Waterproof flexible cement-based dry-mixed overlay repairing mortar

A repairing mortar and waterproof technology, which is applied in the field of building materials, can solve the problems of poor impermeability, poor flexibility, surface cracking, etc., achieve high interface bonding strength, improve water retention capacity, and improve freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

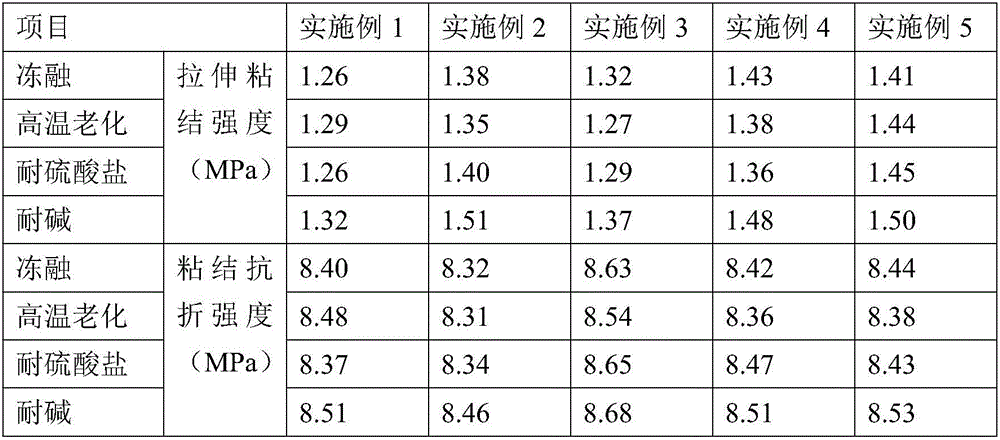

Examples

Embodiment 1

[0037] The quality ratio of waterproof flexible cement-based dry-mix overlay repair mortar is as follows:

[0038] P·O 52.5 grade cement: 22

[0039] Class I fly ash: 2

[0040] Vinyl acetate-ethylene copolymer rubber powder: 0.9

[0041] Hydroxypropyl methylcellulose ether: 0.05

[0042] Polyether modified silicon defoamer: 0.03

[0043] UEA expansion agent: 0.02

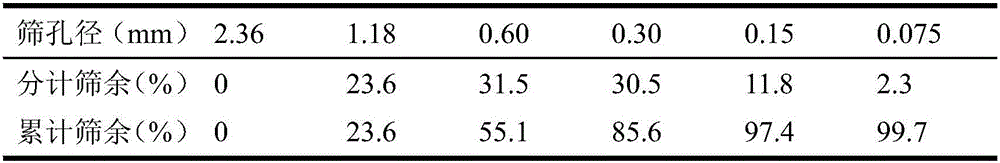

[0044] Natural Sand: 75

[0045] Preparation

[0046]Weigh the composite cementitious material, admixture and aggregate respectively according to the ratio of raw materials; mix the weighed composite cementitious material and admixture evenly in a mixing mixer to form a dry mixture; dry mix the above uniformly mixed The material and the aggregate are mixed evenly in a mixing mixer; the evenly mixed waterproof flexible cement-based dry-mix overlay repair mortar is stored or bagged, and the product is ready.

[0047] In engineering application, the water consumption is 10% of the total mass of waterproof flexi...

Embodiment 2

[0049] The quality ratio of waterproof flexible cement-based dry-mix overlay repair mortar is as follows:

[0050] P·O 42.5 grade cement: 39

[0051] Class I fly ash: 18

[0052] Acrylic copolymer rubber powder: 2.1

[0053] Hydroxyethyl methyl cellulose ether: 0.45

[0055] AEA expansion agent: 0.15

[0056] Natural Sand: 40

[0057] The preparation method is the same as in Example 1. In engineering application, the water consumption is 20% of the total mass of waterproof flexible cement-based dry-mix overlay repair mortar.

Embodiment 3

[0059] The quality ratio of waterproof flexible cement-based dry-mix overlay repair mortar is as follows:

[0060] P·O 52.5 grade cement: 25

[0061] Class I fly ash: 4

[0062] SBR powder: 1.5

[0063] Hydroxypropyl methylcellulose ether: 0.05

[0064] Polyether modified silicon defoamer: 0.3

[0065] CEA expansion agent: 0.15

[0066] Natural Sand: 69

[0067] The preparation method is the same as in Example 1. In engineering application, the water consumption is 12% of the total mass of waterproof flexible cement-based dry-mix overlay repair mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com