Special sprayed concrete material for tunnel high-ground-temperature dry-hot environment

A shotcrete, high ground temperature technology, applied in the field of concrete, can solve the problems of loss of cohesion, increase of concrete rebound, failure of surrounding rock support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: 100°C high ground temperature and dry heat environment

[0016] Application of main raw materials and main proportion parameters of concrete per cubic meter:

[0017] (1) The total amount of cementitious materials is 420kg (83% ordinary Portland cement, 15% sulphoaluminate cement, 2% nano-silicon oxide);

[0018] (2) 775kg of stones;

[0019] (3) Steel fiber 45kg;

[0020] (4) The amount of shrinkage reducing agent is 5%;

[0021] (5) The dosage of water reducer JX-GBNHy2 high-performance polycarboxylic acid is 1.2%;

[0022] (6) Accelerator JX-E 3 Liquid dosage 5%;

[0023] (7) The glue-bone ratio is 1:4.1; the sand rate is 0.55; the water-binder ratio is 0.45.

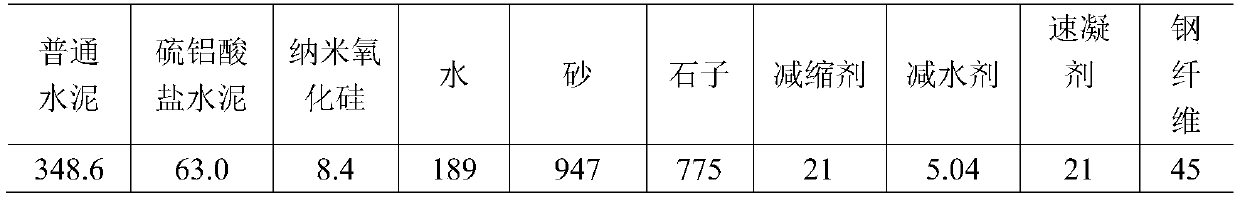

[0024] The specific mix ratio is shown in Table 1 below (unit: kg).

[0025] Table 1 Application of main raw materials per cubic meter of concrete in Example 1

[0026]

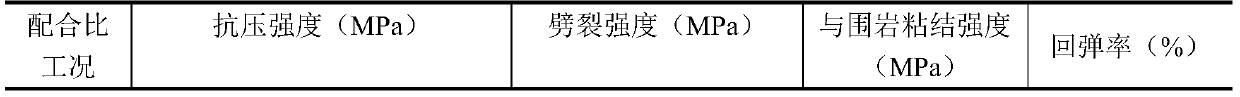

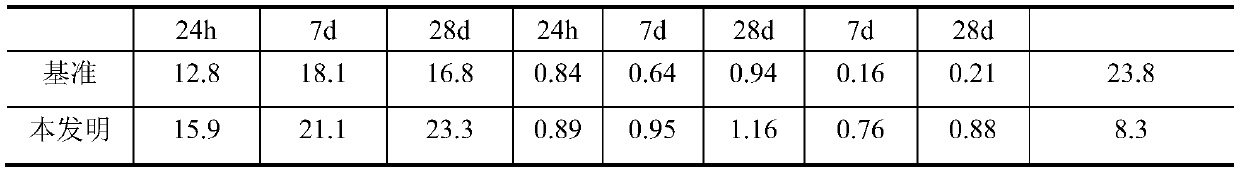

[0027] Technical index tests include: slump, compressive strength, split tensile strength, bond strength and rebound r...

Embodiment 2

[0031] Example 2: Dry and hot environment with high ground temperature of 80°C

[0032] Application of main raw materials and main proportion parameters of concrete per cubic meter:

[0033] (1) The total amount of cementitious materials is 400kg (88% ordinary Portland cement, 11% sulphoaluminate cement, 1% nano-silicon oxide);

[0034] (2) 758kg of stones;

[0035] (3) Steel fiber 40kg;

[0036] (4) The amount of shrinkage reducing agent is 5%;

[0037] (5) The dosage of water reducer JX-GBNHy2 high-performance polycarboxylic acid is 1.2%;

[0038] (6) Accelerator JX-E 3 Liquid dosage 5%;

[0039] (7) The glue-bone ratio is 1:4.3; the sand ratio is 0.56; the water-binder ratio is 0.47.

[0040] The specific mix ratio is shown in the following table 2 (unit: kg).

[0041] Table 3 Application of main raw materials per cubic meter of concrete in Example 2

[0042]

[0043]Technical index tests include: slump, compressive strength, split tensile strength, bond strength...

Embodiment 3

[0047] Example 3: Dry and hot environment with high ground temperature of 60°C

[0048] (1) The total amount of cementitious materials is 400kg (89% ordinary Portland cement, 10% sulphoaluminate cement, 1% nano-silicon oxide);

[0049] (2) 758kg of stones;

[0050] (3) Steel fiber 39kg;

[0051] (4) The amount of shrinkage reducing agent is 5%;

[0052] (5) The dosage of water reducer JX-GBNHy2 high-performance polycarboxylic acid is 1.1%;

[0053] (6) Accelerator JX-E 3 Liquid dosage 5%;

[0054] (7) The glue-bone ratio is 1:4.3; the sand rate is 0.56; the water-binder ratio is 0.48.

[0055] The specific matching ratio is as follows (unit: kg)

[0056] Table 5 Application of main raw materials per cubic meter of concrete in Example 3

[0057]

[0058] Technical index tests include: slump, compressive strength, split tensile strength, bond strength and rebound rate. The comparison results of the concrete test results of Example 3 and the benchmark working condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com