Patents

Literature

201 results about "Pilot plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

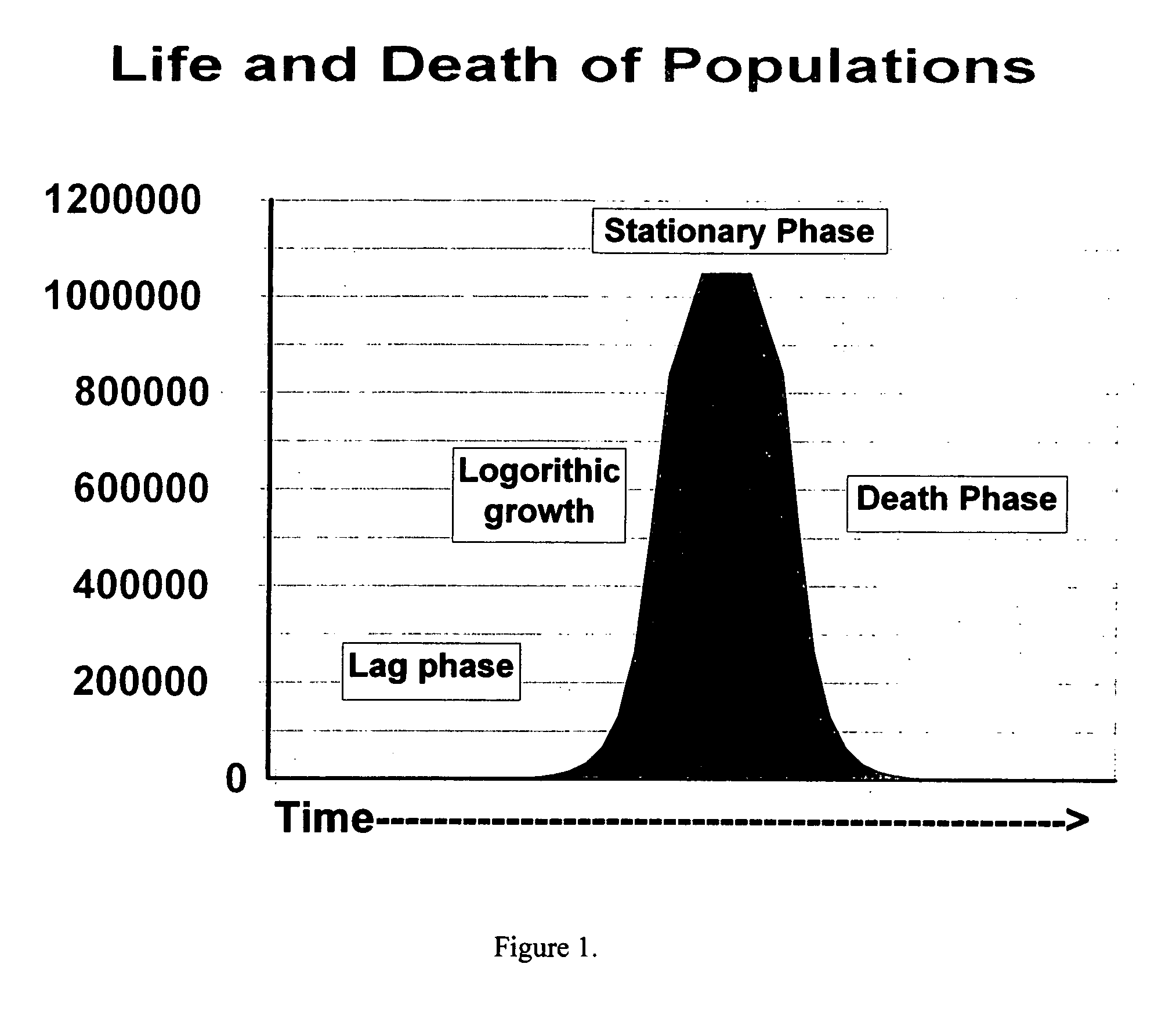

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then used for design of full-scale production systems and commercial products, as well as for identification of further research objectives and support of investment decisions. Other (non-technical) purposes include gaining public support for new technologies and questioning government regulations. Pilot plant is a relative term in the sense that pilot plants are typically smaller than full-scale production plants, but are built in a range of sizes. Also, as pilot plants are intended for learning, they typically are more flexible, possibly at the expense of economy. Some pilot plants are built in laboratories using stock lab equipment, while others require substantial engineering efforts, cost millions of dollars, and are custom-assembled and fabricated from process equipment, instrumentation and piping. They can also be used to train personnel for a full-scale plant. Pilot plants tend to be smaller compared to demonstration plants.

Dilute phosphorus incorporation into a naphtha reforming catalyst

InactiveUS20070215523A1Improve octaneCatalytic naphtha reformingCatalyst activation/preparationNaphthaChloride

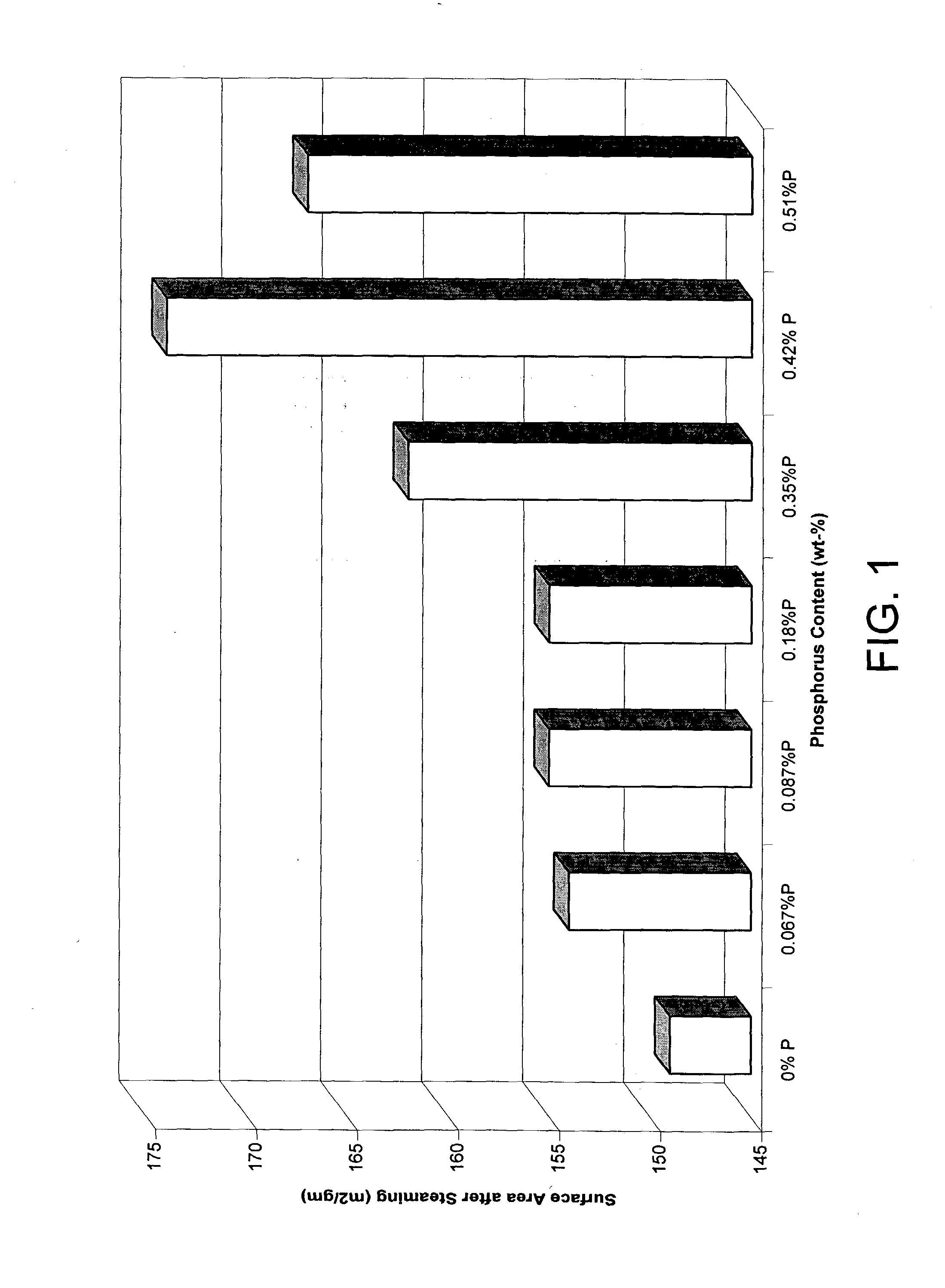

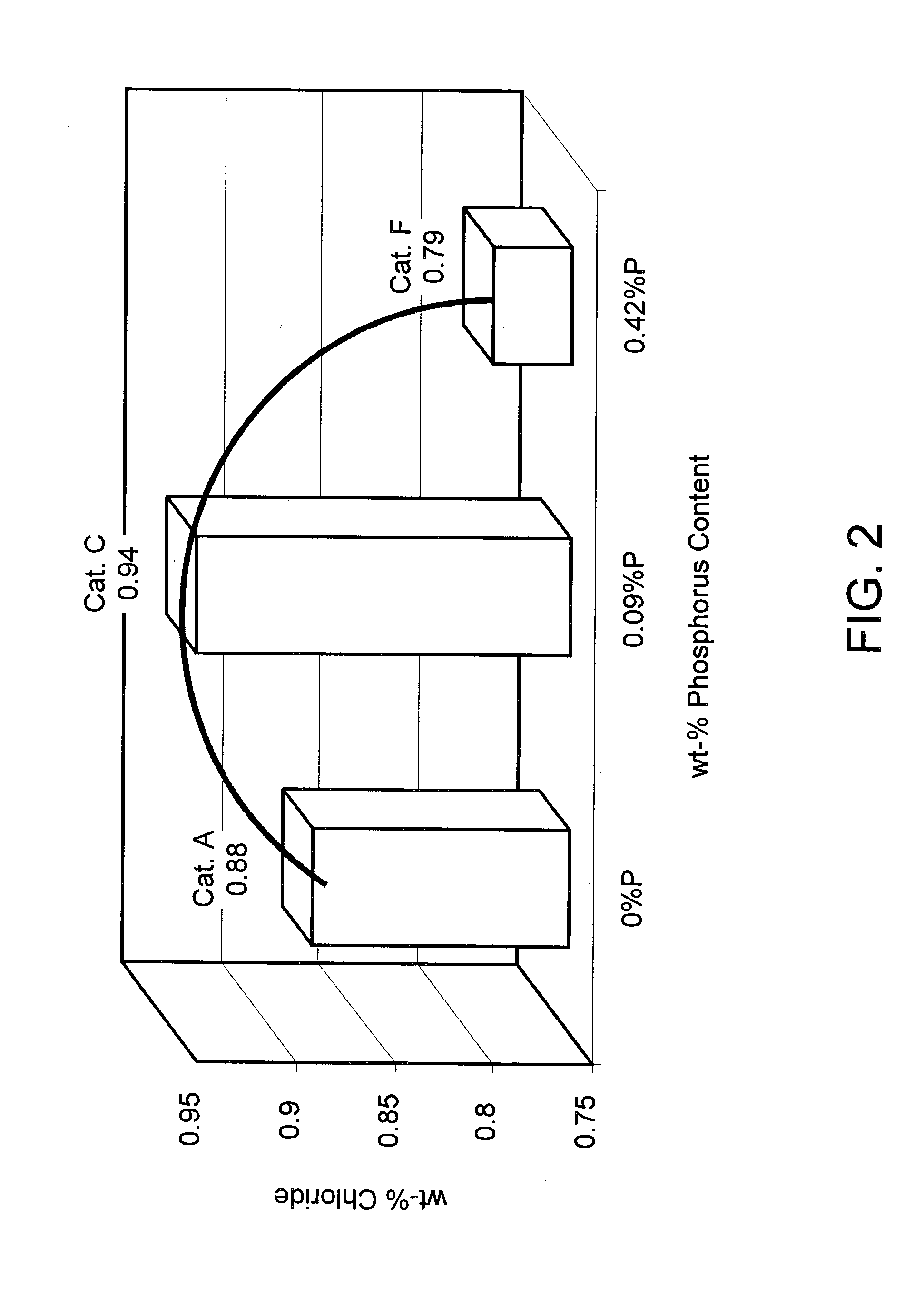

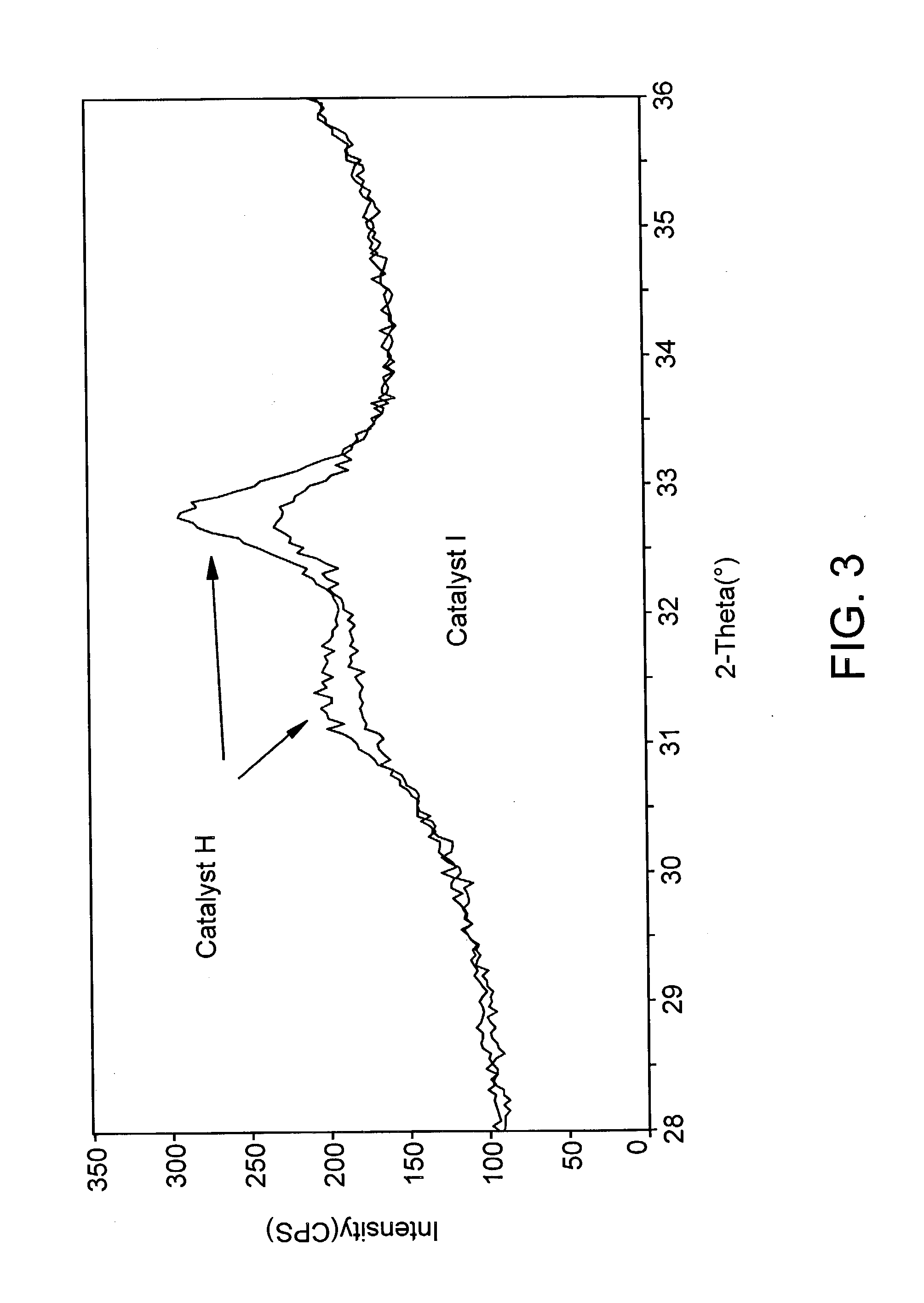

In order to maintain the surface area of an alumina catalyst over the course of operation and regeneration, a method of incorporating phosphorus into the alumina has been developed. By incorporating a small amount of phosphorus, the resulting catalyst is better able to withstand hydrothermal conditions, such as during a carbon burn step, which causes alumina surface area to degrade or decrease. Reduced surface area also desorbs chloride from the catalyst, lowering activity and increasing corrosion. Here, steam treatments have been used to simulate commercial hydrothermal stability and a critically small amount of phosphorus has been discovered which balances an increased surface area against decreased chloride retention. Increased surface area results from increased phosphorus, yet higher levels of phosphorus blocks ability to hold chloride. Moreover, X-ray data shows that an amount as low as 0.2 wt-% phosphorus increases alumina transition temperature, while pilot plant data shows excellent naphtha reforming yields.

Owner:UOP LLC

Soilgas phase extracting monitoring system device and monitoring method

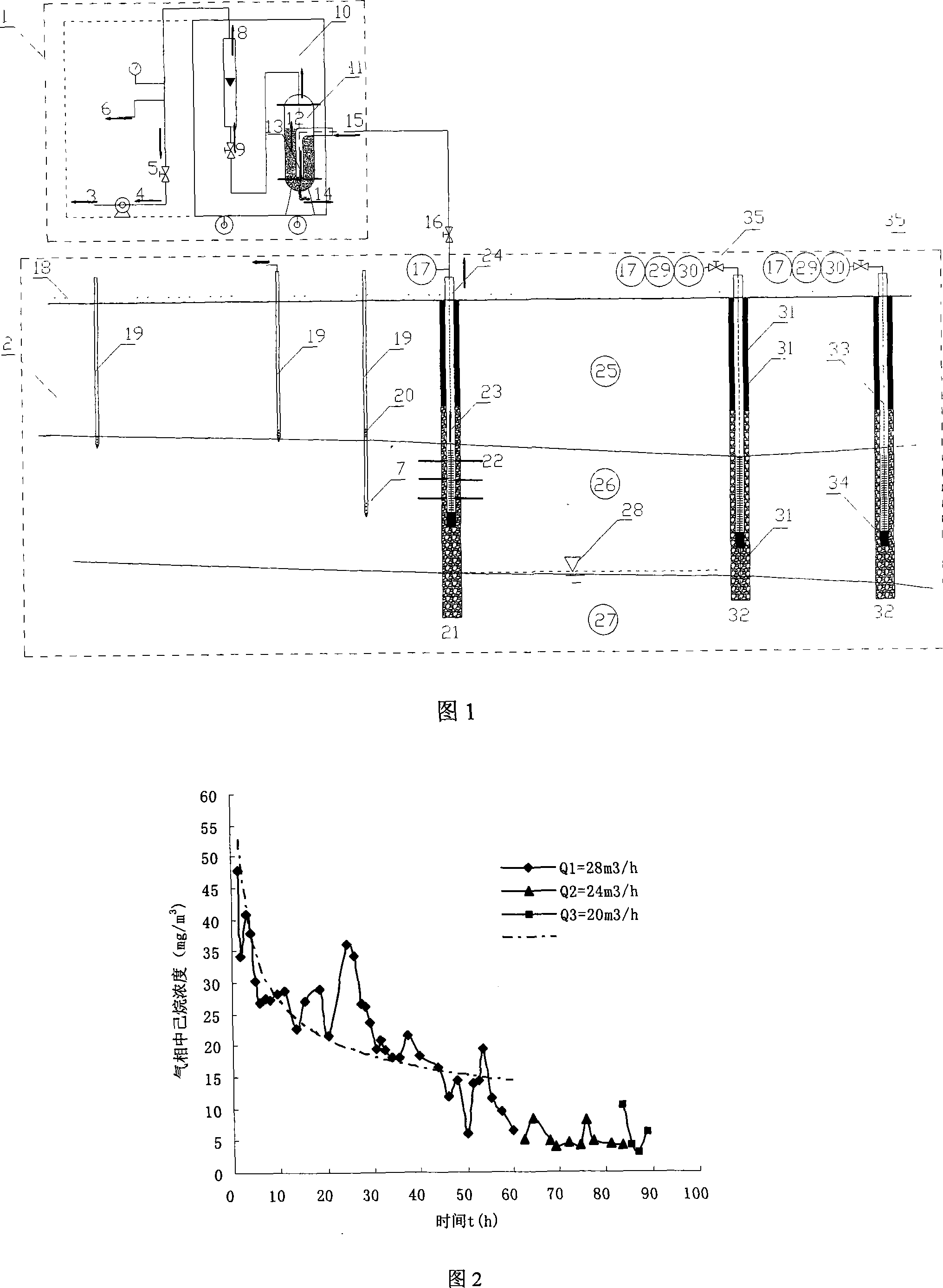

InactiveCN101021520ASimple designAchieve removalContaminated soil reclamationMaterial analysisSoil scienceGas phase

The invention relates to a kind of soil locale testing and in situ repair device and its system. It is composed of the soil gas phase extractive monitor system device and extractive well, monitor well, pressure testing point, the soil gas phase extractive device links the locale extractive well, the monitor well with the ground pipeline. The soil gas phase extractive device and its extractive well, monitor well, the ground extractive device and the pipeline such as measure as well as the underground raise part combined well to compose the locale soil testing and the idea, high-activity system. The invention can reach the anticipate aim of testing or reducing pollution in smaller device invest. The locale testing approves that, the invention has the soil and underground water in situ repair system, which is designed reasonable, the device is simple, the operation are convenience and feasible, it is easy to maintenance, the process of the locale testing and the pilot-plant is easy to control, it will have wide application foreground.

