Patents

Literature

116results about How to "Narrow particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

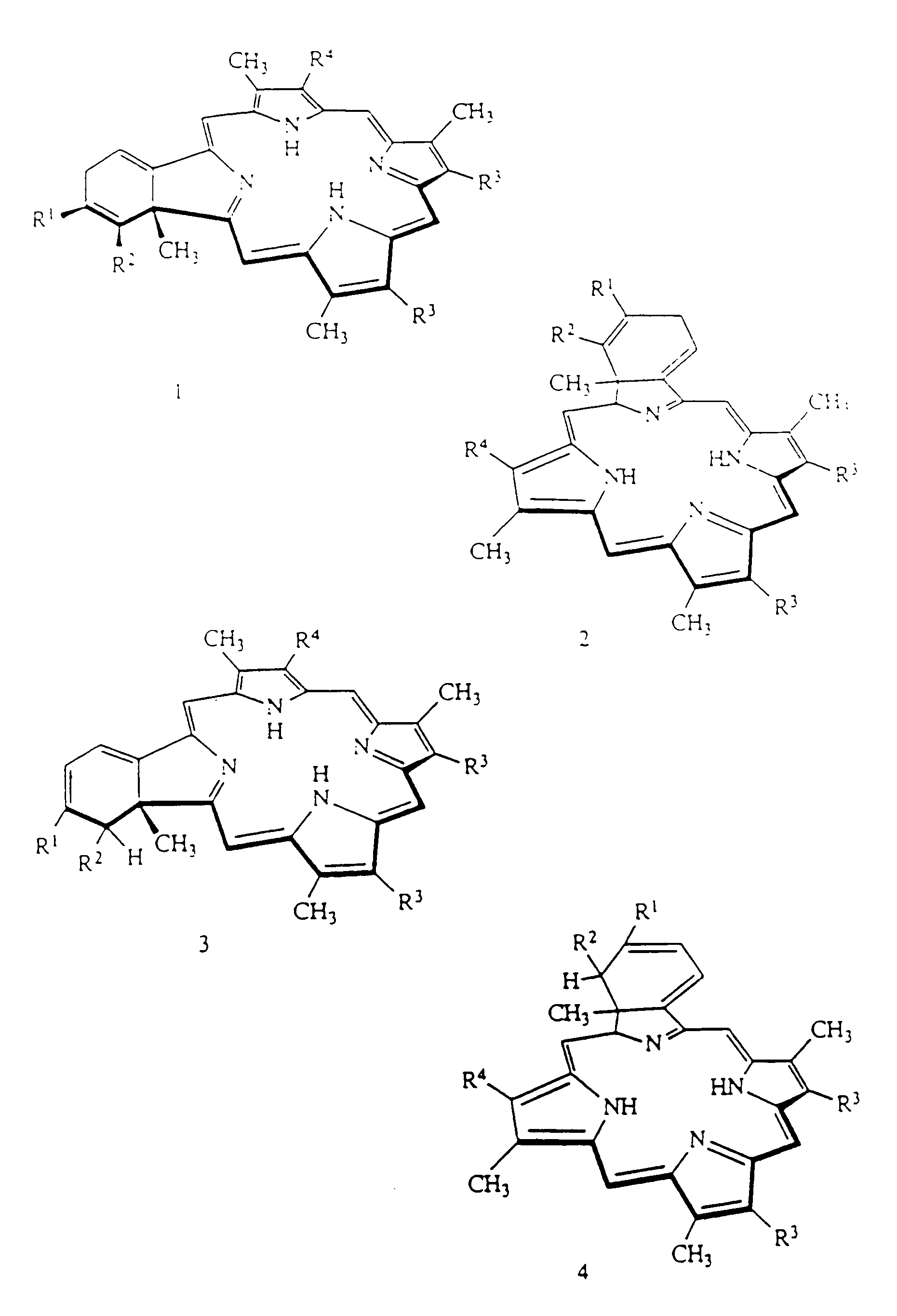

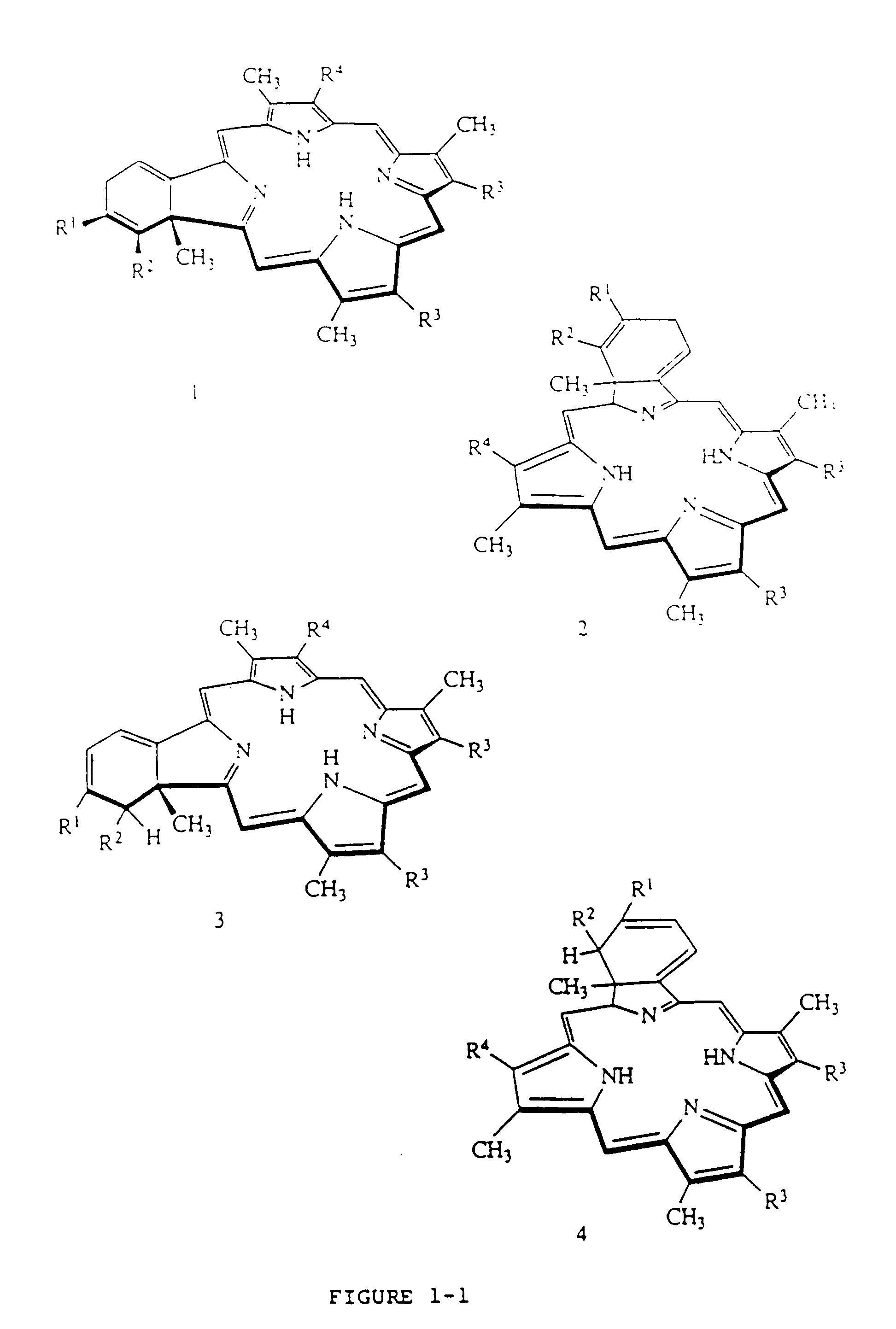

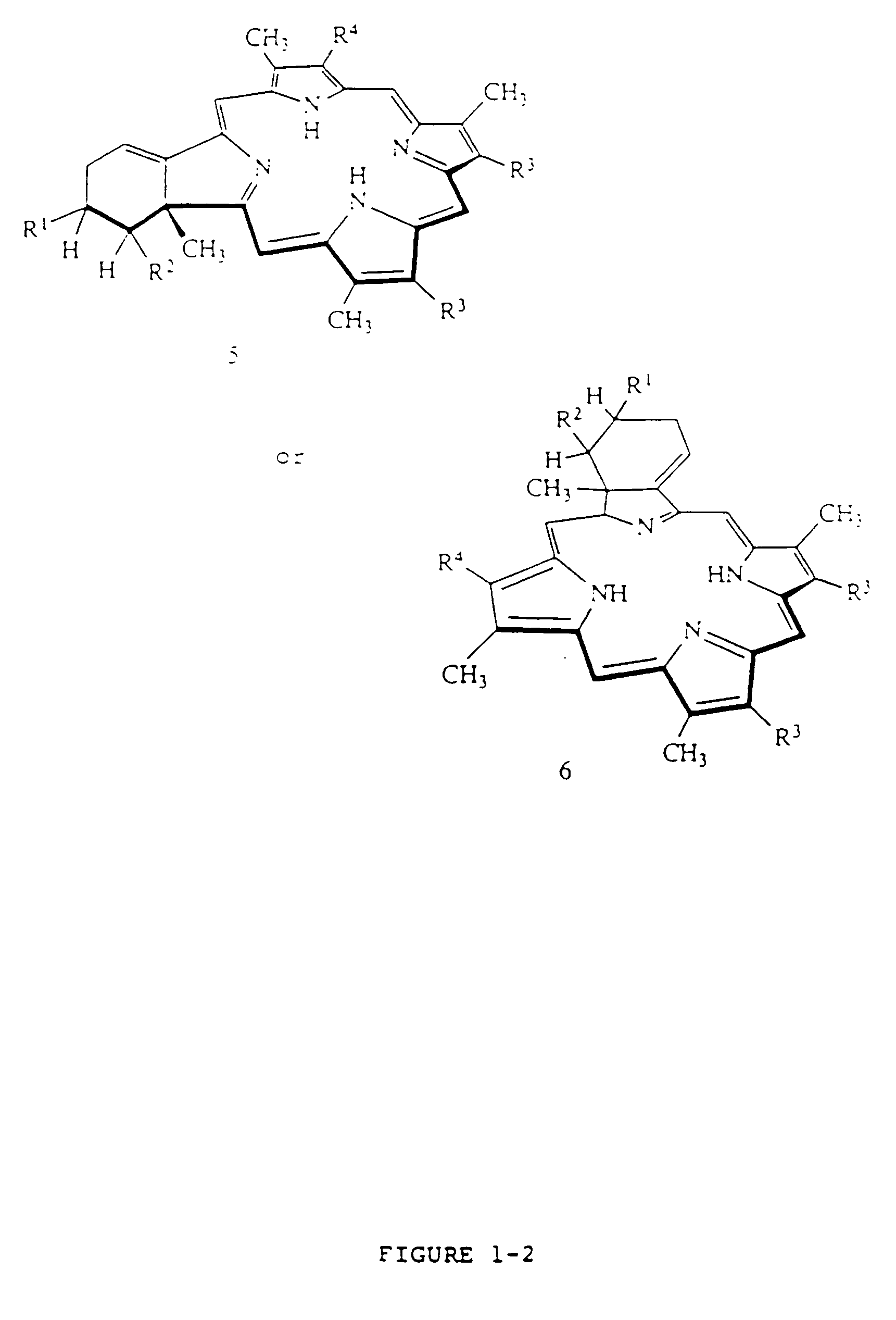

Liposome compositions of porphyrin photosensitizers

InactiveUS6890555B1Good reproducibilityHydrate fastBiocideEnergy modified materialsPhotodynamic therapyPhotosensitizer

