Patents

Literature

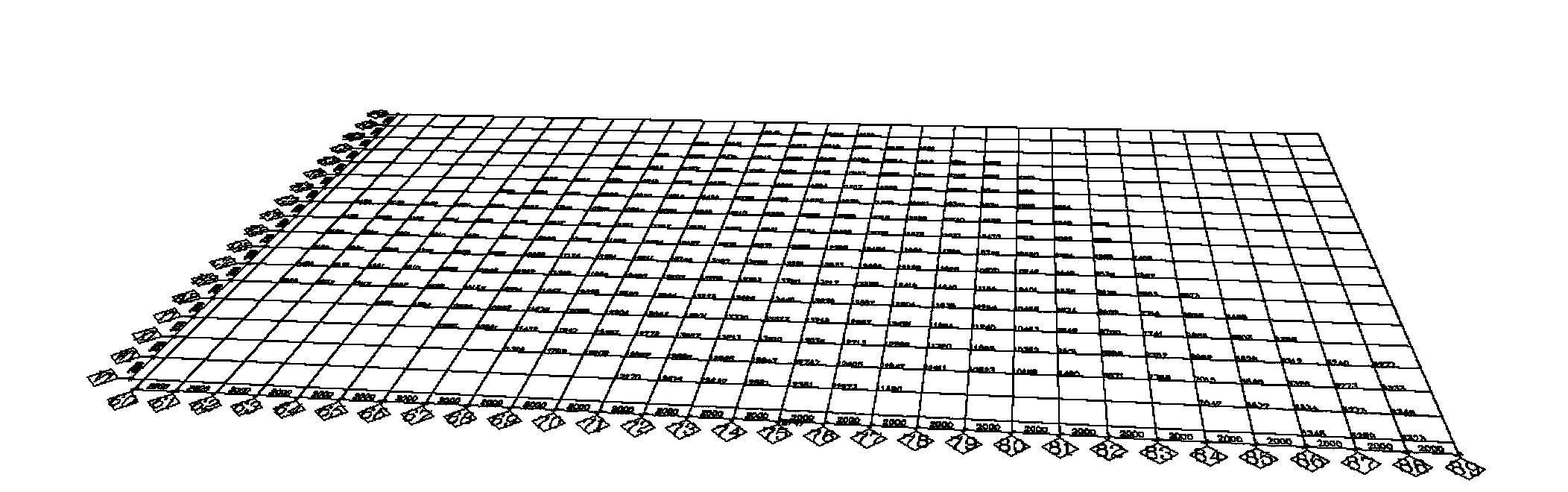

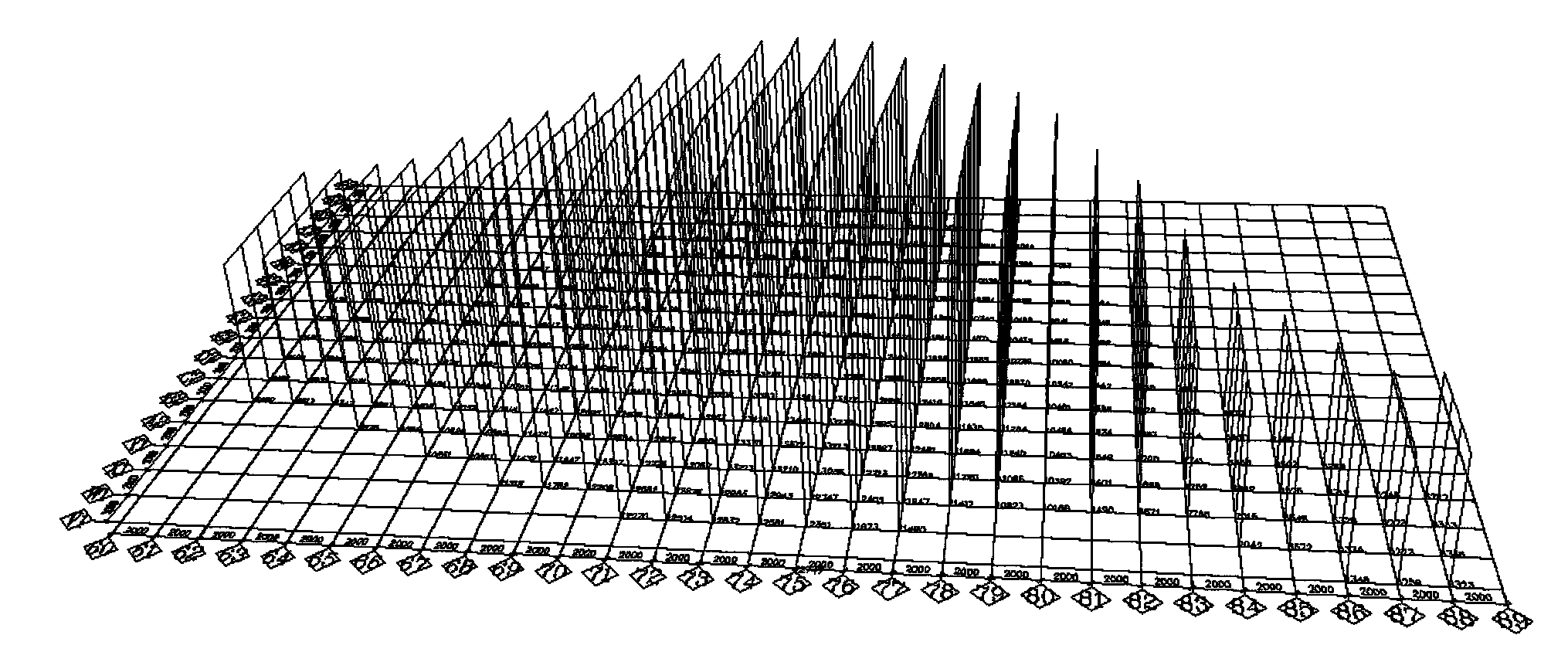

42results about How to "Optimize mix ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Early-strength concrete for non-steam autoclaved PHC pipe piles

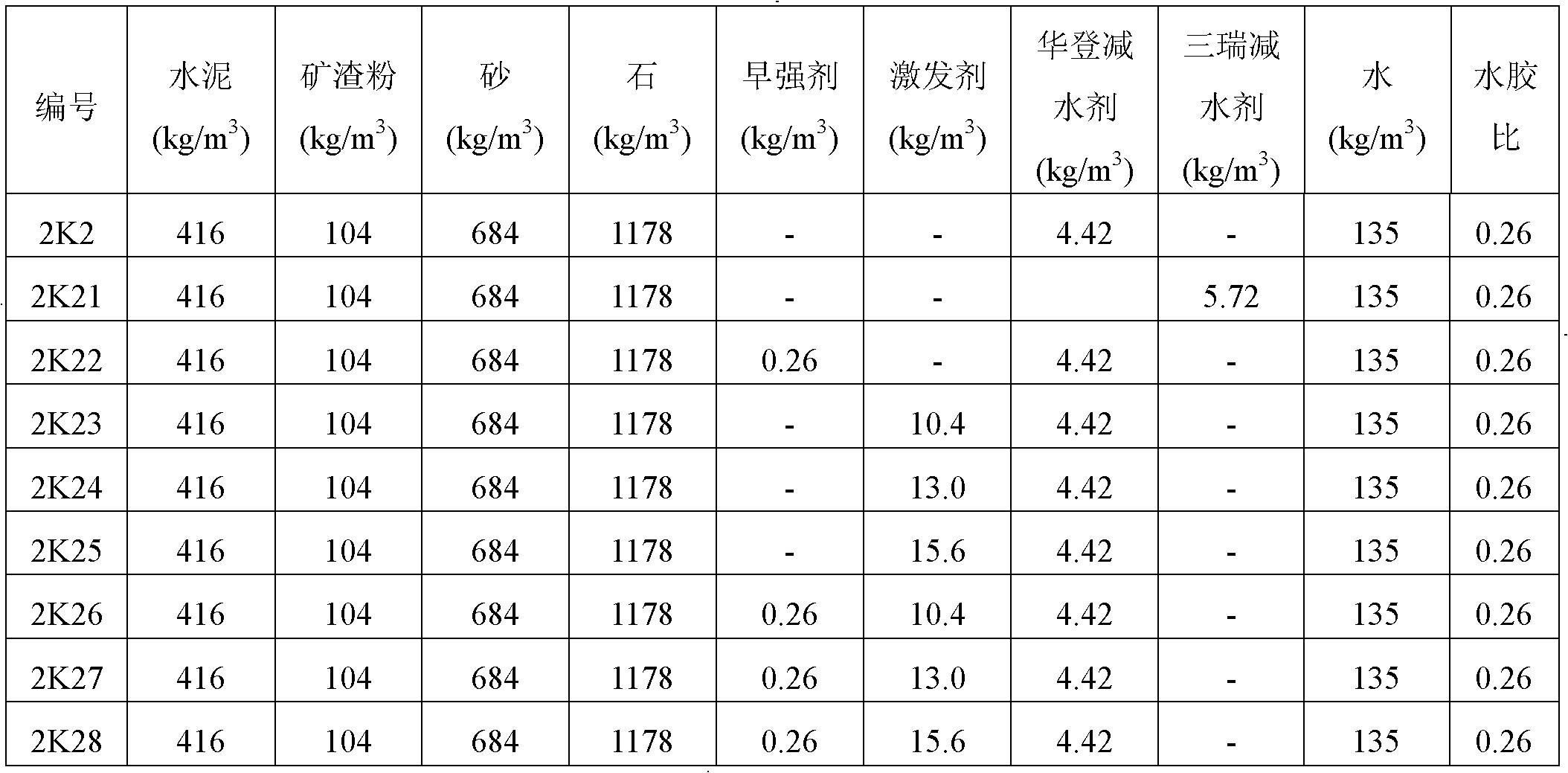

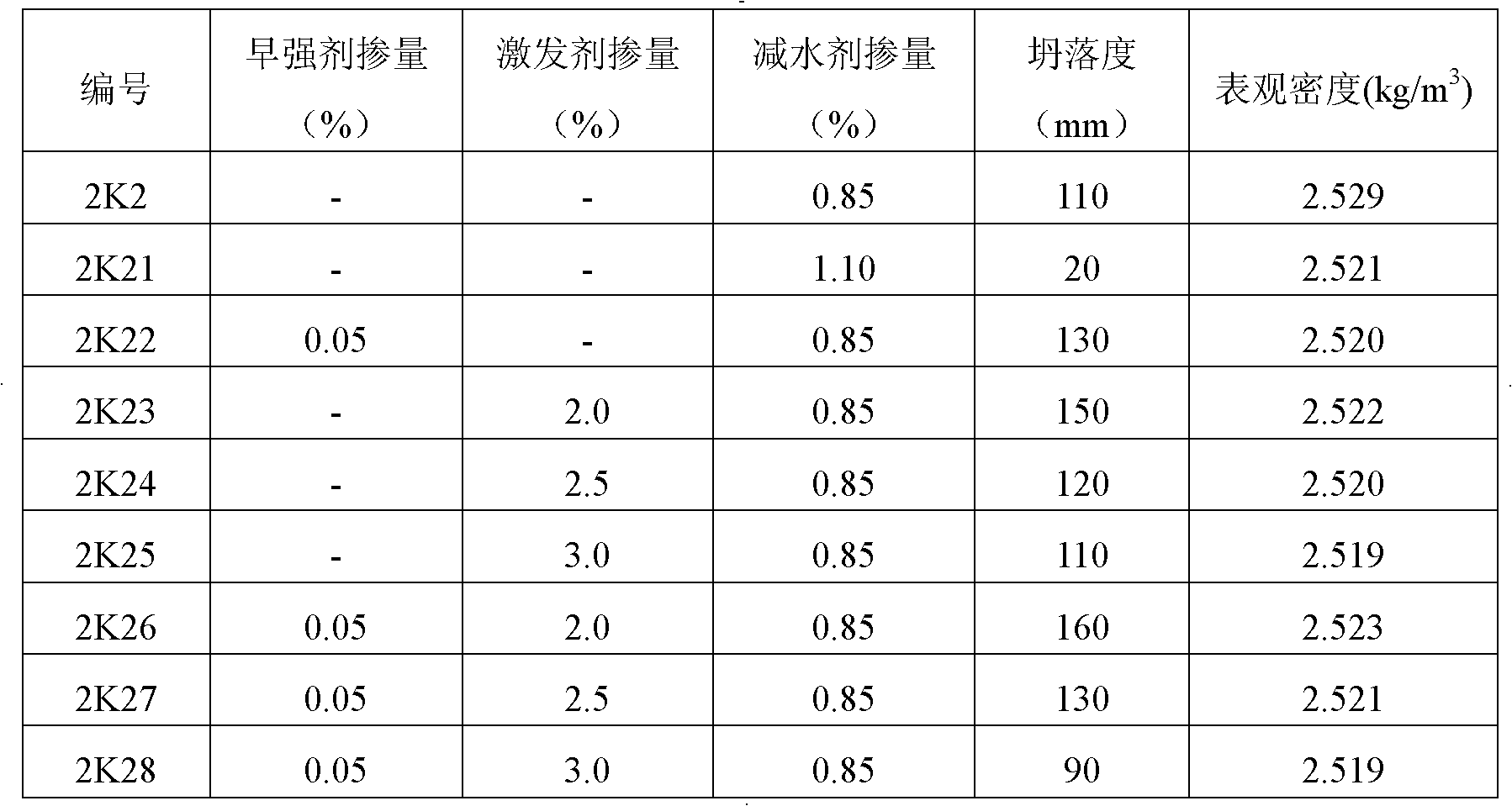

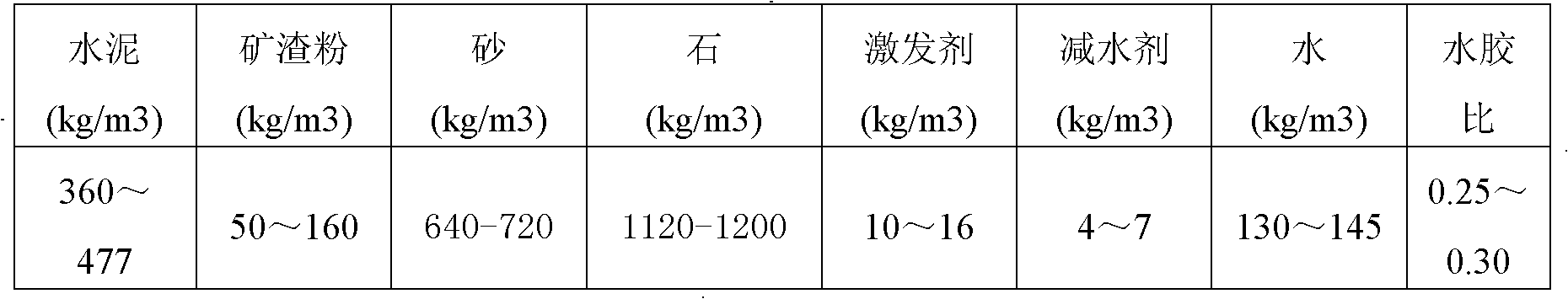

The invention discloses early-strength concrete for non-steam autoclaved PHC pipe piles. The concrete / m3 is prepared from the following raw materials: 360-477kg of Portland cement, 50-160kg of granulated blast furnace slag powder, 640-720kg of fine aggregates with fineness modulus of 2.5-3.0, 1120-1200kg of coarse aggregates with maximum grain size being not more than 25mm, 10-16kg of anhydrous gypsum, 4-7kg of high efficiency water reducing agents and 130-145kg of water. The concrete is used for preparing the PHC pipe piles and can meet the compression strength requirement of C80 concrete for non-steam autoclaved PHC pipe piles in a shorter time.

Owner:CCCC THIRD HARBOR ENG +2

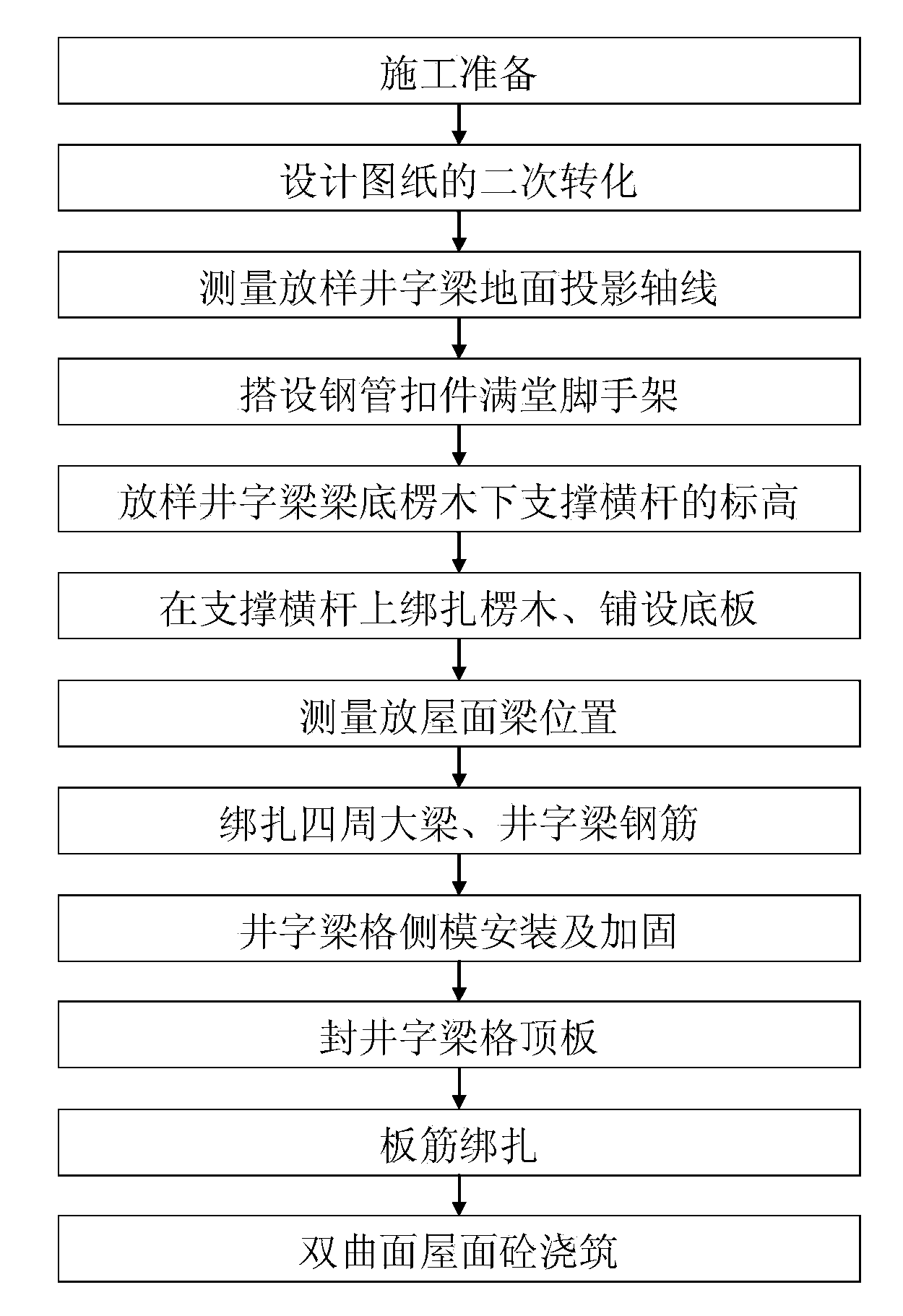

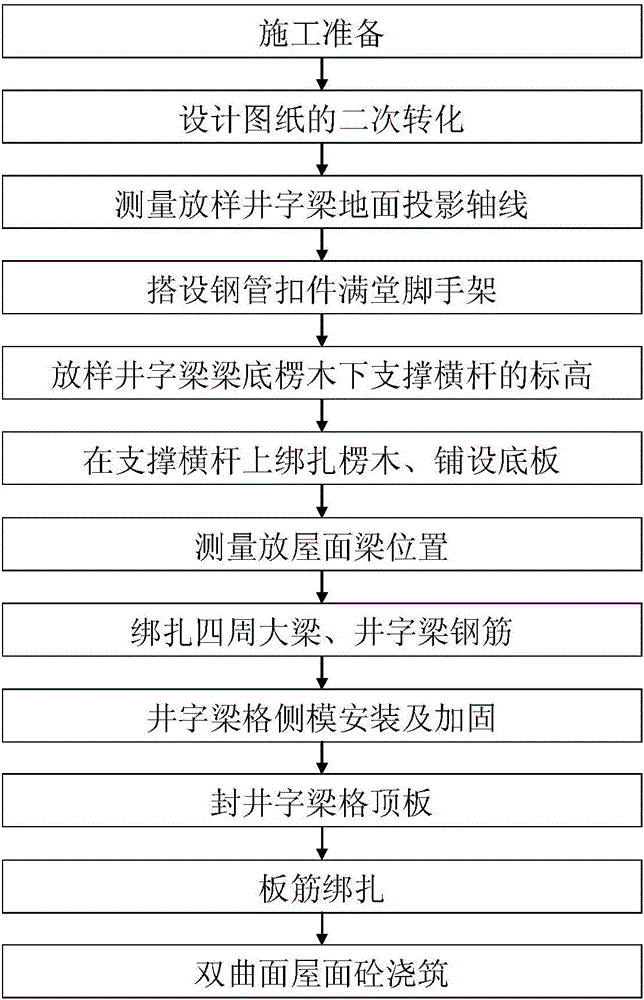

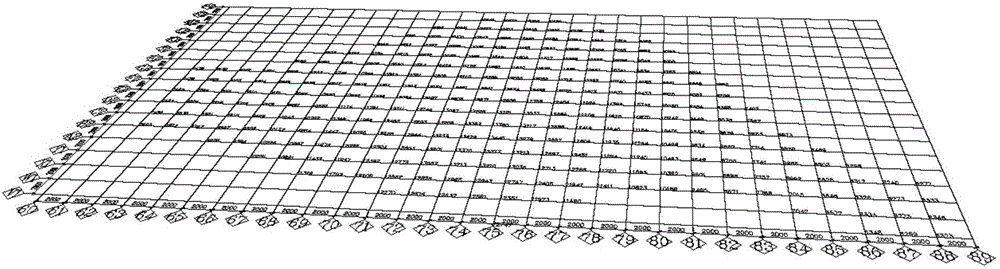

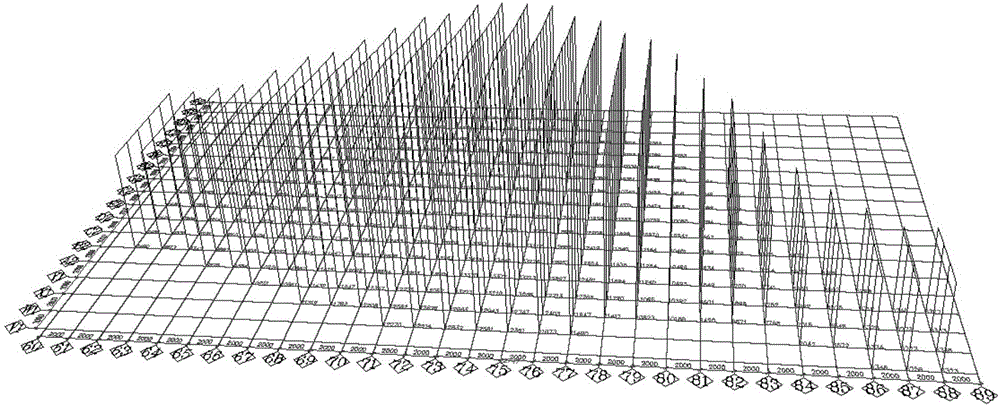

Irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method

ActiveCN103615110AImprove work efficiencyShorten the construction periodBuilding material handlingFalseworkSupporting system

An irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method comprises the steps of construction preparing, secondary conversion of design drawing, lofting grillage beam ground projection axis measuring, steel pipe buckling piece all-round scaffold supporting system erecting, grillage beam bottom wood ridge lower support horizontal rod elevation giving off, wood ridge binding and bottom plate paving on a supporting horizontal rod, given-off roof beam position measuring, bound grillage beam steel rib machining, grillage beam grillage side mould mounting and reinforcing, grillage beam top plate mounting and reinforcing, face plate steel rib binding and hyperbolic roof concrete pouring. Through a space three-dimensional technology, a reasonable supporting system and accurate location of a hyperbolic roof and a grillage beam, the concrete mixing proportion is optimized, the quality and the attractive degree of the hyperbolic roof can be improved, construction difficulty is lowered, and construction efficiency is improved.

Owner:广西建工第一建筑工程集团有限公司

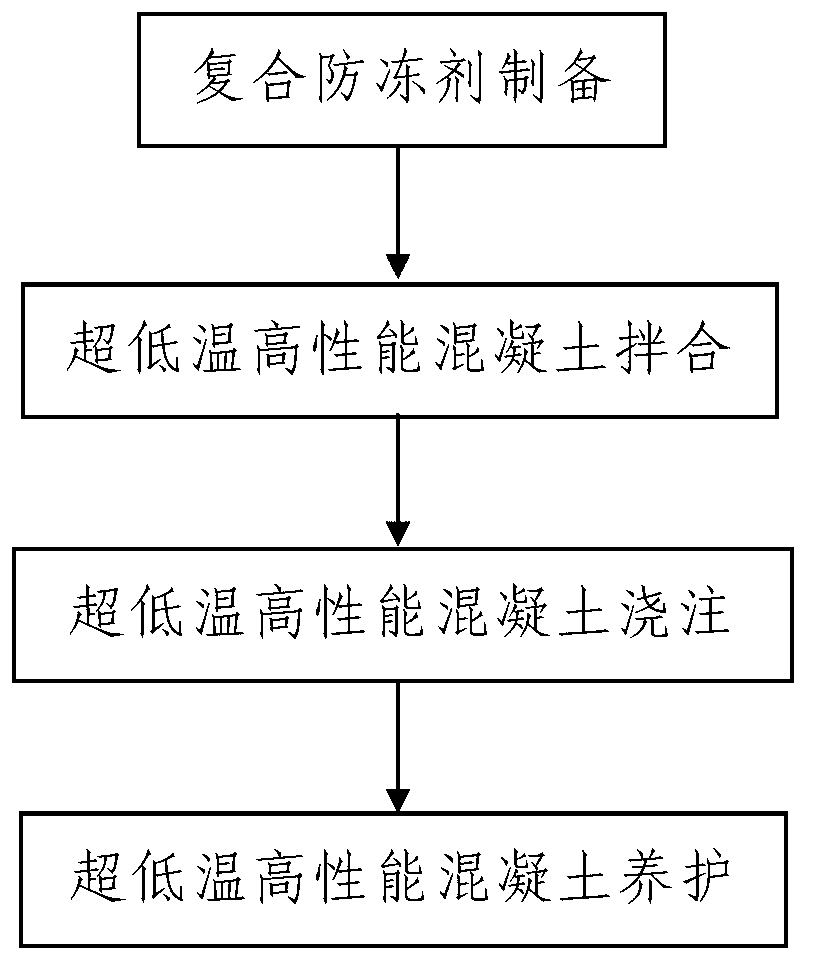

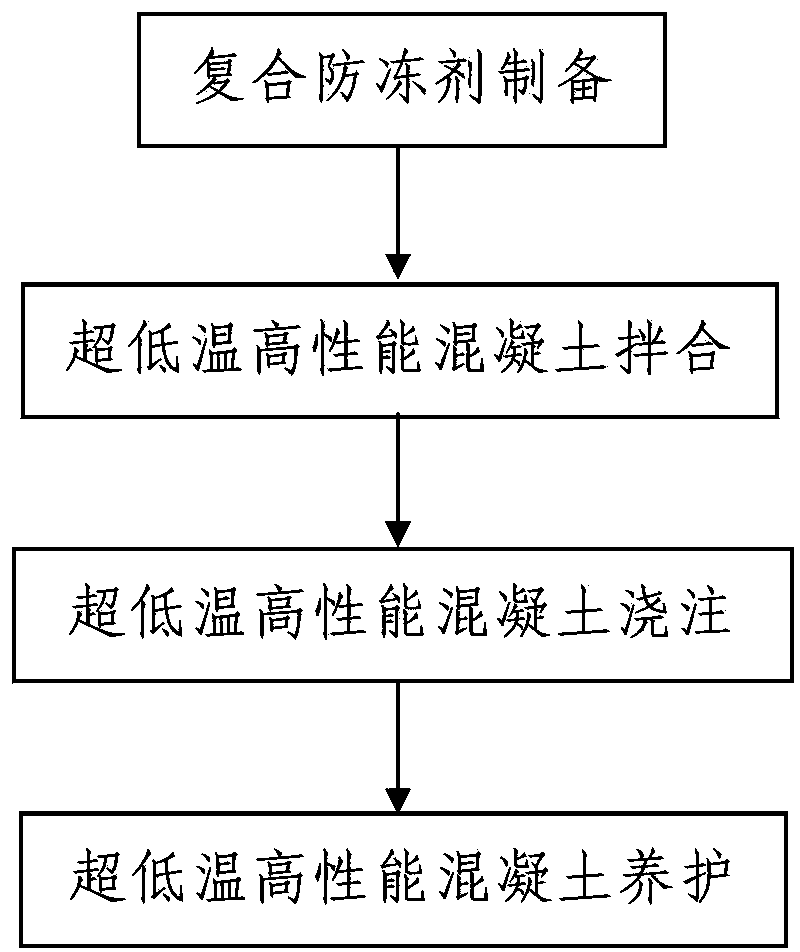

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358AThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

The invention discloses a construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas. The construction technique comprises the steps as follows: A, mixing ultralow-temperature high-property concrete: gelled materials, sand, crushed stone, an efficient water reducing agent, compound antifreeze and water are evenly mixed to obtain the ultralow-temperature high-property concrete; the gelled materials are made by evenly mixing cement and mineral admixtures in the weight ratio of (88-78):(12-22); the weight ratio of the compound antifreeze to the mineral admixtures is (3-6):100; the compound antifreeze comprises 30 to 35 wt% of nitrate, 30 to 33 wt% of organic compound, 0.5 to 1wt% of calcium formate, and water as the rest; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or alcohol; B, pouring the ultralow-temperature high-property concrete; and C, curing the ultralow-temperature high-property concrete. The construction technique has the advantages of reasonable design, simplicity in construction steps, convenience in operation, fast construction progress, low construction cost, and good structural quality of concrete used in construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

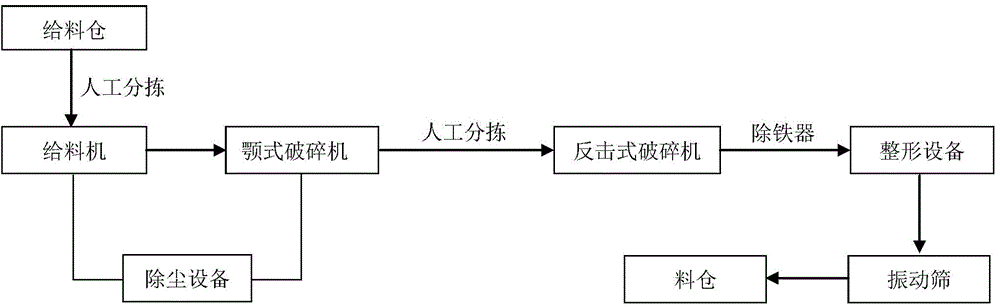

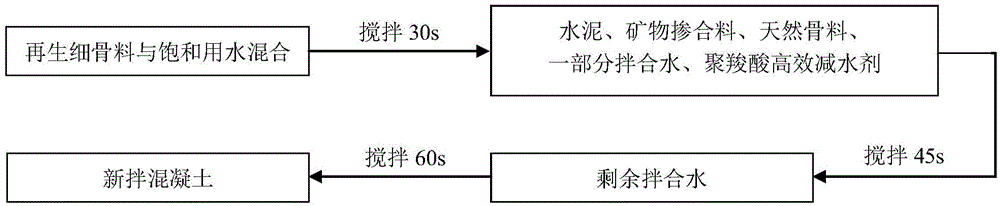

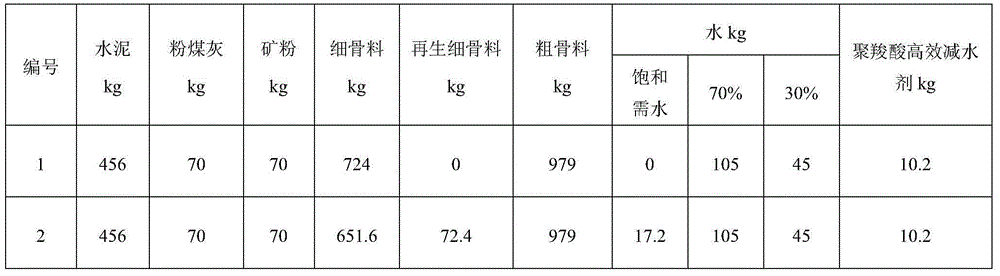

Preparation method for high-strength self-compacting concrete with recycled fine aggregate

InactiveCN104944863ASolve slump lossSolve the problem of large slump lossSolid waste managementWork performanceSuperplasticizer

The invention discloses a preparation method for high-strength self-compacting concrete with recycled fine aggregate. The preparation method comprises the following steps: mixing recycled fine aggregate with required saturated water, stirring the mixture to be uniform, adding and mixing cement, a mineral admixture, natural aggregate, 50-70 % of mixing water and a polycarboxylate superplasticizer, stirring the mixture to be uniform, and finally adding the remaining mixing water to the mixture to be mixed uniformly. According to the preparation method, the problem that the concrete slump loss is large, which is caused by the fact that recycled fine aggregate has the characteristics of higher water absorption, poor strength, irregular shape and the like, is solved, and almost no loss is caused within 2 h, so that the preparation method has wide applicability, and the problem that new mixed concrete is poor in working performance and the like in the actual construction process can be solved. The ratio and the production technology process of the high-strength self-compacting concrete with recycled fine aggregate are optimized; by changing the ratio of mineral admixture and the stirring manners as well as optimizing a recycled fine aggregate demand water saturation process and a mixing water adding process, the new mixed concrete can be excellent in working performance, the slump loss is obviously reduced, the pumpability is excellent and the construction is facilitated.

Owner:中建西部建设北方有限公司

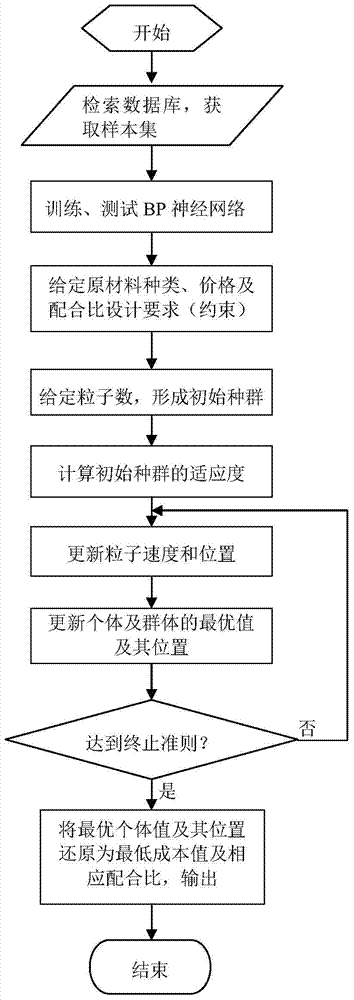

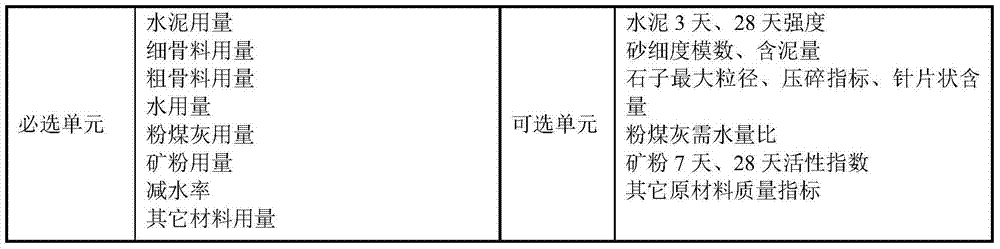

Non-linear optimization method for mix proportion of concrete

InactiveCN104261742AAchieve global optimizationSolve the overfitting control problemBiological neural network modelsNetwork modelGlobal optimization

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

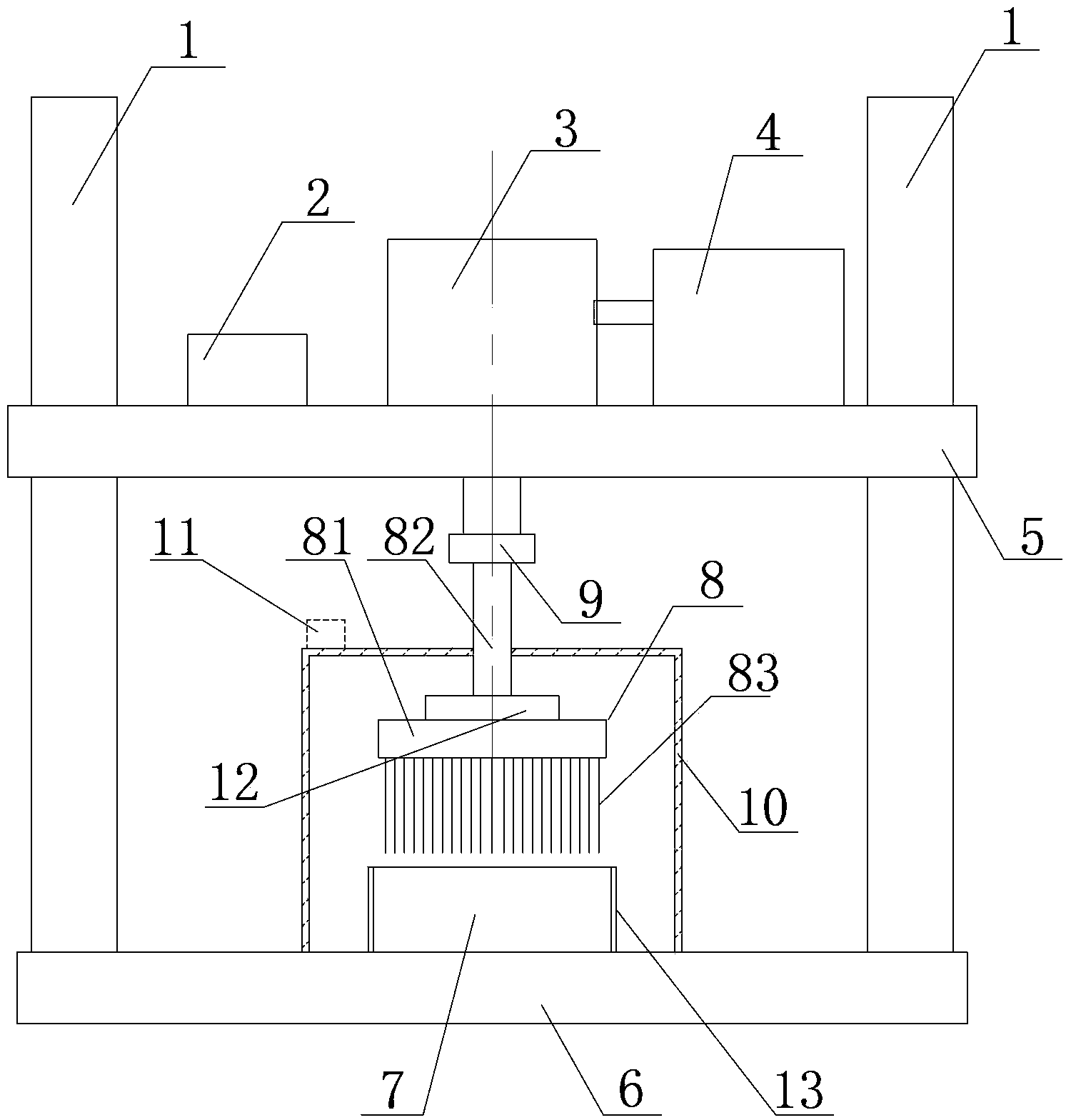

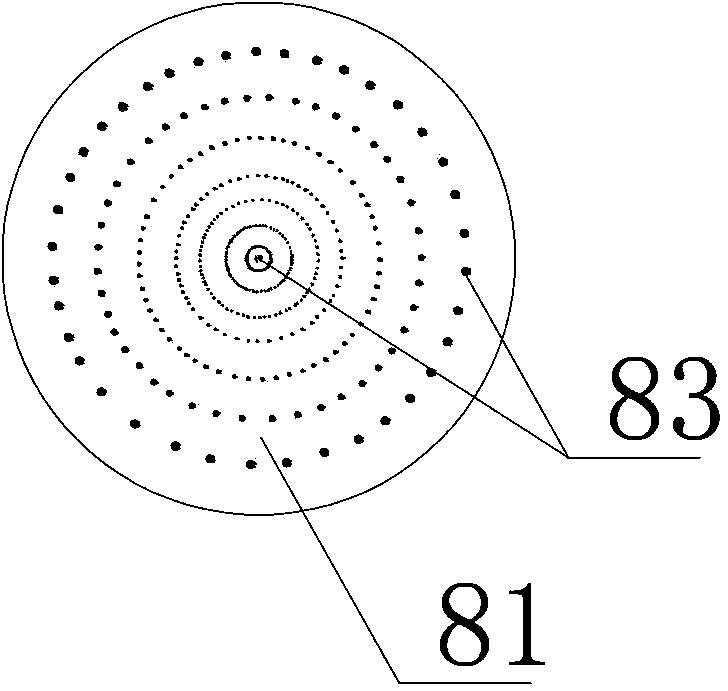

Testing device and evaluation method of antistrip performance of bituminous mixture

InactiveCN102768178AEfficient determination of peeling resistanceSimple structureUsing mechanical meansMaterial analysisEngineeringWire brush