Owner:TIANJIN UNIV

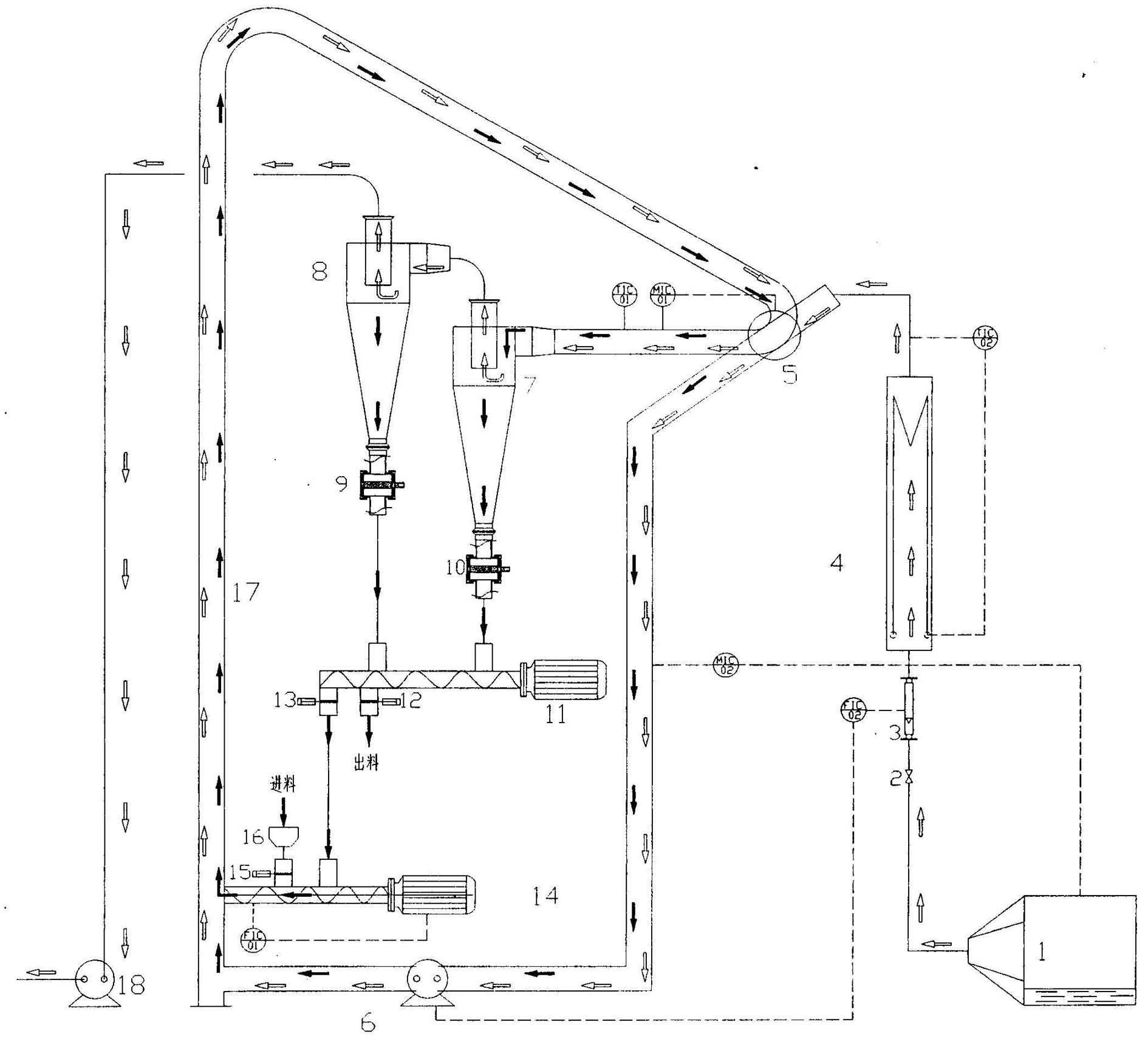

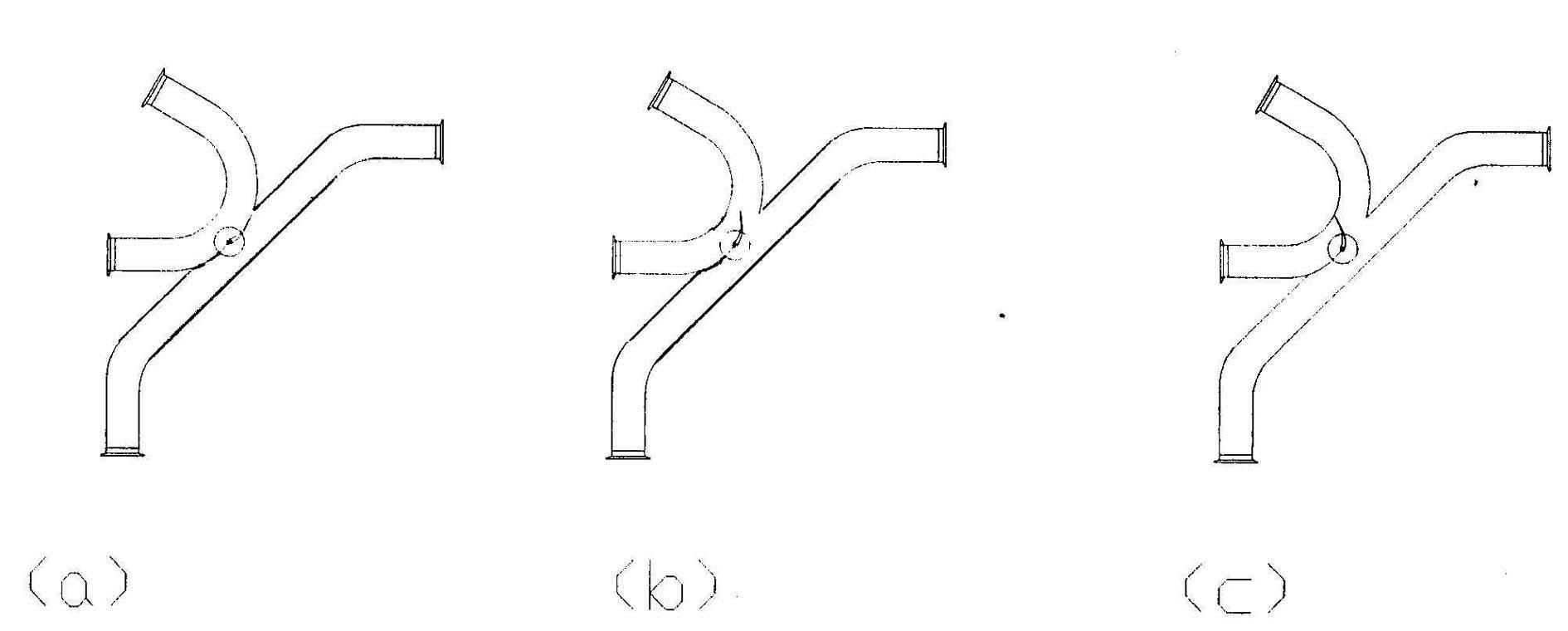

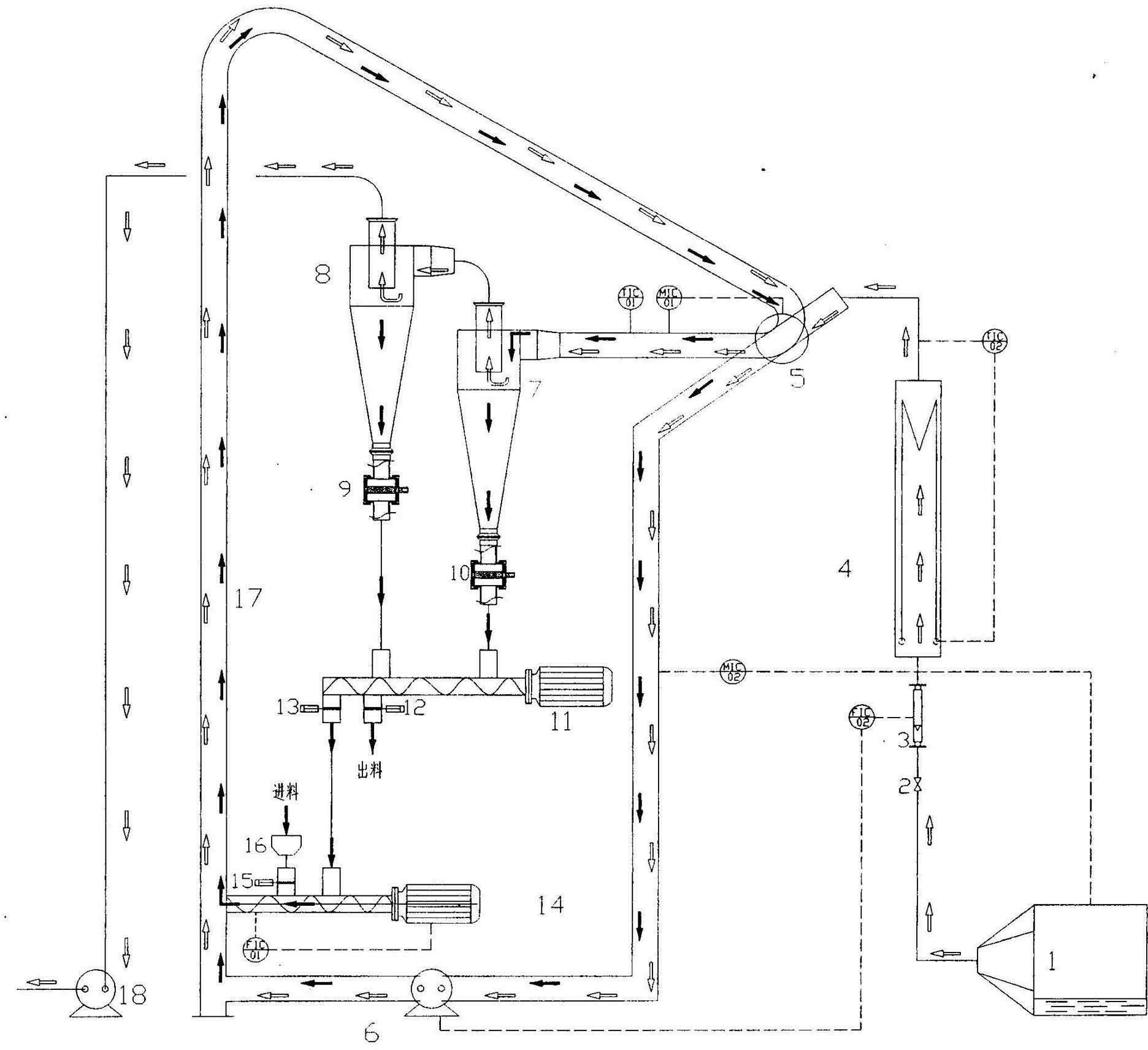

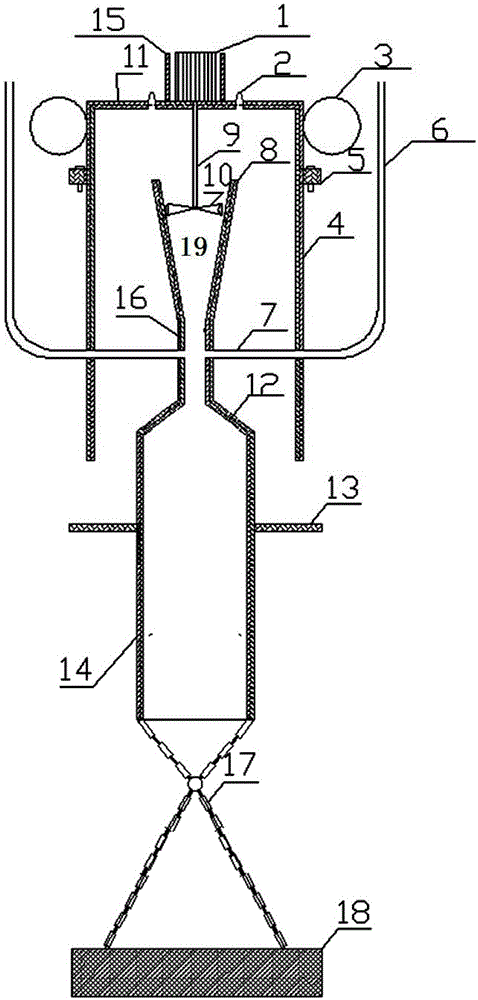

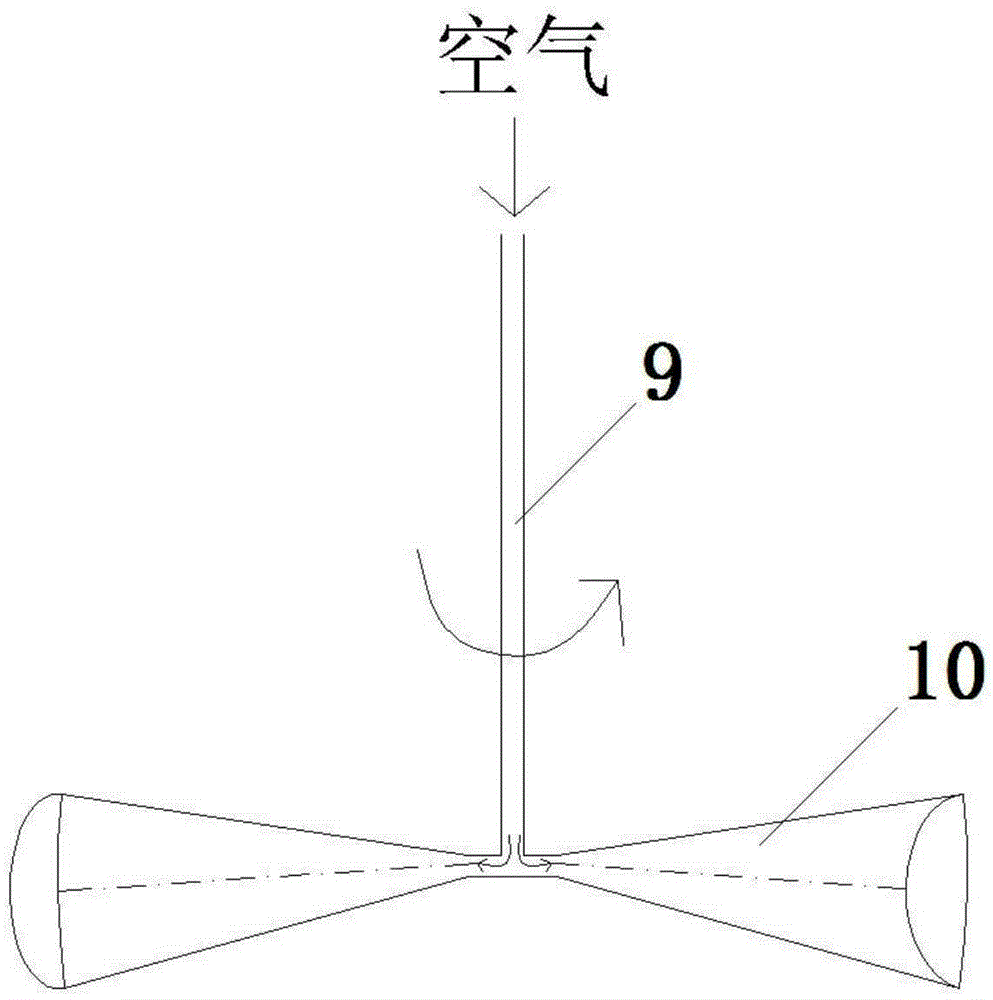

Circulating airflow drying device for pilot plant test

InactiveCN102494524AImplement the function of mixingImprove fitnessDrying gas arrangementsDrying solid materialsCycloneEngineering

The invention discloses a circulating airflow drying device for a pilot plant test. The drying device is characterized by comprising a material drying system which comprises an air blower, a circulating airflow drying pipeline, a spiral feeder, a primary cyclone separator, a secondary cyclone separator, a draught fan, a product screw conveyor and the like, wherein an x-shaped drying material distributor controlled by an opening or closing valve plate is arranged at an intersection of the circulating airflow drying pipeline and the cyclone separators; blanking openings of the primary and secondary cyclone separators are provided with an air lock valve respectively, and the air lock valves are connected with the product screw conveyor; and twelve ultrasonic atomizers for regulating the humidity of the airflow drying pipeline are arranged in an induced air box. The whole device has a complete system, and functions of controlling the flow of airflow, controlling the heating of the airflow, accurately controlling the feeding of wet materials, premixing and feeding dry and wet materials, recovering dry powder, measuring the humidity of a product, controlling a mixing ratio of dry and wet powder, automatically regulating and controlling moisture and the like can be realized.

Owner:HENAN LABPARK CHEM EQUIP MFG

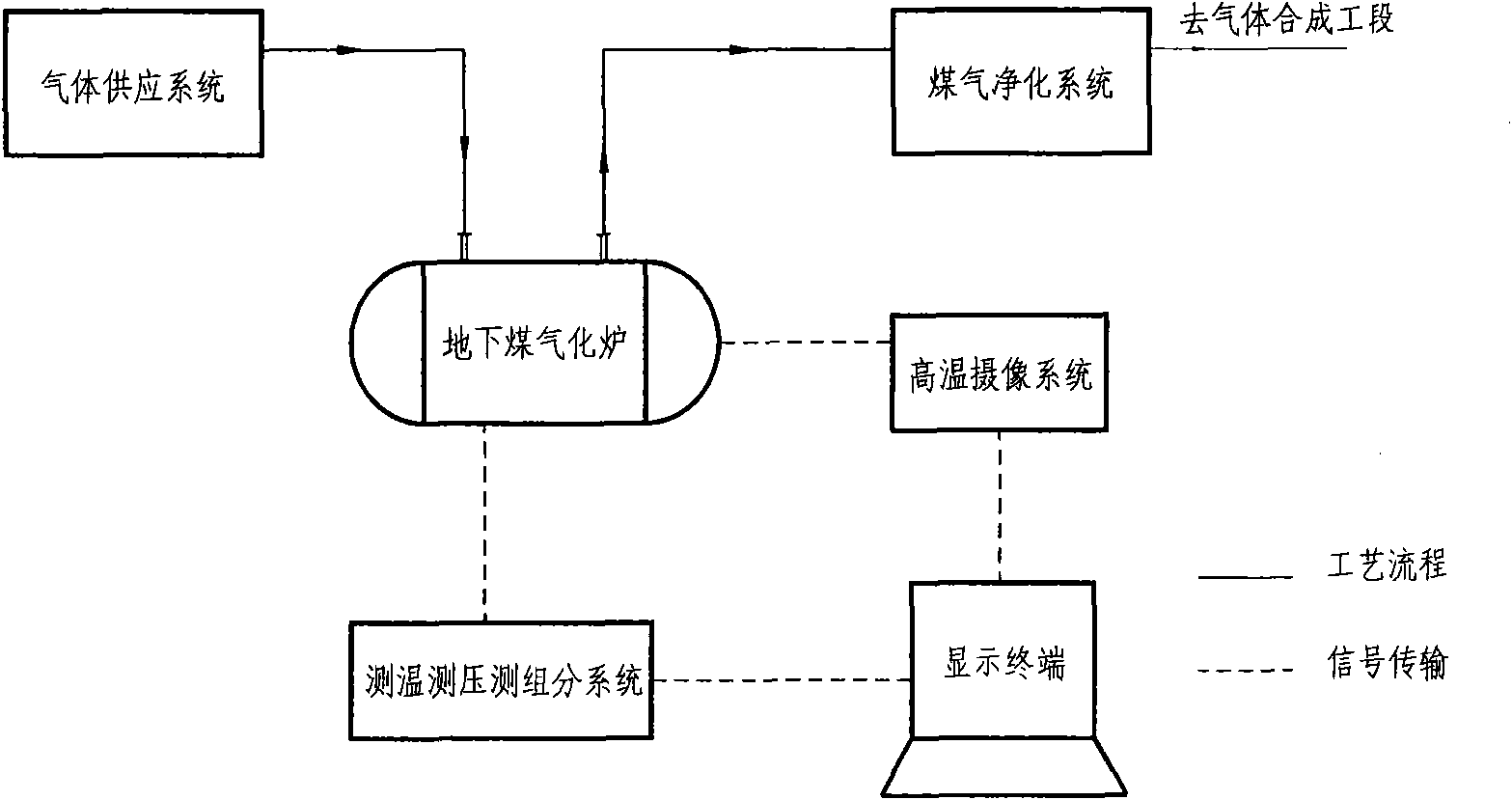

Gasification furnace for the gasification pilot plant test of underground coal and process thereof

Disclosed is a gasification furnace for the gasification pilot plant test of underground coal and the process thereof. The equipment of the process comprises a gas supply system, a gasification furnace, a temperature measuring pressure measuring and ingredient detecting system, a high temperature shooting system and a gas purifying system. The gasification furnace has a refractory material inner liner in the housing, has a grouting hole on the housing for performing seal to the coal bodies inside the furnace, and can perform gasification test in high temperature high pressure condition. The furnace body is formed with a gasifying agents and water-gas input / output hole, a grouting hole, a cooling water input / output hole, a temperature / pressure / ingredient measuring auxiliary hole, a high temperature shooting system viewing hole, a resistor method measuring hole and a manhole. The invention fully considers the pressurized condition in the underground coal gasification process, meets the requirement of gasification pressuring to coal in the pilot plant test, can investigate the technological experiment of normal / high pressure underground coal gasification and combustion point returning. The gasification furnace is equipped with a plurality of temperature measuring, pressure measuring and gas ingredient measuring systems and high temperature visual monitoring systems, can perform on-line monitoring and real time control to various parameters in the pilot plant test process.

Owner:ENN SCI & TECH DEV

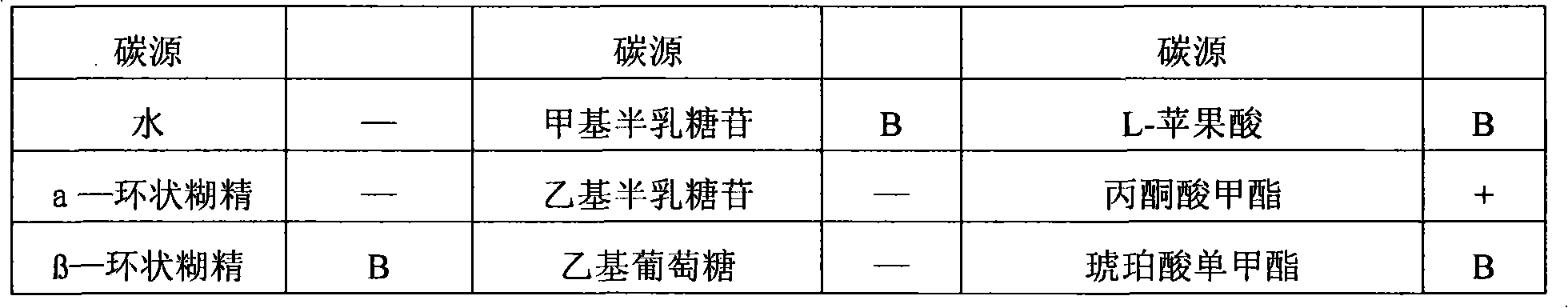

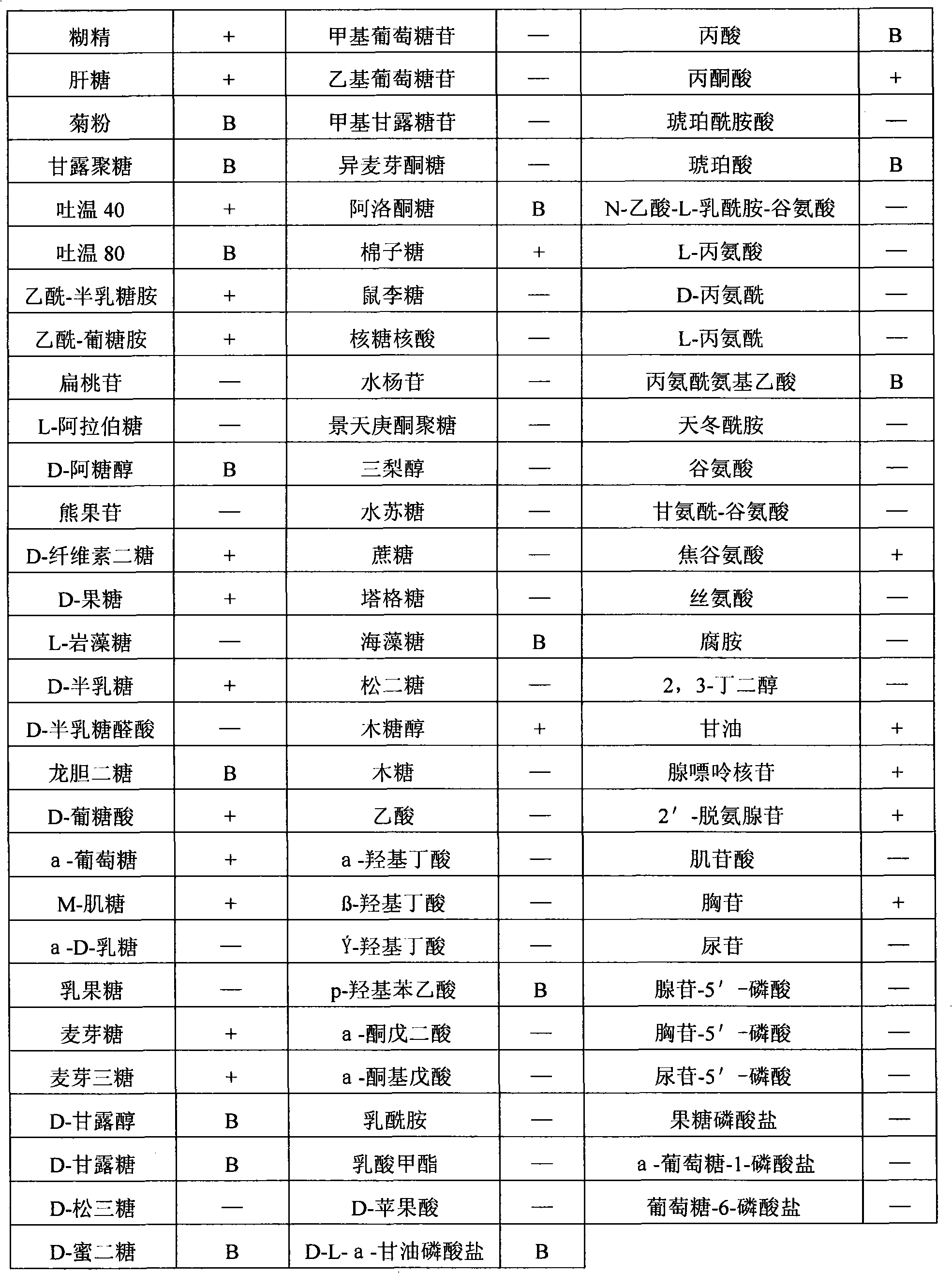

Streptomyces parvus and application thereof for preparing daptomycin

The invention discloses a streptomyces parvus and application thereof for preparing daptomycin. The strain is reserved in the CCTCC and has the reservation number of CCTCC NO: M2010136, and the reservation data is June 4, 2010. The method for preparing the daptomycin is as follows: a, taking streptomyces parvus CCTCC NO: M2010136 as a fermentation strain; b, strain cultivation: inoculating slope lawn into a shake flask seeding tank to cultivate to obtain shake flask seeding liquid; inoculating the shake flask seeding liquid into the seeding tank to be cultivated; inoculating the seeding tank culture solution into fermentation tank culture medium to be cultivated, and collecting fermentation liquor; carrying out feed supplement in the fermentation and cultivation process; and c, extracting a fermentation product. The fermentation technology provided by the invention has stable production capability, high fermentation unit and few fermentation byproducts by the pilot plant test and the experiment in a 10-ton fermentation tank, greatly lowers post-extracting difficulty and is suitable for industrial production.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST +1

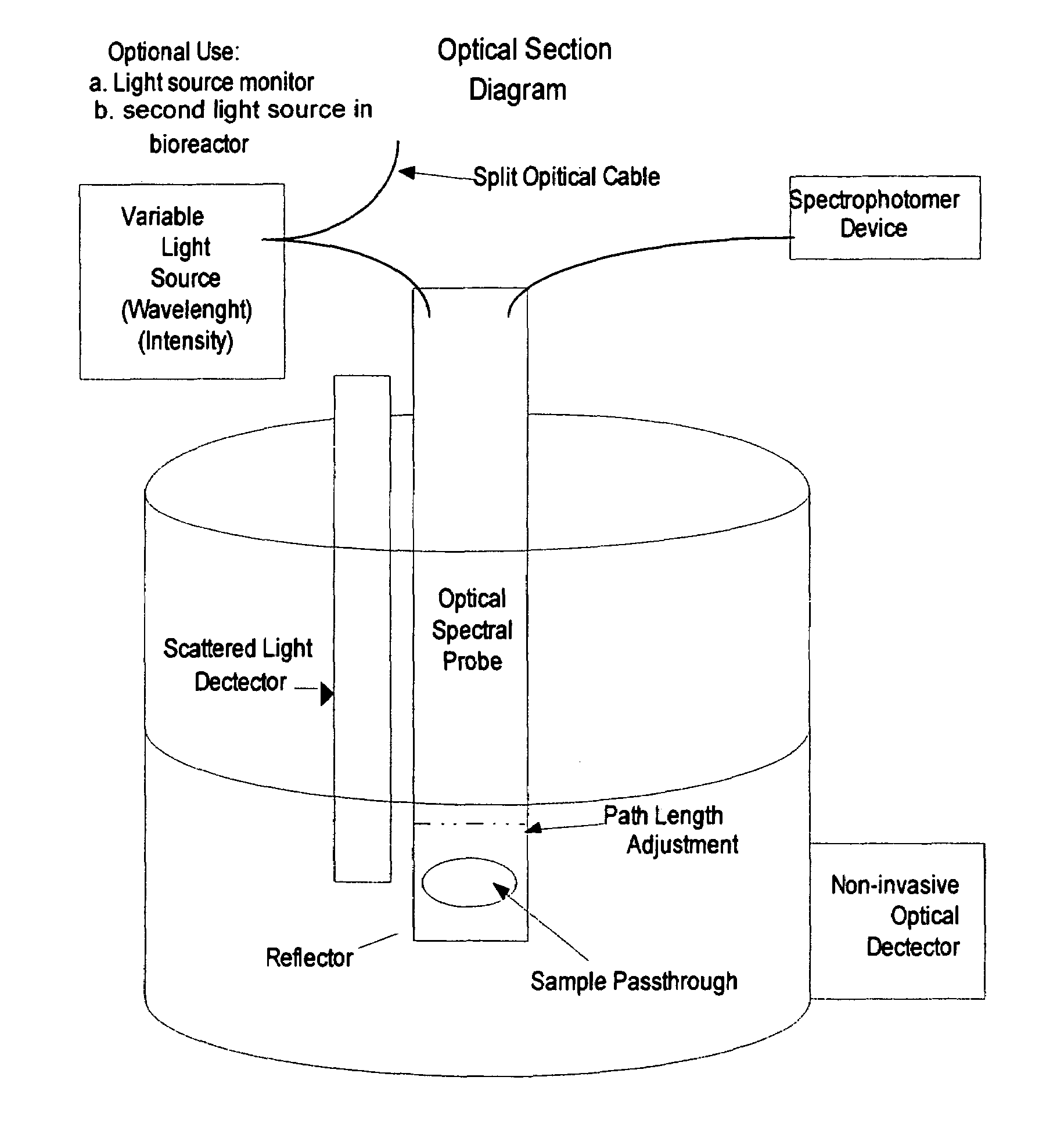

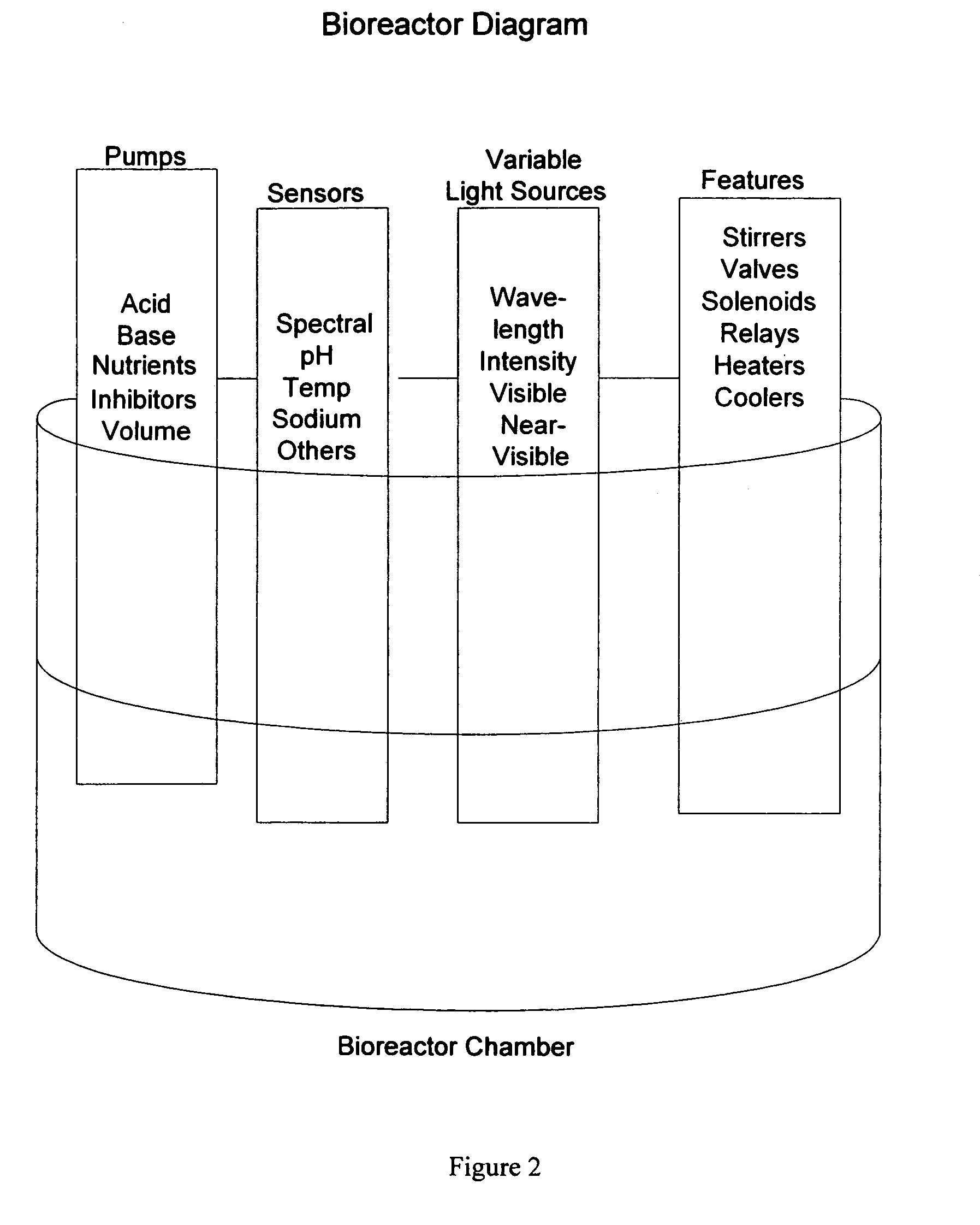

Decision-making spectral bioreactor

InactiveUS7510864B2Bioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteLaboratory scale

This invention fills several voids in bioreactor technology that allows efficient connection of aspects of physical science (optics, electronics, physical chemistry, sensors) to aspects of microbial and cell culture physiology in a uniquely interactive manner. This is accomplished mathematically through decision making software that utilizes detected changes in the course of fermentation. Decisions are aimed at determining the optima for cellular growth, optimizing for production or degradation of metabolites or substrates, or determining the limits of growth under various combinations of conditions. The invention determines optima or limits in a manner more quickly and at less cost than traditional methods. The basis for the computer generated decisions may be first or second derivative changes observed such as inflection points, limits on allowable rates of change, or the like. The most common measured parameter controlling the decision making process is the optically observed growth of the cells (e.g. microbial, animal, or plant cell cultures) under study. Any other measurable parameter (e.g. pH, temperature, pigment production) may be used to control the process (i.e., the independent variable). This process and variations of this process on a laboratory scale are valuable for research and development, education, pilot plant models, and bio-manufacturing optimization, including scale up to production volumes.