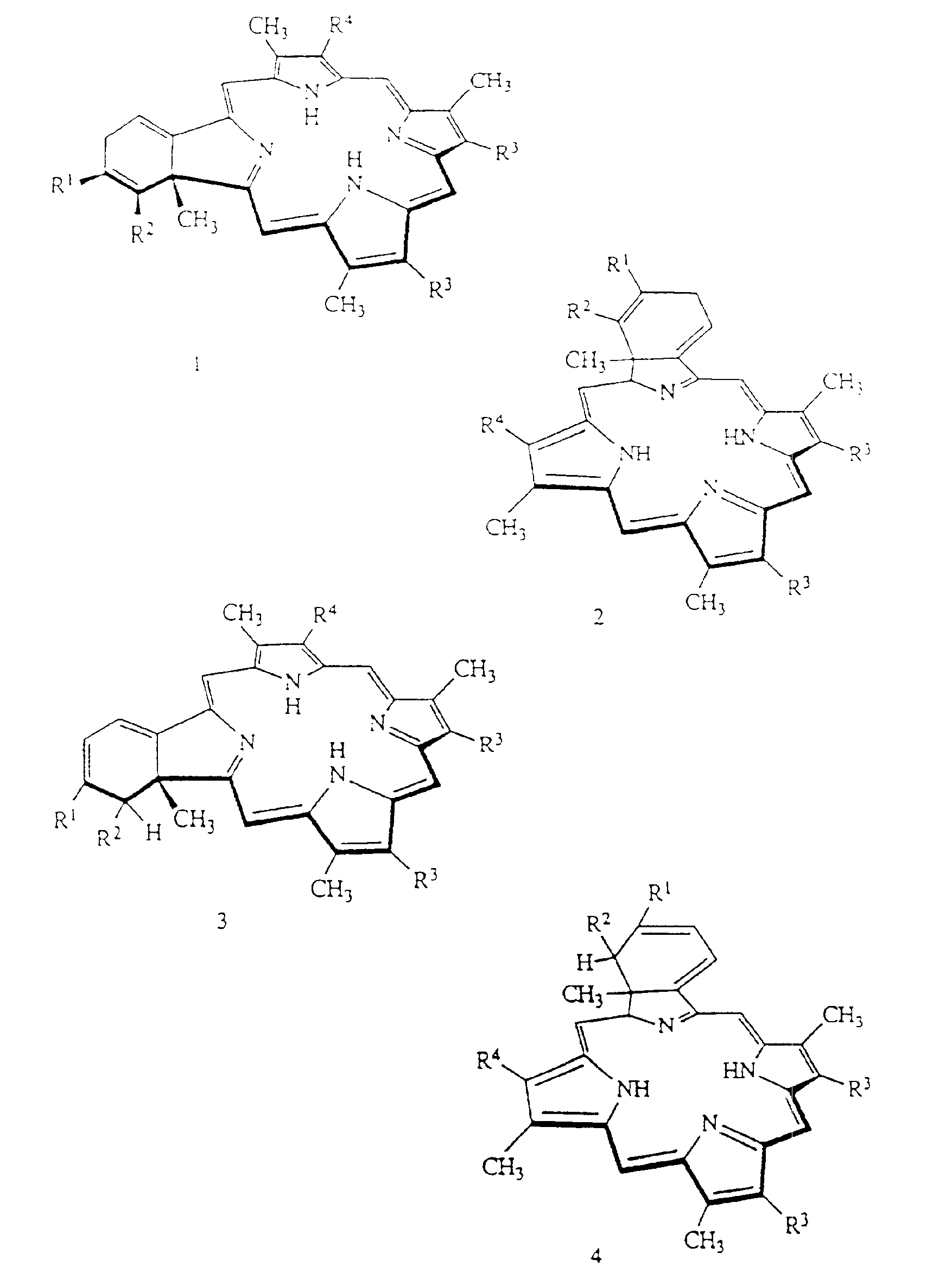

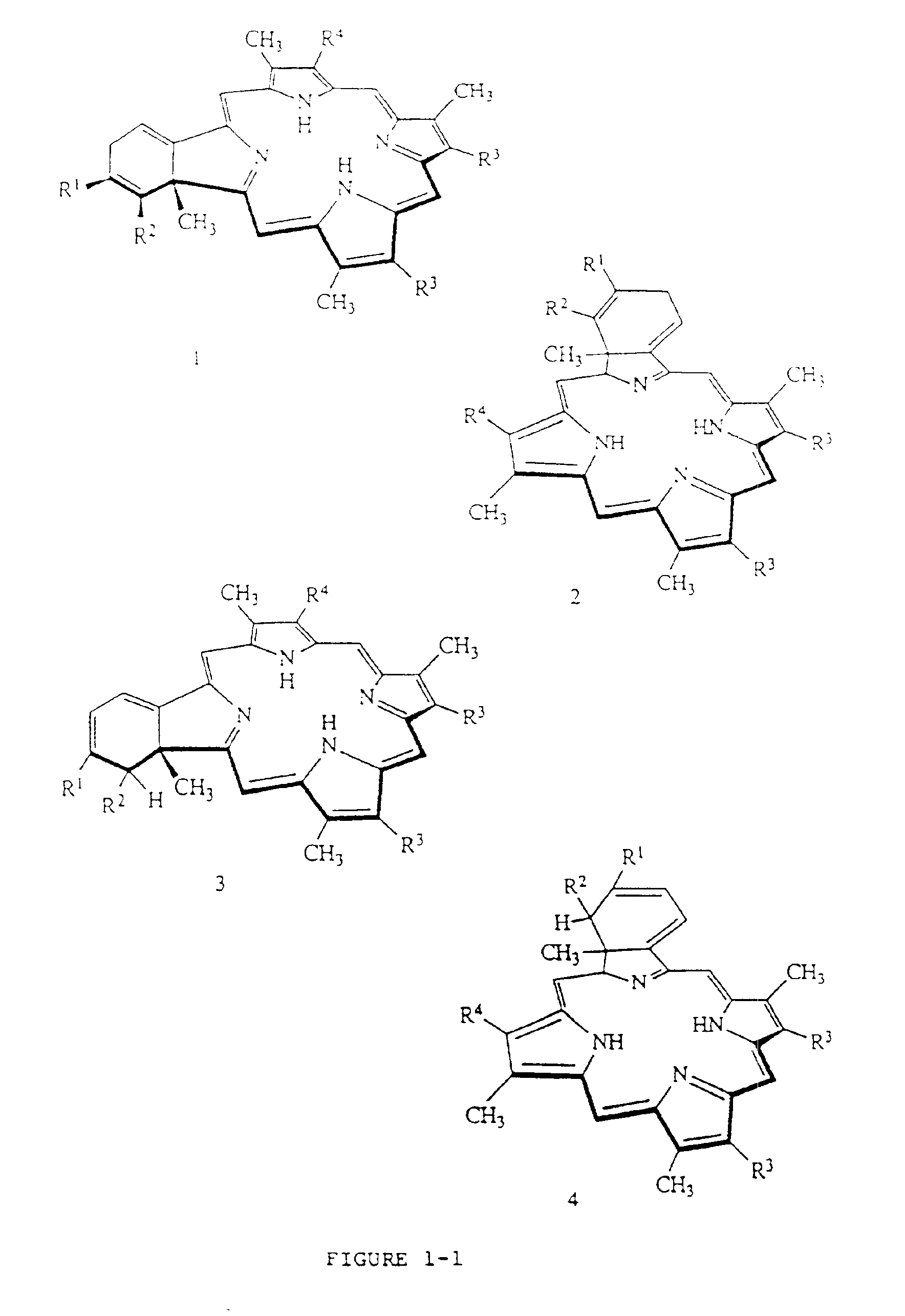

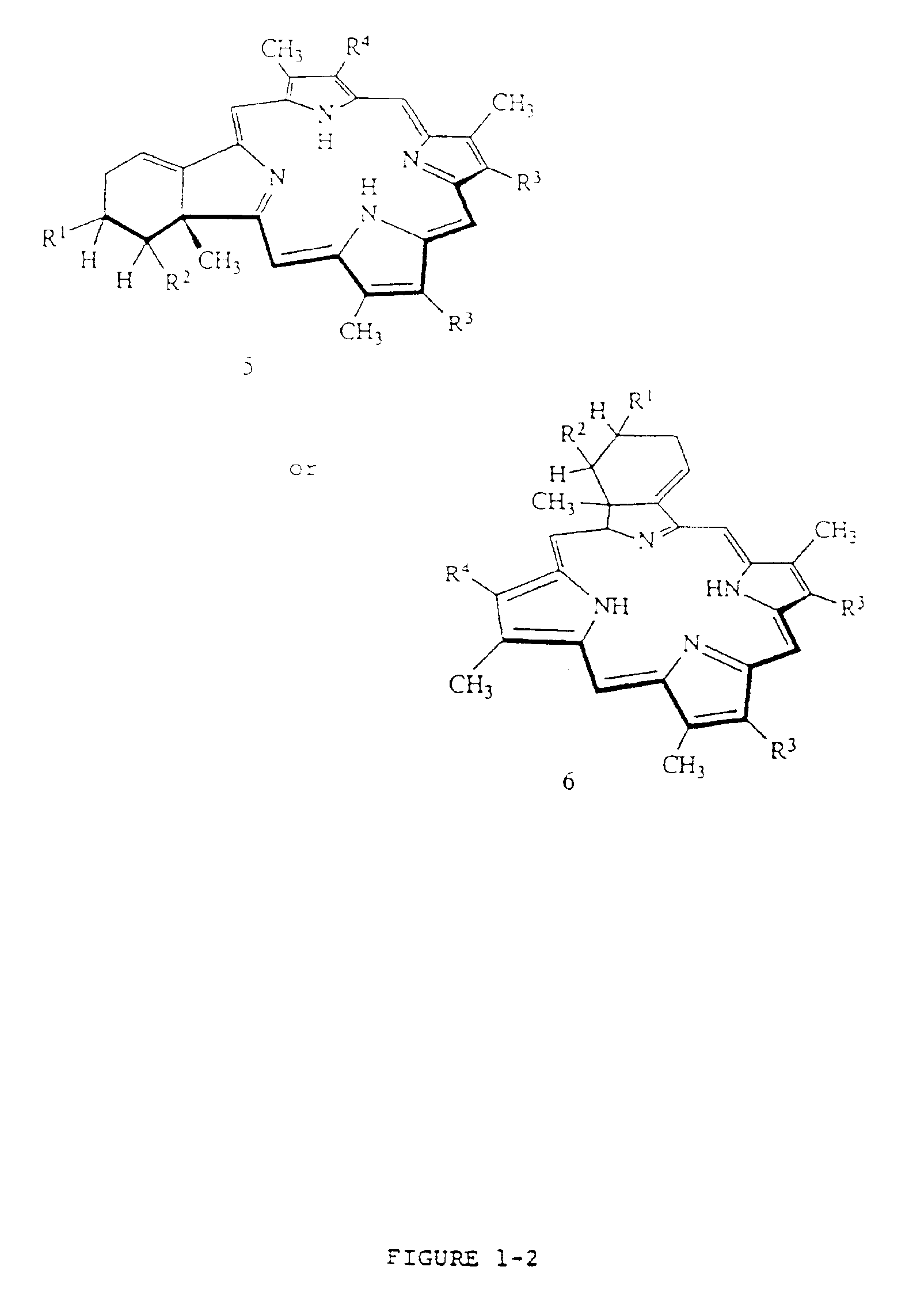

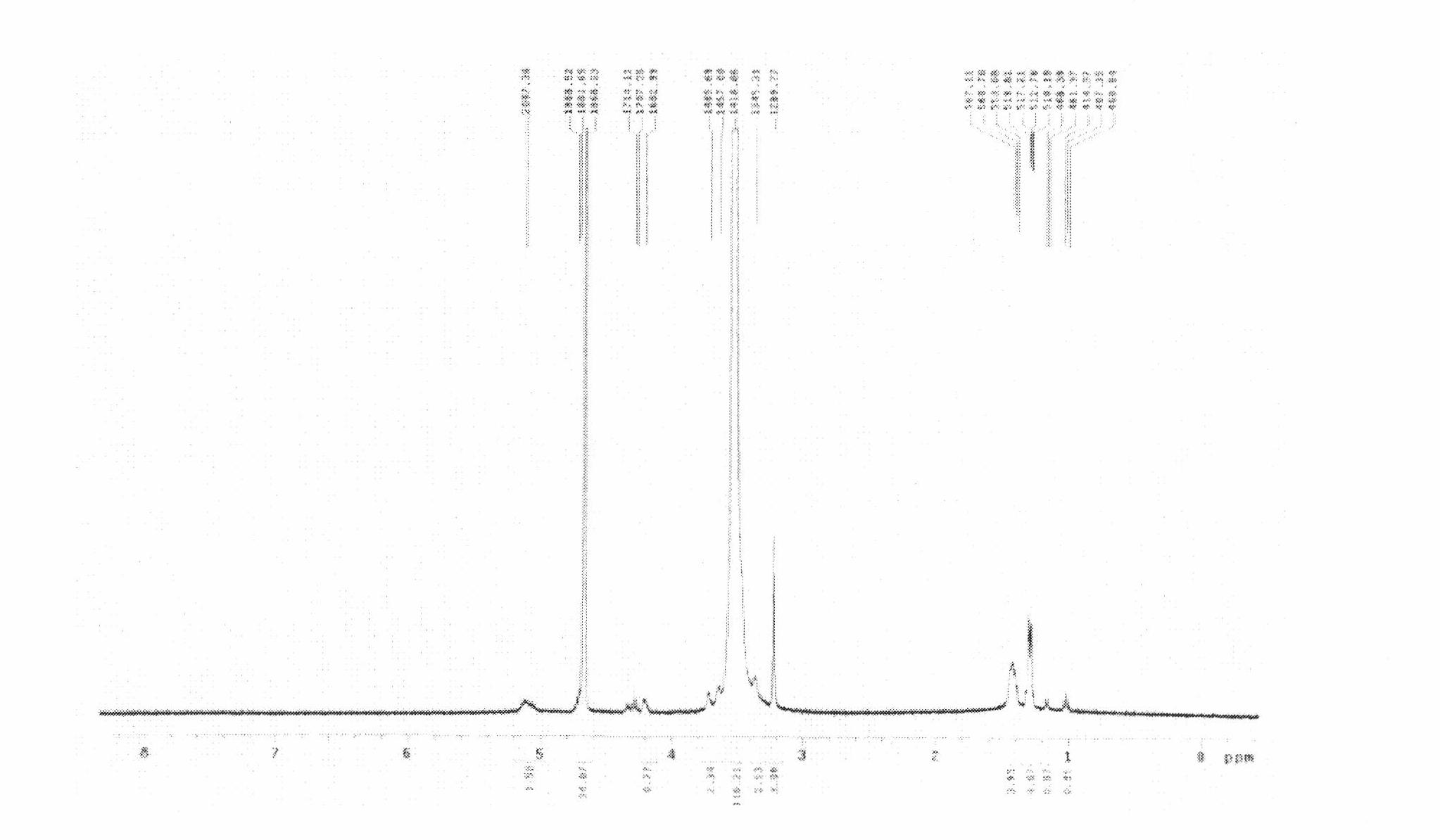

Liposomal pharmaceutical formulations incorporating porphyrin photosensitizers useful for photodynamic therapy or diagnosis of malignant cells. The liposomal formulations comprise a porphyrin photosensitizer, particularly the hydro-mono benzoporphyrine (BPD) having light absorption maxima in the range of 670-780 nanometers, a disaccharide or polysaccharide and one or more phospholipids.

Owner:QLT INC

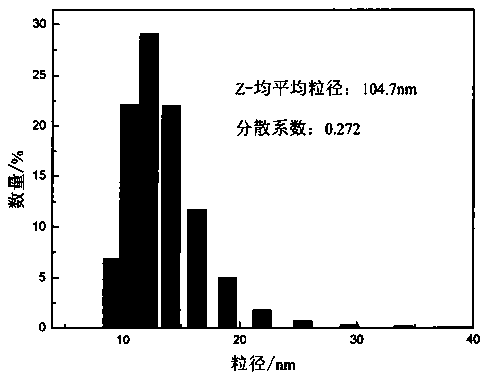

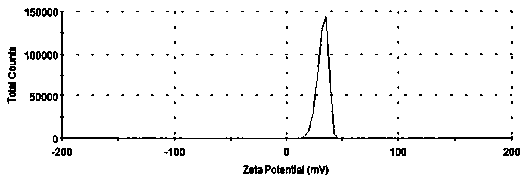

Polymer micelle lyophilized agent encapsulating insoluble antitumor drug

ActiveCN102218027ASmall toxicityGood biocompatibilityOrganic active ingredientsPharmaceutical delivery mechanismPolyesterSide effect

The invention belongs to the field of pharmaceutical agents, relates to a polymer micelle lyophilized agent encapsulating an insoluble antitumor drug as well as a preparation method and an application thereof. The polymer micelle lyophilized agent is prepared by carrying out molecular self-assembly on a methoxy poly(ethylene glycol) 2000-polyester block copolymer to form micelles, and then encapsulating the insoluble antitumor drug in a hydrophobic core formed by the polyester. The lyophilized agent has high encapsulation rate, high drug loading and small particle size, can significantly improve the water solubility of the insoluble drug and result in passive targeting of more antitumor drugs to concentrate in the tumor tissues, thus improving an anti-tumor treatment effect and reducing the toxic and side effects of drugs, and can be used to prepare the drugs used for the treatment of lung cancer, intestinal cancer, mammary cancer, ovarian cancer, etc. The lyophilized agent can also be quickly dissolved and dispersed to form a transparent micellar solution after water for injection, normal saline solution and the like are added, and is used for the preparation of the drugs for treating primary intestinal cell carcinoma.

Owner:上海谊众药业股份有限公司

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

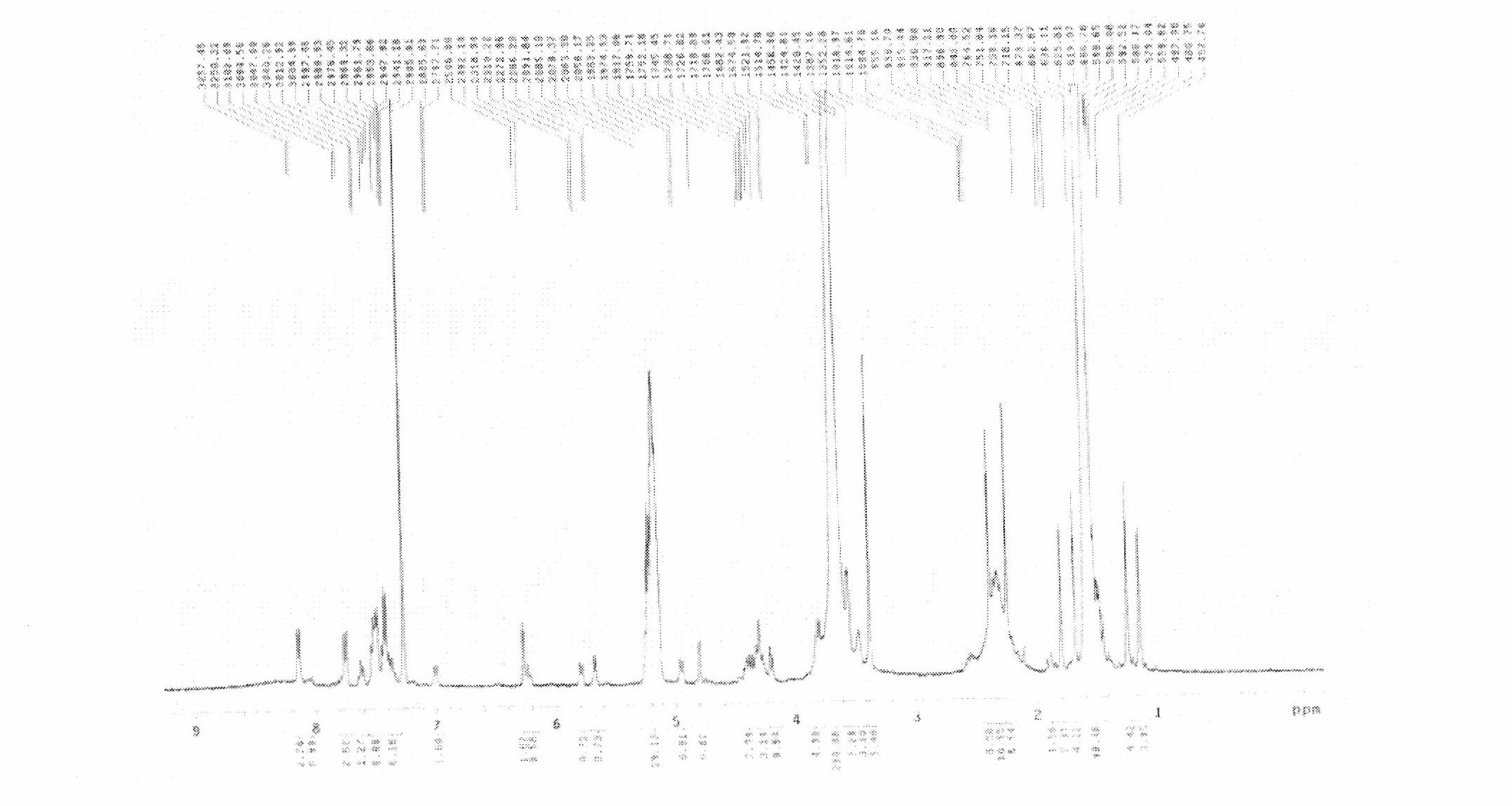

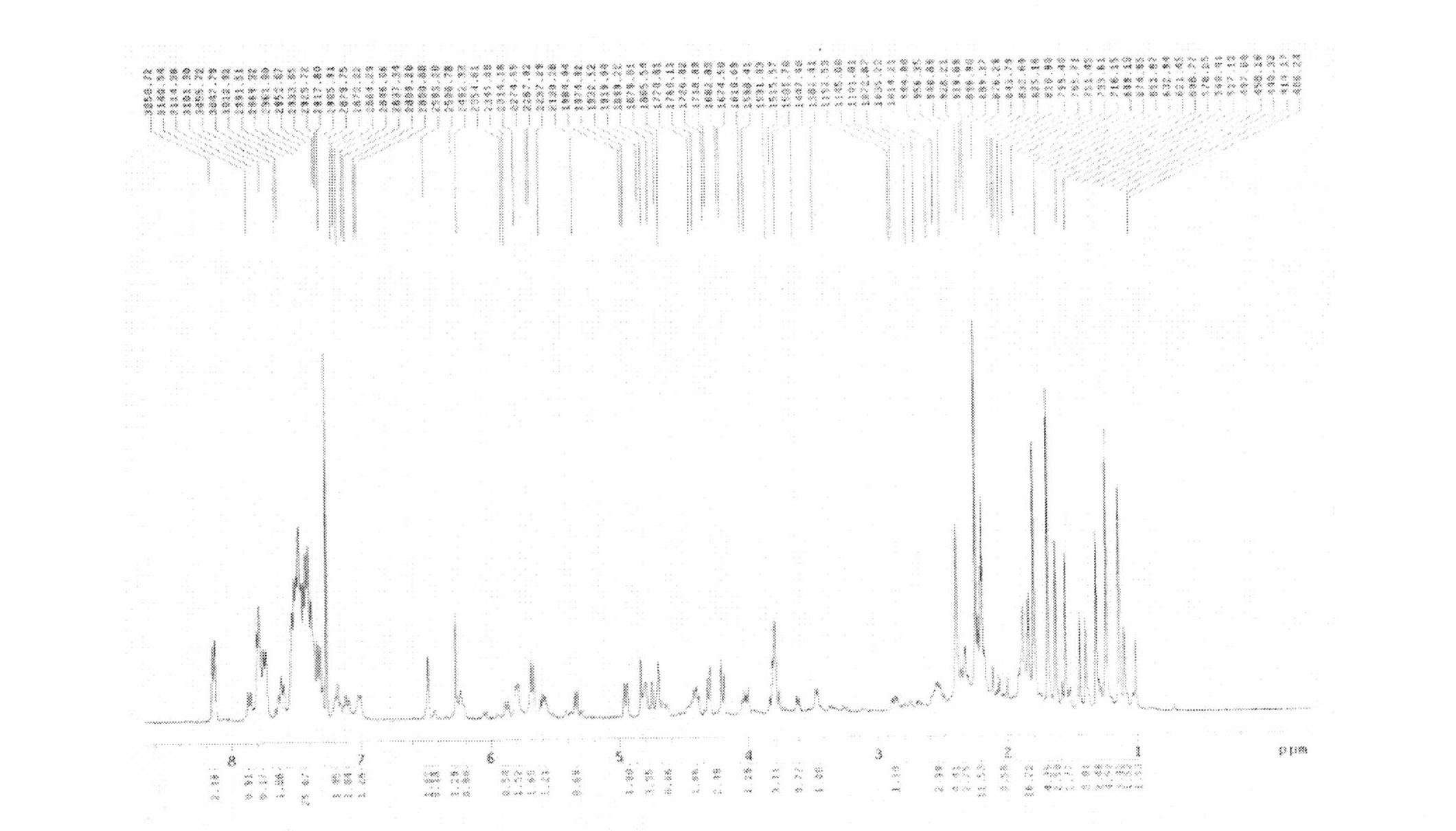

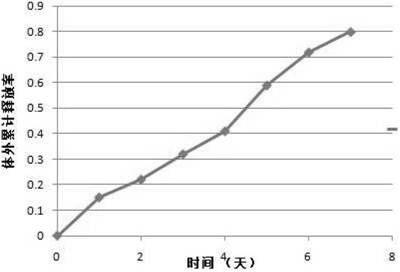

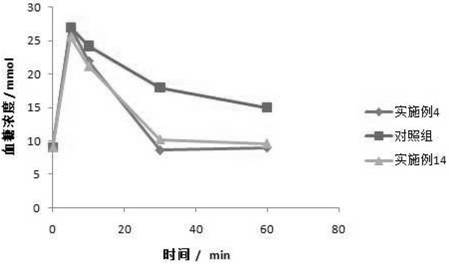

Polypeptide drug sustained-release microsphere preparation and preparation method thereof

ActiveCN102688198AUniform particle sizeNarrow particle sizePeptide/protein ingredientsMetabolism disorderFreeze-dryingMicrosphere

The invention discloses a polypeptide drug sustained-release microsphere preparation and a preparation method thereof. The method comprises the following steps of: dissolving the polylactic acid-glycollic acid copolymer or polylactic acid, a protective agent and a polypeptide drug in an organic solvent to form a completely uniform mixed solution; adding the mixed solution into an oil phase to form emulsion; removing the organic solvent; and performing centrifugal washing and freeze drying to obtain the polypeptide drug sustained-release microsphere. In the invention, an O / O method is adopted, the problem that the drug spreads toward the outer aqueous phase in the multiple-emulsion preparation method is solved, and the drug encapsulation efficiency is improved to 60-95%. The biological active polypeptide drug is degraded in the body and slowly released with the polymer material of the microsphere through the pores on the microsphere surface; the release time can be as long as several weeks and even several months; and the in-vitro release test indicates that the release conforms to similar zero-order release.

