Preparation method of leuprorelin microspheres

A technology of leuprolide and microspheres, which is applied in the field of preparation of leuprolide microspheres, can solve the problems of easy boiling and volatilization, and achieve the effects of stable colostrum, reduced residue, and smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

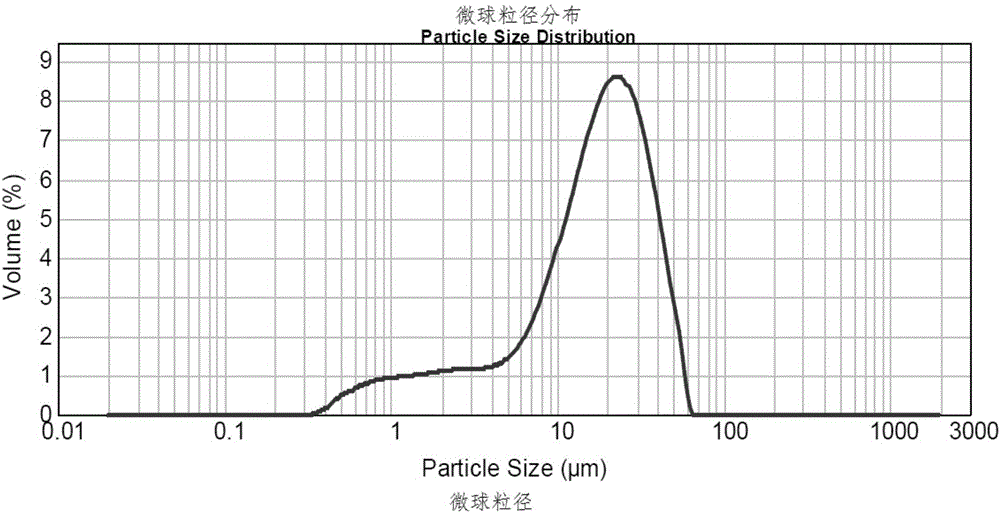

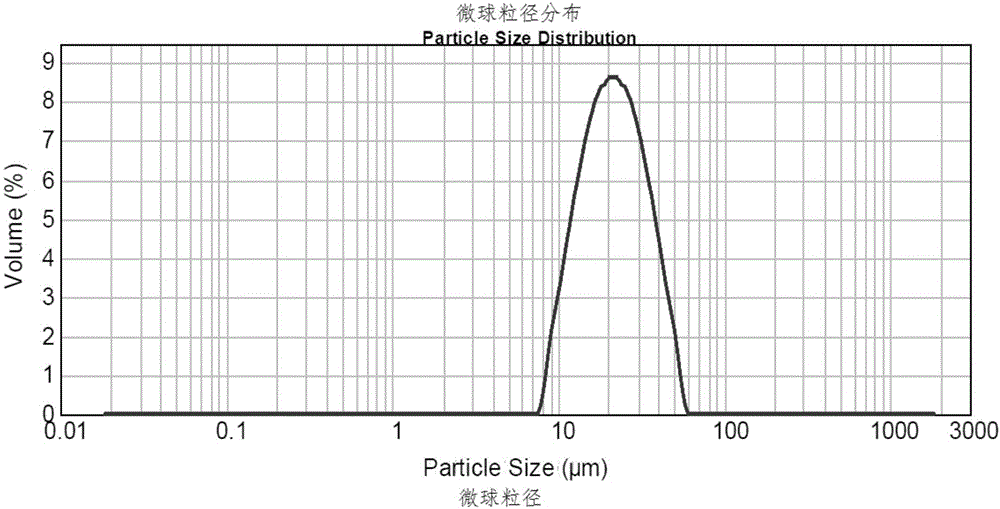

Image

Examples

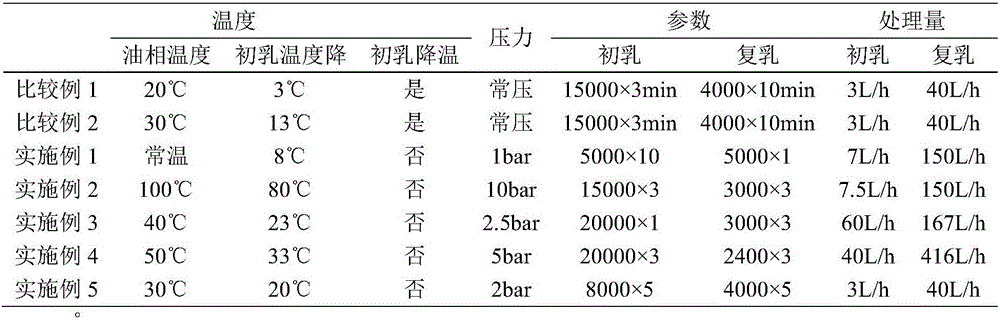

Embodiment 1

[0035] Oil phase: prepare 675g (about 7650 sticks) of 37.5% PLG DCM solution in a closed oil phase tank (material: 316L, pressure resistance: -5~25bar, the same below), and control 1 bar in the tank by nitrogen or compressed air Pressure, keep at room temperature, set aside.

[0036] Inner water phase: Add 29g of leuprolide raw material into the inner water phase tank to prepare 43.7% leuprolide aqueous solution for use.

[0037] External water phase: Prepare 32L of 0.1% PVA solution in the external water phase tank, then cool down to 4°C, and set aside.

[0038] Preparation of colostrum: Open the bottom valve of the oil phase tank, turn on the online shearer 1 (IKA DRS2000 / 03), adjust the speed to 5000rpm, and pump a small amount of oil phase into the shearer to fill it up, so that the shearer is mixed with oil Balance the pressure of the phase tank (up to 1 bar), then adjust the pump speed, mix the oil phase and the inner water phase at a ratio of 10:1, pump it into the onl...

Embodiment 2

[0042] Oil phase: prepare 675g (about 7650 sticks) of 37.5% PLG DCM solution in a closed oil phase tank, control the pressure of 10bar in the tank by nitrogen or compressed air, heat to 100°C, and set aside.