Owner:KRICHEVSKY MICAH I +4

Liquid fermentation method for producing natto kinase in high yield

InactiveCN101979531AIncrease productionReduce pollutionMicroorganism based processesEnzymesHydrolysateNitrogen source

The invention discloses a liquid fermentation method for producing natto kinase in high yield, which comprises a fermentation formula and fermentation conditions. In the method, a natto solid fermentation high-yield strain is selected and subjected to mutation and domestication so as to screen a high-yield strain of natto kinase; and the high-yield strain is inoculated into a liquid nutrient medium for fermentation, wherein the enzyme activity can reach 1,400IU / mL under liquid fermentation of a shake flask. Enzymatic hydrolysate of bean pulp is adopted as a nitrogen source of pilot plant test fermentation, and in a 10L fermentation tank, the fermentation unit can reach 2,650IU / mL. Due to the technical scheme, the yield of the prepared fermentation product natto kinase is high, the enzyme activity is high, the raw materials are saved, the energy is saved, the used raw materials are convenient to obtain and rich, the cost is low, and the extraction technology is easy and practicable.

Owner:HUBEI GOLE BIO TECH DEV

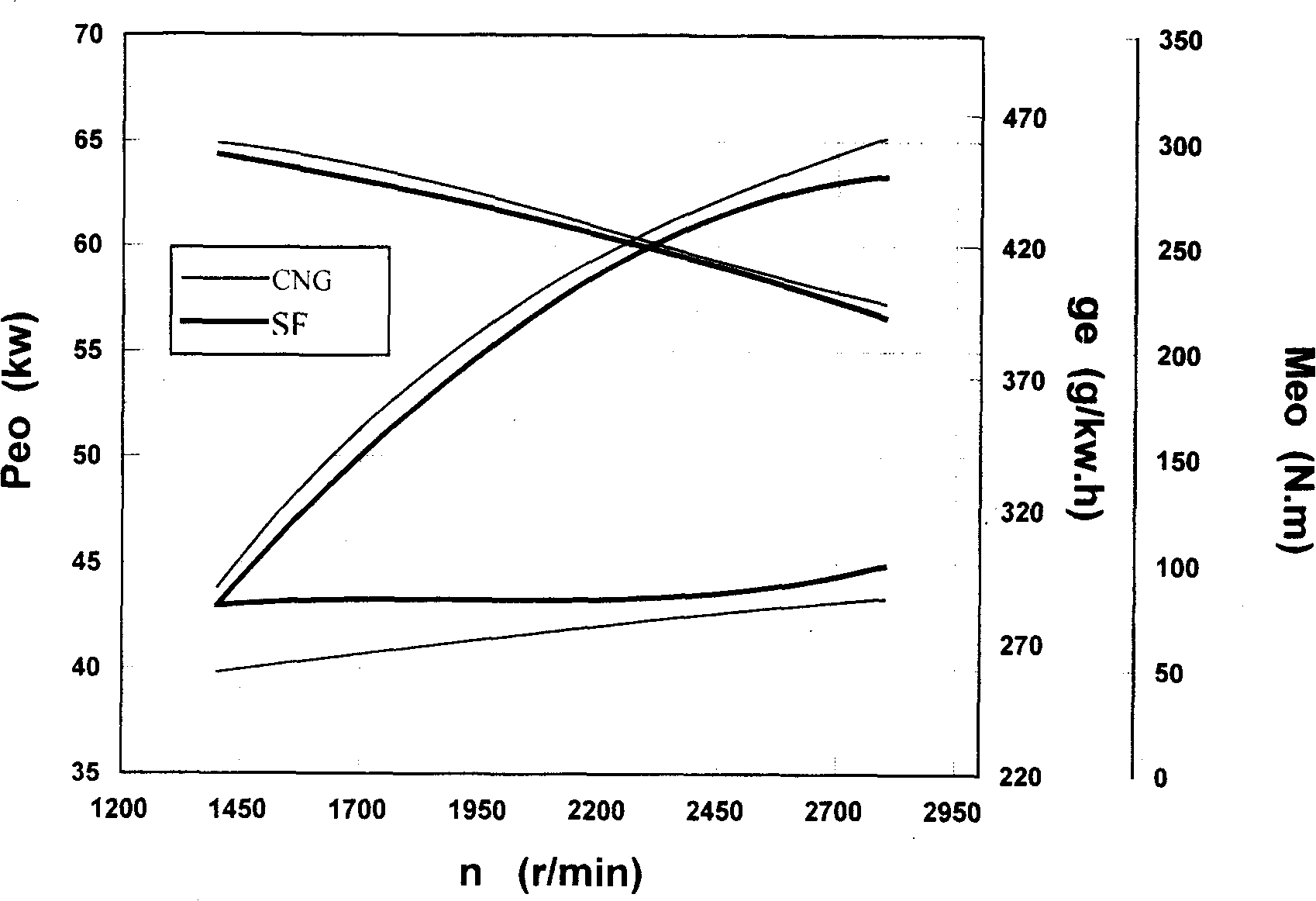

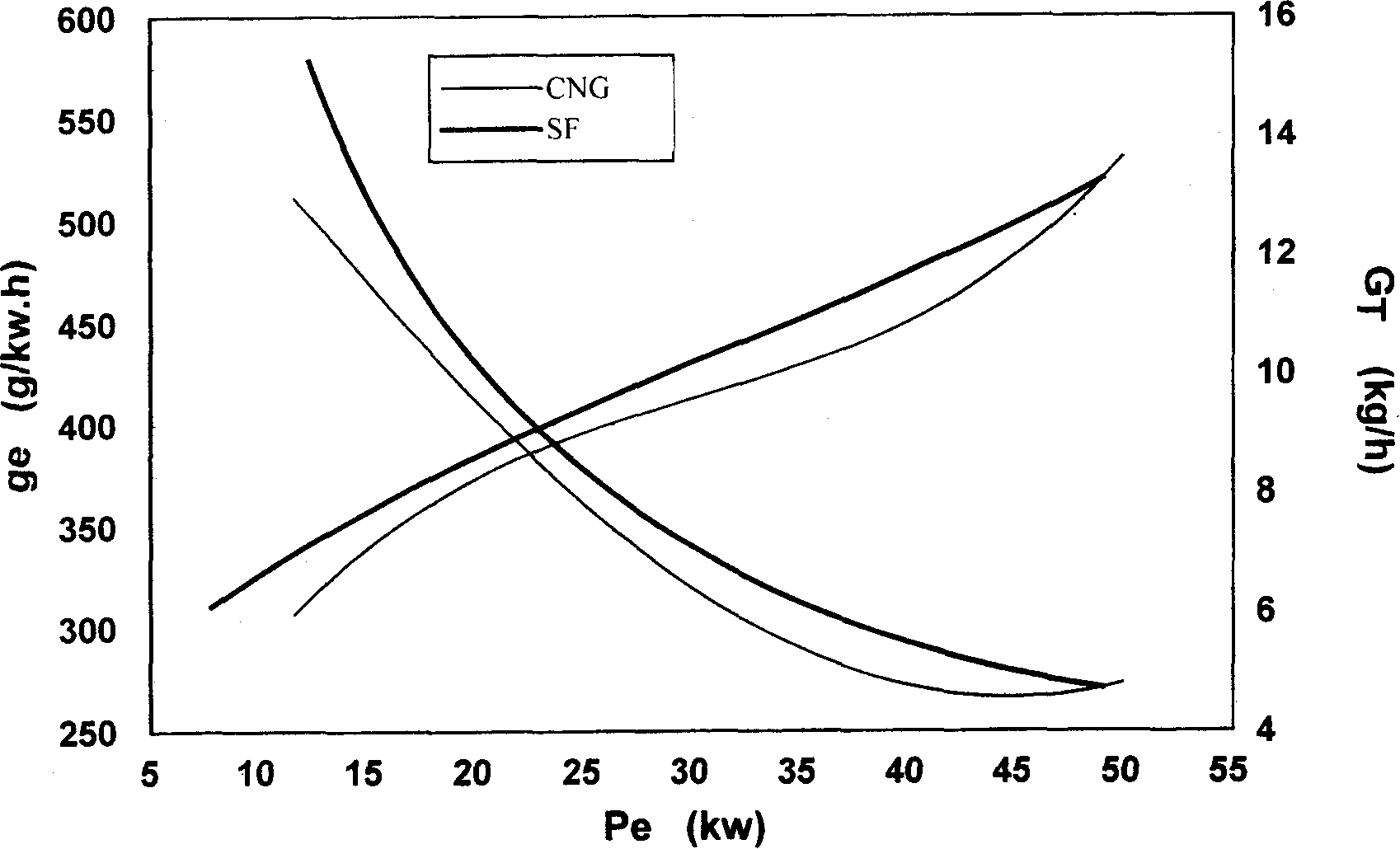

Lubricating oil for natural gas and gasoline dual purpose fuel engine

Owner:CHANGAN UNIV

Preparation method of nanometer zinc oxide composite dispersion liquid

InactiveCN103693674AGood dispersionUniform and stable dispersionMaterial nanotechnologyZinc oxides/hydroxidesZno nanoparticlesOxide composite

The invention discloses a preparation method of a nanometer zinc oxide composite dispersion liquid. The method is characterized by comprising the following steps: mixing an oil phase component and an emulsifier according to certain proportion in an oil phase system; adding a dispersion stabilizing agent, a surfactant and a nano zinc oxide powder according to a certain ratio into water in a water dispersion system; and respectively uniformly mixing the two phases and heating to a certain temperature, rapidly stirring the two phases for homogeneous mixing, and cooling to room temperature to form a stable emulsion dispersion system. The nanometer zinc oxide composite dispersion liquid prepared by the above method, the particle size difference of zinc oxide particle and nano zinc oxide powder raw material is within 20%; in the dispersion liquid, nano zinc oxide particles are suspended in the liquid in a monodispersed form; and placing for more than 60 days, the nano zinc oxide composite dispersion liquid does not generate the phenomena of layering, demulsification or caking. Moreover, the preparation method has the advantages of simple operation, wide adjustable range of parameters, low energy consumption and short cycle, and is suitable for pilot plant test amplification and industrial large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

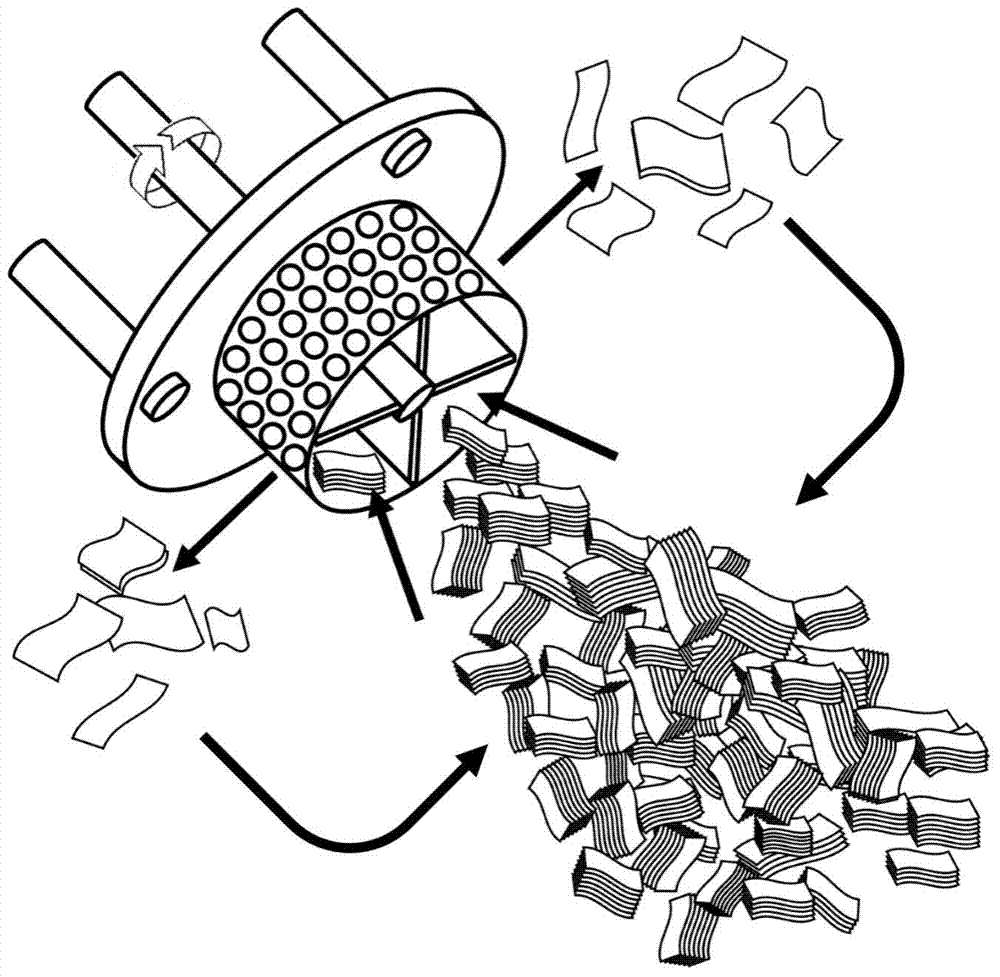

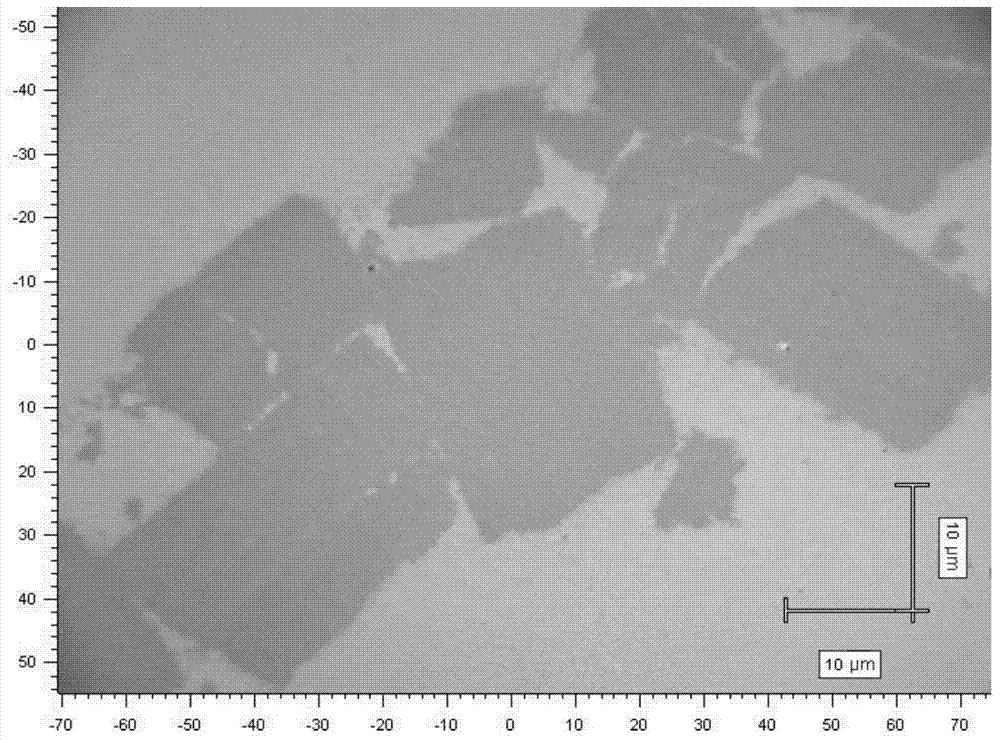

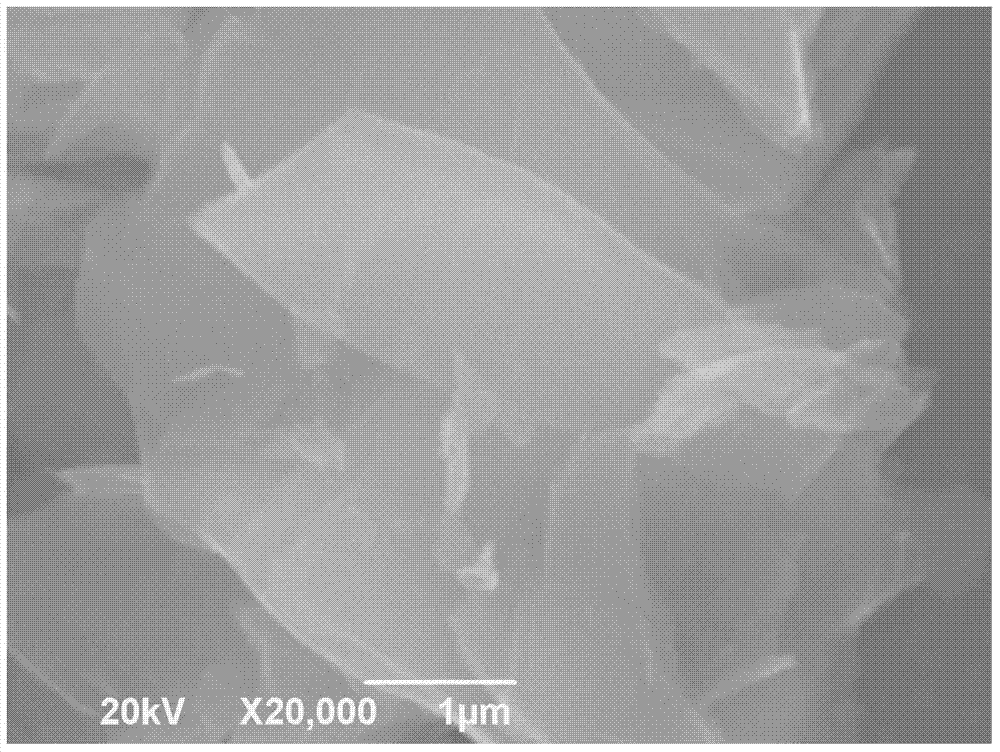

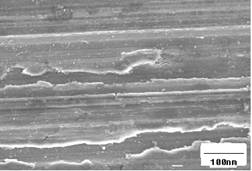

Preparation method of stratified molybdenum disulfide nano material

InactiveCN104495936AGood physical propertiesImprove stripping rateMaterial nanotechnologyMolybdenum sulfidesSolventDislocation

The invention provides a preparation method of a stratified molybdenum disulfide nano material. The preparation method comprises the following steps: adding molybdenum disulfide blocks to a container and adding a stripping solvent to prepare a molybdenum disulfide dispersion; performing hydraulic shearing treatment on molybdenum disulfide dispersion by use of a high-shear emulsifying machine; and centrifuging the hydraulically sheared molybdenum disulfide dispersion, filtering the centrifuged top suspension and drying in vacuum to obtain stratified molybdenum disulfide nanosheets. According to the preparation method of the stratified molybdenum disulfide nano material, the molybdenum disulfide blocks are under a strong combined action in a narrow gap between a stator and a rotor to arouse horizontal dislocation and slippage motion of crystal faces between the molybdenum disulfide layers, and therefore, the molybdenum disulfide is stripped, and finally, stable single-layer or few-layer molybdenum disulfide sheets are obtained; the preparation method is a pure physical method, and is simple in process, low in cost, small in danger, high in stripping ratio, green and environment-friendly; the prepared stratified molybdenum disulfide nanosheets are kept excellent in physical properties and suitable for large-scale industrial production after a pilot plant test.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

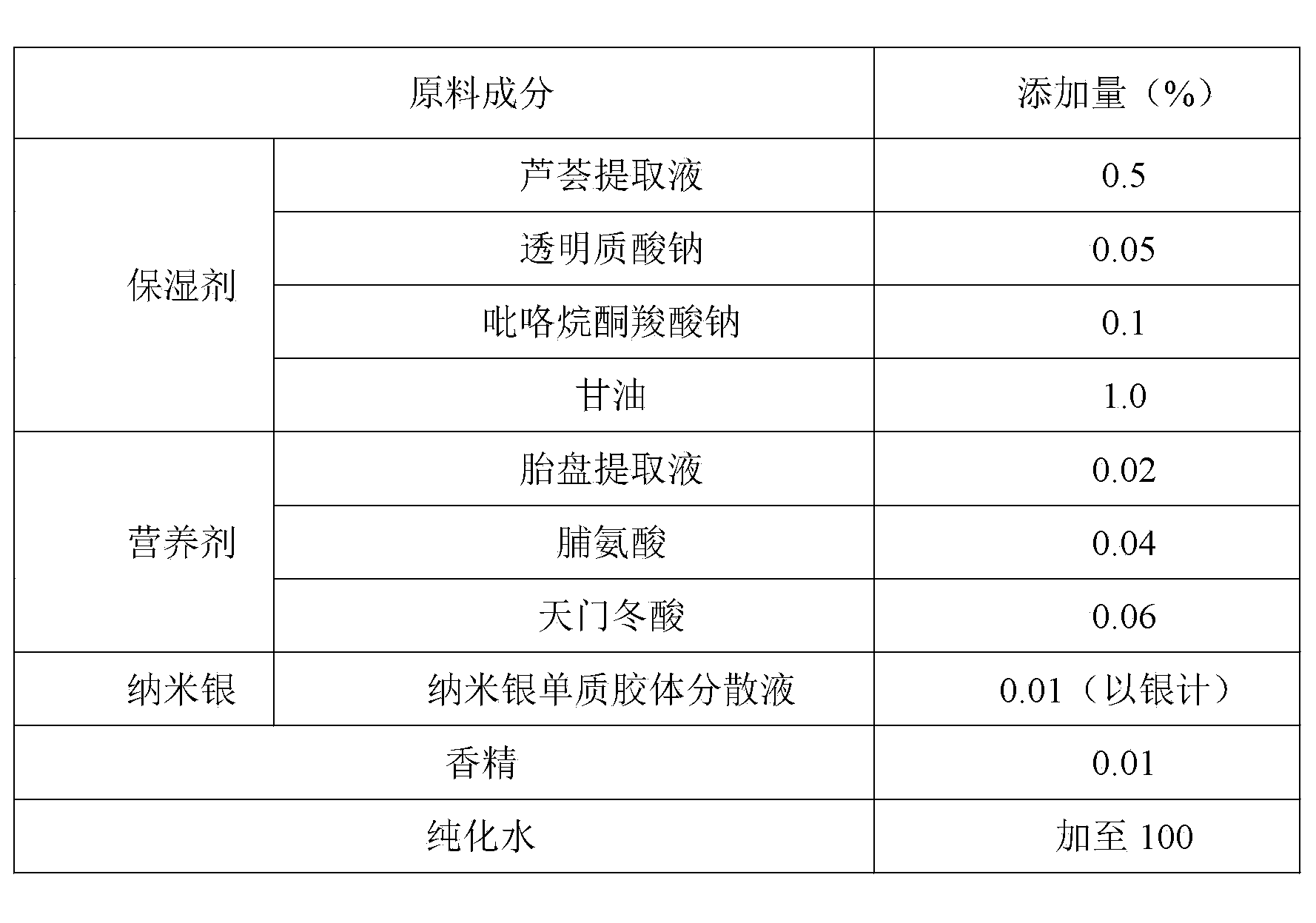

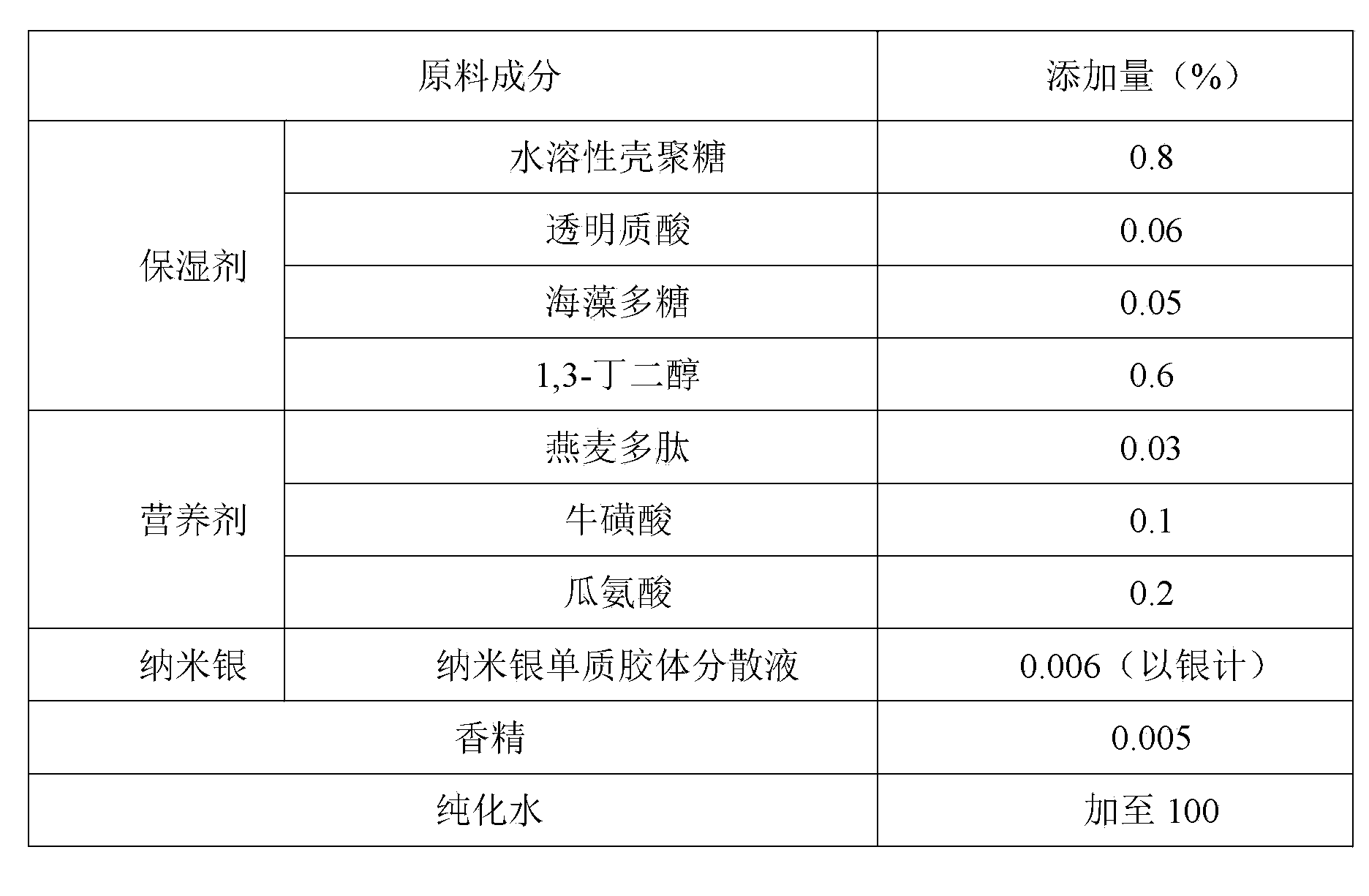

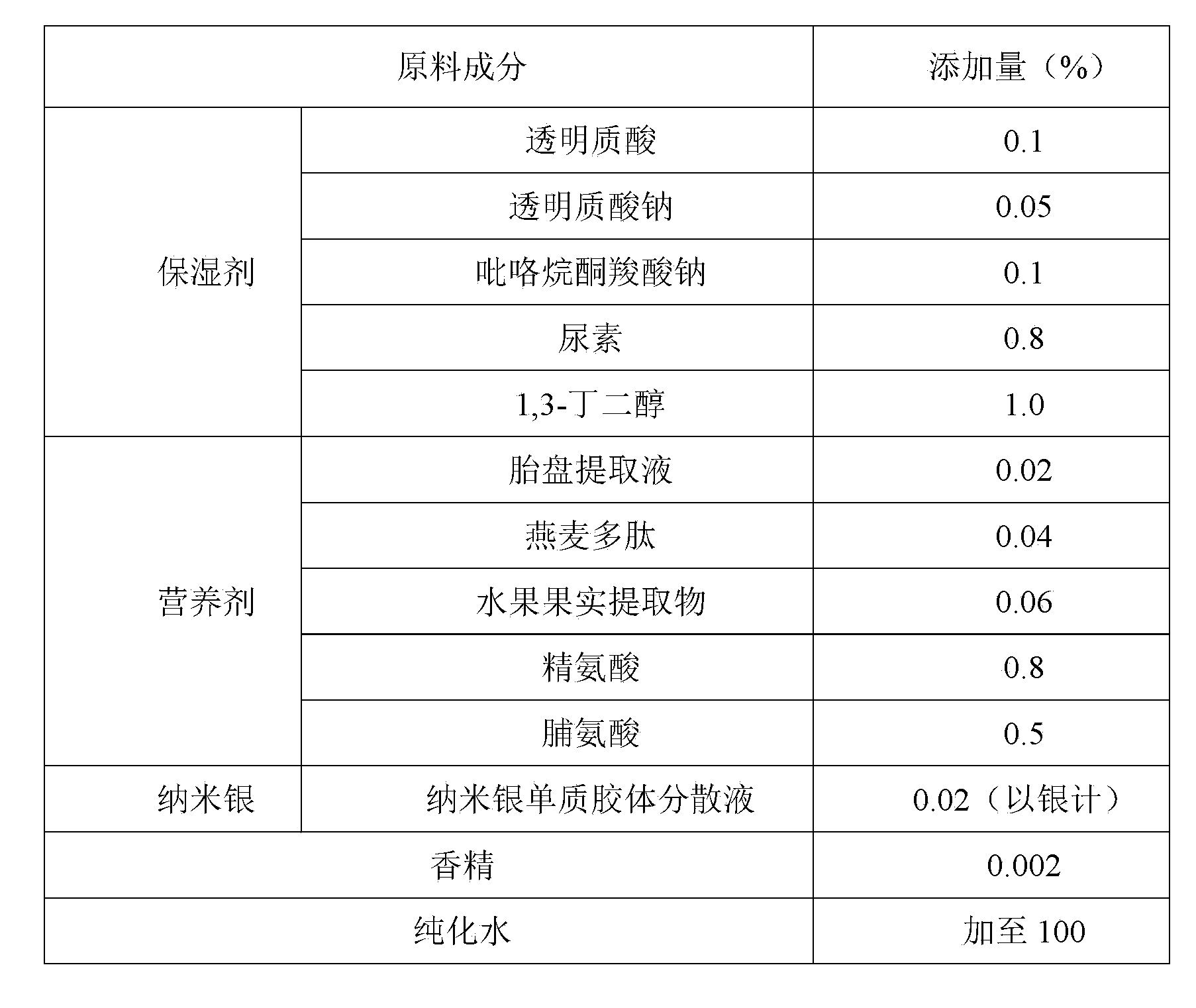

Nano-silver antibacterial moisture-preserving skin refreshing toner

InactiveCN103565709AGood antibacterial effectImprove the bactericidal effectCosmetic preparationsToilet preparationsWrinkly skinPreservative