Owner:AC PHARMA CO LTD

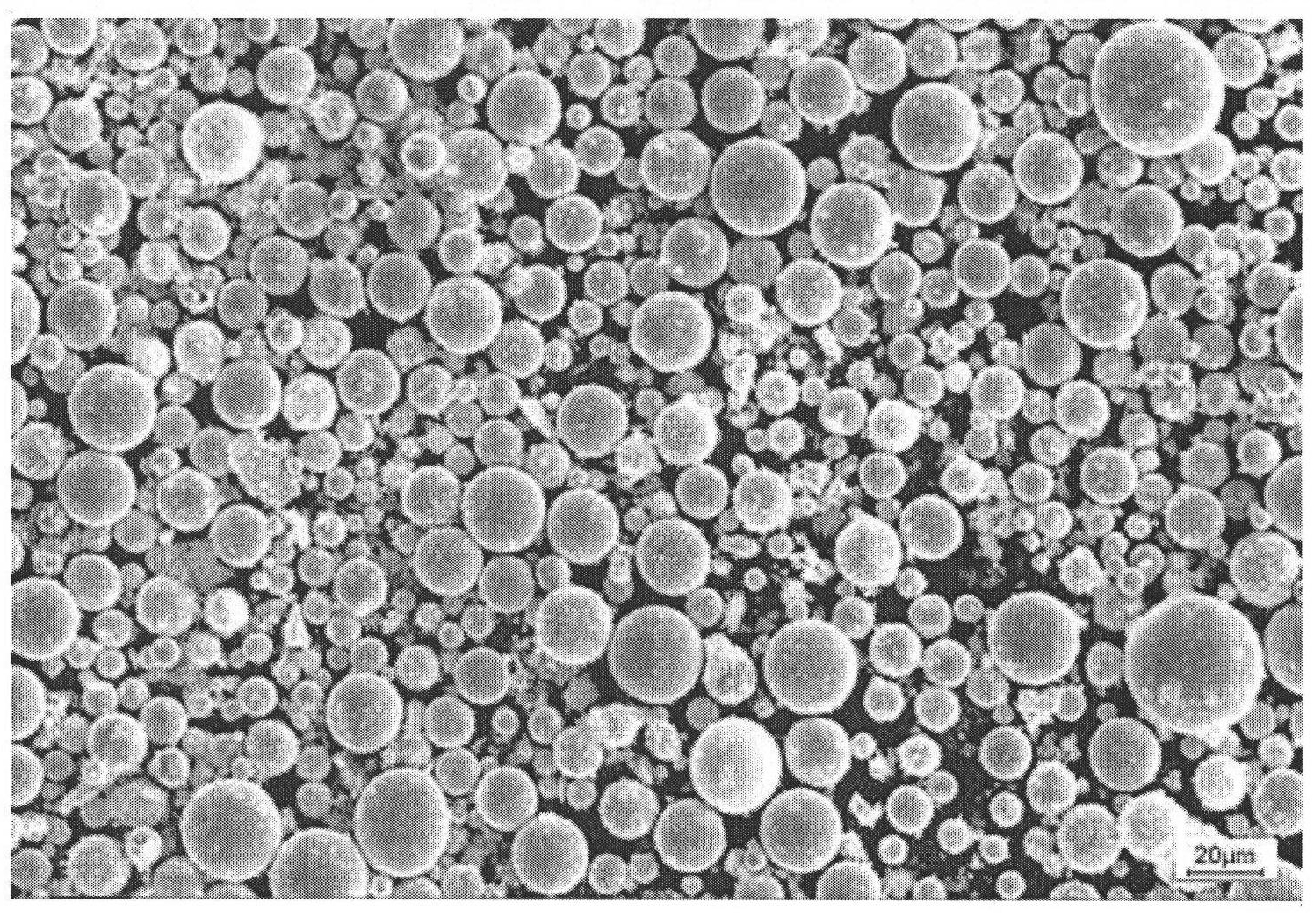

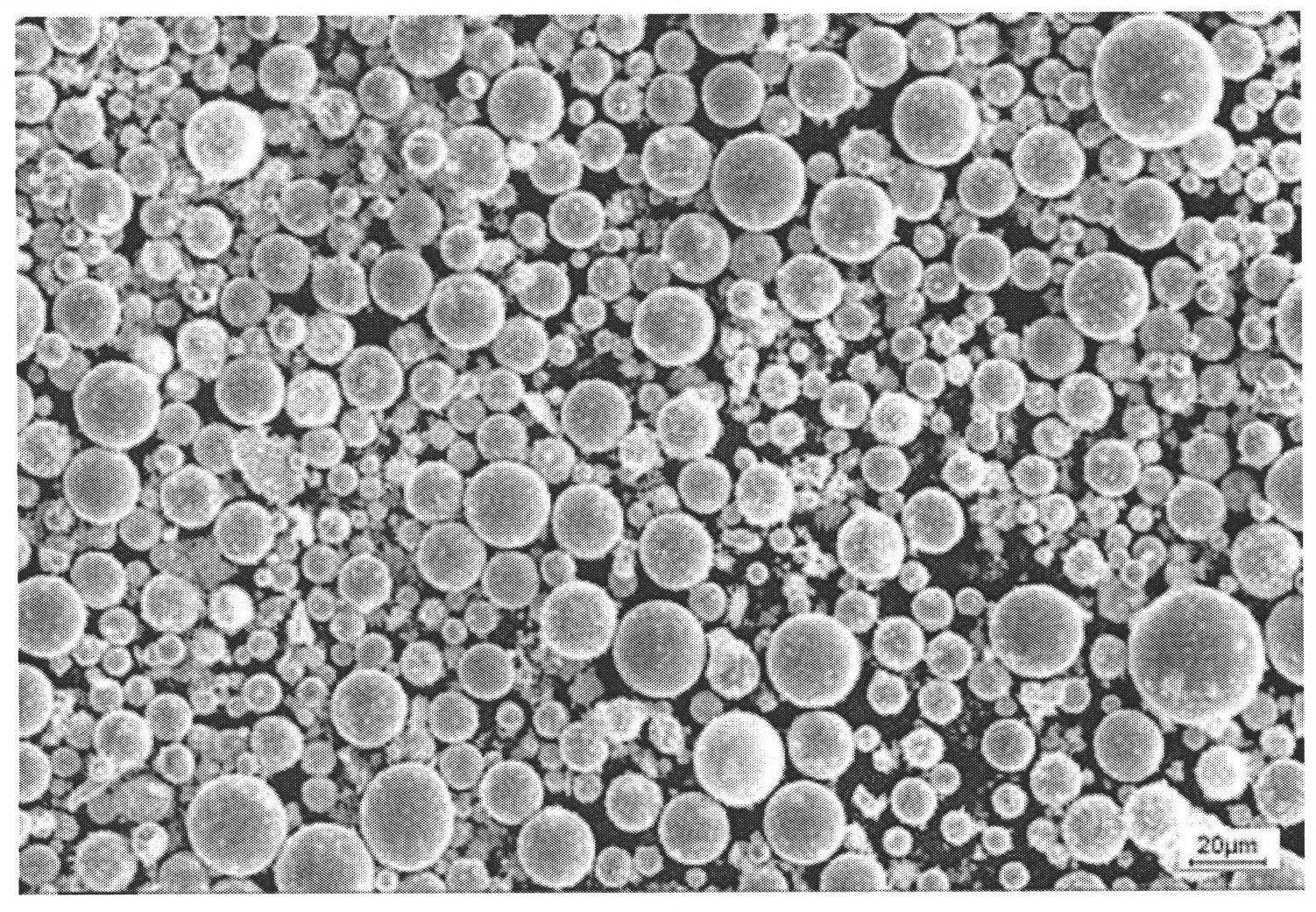

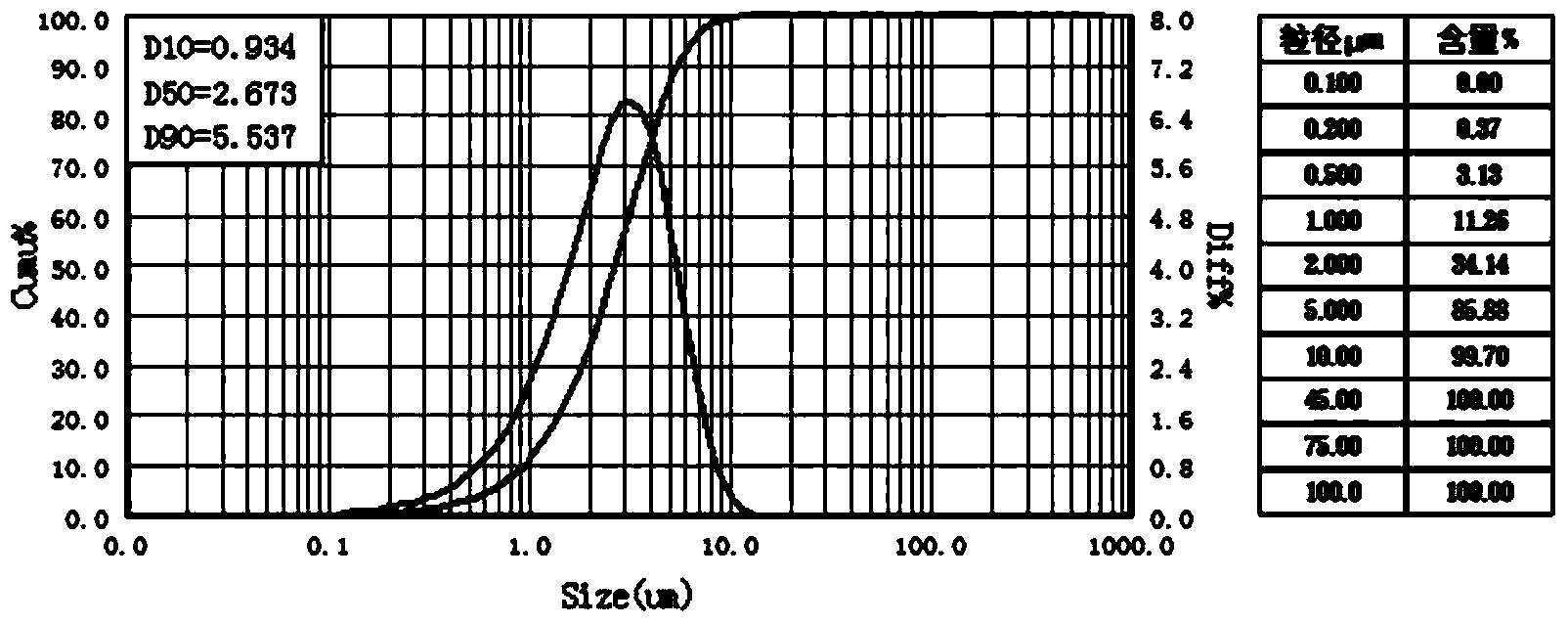

Method for largely preparing superfine spherical titanium aluminium-based alloyed powder

The invention provides a method for largely preparing superfine spherical titanium aluminium-based alloyed powder, which belongs to the technical field of powder preparation. The method comprises the following steps: smelting high-purity aluminium and titanium sponge as main raw materials and Al-Nb intermediate alloy, Ti-B alloy, tungsten powder and high-purity yttrium scraps as auxiliary raw materials into an alloy cast ingot in a vacuum consumable electrode arc skull furnace or a vacuum induction furnace; then carrying out coarse crushing and vortex airflow milling to prepare irregular superfine alloy powder; and finally carrying out plasma spheroidization of radio frequency (RF) and the like to prepare the superfine spherical titanium aluminium-based alloyed powder. The prepared alloy powder has the advantages of high purity, fine particle size, narrow particle size distribution, good uniformity, high sphericity, good flowability and the like and can meet the demands of the technical industrial production of injection forming, gel injection molding forming, thermal spraying and the like.