The invention discloses a testing device of antistrip performance of bituminous mixture. The testing device comprises a base platform, a vertical column, a liftable platform and a steel wire brush, wherein the vertical column is arranged on the base platform, the liftable platform is installed on the vertical column, a motor and a speed reducer are installed on the liftable platform, the speed reducer is connected with the steel wire brush through a coupler, and steel wires densely distributed on the steel wire brush right face a test piece placing groove on the base platform. The invention further discloses an evaluation method which comprises the following steps of drying a test piece to be tested to constant weight, weighing the test piece and fixing the test piece; staring a temperature controller to enable the inner temperature of the test piece to reach the test temperature; placing the steel wire brush on the surface of the test piece and sleeving an annular counter weight on the steel wire brush; staring the motor, driving the steel wire brush to rotate on the surface of the test piece through the speed reducer and the coupler, and performing counting; taking out the test piece to perform weighing after set time; and finally evaluating the antistrip performance of the test piece according to a formula of peeling rate per unit area. The evaluation method has the advantages of being simple and easy to operate, visual, accurate and reliable in evaluation result, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

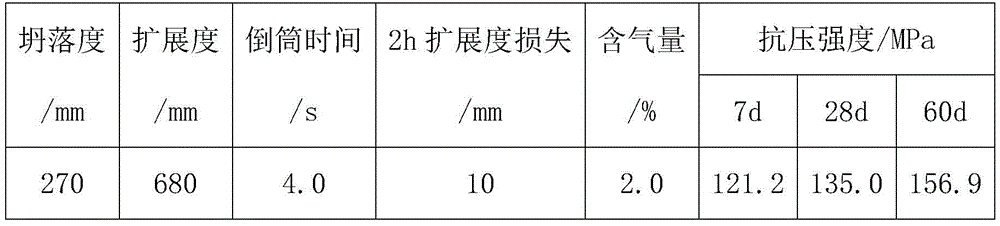

Preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping

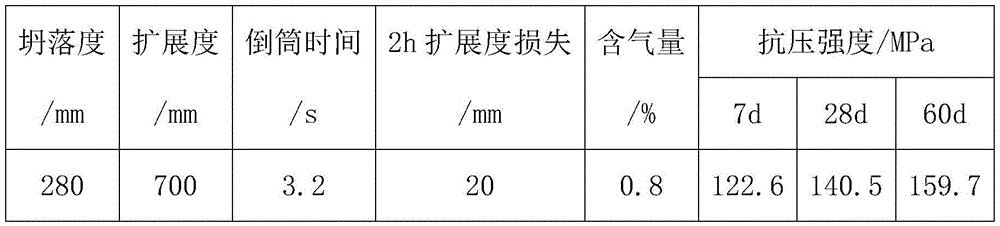

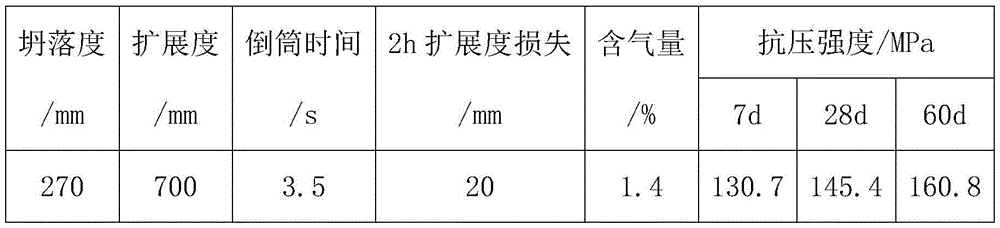

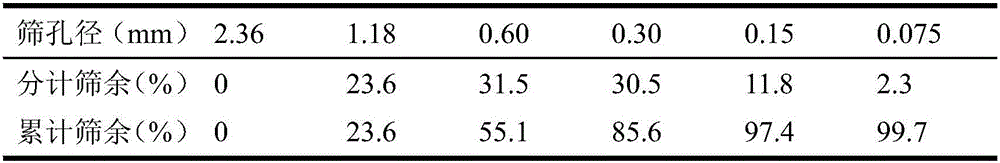

The invention provides a preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping. According to the method, the ultra-high-strength steel fiber reinforced concrete with the strength grade of C150 is prepared by changing proportion of a cementing material and a feeding sequence and can be prepared with conventional production process through a mixing plant, and the problem that concrete with the strength grade of C150 or higher cannot be produced with the conventional process is solved. Common Portland cement as well as coarse and fine aggregate is adopted, and the cement is prepared through technological approaches such as reduction of a water-binder ratio, density enhancement and the like under double-doping actions of a polycarboxylate superplasticizer and a superfine mineral admixture. The prepared concrete has good working performance, the slump flow is 670-700 mm, and loss is basically avoided within 2 h; the viscosity is low, and rewinding time is 3.2-4.2 s; 28 d compressive strength reaches the strength grade of C150, and requirements for pumping construction of super high-rise buildings with height of 600 m or higher can be met.

Owner:中建西部建设北方有限公司 +1

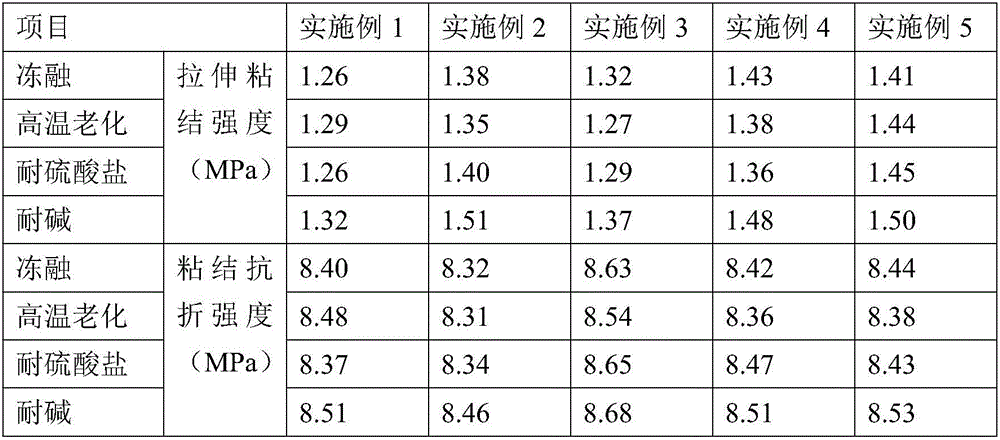

Waterproof flexible cement-based dry-mixed overlay repairing mortar

InactiveCN105906265AImprove freeze-thaw resistanceStrong water retention capacityDefoamerNatural sand

The invention discloses a waterproof flexible cement-based dry-mixed overlay repairing mortar. A dry mixed material includes, by weight, 22-39 parts of ordinary Portland cement, 2-18 parts of fly ash, 0.9-2.1 parts of rubber powder, 0.05-0.45 parts of cellulose ether, 0.03-0.3 parts of a defoamer, 0.02-0.15 parts of an expanding agent, and 40-75 parts of natural sand. During usage, water accounting for 10-20% of the total mass of the mortar is added to the dry mixed material to obtain the waterproof flexible cement-based dry-mixed overlay repairing mortar. The fly ash refines the internal structure of the cement-based repairing mortar, and by means of compounding effects of the additives, the mortar is ensured to have flexibility and anti-permeability and excellent flexural strength and compressive strength. The 3d compressive strength of the mortar is 20-30 MPa and 28 d compressive strength of the mortar is 36-45 MPa, so that the mortar can satisfy repairing strength demand of common concrete building external walls.

Owner:WUHAN UNIV OF TECH

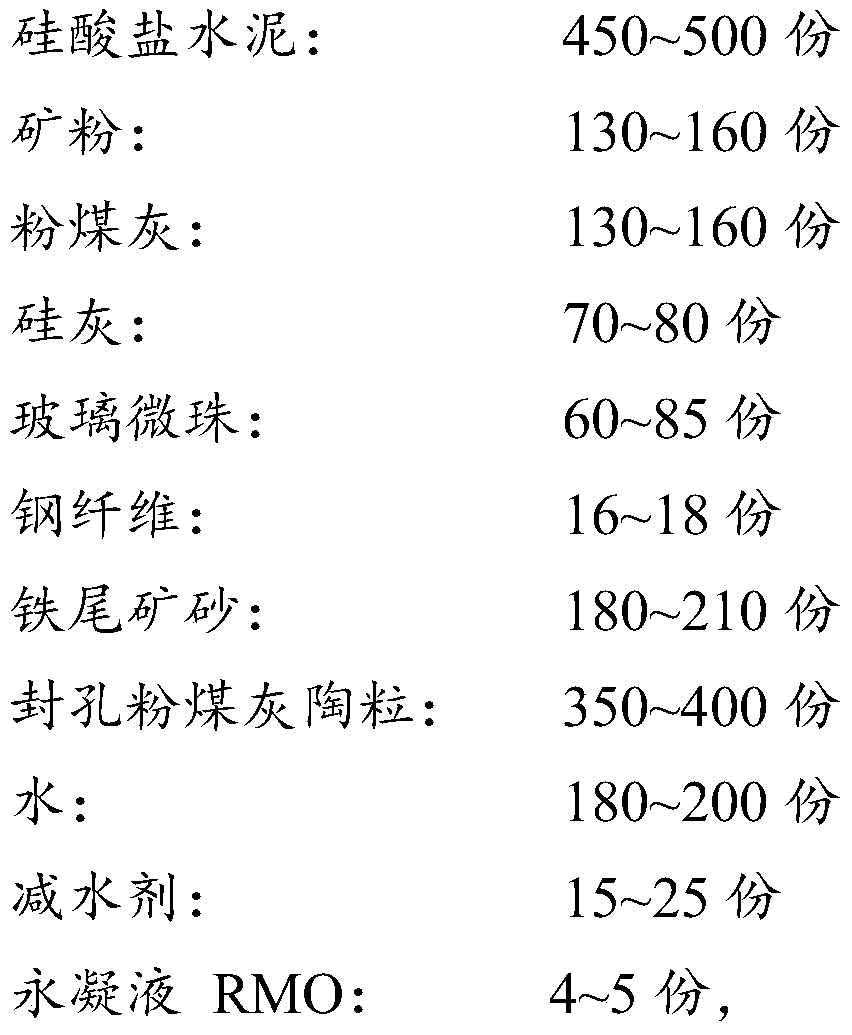

Lightweight high-strength waterproof concrete and preparation method thereof

The invention provides lightweight high-strength waterproof concrete and a preparation method thereof, and belongs to the field of concrete. The lightweight high-strength waterproof concrete comprisesthe following components in parts by mass: 450 to 500 parts of Portland cement, 130 to 160 parts of mineral powder, 130 to 160 parts of fly ash, 70 to 80 parts of silica fume, 60 to 85 parts of glassmicro-beads, 16 to 18 parts of steel fibers, 180 to 210 parts of iron tailing sand, 350 to 400 parts of pore-sealing fly ash ceramsite, 180 to 200 parts of water, 15 to 25 parts of a water reducing agent and 4 to 5 parts of a permanent solidification liquid RMO. The pore-sealing fly ash ceramsite is prepared by a method comprising the following steps: immersing fly ash ceramsite into a mixed solution of RMO and water, pre-wetting, draining off water after 1 hour, and then carrying out coating treatment by using a mixture of Portland cement and iron tailing sand powder, so as to obtain the pore-sealing fly ash ceramsite. The concrete disclosed by the invention has the properties of light weight, high strength and water resistance.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

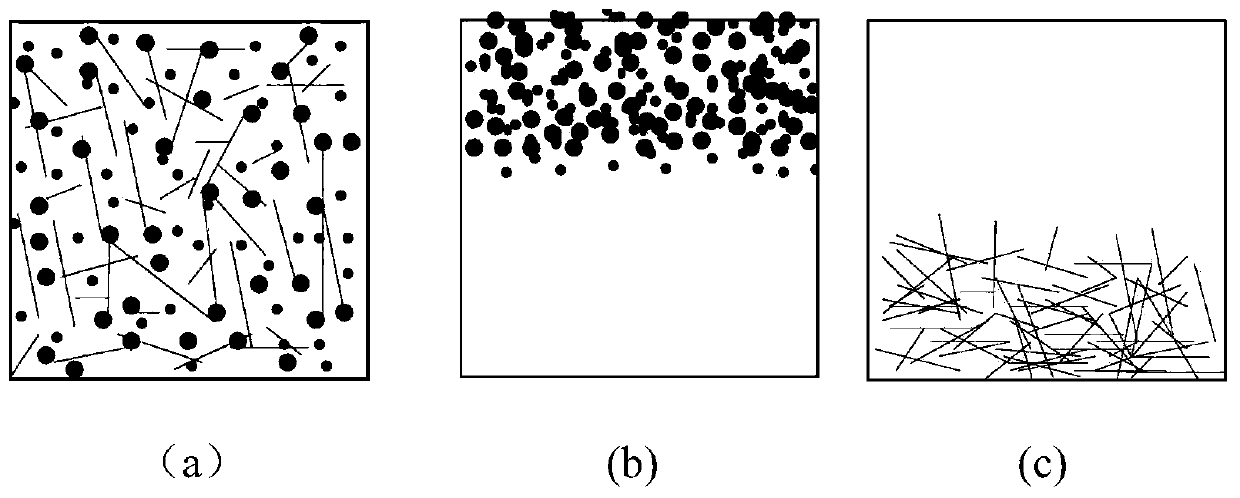

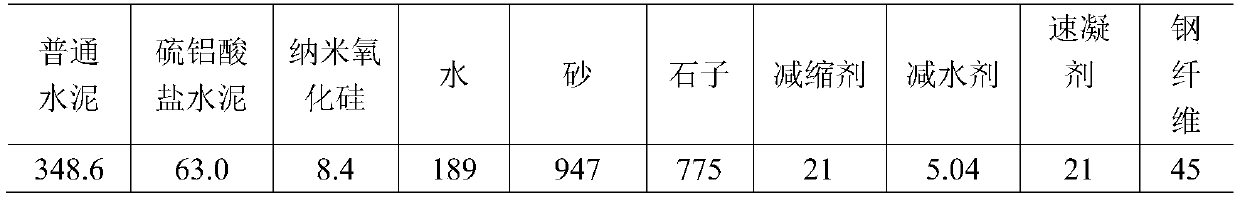

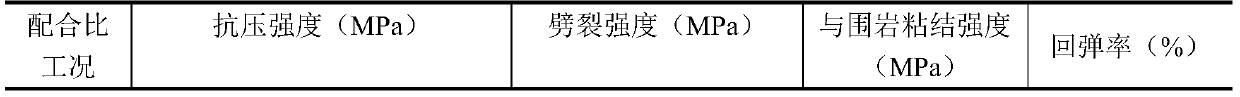

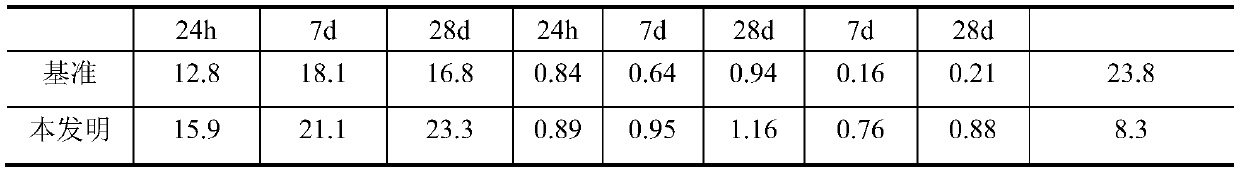

Special sprayed concrete material for tunnel high-ground-temperature dry-hot environment

The invention discloses a special sprayed concrete material for a tunnel high-ground-temperature dry-hot environment. The total amount of cementing materials of concrete is 400-420 kg per cubic meter;the cementing material comprises the components in percentage by weight: 83%-89% of ordinary Portland cement, 10%-15% of sulphoaluminate cement and 1%-2% of nano silicon dioxide. Steel fibers are doped according to the volume ratio of 0.4%-0.6%; a shrinkage reducing agent is doped according to 5% of the weight of the cementing material; a setting accelerator is doped according to 3-5% of the weight of the cementing material when the concrete is prepared; the ratio of glue to bone is 1:4.0-1:4.5; the water-binder ratio is not greater than 0.50. The special sprayed concrete provided by the invention has higher compressive strength and tensile strength than common shotcrete with the same strength grade under the synergistic effect of materials with a certain proportioning ratio. According todifferent dry and hot environment temperatures, the bonding strength is 2-4 times of that of common sprayed concrete, and the rebound rate is only 1 / 3-1 / 2 of that of the common sprayed concrete.

Owner:SOUTHWEST JIAOTONG UNIV

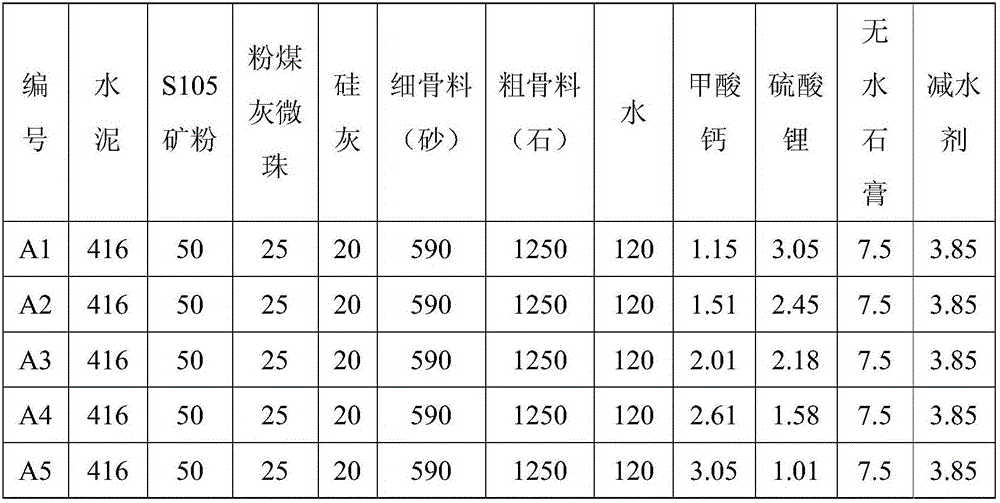

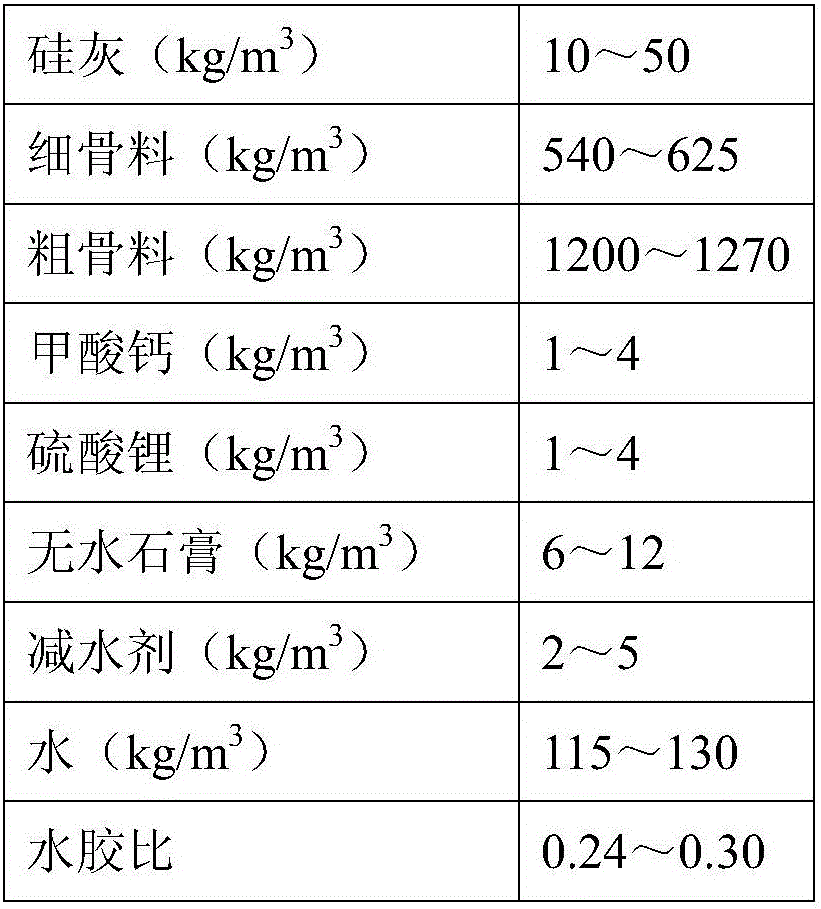

Concrete for large tubular pile of autoclaving-free process

The invention belongs to the technical field of concrete materials, and in particular relates to concrete for a large tubular pile of an autoclaving-free process. Each cubic meter of preparation materials of the concrete comprise the following components: 360-450kg of cement, 30-80kg of slag powder, 10-70kg of coal ash microbeads, 10-50kg of silicon ash, 540-625kg of fine aggregate, 1200-1270kg of coarse aggregate, 1-4kg of calcium formate, 1-4kg of lithium sulfate, 6-12kg of anhydrite, 2-5kg of a water reducing agent and 115-130kg of water. A series of tests and studies on the proportioning ratio of the concrete provided by the invention are implemented, and an optimal concrete proportioning ratio which can meet the requirement of large tubular pile demolding strength and strength of C60 concrete within a relatively short time at a normal temperature can be obtained.