The invention discloses a nano-silver antibacterial moisture-preserving skin refreshing toner. The skin refreshing toner is characterized in that the skin refreshing toner comprises following components by weight: 0.2-10% of a moisture-preserving agent, 0.1-3% of a nutritional agent, 0.0005-0.1% of nano-silver and 0.001-0.1% of an essence, the balance being water. The skin refreshing toner is free from organic preservatives and uses the nano-silver as an anticorrosion antibacterial agent. The nano-silver not only has an anticorrosion function to the product, but also has a function of antisepsis and anti-inflammation and a function of accelerating restoration of damaged skin. In addition, the skin refreshing toner is colorless and transparent, strongly stable, mild, fresh, and nonirritating. The skin refreshing toner has a perfect moisture preserving function, can replenishing skin with water rapidly, and also has functions of weakening skin winkles, enhancing skin elasticity, removing skin toxin, and activating skin. A preparation method has characteristics of simple operation, wide parameter adjustable range, low energy consumption, short period, and the like, and is particularly suitable for pilot plant test amplification and industrialized large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

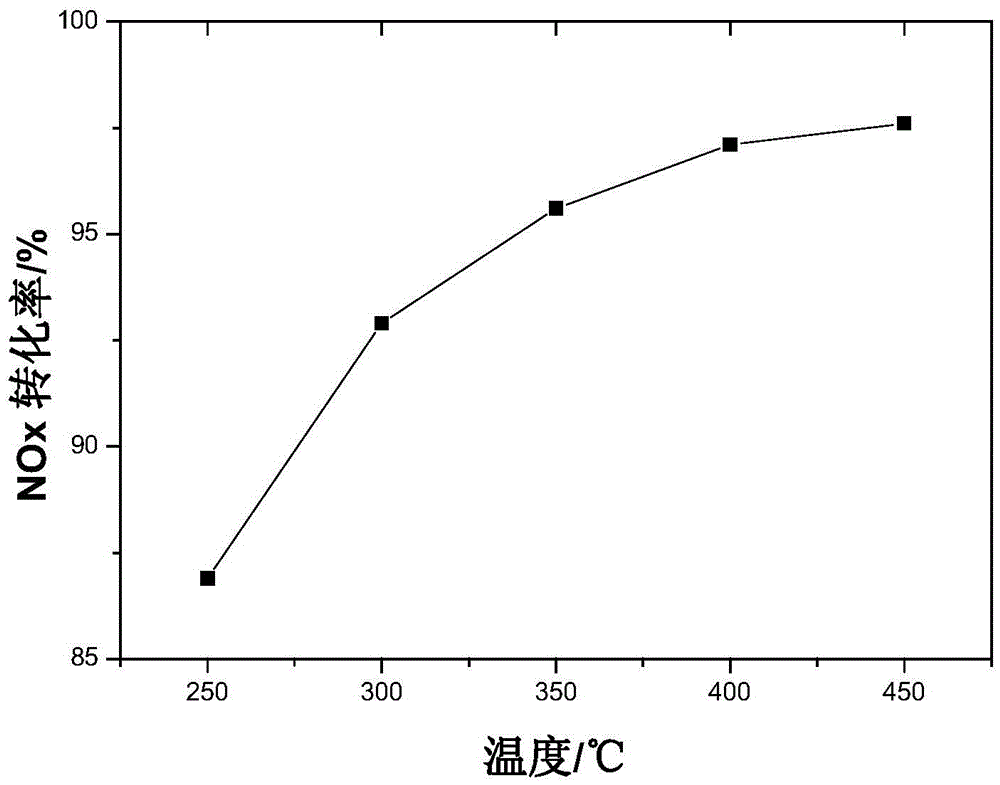

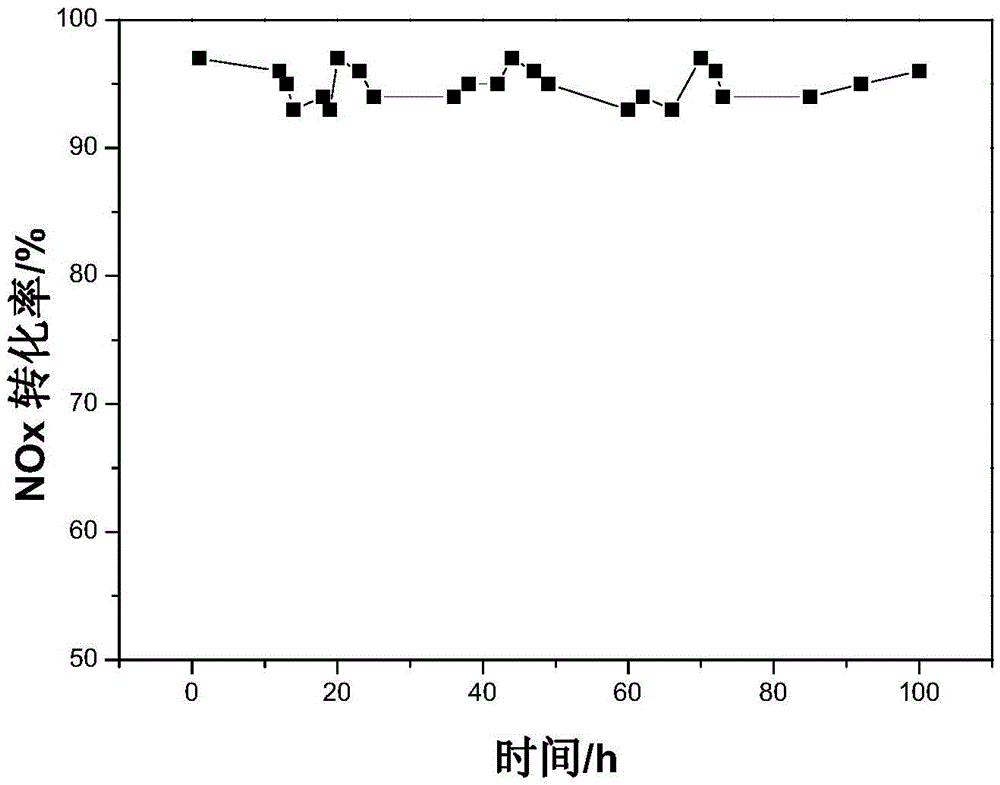

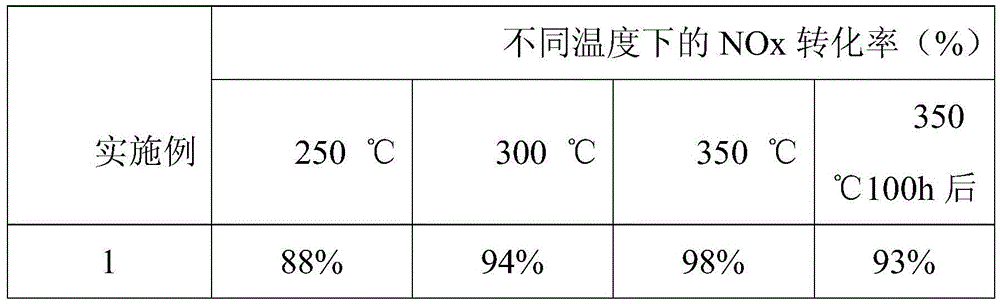

Honeycomb vanadium series denitration preformed catalyst, and preparation method and use thereof

ActiveCN105597730AExcellent resistance to SO <sub>2<</sub> Excellent sub>Dispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention relates to a high-water resistance and high-sulfur resistance honeycomb vanadium series denitration preformed catalyst suitable for FCC flue gas, and a preparation method and a use thereof, and belongs to the technical fields of environment catalysis and environment protection. The preparation method comprises the following steps: preparing catalyst powder through adopting a volume immersion technology with anatase titanium dioxide as a carrier, V2O5 as an active component and WO3 as an active assistant, and adding a forming assistant to prepare the honeycomb preformed catalyst with wide active temperature window, strong water resistance and strong sulfur resistance. The forming assistant mainly comprises a reinforcing agent, an inorganic binder, an organic binder, a pore forming agent and a lubricant. Pilot plant test of the preformed catalyst in a small FCC apparatus shows that the denitration efficiency of the catalyst under an air speed of 4000h<-1>, an NO concentration of 1000ppm, an SO2 concentration of 1500ppm and an H2O content of 5% is 85% or above at 250-450DEG C and reaches 90% or above at 300-450DEG C.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

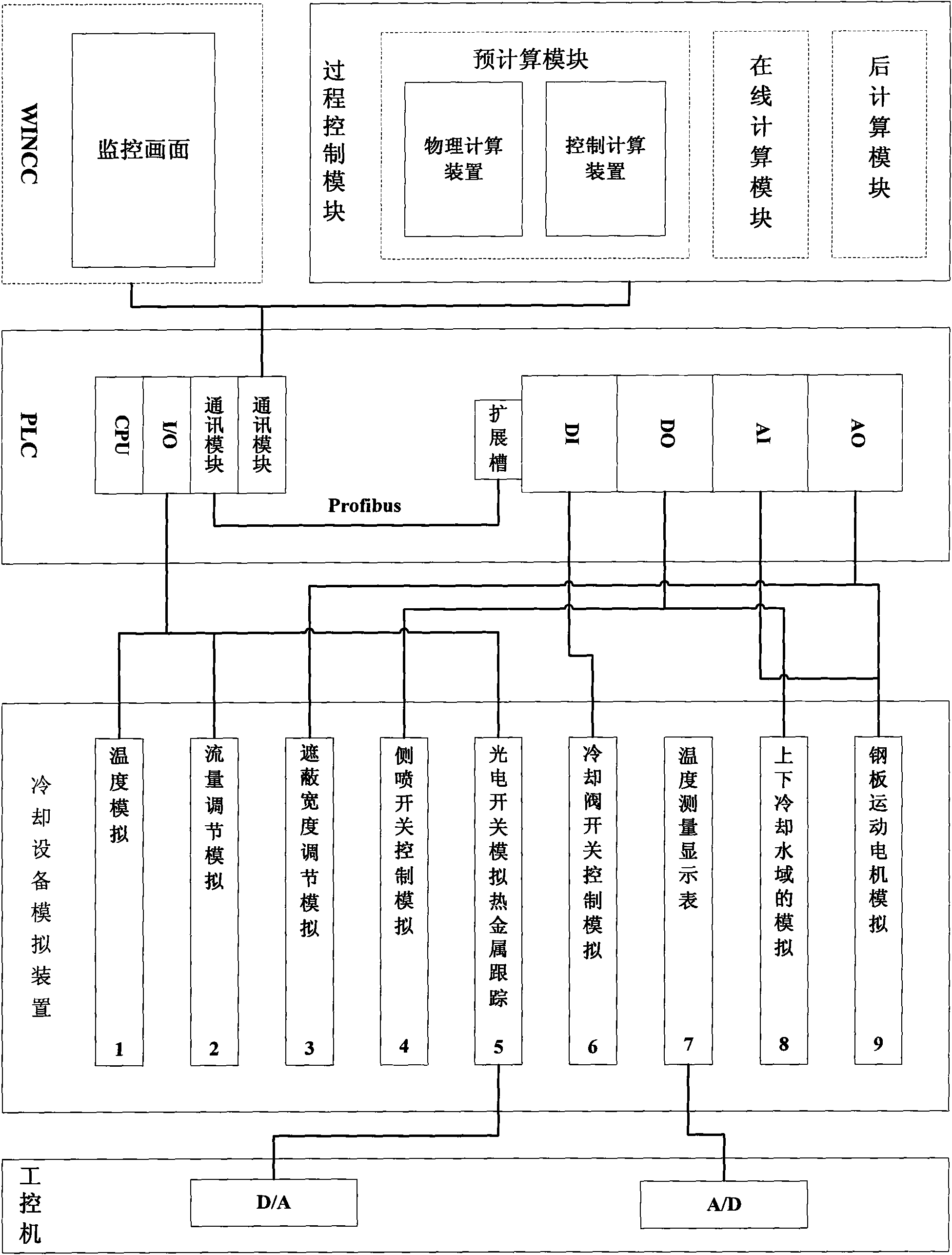

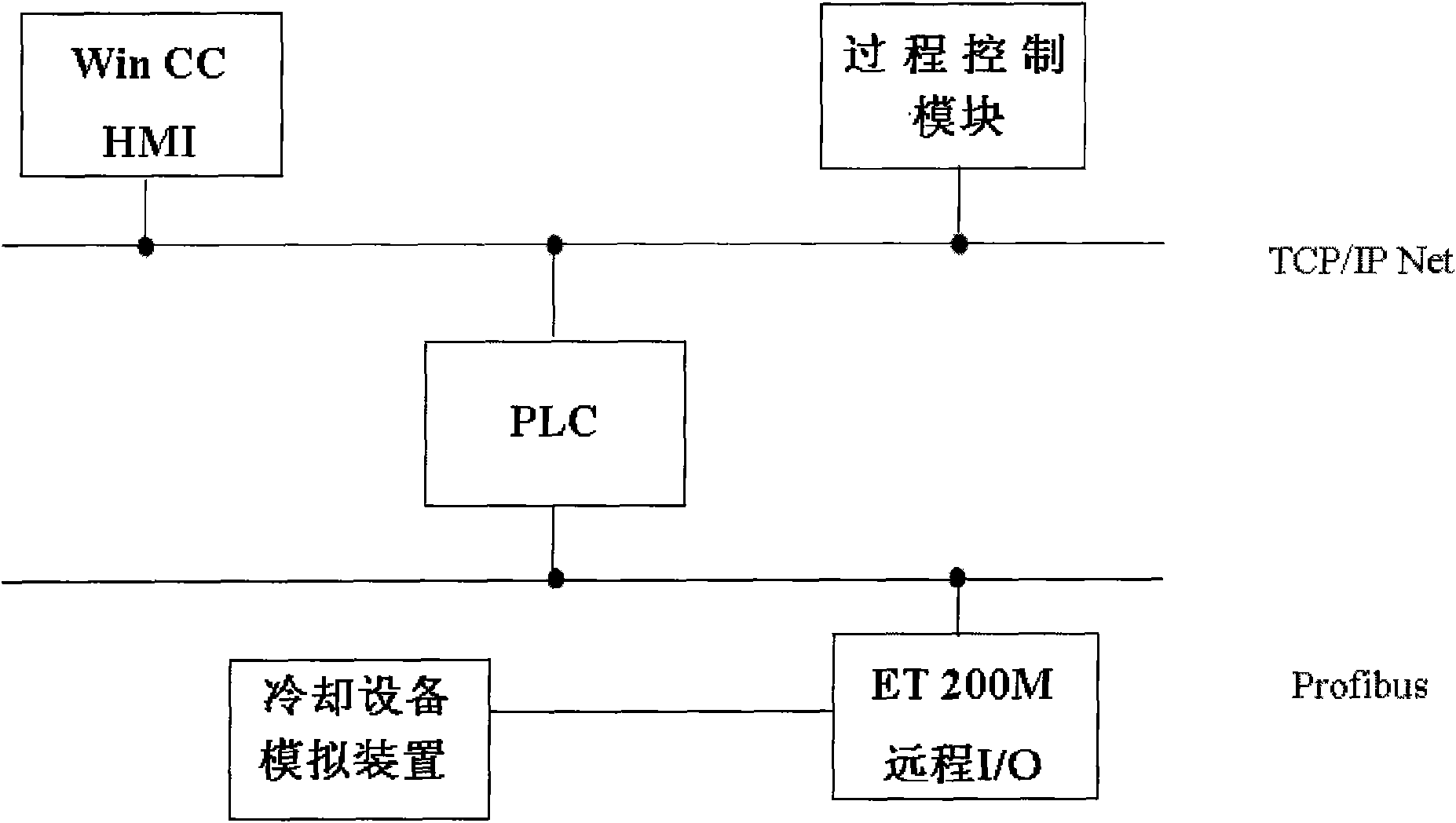

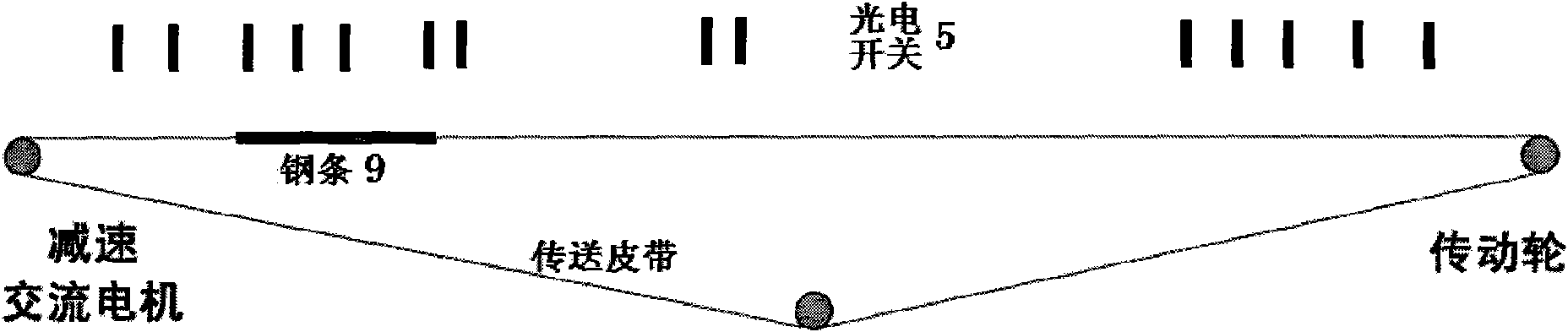

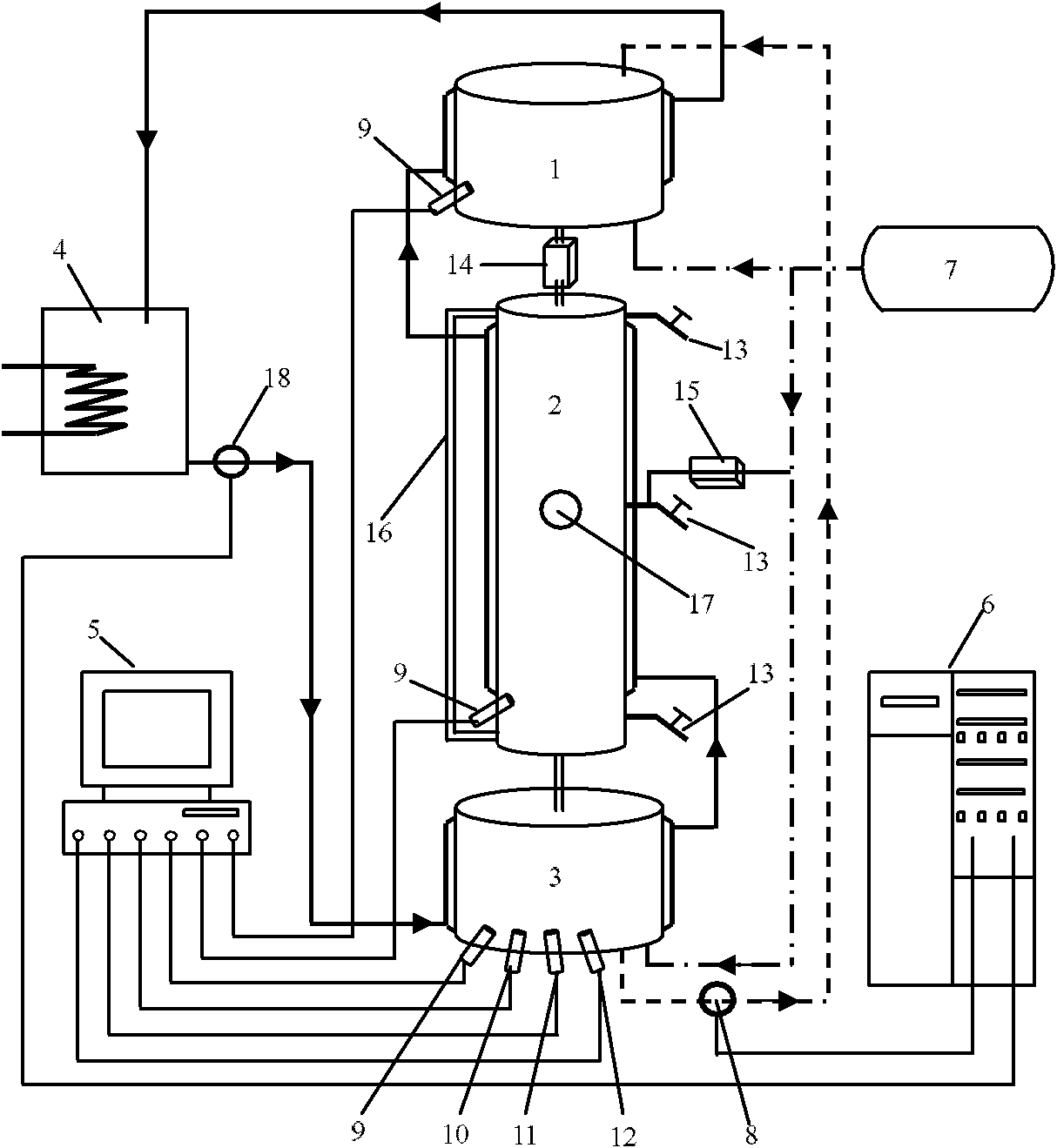

Method for simulating steel board cooling control

ActiveCN101639691ARealize closed-loop controlMeet the mechanical propertiesWork treatment devicesTotal factory controlProcess systemsControl system

The invention discloses a method for simulating steel board cooling control. A process control device is connected with a cooling apparatus simulating device by a PLC. The cooling apparatus simulatingdevice comprises a transmission device on which a steel bar is fixed, a cooling process temperature calculating device for simulating temperature measurement, a polling display instrument for displaying temperature, an electric potentiometer, a photoelectric switch and a position indicator. The photoelectric switch is arranged on a movement path of the steel bar. The process control device accomplishes the optimum setting of PLC control amount. The PLC accomplishes real-time control of a cooling simulating process. The cooling apparatus simulating device actually opens or closes and adjusts asimulating cooling line and realizes real-time data acquisition. Through the hardware mutual connection and software cooperation of the devices, the simulation on a cooling control process system isaccomplished. The invention provides a pilot plant test device of simulation evaluation for the improvement and completion of the control system.

Owner:BAOSHAN IRON & STEEL CO LTD

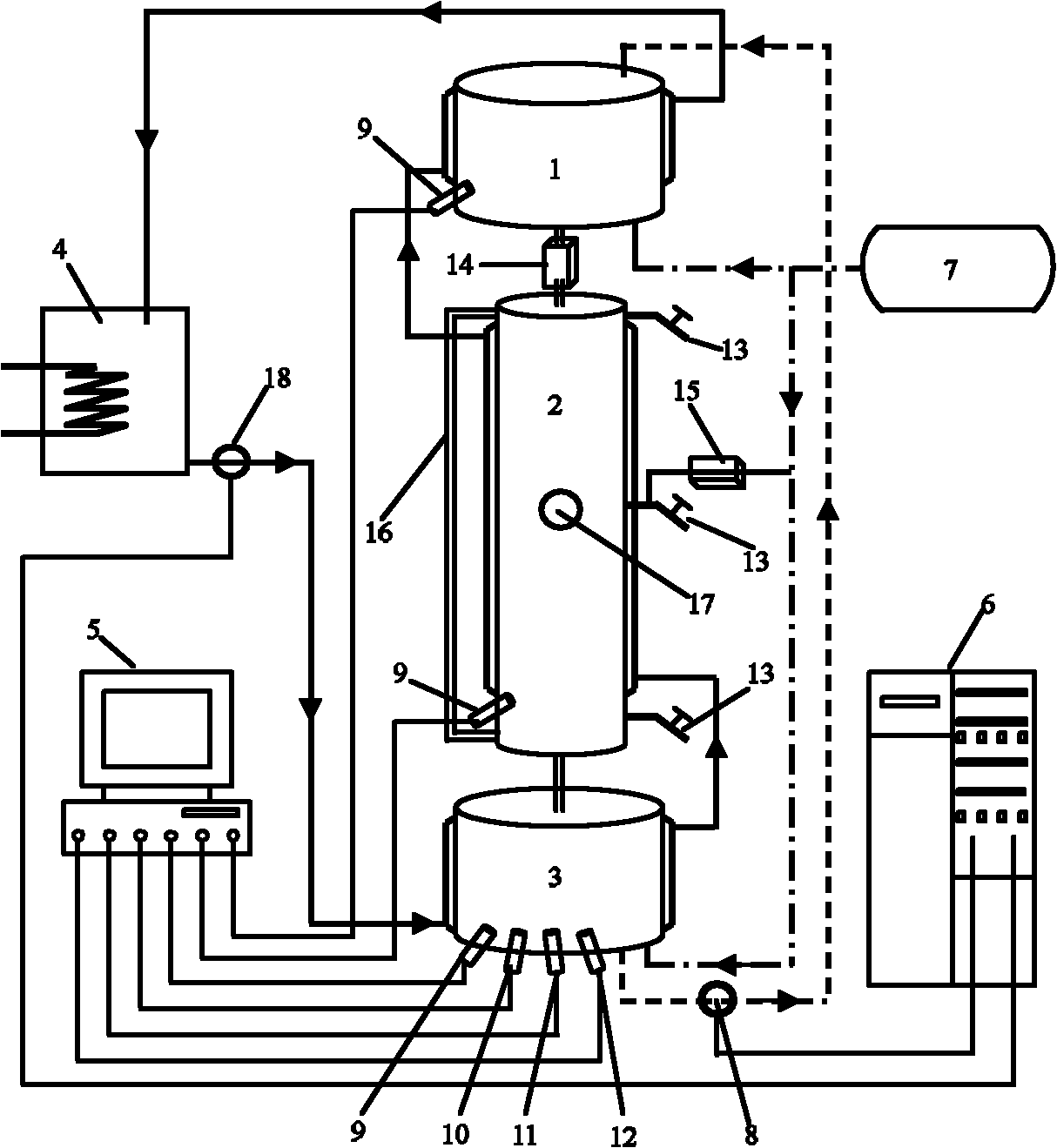

Multifunctional automatic control column leaching experimental facility

InactiveCN102253099AMonitor temperatureMonitor pHMaterial analysis by electric/magnetic meansAutomatic controlSolenoid valve

The invention discloses a multifunctional automatic control column leaching experimental facility, belonging to the field of leaching mining. The experimental facility mainly comprises a liquid circulation system, a water circulation system, an air circulation system, an automatic control system and a data collection system. The liquid circulation system is composed of a reaction column, a high-level tank and a liquid receiving tank; the water circulation system is composed of a hot water tank, a solenoid valve, a liquid receiving tank jacket, a reaction column jacket and a high-level tank jacket; the air circulation system is composed of an air compressor, an air flowmeter and a control valve; the automatic control system is used for automatically regulating and controlling the temperature of the leaching system, oxygen solubility and solution flowing; the data collection system can be used for automatically collecting and storing the solution pH value, the oxygen solubility, electric potential, the temperature and other parameters in real time. The experimental facility can be used for performing indoor simulation experiments and semi-industrial scale pilot plant experiments according to heap-leaching field conditions and actual size of mineral particles, effectively simulating the multiphase and multilevel seepage state of ore bulk and a microbiological leaching and biochemical process, and providing basic data for heap-leaching production practice and technological parameter optimization.