Owner:UNIV OF SCI & TECH BEIJING

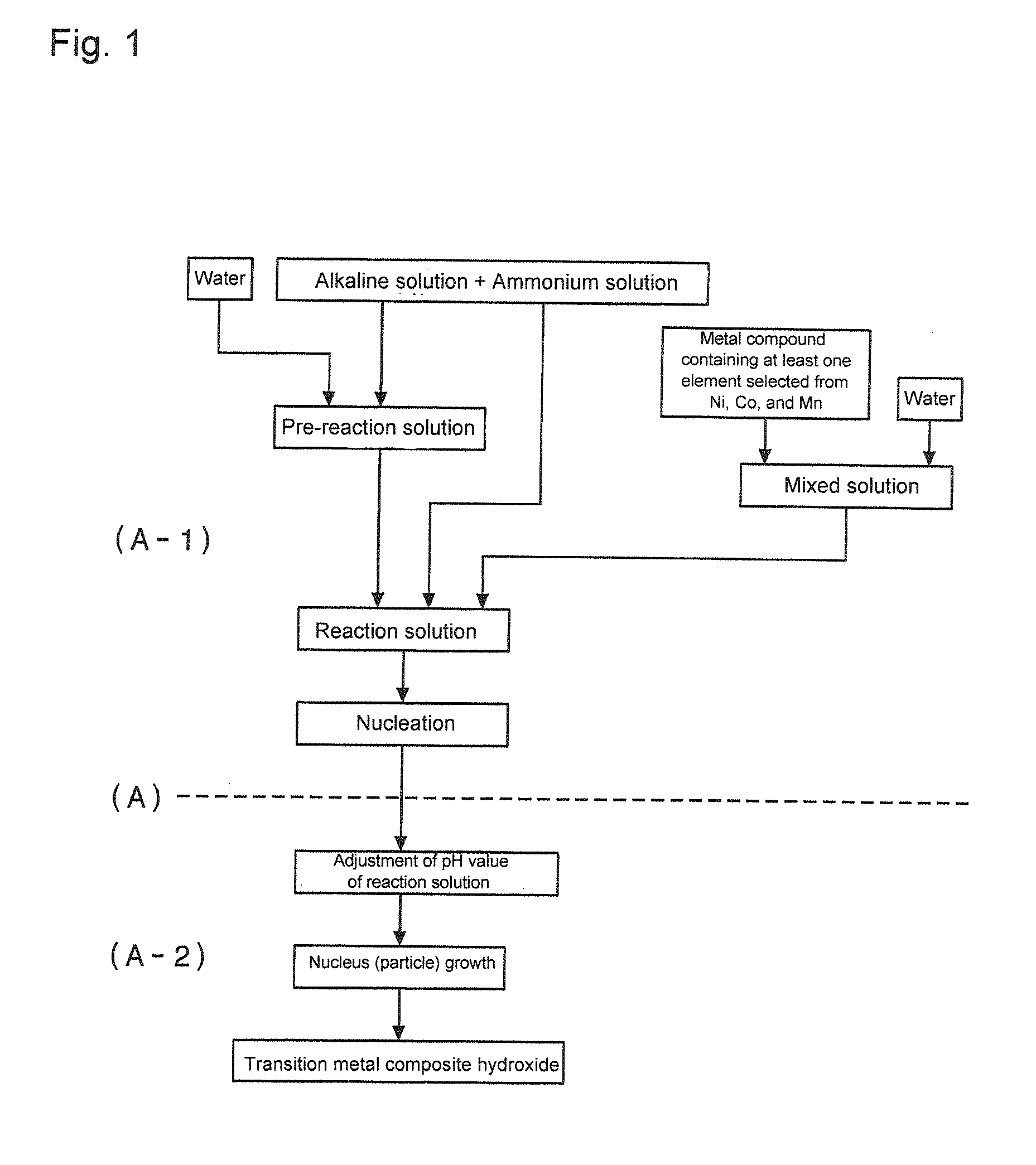

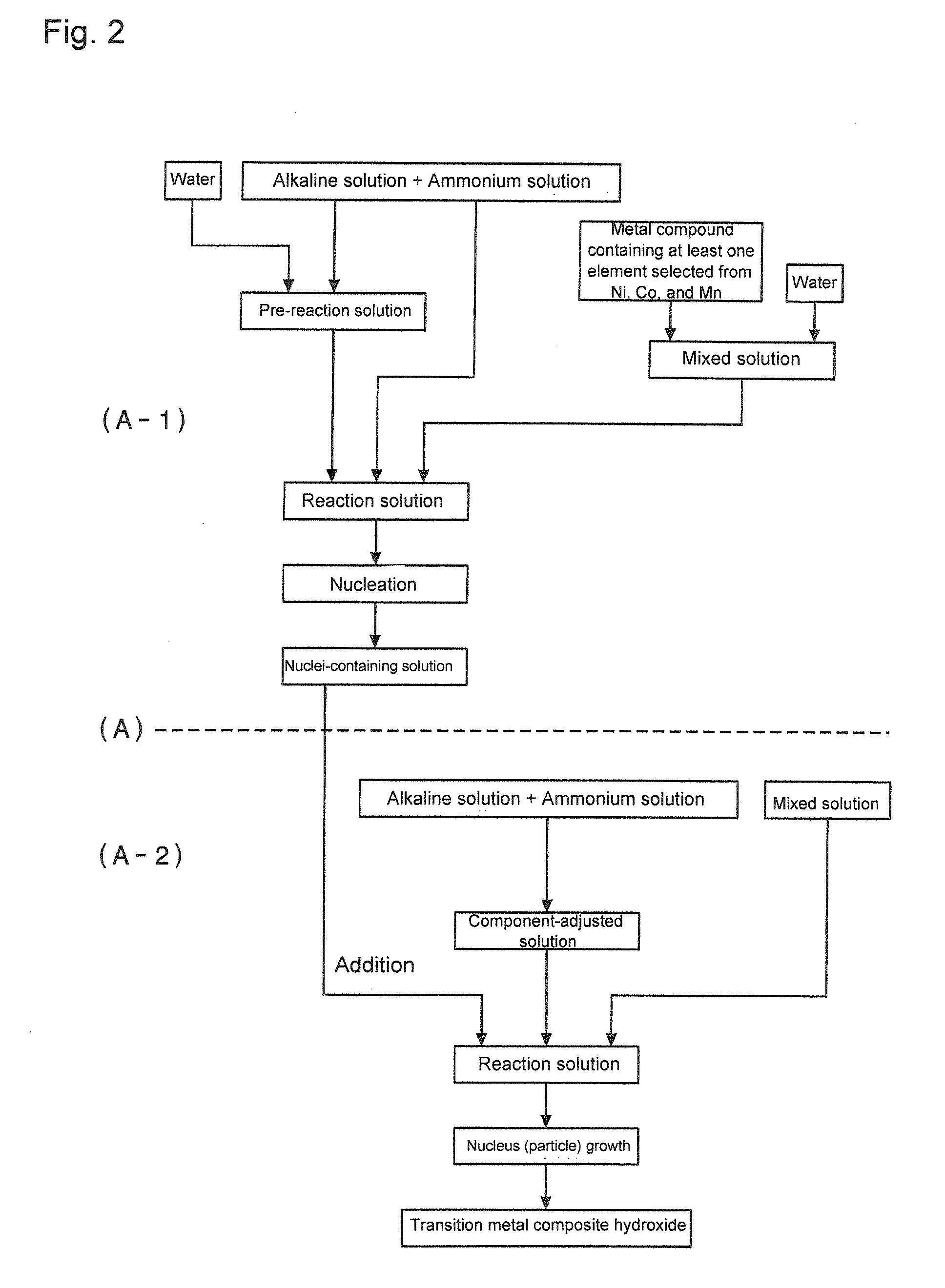

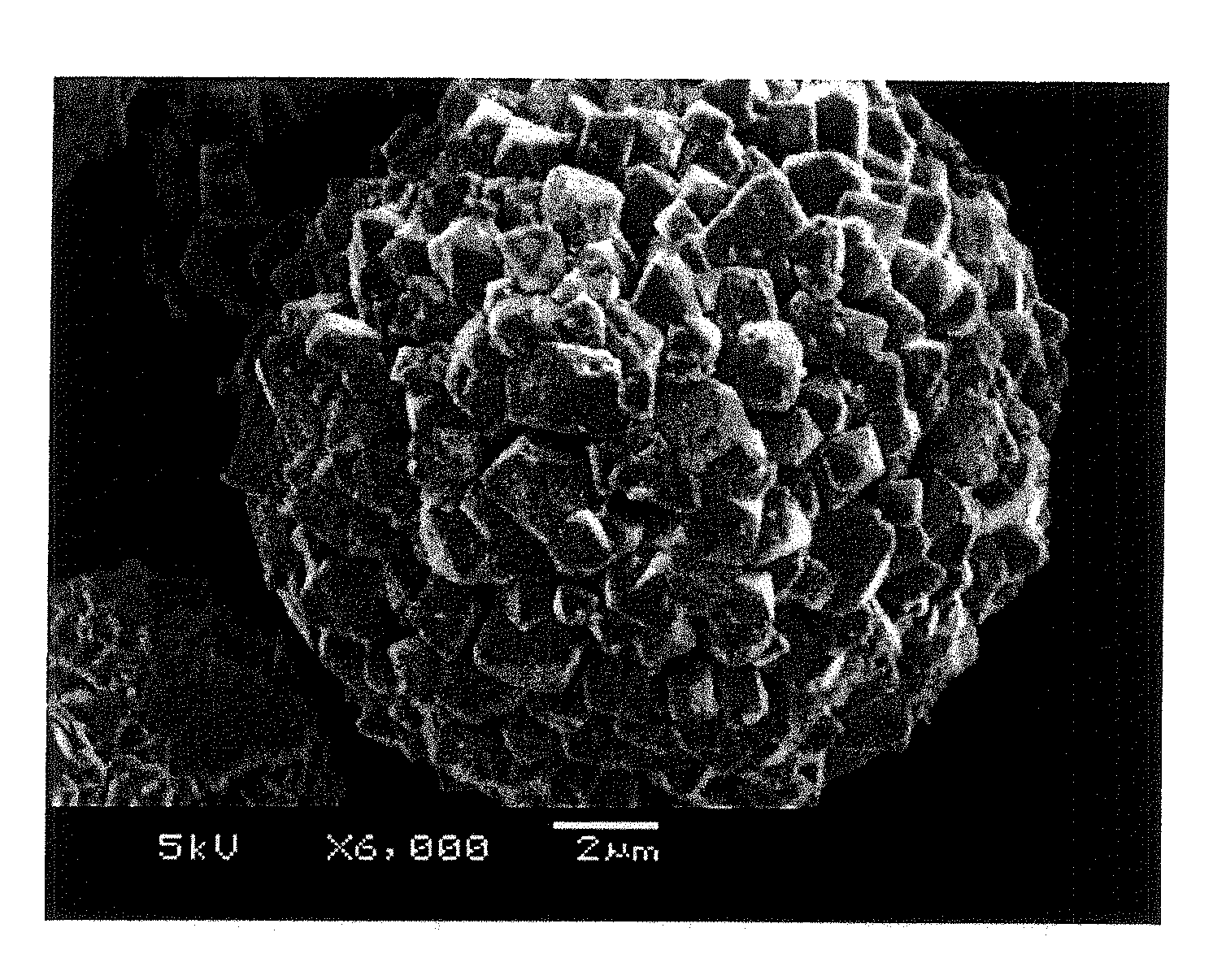

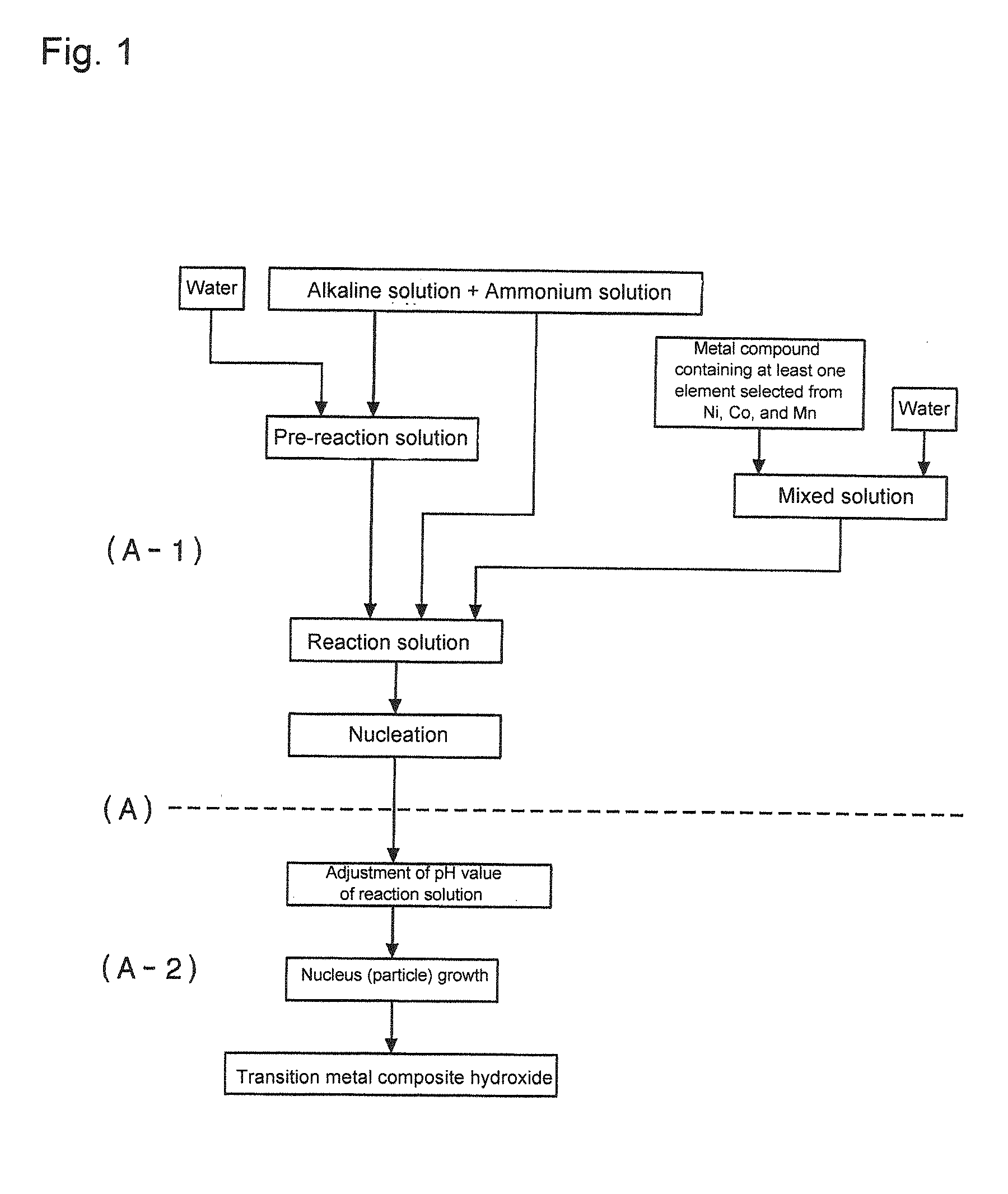

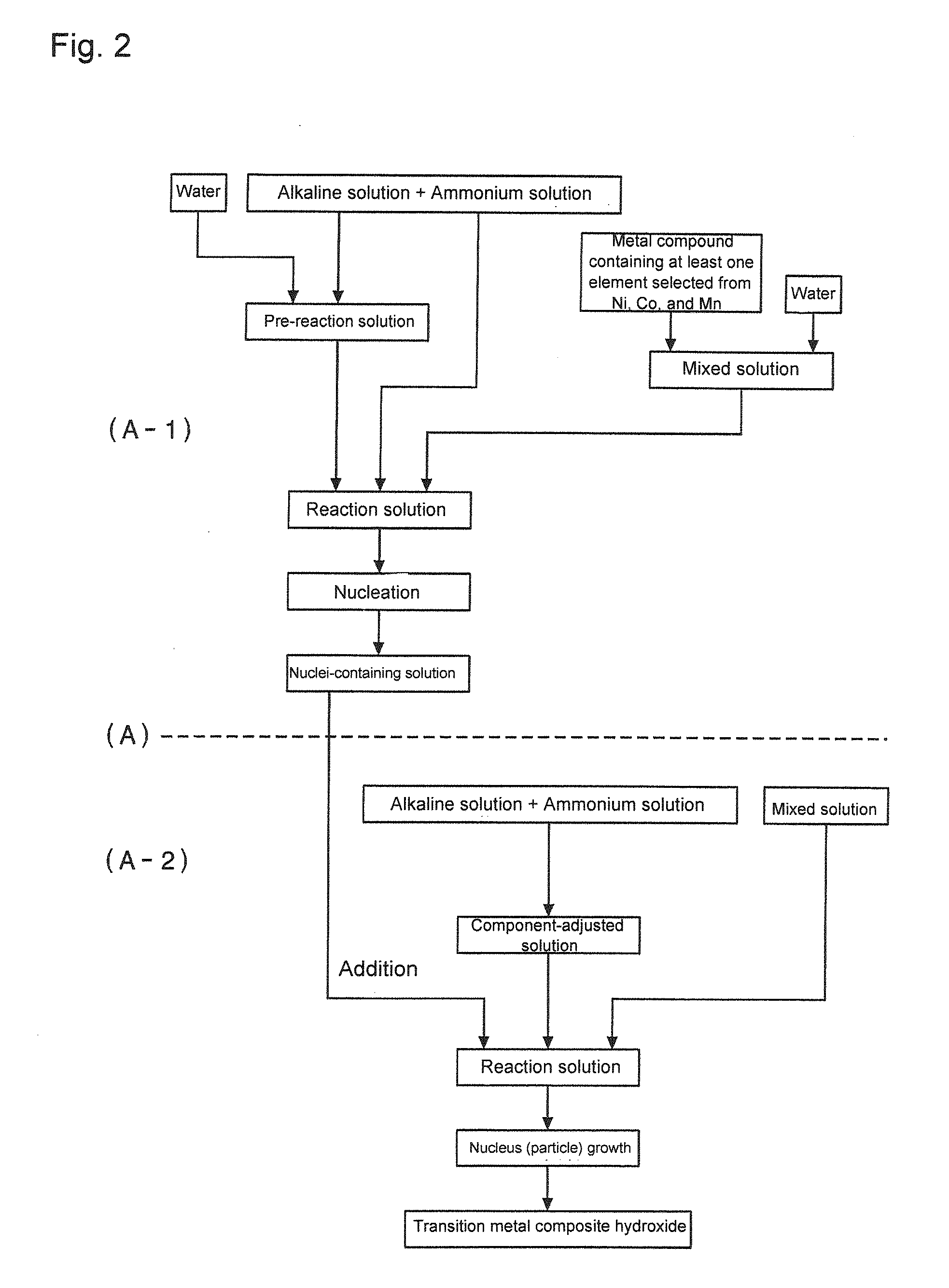

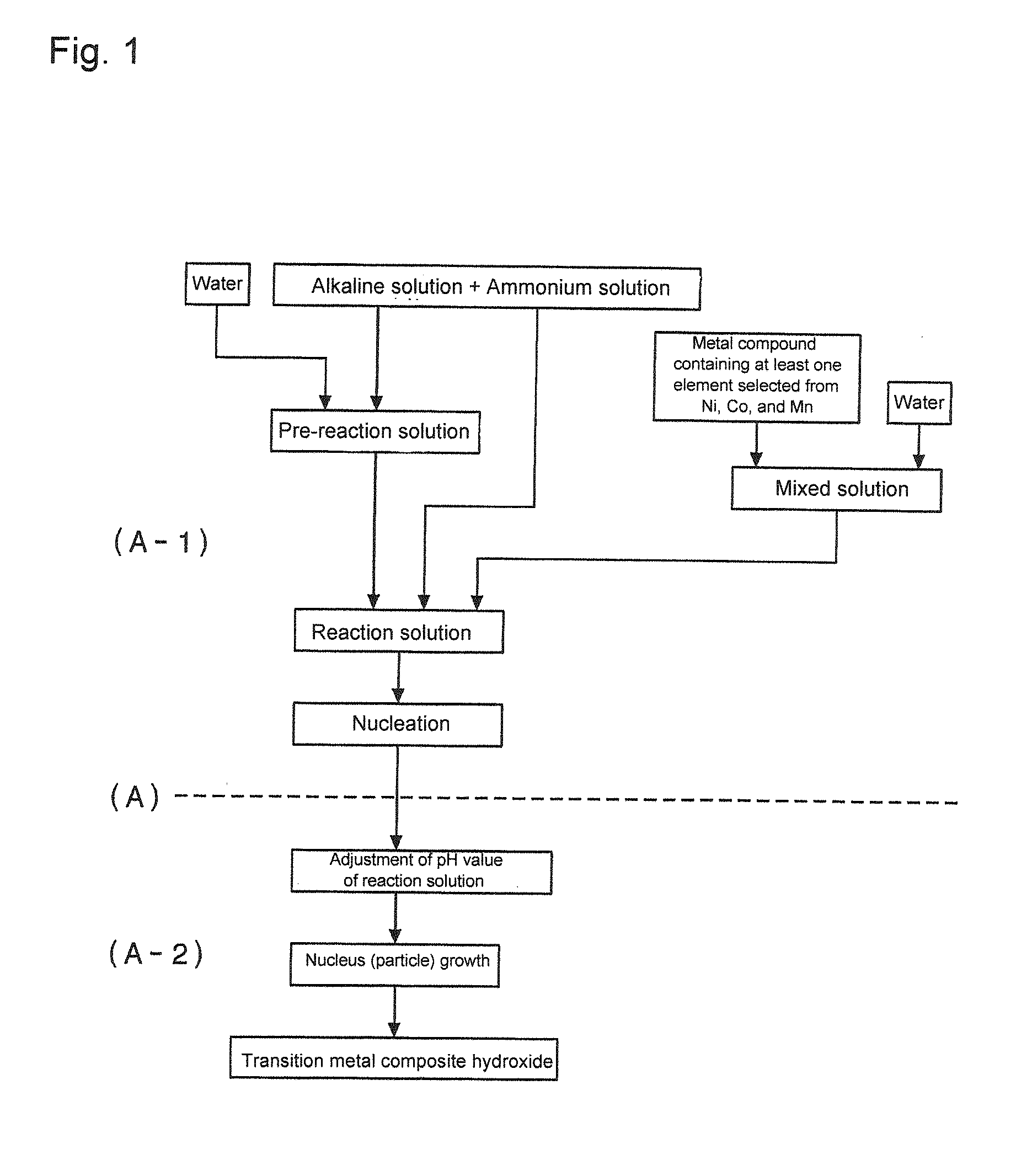

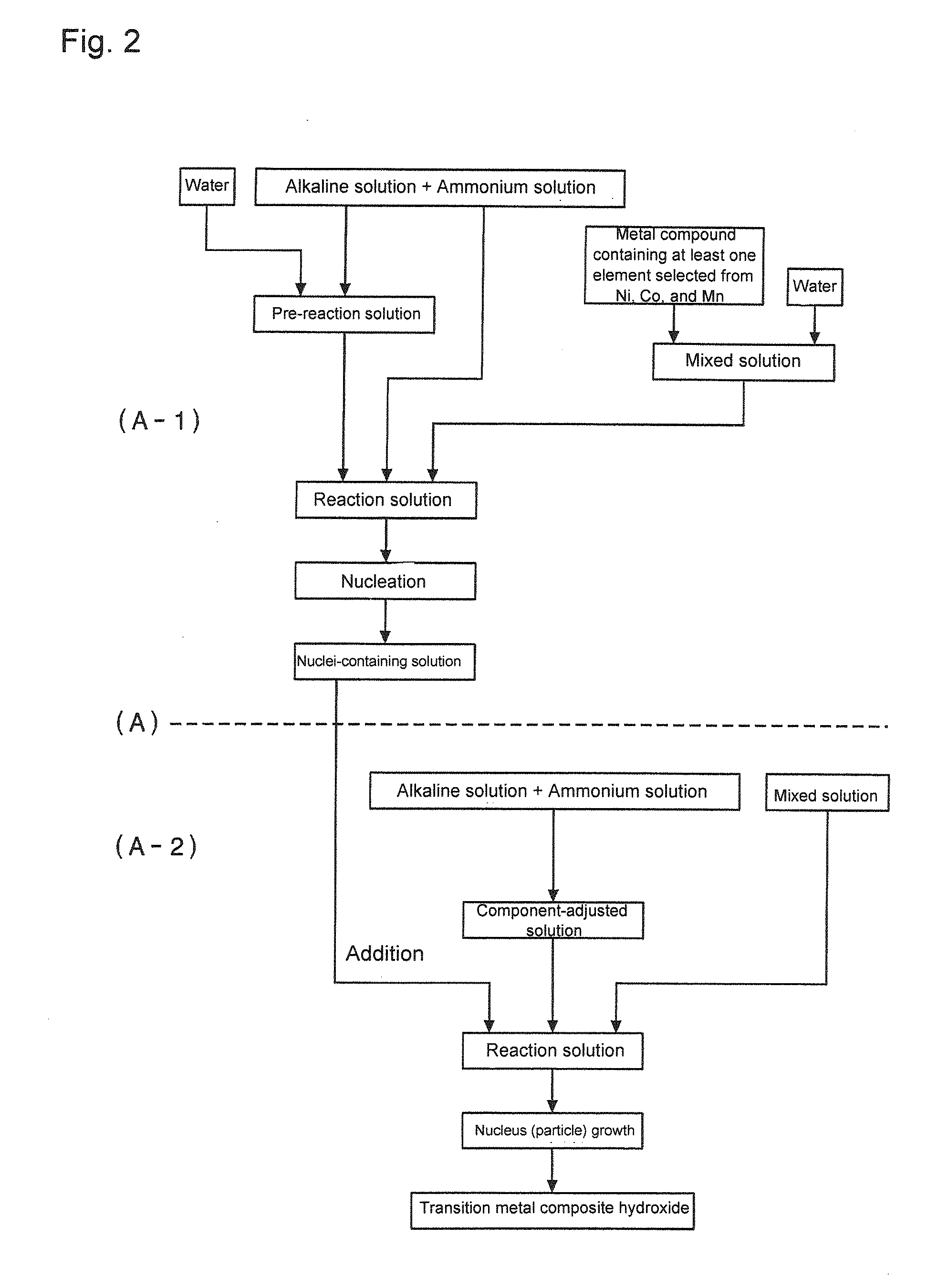

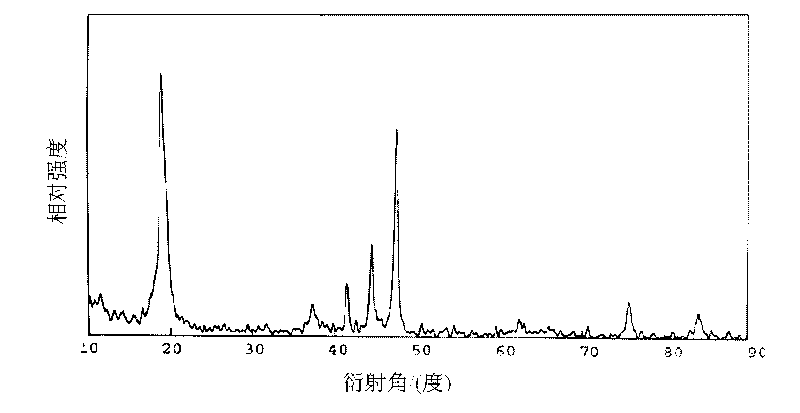

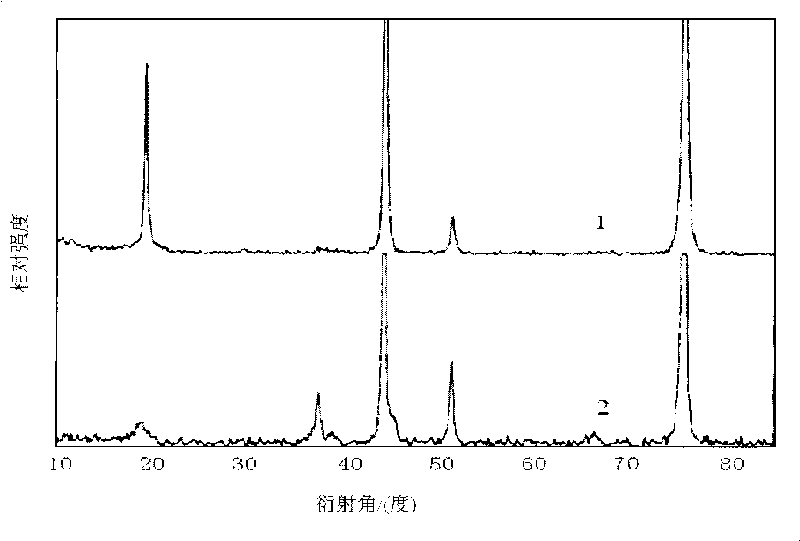

Transition metal composite hydroxide capable of serving as precursor of positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing same, positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing positive electrode active material, and nonaqueous electrolyte secondary battery using positive electrode active material

ActiveUS20140106228A1Small particle sizeNarrow particle sizeElectrode thermal treatmentFinal product manufactureComposite oxideMetal

A transition metal composite hydroxide can be used as a precursor to allow a lithium transition metal composite oxide having a small and highly uniform particle diameter to be obtained. A method also is provided for producing a transition metal composite hydroxide represented by a general formula (1) MxWsAt(OH)2+α, coated with a compound containing the additive element, and serving as a precursor of a positive electrode active material for nonaqueous electrolyte secondary batteries. The method includes producing a composite hydroxide particle, forming nuclei, growing a formed nucleus; and forming a coating material containing a metal oxide or hydroxide on the surfaces of composite hydroxide particles obtained through the upstream step.

Owner:SUMITOMO METAL MINING CO LTD

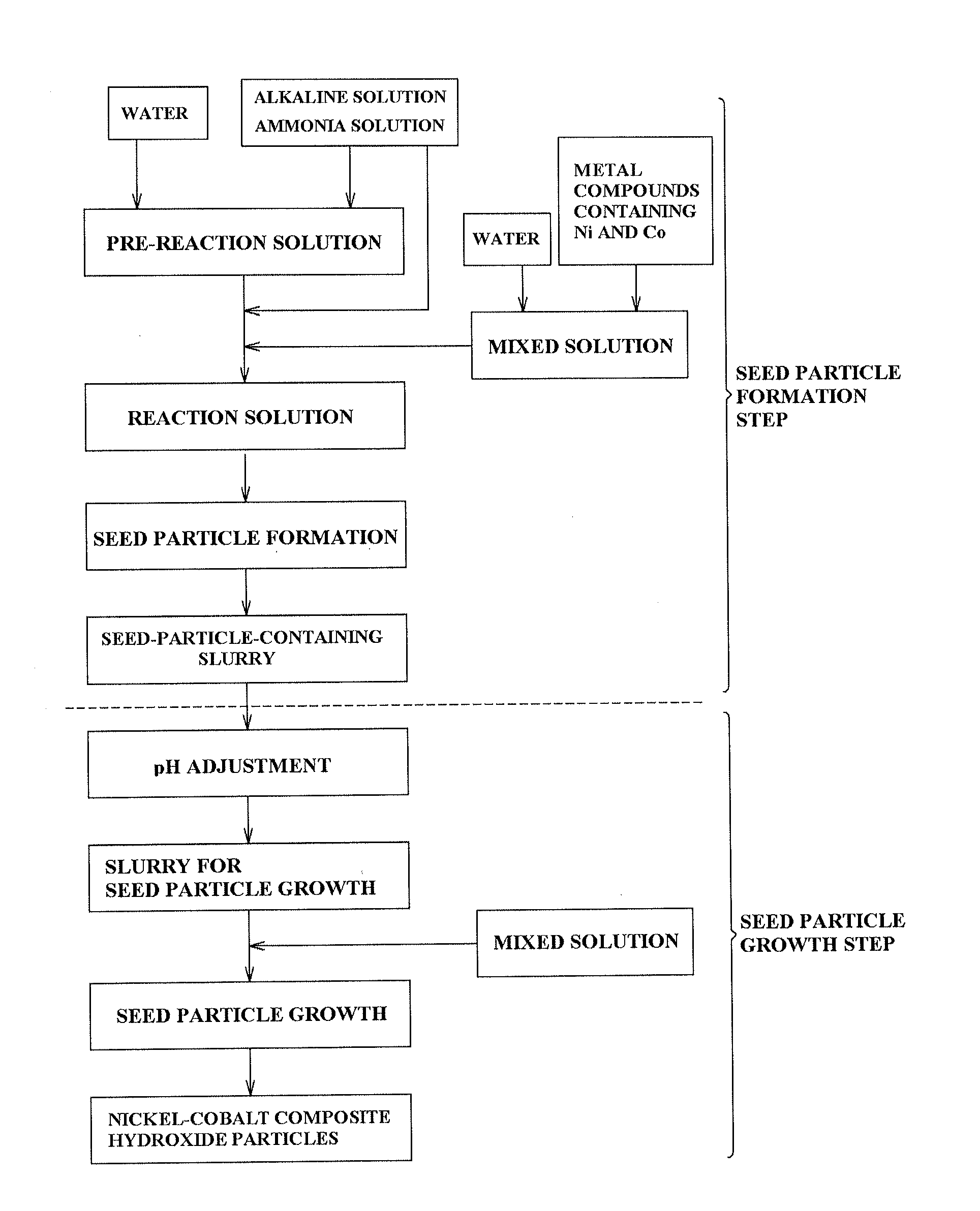

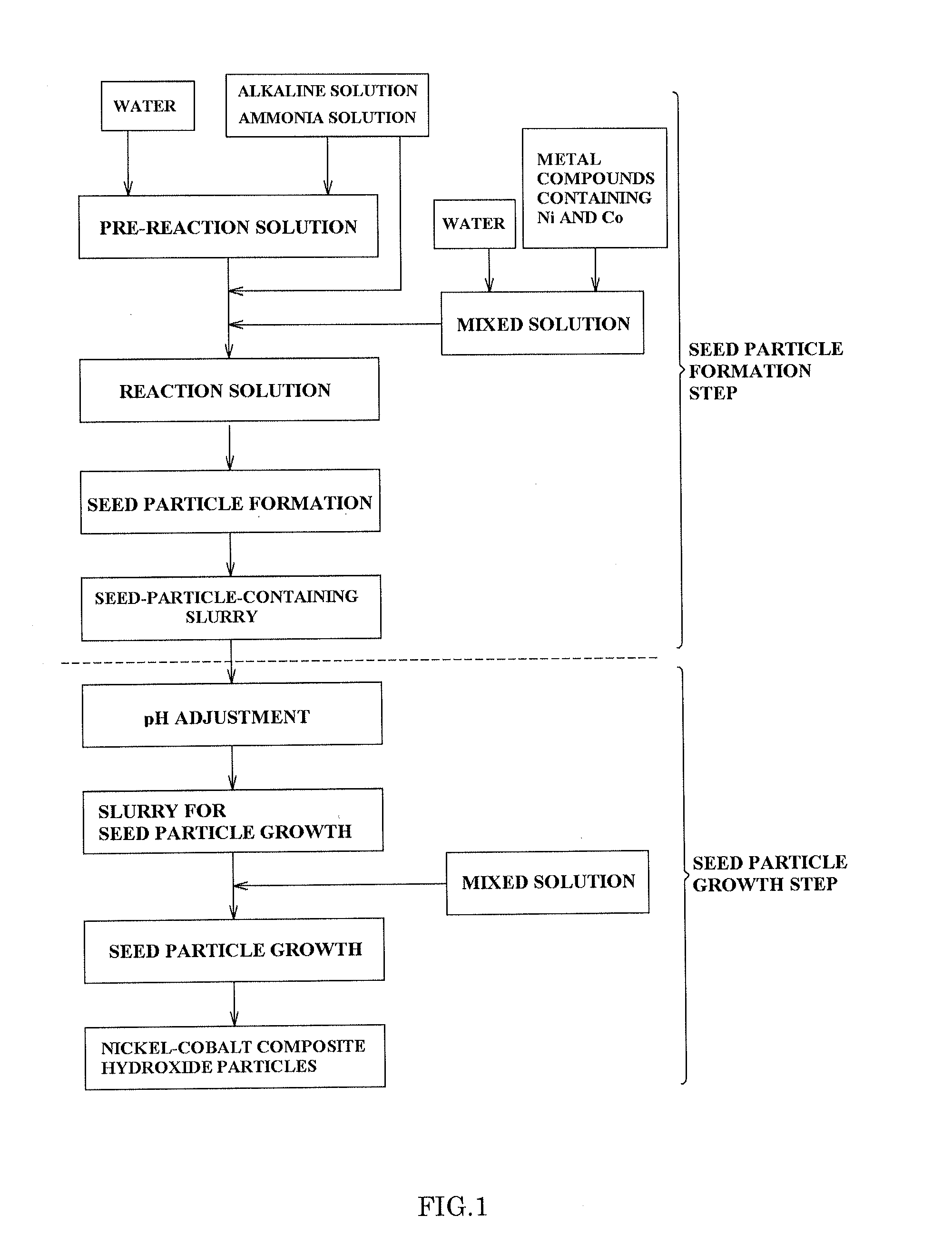

Nickel-cobalt composite hydroxide and process for manufacturing same

ActiveUS20150364759A1Improve particle size uniformityNarrow distributionFinal product manufactureSecondary cellsPhysical chemistryAmmonium hydroxide

Process for manufacturing nickel-cobalt composite represented by Ni1-x-yCoxMnyMz(OH)2 (where, 0.05≦x≦0.95, 0≦y≦0.55, 0≦z≦0.1, x+y+z<1, and M is at least one metal element selected from Al, Mg, and the like), includes: forming seed particle, while reaction solution having mixed solution containing metal compounds and ammonia solution containing ammonium ion supply source at discharge head of an impeller from 50-100 m2 / s2, the concentration of nickel ions is maintained within range 0.1-5 ppm by mass, whereby seed particles are formed; and growing seed particle wherein solution is obtained by supplying mixed and ammonium solutions to reaction solution is agitated with a concentration of nickel ions being maintained within range 5-300 ppm by mass and higher than the concentration of nickel ions in seed particle formation, whereby seed particles are grown up.

