Small bioreactor

A bioreactor and small-scale technology, applied in the field of bioengineering, can solve the problems that manual detection of cell culture density cannot realize the overall repeatability of the overall automatic control system and affect the stability of the system, so as to improve stability and repeatability and reduce friction Loss, the effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

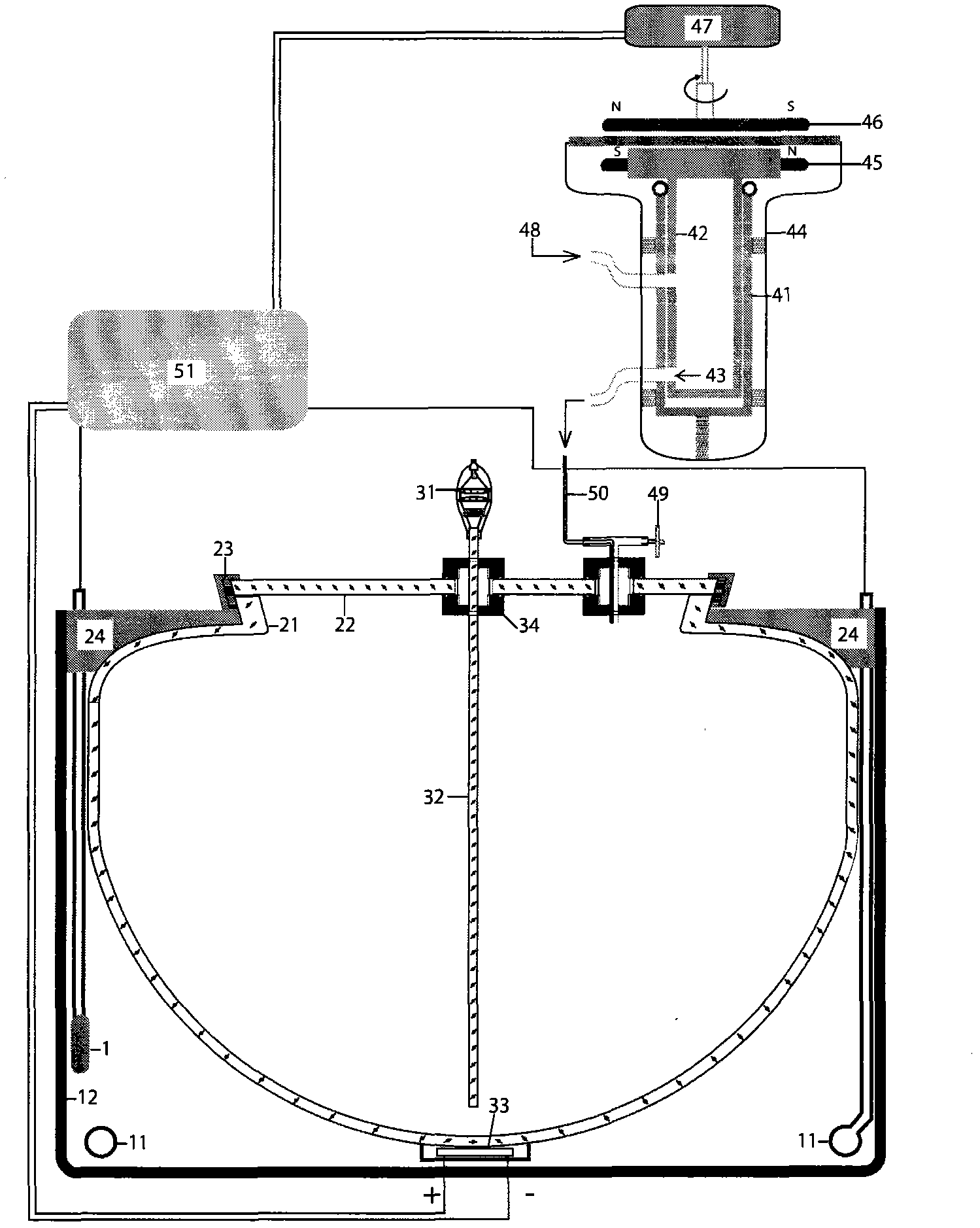

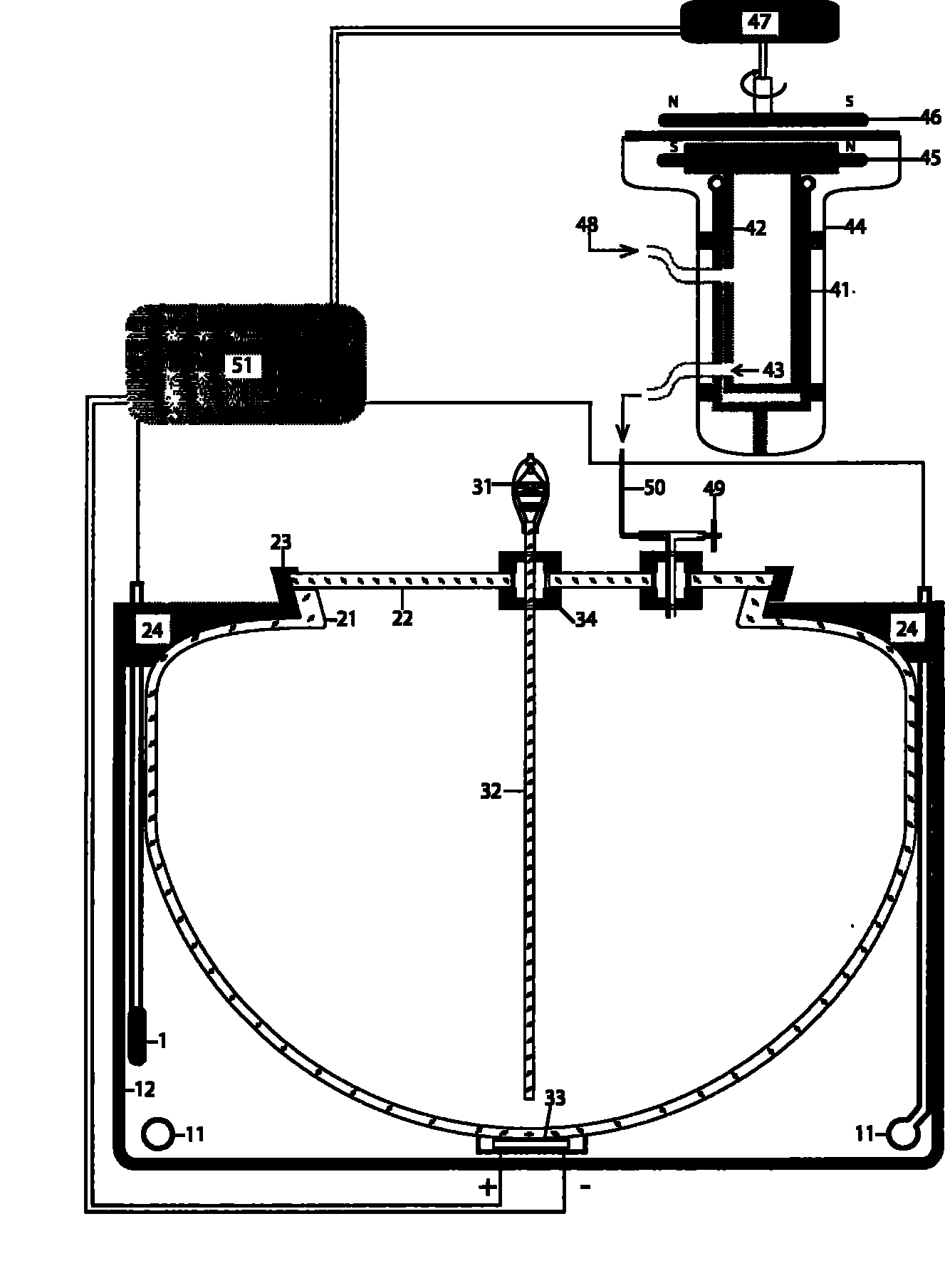

[0027] Bioreactors with a working volume of 1.0-1.5 liters.

[0028] according to figure 1 The bioreactor is designed, and the use environment is a room temperature environment of 22-25°C. First, the cell culture tank 21 is made of inorganic glass material: the radius of the spherical segment is 10 cm, the height is 8 cm, and the radius of the connecting cylinder is 10 cm, and the height is 6 cm. Use inorganic glass to process the top cover 22 of the tank body, use sealing rubber pads and fasteners 23 to assemble with the cell culture tank body, and open at the center of the top cover to access the top cover sealing ring 34 .

[0029] After the light source 31 is assembled with the light guide rod 32, the top cover seal ring is used to make the light guide rod close to the bottom of the tank for a certain distance; the air filter device 49 and the external culture solution inflow pipeline 50 are connected through another top cover seal ring.

[0030] The inner airtight cylin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com