Owner:UNIV OF SCI & TECH BEIJING

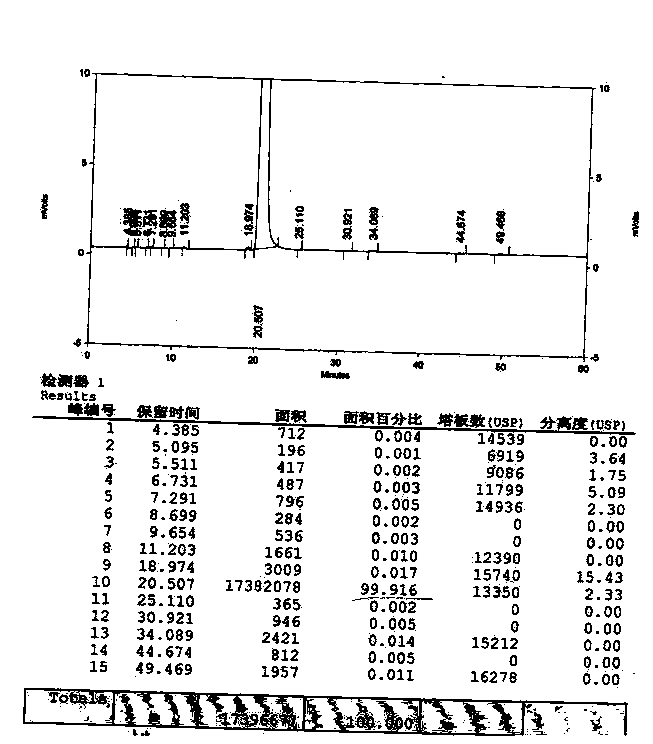

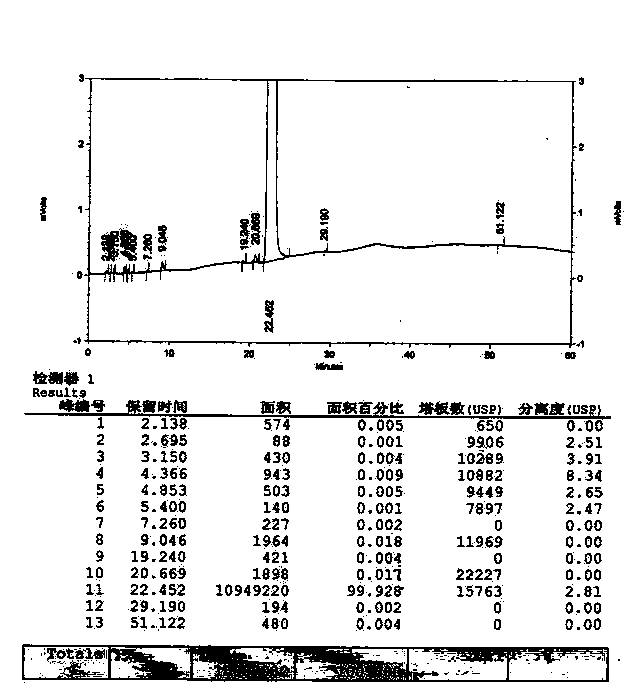

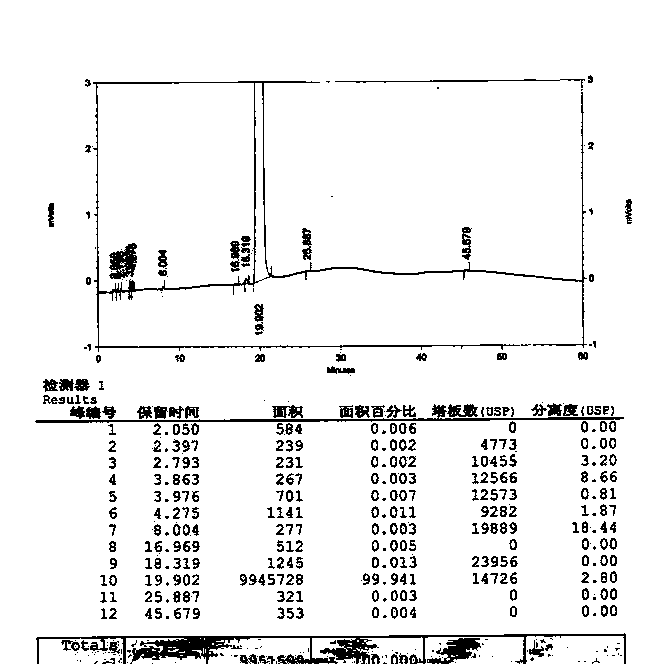

Preparation method of N(2)-L-alanyl-L-glutamine

ActiveCN103626839APrice stabilityMarket sales trend ups and downsPeptide preparation methodsL-alanyl-l-glutamineChloride

The invention belongs to the technical field of medicines, and particularly relates to a preparation method of N(2)-L-alanyl-L-glutamine. The preparation method of the N(2)-L-alanyl-L-glutamine comprises the following steps of (1) preparing L-phthaloyl-alanyl chloride; (2) preparing phthaloyl-L-alanyl-L-glutamic acid; (3) preparing phthaloyl-L-alanyl-L-glutamic acid anhydride; (4) preparing phthaloyl-L-alanyl-L-glutamine; (5) preparing an N(2)-L-alanyl-L-glutamine crude product; (6) preparing an N(2)-L-alanyl-L-glutamine refined product. The product obtained through the final deprotection process of the preparation method as a pilot plant test or a production scale process route is higher in purity; the liquid-phase purity of the product is higher than 99.9% through primary purification, and the product is low in impurity content.

Owner:JINAN CHENGHUI SHUANGDA CHEM

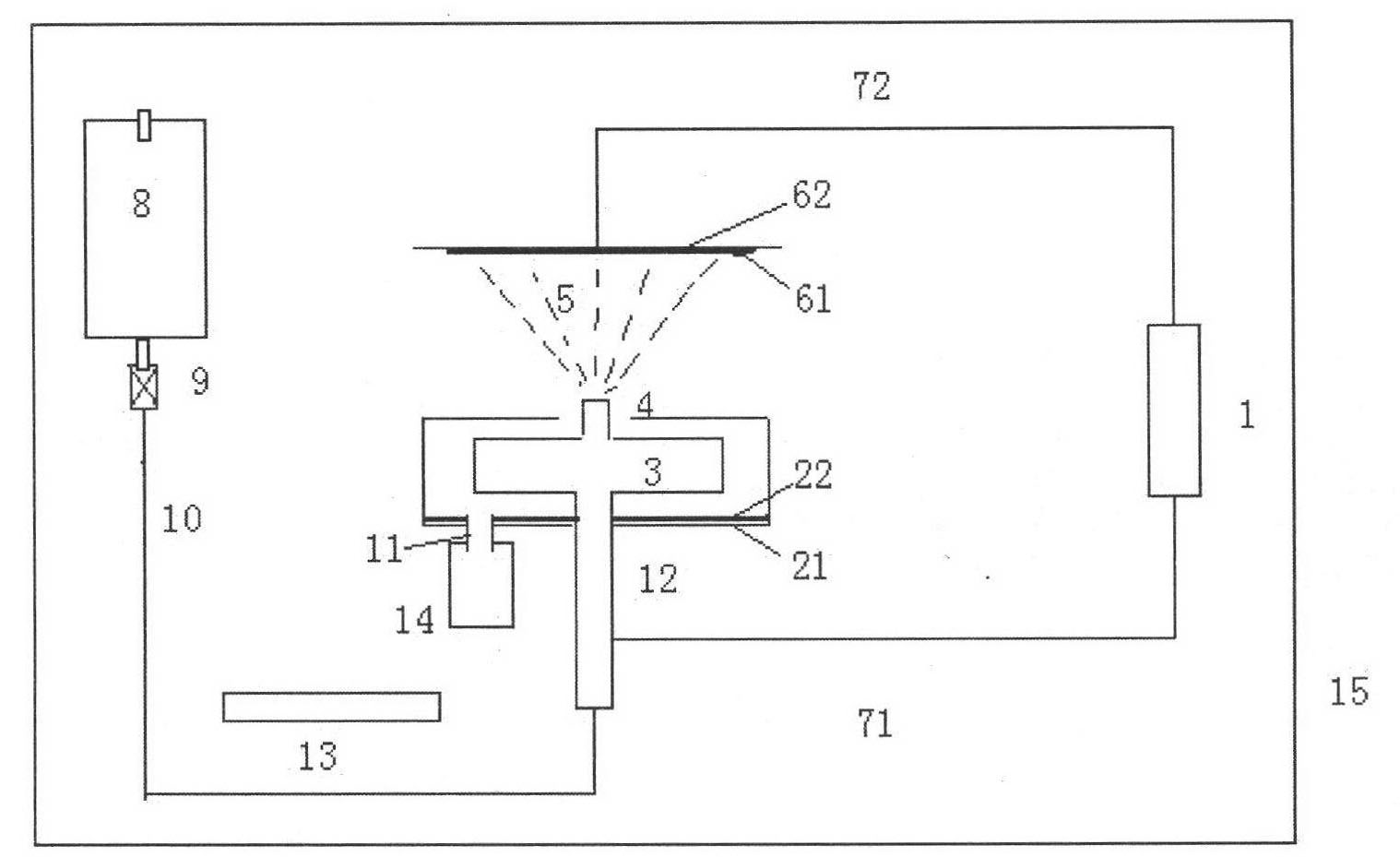

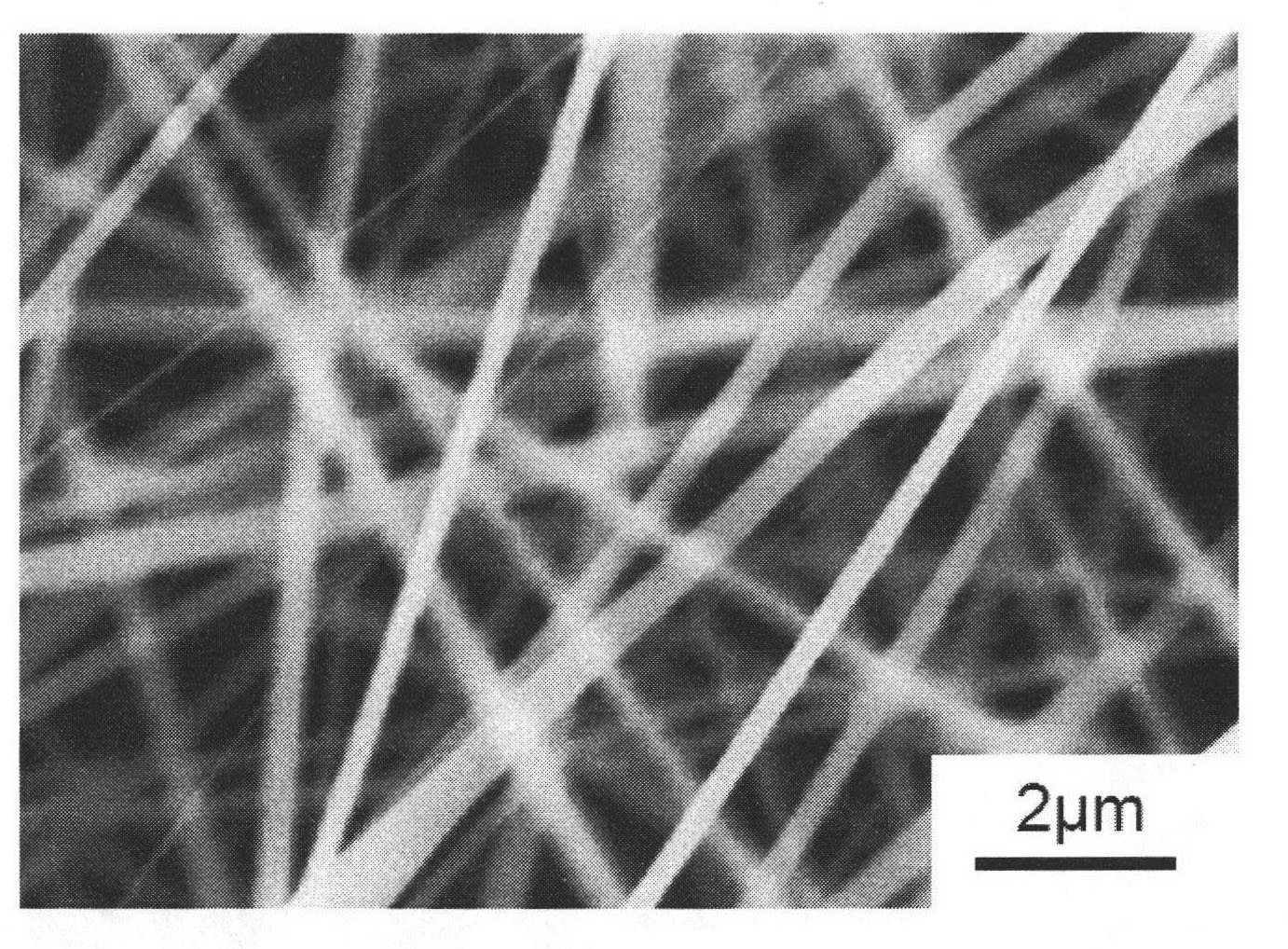

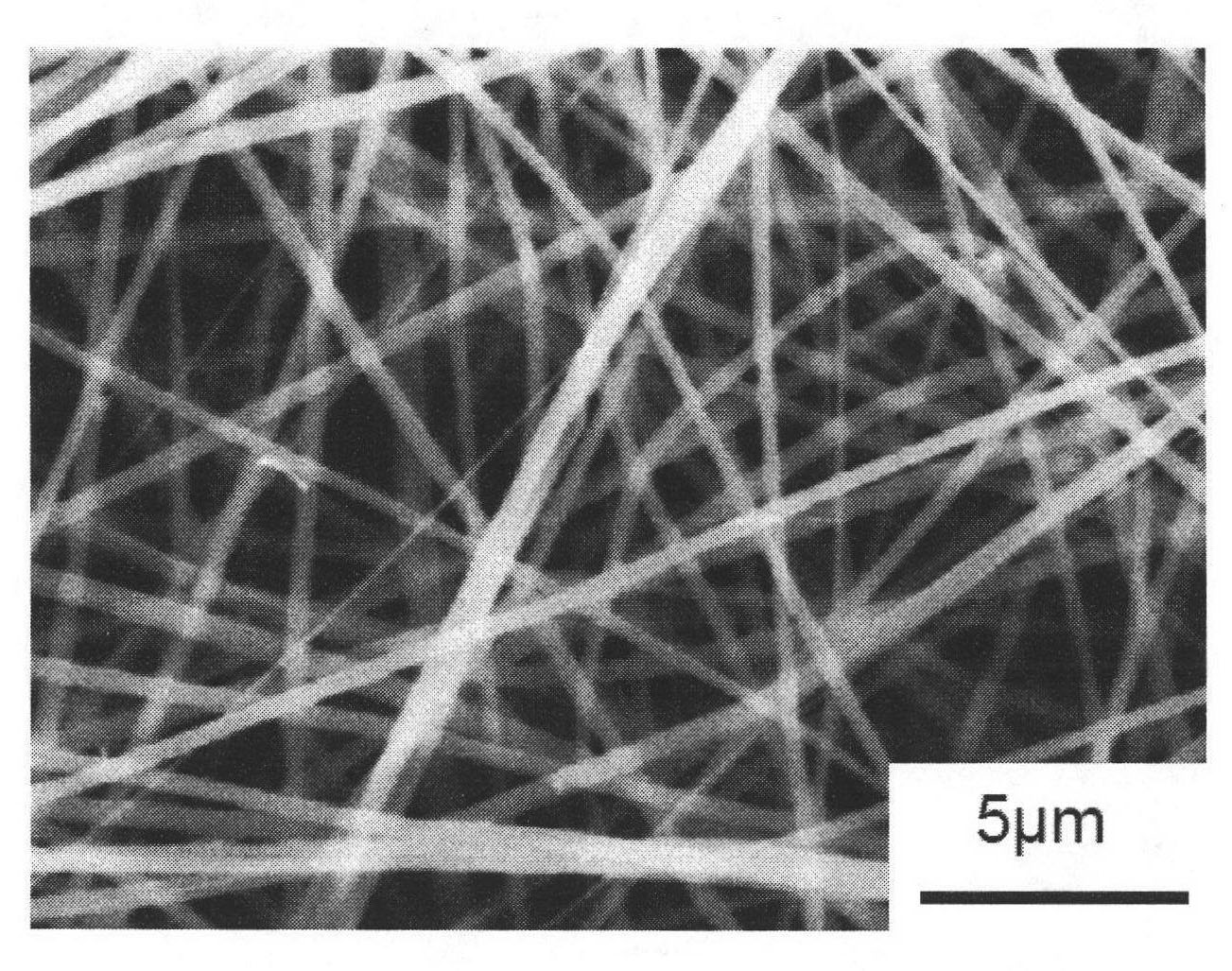

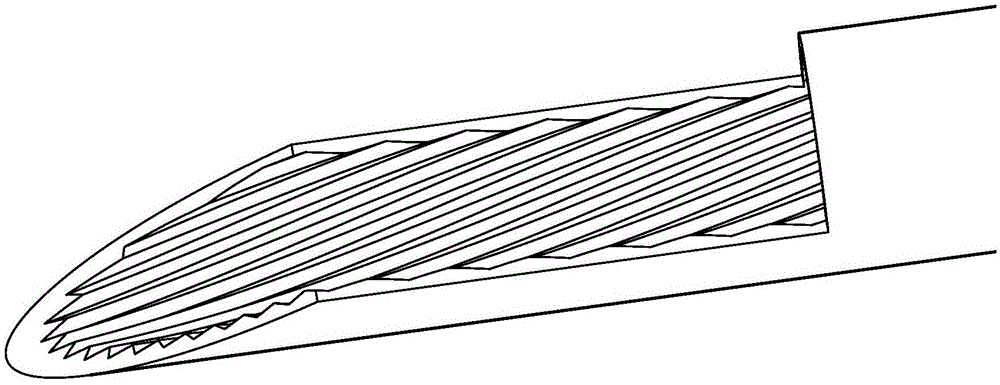

High-voltage electrostatic shuttle nano spinning device

ActiveCN102071484AIncrease the number ofIncrease productivityArtificial thread manufacturing machinesFilament/thread formingBobbinDifferential pressure

The invention relates to a high-voltage electrostatic shuttle nano spinning device, which consists of a box, a storage tank, a valve, an electrostatic shuttle, a supply pipe, a return pipe, an overflow material recycling tank, an electric thermostat, a metal bracket, a receiving device, a receiving substrate and a high-voltage electrostatic generator, wherein the electrostatic shuttle comprises a shuttle sleeve and a shuttle core; and the shuttle core consists of a liquid storage cavity, an electrostatic shuttle mouth and a metal high-voltage electrode. The electrostatic shuttle is arranged, so that an enclosed spinning system is formed and a solvent is prevented from volatilizing; in the presence of the electric thermostat, the system is not influenced by the environment (temperature / humidity); the size of the shutter core and voltage can be adjusted, so that the diameter of nanofiber is adjustable and the breadth of a non-woven fabric can be selected optionally; moreover, due to the adoption of differential-pressure material supply and insert assembly, the electrostatic shutter mouth spinning device has the advantages of low energy consumption, low cost and environmental friendliness, is easy to clean, is safe and reliable, is easy and convenient to operate, and the like. A plurality of electrostatic shuttle mouths are connected in series and in parallel. The high-voltage electrostatic shuttle nano spinning device can be applied to laboratories, pilot plant tests and industrial production.

Owner:盐城大数据资产经营管理有限公司

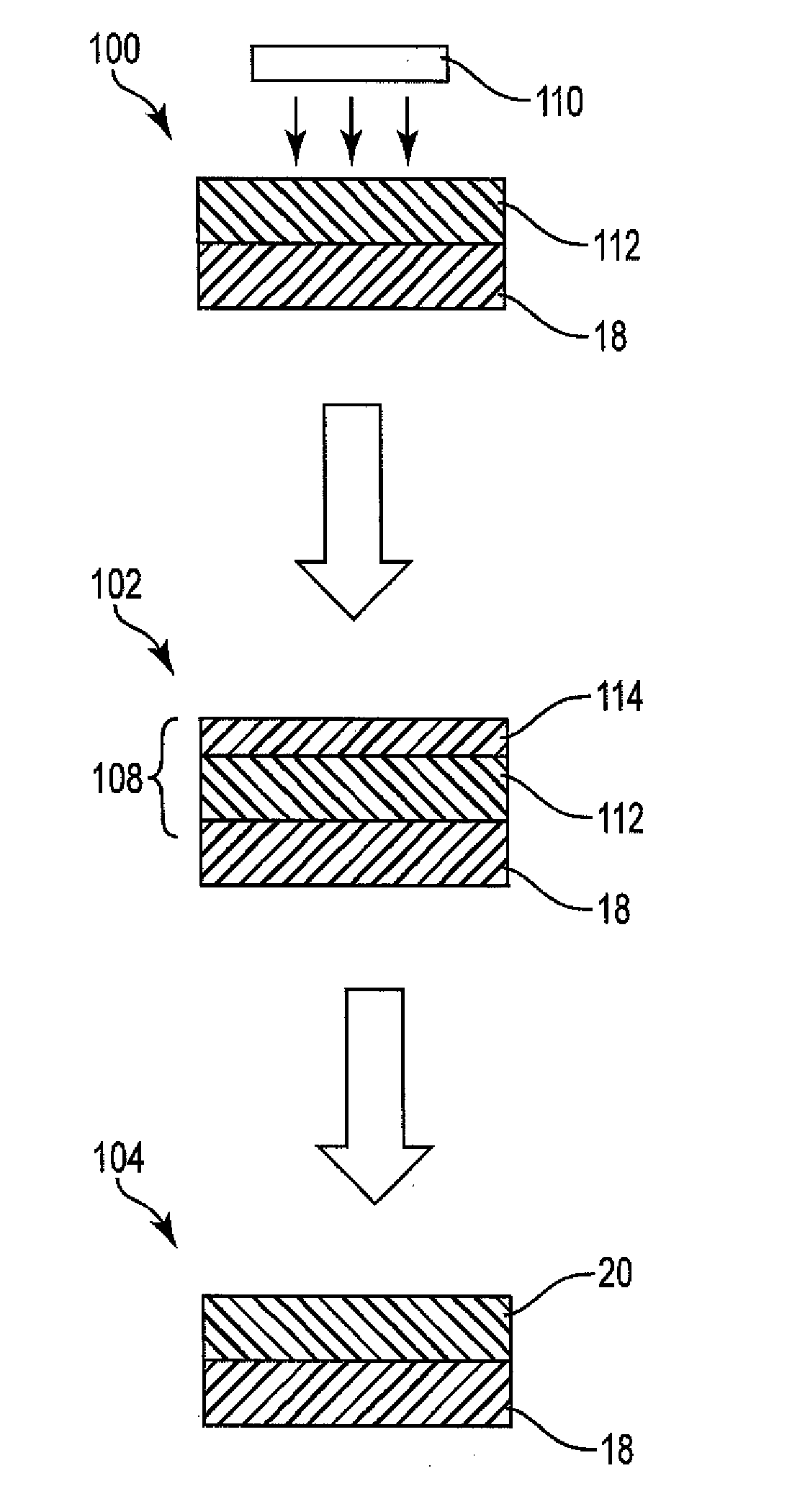

Chalcogenide-based materials and methods of making such materials under vacuum using post-chalcogenization techniques

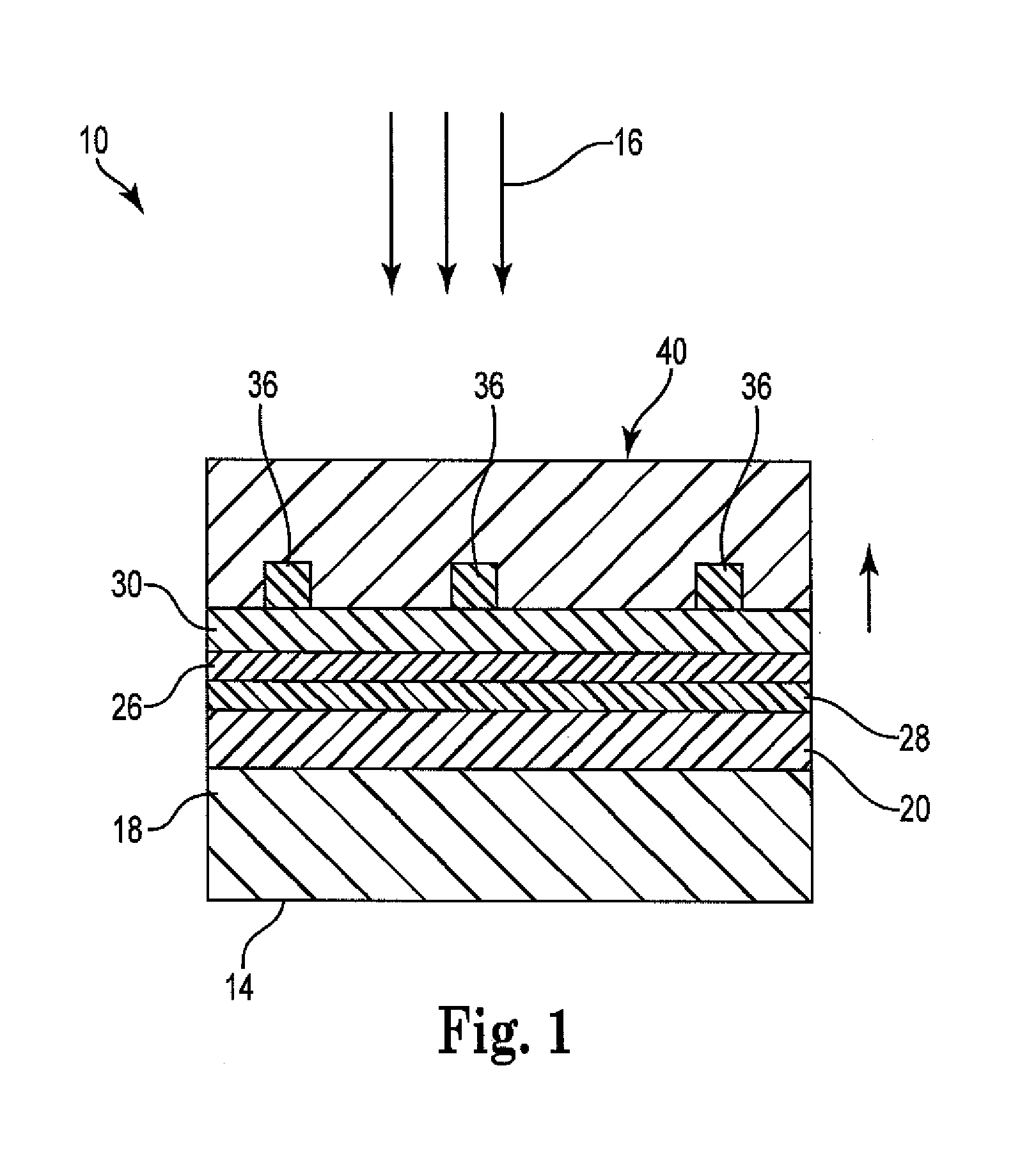

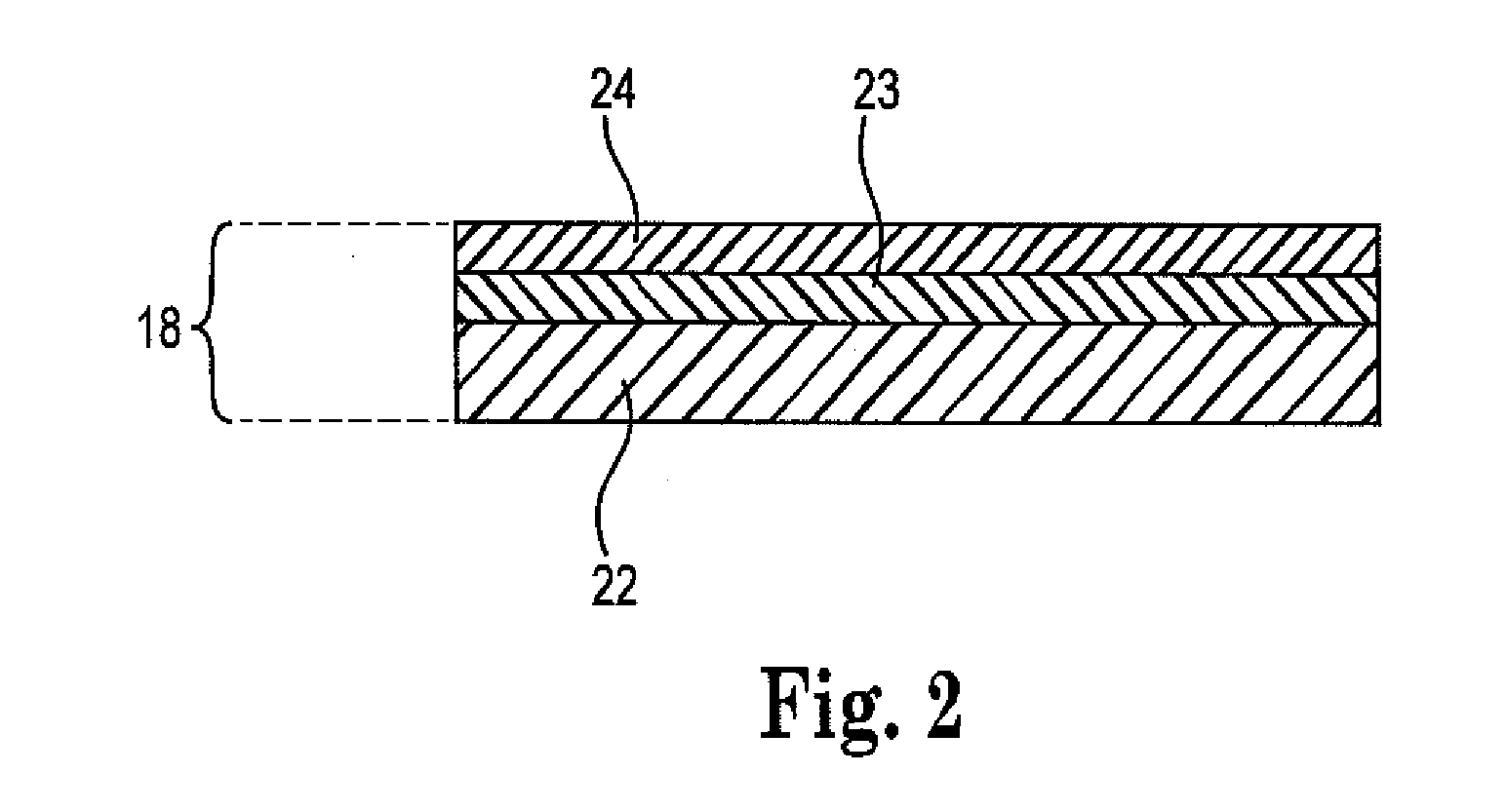

InactiveUS20110284134A1Quality improvementVacuum evaporation coatingSputtering coatingEngineeringChalcogen

The present invention provides strategies for making high quality CIGS photoabsorbing compositions from sputtered precursor film(s). The precursors are converted into CIGS photoabsorbing material via a chalcogenizing treatment (also referred to as “post-chalcogenization,” including, e.g., “post-selenization” when Se is used and / or “post-sulfurization” when S is used) using techniques that allow the post-chalcogenizing treatment to occur under atypically low pressure conditions. Consequently, the strategies of the invention are readily incorporated into batch processes or continuous processes such as roll-to-roll process occurring under vacuum. The present invention is useful at lab, pilot plant, and industrial scales.