Owner:SUMITOMO METAL MINING CO LTD

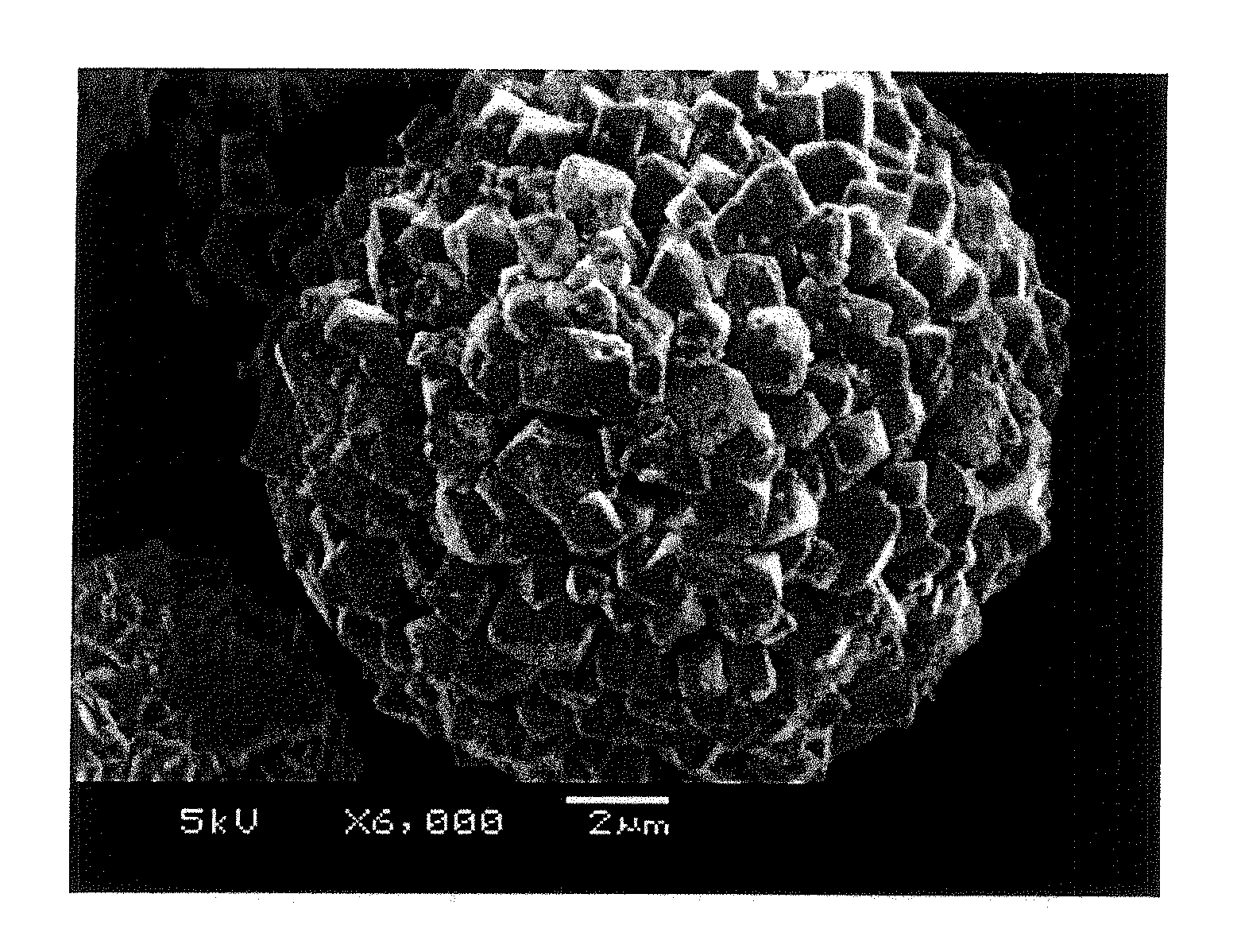

Method for manufacturing metal powder

ActiveUS7066980B2Low costHigh purityTransportation and packagingFixed capacitor dielectricHigh densityDecomposition

A method in which a metal powder is produced by ejecting a thermally decomposable metal compound powder into a reaction vessel through a nozzle together with a carrier gas under the condition V / S>600, where V is the flow rate of the carrier gas per unit time (liter / min), and S is the cross-sectional area of the nozzle opening part (cm2), and heating this metal powder at a temperature which is higher than the decomposition temperature of the metal compound powder and not lower than (Tm−200)° C., where Tm is the melting point of the metal, in a state where the metal compound powder is dispersed in the gas phase at a concentration of 10 g / liter or less. The method provides a fine, spherical, highly-crystallized metal powder which has a high purity, high density, high dispersibility and extremely uniform particle size, at low cost and using a simple process.

Owner:SHOEI CHEM IND CO LTD

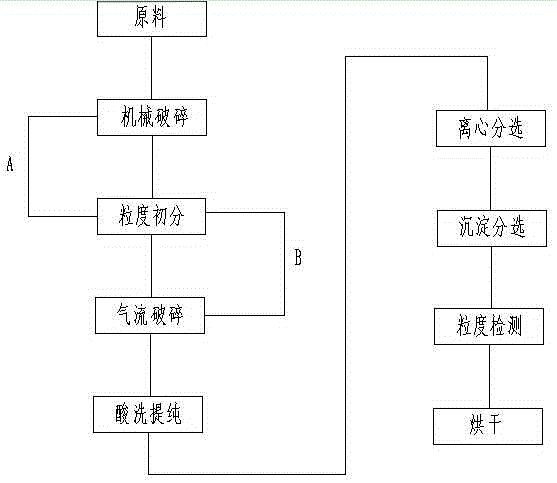

Kiwi fruit micro-powder and preparation process thereof

ActiveCN104473071ASave raw materialsHigh nutritional valueFood preparationAdditive ingredientKiwi fruit

The invention provides kiwi fruit micro-powder and a preparation process thereof, and relates to fruit powder and a preparation method of the fruit powder. According to the technical scheme provided by the invention, the preparation process of the kiwi fruit micro-powder comprises the following steps: cleaning kiwi fruit, draining off, and cutting into slices for later use; enclosing the cut kiwi fruit into a charging tray; putting into a vacuum drying room, dewatering and drying; crushing the dried kiwi fruit in a fully-closed state under the protection of nitrogen, and then sieving, so as to obtain micro-powder; and bagging the micro-powder in a low-temperature environment, and sealing in vacuum. The preparation process disclosed by the invention is advanced; 100% of skin, pulp and seeds of the kiwi fruit are utilized; raw materials are fully saved; the utilization efficiency is improved; and the kiwi fruit micro-powder is good in keeping of nutritional ingredients, good in color and luster, and convenient to store and transport for a long period of time.

Owner:南阳市三辰生物科技有限公司

Nanometer zirconia powder and synthesis method thereof

InactiveCN105366718AHigh crystallinityReunion slightBulk chemical productionZirconium oxidesSynthesis methodsCrystallinity

The invention aims to provide nanometer zirconia powder and a synthesis method thereof. The nanometer zirconia powder is high in crystallinity degree, slight in agglomeration, small in grain size, narrow in distribution and large in specific area. The nanometer zirconia powder is prepared from, by weight, 96.5-97% of ZrO2 and 3-3.5% of Y2O3. The synthesis method for the nanometer zirconia powder comprises the following sequentially-executed steps of preparing a zirconium compound and a yttrium oxide solution; preparing an oxalic acid solution; carrying out filtering; carrying out a precipitation reaction; carrying out a thermal decomposition reaction after washing and drying; carrying out wet grinding; carrying out a supercritical hydrothermal reaction. The synthesis method is applied to the technical field of synthesis of the nanometer zirconia powder.

Owner:ZHUHAI LUCKYMAN TECH CO LTD

High-solid-content anionic self-emulsified water-borne epoxy resin emulsion and preparation method thereof

The invention relates to high-solid-content anionic self-emulsified water-borne epoxy resin emulsion and a preparation method thereof, and solves the technical problems of low solid content, high VOC content, addition of an emulsifier and complex synthesis processes. The high-solid-content anionic self-emulsified water-borne epoxy resin comprises epoxy resin grafted with methacrylic acid, glycidyl methacrylate, a crylic acid monomer segmented copolymer and nano-crystalline cellulose. The invention further provides a preparation method of the high-solid-content anionic self-emulsified water-borne epoxy resin. The high-solid-content anionic self-emulsified water-borne epoxy resin can be applied to the field of preparation of epoxy resin emulsion.

Owner:BEIJING UNIV OF CHEM TECH

Liposome compositions of porphyrin photosensitizers

InactiveUS20050107329A1Good reproducibilityNarrow particle sizeBiocideEnergy modified materialsPhotodynamic therapyPhotosensitizer

Liposomal pharmaceutical formulations incorporating porphyrin photosensitizers useful for photodynamic therapy or diagnosis of malignant cells. The liposomal formulations comprise a porphyrin photosensitizer, particularly the hydro-mono benzoporphyrins (BPD) having light absorption maxima in the range of 670-780 nanometers, a disaccharide or polysaccharide and one or more phospholipids.

Owner:QLT INC

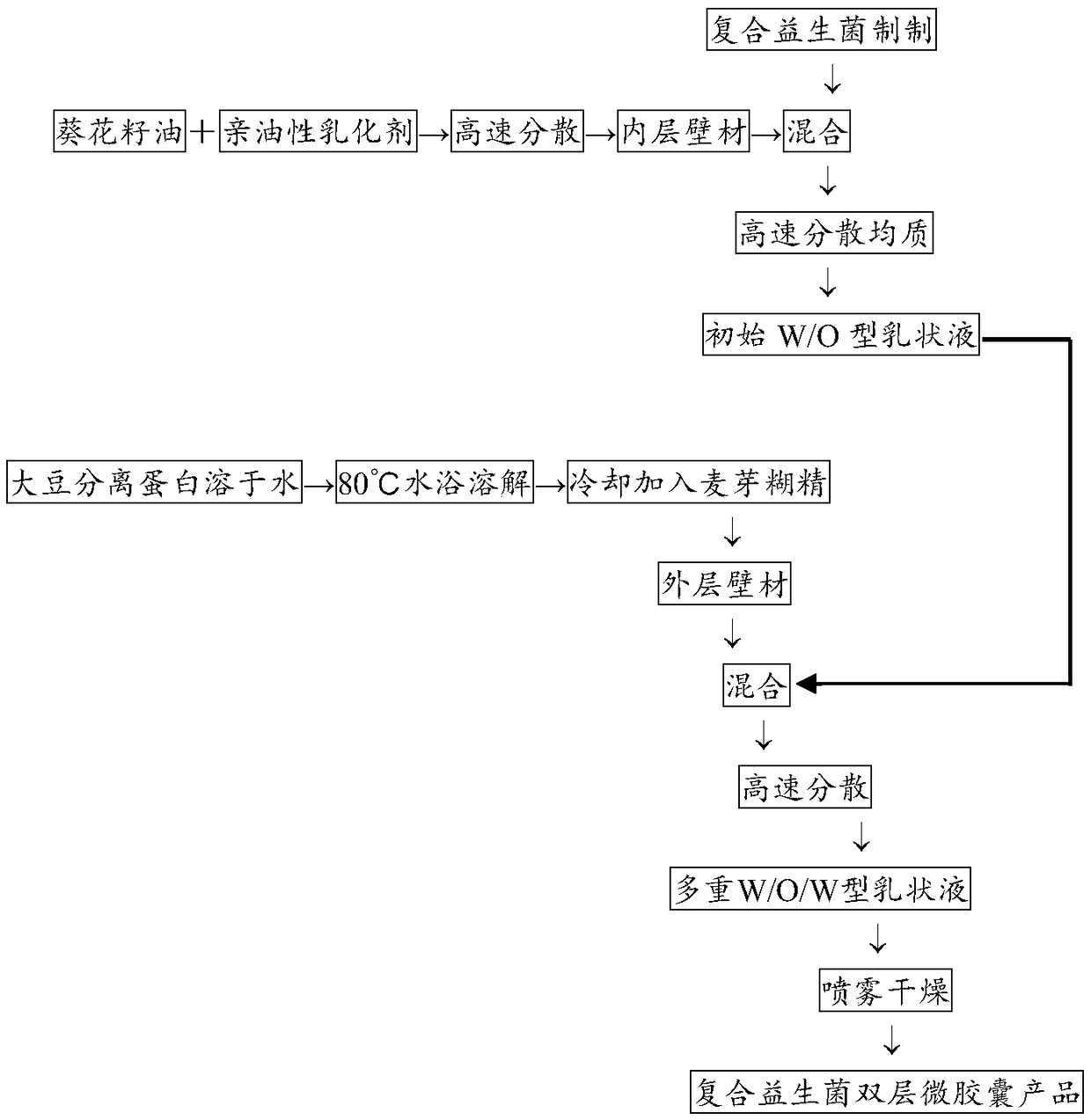

Technological method for producing composite probiotic two-layer microcapsule by virtue of double-emulsification method-spray drying

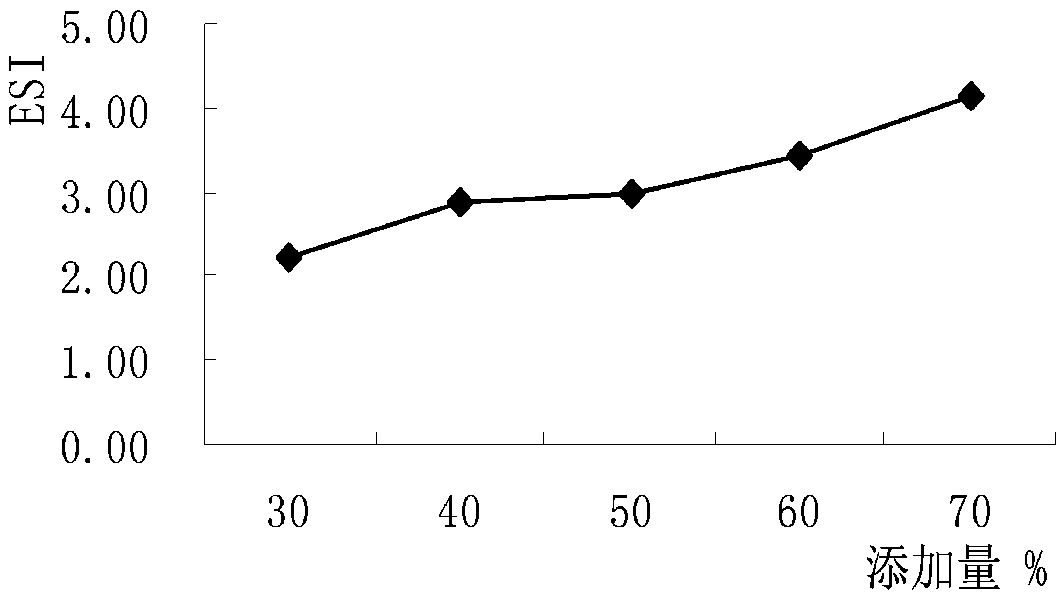

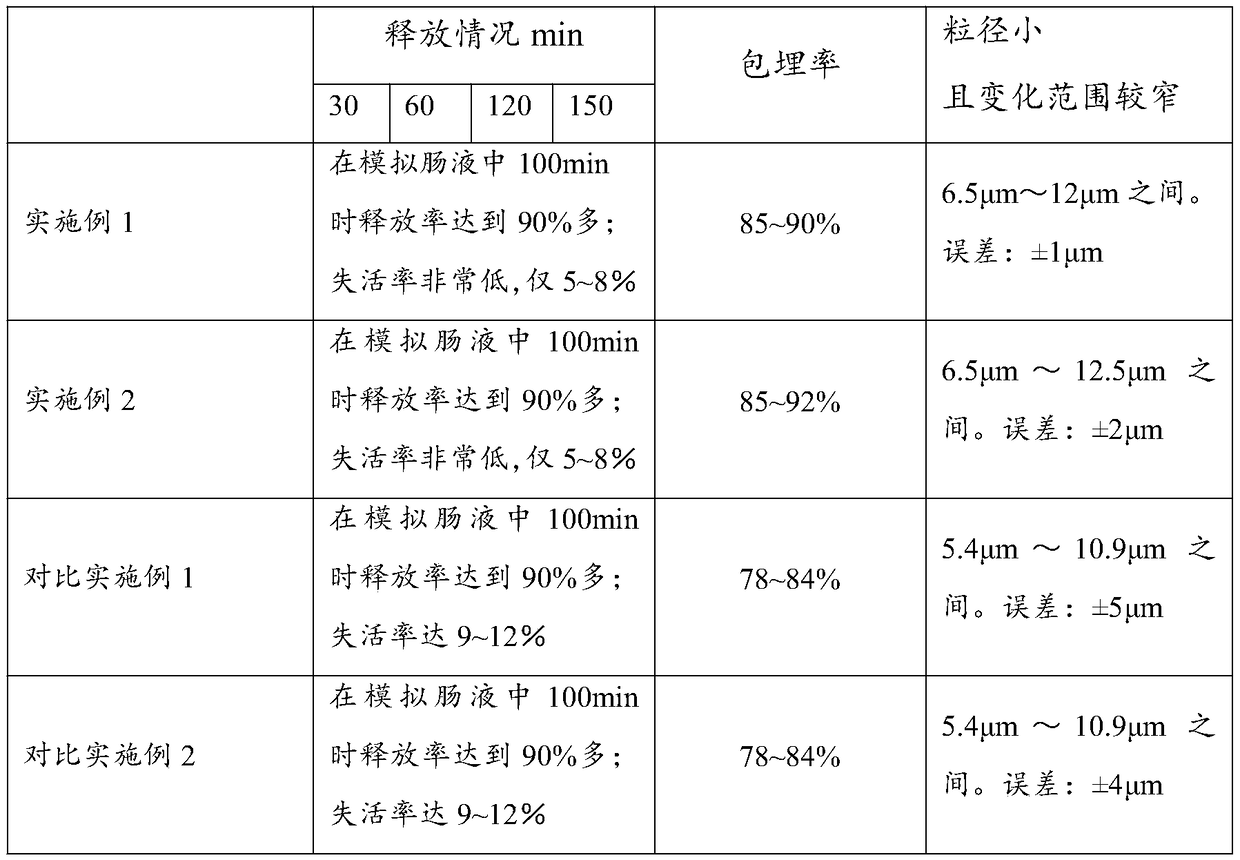

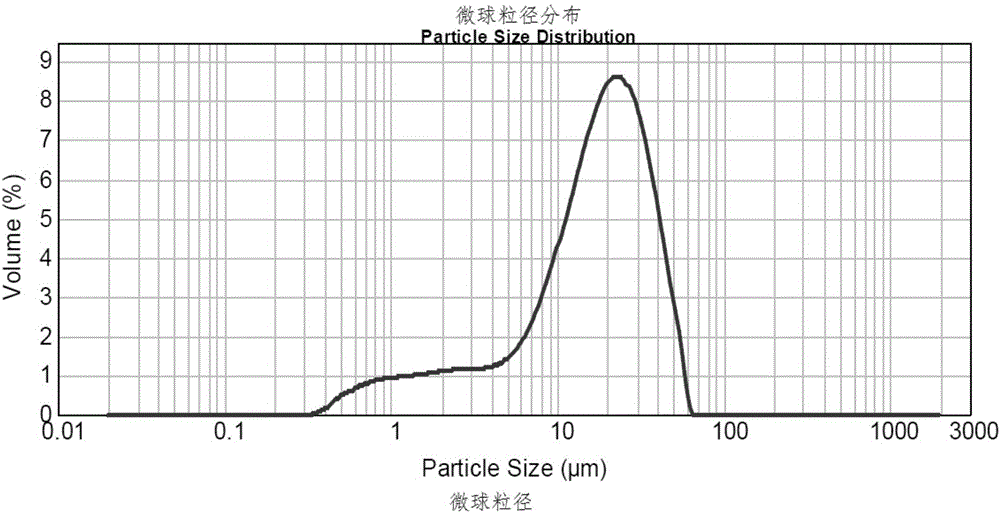

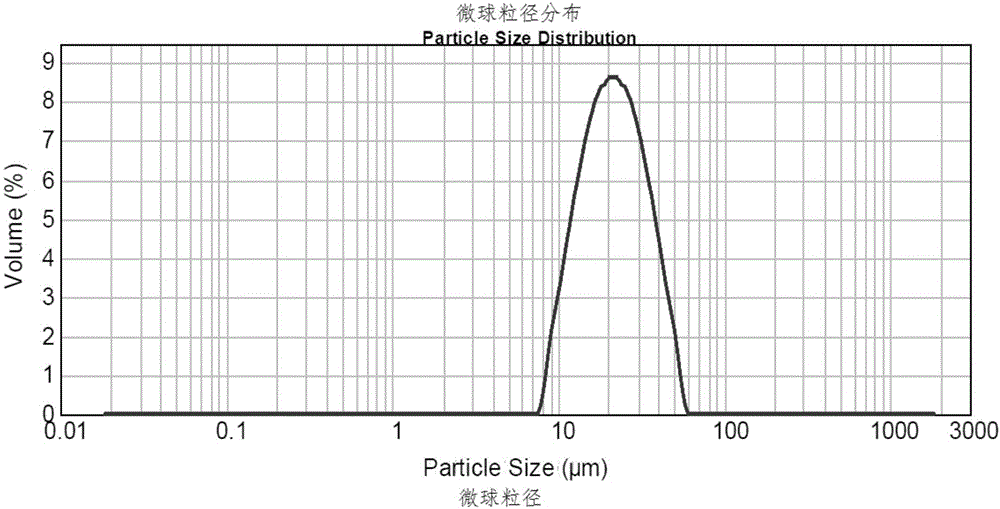

PendingCN108902983AOptimizing the composition mass to volume ratioFlat surfaceFood shapingProduction rateControl release

