Process for continuously producing micron-sized gallium oxide powder

A gallium oxide, micron-scale technology, applied in inorganic chemistry, chemical instruments and methods, gallium/indium/thallium compounds, etc., can solve the problems of inability to achieve full automation, large environmental pollution, complicated operations, etc., and achieve full automation and continuous. The effect of production, low labor intensity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

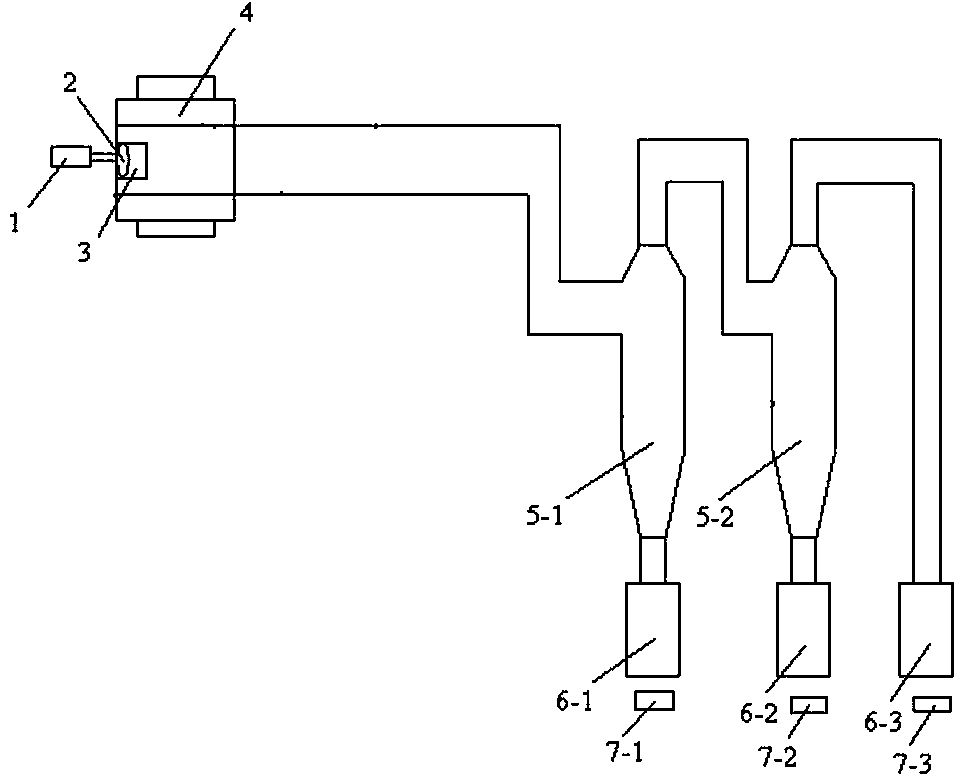

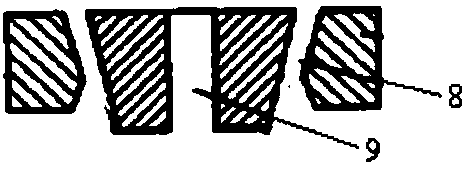

Method used

Image

Examples

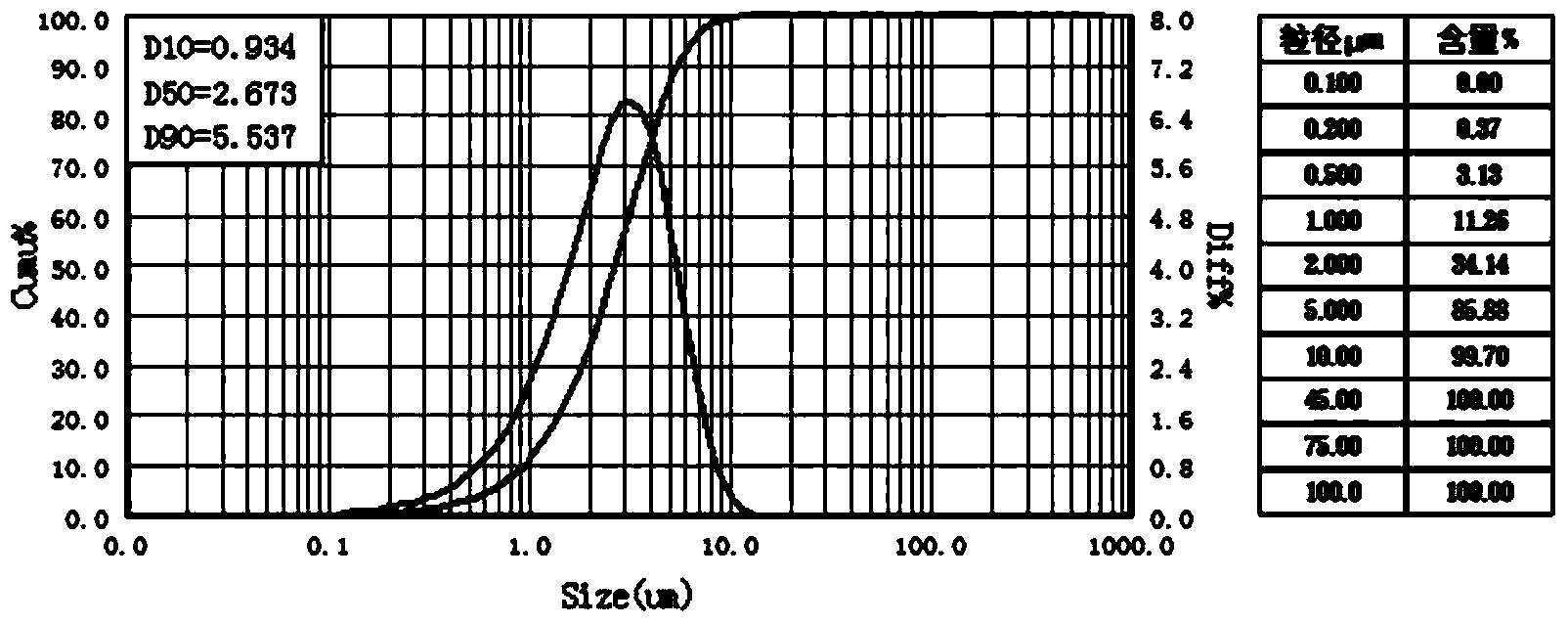

Embodiment 1

[0025] When the micron-sized gallium oxide powder of gallium metal is continuously produced, the gallium metal is heated to 240°C by the electric arc furnace, and the molten gallium metal flows out from the metal liquid hole; at this time, the air compressor is turned on to deliver preheated air at 250°C, and the The preheated air is ejected from the four air holes at the same time at a pressure of 7MPa. The air injection angle is along the axis of the metal liquid hole at 30°. The liquid metal gallium is impacted and sheared by the air flow at the intersection of the air flow, and the oxidation reaction is carried out at the same time, forming an average The particle size is 2.673 μm, and the particle size distribution is less than 10 μm, accounting for 99.70%, and less than 5 μm, accounting for 85.88% of gallium oxide powder; the obtained gallium oxide powder enters cyclone separator I and cyclone separator II in sequence with the airflow for classification, and in the cyclone...

Embodiment 2

