The construction method of sprayed concrete for the mobile formwork of the inner mold of the airbag and the initial support of the tunnel

A technology of shotcrete and mobile formwork, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of insufficient thickness, reduced rebound rate, and long occupation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

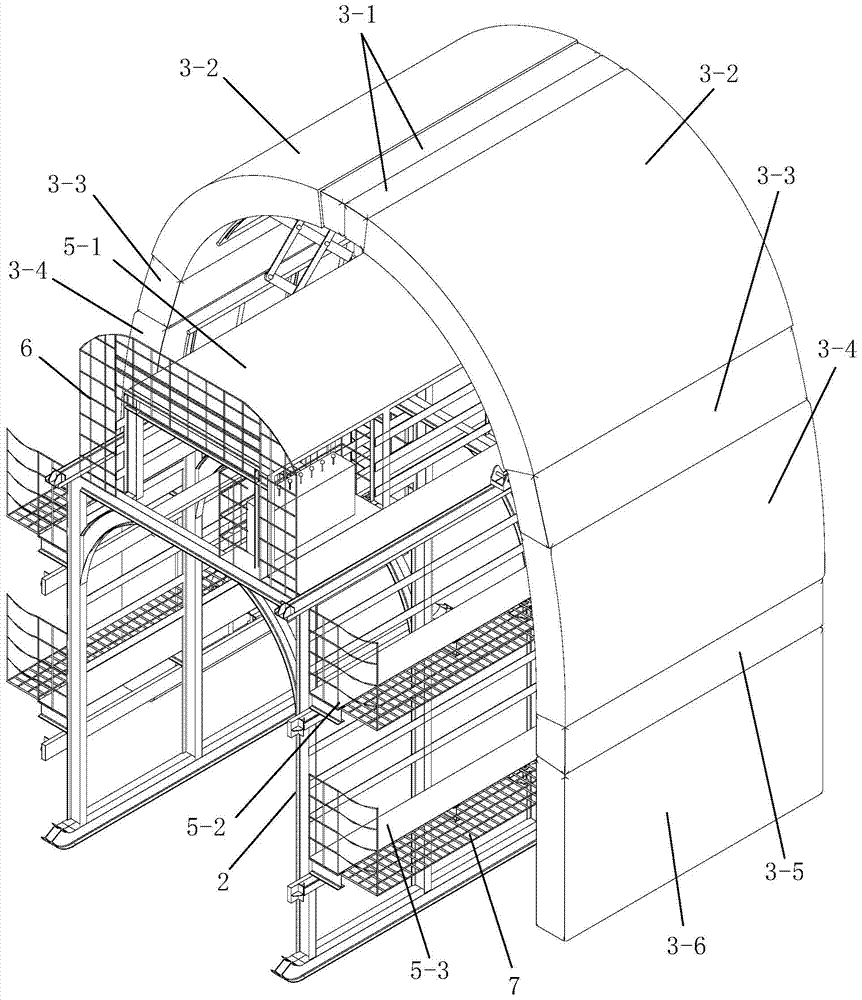

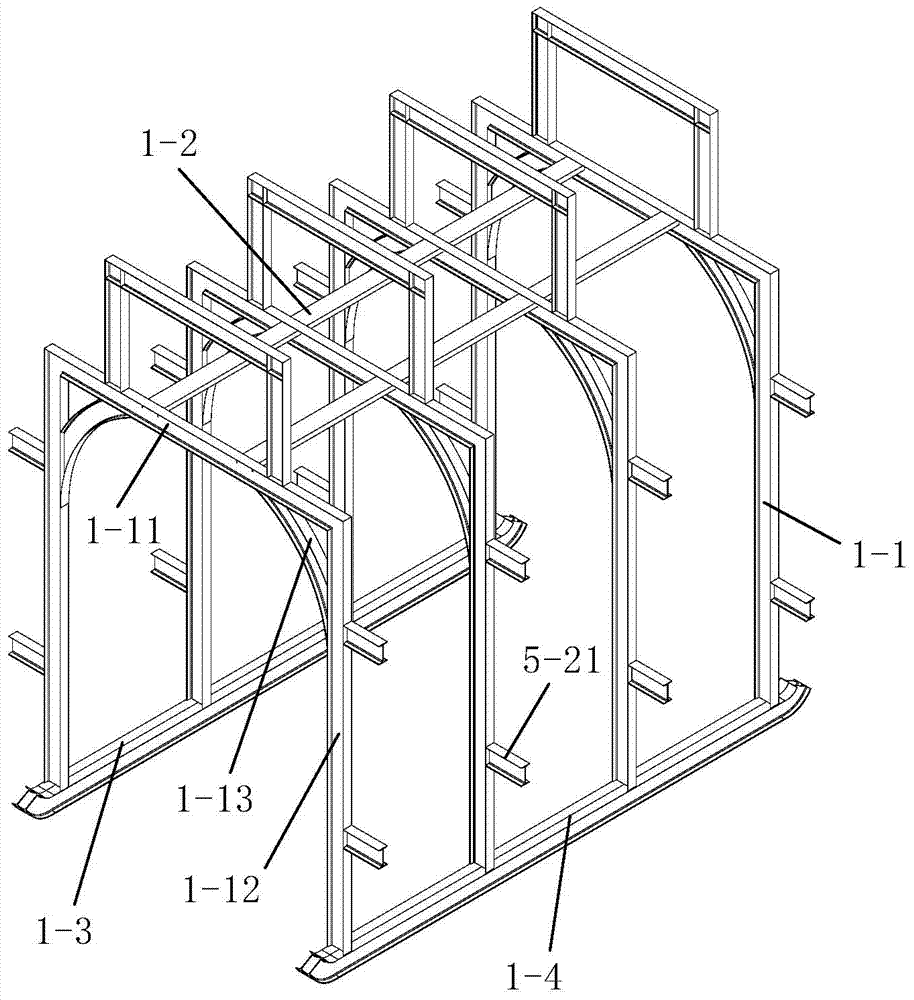

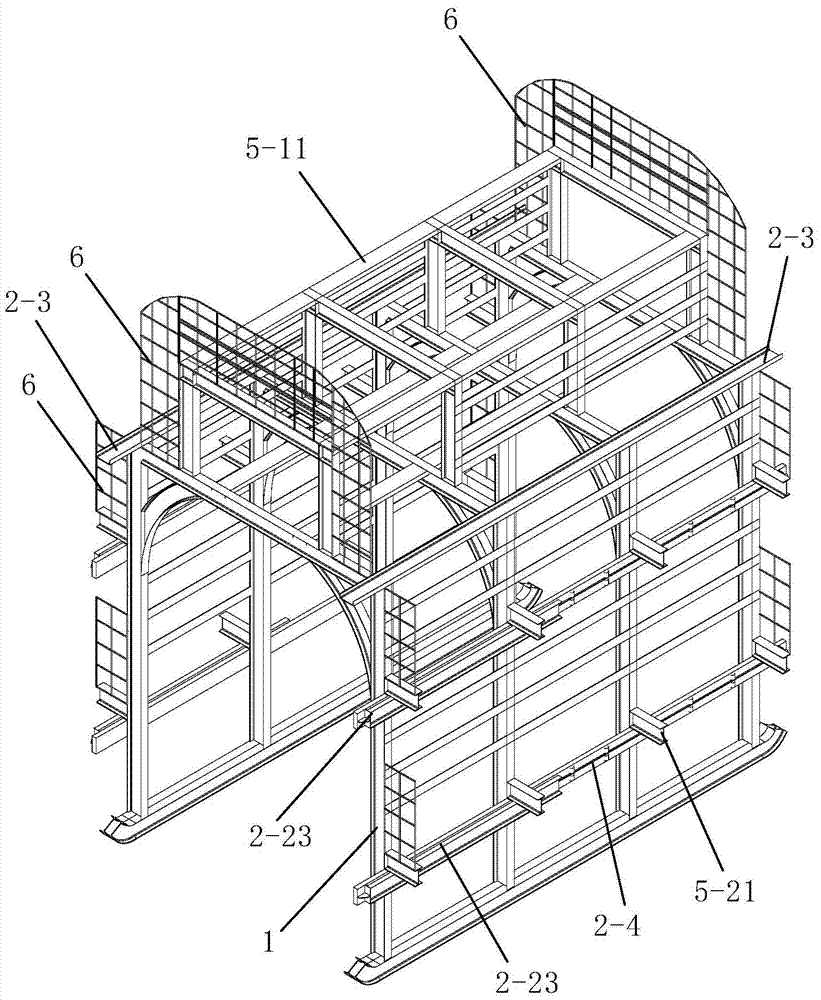

[0092] like figure 1 As shown, the mobile formwork of the airbag inner mold according to the present invention includes a movable support bent frame 1 capable of moving back and forth in the tunnel hole of the constructed tunnel, an inflatable formwork positioned outside the movable support bent frame 1 and a The telescopic support device for supporting the inflatable formwork, the telescopic support device is installed on the mobile support bent frame 1 and is located inside the inflatable formwork.

[0093] The inflatable template is located inside the arch wall of the tunnel hole and has the same shape as the cross-sectional shape of the arch wall. The inflatable formwork includes an airbag inner mold and a formwork support supported inside the airbag inner mold, the airbag inner mold is an arch formwork, and the formwork support is an arch inner support. The airbag inner mold includes a top formwork located directly below the arch of the tunnel and two symmetrically arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com