The invention relates to a technological method for producing a composite probiotic two-layer microcapsule by virtue of a double-emulsification method-spray drying which is suitable for various activeprobiotic composite micro-ecological preparations, which belongs to the technical field of food microorganisms. The two-layer microcapsule prepared by adopting the double-emulsificaiton-spray dryingmethod is high in probiotic embedding efficiency, good variable bacteria stability, complete in surface and is in an approximate spherical shape; and moreover, the embedded component is released afterpassing by two interfaces, so that the burst release phenomenon can be overcome, the release time can be prolonged, and the controlled-release performance is good. The production device is simple, the operation is convenient, the labor protection is facilitated, the process period is short, the productivity is high, the finished product has good acid tolerance and cholate resisting capability, the source of raw materials is wide, the price is low, the industrialized continuous mass production can be realized, and a foundation can be laid for the industrialized production of the probiotic products.

Owner:SHENZHEN POLYTECHNIC

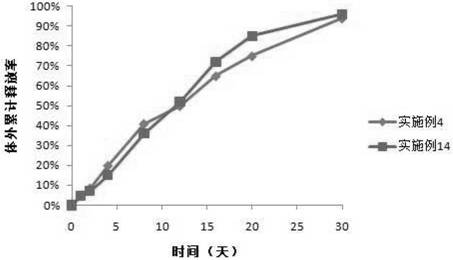

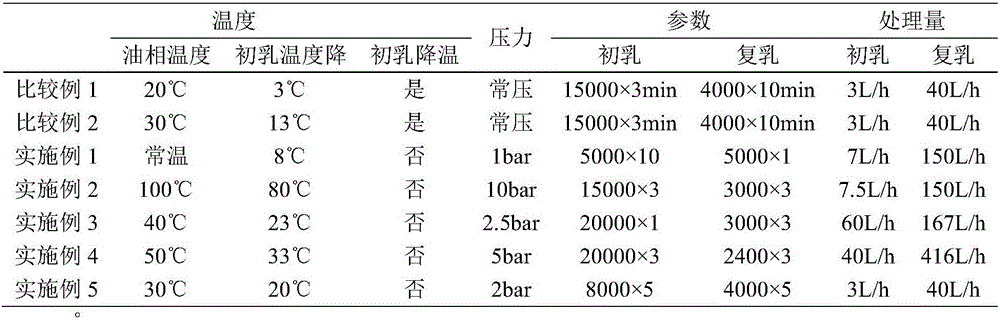

Preparation method of leuprorelin microspheres

ActiveCN106668831ACancel the cooling stepThe process steps are simplePeptide/protein ingredientsGranular deliveryLeuprorelinMicrosphere

The invention discloses a preparation method of leuprorelin microspheres. The method comprises steps of preparation of an oil phase, preparation of an inner water phase, preparation of an outer water phase, preparation of a primary emulsion, preparation of a compound emulsion, drying in a liquid and the like. A total-closed online emulsification and separate tank drying mode is adopted, and the problems of high probability of evaporation and boiling of DCM in the emulsification process are effectively solved by accurately controlling temperatures and pressure; through reduction of the viscosity of the oil phase, the emulsification efficiency is improved, residues of the primary emulsion in tanks are reduced, and the overall yield of a product is increased. Besides, batch production of the leuprorelin microspheres is changed into continuous production, transition from a lab-scale test to a pilot plant test to production is smoother, and room for improvement of the productivity of a workshop is larger.

Owner:ZHEJIANG SUNDOC PHARMA SCI & TECH CO LTD

Barium ferrite pre-sintered material and preparation method thereof

The invention provides a barium ferrite pre-sintered material and a preparation method thereof, wherein the barium ferrite pre-sintered material is suitable for producing product raw materials of refrigerator door seals, toys for children, advertising and the like. The technical scheme comprises the following steps: (1) mixing a by-product ferric oxide powder regenerated by acid with barium carbonate power; (2) performing wet ball-milling on the mixture to form slurry; (3) directly performing pre-sintering on the slurry; and (4) performing dry coarse grinding on the pre-sintered material. The invention has the beneficial effects that pelletizing, drying and granulation are not required and any additive is in no need of being added by reasonably selecting raw materials and optimizing the formula and the technology, thus being capable of producing the barium ferrite pre-sintered material with high performance. The invention has the advantages of simple procedure, low production cost and low energy consumption.

Owner:MCC HENGTONG COLD ROLLING TECH

Method for preparing sintered water-permeable material from pottery clay

InactiveCN109776067AHigh strengthGuaranteed green strengthCeramic materials productionCeramicwareBrickPrill

The invention discloses a method for preparing a water-permeable brick from pottery clay. The method comprises the following steps: mixing and grinding one or more of the following raw materials: 15-85% of clay, 0-30% of bauxite tailings, 0-60% of silicalite, 0-80% of weathered rocks and 0-20% of calcareous rocks according to the mass percentage, and controlling the screen residue rate of powder of 200 meshes to be less than 3%; directly granulating the powder to prepare ceramic powder particles, screening the particles to obtain graded particles, and drying the graded particles until the water content of the dried particles is 6-13 mass%; carrying out compression molding on the dried particles at a compression ratio of 0.38-0.48; and drying the obtained compressed green body, and firingthe dried compressed green body at 1100-1180 DEG C to obtain the sintered water-permeable material. The preparation method has the advantages of realization of high value-added value batch use of thepottery clay and tailings, simplicity, easiness in implementation, and facilitation of realization of industrial production; and the prepared sintered water-permeable brick can be used as a sponge city water-permeable paving material, a filter material and an adsorption material, has a flexural strength of above 4.5 MPa and a water permeability coefficient of 2 * 10<-2> cm / s, and has excellent performances.

Owner:ZUNYI ENERGY & MINERAL INVESTMENT CO LTD +1

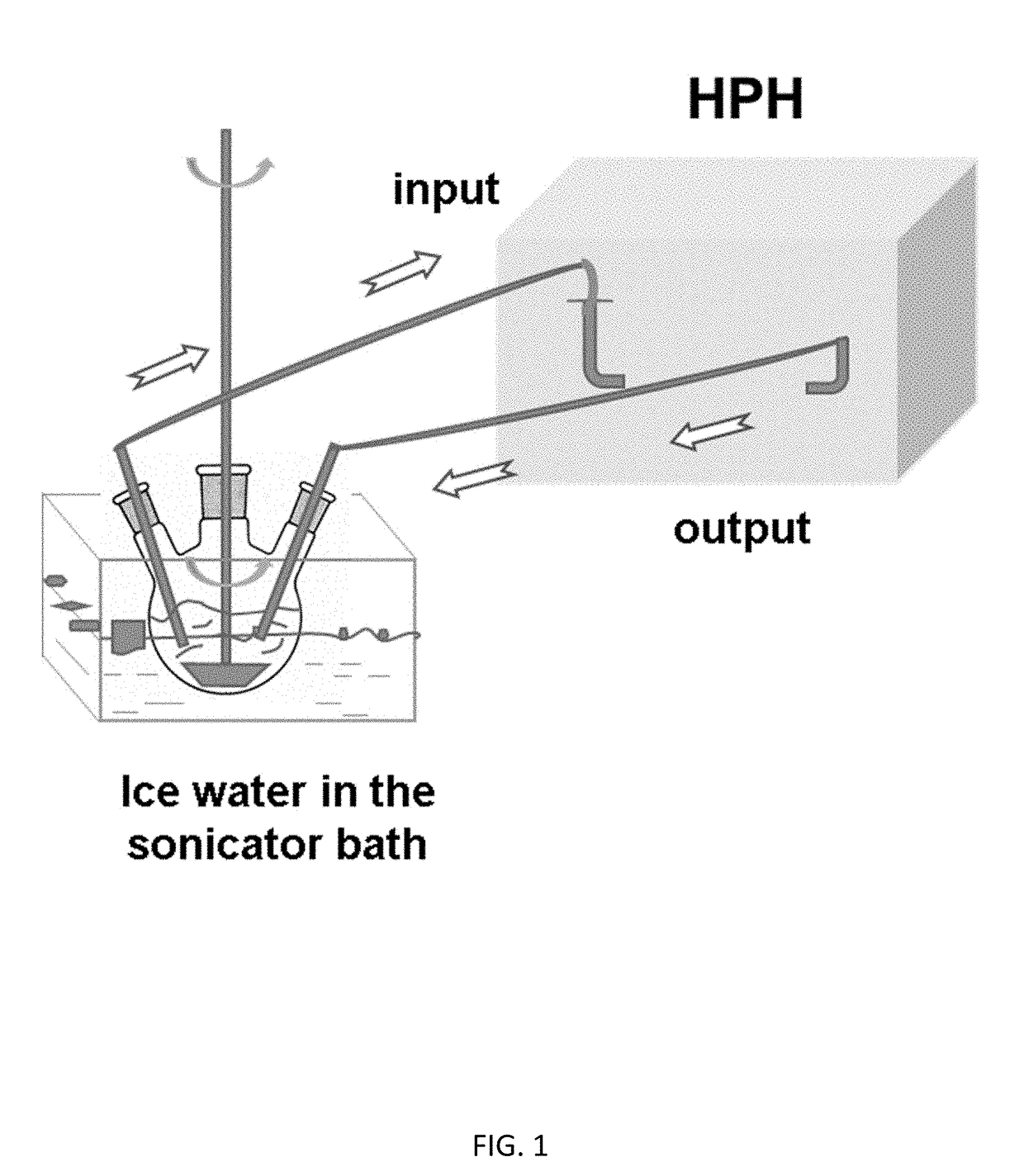

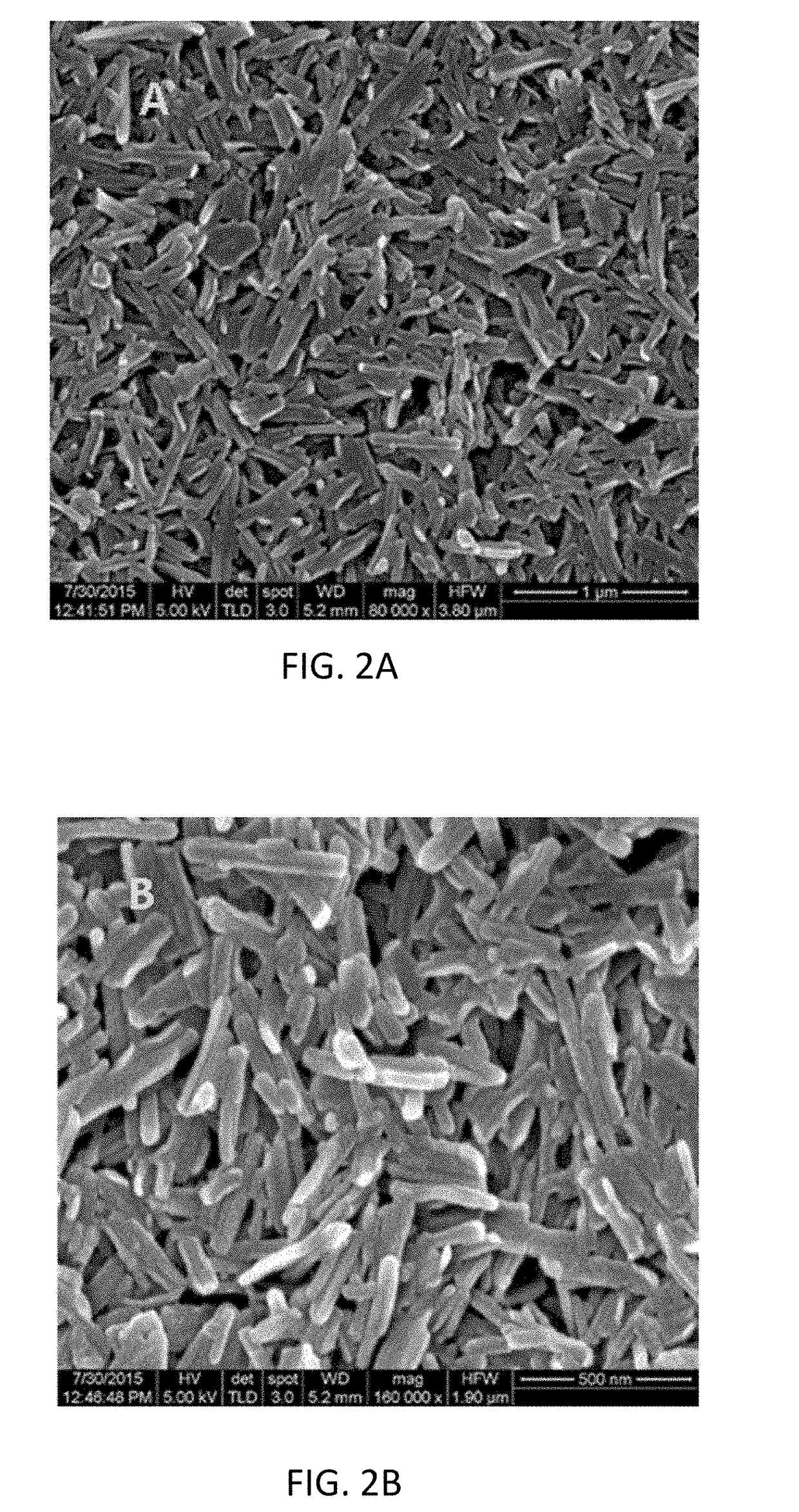

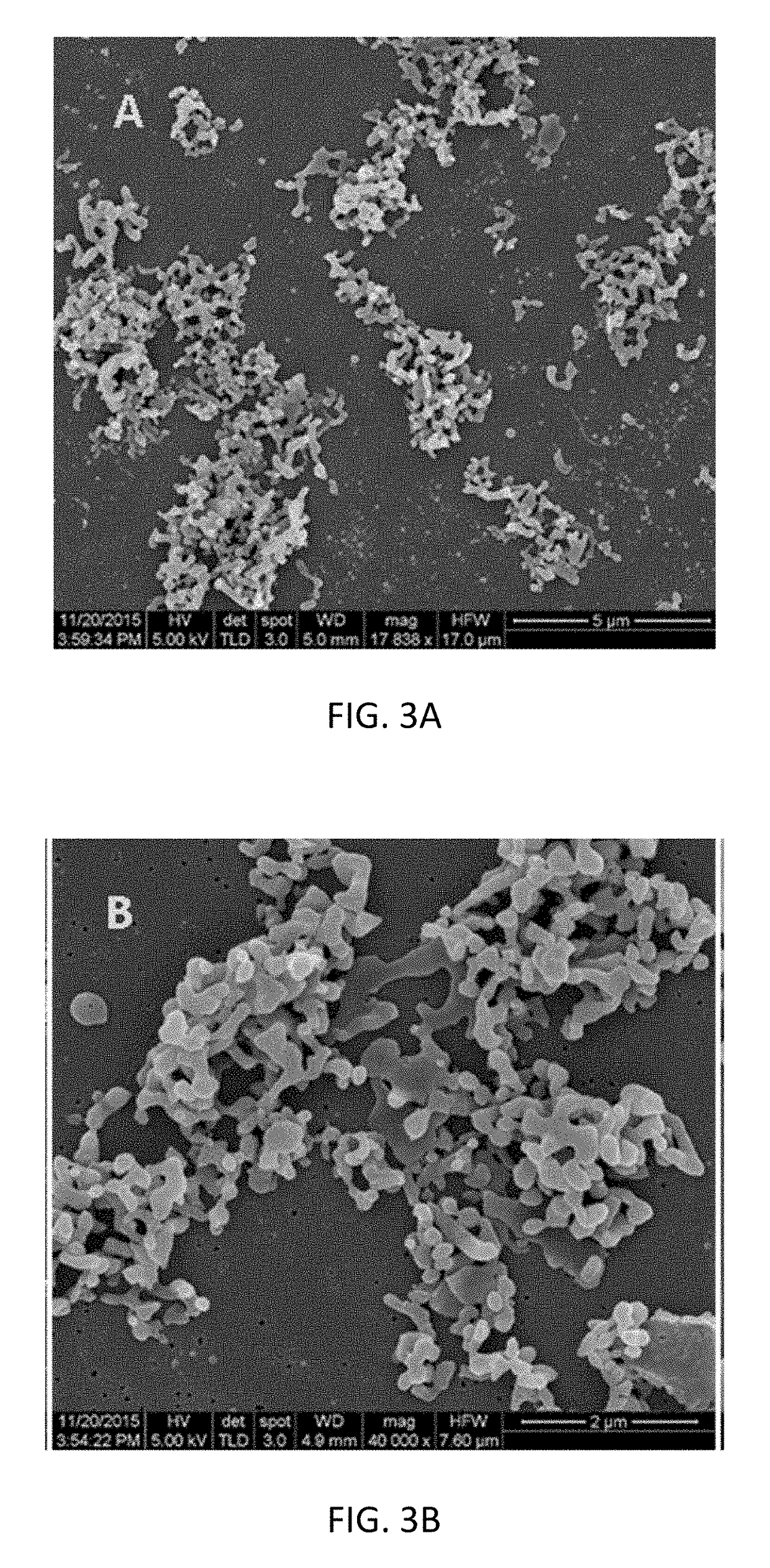

Prepartion of nanocrystals and nanaoparticles of narrow distribution and uses thereof

InactiveUS20180344645A1Improved delivery and therapeutic effectReduce deliveryPowder deliveryOrganic active ingredientsDrugSingle process

The present invention generally relates to preparation methods of nanoparticles or nanocrystals of narrowly distributed particle sizes of a poorly water soluble material. In particular, this invention is an effective integration of the bottom-up and top-down preparation methods of nanoparticles and nanocrystals of a poorly water soluble material or active pharmaceutical ingredient into a single process, which affords an efficient and simple process with a product of improved delivery and therapeutic effects.