[0027] When the micron-sized gallium oxide powder of gallium metal is continuously produced, the gallium metal is heated to 250°C by the electric arc furnace, and the molten gallium metal flows out from the metal liquid hole; at this time, the air compressor is turned on to deliver preheated air at 260°C, and the The preheated air is ejected from the four air holes at the same time at a pressure of 6MPa. The air injection angle is along the axis of the metal liquid hole at 30°. The liquid metal gallium is impacted and sheared by the air flow at the intersection of the air flow, and the oxidation reaction is carried out at the same time, forming an average The particle size is 2.875 μm, and the particle size distribution is less than 10 μm, accounting for 99.52%, and less than 5 μm, accounting for 84.62% of gallium oxide powder; the obtained gallium oxide powder enters cyclone separator I and cyclone separator II in sequence with the airflow for classification, and in the cyclone...

Embodiment 3

[0029]When the micron-sized gallium oxide powder of gallium metal is continuously produced, the gallium metal is heated to 200°C by the electric arc furnace, and the molten gallium metal flows out from the metal liquid hole; at this time, the air compressor is turned on to deliver preheated air at 220°C, and the The preheated air is ejected from the four air holes at the same time at a pressure of 5 MPa. The air injection angle is along the axis of the metal liquid hole at 40°. The liquid metal gallium is impacted and sheared by the air flow at the intersection of the air flow, and the oxidation reaction is carried out at the same time, forming an average The particle size is 2.985 μm, and the particle size distribution is less than 10 μm, accounting for 99.50%, and less than 5 μm, accounting for 83.79% of gallium oxide powder; the obtained gallium oxide powder enters cyclone separator I and cyclone separator II in sequence with the airflow for classification, and in the cyclone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com