Owner:DOW GLOBAL TECH LLC

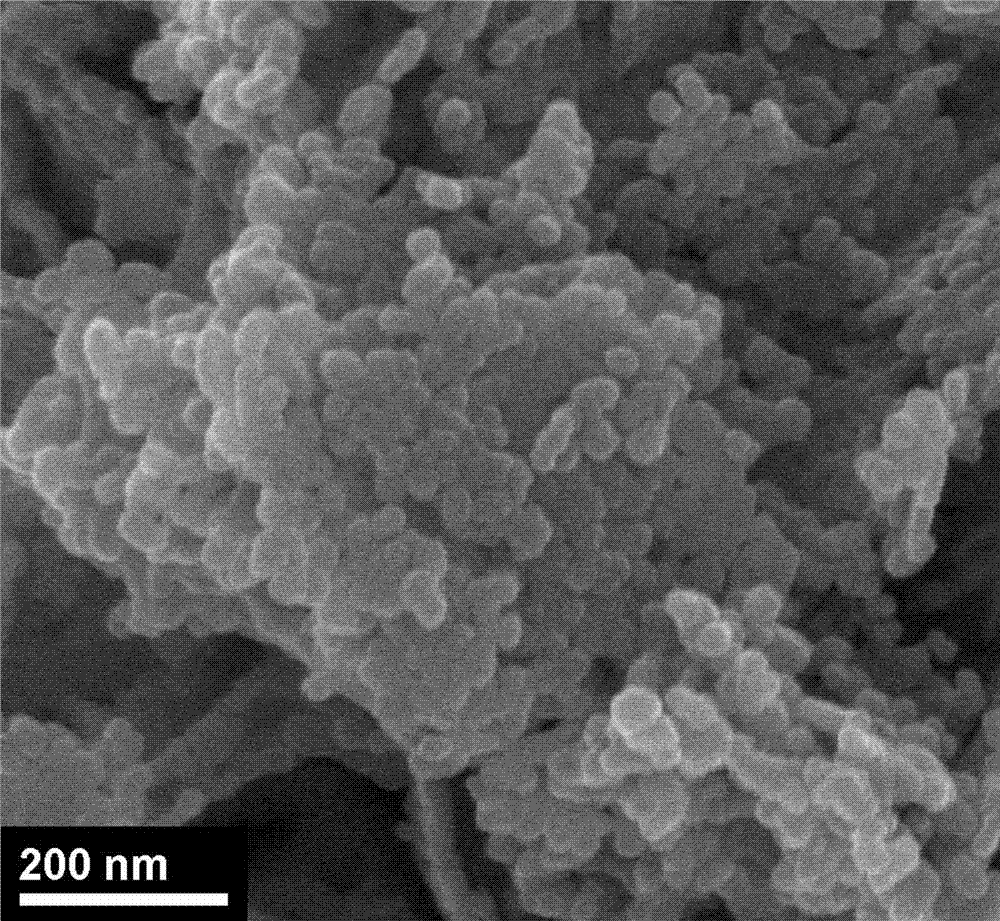

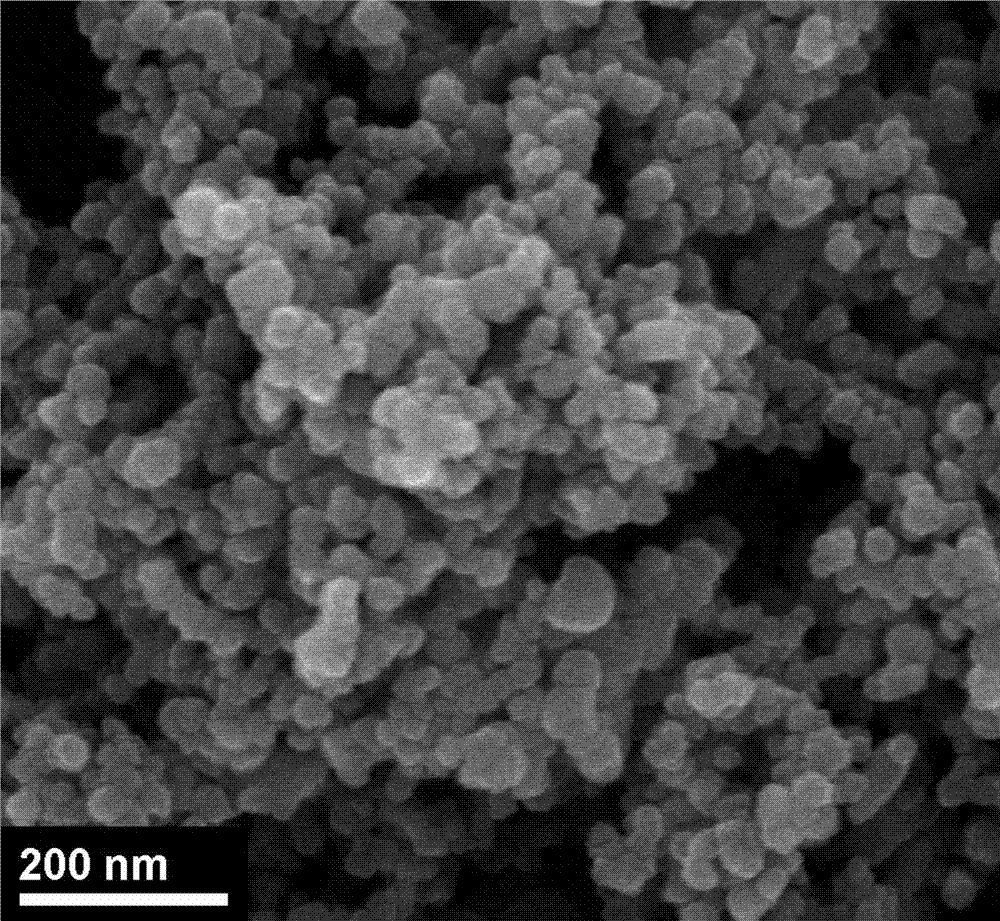

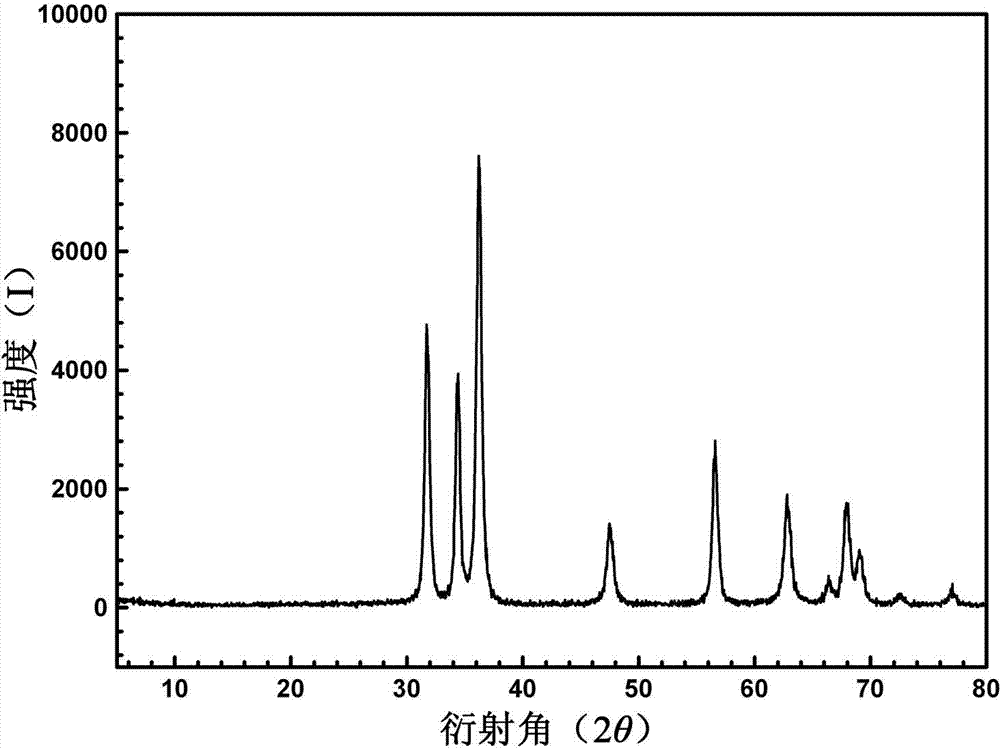

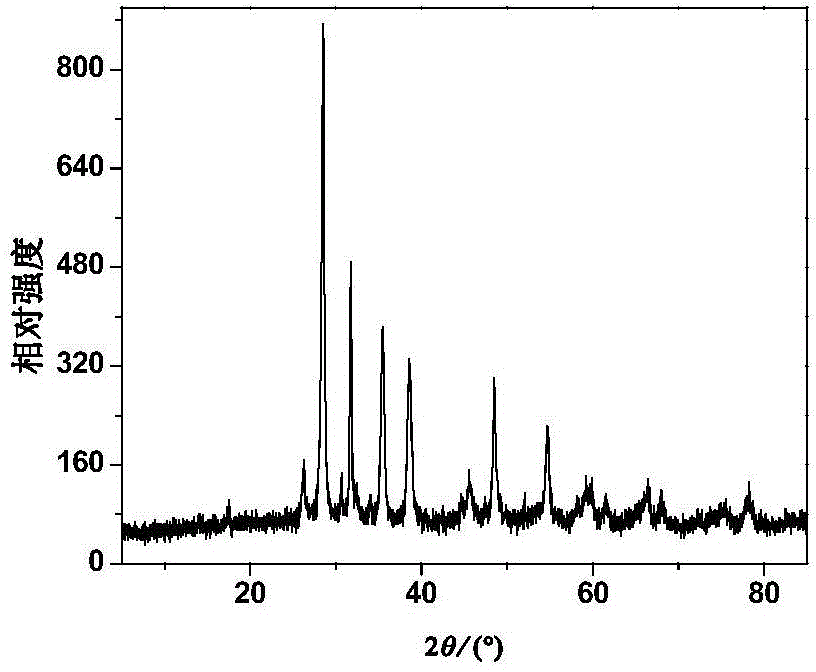

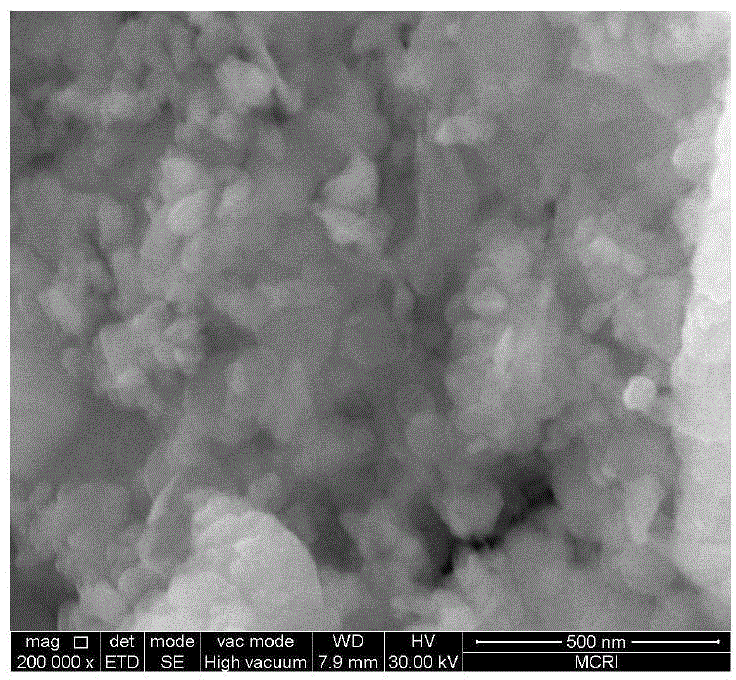

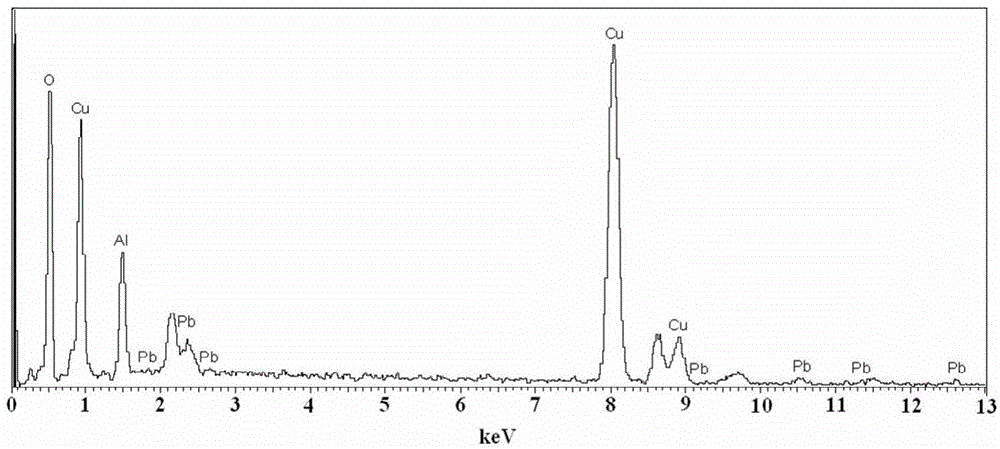

Energetic polyoxide compound super-thermite and preparation method thereof

The invention discloses an energetic polyoxide compound super-thermite. The energetic polyoxide compound super-thermite has the chemical formula represented by n-Al / Ax1Oy1.Bx2Oy2 or n-Al / Ax1Oy1.Bx2Oy2.Cx3Oy3, wherein n represents nanometer super-thermite, Ax1Oy1, Bx2Oy2 and Cx3Oy3 are different metal oxides, A, B and C are selected from Group II, III, IV and V main group metal elements, transition metal elements or lanthanide elements, x and y are positive integers and meet chemically reasonable values and the particle size of nanometer aluminum powder is 20-100nm. The energetic polyoxide compound super-thermite is prepared by virtue of a room-temperature solid-phase reaction-ultrasonic oscillation composite method which has the advantages of being low in cost, high in yield, simple and feasible in preparation process, environment friendly, free of pollution and the like and is suitable for pilot-plant-scale and large-scale popularization and production. The compound super-thermite as a combustion catalyst, which is prepared by the method has excellent catalytic effect on the combustion of a double-base propellant and is an efficient combustion catalyst.

Owner:XIAN MODERN CHEM RES INST

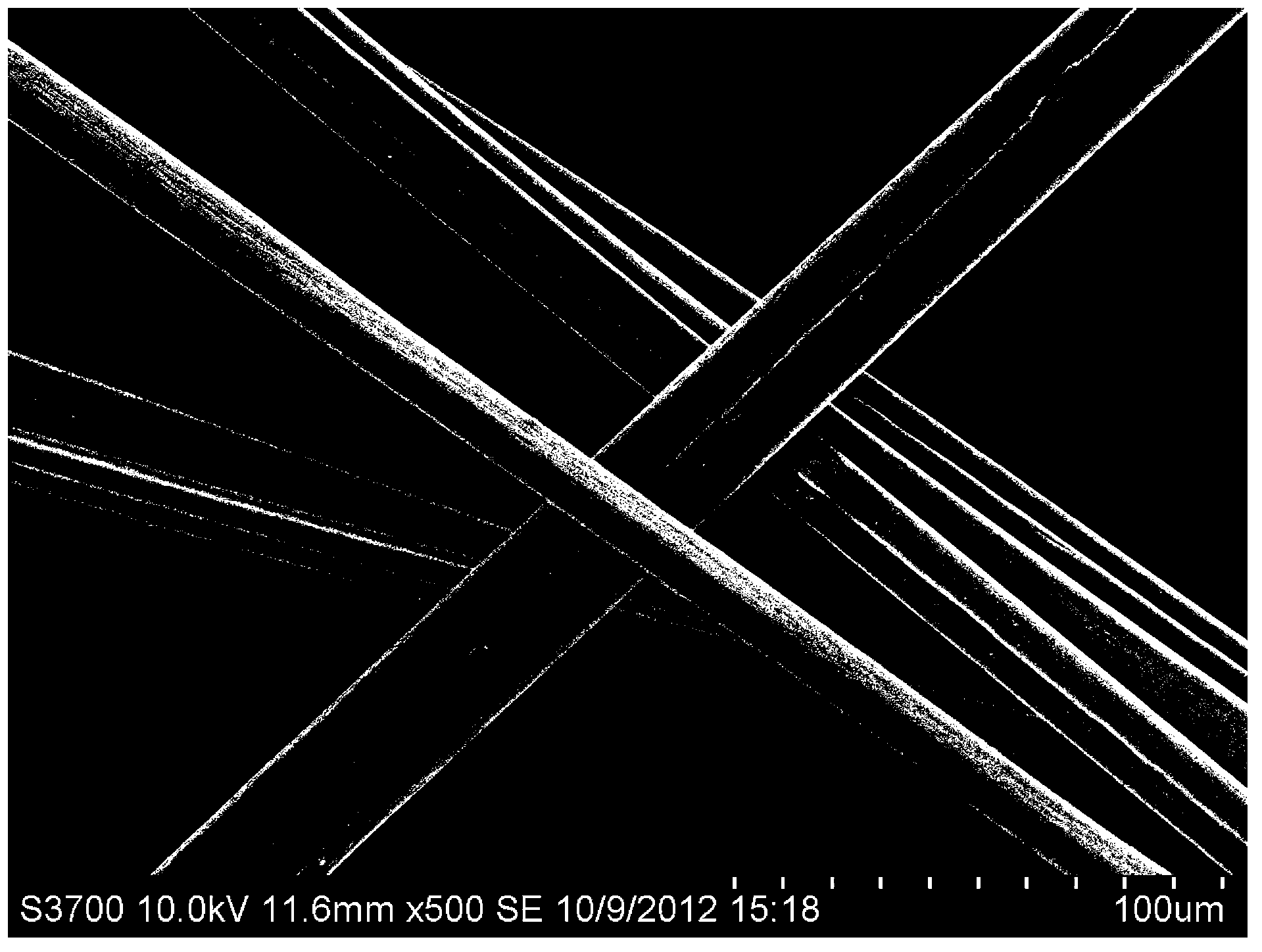

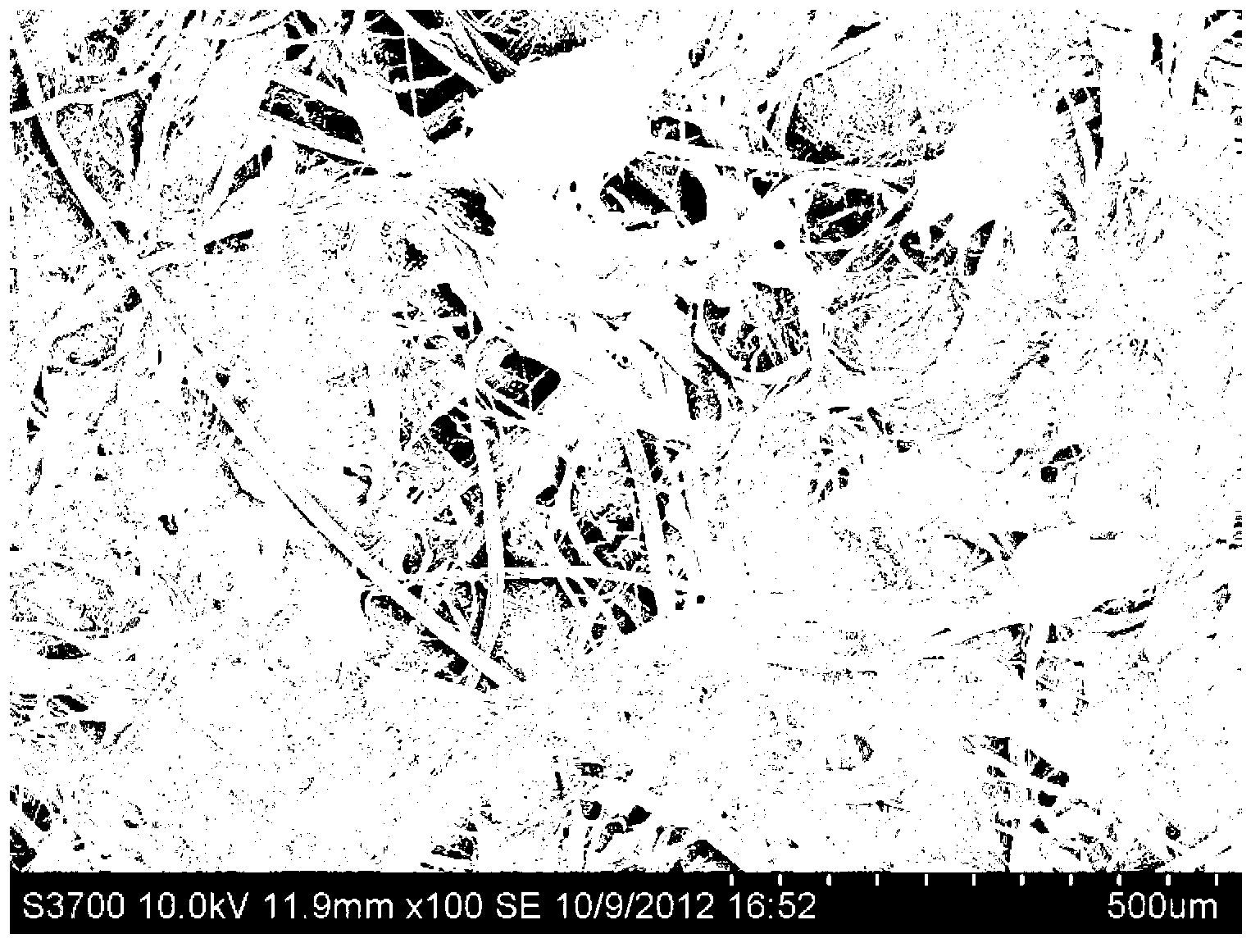

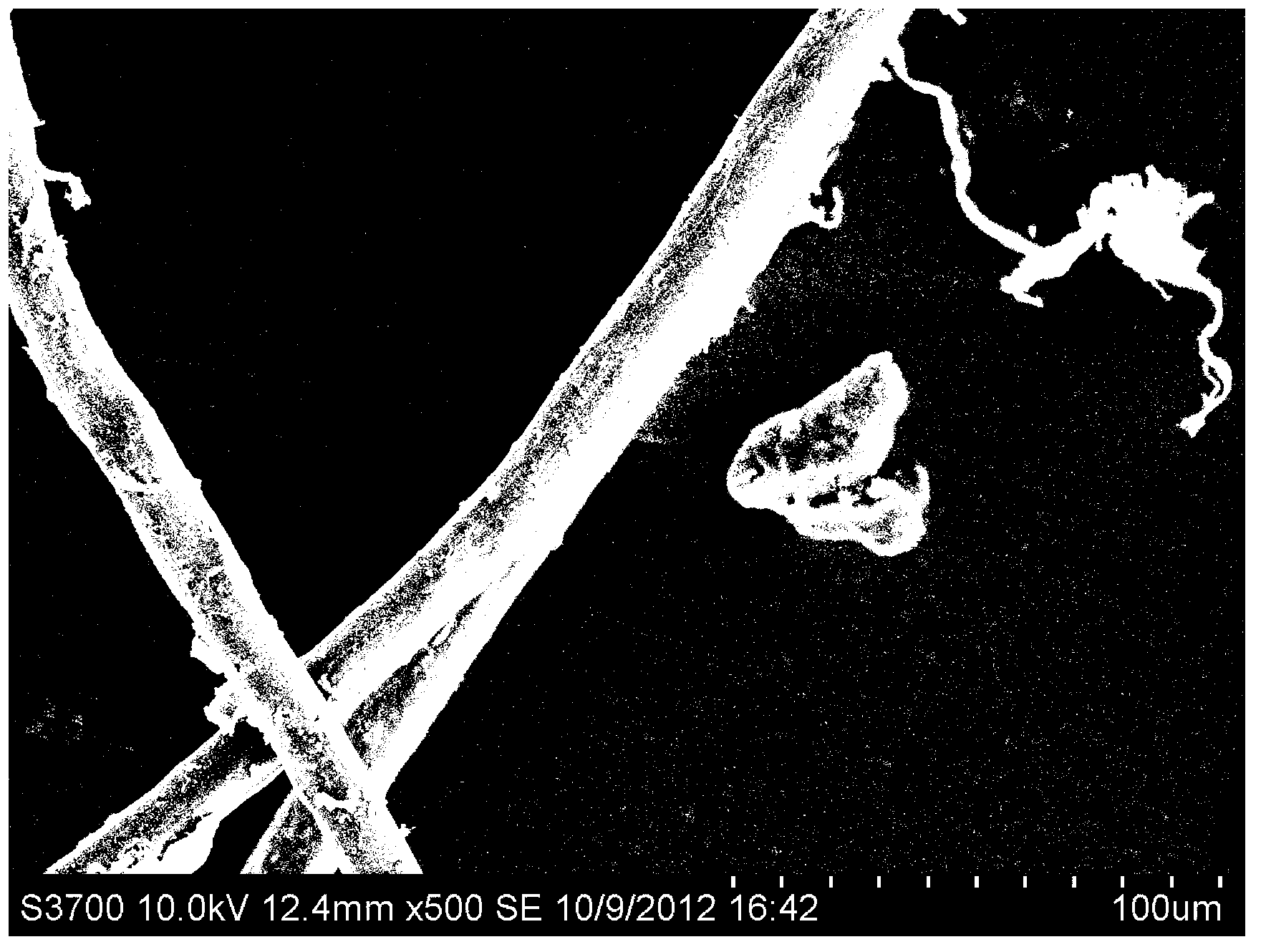

Meta-position aramid fiber paper with high physical strength insulativity as well as preparation method and application thereof

InactiveCN103321085AEasy to operateHigh specific surface areaPulp beating methodsPaper/cardboardFlocculationPaper production

The invention belongs to the field of special paper production, and discloses meta-position aramid fiber paper with high physical strength insulativity as well as a preparation method and application of the meta-position aramid fiber paper. According to the aramid fiber paper, by using a method of reasonably blending 1313 aramid fiber chopped fibers, 1313 aramid fiber fibrids and 1313 aramid fiber pulps, and the advantages of various kinds of fibers are combined and compared in experiment and pilot plant test processes to obtain an optimal fiber pretreatment process (a composite pulping process), a fiber blending proportion and a using amount range of the dispersing agent, so that the flocculation problem of the aramid fiber in a dispersion medium is solved, finished product paper is high in physical strength including tensile indexes and tear indexes while the paper is high in electrical insulativity and is good in bulk degree; and therefore, the paper can be used in the fields of electrical insulation, cellular materials, communication and transportation and the like.