Owner:CCCC THIRD HARBOR ENG +2

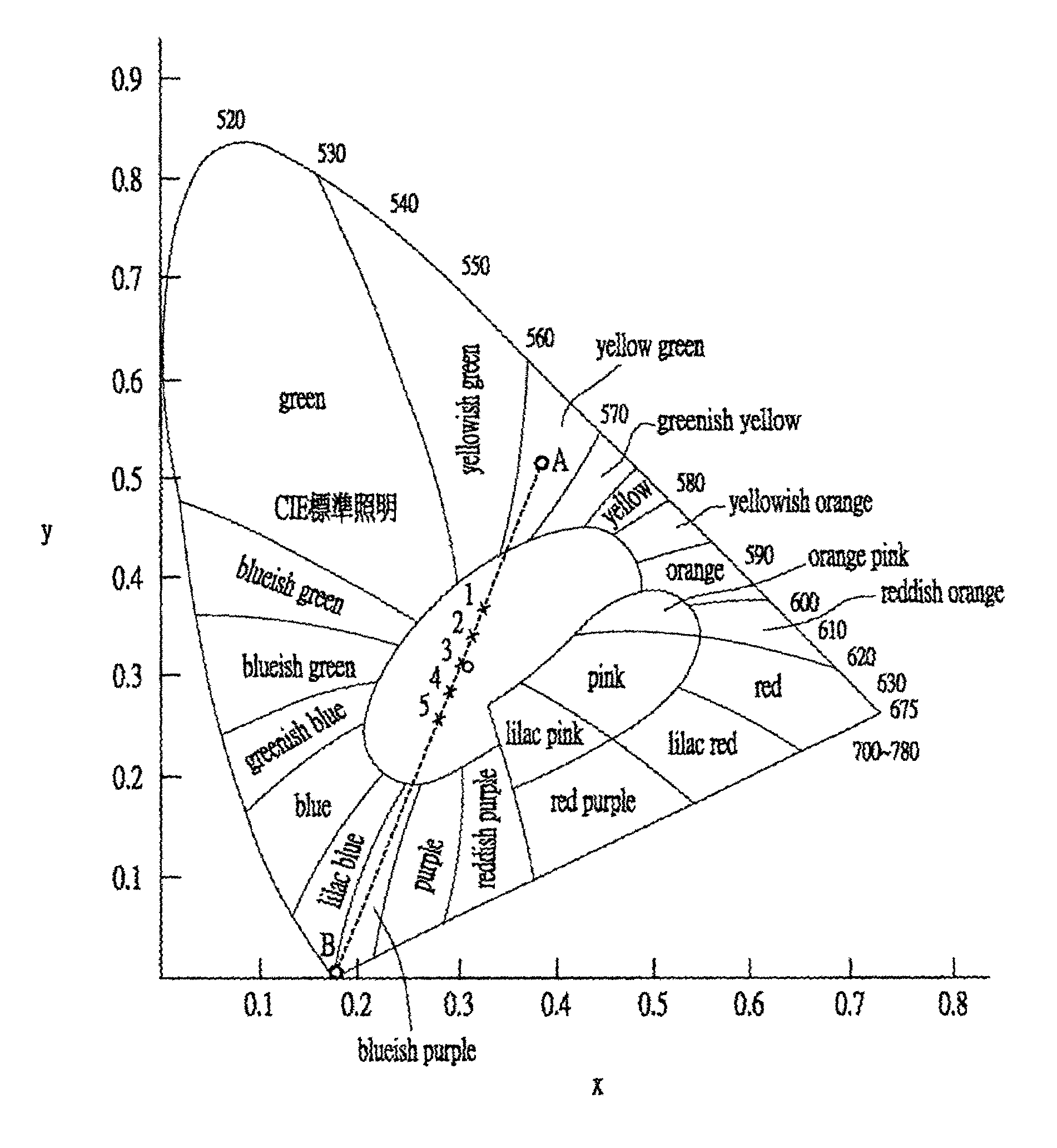

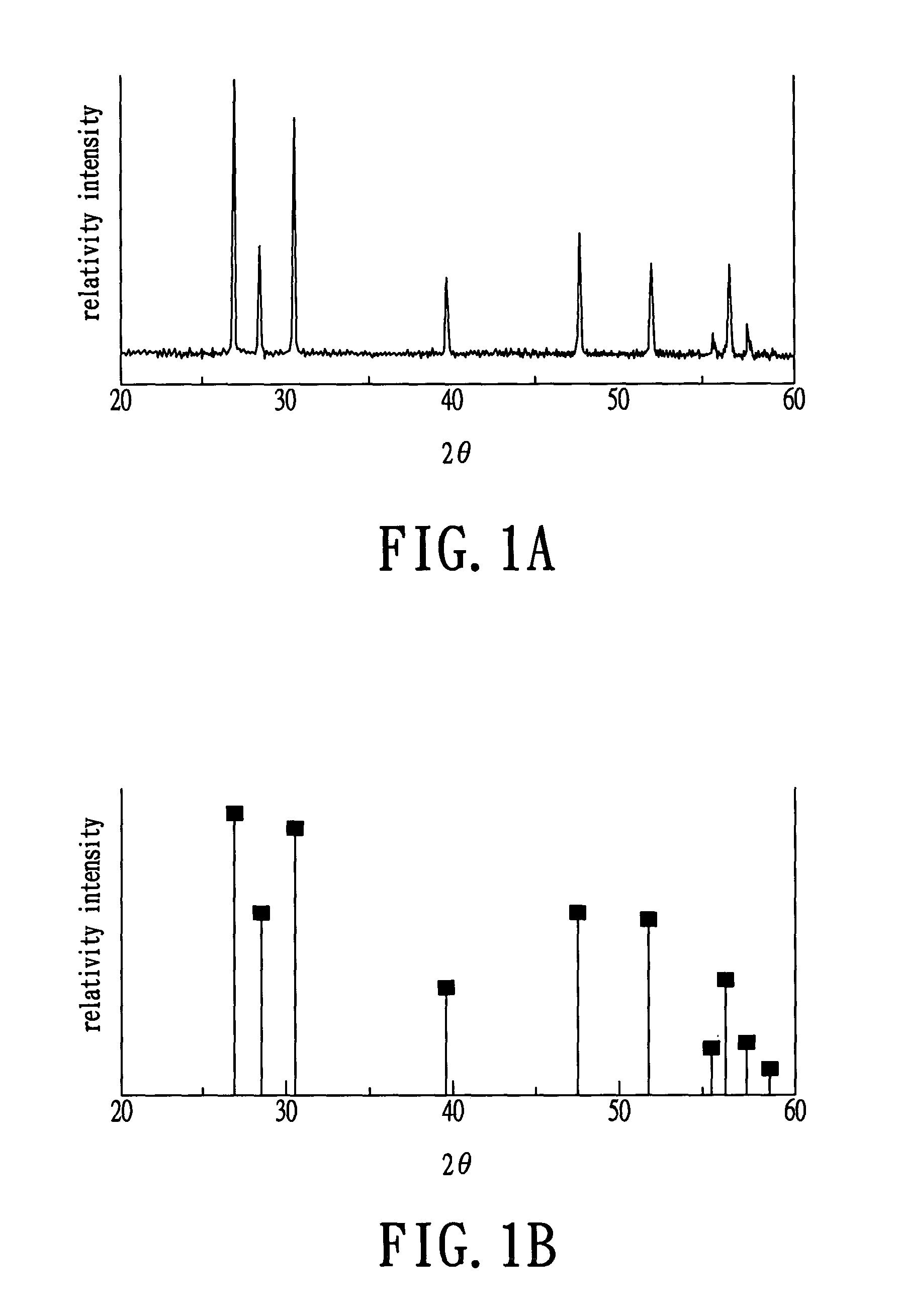

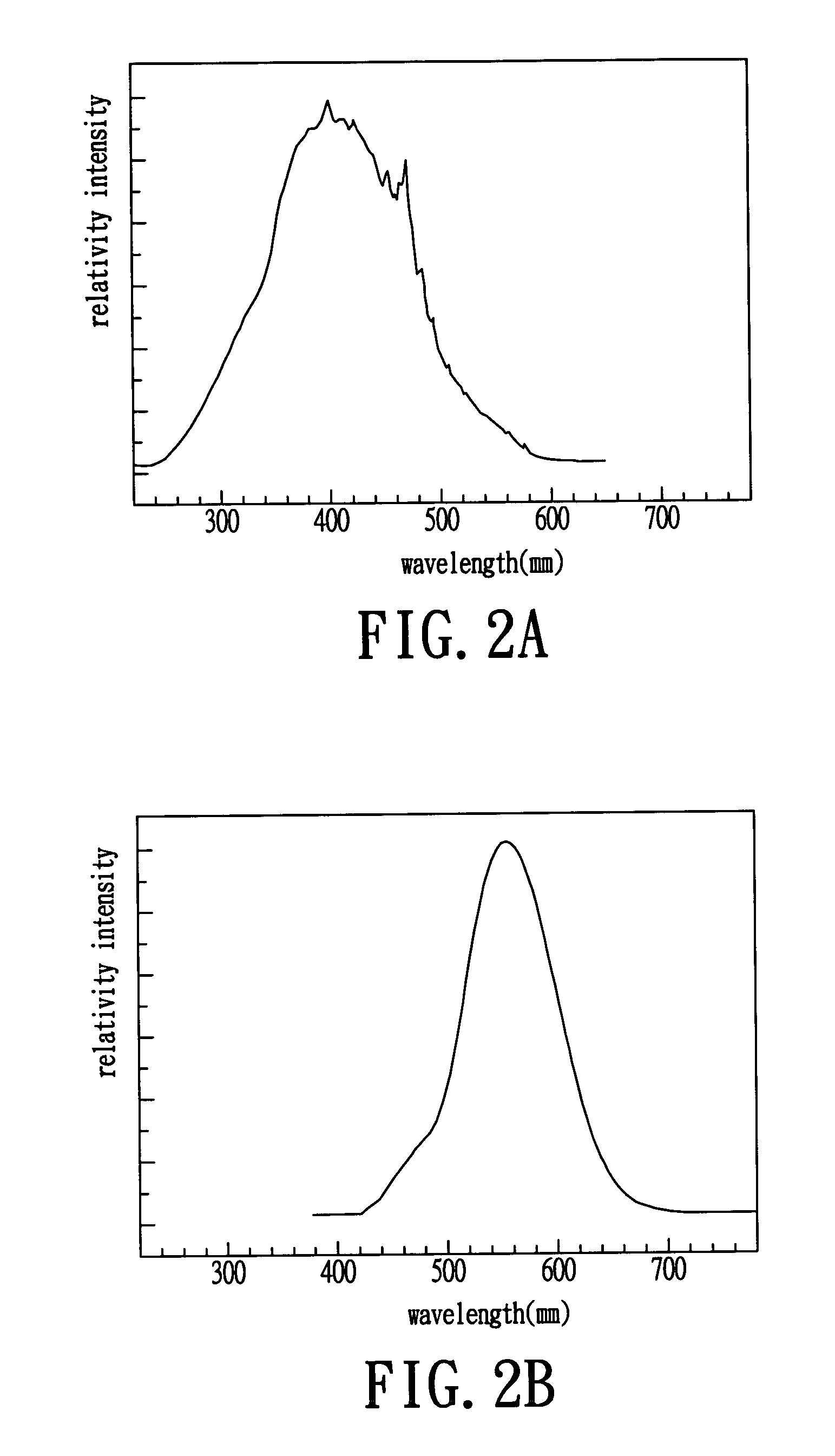

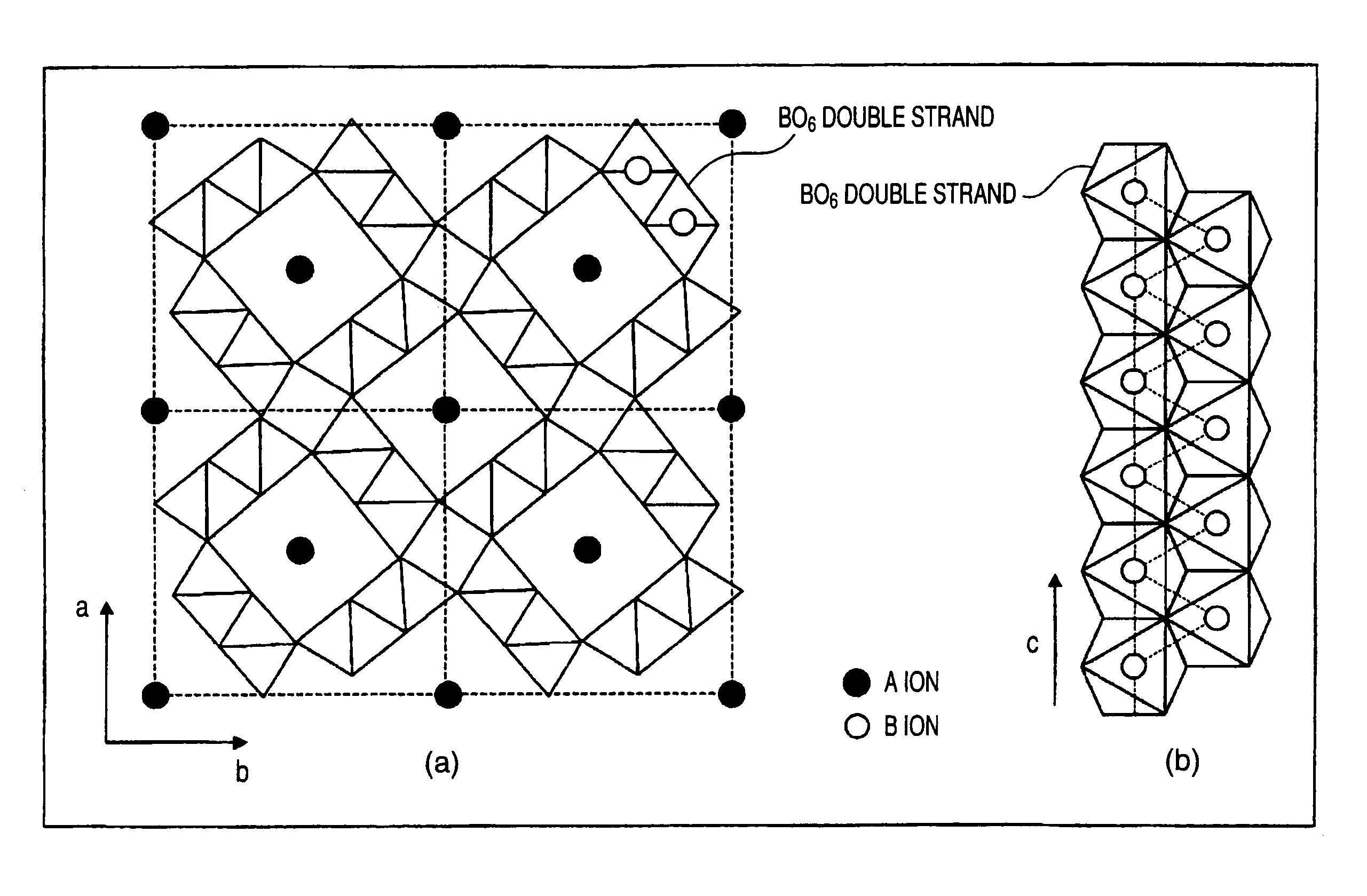

Method for manufacturing white light source

ActiveUS7229332B2Good color propertiesQuality improvementDischarge tube luminescnet screensLamp detailsUltravioletGreen-light

A method for manufacturing a white light source provides an LED light source and a semiconductor-type phosphor with (Zn, Cd)S being the host with foreign ions added thereto as luminescence centers. The LED light source emits light ranging from 495 nm about (blue-green light) to about 340 nm (ultra-violet).

Owner:LITE ON TECH CORP

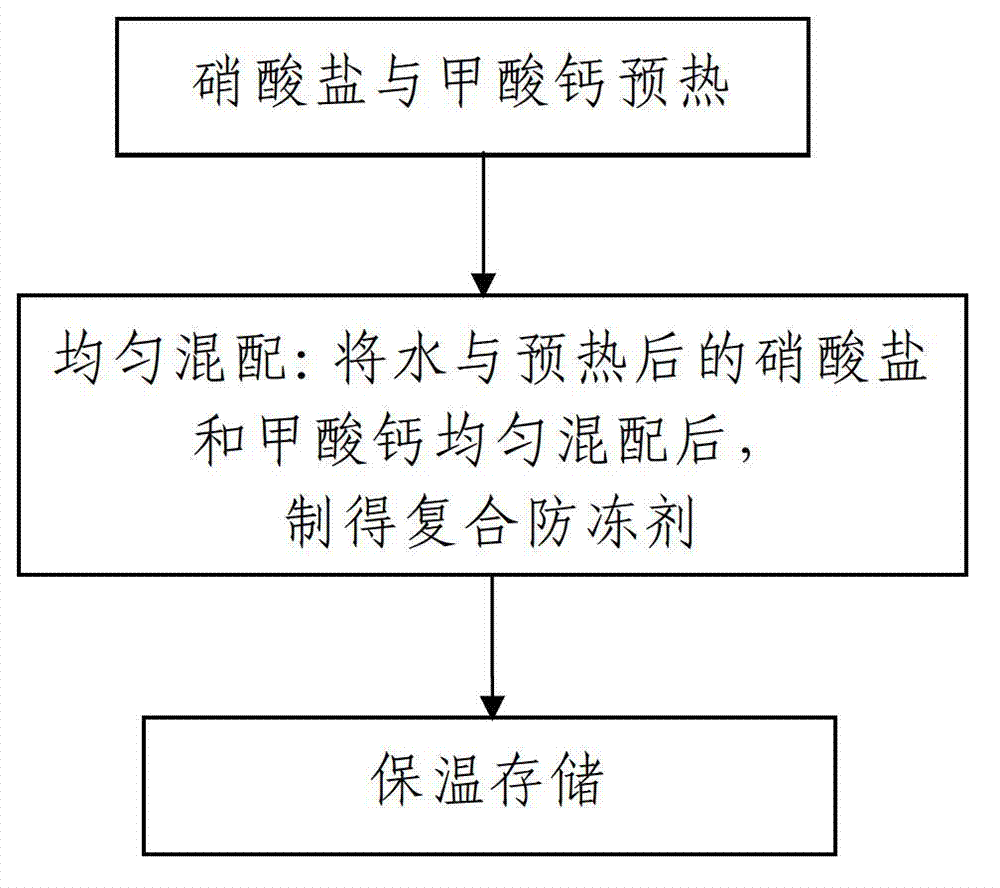

Ultralow temperature high-performance concrete composite anti-freezing agent and preparation technology thereof

The invention discloses an ultralow temperature high-performance concrete composite anti-freezing agent and a preparation technology for the ultralow temperature high-performance concrete composite anti-freezing agent. The composite anti-freezing agent comprises the following components in percentage by weight: 30 to 35% of nitrate, 30 to 33% of organic compound, 0.5 to 1% of calcium formate, and the balance of water, wherein the nitrate is calcium nitrate or calcium nitrite, and the organic compound is methanol or ethanol; and the preparation technology comprises the following steps: 1, preheating the nitrate and calcium formate: heating the nitrate and calcium formate to 40 to 70 DEG C, respectively; and 2, uniformly mixing: uniformly mixing the water and the heated nitrate and calcium formate in step 1 based on a design ratio, thus obtaining the composite anti-freezing agent. The preparation technology disclosed by the invention is simple in steps, simple and convenient to operate, has low input cost and a good using effect, and a performance of the ultralow temperature high-performance concrete can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