Owner:PURDUE RES FOUND INC

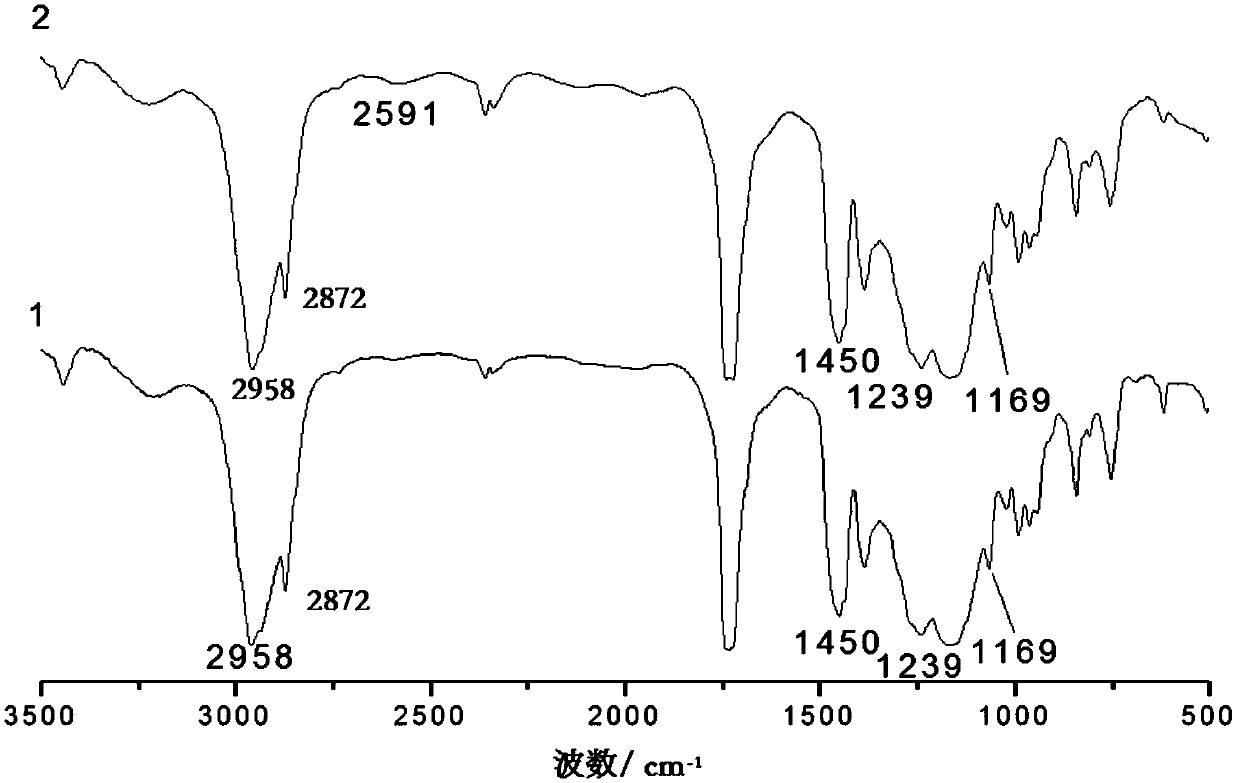

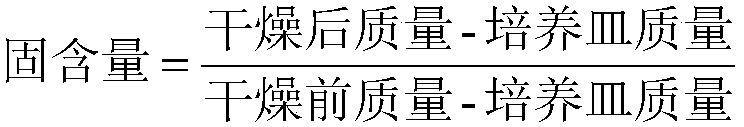

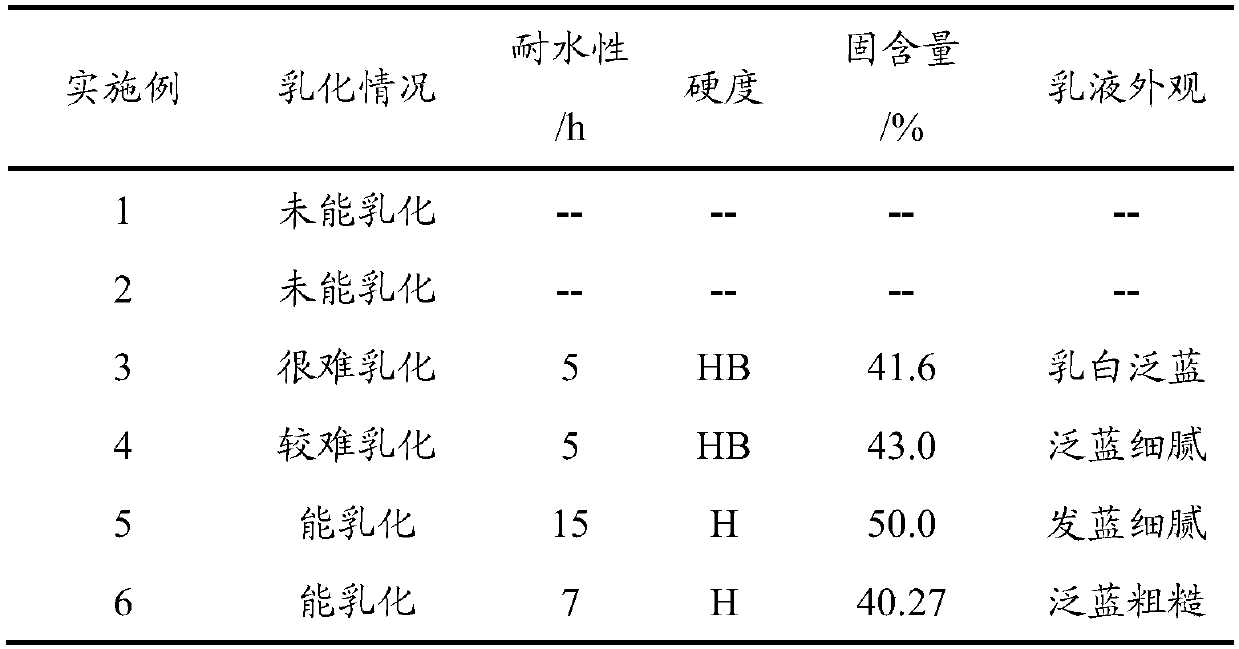

Acrylate emulsion and preparation method thereof

The invention discloses an acrylate emulsion and a preparation method thereof. The acrylate emulsion comprises the raw materials: a mixed monomer, an emulsifier, an initiator and water. The acrylate emulsion is prepared by semi continuous emulsion polymerization. A latex film formed by the obtained acrylate emulsion has good water resistance, hardness and adhesion force, the preparation process issimple, the raw materials are easy to obtain, the conditions are mild, and the acrylate emulsion is suitable for large-scale industrial production.

Owner:FUYANG NORMAL UNIVERSITY

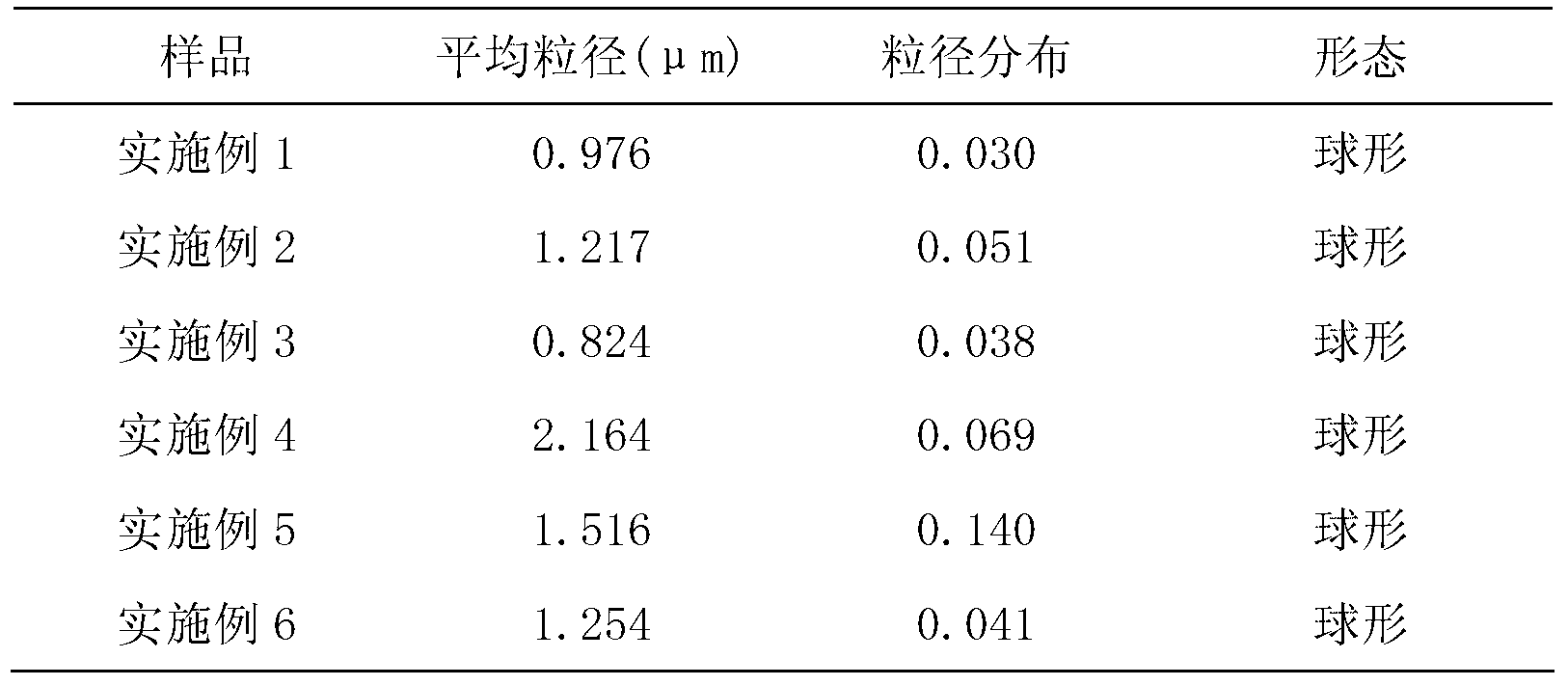

Preparation method of monodisperse rosinyl polymer microsphere

The invention discloses a preparation method of monodisperse rosinyl polymer microspheres. The monodisperse rosinyl polymer microspheres are obtained by taking rosin acrylics as monomers and adopting a conventional radical inhibitor and a dispersing agent in a mixed solution of alcohol and water through dispersion copolymerization. The preparation method is simple in process and easy to operate; and the prepared monodisperse rosinyl polymer microspheres are uniform in particle size and are controllable in the range from 0.8 microns to 3.0 microns. Due to adoption of the preparation method, rosins are endowed with wide applications, and the obtained polymer microspheres have good application prospect in the aspect of drug sustained release.

Owner:GUANGXI UNIV

Antibacterial botanic liquid detergent and preparing method thereof

InactiveCN105838520ALarge specific surface areaHigh specific surface activityInorganic non-surface-active detergent compositionsChemical compositionAdditive ingredient

The invention discloses an antibacterial botanic liquid detergent .The antibacterial botanic liquid detergent is prepared from, by weight, 0.5-1.5 parts of nanocarbon crystals, 25-35 parts of Chinese honeylocust fruits, 20-30 parts of Chinese soapberry fruit peel, 20-25 parts of tea seeds, 20-30 parts of artemsia argyi oil, 15-25 parts of orange peel, 1-10 parts of egg white powder and 70-90 parts of deionized water .A corresponding preparing method of the antibacterial botanic liquid detergen comprises the following steps that firstly, Chinese honeylocust fruits, Chinese soapberry fruit peel, tea seeds and orange peel are smashed, dried, sterilized, soaked with deionized water for 0.5-1 h and then decocted for 135-270 min, then cooling and filtering are carried out, and an extract solution is obtained; secondly, nanocarbon crystals and egg white powder are added into the extract solution obtained in the first step and are mixed, the mixture is subjected to heating concentration, heat preservation and cooling, then artemsia argyi oil is added, and the antibacterial botanic liquid detergent is obtained .According to the antibacterial botanic liquid detergent and the preparing method thereof, Chinese honeylocust fruits, Chinese soapberry fruit peel, tea seeds, orange peel and the like in the formula come from the nature, contain no chemical ingredient, contain ingredients good in oil contamination washing effect and also contain a large quantity of vitamins and other nutrient elements needed by the human body, and thus the skin can be nourished and protected while articles are cleaned .

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Method of using low-grade zinc oxide ore to produce high-purity nano zinc oxide by means of ammonia process

ActiveCN102863011AEvenly distributedEfficient leachingZinc oxides/hydroxidesNanotechnologyEnvironmental resistanceZno nanoparticles

The invention discloses a method of using low-grade zinc oxide ore to produce high-purity nano zinc oxide by means of the ammonia process. The method includes: using slaked lime of 3-5% mass of the low-grade zinc oxide ore for activating before leaching, using ammonia water-ammonium bicarbonate solution as leaching agent, adding 0.3-0.5kg of sodium fluorosilicate into per stere of the leaching agent for leaching, purifying for impurity removal, and refining. On one hand, efficient leaching of the low-grade zinc oxide ore is realized, high-purity zinc oxide with large specific surface area can be obtained at low calcinations temperature, and extremely high practical value and economic value are obtained; and on the other hand, the treatment method is low in energy consumption and high in efficiency. Valuable and poisonous heavy metal in the low-grade zinc oxide ore can be leached out for use and cleaned by means of water washing, and accordingly economy, environment friendliness and reasonable utilization of renewable resources are realized.

Owner:SICHUAN JUHONG TECH

Transition metal composite hydroxide capable of serving as precursor of positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing same, positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing positive electrode active material, and nonaqueous electrolyte secondary battery using positive electrode active material

ActiveUS20160244336A1Small particle sizeNarrow particle sizeElectrode thermal treatmentCobalt compoundsElectrical batteryComposite oxide

A transition metal composite hydroxide can be used as a precursor to allow a lithium transition metal composite oxide having a small and highly uniform particle diameter to be obtained. A method also is provided for producing a transition metal composite hydroxide represented by a general formula (1) MxWsAt(OH)2+α, coated with a compound containing the additive element, and serving as a precursor of a positive electrode active material for nonaqueous electrolyte secondary batteries. The method includes producing a composite hydroxide particle, forming nuclei, growing a formed nucleus; and forming a coating material containing a metal oxide or hydroxide on the surfaces of composite hydroxide particles obtained through the upstream step.

Owner:SUMITOMO METAL MINING CO LTD

Preparation method for producing hydrolysis crystal seeds in titanium white technique, and titanium white for matting agents prepared by method

ActiveCN106186055ANot easy to sinter and reuniteSmall particle sizeTitanium dioxideWater basedSulfate

The invention relates to a method for preparing hydrolysis crystal seeds by reaction between a titanyl sulfate solution and a Na3PO4 solution. The method comprises the following steps: adding the titanyl sulfate solution at certain temperature into the Na3PO4 solution according to a certain mass ratio, and curing by stirring until the stability of the crystal seeds drops to the specified requirement; and producing the titanium white product for matting agents by the process. The titanium white obtained by hydrolysis has the advantages of excellent whiteness, high water-based dispersing power, favorable matting capacity, low impurity content, moderate particle size, narrow particle size distribution and the like, and is suitable to be used as a matting agent.

Owner:GUANGXI JINMAO TITANIUM

New material for electric heating parquet with built-in heating layer

ActiveCN105507550ASimple preparation processHigh viscosityLighting and heating apparatusElectric heating systemEpoxyFiber

The invention discloses a new material for electric heating parquet with a built-in heating layer. The new material contains melamine modified urea-formaldehyde resin adhesive bonded with carbon fiber paper. A preparing method for the melamine modified urea-formaldehyde resin adhesive includes the following steps that 1, polyamide is prepared, wherein an appropriate amount of water is added into 30-40 parts of diethylenetriamine, the mixture is stirred, 40-50 parts of hexanedioic acid are added in the stirring process, after stirring is conducted for 30 min, temperature is uniformly raised to 150 DEG C-170 DEG C within 1-5 h, kept for 15 min and then lowered to 80 DEG C-120 DEG C, an appropriate amount of water is added for cooling, and the mixture is heated to 80 DEG C-120 DEG C again and uniformly stirred to obtain polyamide; 2, the pH value of 40-60 parts of a formaldehyde solution is adjusted to 9.5, then 15-30 parts of urea are added, the mixed solution is heated to 85 DEG C-95 DEG C to react for 40-60 min, the pH value is adjusted to 5, after the sufficient reaction, 10-20 parts of polyamide and 20-30 parts of melamine are added, 5-10 parts of epoxy chloropropane are added dropwise, and all the substances react while stirred so that melamine modified urea-formaldehyde resin adhesive can be obtained after the reaction is finished.

Owner:JIUSHENG WOOD

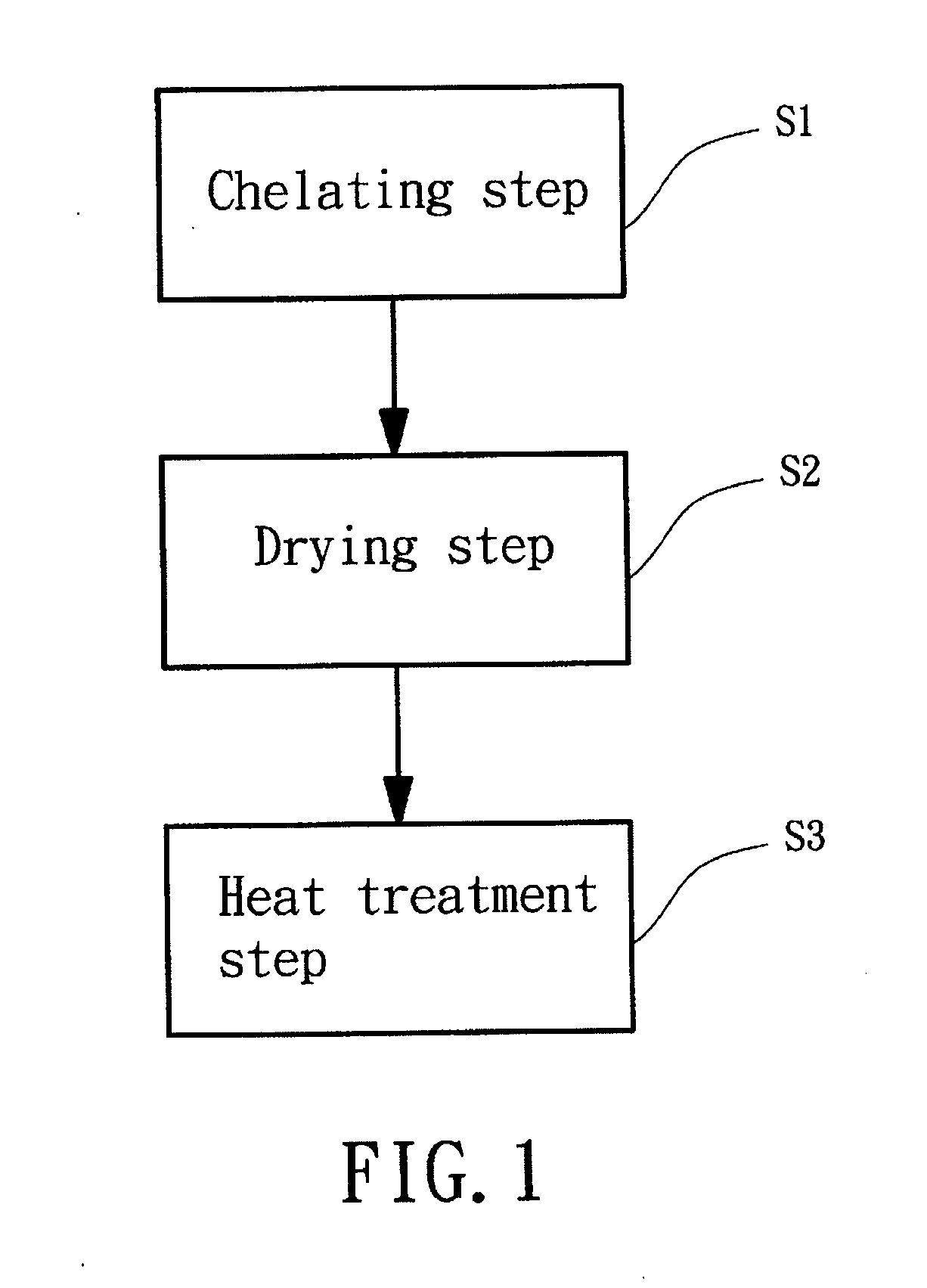

Iron complex, manufacturing method thereof and supported iron oxide catalyst constructed thereby

InactiveUS20110160045A1Improve stabilityImprove uniformityMaterial nanotechnologyCell electrodesEthylenediaminePhenanthroline

A manufacturing method of an iron complex is mixing ferric chloride and at least one chelating agent with a solvent, wherein Fe3+ ions of ferric chloride is reacted with the at least one chelating agent to form an iron complex Fe[R1]a[R2]b[H2O]c3+ or Fe[R1]a[H2O]c3+, wherein the at least one chelating agent is selected from a group including ethylenediamine, 1,10-phenanthroline, 2,2′-Bipyridine, diethylenetriamine, triethylenetetraamine, phenanthroline, or bipyridine. Moreover, a method for producing an iron oxide catalyst is mixing ferric chloride, at least one chelating agent and the support with a slovent to form an iron complex, which is incorporated with the support. Following, a drying step and a heat treatment step are processed to get the iron oxide catalyst.

Owner:NAT CHENG KUNG UNIV

Transition metal composite hydroxide capable of serving as precursor of positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing same, postive electrode active material for nona queous electrolyte secondary batteries, method for producing positive electrode active material, and nonaqueous electrolyte secondary battery using postivie electrode active material

ActiveUS20160248091A1Small particle sizeNarrow particle sizeElectrode thermal treatmentCobalt compoundsBattery cellComposite oxide

A transition metal composite hydroxide can be used as a precursor to allow a lithium transition metal composite oxide having a small and highly uniform particle diameter to be obtained. A method also is provided for producing a transition metal composite hydroxide represented by a general formula (1) MxWsAt(OH)2+α, coated with a compound containing the additive element, and serving as a precursor of a positive electrode active material for nonaqueous electrolyte secondary batteries. The method includes producing a composite hydroxide particle, forming nuclei, growing a formed nucleus; and forming a coating material containing a metal oxide or hydroxide on the surfaces of composite hydroxide particles obtained through the upstream step.

