Production method of high crack resistance concrete

A production method and concrete technology, applied in the field of comparison, can solve the problems of concrete structure damage, affecting the appearance of the structure, weakening the durability of the concrete structure, etc., and achieving the effect of not easy to break and high crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

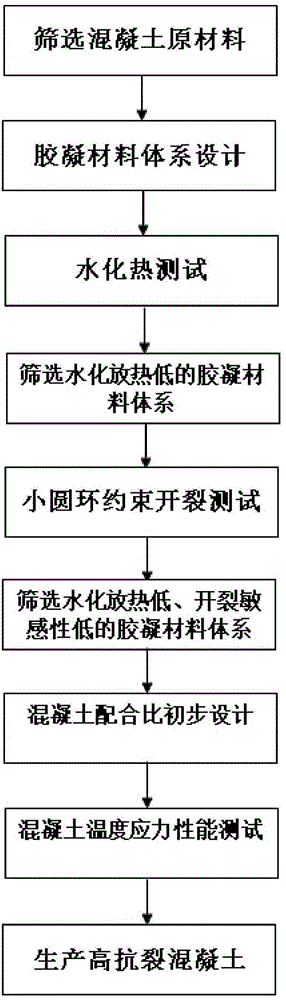

[0029] see figure 1 Shown, high anti-cracking concrete production method of the present invention, described production method comprises the following steps:

[0030] 1. Detect and screen out concrete raw materials that meet the range of crack resistance and durability indicators: use the methods specified in the standard specifications to test the performance of various raw materials that make up the concrete. In addition to meeting the index requirements specified in the specifications for concrete raw materials, special Specifications for concrete raw materials with high crack resistance and durability.

[0031] The concrete raw materials include cement, fly ash, ground slag powder, water, sand, gravel and water reducer; the indicators of the concrete raw materials that meet the crack resistance and durability indicators include:

[0032] Cement clinker: C3A content ≤ 8%, alkali content ≤ 0.6%, cement specific surface area 300 ~ 350m 2 / kg;

[0033] Fly ash: Class II or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Chloride diffusion coefficient | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com