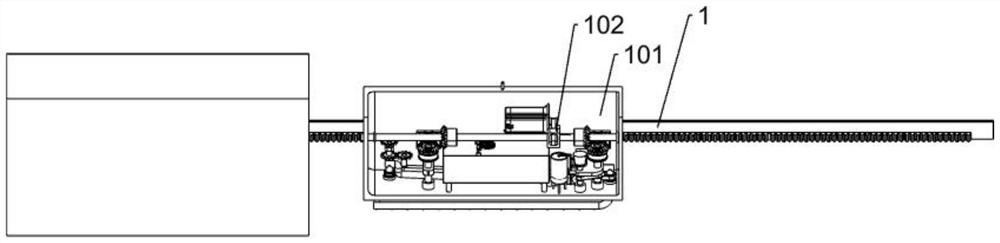

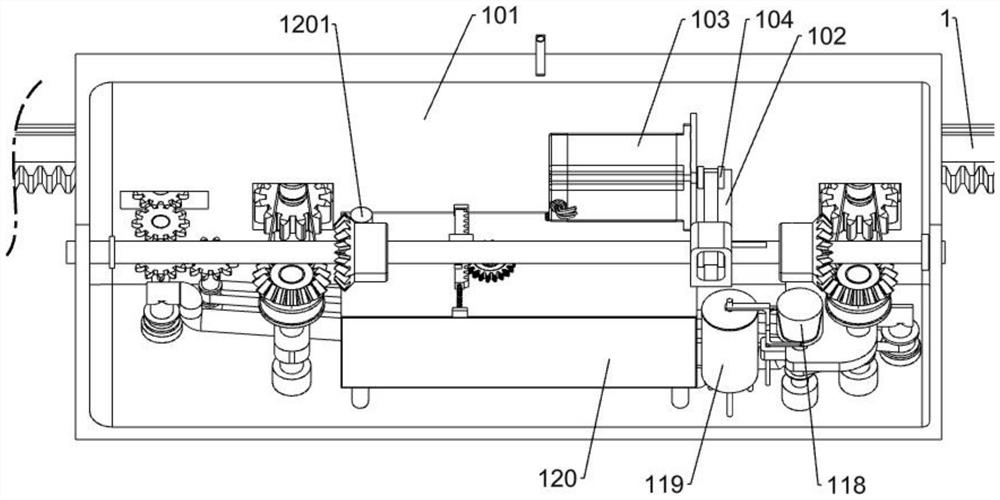

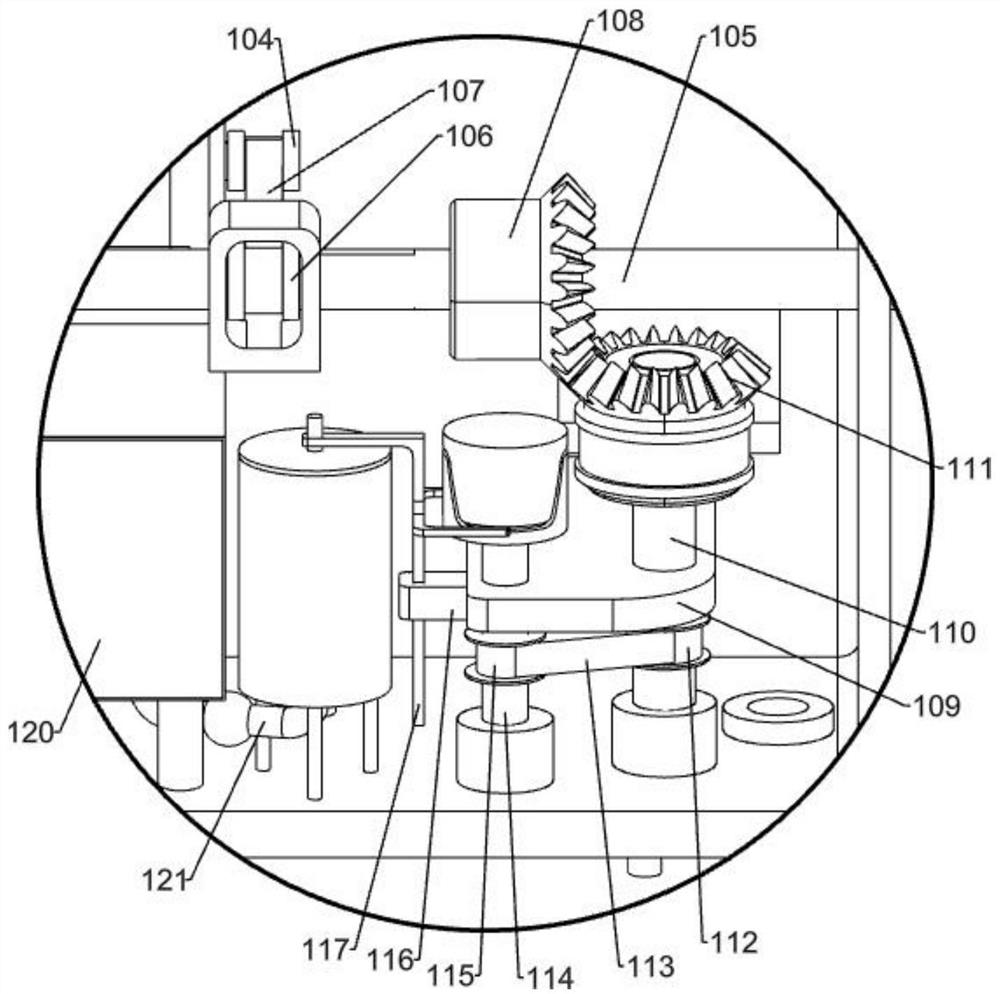

Hospital corridor positioning track hidden disinfection machine

InactiveCN112220952ALarge coverage areaReduce work intensityLavatory sanitoryChemicalsElectric machineryProcess engineering

The invention relates to a disinfection machine, in particular to a hospital corridor positioning track hidden disinfection machine. The aim of the invention is to provide the hospital corridor positioning track hidden disinfection machine. According to the hospital corridor positioning track hidden disinfection machine, the water storage capacity is large, workers do not need to bear loads, the spraying area is large, operation is easy, advancing and automatic returning can be conducted according to a designated route, and automatic storage can be achieved. According to the technical scheme,the hospital corridor positioning track hidden disinfection machine comprises a rack sliding groove, a disinfection rack, a motor supporting plate, a power motor and the like, wherein the rack slidinggroove is fixed to a wall body; the rear side of the disinfection rack slides on the rack sliding groove; the motor supporting plate is fixedly connected to the disinfection rack; and the power motoris fixedly connected to the motor supporting plate. According to the invention, the loads can be mechanically borne, the spraying coverage area is large, and a sprayer does not need to be manually carried on the back for disinfection, so that the working intensity of the workers is relieved, and the working efficiency is improved.

Owner:赵荣菊

C40 regenerated concrete and preparation method thereof

InactiveCN108314385AGuaranteed StrengthImprove protectionSolid waste managementPortland cementConstruction aggregate

The invention has a core task for providing C40 regenerated concrete and a preparation method thereof. The C40 regenerated concrete is prepared from the following components: cement, water, fine aggregates and coarse aggregates, wherein a mixing ratio of the cement to the water to the fine aggregates to the coarse aggregates is 1:0.49:1.55:3.3, wherein the coarse aggregates comprise common coarseaggregates and regenerated coarse aggregates; the mixing ratio of the common coarse aggregates to the regenerated coarse aggregates is 1:1.5, and a particle size range of the common coarse aggregatesand the regenerated coarse aggregates is 5 to 26.5 mm; the cement used by a test piece is common Portland cement, and the used regenerated coarse aggregates are concrete waste. The C40 regenerated concrete provided by the invention has the advantages of simple technology and low production cost while the strength of the regenerated concrete is ensured, so that a popularization and application value of the regenerated concrete is increased.

Owner:FOSHAN UNIVERSITY

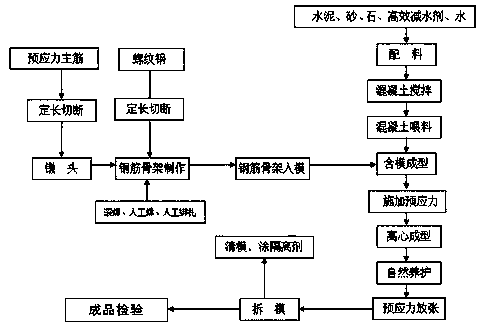

Manufacturing technology for autoclaving-free pole

InactiveCN108908685AImprove qualityGuaranteed physical and mechanical propertiesShaping reinforcementsManufacturing technologySuperplasticizer

The invention provides a manufacturing technology for an autoclaving-free pole. The specific machining technology comprises the following steps that one, prestressed steel bars and screw-thread steelare machined; two, a steel bar framework is manufactured; three, a concrete mixture is manufactured; four, mold closing and formation of the autoclaving-free pole are conducted; five, natural curing is conducted; six, mold removing is conducted; and seven, finished product inspection is conducted. The manufacturing technology for the autoclaving-free pole has the beneficial effects that by means of improvement of raw material quality, optimization of mixing proportion and adoption of an efficient water reducing agent, a large amount of energy consumption is saved on the premise that physical and mechanical properties, durability and production time of the pole are guaranteed; a cost ranging from 30 rmb to 60 rmb can be saved by each pole; production cost is reduced greatly; the history ofhigh energy consumption of the pole is changed completely; a novel breakthrough of the pole is achieved; the concrete of the autoclaving-free pole is high in durability such as chloride corrosion resistance property, freezing resistance and the like and high in latter strength; a strength loss of 17% of steam curing is avoided; the autoclaving-free pole is artistic in appearance; a non-pulp-pouring technology is adopted; meanwhile, numerous troubles of the remaining pulp are avoided; and the manufacturing technology is environmentally friendly.

Owner:泰州桓通管业有限公司

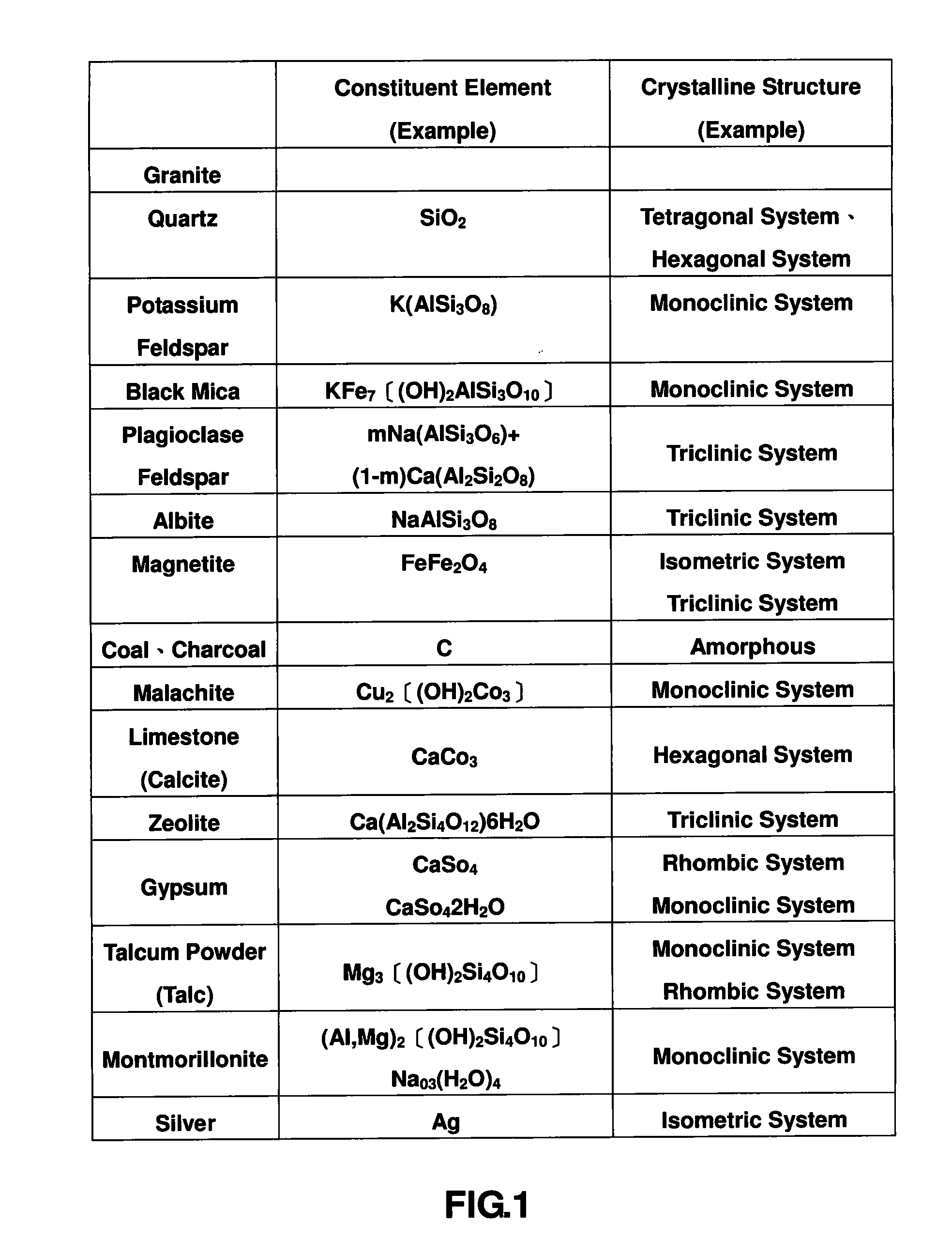

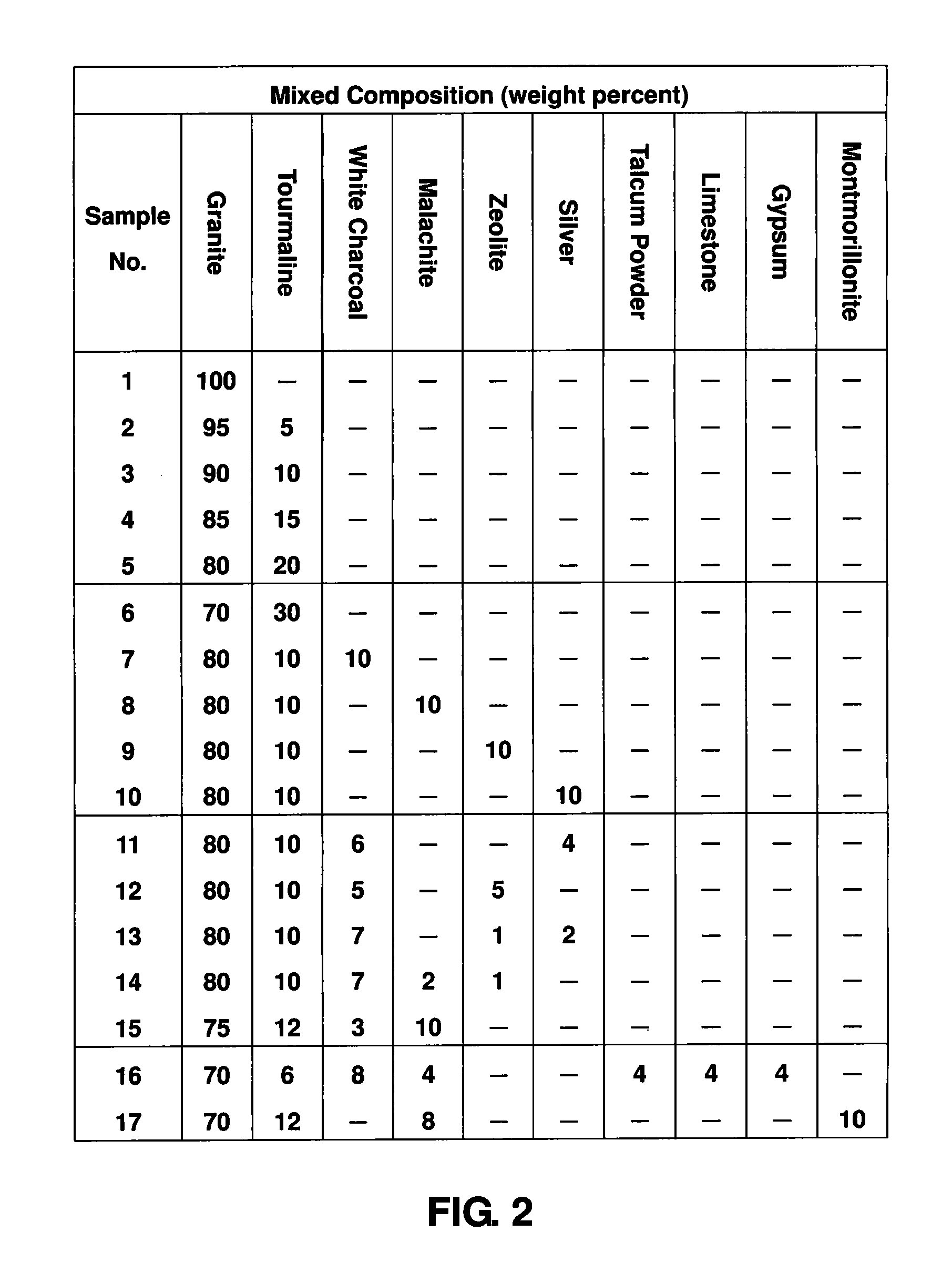

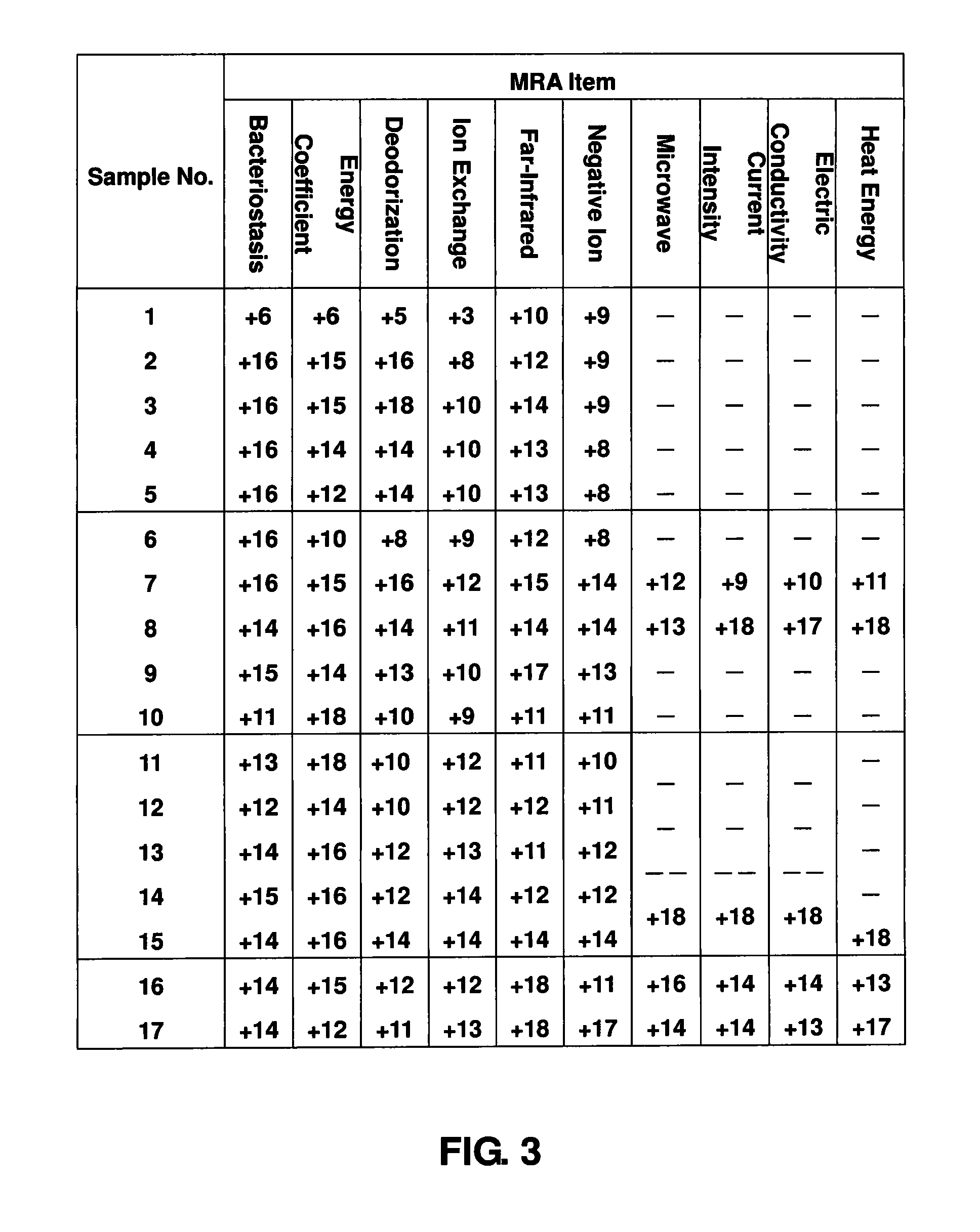

Lead-acid accumulator material and a forming method thereof

InactiveUS20130015390A1Increase charging rateImprove conversion rateElectrochemical processing of electrodesElectrode thermal treatmentResonanceIon exchange

In the present invention, characteristics specific to all kinds of natural mineral and metal are analyzed by a magnetic resonance analyzer. The natural mineral and metal are combined and ground into powder and made into a lead plate, ceramic and a separator of a lead-acid accumulator to produce an undulation frequency and change a molecule structure of an electrolyte, thereby accelerating an ion exchange rate, speeding up a charging rate, increasing a conversion rate, decreasing stacking of lead sulfate crystalloids, reducing a corrosion rate of a positive electrode lattice body and extending a lifetime of use of the lead-acid accumulator.