[0043] Inner water phase: Add 29g of leuprolide raw material into the inner water phase tank to prepare 43.7% leuprolide aqueous solution for use.

[0044] External water phase: prepare 32L of 0.1% PVA solution in the external water phase tank, then cool down to 20°C, and set aside.

[0045] Preparation of colostrum: Open the bottom valve of the oil phase tank, turn on the online shearer 1 (IKA DRS2000 / 03), adjust the speed to 15000rpm, and pump a small amount of oil phase into the shearer to fill it up, so that the shearer is mixed with oil Balance the pressure of the phase tank (up to 10bar), then adjust the pump speed, mix the oil phase and the inner water phase at a ratio of 10:1, pump it into the online shearer, open the corresponding valve group, and let the sheare...

Embodiment 3

[0049] Oil phase: prepare 2700g of 37.5% PLG DCM solution (about 30,500 sticks) in a closed oil phase tank, control the pressure of 2.5bar in the tank with nitrogen or compressed air, heat to 40°C, and set aside.

[0050] Inner water phase: add 116g of leuprolide raw material into the inner water phase tank to prepare 43.7% leuprolide aqueous solution for use.

[0051] External water phase: Prepare 128L of 0.1% PVA solution in the external water phase tank, then cool down to 17°C and set aside.

[0052] Preparation of colostrum: Open the bottom valve of the oil phase tank, turn on the online shearer 1 (IKA DRS2000 / 03), adjust the speed to 20000rpm, and pump a small amount of oil phase into the shearer to fill it up, so that the shearer is mixed with oil Balance the pressure of the phase tank (up to 2.5bar), then adjust the pump speed, mix the oil phase and the inner water phase according to the ratio of 10:1, pump it into the online shearer, open the corresponding valve group,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com