Owner:SOUTH CHINA UNIV OF TECH

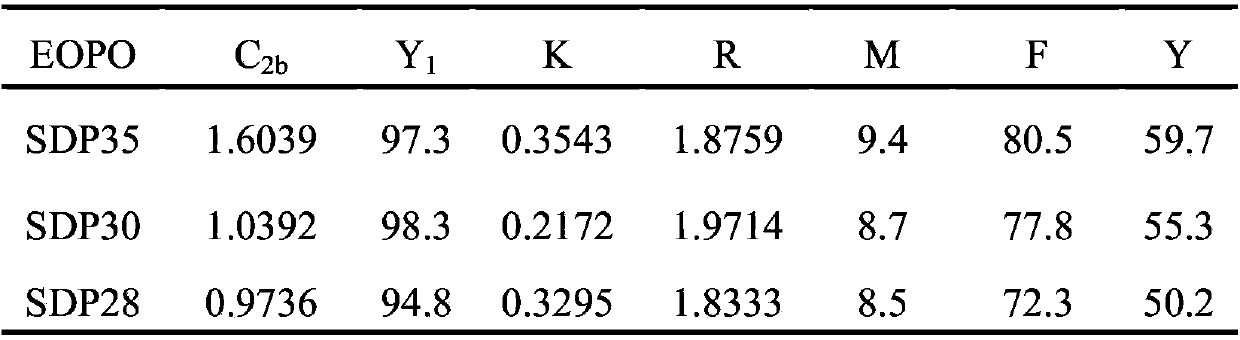

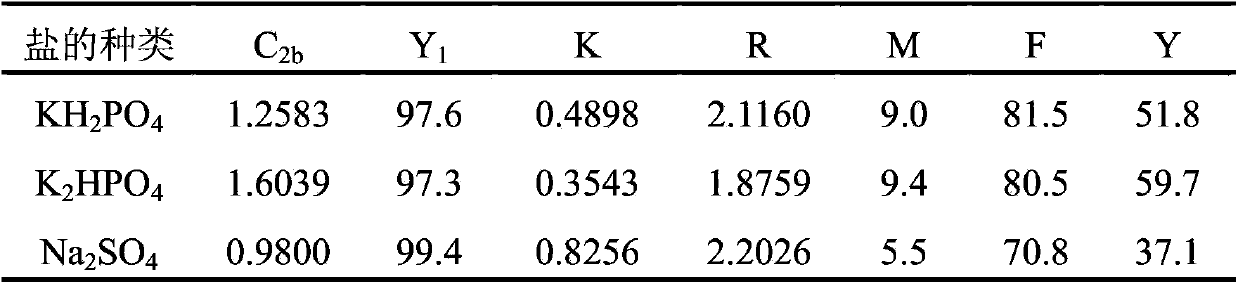

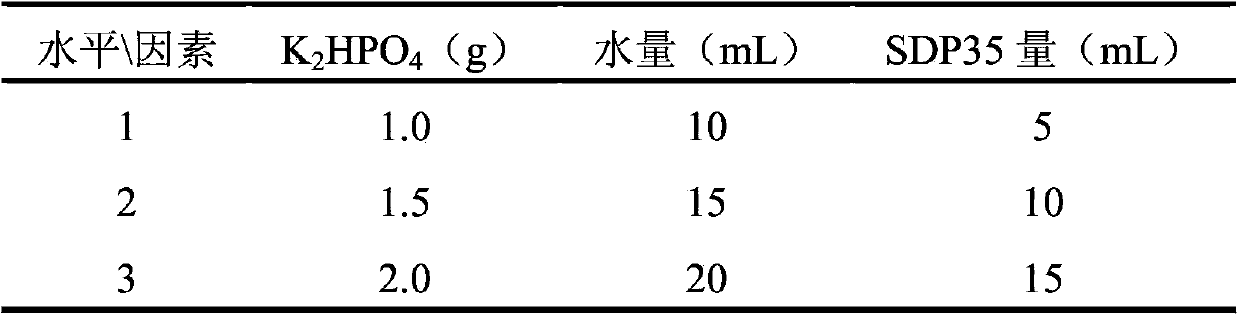

Method for separating and purifying chlorogenic acid by utilizing temperature to induce aqueous two-phase system

InactiveCN103420838AHigh puritySimple processOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidRoom temperature

The invention relates to a method for separating and purifying chlorogenic acid by utilizing temperature to induce an aqueous two-phase system, which comprises the following steps: (1) smashing folium cortex eucommiae to be placed in an extracting tank, adding 5 to 7 times of water in weight, heating and back flowing for 1.5 to 2 h, and concentrating until paste is soaked, that is chlorogenic acid crude product; (2) mixing EOPO and water according to the volume ratio of (1-3):(1-4), then adding salt in the mixture, uniformly mixing, adding the chlorogenic acid crude product in the solution, uniformly mixing, centrifugally separating water phase and organic phase rich in EOPO, enriching chlorogenic acid in organic phase, and enriching impurity in water phase; (3) water bathing the organic phase gained in the step (2) at the temperature of 50 to 70 DEG C for 10 to 30 min, grouping the solution into two phases automatically, centrifugally separating the organic phase and the water phase, enriching the chlorogenic acid in water phase, and enriching EOPO in organic phase to be recycled; (4) cooling the obtained water phase to the room temperature, placing overnight, dissolving out crystal, and filtering to obtain chlorogenic acid pure product. The method is simple in technology and short in time consumption, reduces the material consumption, facilitates industrial pilot plant test enlargement, and is higher in yield coefficient.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

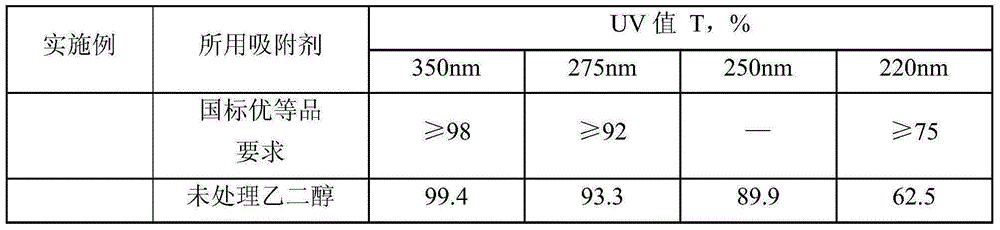

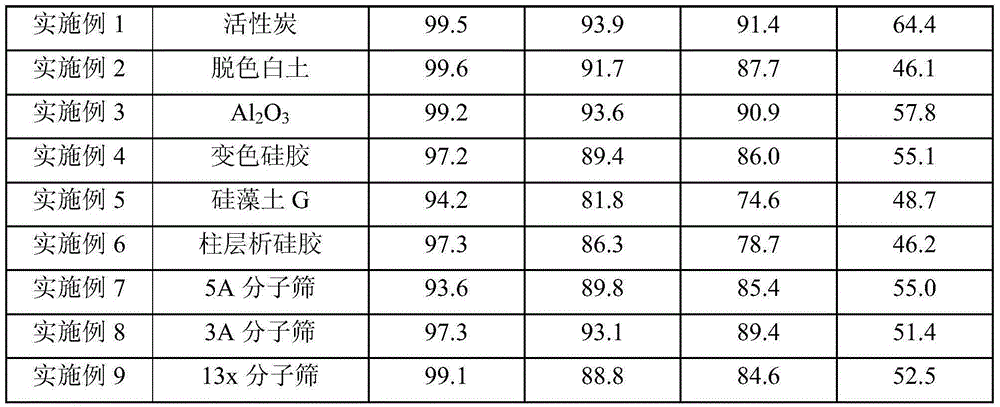

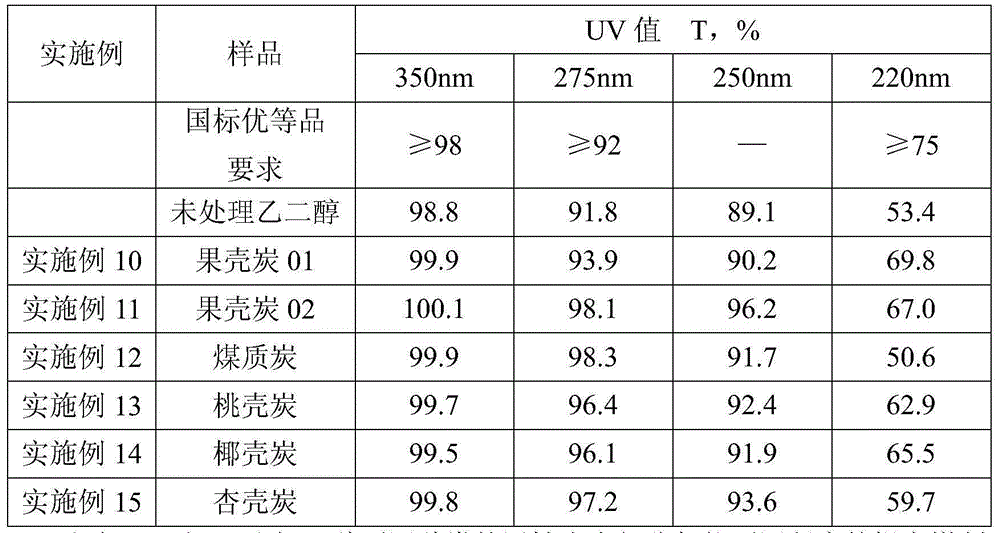

Refining agent and refining method of coal polymer grade glycol

ActiveCN105085175AImprove adsorption capacitySimple processHydroxy compound separation/purificationAcid etchingActivated carbon

The invention provides a refining agent and a refining and purifying method of coal polymer grade glycol. The refining agent of coal polymer grade glycol is characterized by being activated carbon modified by acid etching pretreatment, wherein an acid solution used by pretreatment is a ternary mixed solution of inorganic acid, low carbon alcohol and water. The refining method of coal polymer grade glycol is characterized in that coal glycol sequentially passes through fixed bed layers filled with the refining agent, an over-entering and down-out sampling way is adopted, the refining temperature is 10-100 DEG C, and the liquid hourly space velocity is 0.5-8 / h. The UV value of coal glycol refined by the method can reach the polymer grade standard (220nm>=75%, 275nm>=92%, 350nm>=99%). Compared with the prior art, the refining method provided by the invention has the advantages of simple process flow, high adsorption capacity and simple regeneration method. Verified by pilot plant tests of 300 tons of coal glycol per year, the effect is good.

Owner:HAISO TECH

Small bioreactor

InactiveCN102212474AReduce frictional resistanceReduce operating energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic control3D cell culture

The invention belongs to the technical field of bioengineering, and particularly relates to a small bioreactor which comprises a culture tank body, a temperature control kit, a liquid (gas) supplying device, a cell optical density detection device and a culture control device. The small bioreactor can meet steam sterilization requirements by adopting the small culture tank body made from inorganic materials as a cell culture main component, and inorganic glass and Teflon materials as main materials of the liquid supplying device, provide optimization conditions for cell culture by matching a high-precision temperature control system with the cell optical density detection device. In the invention, the cell culture main component has high surface smoothness so as to reduce the surface friction loss on cells to a greatest extent; and the small bioreactor has the characteristics of high integration, automatic control, amplification, high reliability, energy conversation, environmental friendliness and suitability for demands on small medium-scale cell culture and gene recombination protein expression in a bioengineering laboratory and pilot plant test production.

Owner:北京新节点生物工程技术有限责任公司

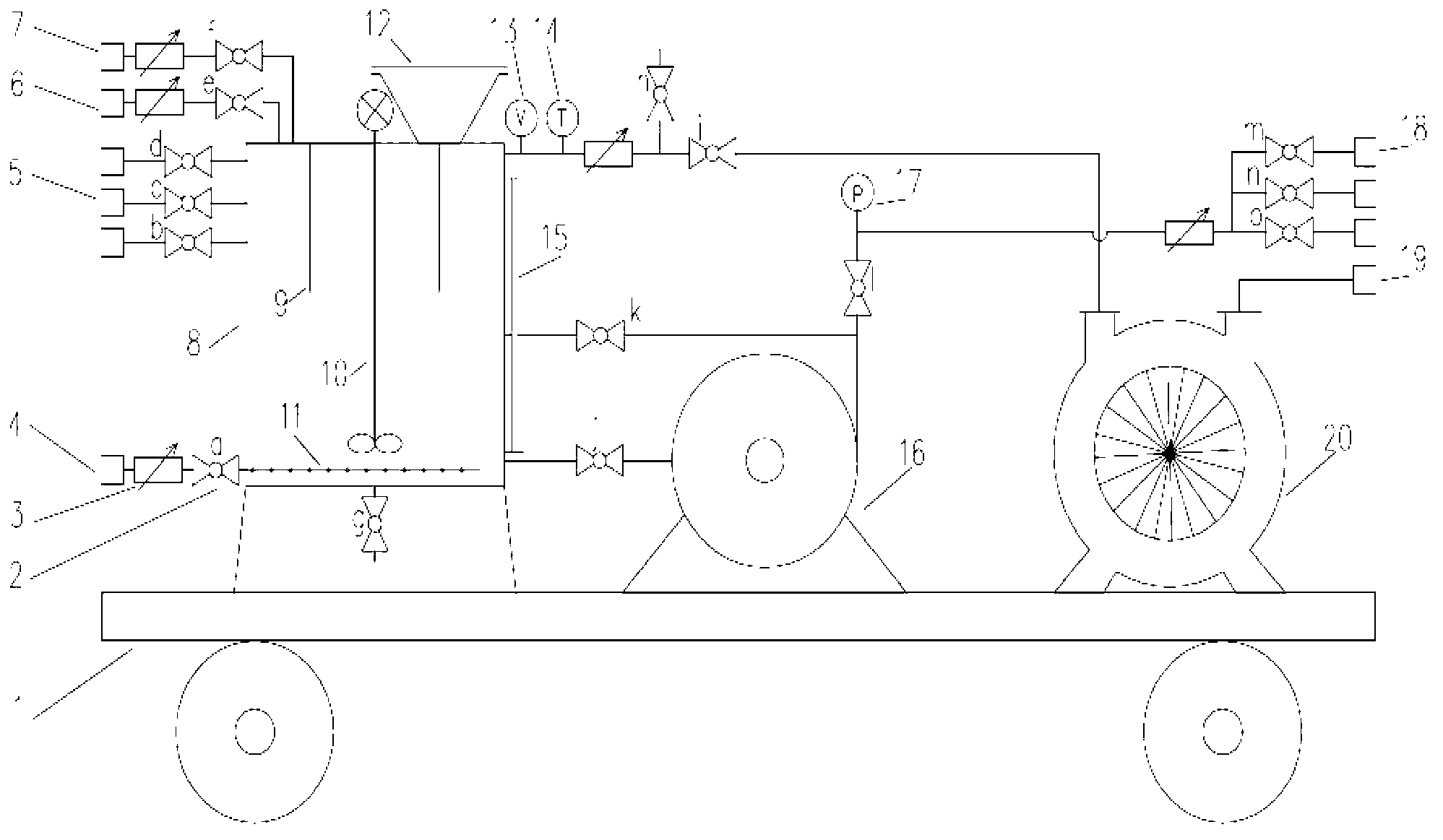

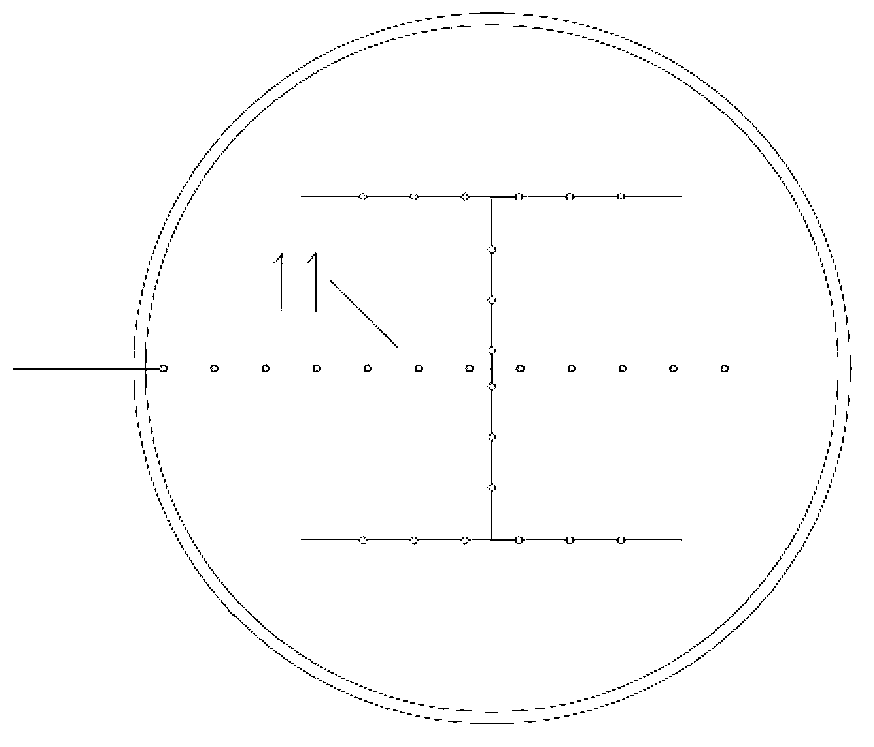

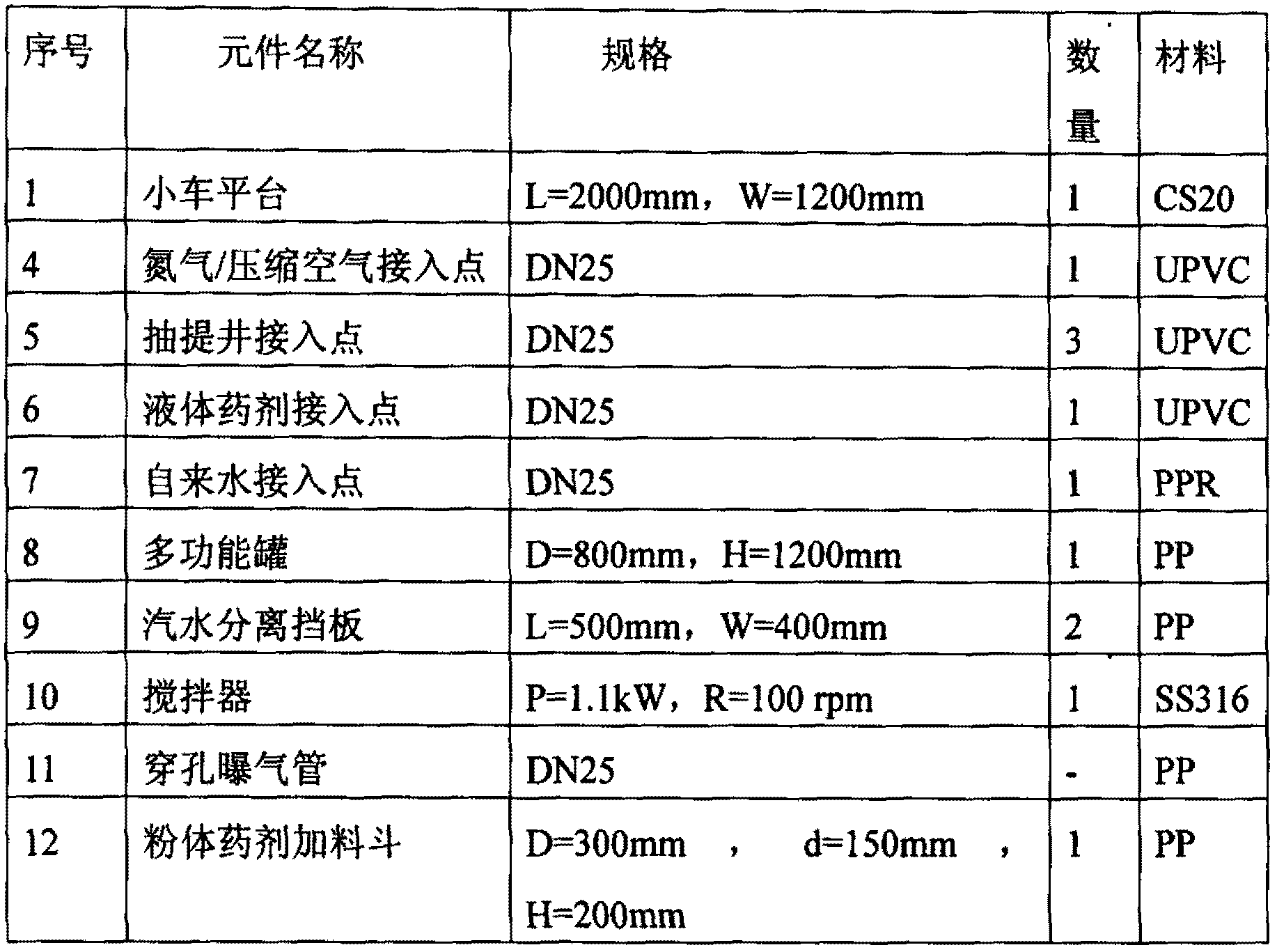

Integrated type multifunctional movable soil underground water repairing equipment and application thereof

ActiveCN103302089ASimple structureEasy to operateContaminated soil reclamationMultistage water/sewage treatmentGroundwater remediationMovable type

The invention relates to integrated type multifunctional movable soil underground water repairing equipment. The equipment comprises a trolley platform, a multifunctional pot, a liquid lifting pump and a vacuum pump, wherein the multifunctional pot, the liquid lifting pump and the vacuum pump are fixed on the trolley platform. Due to the adoption of the equipment, various soil underground water repairing processes can be respectively realized, so that heavy metals and / or organic pollution in soil and / or underground water is subjected to in-situ or ex-situ repairing operation. Compared with the prior art, the integrated type equipment disclosed by the invention is simple in structure, small in occupied area, convenient to operate and flexible in combination; movable type equipment is convenient to apply in actual engineering and can be repeatedly applied to repairing engineering of different fields for a plurality of times; multifunctional equipment can respectively realize field pilot plant tests of various repairing processes by utilizing a set of equipment or a complicated repairing technology scheme for coupling the various repairing processes or an engineering repairing application of different range fields can be implemented by utilizing a manner of combining a plurality of sets of the equipment; and a repairing process can be conveniently changed in a field repairing implementation process.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

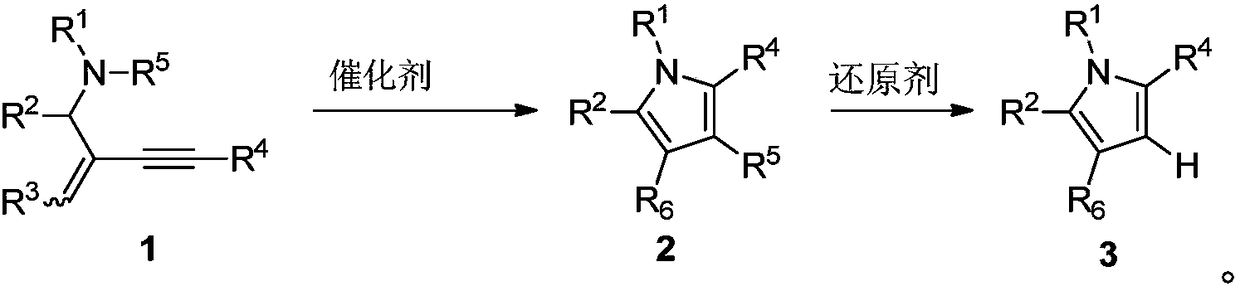

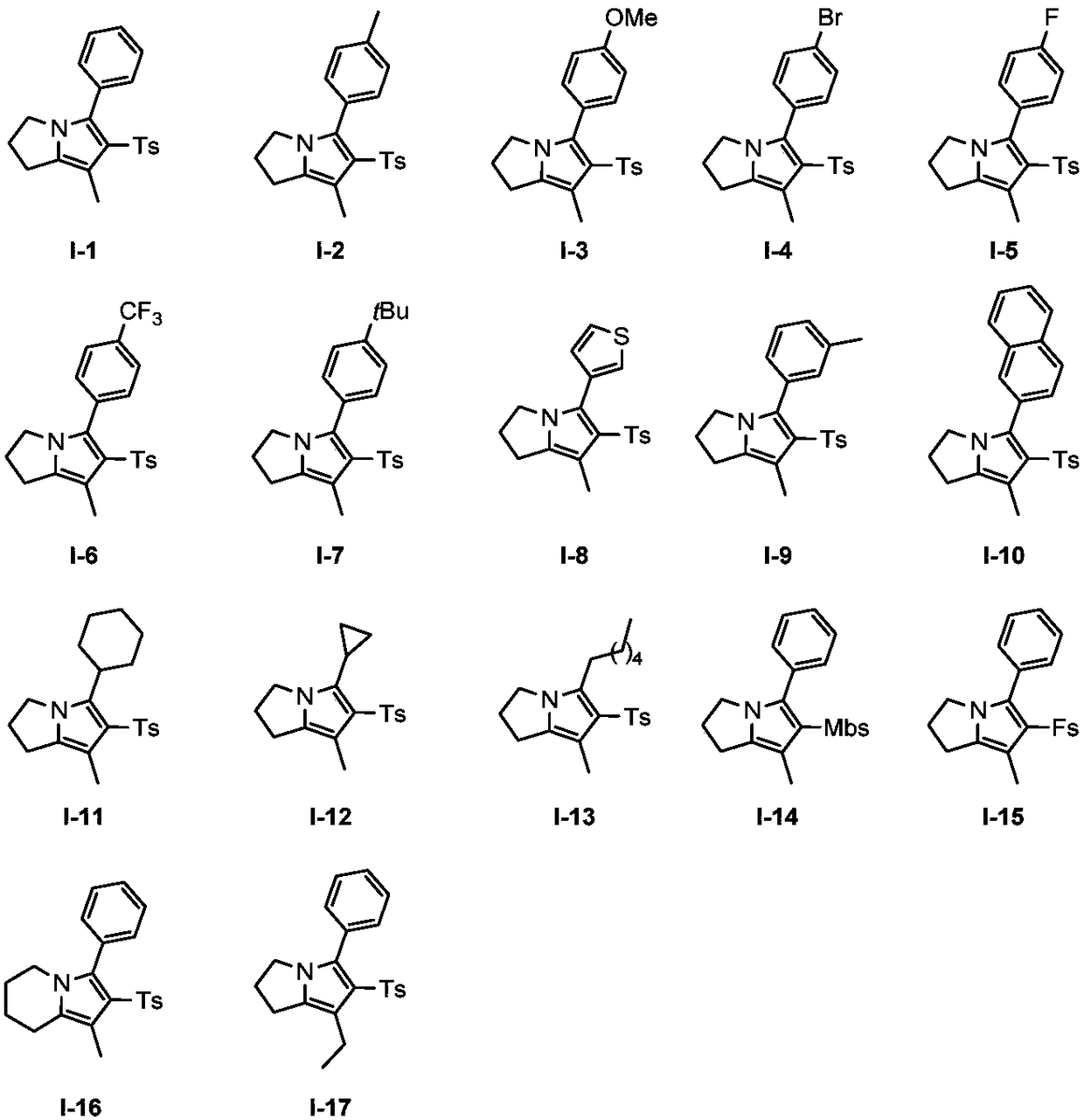

Preparation method of polysubstituted pyrrole compound

The invention discloses a preparation method of a polysubstituted pyrrole compound. The preparation method comprises steps as follows: an alkyne enamine compound is subjected to a cyclization reactionunder the catalytic action of univalent gold, a product is subjected to column chromatography or recrystallization separation, and a fully substituted pyrrole compound is obtained; substituent groupscan be removed from the pyrrole compound under the proper condition, and a tetra-substituted pyrrole compound is obtained. The chain-like alkyne enamine compound is subjected to the cyclization reaction, and the fully substituted or tetra-substituted pyrrole compound is obtained. The preparation method has the advantages that the operation is simple, steps are simple, the reaction is efficient, raw materials are cheap and easy to obtain, the pilot plant test can be amplified and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Technology method for preparing active components of chlorella through scale classification

InactiveCN103740794AValue maximizationAchieve step-by-step preparationOrganic chemistryMicroorganism based processesSolventPilot plant

The invention discloses a technology process for preparing active components of chlorella through scale classification. The technology process comprises the steps of preprocessing raw materials, breaking walls for extracting, dissolving lipid, concentrating chlorella oil, drying chlorophyll, extracting growth factors of chlorella and preparing hydrolyzed protein peptide. According to the technology process, products such as coarse chlorella oil, chlorophyll crude product, growth factors of chlorella and hydrolyzed protein peptide are prepared through classification; the technology process is applicable to processing and production of the chlorella higher than pilot plant test level, even kilogram level small batch production and larger scale production. Through the technology process, various functional components of the chlorella are prepared step by step; the obtained components can be further processed, refined and used for developing downstream products so as to realize maximum value of the chlorella; reagents used in the technology process is innocuous and unpoisonous and low in cost; main solvents can be recycled and reused. In addition, the technology process is low in equipment requirement; the production requirement can be met by using normal plant extraction devices; the technology process is short in extraction time, high in efficiency and low in energy consumption.