Owner:HUANG HSUEH HUNG

Coal ash corrective material substituted for clay

The invention provides a coal ash cementing material substituted for cement, which is used for mass concrete, and particularly relates to a coal ash corrective material substituted for clay. In the production of cement, when the content of silicon dioxide in the clay is comparatively high, coal ash is substituted for a part of the clay and taken as a clay corrective material to adjust values of KH, n and p. According to the coal ash corrective material substituted for the clay, the coal ash is reasonably matched with the raw material of the high-silicon clay at a certain ratio, so that the matching ratio of raw materials of the cement can be optimized; at the same time of optimizing the matching ratio, the coal consumption can be reduced, the generation of a firing liquid phase is promoted, the dosing of an iron raw material is decreased, the lime saturation coefficient is increased, more silicate minerals are generated, the early strength and the later strength of clinkers are enhanced, the clay resource is protected, the utilization approach of the coal ash is expanded, more lands are protected well while the production cost is lowered, the national industrial policy is met, industrial wastes are treated, and the product quality of the clinkers is enhanced.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

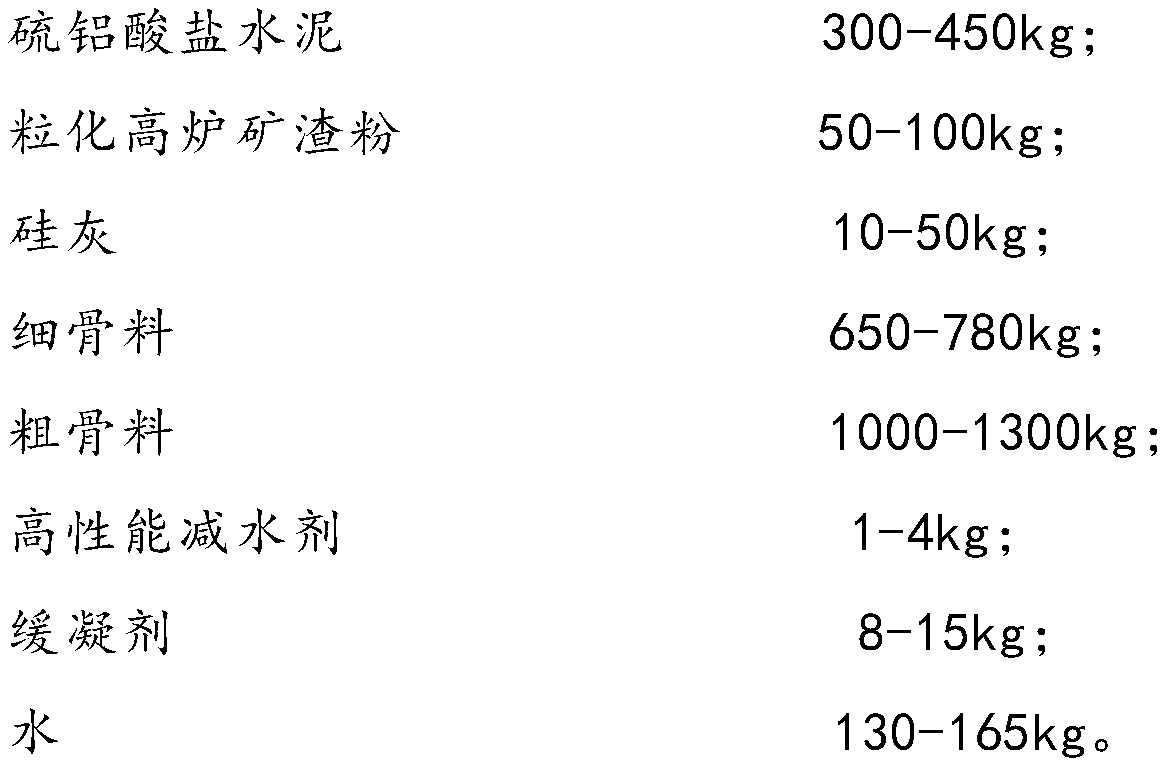

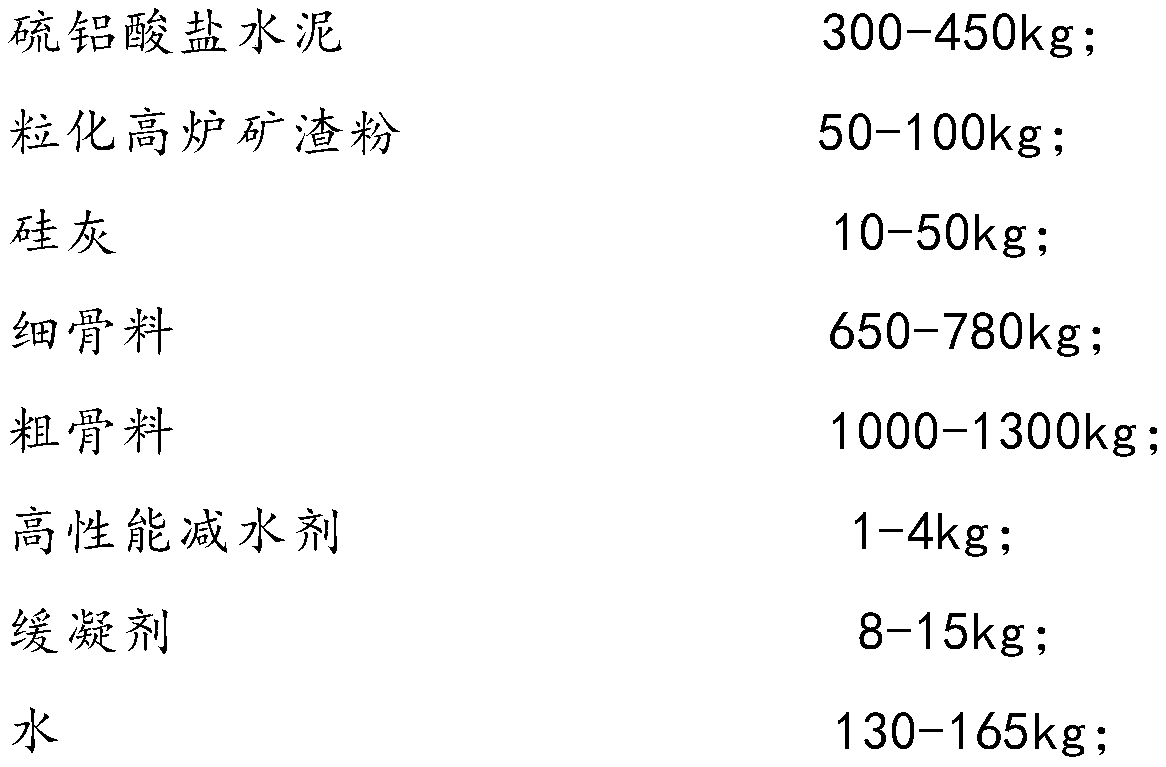

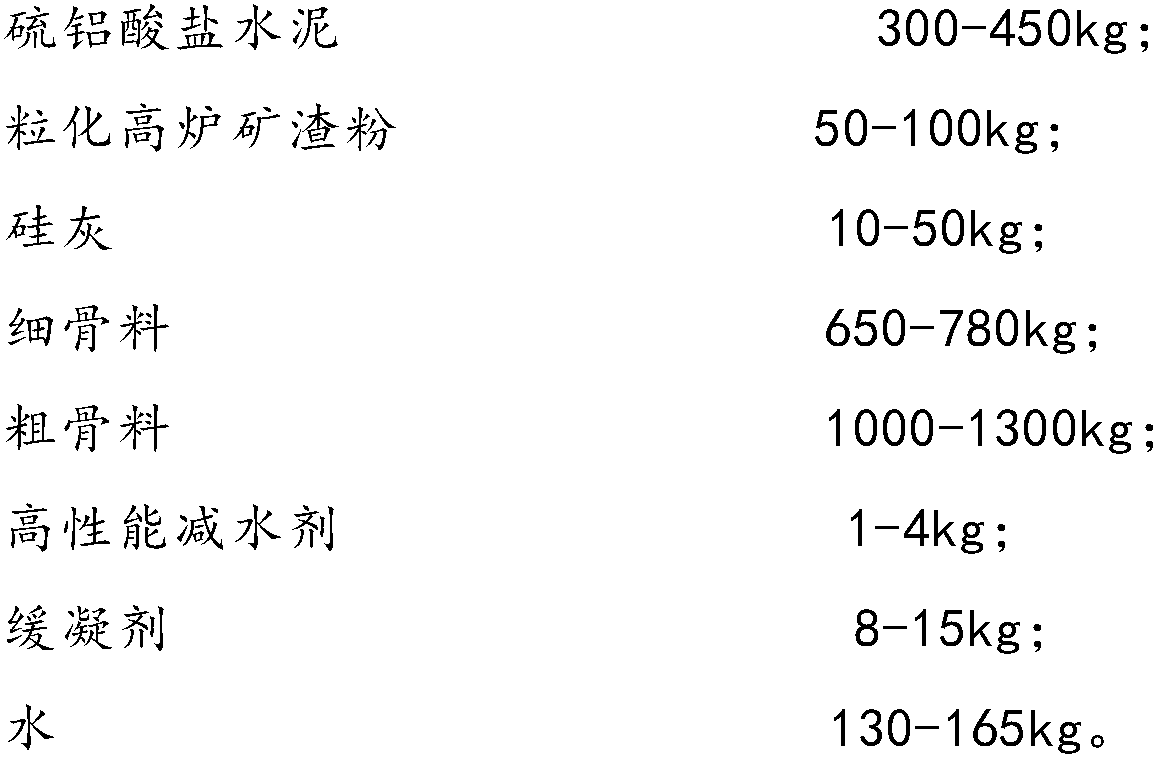

Concrete for rapid construction under marine environment and preparation method thereof

The invention discloses concrete for rapid construction under the marine environment. The concrete is prepared from, per cubic meter, 300-450 kg of sulphate aluminum cement, 50-100 kg of granulated blast-furnace slag powder, 10-50 kg of silica fume, 650-780 kg of fine aggregates, 1,000-1,300 kg of coarse aggregates, 1-4 kg of high-performance water reducer, 8-15 kg of retarder and 130-165 kg of water. The concrete for rapid construction under the marine environment achieves the demolding strength earlier under the normal temperature and low temperature conditions, and can be widely applied tothe environment under the low-temperature condition such as anti-chloride corrosion and freezing resistance in the North under the marine environment.

Owner:CCCC THIRD HARBOR ENG +2

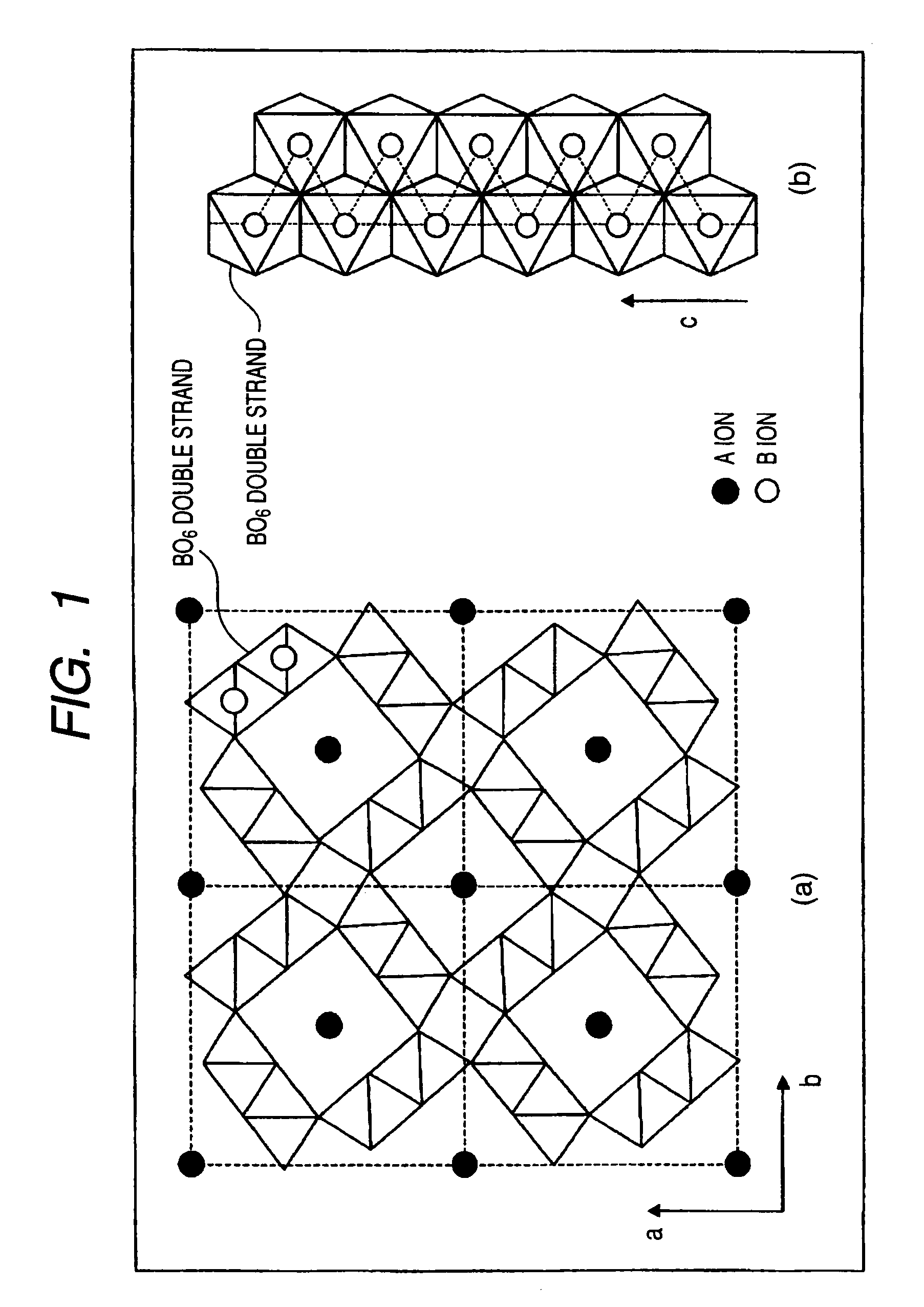

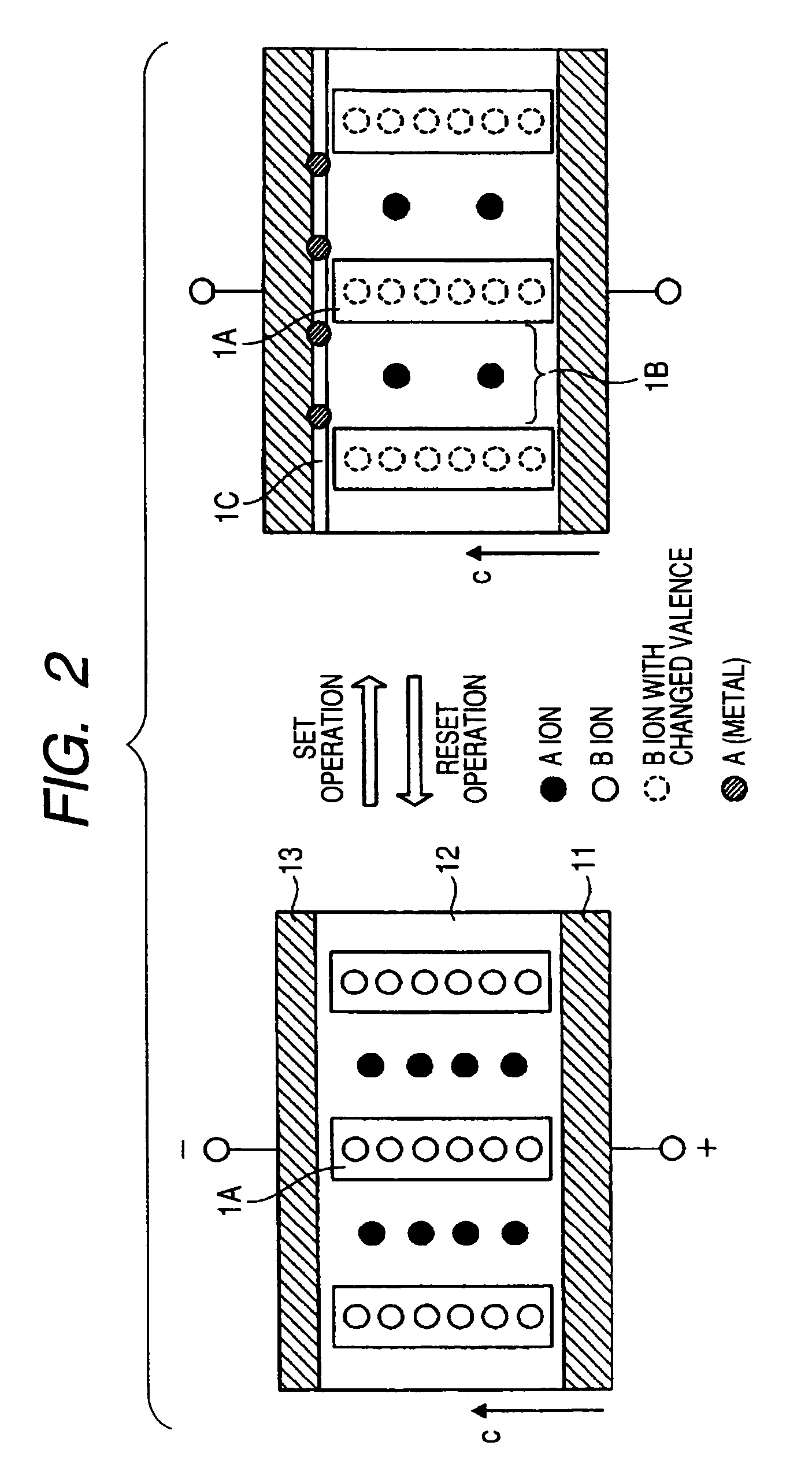

Information recording and reproducing apparatus

InactiveUS7838877B2Optimize mix ratioNanoinformaticsSolid-state devicesSoftware engineeringHeat stability

