Technological method for producing composite probiotic two-layer microcapsule by virtue of double-emulsification method-spray drying

A technology of compound probiotics and double emulsification method, which is applied in the directions of Lactobacillus, Bifidobacterium, Streptococcus/Lactococcus, etc., can solve the problems of not being able to increase the production scale, not being widely used, and low embedding efficiency. High embedding efficiency, no cracks and depressions, and rounded shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

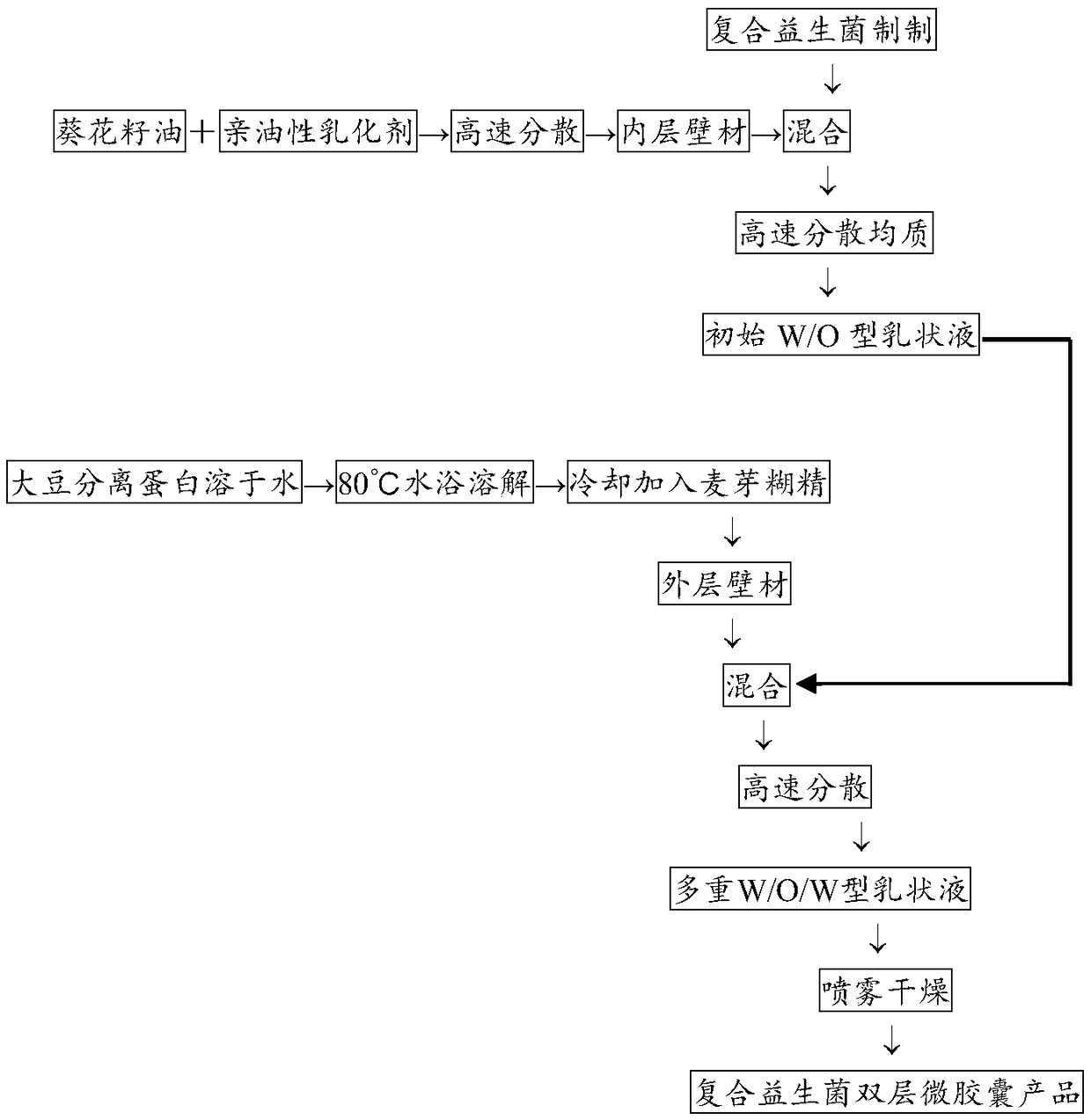

[0040] refer to figure 1 The process flow diagram of double emulsification method-the technical method of spray drying to produce compound probiotic double-layer microcapsules, including:

[0041] (1), select the wall material: use soybean protein isolate, maltodextrin, and sunflower oil as the composition material of the wall material, and the mass ratio of soybean protein isolate: maltodextrin: sunflower oil is 30% of soybean protein isolate, maltodextrin 30%, 40% of live bacteria mixture in sunflower oil.

[0042] (2), the preparation of initial W / O type emulsion: lipophilic emulsifier lecithin is used as the first emulsifier, and its consumption is 1.5% (m / v), joins in the sunflower seed oil, disperses and mixes evenly at high speed, Emulsify to obtain the inner wall material, then add the compound probiotic live bacteria preparation-probiotic solution to mix, 7500r / min high-speed dispersion emulsification, and obtain the initial W / O type emulsion, the core material addi...