Owner:东莞市绿安奇生物工程有限公司

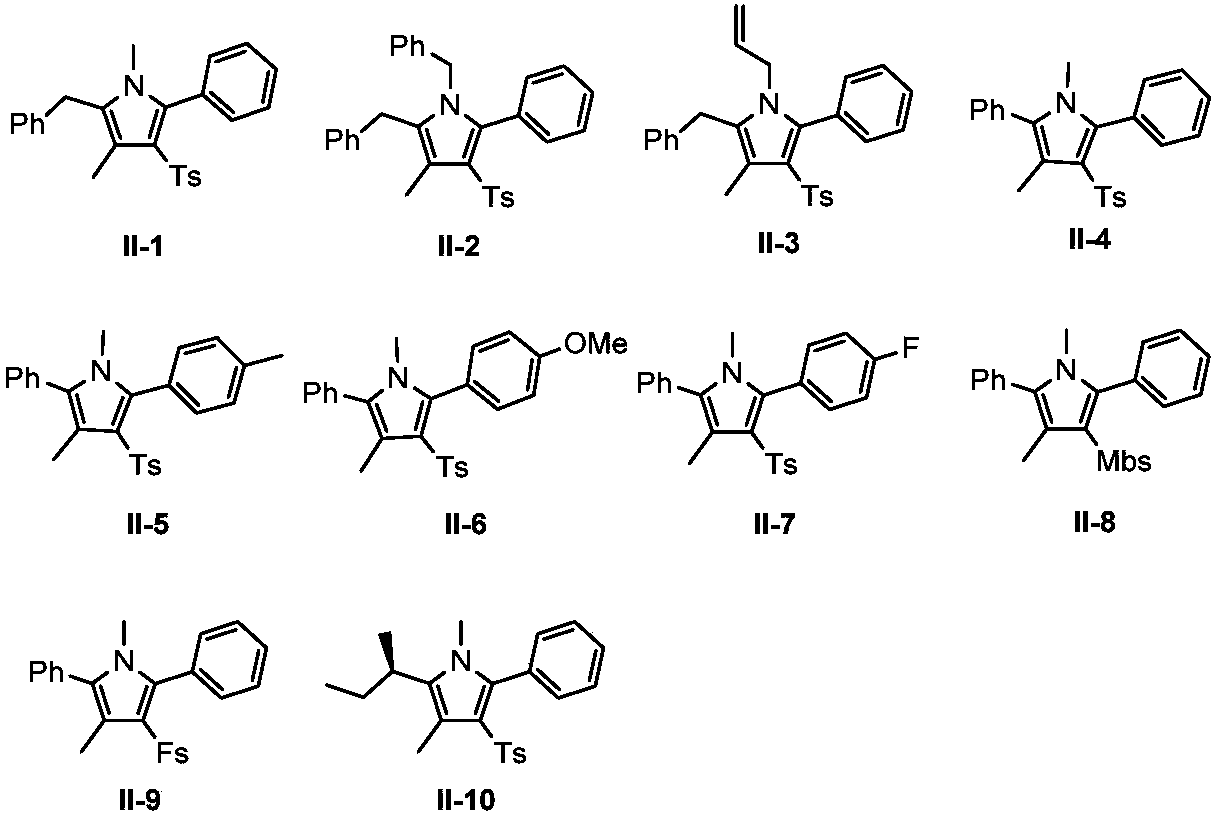

Low-temperature denitration and desulfurization device for coking furnace flue gas and process

InactiveCN106178864AContinuous and stable productionHigh denitrification and desulfurization efficiencyGas treatmentDispersed particle separationFlue gasCoke oven

The invention discloses a low-temperature denitration and desulfurization device for coking furnace flue gas and a process and belongs to the technical field of pollutant treatment of flue gas of a coking furnace in the coking industry. The device mainly comprises a denitration reactor, a reheater, an induced draft fan, a desulfurizing tower, a desulfurization absorption liquid heat exchanger, an ammonium sulfate mother liquor tank, an ammonium sulfate mother liquor circulating pump, a desulfurizing liquid circulating pump and a desulfurizing liquid metering and conveying pump. The coking furnace flue gas is denitrated by the denitration reactor, heat exchange of high and low temperature coking furnace gas is performed by the aid of the reheater, desulfurization is performed by the aid of a desulfurization absorption, and finally, low-temperature denitration and desulfurization purification treatment of the coking furnace flue gas is completed. The low-temperature denitration and desulfurization device has the advantages as follows: resources of a coking plant are sufficiently utilized, the idea of treating waste with waste is realized, and continuous and stable production of the coking furnace is guaranteed while the working condition of the coking furnace flue gas and the denitration and desulfurization requirements are met through a pilot plant test and an industrialized application test.

Owner:BEIJING SHOUGANG INT ENG TECH

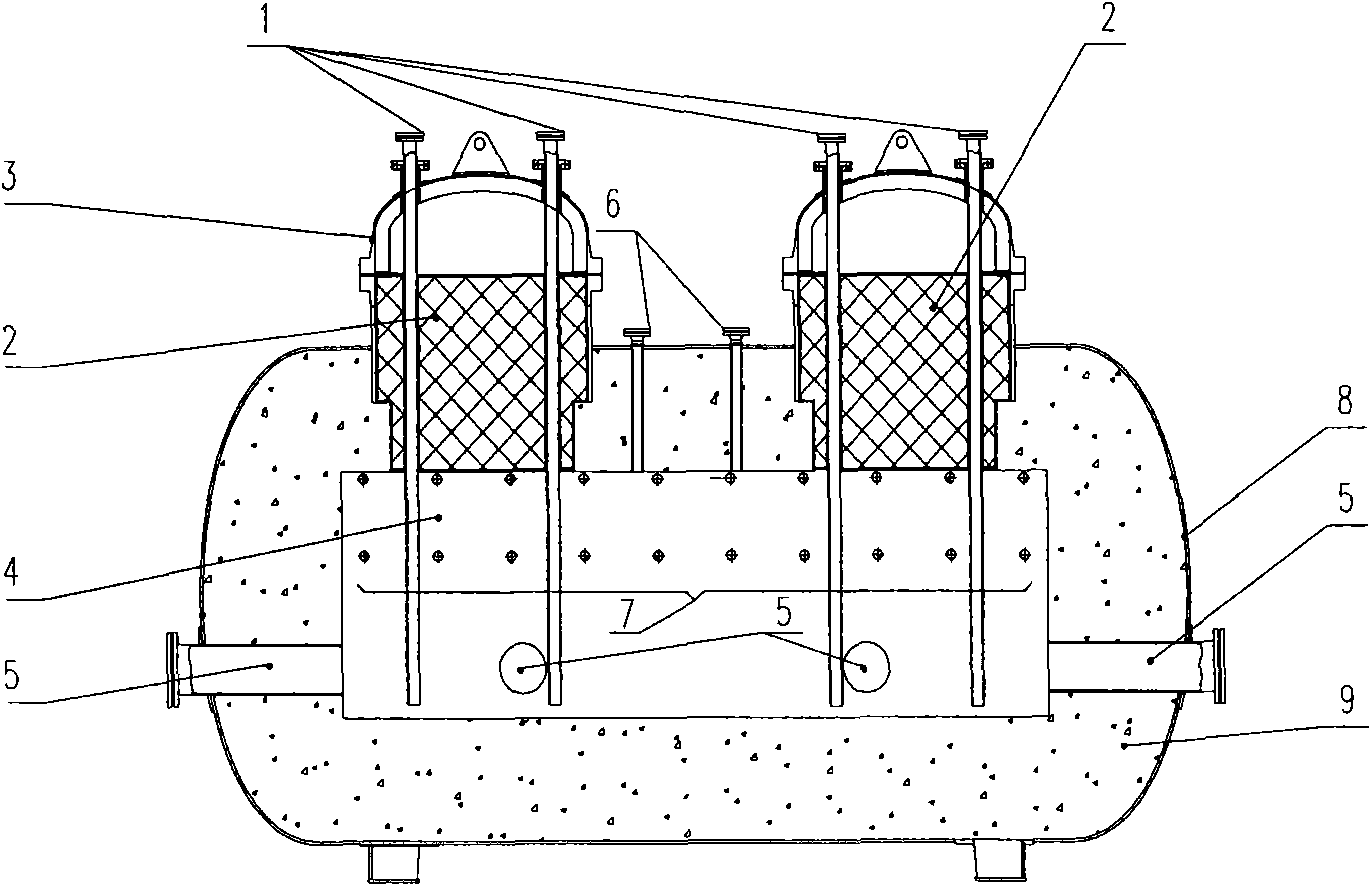

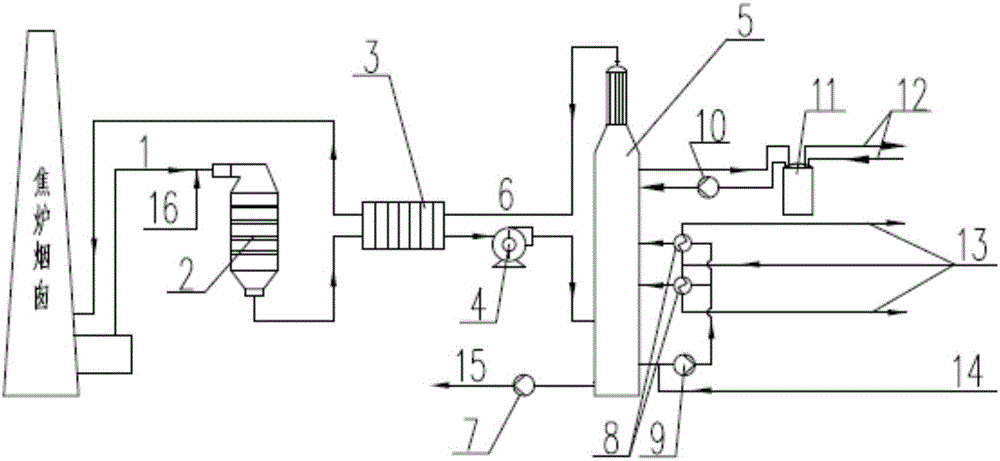

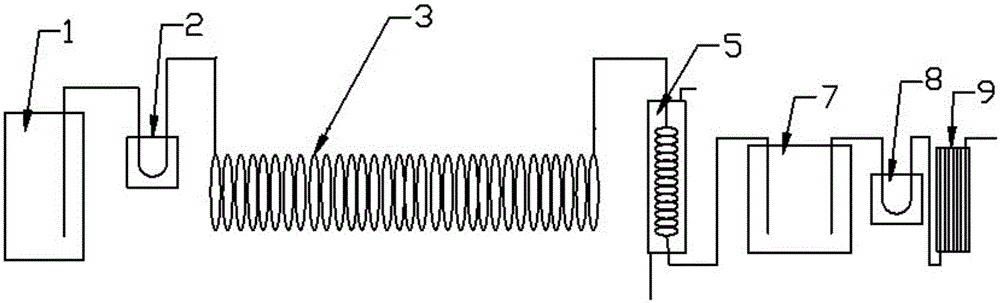

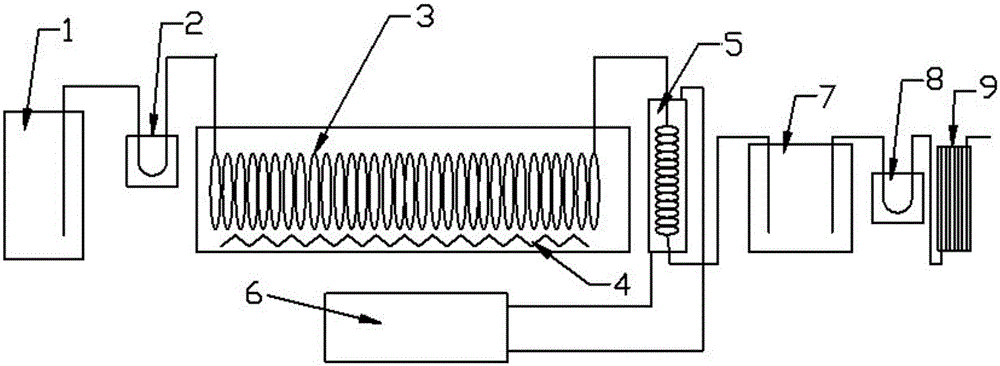

Pilot plant test sterilization system

InactiveCN103892402AReach high temperature sterilization conditionsCompact structureFood thermal treatmentFood preservationEngineeringSmall footprint

The invention relates to a pilot plant test sterilization system which comprises a balance cylinder, a material pump, a preheating device, a sterilization device, a constant temperature tube and a cooling device which are connected in sequence through pipelines, wherein a safety valve, a pressure sensor, a temperature probe and a back pressure valve are arranged on the pipelines; a material inside the balance cylinder enters the preheating device through the material pump, is preheated by the preheating device, subsequently is fed into the sterilization device for heating and sterilization, is fed into the cooling device for cooling through the constant temperature tube, and is finally fed back to the balance cylinder or other recycling devices. Compared with the prior art, the system can achieve the sterilization effect required in industrial production lines, does not need to be large in equipment structure and size and complex in operation in industrial production, and is relatively compact in structure, small in size, small in occupying area and easy to operate and repair.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

Millimeter channel type continuous preparation system

ActiveCN105080448AIncreased turbulenceEnhance heat and mass transferChemical/physical/physico-chemical processesUltrafiltrationEngineering

The invention provides a millimeter channel type continuous preparation system which can be used in preparation of various inorganic nonmetal nanocrystallines (such as oxides and sulfides). Compared with the prior art, the system has the advantages that 1, a millimeter channel type reaction pipe is adopted, and is internally provided with inner threads, so that turbulent flows are promoted to be generated in the channel, and heat and mass transfer is promoted effectively in the channel; 2, an ultrafiltration purification device is adopted for filtering out raw material molecules or ions which are subjected to non-complete reaction in a reaction mixed liquid, so that the continuous preparation of products is realized; 3, if a material tank is improved further, nitrogen can be introduced, so that the materials can be isolated from oxygen at the normal temperature, and channel type heat reaction is realized under an inert atmosphere. The millimeter channel type continuous preparation system can be used for the pilot plant test preparation of the nanocrystallines and high-molecular polymers, and can be used for effectively controlling the sizes or the molecular weight distribution of the materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Nanocomposite nickel-plated coating material and preparation method and application thereof

InactiveCN101935829AHigh resistance to vacuum cold weldingReduce coefficient of frictionLiquid/solution decomposition chemical coatingChemical industryCarbon nanotube

The invention discloses a nanocomposite nickel-plated coating material and a preparation method and application thereof. The nanocomposite nickel-plated coating material comprises the following components in percentage by weight: 0.02 to 0.5 percent of nano-rare earth oxide and 0.02 to 0.3 percent of carbon nanotube. The preparation method comprises the following steps of: removing oil from a plated part; activating; pre-plating; plating and the like. A nanocomposite nickel-plated coating obtained by the method has the advantages of effectively preventing cold welding effect, prolonging the service life of metal parts, reducing energy consumption, saving energy, avoiding environmental pollution and preventing a moving member or a contact pair in a aerospace craft from performing vacuum cold welding on a friction pair, along with very high vacuum cold welding resistance, extremely low friction coefficient and wide application prospects in the fields of aerospace, machinery, chemical industry and the like. The preparation method has the advantages of no need of complex equipment, simple process, wide material source, low price, low preparation cost, no pollution in a production process and suitability for pilot plant test and industrialized production.

Owner:SHANGHAI INST OF TECH

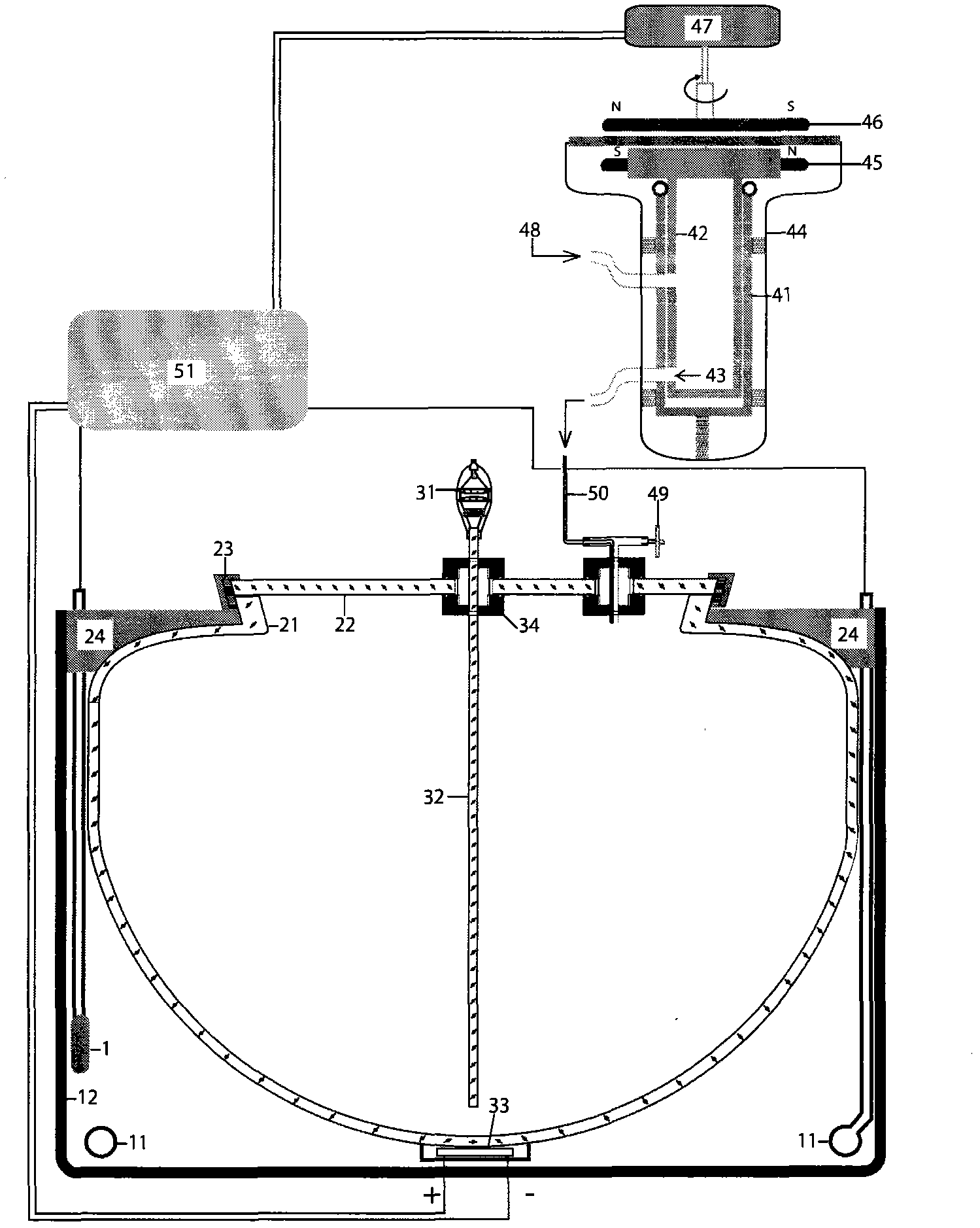

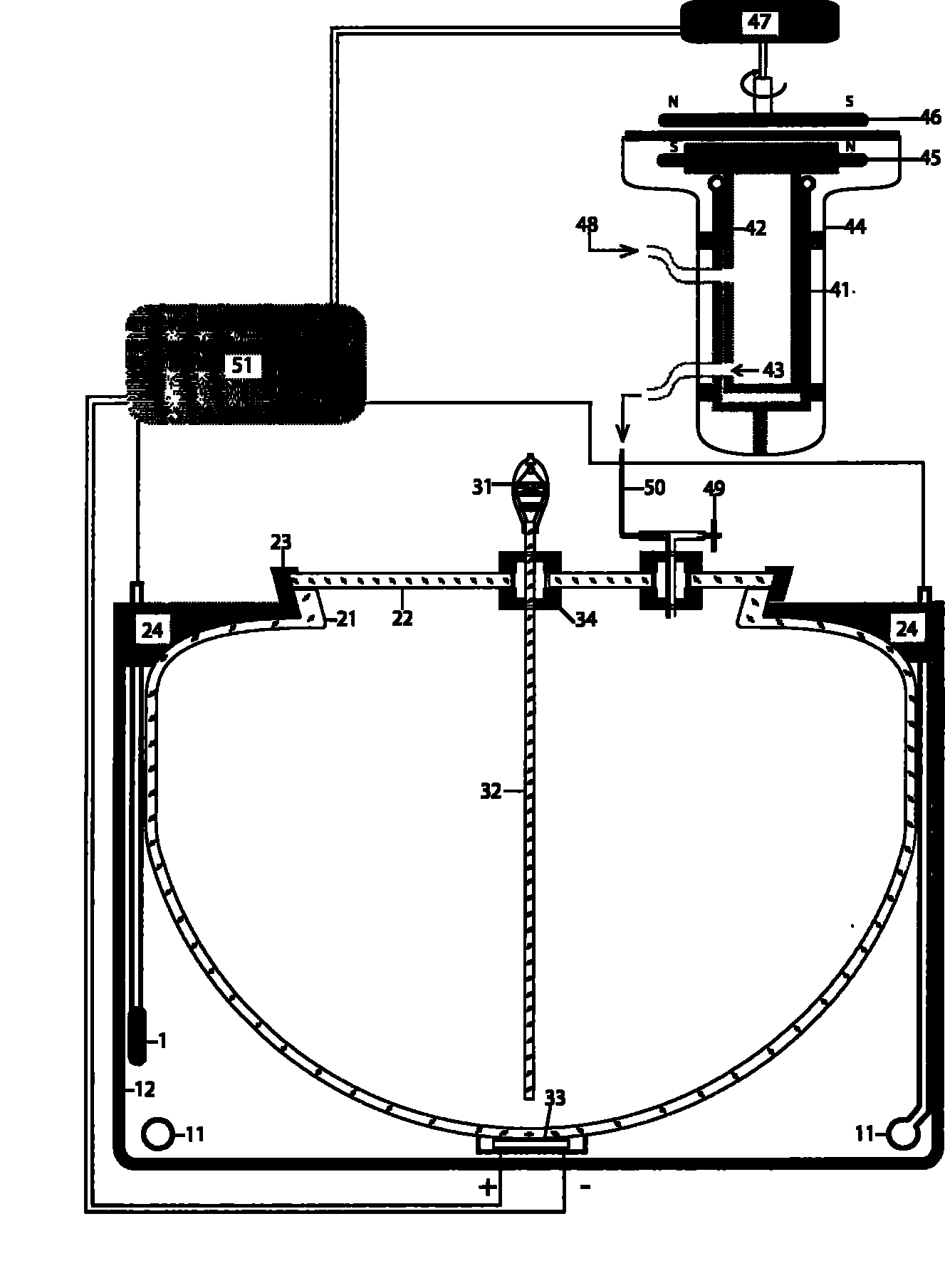

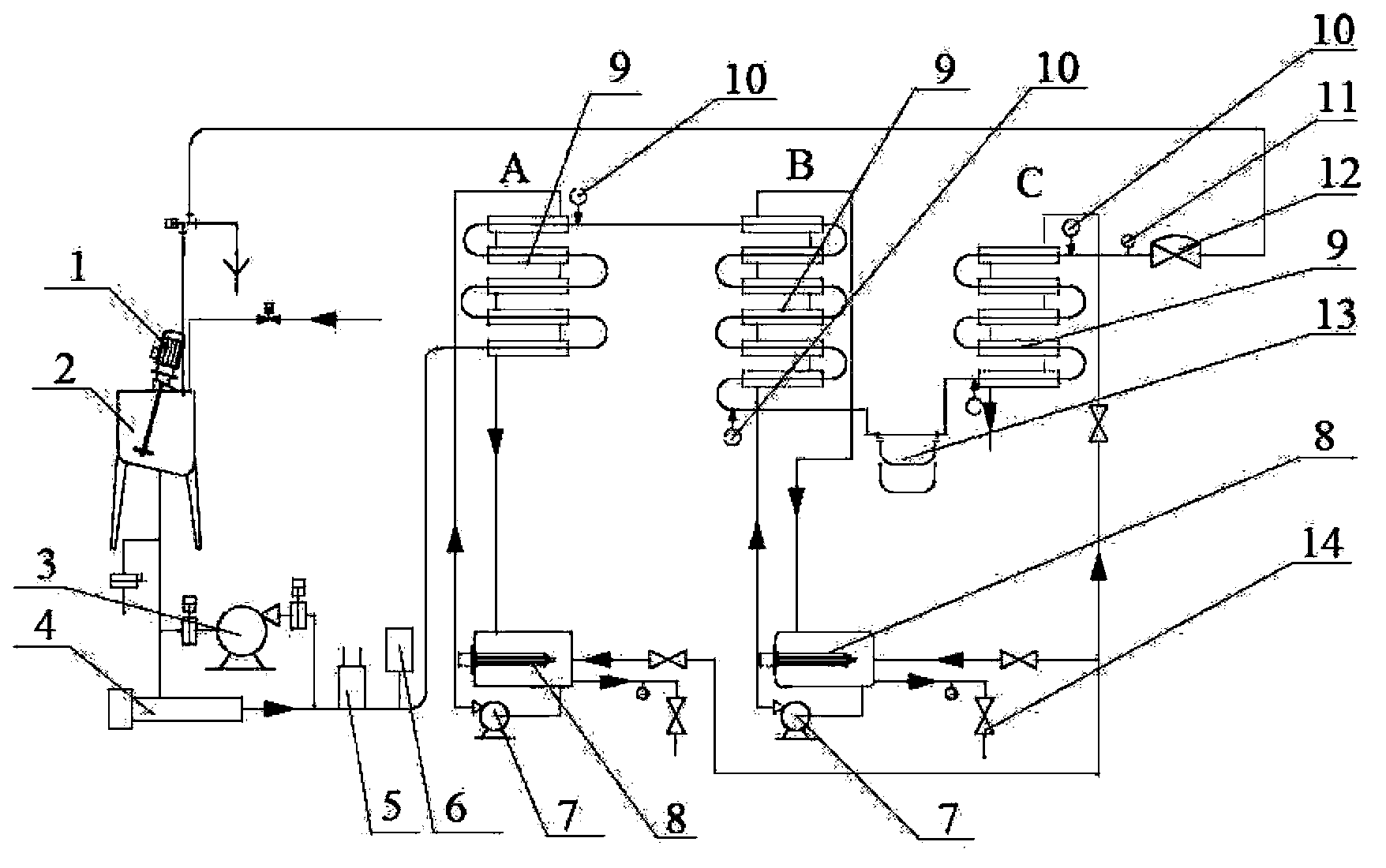

Intermittent mechanical mixing-surface layer oxygenation integrated pilot plant test device

ActiveCN105417743AIncrease dissolved oxygenReduce lossesWater aerationEnergy based wastewater treatmentSurface layerMotor drive

The invention discloses an intermittent mechanical mixing-surface layer oxygenation integrated pilot plant test device. The device comprises a conical ascending cylinder device, an outflowing cylinder device, a Venturi air inlet device, a motor driving device and an intelligent power source switch system. An intelligent power source switch controls a motor to intermittently drive blades to rotate to generate upward lifting power, bottom water sequentially flows through an ascending cylinder, a shrinkage pipe, an aeration chamber and the outflowing cylinder device, and water on the upper layer of a lake and reservoir and water on the lower layer of the lake and reservoir are mixed; negative pressure is generated at the shrinkage pipe due to the fact that the flow rate is high; due to the Venturi principle, air is sucked into the shrinkage pipe sequentially through an air inlet pipe and a flexible hose and enters the aeration chamber with water from the bottom of the ascending cylinder, the aeration blades aerate the water with the air in the periodic running process, and the aerated water enters external water through the outflowing cylinder device. The mixed aerated core units are arranged on the surface layer of the water, no complex air supply device or underwater pipeline system is needed, use and maintenance are convenient, and the investment and running cost for improving the water quality of the lake and reservoir is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com