Owner:KK TOSHIBA

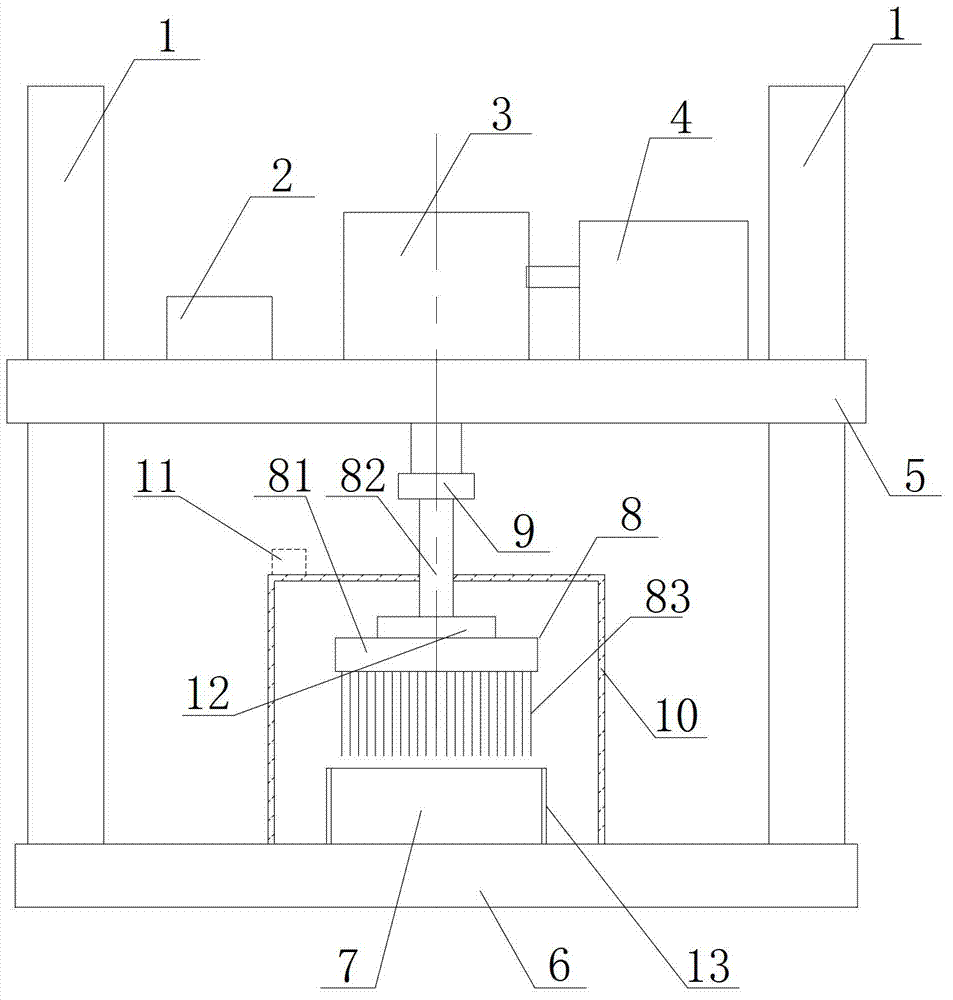

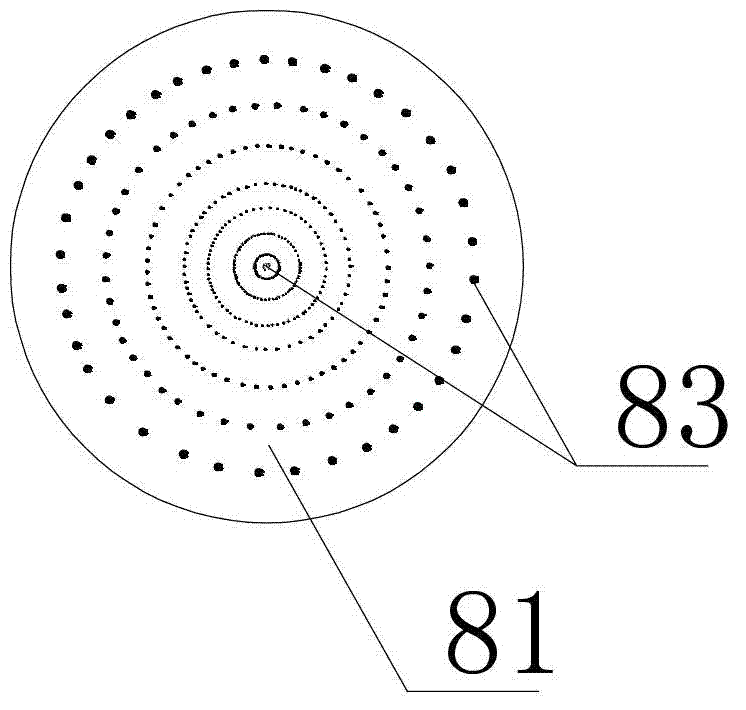

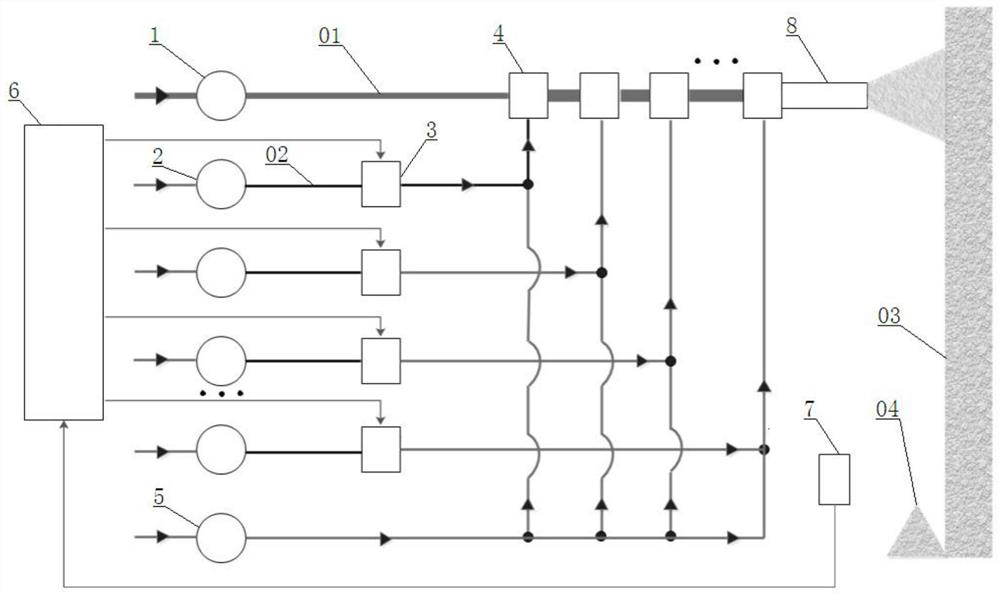

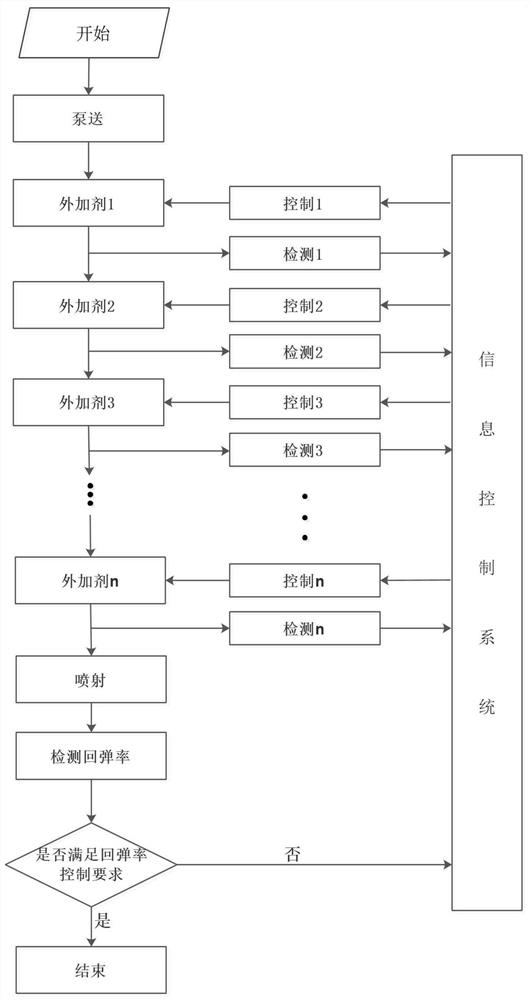

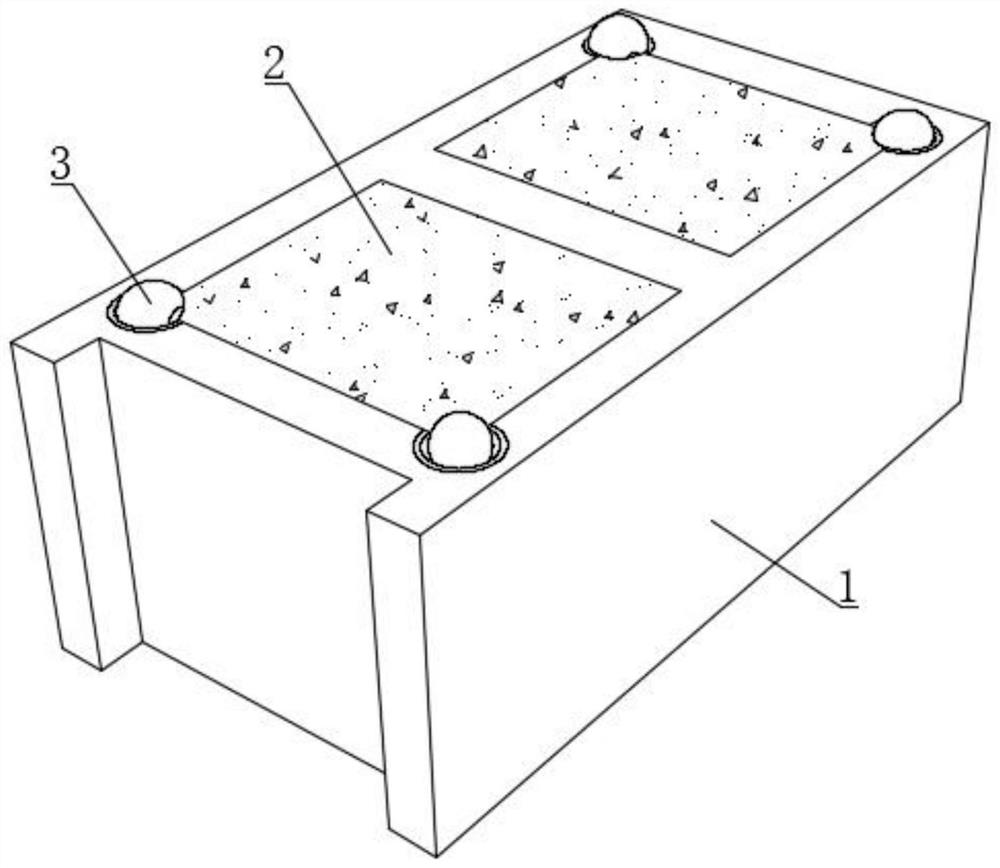

Concrete injection system and control method thereof

ActiveCN111828046ARebound rate controlEasy to adjustSolid waste managementUnderground chambersInformation controlMixed flow

The invention provides a concrete injection system and a control method thereof. The concrete injection system comprises a concrete pump, a compressed air pump, a plurality of additive control units,an information control system and a rebound rate detection system. Each additive control unit comprises an additive pump, a control device and a flow mixing device. The control method includes the following steps of firstly, setting a parameter value in the information control system; secondly, starting pumping, conveying additives to the corresponding flow mixing devices, making concrete sequentially pass through all the flow mixing devices to be mixed with the additives, and controlling the initial flow rate and mixing time of the additives by the control devices according to an instructionof the information control system; thirdly, injecting the concrete; and fourthly, detecting the rebound rate data of the concrete and feeding back the data by the rebound rate detection system, and ifthe information control system judges that the current data is not up to standard, sending additive adjusting instructions to the control devices, and executing the process repeatedly until the datais up to standard. By means of the concrete injection system and the control method thereof, online optimization of proportions of concrete mix is realized, and construction cost is reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Production method of lightweight concrete prefabricated big panels

ActiveCN105906371AOptimize mix ratioExcellent preparation strengthCeramicwareFoaming agentArchitectural engineering

The invention discloses a production method of lightweight concrete prefabricated big panels. The method comprises the following steps: 1, selecting raw materials according to a case that every cubic meter of lightweight concrete prefabricated big panels contains 450-550kg of cement, 65-195kg of stone flour, 3.25-9.75kg of a water reducer and 0.01-0.05kg of a foaming agent, foaming the foaming agent, uniformly mixing cement, the stone flour and the water reducer to prepare a cement mortar, adding the foamed foaming agent to the cement mortar, and uniformly stirring the foamed foaming agent and the cement mortar to prepare lightweight concrete; and 2, pouring the lightweight concrete in a die, and carrying out demolding treatment and curing to produce the lightweight concrete prefabricated big panels. The method solves the problem of adverseness of too large weight of common prefabricated big panels to transportation and hoisting installation, the weight of the lightweight concrete prefabricated big panels produced in the invention is about 50% lower than that of common concrete prefabricated big panels, and the construction efficiency of prefabricated wallboards is effectively increased.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

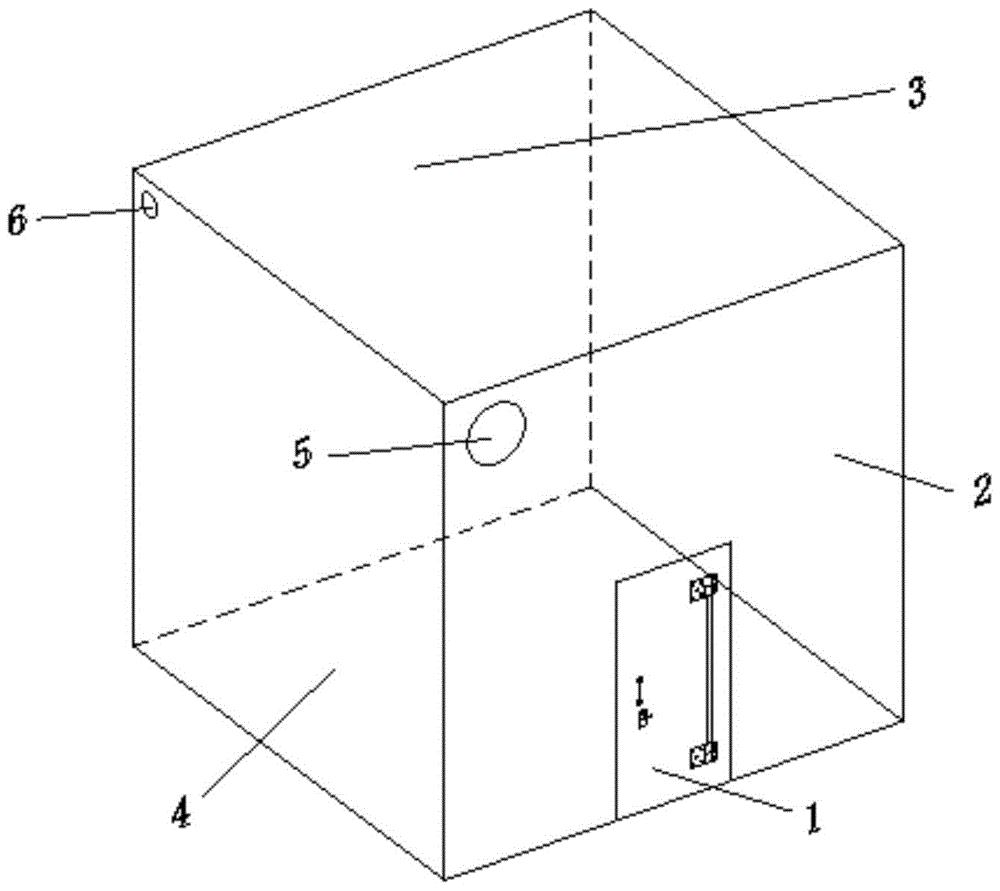

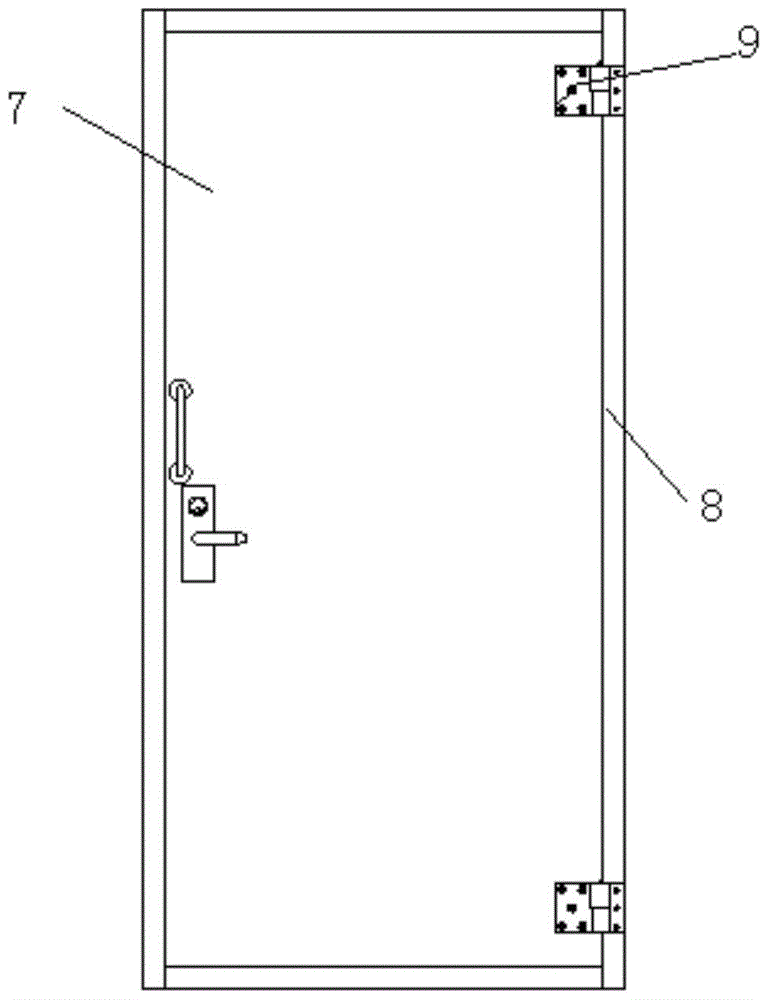

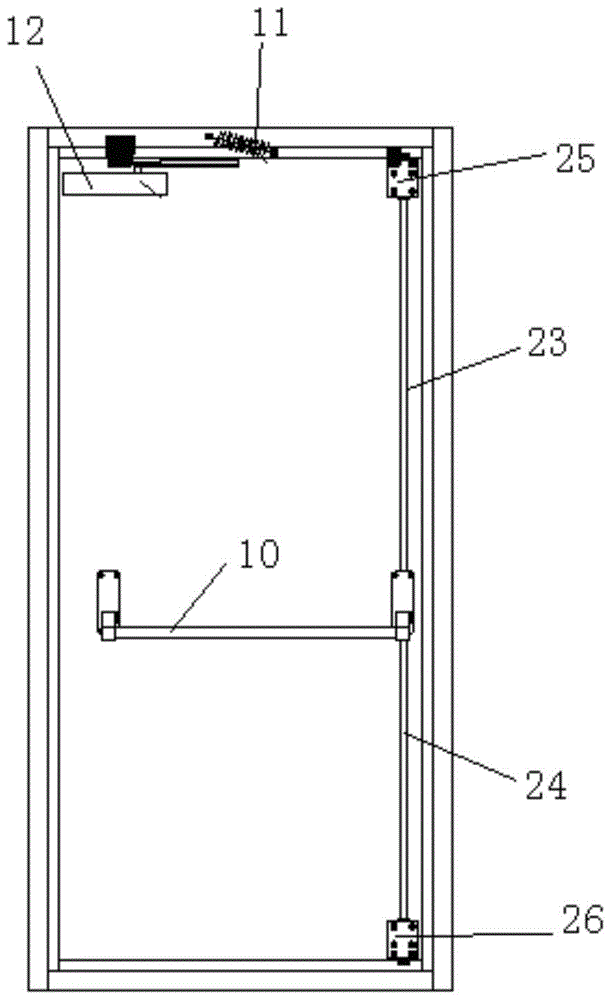

A Kind of Home Safe Shelter

ActiveCN104153628BEnsure the safety of life and propertyEffective isolation of radioactive contaminationSolid waste managementProtective buildings/sheltersNuclear radiationEngineering

Owner:江苏爵格工业集团有限公司

MU five-point zero ceramsite composite self-insulation building block

PendingCN111677150AOptimize mix ratioReduce breakageConstruction materialWallsFoaming agentThermal insulation

The invention discloses an MU five-point zero ceramsite composite self-insulation building block, and belongs to the field of insulation building blocks. The MU five-point zero ceramsite composite self-insulation building block is characterized in that ceramsite and pottery sand with high strength, light weight and various shapes are used as aggregate, and ultra-light foaming concrete is filled ina composite insulation hollow building block. The MU five-point zero ceramsite composite self-insulation building block with light weight, thermal insulation, high strength, seismic resistance, fireresistance and other properties can be prepared without any interface agent or special mortar, and the added foaming agent can greatly enhance the assembly strength and stability of the MU five-pointzero ceramsite composite self-insulation building block in the construction process; and auxiliary grooves in the upper layer of building blocks are matched with the foaming agent on the lower layer of building blocks, so that the breakage condition of the building blocks caused by bearing force in the construction process is reduced, meanwhile, the building blocks can be quickly positioned in theconstruction process, the building blocks are not prone to displacement, and the construction efficiency is greatly improved.

