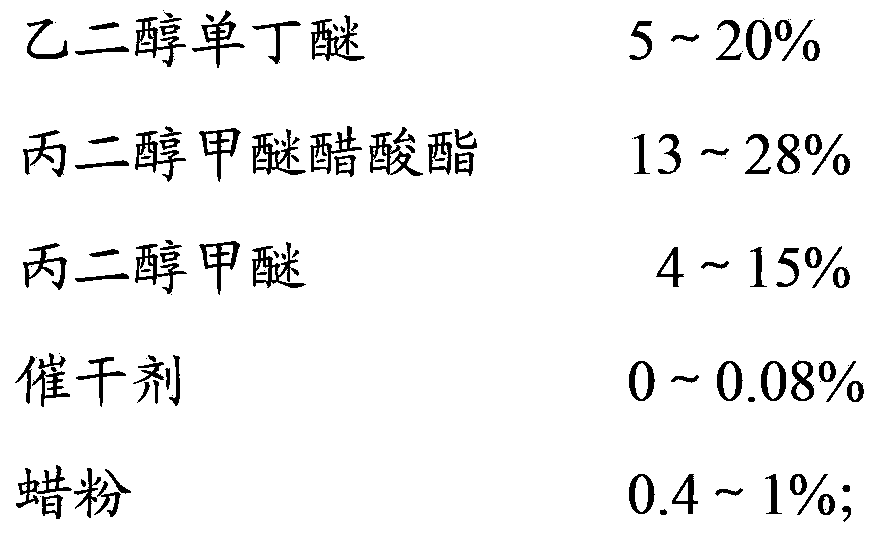

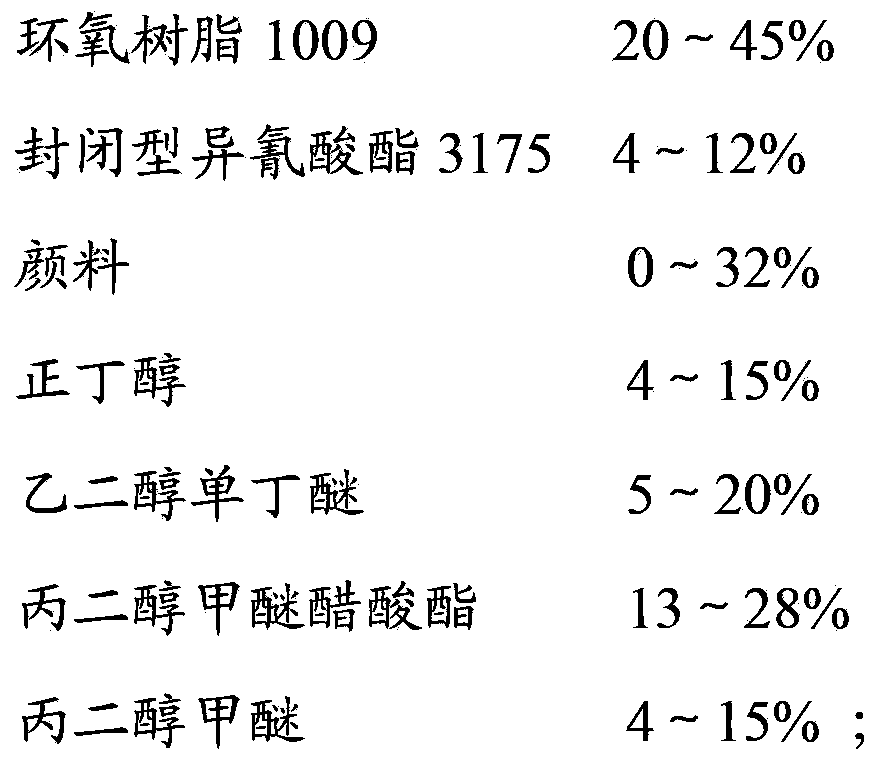

[0070] A sulfur-resistant and acid-resistant food tank inner wall coating and a preparation method thereof, the sulfur-resistant and acid-resistant food tank inner wall coating includes components in weight percentages in Table 1 below.

[0071] Its preparation method is as follows:

[0072] Step 01. Start the mixer until the speed is 60 rpm, put solid epoxy resin, ethylene glycol monobutyl ether, propylene glycol methyl ether acetate and n-butanol into the reaction kettle with reflux device respectively, then raise the temperature to 90°C, and keep the temperature constant Reflux for 1 hour until the solid resin is completely dissolved;

[0073] Step 02. Cool the above solution to 40°C, transfer it to a stainless steel container, put titanium dioxide into it, stir evenly, start the disperser at a speed of 1000 rpm, and disperse for 15 to 20 minutes;

[0074] Step 03. Grind the above mixture through a horizontal sand mill to a fineness of less than 10 microns;

[0075] Step ...

Embodiment 2

[0079] A sulfur-resistant and acid-resistant food tank inner wall coating and a preparation method thereof, the sulfur-resistant and acid-resistant food tank inner wall coating includes components in weight percentages in Table 1 below.

[0080] Its preparation method is as follows:

[0081] Step 01, start the mixer until the rotating speed is 100 rpm, put solid epoxy resin, ethylene glycol monobutyl ether, propylene glycol methyl ether, propylene glycol methyl ether acetate and n-butanol into the reaction kettle with reflux device respectively, and then heat up to 100°C, constant temperature reflux for 1 hour, until the solid resin is completely dissolved;

[0082] Step 02. Cool the above solution to 40°C, transfer it to a stainless steel container, put titanium dioxide into it, stir evenly, start the disperser at a speed of 800 rpm, and disperse for 15 to 20 minutes;

[0083] Step 03. Grind the above mixture through a horizontal sand mill to a fineness of less than 10 micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com