Embodiment 2

[0048] refer to figure 1 The process flow chart of double emulsification method-spray drying technology method for producing compound probiotic double-layer microcapsules, including: (1), select wall material: use soybean protein isolate, maltodextrin, sunflower oil as the composition of wall material Materials, soybean protein isolate: maltodextrin: sunflower oil The mass ratio is 30% of soybean protein isolate, 30% of maltodextrin, and 40% of sunflower oil live bacteria mixture.

[0049] (2), the preparation of initial W / O type emulsion: lipophilic emulsifier lecithin is used as the first emulsifier, and its consumption is 1.0% (m / v), joins in the sunflower seed oil, disperses and mixes evenly at high speed, Emulsify to obtain the inner wall material, then add the compound probiotic live bacteria preparation-probiotic solution to mix, 8000r / min high-speed dispersion emulsification, and obtain the initial W / O emulsion, the core material addition is 10% (v / v) ; High-speed di...

Embodiment 3

[0058] Embodiment 3 effect detection

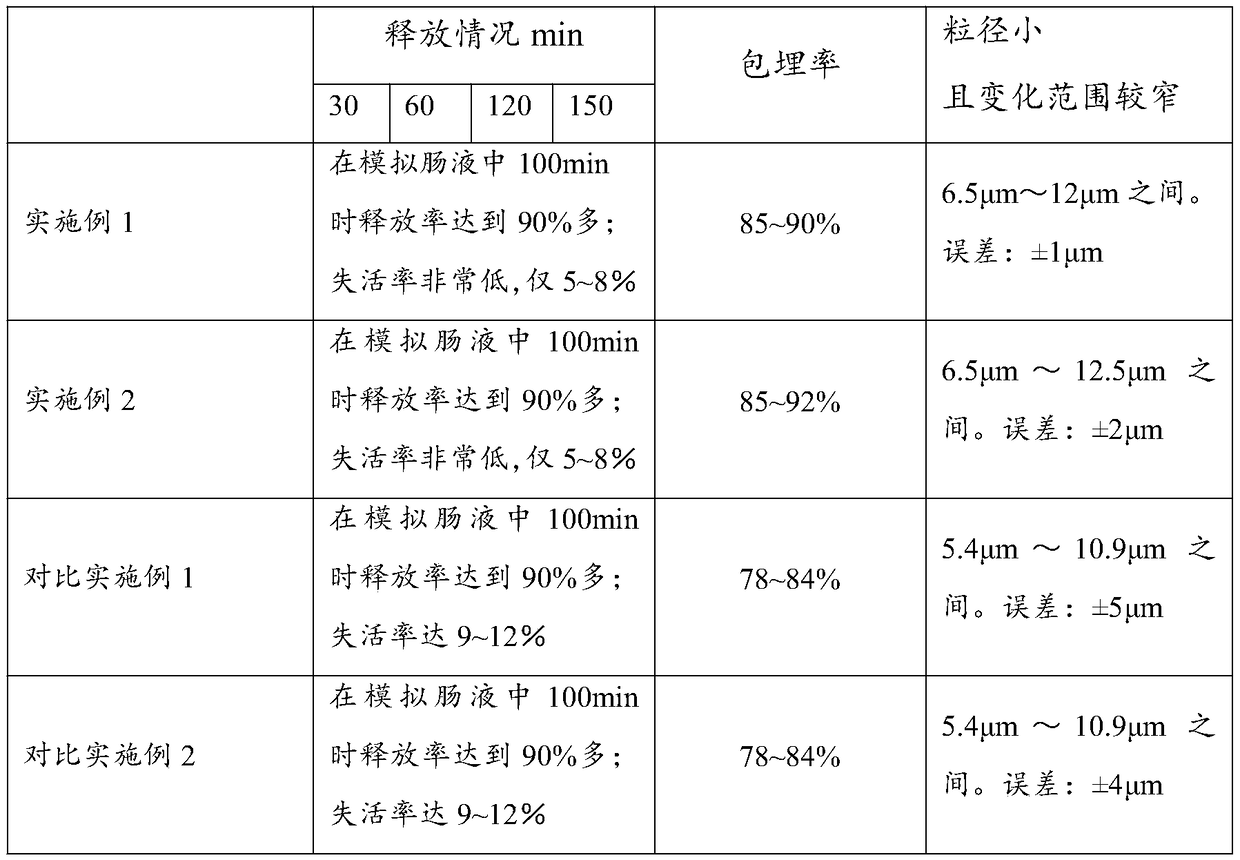

[0059] Artificial intestinal juice: Take 6.8g of potassium dihydrogen phosphate, add 500mL of water to dissolve, adjust the pH value to 6.8 with 0.4% sodium hydroxide solution; take another 10g of pancreatin, add water to dissolve, mix the two liquids, add water to dilute to 1000mL , that is. Prepare just before use. The measurement results are as follows:

[0060]

[0061] From the above results, it can be seen that compared with the conventional technical solution, the technical solution of the present invention reduces burst release, has a high embedding rate, and has small particle size differences among particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com