Owner:江苏鑫康新型墙体材料有限公司

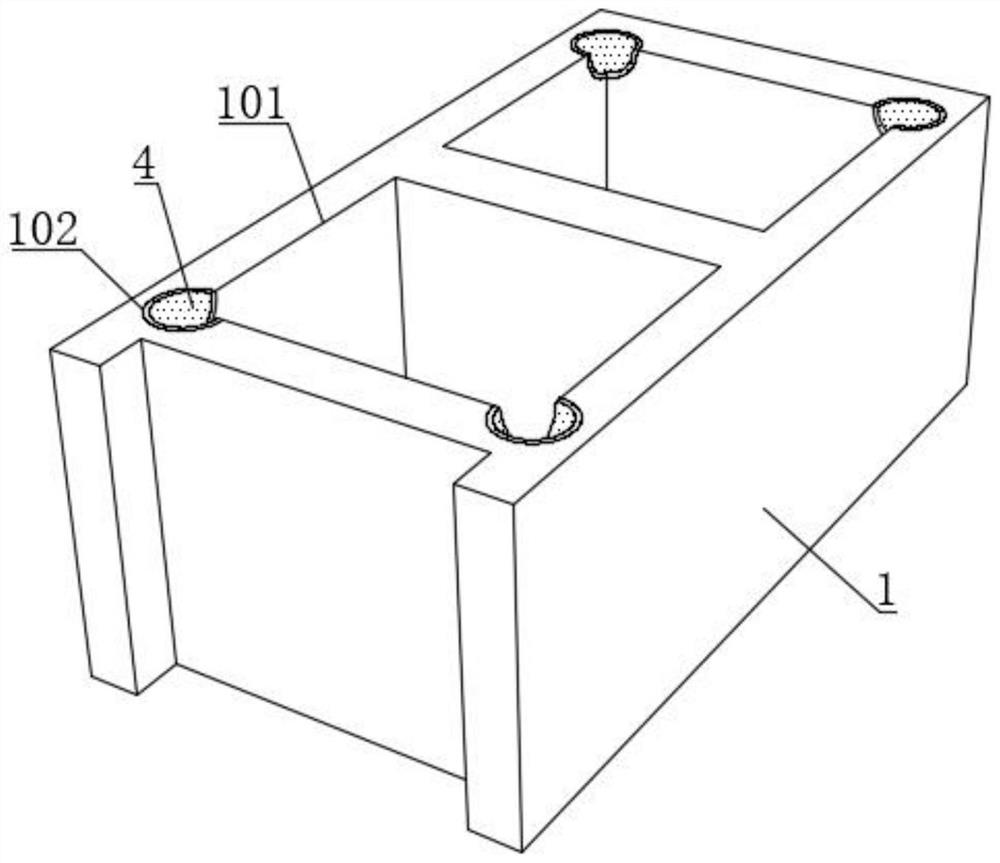

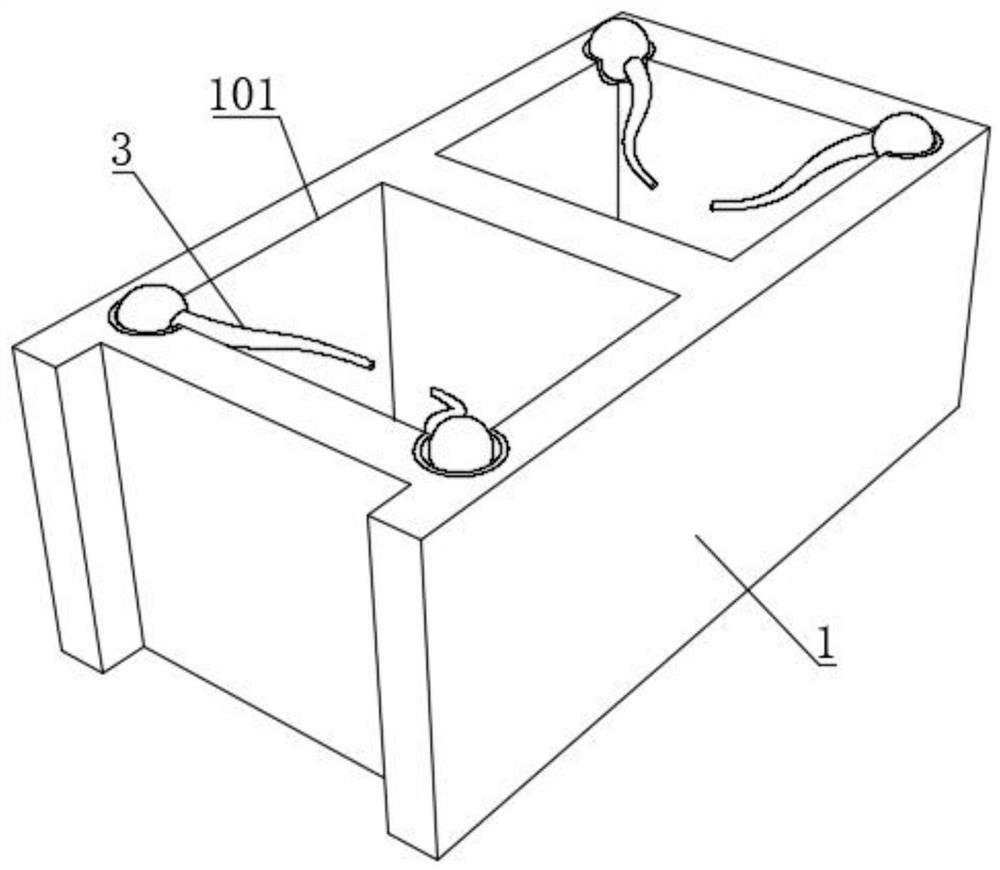

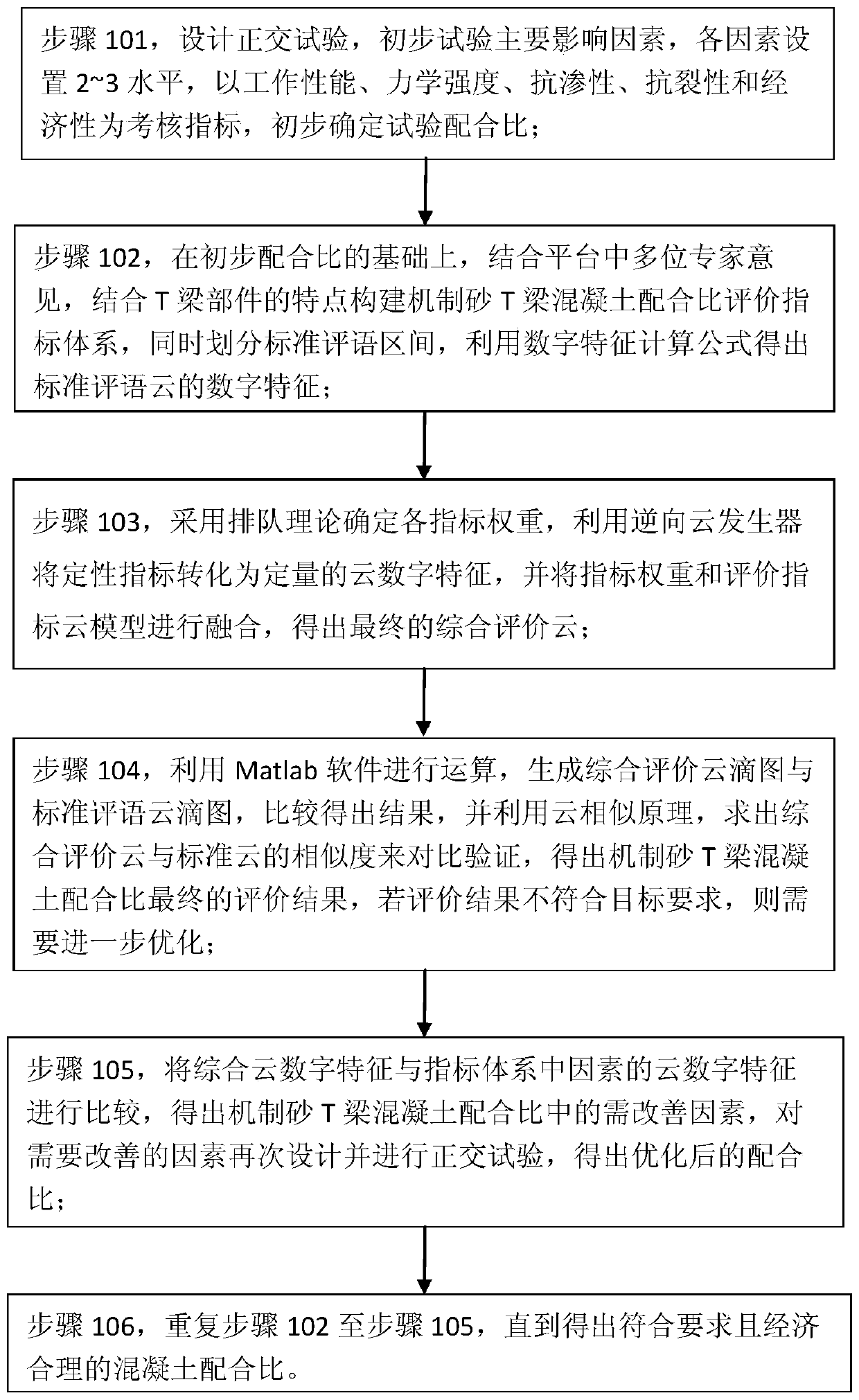

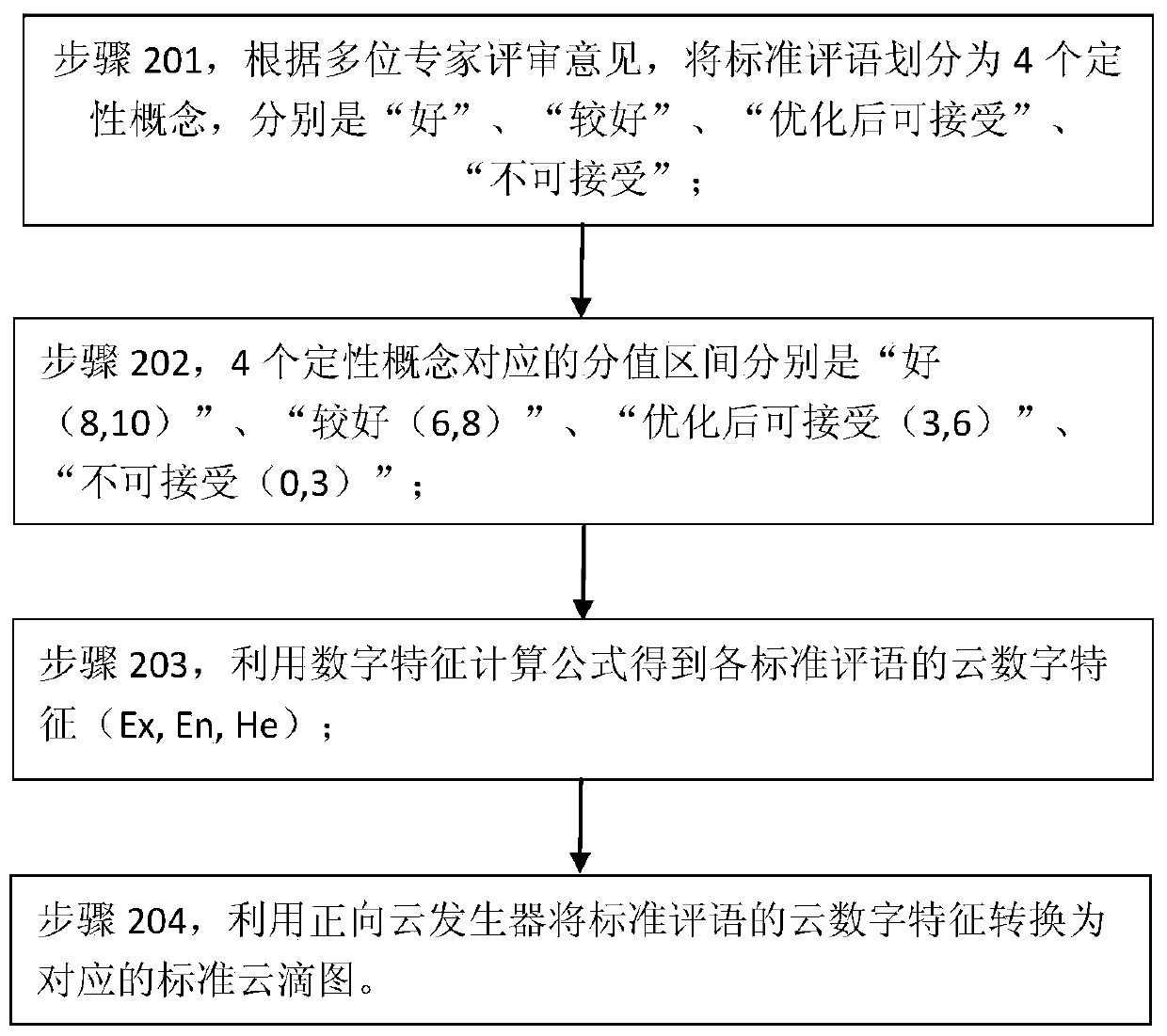

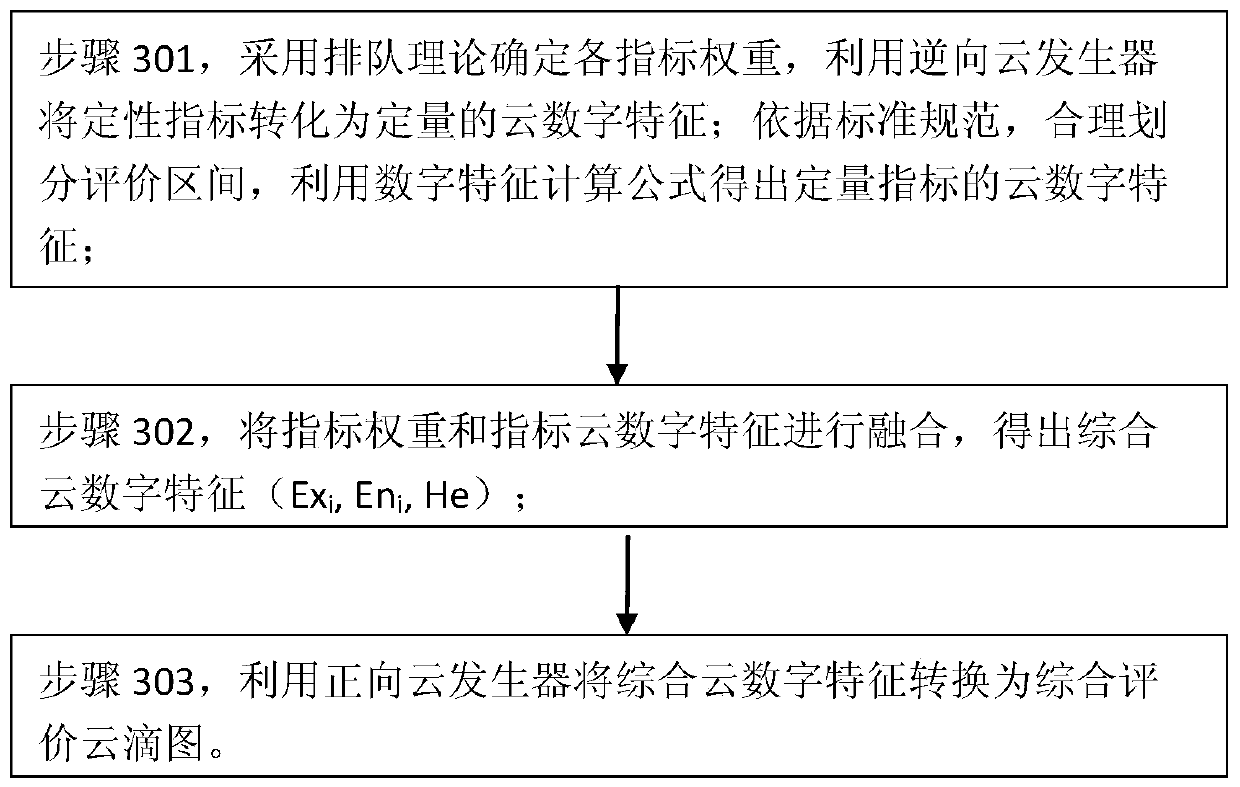

T-beam concrete mix proportion method based on orthogonal design and normal cloud model machine-made sand

ActiveCN110046427AOptimize mix ratioQuality improvementForecastingDesign optimisation/simulationEvaluation IntervalT-beam

The invention discloses a novel concrete mix proportion design method, which comprises the following steps of determining the mix proportion evaluation intervals and the standard comment cloud digitalcharacteristics through a mix proportion evaluation system established by expert evaluation; according to a specific mix proportion scheme, adopting a queuing theory to determine the importance orderand the distribution weight of each index in a mix proportion control factor, utilizing a reverse normal cloud generator to convert a qualitative index into a quantitative cloud digital feature, andfusing the index weight and an evaluation index cloud model to obtain a final comprehensive evaluation cloud, calculating the mix proportion scheme by using Matlab to generate a mix proportion schemecomprehensive evaluation cloud drop graph; evaluating the cloud similarity and the standard cloud similarity comprehensively by utilizing a cloud similarity principle comparison scheme; obtaining a final evaluation result of the scheme, determining factors needing to be improved and the improvement scheme of the scheme, redesigning an orthogonal test, further adjusting the mix proportion, improving the mix proportion scheme, obtaining an optimized new mix proportion, and circulating a design-evaluation-optimization process to enable the mix proportion to meet the requirements.

Owner:CENT SOUTH UNIV

Testing device and evaluation method of antistrip performance of bituminous mixture

InactiveCN102768178BEfficient determination of peeling resistanceSimple structureUsing mechanical meansMaterial analysisCouplingEngineering

The invention discloses a testing device of antistrip performance of bituminous mixture. The testing device comprises a base platform, a vertical column, a liftable platform and a steel wire brush, wherein the vertical column is arranged on the base platform, the liftable platform is installed on the vertical column, a motor and a speed reducer are installed on the liftable platform, the speed reducer is connected with the steel wire brush through a coupler, and steel wires densely distributed on the steel wire brush right face a test piece placing groove on the base platform. The invention further discloses an evaluation method which comprises the following steps of drying a test piece to be tested to constant weight, weighing the test piece and fixing the test piece; staring a temperature controller to enable the inner temperature of the test piece to reach the test temperature; placing the steel wire brush on the surface of the test piece and sleeving an annular counter weight on the steel wire brush; staring the motor, driving the steel wire brush to rotate on the surface of the test piece through the speed reducer and the coupler, and performing counting; taking out the test piece to perform weighing after set time; and finally evaluating the antistrip performance of the test piece according to a formula of peeling rate per unit area. The evaluation method has the advantages of being simple and easy to operate, visual, accurate and reliable in evaluation result, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Construction Method of Hyperbolic Roof Structure with Random Oblique Mesh Tic-Tac Beams

ActiveCN103615110BImprove work efficiencyShorten the construction periodBuilding material handlingFalseworkSupporting system

An irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method comprises the steps of construction preparing, secondary conversion of design drawing, lofting grillage beam ground projection axis measuring, steel pipe buckling piece all-round scaffold supporting system erecting, grillage beam bottom wood ridge lower support horizontal rod elevation giving off, wood ridge binding and bottom plate paving on a supporting horizontal rod, given-off roof beam position measuring, bound grillage beam steel rib machining, grillage beam grillage side mould mounting and reinforcing, grillage beam top plate mounting and reinforcing, face plate steel rib binding and hyperbolic roof concrete pouring. Through a space three-dimensional technology, a reasonable supporting system and accurate location of a hyperbolic roof and a grillage beam, the concrete mixing proportion is optimized, the quality and the attractive degree of the hyperbolic roof can be improved, construction difficulty is lowered, and construction efficiency is improved.

Owner:广西建工第一建筑工程集团有限公司

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358BThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD

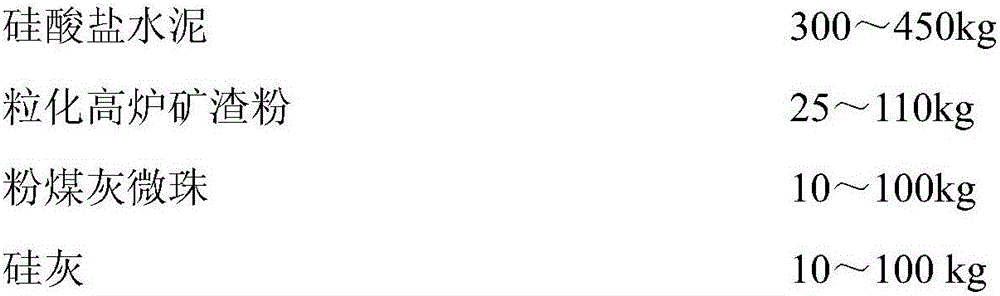

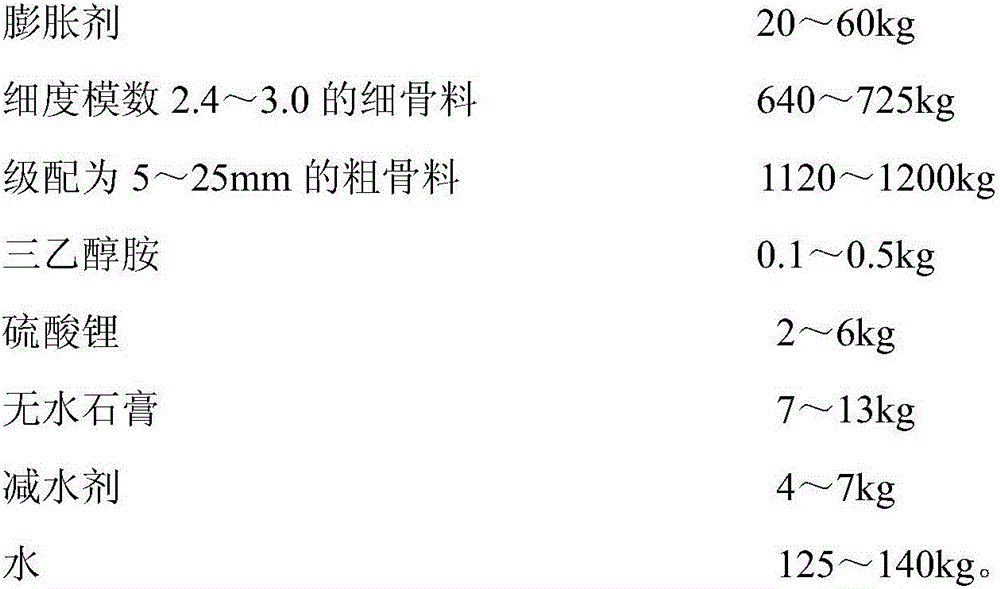

Steam-free phc pipe pile concrete

The invention discloses a curing-free PHC pipe pile concrete. Production raw materials of every cubic meter of the concrete comprise 300-450kg of portland cement, 25-110kg of granulated blast-furnace slag powder, 10-100kg of fly ash microspheres, 10-100kg of silica fume, 20-60kg of an expanding agent, 640-725kg of fine aggregates with the fineness modulus of 2.4-3.0, 1120-1200kg of coarse aggregates with the granular composition of 5-25mm, 0.1-0.5kg of triethanolamine, 2-6kg of lithium sulfate, 7-13kg of anhydrous gypsum, 4-7kg of a water reducer, and 125-140kg of water. The concrete is used for producing PHC pipe piles, and can reach the demolding strength requirement of the curing-free PHC pipe piles and the strength requirement of C80 concrete at normal temperature in a short time.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +3

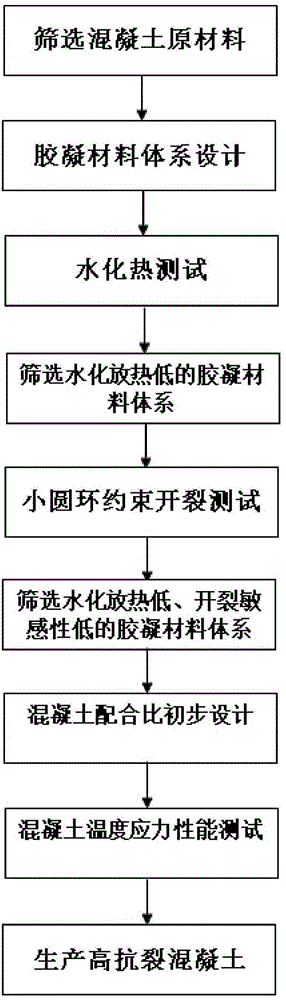

Production method of high crack resistance concrete

The invention relates to a production method for high-crack-resistance concrete, and especially the production method comprises: screening concrete raw materials, testing gelling material system hydration heat, testing gelling material system restriction crack, testing concrete temperature stress, optically selecting a high-crack-resistance concrete mix ratio through primary design on the concrete mix ratio, and producing the high-crack-resistance concrete according to the concrete mix ratio. The production method comprises: screening the concrete raw materials, testing the gelling material system hydration heat, testing the gelling material system restriction crack, testing the concrete temperature stress, optically selecting the best high-crack-resistance concrete mix ratio, and producing the high-crack-resistance concrete according to the concrete mix ratio. According to the production method, the best high-crack-resistance concrete mix ratio is optically selected, and the produced concrete has relatively high crack resistance, is not easy to crack and deform, and has safety and quality guarantees.

Owner:CCCC FOURTH HARBOR ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com