Owner:SUMITOMO METAL MINING CO LTD

Environment-friendly titanium pigment prepared by using complexation-precipitation process

ActiveCN103613958ANarrow particle sizeBright colorPigment treatment with non-polymer organic compoundsAir atmosphereAntimony trioxide

The invention discloses environment-friendly titanium pigment prepared by using a complexation-precipitation process. The process comprises the following steps: quantitatively weighing titanium dioxide or titanium dioxide and antimonous oxide to be added into a solution into which a surfactant is dissolved, and dispersing uniformly; adding a mixture solution of coloring ions R<+1> and a complexing agent, controlling the contents of the complexing agent and the coloring ions so as to establish a stable system of the coloring irons and the complexing agent, adjusting the pH value of the system and enabling the system to be in a stable state; performing precipitation reaction on the coloring ions and an dropped alkali solution; aging and subsequently washing and filtering the reaction system so as to remove impurity ions; performing spraying drying treatment; adding a mineralizer into the dry powder, uniformly mixing, subsequently calcining in air atmosphere in a muffle furnace, and controlling the temperature and the temperature preserving time so as to obtain expected powder. The pigment overcomes the defects that in the conventional titanium yellow preparation, the particle size of the pigment is large, the distribution interval is wide, the color is not bright, agglomeration happens, the coloring capability is poor, and the like, and the cost of the titanium pigment is greatly lower than that of a developed product in market.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Method for preparing lithium cobaltoxide anode thin film of lithium ion battery

InactiveCN101714625AIncrease reaction rateGood chemical uniformityCell electrodesLithium electrodeThin film electrode

The invention relates to a method for preparing a LiCoO2 anode thin film of a lithium ion battery, which is technically characterized by taking metal cobalt, cobalt nitrate and cobalt chloride as cobalt sources, taking lithium hydroxide as a lithium source, and preparing the LiCoO2 thin film electrode on the matrixes such as metal cobalt, nickel, tantalum, columbium or platinum and the like. The whole reaction is performed in aqueous solution; the diffusion speed, absorption speed, reaction speed and crystallization speed of cobalt ions and lithium ions are high; and the electrode reaction speed of LiCoO2 generation can be changed by adjusting an electrode potential so as to fulfill the aim of improving the reaction speed and reaction efficiency. A LiCoO2 thin film electrode with high purity, uniform granularity distribution and good electrical property can be prepared by one step at the temperature of below 200 DEG C in a sealed reaction kettle. The preparation process with low energy consumption and environmental protection provides a new study idea for preparing the LiCoO2 thin film electrode and other thin film electrode materials and has a relatively high utility value.

Owner:CENT SOUTH UNIV

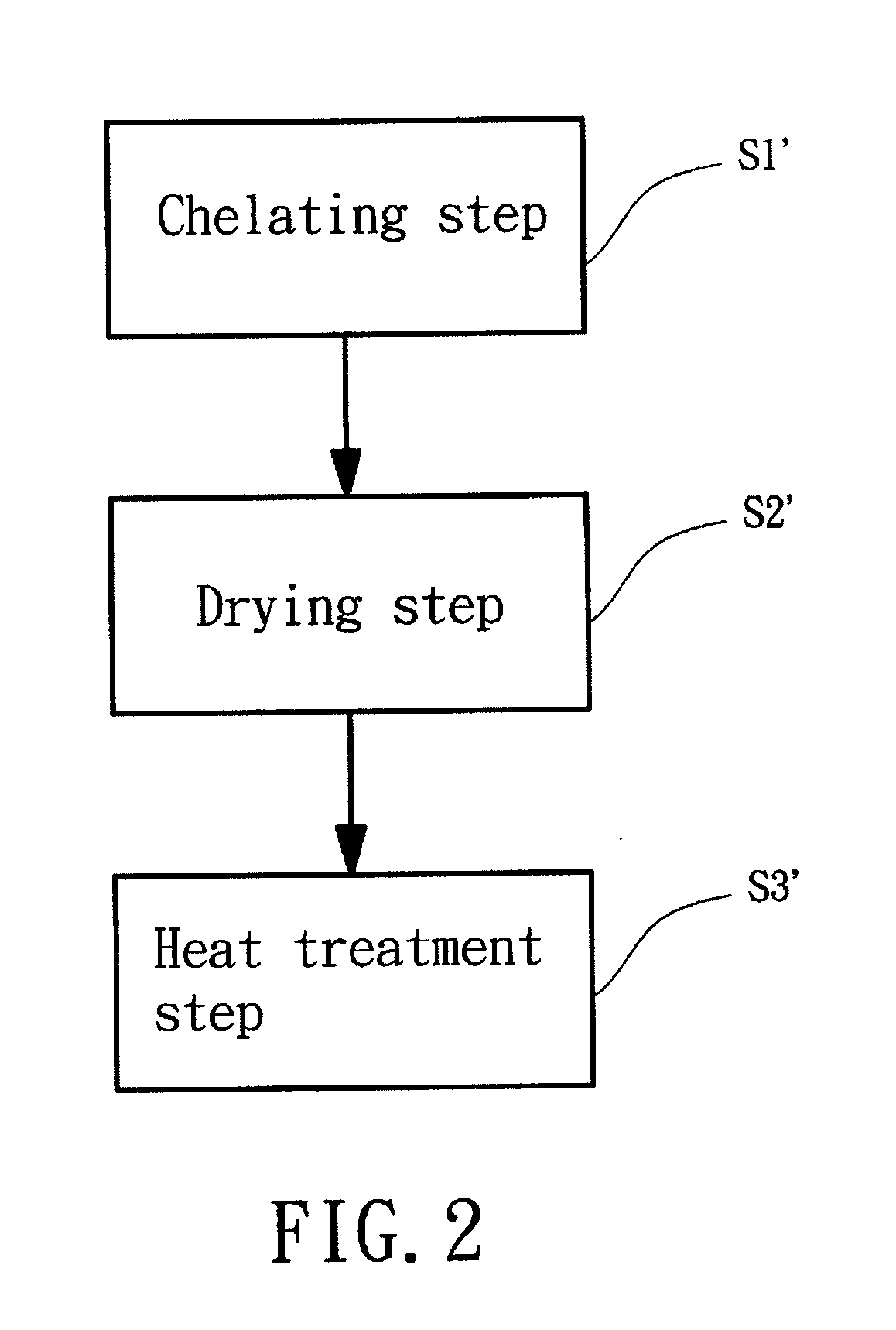

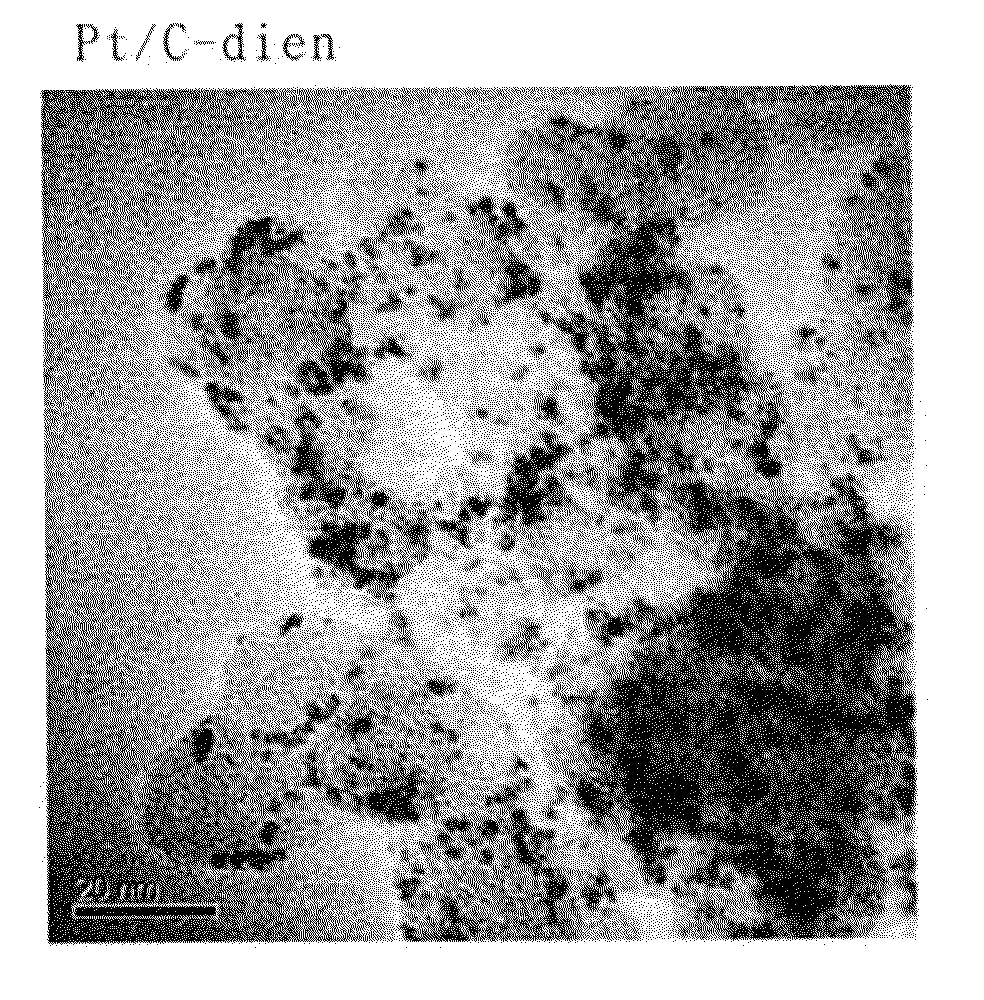

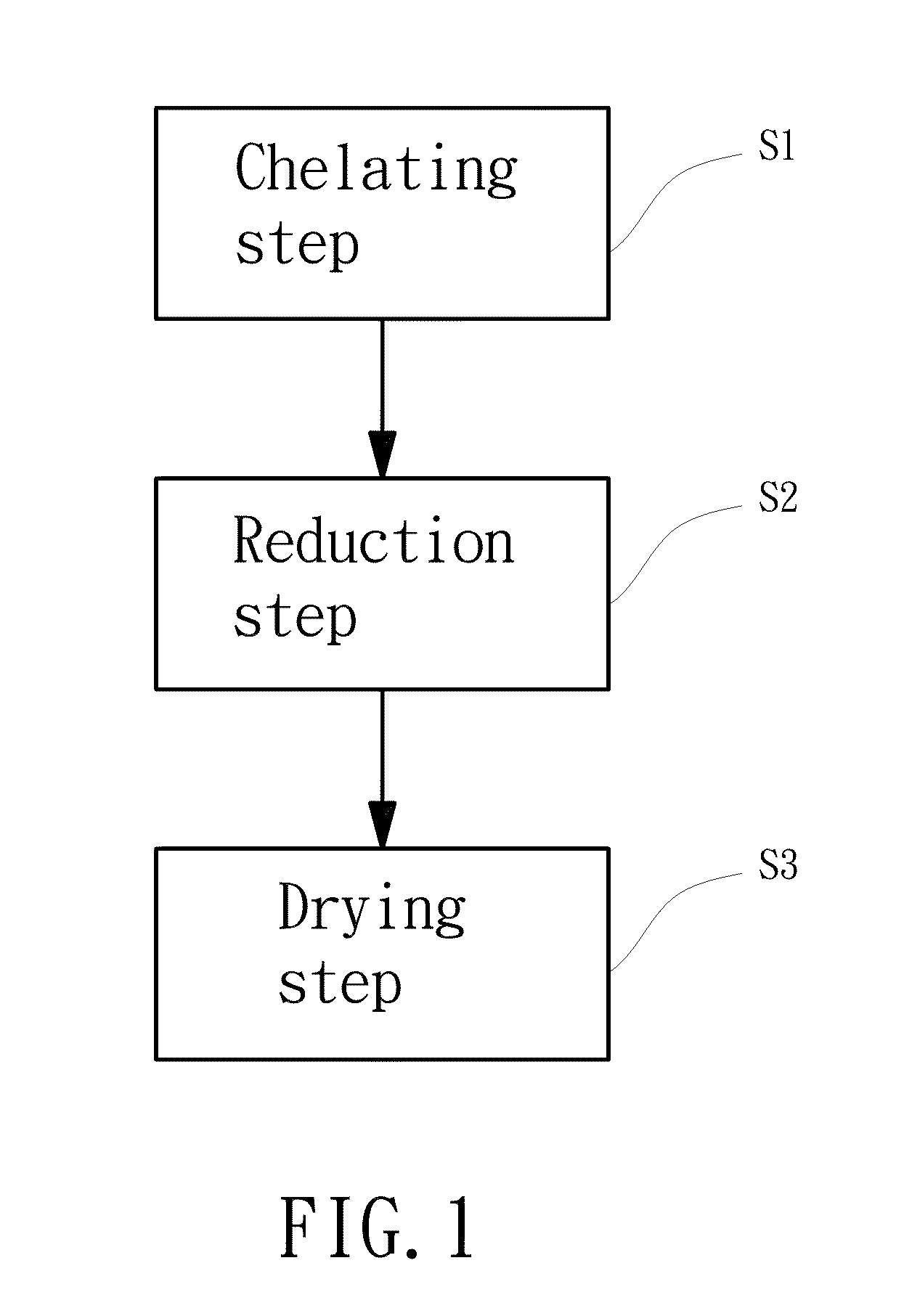

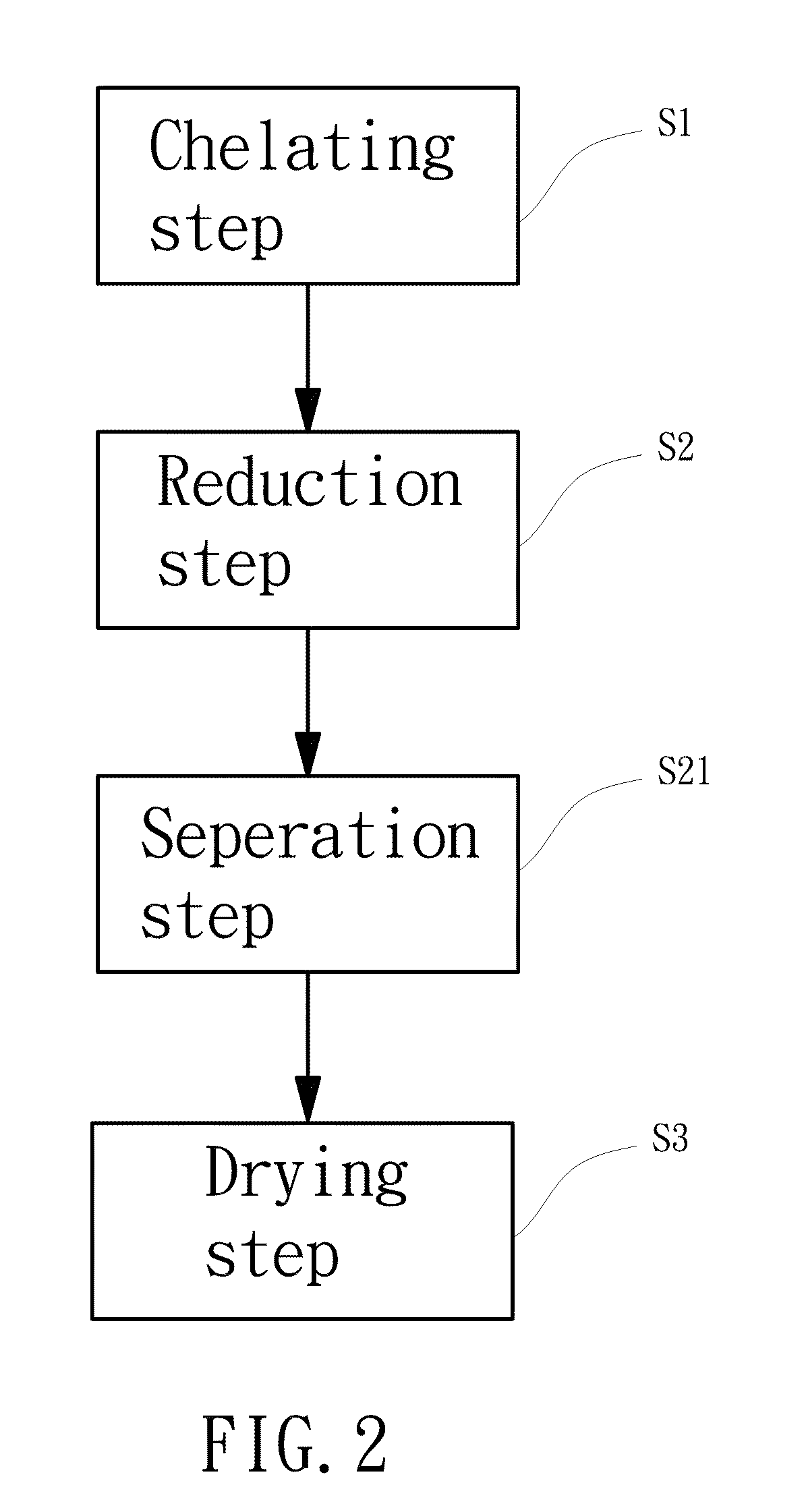

Platinum complex, manufacturing method thereof and platinum catalyst constructed thereby

InactiveUS20110177937A1Improve stabilityImprove uniformityRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEthylenediamineMethylating Agent

A manufacturing method of a platinum complex is mixing chloroplatinic acid and a chelating agent with a solvent, wherein [PtCl6]2− ions of the chloroplatinic acid is reacted with the chelating agent to form a platinum complex Pt[R]2+, wherein the chelating agent(R) is selected from ethylenediamine , 1,10-phenanthroline, 2,2′-Bipyridine, diethylenetriamine, triethylenetetraamine, phenanthroline, or bipyridine. Moreover, a method for producing a platinum catalyst on supports is mixing the chloroplatinic acid, a chelating agent and supports with a slovent to form a platinum complex, which is incorporated onto the supports. Following, a reduction step and a drying step are processed to get the platinum catalyst on the supports.

Owner:NAT CHENG KUNG UNIV

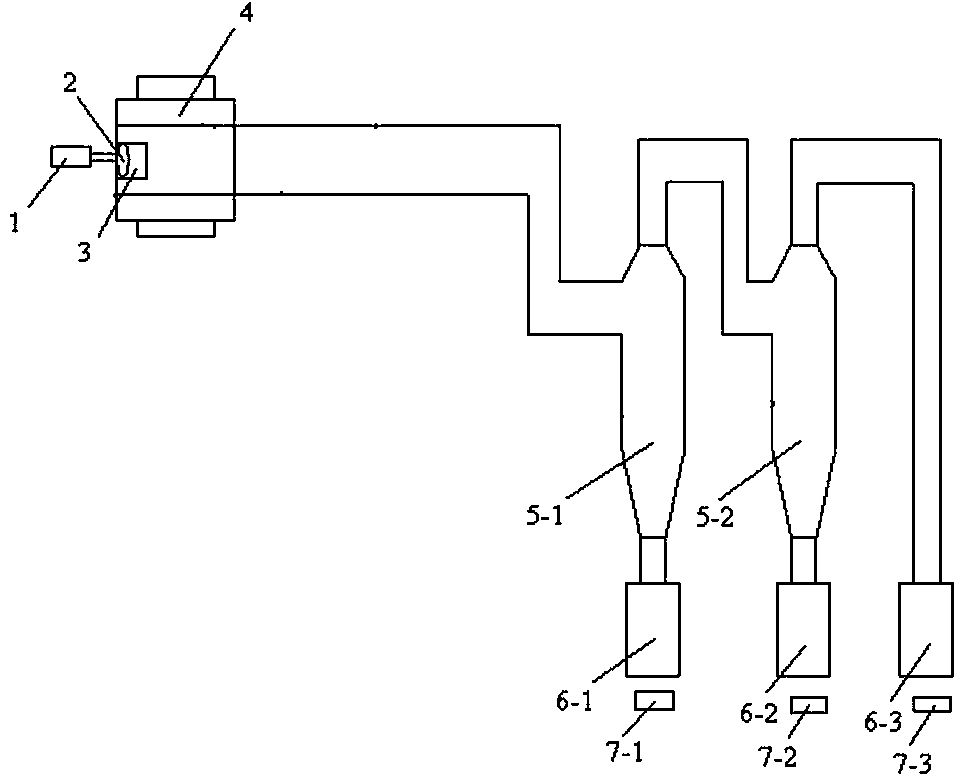

Process for continuously producing micron-sized gallium oxide powder

ActiveCN104229872ARealize continuous productionSmall particle size distributionGallium/indium/thallium compoundsEnergy inputCycloneElectric arc furnace

The invention discloses a process for continuously producing micron-sized gallium oxide powder. According to the process, micron-sized gallium oxide powder is prepared by a full-automatic gallium oxide producing device; the full-automatic gallium oxide producing device comprises a reactor, cyclone separators, collectors and automatic packing machines; when micron-sized gallium oxide powder is continuously produced by metal gallium, the metal gallium flows out of a molten metal hole after heated and melted by an electric arc furnace; preheated air is sprayed out from four air flow holes simultaneously, liquid metal gallium is impacted and sheared in the air flow intersection position, an oxidation reaction is performed simultaneously, and the micron-sized gallium oxide powder is formed; and the micron-sized gallium oxide powder sequentially enters a cyclone separator I and a cyclone separator II for classification with air flow and then is collected in the collectors, and continuous production of the micron-sized gallium oxide powder prepared by the metal gallium is completed. The process completely realizes full-automatic continuous production of micron-sized gallium oxide, the purity of the prepared gallium oxide is high, the grain diameter is small, the distribution range is small, gallium oxide with different grain diameters is obtained through classification and meet different use demands, and the process is environment-friendly and low in cost.

Owner:ZHUZHOU KENENG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com