Concrete injection system and control method thereof

A concrete spraying and concrete technology, which is applied in earth cube drilling, comprehensive factory control, sustainable waste treatment, etc., can solve problems such as high rebound rate, pipe plugging, and inability to optimize concrete mix ratio in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

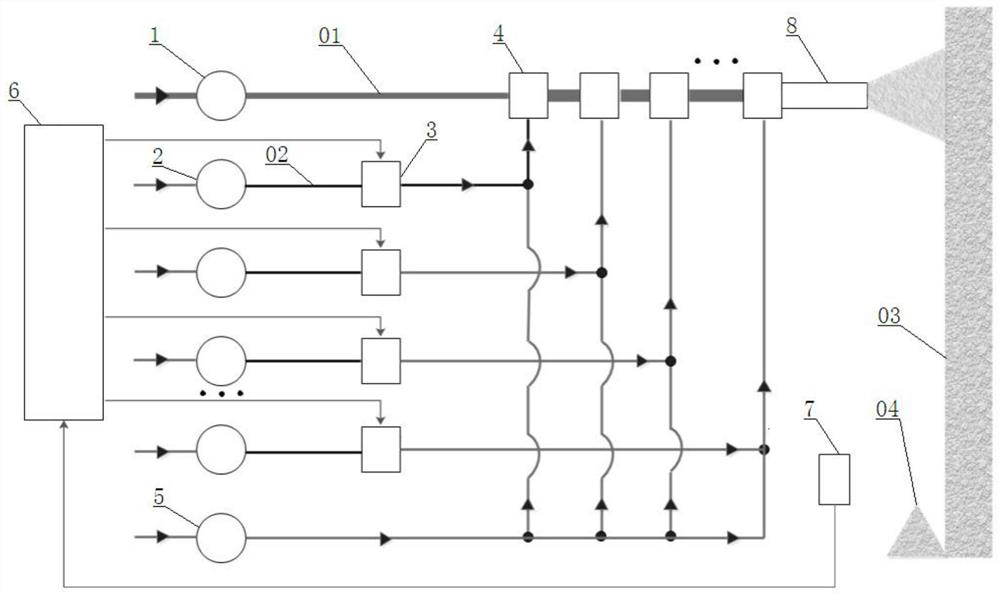

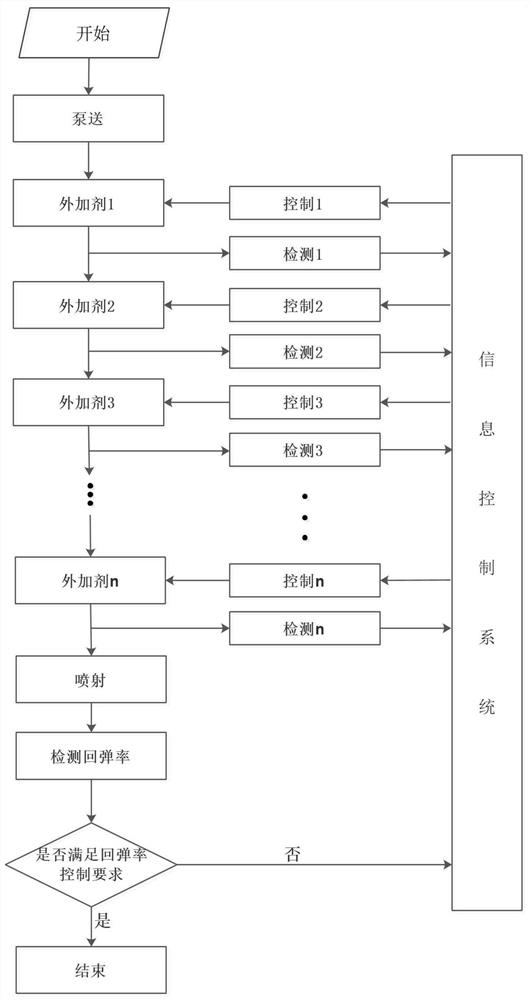

[0038] See figure 1 , A concrete spraying system, including a power system, an admixture control system, an information control system 6, a rebound rate detection system 7 and a sprinkler 8.

[0039] The power system includes a concrete pump 1, which is arranged on a concrete pipeline 01 and is used for densely squeezing and conveying concrete.

[0040] The admixture control system includes multiple groups of admixture control equipment, and each group of admixture control equipment includes an admixture pump 2, a control device 3, and a mixing device 4. The admixture pump 2 is arranged on the admixture pipeline 02 and used to provide power for conveying the admixture, and the control device 3 is arranged on the admixture pipeline 02 and is used for detecting and regulating various parameters of the admixture, including flow rate , Density, pressure, temperature, mixing time, etc., the mixing device 4 is set at the intersection of the admixture pipeline 02 and the concrete pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com